The Impact of Carbon Quota Benchmark Allocation on Cement Company Competitiveness: A System Dynamics Approach

Abstract

1. Introduction

2. Literature Review

2.1. ETS and Benchmark Allocation

2.2. Company Competitiveness under the Benchmark Allocation

2.3. Carbon-Reduction Measures in Cement Companies

2.4. Application of System Dynamics in the Cement Industry

3. Methodology

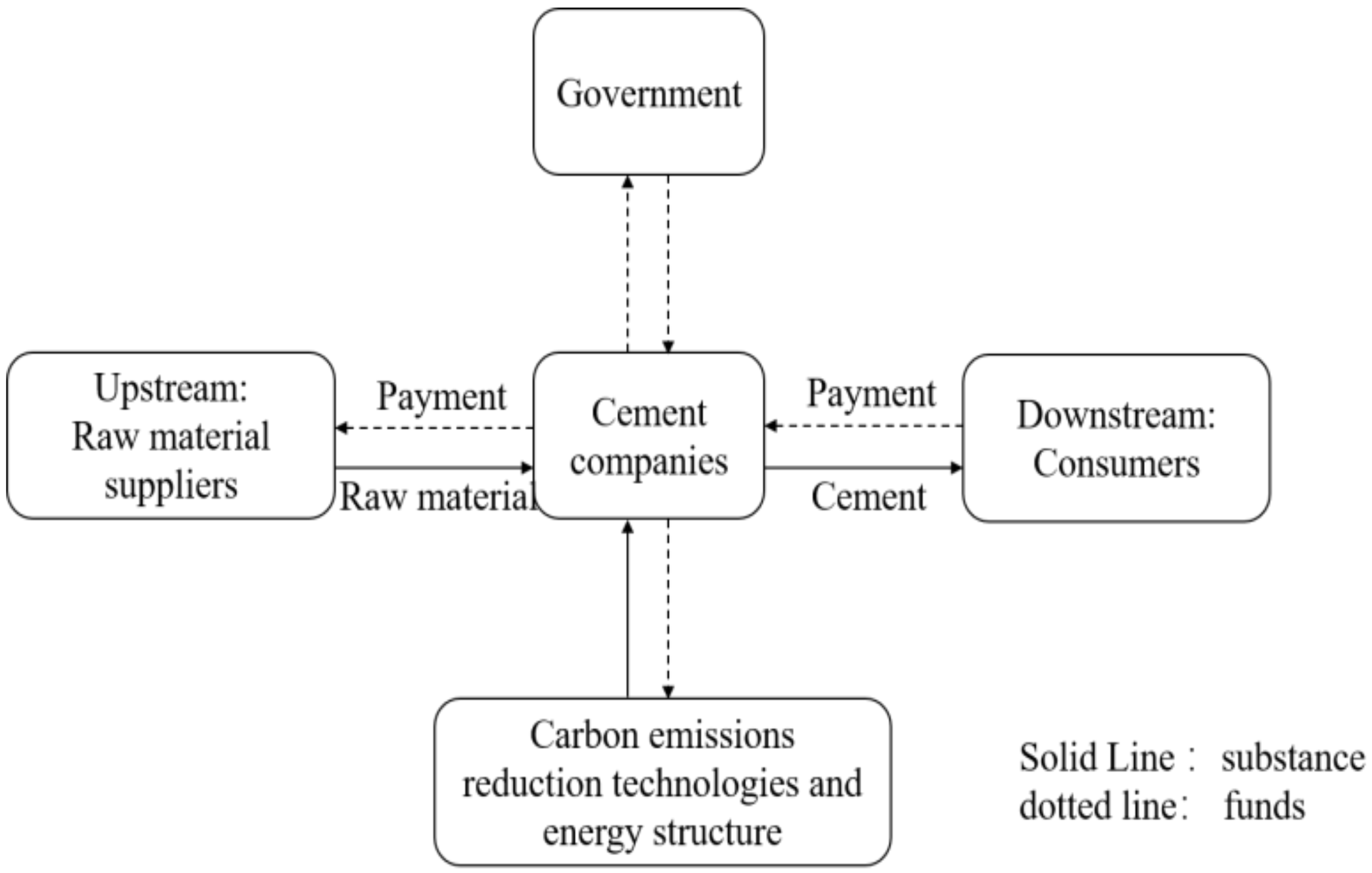

3.1. System Framework for Cement Companies

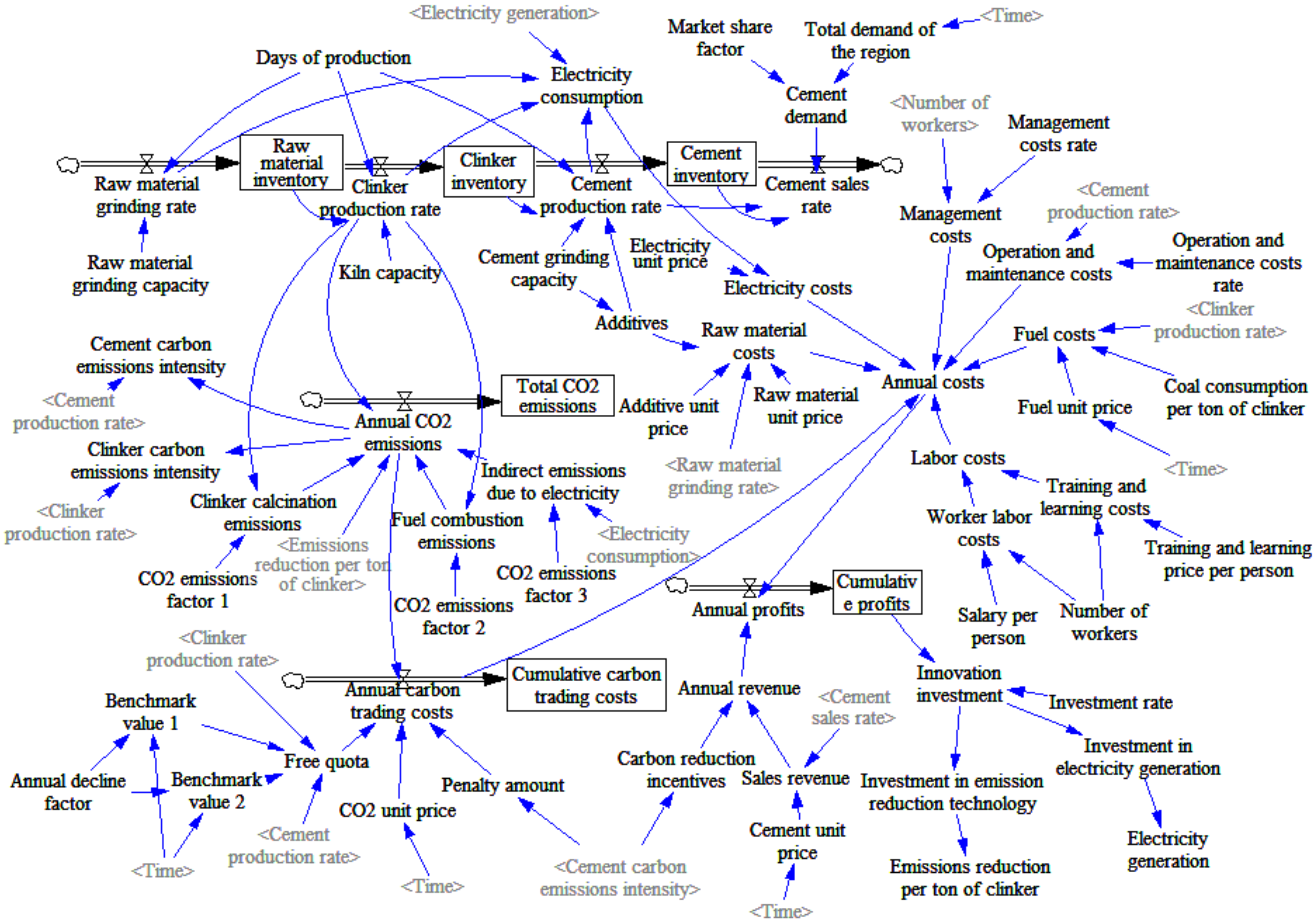

3.2. The Stock-Flow Diagram of the System Dynamics Model

- the government has developed a mature carbon trading market without considering carbon tax;

- the issue of corporate profit distribution is not considered;

- the domestic market can meet the needs of companies for raw materials;

- the market has a sound regulatory and information-sharing mechanism to avoid system collapse caused by other non-market behaviors;

- only the spot market for carbon emissions trading is considered, and the forward market is not considered;

- only carbon trading within the cement industry is considered, and carbon trading between the cement industry and other industries is not considered;

- the export trade of cement is not considered;

- only the sales of cement products are considered, and the sales of clinker and concrete are not considered.

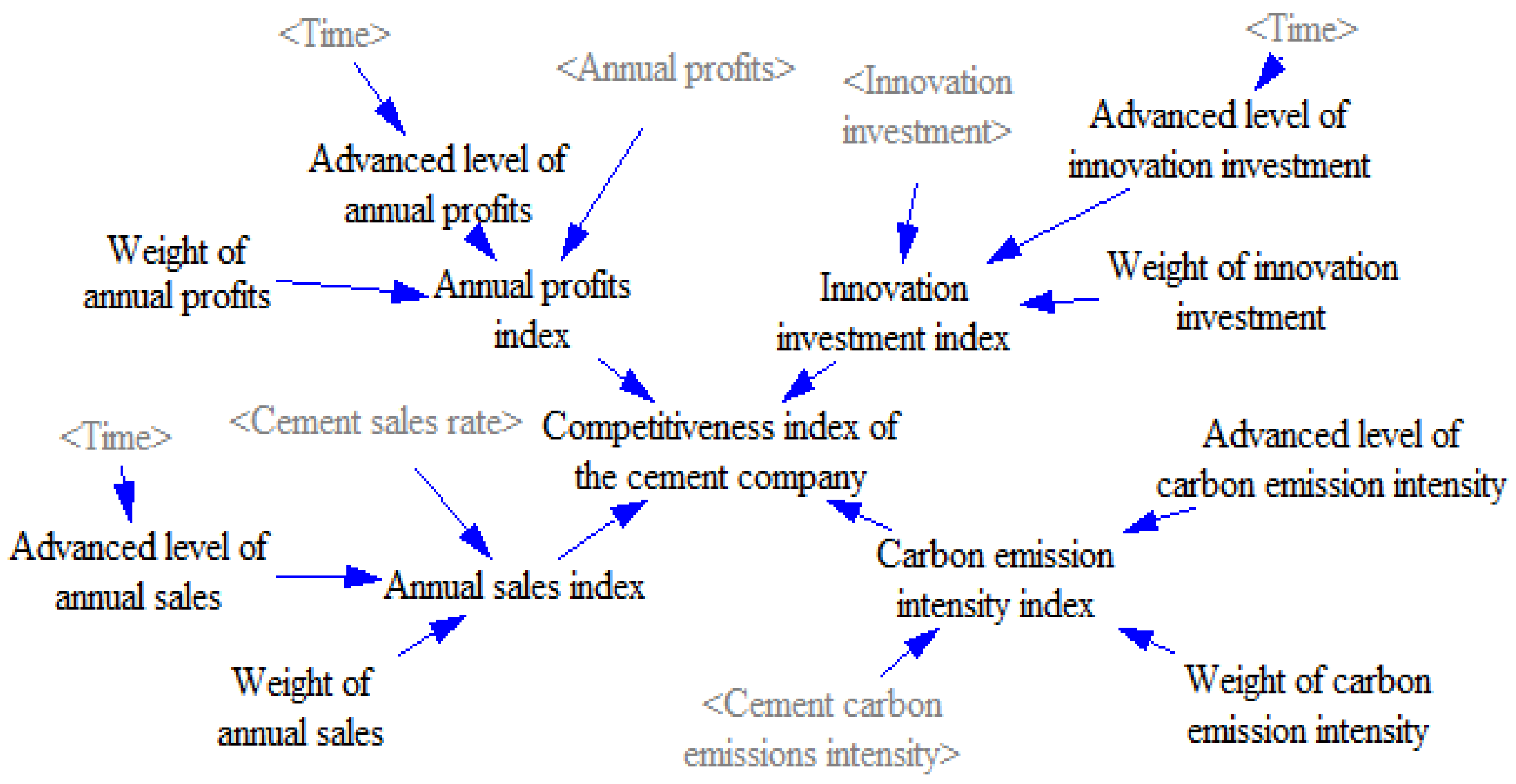

- Competitiveness index of the cement company = annual profits index+ annual sales index + innovation investment index + carbon emission intensity index

- Annual profits index = (annual profits/advanced level of annual profits) * weight of annual profits

- Annual sales index = (cement sales rate/advanced level of annual sales) * weight of annual sales

- Innovation investment index = (innovation investment/advanced level of Innovation investment) * weight of innovation investment

- Carbon emission intensity index = (advanced level of carbon emission intensity/cement carbon emissions intensity) * weight of carbon emission intensity

4. Case Study

4.1. Case Description

4.2. Model Development and Validation

4.3. Simulation Experiments Design

4.4. Results and Discussion

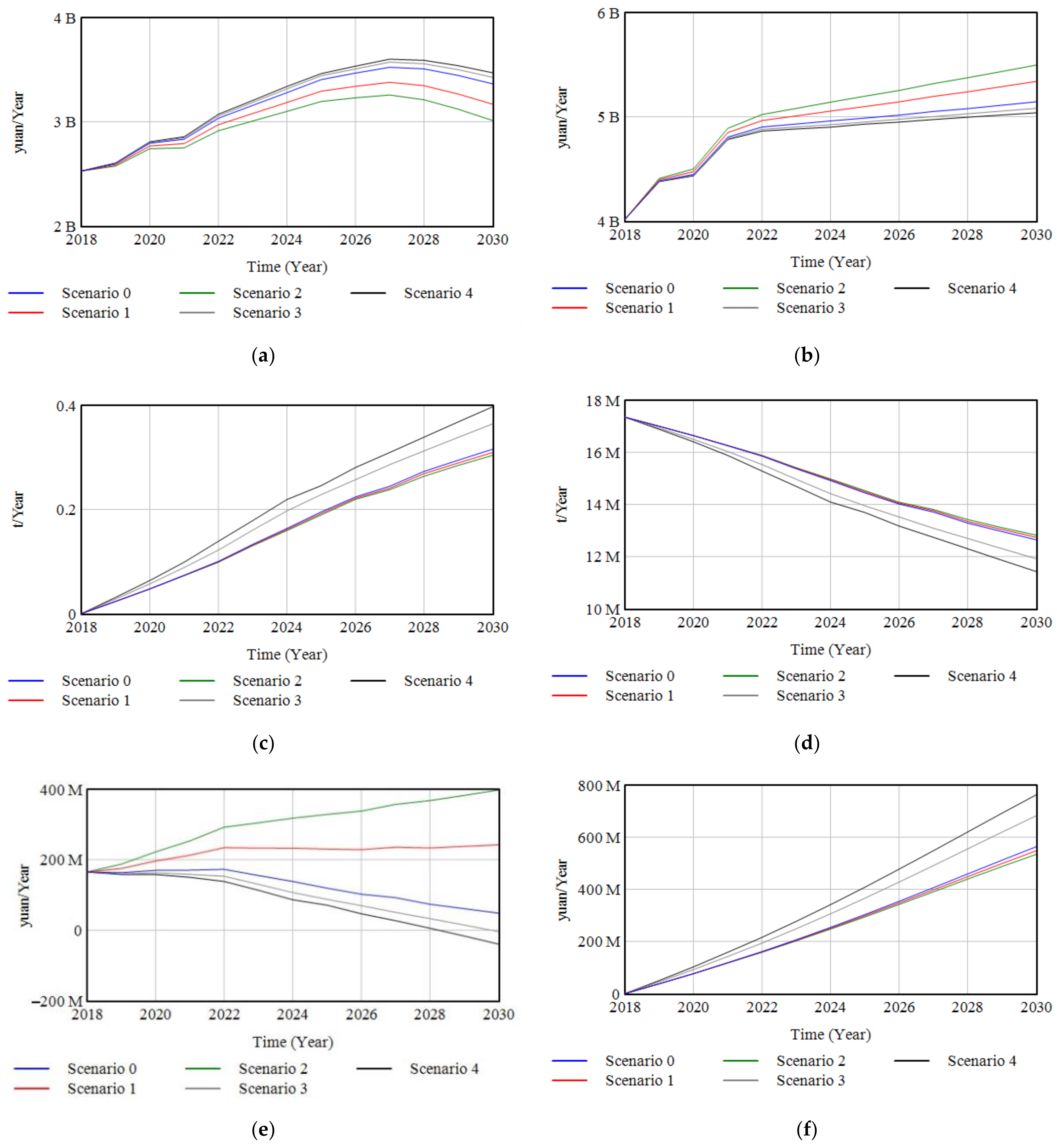

4.4.1. Simulation Results and Analysis of Single Scenarios

4.4.2. Simulation Results and Analysis of Combined Scenarios

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Model Equations

Appendix B. Parameters Setting

| Parameter | Value | Unit | Source |

|---|---|---|---|

| Total demand of the region | Table functions in Appendix A | t/year | China Statistical Yearbook, Zhang et al. [50] |

| Market share factor | 0.12 | - | T Cement company data |

| Raw material grinding capacity | 76,000 | t/d | T Cement company data |

| Kiln capacity | 47,500 | t/d | T Cement company data |

| Cement grinding capacity | 64,000 | t/d | T Cement company data |

| Clinker-cement ratio | 0.74 | - | T Cement company data |

| Raw material-clinker ratio | 1.60 | - | T Cement company data |

| Days of production | 310 | d/year | T Cement company data |

| Number of workers | 900 | people | T Cement company data |

| Electricity consumption of raw material grinding | 19 | kWh/t | Industry average, the norm of energy consumption per unit product of cement (GB16780-2021) |

| Electricity consumption of clinker calcination | 29 | kWh/t | Industry average, the norm of energy consumption per unit product of cement (GB16780-2021) |

| Electricity consumption of cement production | 34 | kWh/t | Industry average, the norm of energy consumption per unit product of cement (GB16780-2021) |

| Electricity generation | Table functions in Appendix A | kWh/year | Lu et al. [55] |

| Parameter | Value | Unit | Source |

|---|---|---|---|

| Training and learning price per person | 1000 | yuan/people·year | T Cement company data |

| Salary per person | 80.000 | yuan/people·year | T Cement company data |

| Management costs rate | 1200 | yuan/people·year | T Cement company data |

| Coal consumption per ton of clinker | 0.108 | tce/t | Industry average, the norm of energy consumption per unit product of cement (GB16780-2021) |

| Investment rate | 0.015 | - | T Cement company data |

| Additive unit price | 63 | yuan/t | Average market price |

| Raw material unit price | 42 | yuan/t | Average market price |

| Electricity unit price | 0.73 | yuan/kWh | Electricity price list of Guangdong Province |

| CO2 unit price | Table functions in Appendix A | yuan/t | Guangzhou Carbon Emissions Rights Exchange |

| Cement unit price | Table functions in Appendix A | yuan/t | China Cement Association |

| Fuel unit price | Table functions in Appendix A | yuan/t | China Coal Economic Network |

| Operation and maintenance costs rate | 8.9 | yuan/t·year | T Cement company data |

| Parameter | Value | Unit | Source |

|---|---|---|---|

| CO2 emissions factor 1 | 0.65 | - | Industry research data, Tan et al. [56] |

| CO2 emissions factor 2 | 0.44 | - | Industry research data, Tan et al. [56] |

| CO2 emissions factor 3 | 0.0008042 | tCO2/kWh | China Electricity Yearbook |

| Benchmark value 1 | 0.884 | tCO2/t.cl | Guangzhou Carbon Emissions Rights Exchange |

| Benchmark value 2 | 0.025 | tCO2/t | Guangzhou Carbon Emissions Rights Exchange |

| Annual decline factor | 0.99 | - | Guangzhou Carbon Emissions Rights Exchange |

| Emission reduction per ton of clinker | Table functions in Appendix A | tCO2/t.cl | Price, Tan et al. [51,52] |

| Parameter | Value | Unit | Source |

|---|---|---|---|

| Weight of annual profits | 0.25 | - | Gao [53] |

| Weight of annual sales | 0.37 | - | Gao [53] |

| Weight of innovation investment | 0.17 | - | Gao [53] |

| Weight of carbon emission intensity | 0.21 | - | Gao [53] |

| Advanced level of annual profits | Table functions in Appendix A | yuan/year | H and J Company data |

| Advanced level of annual sales | Table functions in Appendix A | t/year | H and J Company data |

| Advanced level of innovation investment | Table functions in Appendix A | yuan/year | H and J Company data |

| Advanced level of carbon emission intensity | Table functions in Appendix A | tCO2/year | H and J Company data |

References

- Tang, L.; Wang, H.; Li, L.; Yang, K.; Mi, Z. Quantitative models in emission trading system research: A literature review. Renew. Sustain. Energy Rev. 2020, 132, 110052. [Google Scholar] [CrossRef]

- IPCC. AR6 Climate Change 2021: The Physical Science Basis; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2021. [Google Scholar]

- Wang, A.; Cao, S.; Yilmaz, E. Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill. Constr. Build. Mater. 2022, 344, 128179. [Google Scholar] [CrossRef]

- Luo, Y.; Li, X.; Qi, X.; Zhao, D. The impact of emission trading schemes on firm competitiveness: Evidence of the mediating effects of firm behaviors from the guangdong ETS. J. Environ. Manag. 2021, 290, 112633. [Google Scholar] [CrossRef] [PubMed]

- Peasco, C.; Anadón, L.; Verdolini, E. Systematic review of the outcomes and trade-offs of ten types of decarbonization policy instruments. Nat. Clim. Change 2021, 11, 274. [Google Scholar] [CrossRef]

- Peace, J.; Juliani, T. The coming carbon market and its impact on the American economy. Policy Soc. 2017, 27, 305–316. [Google Scholar] [CrossRef]

- Akan, M.O.A.; Dhavale, D.G.; Sarkis, J. Greenhouse gas emissions in the construction industry: An analysis and evaluation of a concrete supply chain. J. Clean. Prod. 2017, 167, 1195–1207. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, X.; Liang, K. The impact of environmental regulation on firm performance: Evidence from the Chinese cement industry. J. Environ. Manag. 2021, 299, 113596. [Google Scholar] [CrossRef]

- Technology Roadmap-Low-Carbon Transition in the Cement Industry; International Energy Agency: Paris, France; World Business Council For Sustainable Development (WBCSD): Geneva, Switzerland, 2016.

- Wu, Q.; Ma, Z.; Meng, F. Long-term impacts of carbon allowance allocation in China: An IC-DCGE model optimized by the hypothesis of imperfectly competitive market. Energy 2022, 241, 122907. [Google Scholar] [CrossRef]

- Demailly, D.; Quirion, P. CO2 abatement, competitiveness and leakage in the European cement industry under the EU ETS: Grandfathering versus output-based allocation. Clim. Policy 2006, 6, 93–113. [Google Scholar] [CrossRef]

- Peng, H.; Qi, S.; Cui, J. The environmental and economic effects of the carbon emissions trading scheme in China: The role of alternative allowance allocation. Sustain. Prod. Consum. 2021, 28, 105–115. [Google Scholar] [CrossRef]

- Lyon, R.M. Equilibrium properties of auctions and alternative procedures for allocating transferable permits. J. Environ. Econ. Manag. 1986, 13, 129–152. [Google Scholar] [CrossRef]

- Zetterberg, L. Benchmarking in the European Union Emissions Trading System: Abatement incentives. Energy Econ. 2014, 43, 218–224. [Google Scholar] [CrossRef]

- Huebler, M.; Voigt, S.; Loeschel, A. Designing an emissions trading scheme for China—An up-to-date climate policy assessment. Energy Policy 2014, 75, 57–72. [Google Scholar] [CrossRef]

- Ellerman, A.; Marcantonini, C.; Zaklan, A. The EU ETS: Eight Years and Counting; Social Science Electronic Publishing: New York, NY, USA, 2014. [Google Scholar]

- Dai, F.; Xiong, L.; Ma, D. How to Set the Allowance Benchmarking for Cement Industry in China’s Carbon Market: Marginal Analysis and the Case of the Hubei Emission Trading Pilot. Sustainability 2017, 9, 322. [Google Scholar] [CrossRef]

- Sartor, O.; Palliere, C.; Lecourt, S. Benchmark-based allocations in EU ETS Phase 3: An early assessment. Clim. Policy 2014, 14, 507–524. [Google Scholar] [CrossRef]

- Branger, F.; Sato, M. Solving the Clinker Dilemma with Hybrid Output-based Allocation. Clim. Change Sustain. Dev. 2017, 140, 483–501. [Google Scholar] [CrossRef]

- Cong, R.; Wei, Y. Potential impact of (CET) carbon emissions trading on China’s power sector: A perspective from different allowance allocation options. Energy 2010, 35, 3921–3931. [Google Scholar] [CrossRef]

- Yang, W.; Pan, Y.; Ma, J.; Yang, T.; Ke, X. Effects of allowance allocation rules on green technology investment and product pricing under the cap-and-trade mechanism. Energy Policy 2020, 139, 111333. [Google Scholar] [CrossRef]

- Arlinghaus, J. Impacts of Carbon Prices on Indicators of Competitiveness: A Review of Empirical Findings; OECD Environment Working Papers No. 87; OECD: Paris, France, 2015. [Google Scholar]

- Zhang, Y.; Wang, A.; Tan, W. The impact of China’s carbon allowance allocation rules on the product prices and emission reduction behaviors of ETS-covered enterprises. Energy Policy 2015, 86, 176–185. [Google Scholar] [CrossRef]

- Porter, M.E.; Linde, C. Toward a New Conception of the Environment-Competitiveness Relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Yu, P.; Hao, R.; Cai, Z.; Sun, Y.; Zhang, X. Does emission trading system achieve the win-win of carbon emission reduction and financial performance improvement?—Evidence from Chinese A-share listed firms in industrial sector. J. Clean. Prod. 2022, 333, 130121. [Google Scholar] [CrossRef]

- Xiao, J.; Li, G.; Zhu, B.; Xie, L.; Huang, J. Evaluating the impact of carbon emissions trading scheme on Chinese firms’ total factor productivity. J. Clean. Prod. 2021, 306, 127104. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.; Ke, R.Y.; Wang, J. Integrated impact of the carbon quota constraints on enterprises within supply chain: Direct cost and indirect cost. Renew. Sustain. Energy Rev. 2018, 92, 774–783. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Chen, F. Do carbon emission trading schemes stimulate green innovation in enterprises? Evidence from China. Technol. Forecast. Soc. Change 2021, 168, 120744. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, M. China’s pilot emissions trading schemes and competitiveness: An empirical analysis of the provincial industrial sub-sectors. J. Environ. Manag. 2020, 258, 109997. [Google Scholar] [CrossRef]

- Smale, R.; Hartley, M.; Hepburn, C.; Ward, J.; Grubb, M. The impact of CO2 emissions trading on firm profits and market prices. Clim. Policy 2006, 6, 31–48. [Google Scholar] [CrossRef]

- Demailly, D.; Quirion, P. European Emission Trading Scheme and competitiveness: A case study on the iron and steel industry. Energy Econ. 2008, 30, 2009–2027. [Google Scholar] [CrossRef]

- Technology Roadmap-Low-Carbon Transition in the Cement Industry; International Energy Agency: Paris, France; World Business Council For Sustainable Development (WBCSD): Geneva, Switzerland, 2018.

- Branger, F.; Quirion, P. Reaping the carbon rent: Abatement and overallocation profits in the European cement industry, insights from an LMDI decomposition analysis. Energy Econ. 2015, 47, 189–205. [Google Scholar] [CrossRef]

- Rolfe, A.; Huang, Y.; Haaf, M.; Pita, A.; Rezvani, S.; Dave, A.; Hewitt, N.J. Technical and environmental study of calcium carbonate looping versus oxy-fuel options for low CO2 emission cement plants. Int. J. Greenh. Gas Control 2018, 75, 85–97. [Google Scholar] [CrossRef]

- Gardarsdottir, S.; Lena, E.D.; Romano, M.; Roussanaly, S.; Cinti, G. Comparison of Technologies for CO2 Capture from Cement Production—Part 2: Cost Analysis. Energies 2019, 12, 542. [Google Scholar] [CrossRef]

- Strunge, T.; Naims, H.; Ostovari, H.; Olfe-Kraeutlein, B. Priorities for supporting emission reduction technologies in the cement sector-A multi-criteria decision analysis of CO2 mineralisation. J. Clean. Prod. 2022, 340, 130712. [Google Scholar] [CrossRef]

- Report of the High-Level Commission on Carbon Pricing and Competitiveness; World Bank Group: Washington, DC, USA, 2019.

- Kunche, A.; Mielczarek, B. Application of System Dynamic Modelling for Evaluation of Carbon Mitigation Strategies in Cement Industries: A Comparative Overview of the Current State of the Art. Energies 2021, 14, 1464. [Google Scholar] [CrossRef]

- Proao, L.; Sarmiento, A.T.; Figueredo, M.; Cobo, M. Techno-economic evaluation of indirect carbonation for CO2 emissions capture in cement industry: A system dynamics approach. J. Clean. Prod. 2020, 263, 121457. [Google Scholar] [CrossRef]

- Yao, X.; Yuan, X.; Yu, S.; Lei, M. Economic feasibility analysis of carbon capture technology in steelworks based on system dynamics. J. Clean. Prod. 2021, 322, 129046. [Google Scholar] [CrossRef]

- Dong, S.; Wang, Z.; Li, Y.; Li, F.; Li, Z.; Chen, F.; Cheng, H. Assessment of Comprehensive Effects and Optimization of a Circular Economy System of Coal Power and Cement in Kongtong District, Pingliang City, Gansu Province, China. Sustainability 2017, 9, 787. [Google Scholar] [CrossRef]

- Ghaffarzadegan, N.; Tajrishi, A.T. Economic transition management in a commodity market: The case of the Iranian cement industry. Syst. Dyn. Rev. 2010, 26, 139–161. [Google Scholar] [CrossRef]

- Suryani, E.; Chou, S.; Hartono, R.; Chen, C. Demand scenario analysis and planned capacity expansion: A system dynamics framework. Simul. Model. Pract. Theory 2010, 18, 732–751. [Google Scholar] [CrossRef]

- Jokar, Z.; Mokhtar, A. Policy making in the cement industry for CO2 mitigation on the pathway of sustainable development—A system dynamics approach. J. Clean. Prod. 2018, 201, 142–155. [Google Scholar] [CrossRef]

- Ansari, N.; Seifi, A. A system dynamics model for analyzing energy consumption and CO2 emission in Iranian cement industry under various production and export scenarios. Energy Policy 2013, 58, 75–89. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, M.; Wu, S.; Liu, F. A complex path model for low-carbon sustainable development of enterprise based on system dynamics. J. Clean. Prod. 2021, 321, 128934. [Google Scholar] [CrossRef]

- Prahalad, C.K.; Hamel, G. The Core Competence of the Corporation. Harv. Bus. Rev. 1990, 68, 79–91. [Google Scholar]

- Prahalad, C.K.; Hamel, G. The Core Competence of the Corporation. Strateg. Learn. A Knowl. Econ. 2000, 3–22. [Google Scholar]

- Leonardbarton, D.; Deschamps, I. Managerial influence in the implementation of new technology. Manag. Sci. 1988, 34, 1252–1265. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Han, R.; Yu, B.Y.; Wei, Y.M. Accounting process-related CO2 emissions from global cement production under Shared Socioeconomic Pathways. J. Clean. Prod. 2018, 184, 451–465. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lu, H.; Lan, W. Analysis of energy-efficiency opportunities for the cement industry in Shandong Province, China: A case study of 16 cement plants. Energy 2010, 35, 3461–3473. [Google Scholar] [CrossRef]

- Tan, Q.; Wen, Z.; Chen, J. Goal and technology path of CO2 mitigation in China’s cement industry: From the perspective of co-benefit. J. Clean. Prod. 2016, 114, 299–313. [Google Scholar] [CrossRef]

- Gao, X. Research on Systematic Evaluation of Enterprise Low Carbon Competitiveness in the Perspective of Carbon Intangible Asset. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2014. [Google Scholar]

- Ramos, L.C.; Stopiglia, F.S.; de Gouvea, M.T.; Guimaraes, D.H.P.; Dias, A.L.B.; Rosa, M.T.M.G. Efficient and Sustainable Engines: Case Study of a Cement Industry Aiming at Energy Management. Rev. Virtual Quim. 2022, 14, 21–25. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, Y.; Fan, Q. Study on Feasibility of Photovoltaic Power to Grid Parity in China Based on LCOE. Sustainability 2021, 13, 12762. [Google Scholar] [CrossRef]

- Cao, Z.; Shen, L.; Zhao, J.; Liu, L.; Zhong, S.; Sun, Y.; Yang, Y. Toward a better practice for estimating the CO2 emission factors of cement production: An experience from China. J. Clean. Prod. 2016, 139, 527–539. [Google Scholar] [CrossRef]

| Annual Profits | Annual Sales | Innovation Investment | Carbon Emission Intensity | |

|---|---|---|---|---|

| Weights | 0.25 | 0.37 | 0.17 | 0.21 |

| Parameter | Value | Unit |

|---|---|---|

| Days of production | 310 | d/year |

| Raw material grinding capacity | 76,000 | t/d |

| Kiln capacity | 47,500 | t/d |

| Cement grinding capacity | 64,000 | t/d |

| Clinker-cement ratio | 0.74 | - |

| Raw material-clinker ratio | 1.60 | - |

| Electricity unit price | 0.73 | yuan/kWh |

| Electricity consumption of raw material grinding | 19 | kWh/t.raw |

| Electricity consumption of clinker calcination | 29 | kWh/t.cl |

| Electricity consumption of cement production | 34 | kWh/t |

| Coal consumption per ton of clinker | 0.108 | tce/t.cl |

| Time | Annual Costs | Annual Revenue | Annual Profits | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Simulation Value | Actual Value | Deviation(%) | Simulation Value | Actual Value | Deviation (%) | Simulation Value | Actual Value | Deviation (%) | |

| 2018 | 40.173 | 39.391 | 1.98 | 65.445 | 65.914 | −0.71 | 25.272 | 26.523 | −4.71 |

| 2019 | 43.845 | 42.835 | 2.36 | 69.837 | 68.373 | 2.14 | 25.992 | 25.539 | 1.78 |

| 2020 | 44.473 | 42.433 | 4.81 | 72.416 | 69.976 | 3.49 | 27.943 | 27.543 | 1.45 |

| 2021 | 48.055 | 48.368 | −0.65 | 76.384 | 76.702 | −0.41 | 28.329 | 28.334 | −0.02 |

| Technology | Investment Amount (yuan/t.cl) (1) | Emission-Reduction Potential (kgCO2/t.cl) (2) | Cost-Effectiveness (2)/(1) | Rank |

|---|---|---|---|---|

| Alternative fuels | 7.52 | 125 | 16.62 | 1 |

| Waste heat utilization | 2 | 32 | 16 | 2 |

| Energy efficiency improvement | 0.4 | 6 | 15 | 3 |

| Clinker-cement ratio reduction, | 6.7 | 95 | 14.18 | 4 |

| Low-carbon clinker | 3.2 | 45 | 14.06 | 5 |

| Smart industrial systems | 0.42 | 5 | 11.9 | 6 |

| Fuel efficiency improvement | 1.7 | 20 | 11.76 | 7 |

| Alternative raw materials | 1.2 | 14 | 11.67 | 8 |

| Carbon capture, utilization and storage (CCUS) | 24 | 195 | 8.13 | 9 |

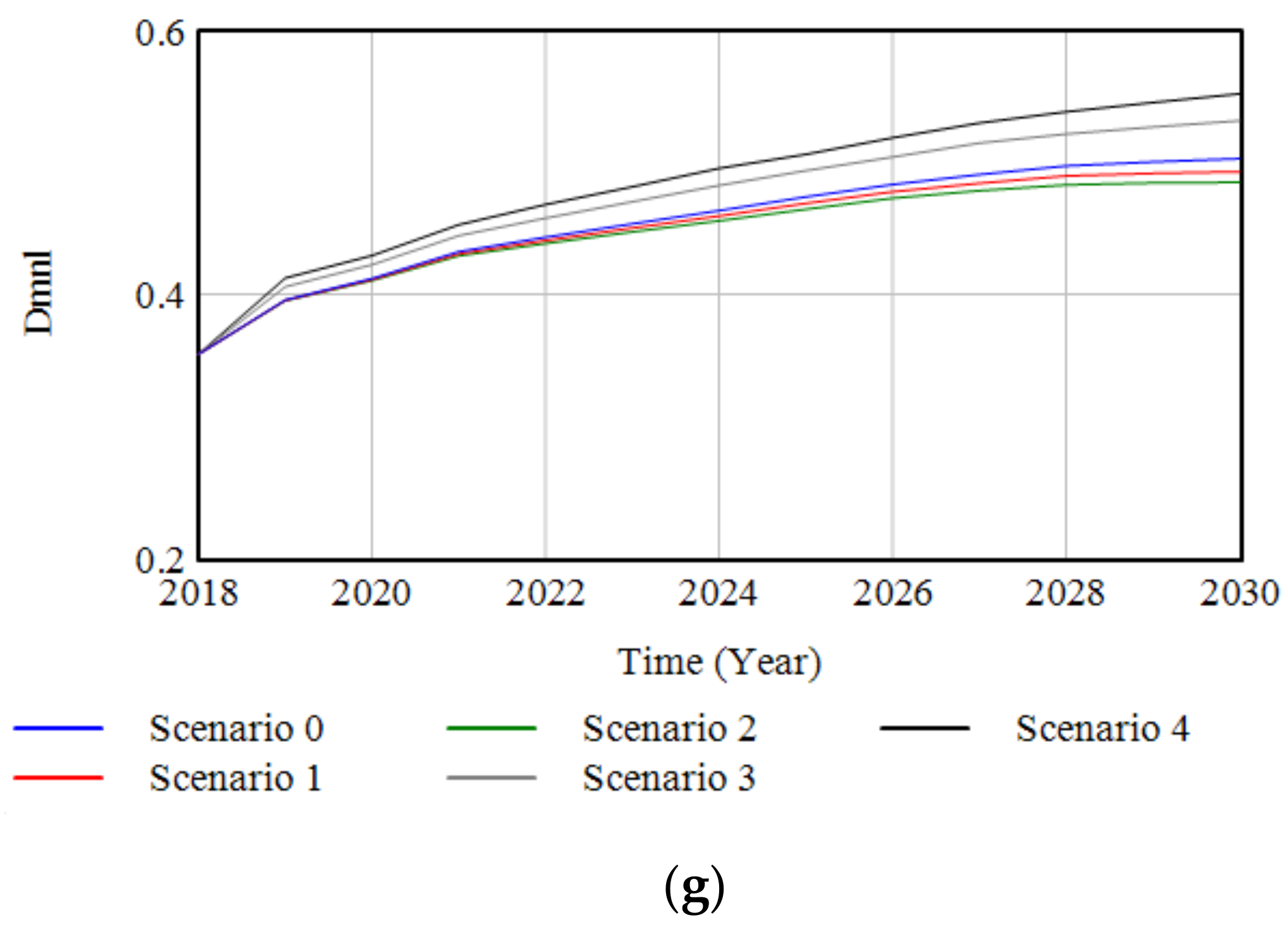

| Scenario Design | Annual Decline Factor of the Benchmark Value | Innovation Investment Rate (%) |

|---|---|---|

| Scenario 0 (baseline scenario) | 0.99 | 1.5 |

| Scenario 1 (annual decline factor reduced by 0.02) | 0.97 | 1.5 |

| Scenario 2 (annual decline factor reduced by 0.04) | 0.95 | 1.5 |

| Scenario 3 (investment rate improved by 0.3%) | 0.99 | 1.8 |

| Scenario 4 (investment rate improved by 0.5%) | 0.99 | 2.0 |

| Scenario 5 (two indicators adjusted simultaneously) | 0.97 | 1.8 |

| Scenario 6 (two indicators adjusted simultaneously to a greater extent) | 0.95 | 2.0 |

| Time | Scenario 0 | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | Scenario 6 |

|---|---|---|---|---|---|---|---|

| 2018 | 0.3547 | 0.3547 | 0.3547 | 0.3547 | 0.3547 | 0.3547 | 0.3547 |

| 2019 | 0.3959 | 0.3956 | 0.3953 | 0.4059 | 0.4125 | 0.4056 | 0.4120 |

| 2020 | 0.4121 | 0.4113 | 0.4105 | 0.4226 | 0.4296 | 0.4218 | 0.4279 |

| 2021 | 0.4325 | 0.4309 | 0.4294 | 0.4447 | 0.4529 | 0.4430 | 0.4496 |

| 2022 | 0.4434 | 0.4410 | 0.4387 | 0.4579 | 0.4682 | 0.4554 | 0.4632 |

| 2023 | 0.4537 | 0.4505 | 0.4475 | 0.4703 | 0.4817 | 0.4669 | 0.4749 |

| 2024 | 0.4636 | 0.4596 | 0.4559 | 0.4827 | 0.4956 | 0.4784 | 0.4872 |

| 2025 | 0.4741 | 0.4691 | 0.4647 | 0.4940 | 0.5063 | 0.4890 | 0.4962 |

| 2026 | 0.4834 | 0.4779 | 0.4730 | 0.5042 | 0.5188 | 0.4979 | 0.5070 |

| 2027 | 0.4909 | 0.4843 | 0.4787 | 0.5148 | 0.5301 | 0.5078 | 0.5162 |

| 2028 | 0.4975 | 0.4899 | 0.4831 | 0.5217 | 0.5385 | 0.5135 | 0.5225 |

| 2029 | 0.5005 | 0.4919 | 0.4846 | 0.5270 | 0.5456 | 0.5175 | 0.5271 |

| 2030 | 0.5030 | 0.4932 | 0.4851 | 0.5318 | 0.5522 | 0.5209 | 0.5311 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Zhao, M.; Zhu, J. The Impact of Carbon Quota Benchmark Allocation on Cement Company Competitiveness: A System Dynamics Approach. Buildings 2022, 12, 1599. https://doi.org/10.3390/buildings12101599

Du J, Zhao M, Zhu J. The Impact of Carbon Quota Benchmark Allocation on Cement Company Competitiveness: A System Dynamics Approach. Buildings. 2022; 12(10):1599. https://doi.org/10.3390/buildings12101599

Chicago/Turabian StyleDu, Jing, Min Zhao, and Jin Zhu. 2022. "The Impact of Carbon Quota Benchmark Allocation on Cement Company Competitiveness: A System Dynamics Approach" Buildings 12, no. 10: 1599. https://doi.org/10.3390/buildings12101599

APA StyleDu, J., Zhao, M., & Zhu, J. (2022). The Impact of Carbon Quota Benchmark Allocation on Cement Company Competitiveness: A System Dynamics Approach. Buildings, 12(10), 1599. https://doi.org/10.3390/buildings12101599