Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review

Abstract

1. Introduction

2. Previous Review Work

3. Methodology

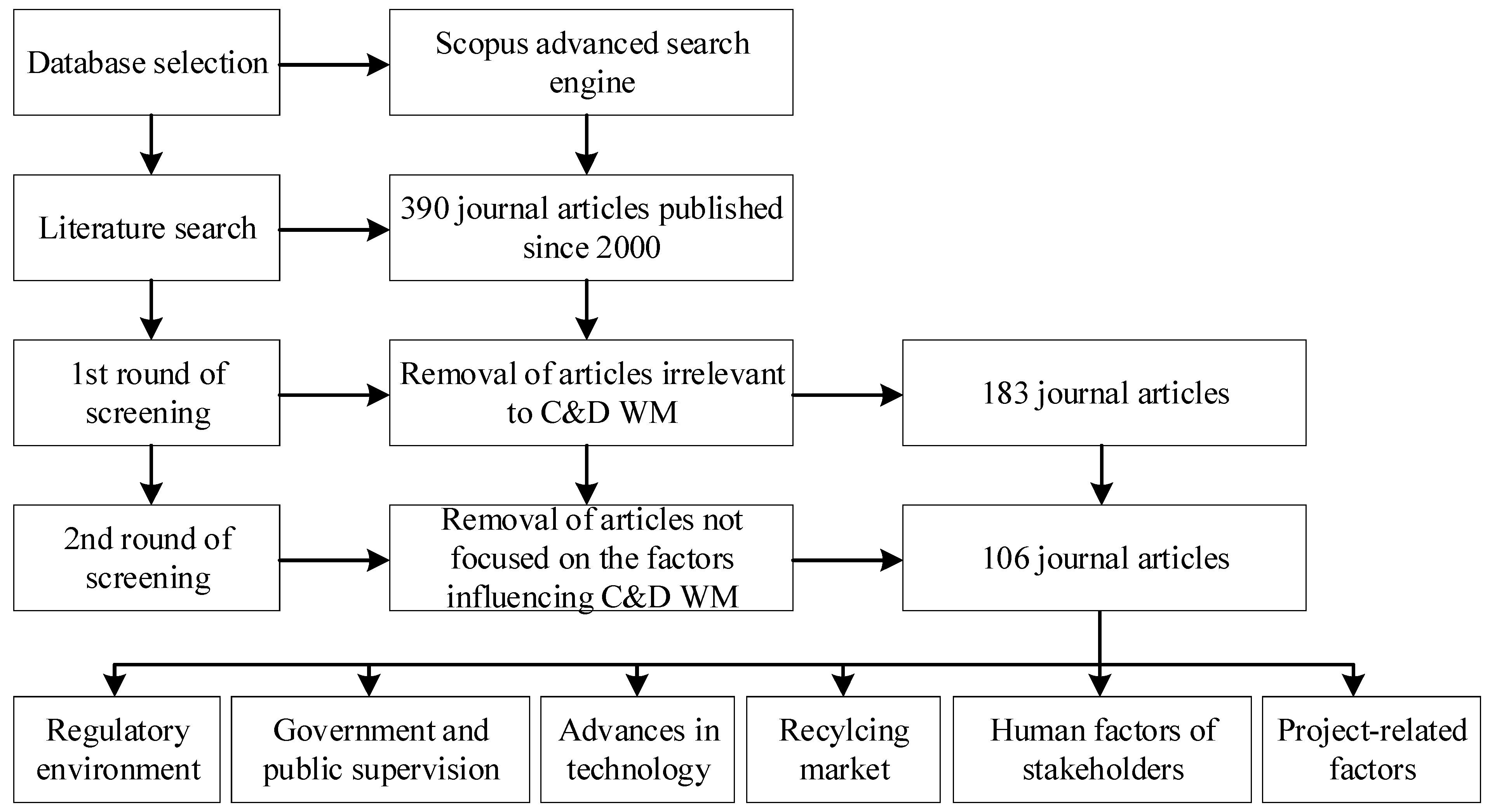

3.1. Database Selection

3.2. Literature Search

3.3. Screening

4. Stakeholder-Associated Factors

4.1. Regulatory Environment

4.1.1. Legislation and Enforcement

4.1.2. Incentive, Penalty, and Fee

4.2. Government and Public Supervision

4.3. Advances in Relevant Technologies

4.4. C&D Waste Recycling Market

4.5. Knowledge, Awareness, Attitude, and Behaviour of Stakeholders

4.5.1. Knowledge and Skills

4.5.2. Awareness, Attitude, and Behaviour

4.5.3. Training and Education

4.5.4. Organizational Context

4.6. Project-Specific Factors

4.6.1. Communication and Coordination among Project Participants

4.6.2. Selecting Contractors with C&D WM Capability

4.6.3. Effective Contract Management

4.6.4. Formal WM Plans

4.6.5. Site Conditions for On-Site Waste Treatment

4.6.6. Effective Site Management

4.6.7. Adoption of Low-Waste Methods in Design and Construction

5. Conclusions and Recommendations

Funding

Conflicts of Interest

References

- Yuan, H. A SWOT analysis of successful construction waste management. J. Clean. Prod. 2013, 39, 1–8. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Eliassen, R.; Theisen, H. Solid Wastes; Engineering Principles and Management Issues; Mcgraw-Hill: New York City, NY, USA, 1977. [Google Scholar]

- Poon, C.S.; Yu, A.T.W.; Ng, L.H. On-site sorting of construction and demolition waste in Hong Kong. Resour. Conserv. Recycl. 2001, 32, 157–172. [Google Scholar] [CrossRef]

- Yuan, H.; Lu, W.; Jianli Hao, J. The evolution of construction waste sorting on-site. Renew. Sustain. Energy Rev. 2013, 20, 483–490. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Ronkanen, M.; Kärki, T. Sorting efficiency in mechanical sorting of construction and demolition waste. Waste Manag. Res. 2020, 38, 812–816. [Google Scholar] [CrossRef]

- Modak, P.; Wilson, D.C.; Velis, C. Waste Management: Global Status. In Global Waste Management Outlook; Wilson, D.C., Ed.; United Nations Environment Programme: Nairobi, Kenya, 2015. [Google Scholar]

- Eurostat. Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics#Waste_generation_excluding_major_mineral_waste (accessed on 24 November 2020).

- Pickin, J.; Randell, P.; Trinh, J.; Grant, B. National Waste Report 2018; Department of the Environment and Energy Australia: Canberra, Australia, 2018.

- Rosado, L.P.; Vitale, P.; Penteado, C.S.; Arena, U. Life cycle assessment of construction and demolition waste management in a large area of São Paulo State, Brazil. Waste Manag. 2019, 85, 477–489. [Google Scholar] [CrossRef]

- Forward. Report of Market Research and Investment Forecast Analysis on China Construction and Demolition Waste Disposal Industry (2020–2025); Forward Business Information Co. Ltd.: Shenzhen, China, 2020. [Google Scholar]

- US Environmental Protection Agency. Facts and Figures about Materials, Waste and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/construction-and-demolition-debris-material (accessed on 9 December 2020).

- Bao, Z.; Lu, W. Developing efficient circularity for construction and demolition waste management in fast emerging economies: Lessons learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138264. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- El-Haggar, S.M. Sustainable Industrial Design and Waste Management: Cradle-to-Cradle for Sustainable Development; Elsevier Academic Press: Maryland Heights, MO, USA, 2007. [Google Scholar]

- Hwang, B.G.; Yeo, Z.B. Perception on benefits of construction waste management in the Singapore construction industry. Eng. Constr. Archit. Manag. 2011, 18, 394–406. [Google Scholar] [CrossRef]

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, S. Pollution Control and Resource Recovery: Industrial Construction and Demolition Wastes; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Ding, Z.; Wang, Y.; Zou, P.X.W. An agent based environmental impact assessment of building demolition waste management: Conventional versus green management. J. Clean. Prod. 2016, 133, 1136–1153. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, W. Demolition waste recycling in China: New evidence from a demolition project for highway development. Waste Manag. Res. 2020, 38, 696–702. [Google Scholar] [CrossRef]

- Saju, M.T. India Recycles Only 1% of Construction and Demolition Waste. Available online: https://timesofindia.indiatimes.com/business/india-business/india-recycles-only-1-of-construction-and-demolition-waste-study-finds/articleshow/77747060.cms (accessed on 24 November 2020).

- Yuan, H.; Shen, L. Trend of the research on construction and demolition waste management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. Exploring critical success factors for waste management in construction projects of China. Resour. Conserv. Recycl. 2010, 55, 201–208. [Google Scholar] [CrossRef]

- Yuan, H. Barriers and countermeasures for managing construction and demolition waste: A case of Shenzhen in China. J. Clean. Prod. 2017, 157, 84–93. [Google Scholar] [CrossRef]

- Bao, Z.; Lee, W.M.W.; Lu, W. Implementing on-site construction waste recycling in Hong Kong: Barriers and facilitators. Sci. Total Environ. 2020, 747, 141091. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Improving waste management in construction projects: An Australian study. Resour. Conserv. Recycl. 2015, 101, 73–83. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Critical design factors for minimising waste in construction projects: A structural equation modelling approach. Resour. Conserv. Recycl. 2018, 137, 302–313. [Google Scholar] [CrossRef]

- Manowong, E. Investigating factors influencing construction waste management efforts in developing countries: An experience from Thailand. Waste Manag. Res. 2012, 30, 56–71. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Wong, S.W.; Cheung, E. Management of construction waste in public housing projects in Hong Kong. Constr. Manag. Econ. 2004, 22, 675–689. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Attitudinal and behavioural approaches to improving waste management on construction projects in Australia: Benefits and limitations. Int. J. Constr. Manag. 2015, 15, 137–147. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Yuan, H.; Zillante, G.; Elmualim, A. Major factors impeding the implementation of waste management in Australian construction projects. J. Green Build. 2018, 13, 101–121. [Google Scholar] [CrossRef]

- Kim, S.Y.; Nguyen, M.V.; Luu, V.T. A performance evaluation framework for construction and demolition waste management: Stakeholder perspectives. Eng. Constr. Archit. Manag. 2020, 27, 3189–3213. [Google Scholar] [CrossRef]

- Lingard, H.; Graham, P.; Smithers, G. Employee perceptions of the solid waste management system operating in a large Australian contracting organization: Implications for company policy implementation. Constr. Manag. Econ. 2000, 18, 383–393. [Google Scholar] [CrossRef]

- Du, L.; Feng, Y.; Lu, W.; Kong, L.; Yang, Z. Evolutionary game analysis of stakeholders’ decision-making behaviours in construction and demolition waste management. Environ. Impact Assess. Rev. 2020, 84. [Google Scholar] [CrossRef]

- Su, Y.; Si, H.; Chen, J.; Wu, G. Promoting the sustainable development of the recycling market of construction and demolition waste: A stakeholder game perspective. J. Clean. Prod. 2020, 277, 122281. [Google Scholar] [CrossRef]

- Li, J.; Tam, V.W.; Zuo, J.; Zhu, J. Designers’ attitude and behaviour towards construction waste minimization by design: A study in Shenzhen, China. Resour. Conserv. Recycl. 2015, 105, 29–35. [Google Scholar] [CrossRef]

- Osmani, M.; Glass, J.; Price, A. Architect and Contractor Attitudes to Waste Minimization. In Proceedings of the Institution of the Civil Engineers-Waste and Resource Management, London, UK, 1 November 2017; Volume 170, pp. 65–72. [Google Scholar]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. A benefit–cost analysis on the economic feasibility of construction waste minimisation: The case of Malaysia. Resour. Conserv. Recycl. 2006, 48, 86–98. [Google Scholar] [CrossRef]

- Shen, H.; Peng, Y.; Guo, C. Analysis of the evolution game of construction and demolition waste recycling behavior based on prospect theory under environmental regulation. Int. J. Environ. Res. Public Health 2018, 15, 1518. [Google Scholar] [CrossRef] [PubMed]

- Osmani, M.; Glass, J.; Price, A.D.F. Architects’ perspectives on construction waste reduction by design. Waste Manag. 2008, 28, 1147–1158. [Google Scholar] [CrossRef] [PubMed]

- Baumeister, R.F.; Leary, M.R. Writing narrative literature reviews. Rev. Gen. Psychol. 1997, 1, 311–320. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, xiii–xxiii. [Google Scholar]

- Zhao, X.; Ke, Y.; Zuo, J.; Xiong, W.; Wu, P. Evaluation of sustainable transport research in 2000–2019. J. Clean. Prod. 2020, 256, 120404. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhao, Y.; Xiao, B.; Yu, B.; Tam, V.W.Y.; Chen, Z.; Ya, Y. Research trend of the application of information technologies in construction and demolition waste management. J. Clean. Prod. 2020, 263. [Google Scholar] [CrossRef]

- Faruqi, M.H.Z.; Siddiqui, F.Z. A mini review of construction and demolition waste management in India. Waste Manag. Res. 2020, 38, 708–716. [Google Scholar] [CrossRef]

- Daoud, A.O.; Othman, A.A.E.; Robinson, H.; Bayyati, A. An investigation into solid waste problem in the Egyptian construction industry: A mini-review. Waste Manag. Res. 2020, 38, 371–382. [Google Scholar] [CrossRef]

- Bergsdal, H.; Bohne, R.A.; Brattebø, H. Projection of construction and demolition waste in Norway. J. Ind. Ecol. 2007, 11, 27–39. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Boltakova, N.V.; Faseeva, G.R.; Kabirov, R.R.; Nafikov, R.M.; Zakharov, Y.A. Utilization of inorganic industrial wastes in producing construction ceramics. Review of Russian experience for the years 2000–2015. Waste Manag. 2017, 60, 230–246. [Google Scholar] [CrossRef]

- Goldstein, J. Just how “wicked” is Beijing’s waste problem? A response to “The rise and fall of a “waste city” in the construction of an “urban circular economic system”: The changing landscape of waste in Beijing” by Xin Tong and Dongyan Tao. Resour. Conserv. Recycl. 2017, 117, 177–182. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Utilization of wood waste ash in construction technology: A review. Constr. Build. Mater. 2020, 237. [Google Scholar] [CrossRef]

- Sudharsan, N.; Palanisamy, T.; Yaragal, S.C. Environmental sustainability of waste glass as a valuable construction material—A critical review. Ecol. Environ. Conserv. 2018, 24, S331–S338. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Construction and demolition waste research: A bibliometric analysis. Archit. Sci. Rev. 2019, 62, 354–365. [Google Scholar] [CrossRef]

- Borrego, M.; Foster, M.J.; Froyd, J.E. Systematic literature reviews in engineering education and other developing interdisciplinary fields. J. Eng. Educ. 2014, 103, 45–76. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, web of science, and Google scholar: Strengths and weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef] [PubMed]

- Jin, R.; Zou, P.X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A science mapping approach based review of construction safety research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Huo, X.; Owusu-Manu, D.-G. A scientometric analysis and visualization of global green building research. Build. Environ. 2019, 149, 501–511. [Google Scholar] [CrossRef]

- Zhao, X.; Zuo, J.; Wu, G.; Huang, C. A bibliometric review of green building research 2000-2016. Archit. Sci. Rev. 2019, 62, 74–88. [Google Scholar] [CrossRef]

- Eva, N.; Newman, A.; Jiang, Z.; Brouwer, M. Career optimism: A systematic review and agenda for future research. J. Vocat. Behav. 2020, 116, 103287. [Google Scholar] [CrossRef]

- Luo, L.; He, Q.; Jaselskis, E.J.; Xie, J. Construction project complexity: Research trends and implications. J. Constr. Eng. Manag. 2017, 143, 04017019. [Google Scholar] [CrossRef]

- Park, J.; Tucker, R. Overcoming barriers to the reuse of construction waste material in Australia: A review of the literature. Int. J. Constr. Manag. 2017, 17, 228–237. [Google Scholar] [CrossRef]

- Liu, H.; Long, H.; Li, X. Identification of critical factors in construction and demolition waste recycling by the grey-DEMATEL approach: A Chinese perspective. Environ. Sci. Pollut. Res. 2020, 27, 8507–8525. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.-S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econom. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Liu, J.; Yi, Y.; Wang, X. Exploring factors influencing construction waste reduction: A structural equation modeling approach. J. Clean. Prod. 2020, 276, 123185. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Clark, C.; Jambeck, J.; Townsend, T. A review of construction and demolition debris regulations in the United States. Crit. Rev. Environ. Sci. Technol. 2006, 36, 141–186. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241. [Google Scholar] [CrossRef]

- Seror, N.; Portnov, B.A. Estimating the effectiveness of different environmental law enforcement policies on illegal C&D waste dumping in Israel. Waste Manag. 2020, 102, 241–248. [Google Scholar] [CrossRef]

- Kolaventi, S.S.; Tezeswi, T.P.; Siva Kumar, M.V.N. An assessment of construction waste management in India: A statistical approach. Waste Manag. Res. 2019. [Google Scholar] [CrossRef]

- Bakshan, A.; Srour, I.; Chehab, G.; El-Fadel, M.; Karaziwan, J. Behavioral determinants towards enhancing construction waste management: A Bayesian Network analysis. Resour. Conserv. Recycl. 2017, 117, 274–284. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Policy imperatives for diverting construction waste from landfill: Experts’ recommendations for UK policy expansion. J. Clean. Prod. 2017, 147, 57–65. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Khalfan, M.; Yang, R.J.; Wong, P. Landfill levy imposition on construction and demolition waste: Australian stakeholders’ perceptions. Sustainability 2020, 12, 4496. [Google Scholar] [CrossRef]

- Del Río Merino, M.; Gracia, P.I.; Azevedo, I.S.W. Sustainable construction: Construction and demolition waste reconsidered. Waste Manag. Res. 2010, 28, 118–129. [Google Scholar] [CrossRef]

- Calvo, N.; Varela-Candamio, L.; Novo-Corti, I. A dynamic model for construction and demolition (C&D) waste management in Spain: Driving policies based on economic incentives and tax penalties. Sustainability 2014, 6, 416–435. [Google Scholar] [CrossRef]

- Hiete, M.; Stengel, J.; Ludwig, J.; Schultmann, F. Matching construction and demolition waste supply to recycling demand: A regional management chain model. Build. Res. Inf. 2011, 39, 333–351. [Google Scholar] [CrossRef]

- Yu, A.T.W.; Poon, C.S.; Wong, A.; Yip, R.; Jaillon, L. Impact of Construction Waste Disposal Charging Scheme on work practices at construction sites in Hong Kong. Waste Manag. 2013, 33, 138–146. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Wong, A.; Yip, R. Quantifying the impact of construction waste charging scheme on construction waste management in Hong Kong. J. Constr. Eng. Manag. 2013, 139, 466–479. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, J. A system dynamics model for determining the waste disposal charging fee in construction. Eur. J. Oper. Res. 2014, 237, 988–996. [Google Scholar] [CrossRef]

- Rameezdeen, R.; Chileshe, N.; Hosseini, M.R.; Lehmann, S. A qualitative examination of major barriers in implementation of reverse logistics within the South Australian construction sector. Int. J. Constr. Manag. 2016, 16, 185–196. [Google Scholar] [CrossRef]

- Au, L.S.; Ahn, S.; Kim, T.W. System dynamic analysis of impacts of government charges on disposal of construction and demolition waste: A Hong Kong case study. Sustainability 2018, 10, 1077. [Google Scholar] [CrossRef]

- Liu, J.; Teng, Y.; Wang, D.; Gong, E. System dynamic analysis of construction waste recycling industry chain in China. Environ. Sci. Pollut. Res. 2020, 27, 37260–37277. [Google Scholar] [CrossRef]

- Chen, J.; Hua, C.; Liu, C. Considerations for better construction and demolition waste management: Identifying the decision behaviors of contractors and government departments through a game theory decision-making model. J. Clean. Prod. 2019, 212, 190–199. [Google Scholar] [CrossRef]

- Mahpour, A.; Mortaheb, M.M. Financial-Based Incentive Plan to Reduce Construction Waste. J. Constr. Eng. Manag. 2018, 144. [Google Scholar] [CrossRef]

- Ding, Z.; Yi, G.; Tam, V.W.Y.; Huang, T. A system dynamics-based environmental performance simulation of construction waste reduction management in China. Waste Manag. 2016, 51, 130–141. [Google Scholar] [CrossRef] [PubMed]

- Mahamid, I. Impact of rework on material waste in building construction projects. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.; Shen, L. Investigating the determinants of contractor’s construction and demolition waste management behavior in Mainland China. Waste Manag. 2017, 60, 290–300. [Google Scholar] [CrossRef]

- Long, H.; Liu, H.; Li, X.; Chen, L. An evolutionary game theory study for construction and demolition waste recycling considering green development performance under the chinese government’s reward–penalty mechanism. Int. J. Environ. Res. Public Health 2020, 17, 6303. [Google Scholar] [CrossRef]

- Su, Y. Multi-agent evolutionary game in the recycling utilization of construction waste. Sci. Total Environ. 2020, 738. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. A framework for understanding waste management studies in construction. Waste Manag. 2011, 31, 1252–1260. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J. Estimation of building-related construction and demolition waste in Shanghai. Waste Manag. 2014, 34, 2327–2334. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Ding, G.; Feng, Z. Developing a quantitative construction waste estimation model for building construction projects. Resour. Conserv. Recycl. 2016, 106, 9–20. [Google Scholar] [CrossRef]

- Maués, L.M.F.; Nascimento, B.D.M.O.D.; Lu, W.; Xue, F. Estimating construction waste generation in residential buildings: A fuzzy set theory approach in the Brazilian Amazon. J. Clean. Prod. 2020, 265. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Wong, C.T.C. Barcode technology for an incentive reward program to reduce construction wastes. Comput. Aided Civ. Infrastruct. Eng. 2003, 18, 313–324. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Yong, L.; Kong, S.C.W. Application of integrated GPS and GIS technology for reducing construction waste and improving construction efficiency. Autom. Constr. 2005, 14, 323–331. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Duan, H.; Zillante, G.; Zuo, J.; Yuan, H. Combining life cycle assessment and Building Information Modelling to account for carbon emission of building demolition waste: A case study. J. Clean. Prod. 2018, 172, 3154–3166. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F.; Faust, K.M. 4D-BIM to enhance construction waste reuse and recycle planning: Case studies on concrete and drywall waste streams. Waste Manag. 2020, 116, 79–90. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J.; Duan, H.; Ouyang, L.; Huang, W.; Zuo, J. An innovative approach to managing demolition waste via GIS (geographic information system): A case study in Shenzhen city, China. J. Clean. Prod. 2016, 112, 494–503. [Google Scholar] [CrossRef]

- Paz, D.H.F.; Lafayette, K.P.V.; Sobral, M.C. GIS-based planning system for managing the flow of construction and demolition waste in Brazil. Waste Manag. Res. 2018, 36, 541–549. [Google Scholar] [CrossRef]

- Seror, N.; Portnov, B.A. Identifying areas under potential risk of illegal construction and demolition waste dumping using GIS tools. Waste Manag. 2018, 75, 22–29. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.O.; Akinade, O.O.; Ajayi, S.O.; Alaka, H.A.; Owolabi, H.A.; Qadir, J.; Pasha, M.; Bello, S.A. Big data architecture for construction waste analytics (CWA): A conceptual framework. J. Build. Eng. 2016, 6, 144–156. [Google Scholar] [CrossRef]

- Lu, W. Big data analytics to identify illegal construction waste dumping: A Hong Kong study. Resour. Conserv. Recycl. 2019, 141, 264–272. [Google Scholar] [CrossRef]

- Chen, X.; Lu, W. Identifying factors influencing demolition waste generation in Hong Kong. J. Clean. Prod. 2017, 141, 799–811. [Google Scholar] [CrossRef]

- Zhang, L.; Atkins, A.S. A Decision Support Application in Tracking Construction Waste Using Rule-based Reasoning and RFID Technology. Int. J. Comput. Intell. Syst. 2015, 8, 128–137. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Zhang, X. Construction waste recycling robot for nails and screws: Computer vision technology and neural network approach. Autom. Constr. 2019, 97, 220–228. [Google Scholar] [CrossRef]

- Yu, B.; Wang, J.; Li, J.; Zhang, J.; Lai, Y.; Xu, X. Prediction of large-scale demolition waste generation during urban renewal: A hybrid trilogy method. Waste Manag. 2019, 89, 1–9. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Taffese, W.Z. Suitability investigation of recycled concrete aggregates for concrete production: An experimental case study. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Lu, J.X.; Zhou, Y.; He, P.; Wang, S.; Shen, P.; Poon, C.S. Sustainable reuse of waste glass and incinerated sewage sludge ash in insulating building products: Functional and durability assessment. J. Clean. Prod. 2019, 236. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Analysis of the implementation of effective waste management practices in construction projects and sites. Resour. Conserv. Recycl. 2014, 93, 99–111. [Google Scholar] [CrossRef]

- Nikmehr, B.; Reza Hosseini, M.; Rameezdeen, R.; Chileshe, N.; Ghoddousi, P.; Arashpour, M. An integrated model for factors affecting construction and demolition waste management in Iran. Eng. Constr. Archit. Manag. 2017, 24, 1246–1268. [Google Scholar] [CrossRef]

- Dosal, E.; Coronado, M.; Muñoz, I.; Viguri, J.R.; Andrés, A. Application of Multi-Criteria decision-making tool to locate construction and demolition waste (C&DW) recycling facilities in a northern Spanish region. Environ. Eng. Manag. J. 2012, 11, 545–556. [Google Scholar] [CrossRef]

- Mousavi, M.; Ventura, A.; Antheaume, N. Decision-based territorial life cycle assessment for the management of cement concrete demolition waste. Waste Manag. Res. 2020. [Google Scholar] [CrossRef]

- Hu, Q.; Peng, Y.; Guo, C.; Cai, D.; Su, P. Dynamic incentive mechanism design for recycling construction and Demolition waste under dual information asymmetry. Sustainability 2019, 11, 2943. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Waste generation, composition, and handling in building-related construction and demolition in Hanoi, Vietnam. Waste Manag. 2020, 117, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T. Using Recycled Construction and Demolition Waste Products: A Review of Stakeholders’ Perceptions, Decisions, and Motivations. Recyclle 2020, 5, 31. [Google Scholar] [CrossRef]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Kotrayothar, D.; Loo, Y.C. On the prevailing construction waste recycling practices: A South East Queensland study. Waste Manag. Res. 2009, 27, 167–174. [Google Scholar] [CrossRef]

- Newaz, M.T.; Davis, P.; Sher, W.; Simon, L. Factors affecting construction waste management streams in Australia. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Liu, J.; Gong, E.; Wang, D.; Lai, X.H.; Zhu, J. Attitudes and behaviour towards construction waste minimisation: A comparative analysis between China and the USA. Environ. Sci. Pollut. Res. 2019, 26, 13681–13690. [Google Scholar] [CrossRef]

- Sezer, A.A.; Bosch-Sijtsema, P. Actor-to-actor tensions influencing waste management in building refurbishment projects: A service ecosystem perspective. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Jain, S.; Singhal, S.; Jain, N.K.; Bhaskar, K. Construction and demolition waste recycling: Investigating the role of theory of planned behavior, institutional pressures and environmental consciousness. J. Clean. Prod. 2020, 263. [Google Scholar] [CrossRef]

- Li, J.; Zuo, J.; Cai, H.; Zillante, G. Construction waste reduction behavior of contractor employees: An extended theory of planned behavior model approach. J. Clean. Prod. 2018, 172, 1399–1408. [Google Scholar] [CrossRef]

- Venugopal, K.; Ambatipudi, A. The human resource (HR) factor and the impact of construction and demolition (C&D) waste on environment: An integrated remedial method. Int. J. Recent Technol. Eng. 2019, 8, 535–538. [Google Scholar] [CrossRef]

- Hao, J.L.; Hill, M.J.; Shen, L.Y. Managing Construction Waste On-site through System Dynamics Modelling: The Case of Hong Kong; Emerald Group Publishing Limited: Hong Kong, China, 2008. [Google Scholar]

- Ekanayake, L.L.; Ofori, G. Building waste assessment score: Design-based tool. Build. Environ. 2004, 39, 851–861. [Google Scholar] [CrossRef]

- Kpamma, E.Z.; Adjei-Kumi, T. Management of Waste in the Building Design Process: The Ghanaian Consultants’ Perspective. Arch. Eng. Des. 2011, 7, 102–112. [Google Scholar] [CrossRef]

- Baldwin, A.; Poon, C.S.; Shen, L.Y.; Austin, S.; Wong, I. Designing out waste in high-rise residential buildings: Analysis of precasting methods and traditional construction. Renew. Energy 2009, 34, 2067–2073. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Jaillon, L. Reducing building waste at construction sites in Hong Kong. Constr. Manag. Econ. 2004, 22, 461–470. [Google Scholar] [CrossRef]

- Luangcharoenrat, C.; Intrachooto, S.; Peansupap, V.; Sutthinarakorn, W. Factors influencing construction waste generation in building construction: Thailand’s perspective. Sustainability 2019, 11, 3638. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Ajayi, S.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Arawomo, O.O. Designing out construction waste using BIM technology: Stakeholders’ expectations for industry deployment. J. Clean. Prod. 2018, 180, 375–385. [Google Scholar] [CrossRef]

- Wang, J.; Yu, B.; Tam, V.W.Y.; Li, J.; Xu, X. Critical factors affecting willingness of design units towards construction waste minimization: An empirical study in Shenzhen, China. J. Clean. Prod. 2019, 221, 526–535. [Google Scholar] [CrossRef]

- Doust, K.; Battista, G.; Rundle, P. Front-end construction waste minimization strategies. Aust. J. Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Teo, M.M.M.; Loosemore, M. A theory of waste behaviour in the construction industry. Constr. Manag. Econ. 2001, 19, 741–751. [Google Scholar] [CrossRef]

- Sezer, A.A. Factors influencing building refurbishment site managers’ waste management efforts. J. Facil. Manag. 2017, 15, 318–334. [Google Scholar] [CrossRef]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. Attitude and behavioral factors in waste management in the construction industry of Malaysia. Resour. Conserv. Recycl. 2009, 53, 321–328. [Google Scholar] [CrossRef]

- Li, J.; Zuo, J.; Jiang, W.; Zhong, X.; Li, J.; Pan, Y. Policy instrument choice for construction and demolition waste management: The case study of Shenzhen, China. Eng. Constr. Archit. Manag. 2020, 27, 1283–1297. [Google Scholar] [CrossRef]

- Lu, W.; Lee, W.M.W.; Bao, Z.; Chi, B.; Webster, C. Cross-jurisdictional construction waste material trading: Learning from the smart grid. J. Clean. Prod. 2020, 277. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Warren, J.D.; Chong, W.K.; Kim, C. Recycling construction and demolition waste for construction in Kansas City metropolitan area, Kansas and Missouri. Transp. Res. Rec. J. Transp. Res. Board 2007, 193–200. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L.; Wang, J. Major obstacles to improving the performance of waste management in China’s construction industry. Facilities 2011, 29, 224–242. [Google Scholar] [CrossRef]

- Ling, F.Y.Y.; Nguyen, D.S.A. Strategies for construction waste management in Ho Chi Minh City, Vietnam. Built Environ. Proj. Asset Manag. 2013, 3, 141–156. [Google Scholar] [CrossRef]

- Al-Hajj, A.; Hamani, K. Material waste in the UAE construction industry: Main causes and minimization practices. Arch. Eng. Des. 2011, 7, 221–235. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Waste reduction through incentives: A case study. Build. Res. Inf. 2008, 36, 37–43. [Google Scholar] [CrossRef]

- Wang, J.Y.; Kang, X.P.; Tam, V.W.Y. An investigation of construction wastes: An empirical study in Shenzhen. J. Eng. Des. Technol. 2008, 6, 227–236. [Google Scholar] [CrossRef]

- Ling, F.Y.Y.; Lim, M.C.H. Implementation of a waste management plan for construction projects in Singapore. Archit. Sci. Rev. 2002, 45, 73–81. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Karunasena, G.; Amaratunga, D. Capacity gaps in post disaster construction & demolition waste management. Eng. Constr. Archit. Manag. 2015, 22, 446–466. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Identifying and Managing Critical Waste Factors for Lean Construction Projects. Eng. Manag. J. 2020, 32, 2–13. [Google Scholar] [CrossRef]

- Laovisutthichai, V.; Lu, W.; Bao, Z. Design for construction waste minimization: Guidelines and practice. Arch. Eng. Des. 2020. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization in construction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef]

- Mendis, D.; Hewage, K.N.; Wrzesniewski, J. Reduction of construction wastes by improving construction contract management: A multinational evaluation. Waste Manag. Res. 2013, 31, 1062–1069. [Google Scholar] [CrossRef]

- Mendis, D.; Hewage, K.N.; Wrzesniewski, J. Contractual obligations analysis for construction waste management in Canada. J. Civ. Eng. Manag. 2015, 21, 866–880. [Google Scholar] [CrossRef]

- Saez, P.V.; Del Río Merino, M.; San-Antonio González, A.; Porras-Amores, C. Best practice measures assessment for construction and demolition waste management in building constructions. Resour. Conserv. Recycl. 2013, 75, 52–62. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, H.; Kang, X.; Lu, W. Critical success factors for on-site sorting of construction waste: A China study. Resour. Conserv. Recycl. 2010, 54, 931–936. [Google Scholar] [CrossRef]

- Shen, L.Y.; Tam, V.W.Y.; Tam, C.M.; Drew, D. Mapping approach for examining waste management on construction sites. J. Constr. Eng. Manag. 2004, 130, 472–481. [Google Scholar] [CrossRef]

- Li, M.; Yang, J. Critical factors for waste management in office building retrofit projects in Australia. Resour. Conserv. Recycl. 2014, 93, 85–98. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A. Optimising material procurement for construction waste minimization: An exploration of success factors. Sustain. Mater. Technol. 2017, 11, 38–46. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Waste-efficient materials procurement for construction projects: A structural equation modelling of critical success factors. Waste Manag. 2018, 75, 60–69. [Google Scholar] [CrossRef]

- Khanh, H.D.; Kim, S.Y. Development of waste occurrence level indicator in Vietnam construction industry. Eng. Constr. Archit. Manag. 2015, 22, 715–731. [Google Scholar] [CrossRef]

- Cha, H.S.; Kim, J.; Han, J.Y. Identifying and assessing influence factors on improving waste management performance for building construction projects. J. Constr. Eng. Manag. 2009, 135, 647–656. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. Effects of lean construction on sustainability of modular homebuilding. J. Archit. Eng. 2012, 18, 155–163. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M.; Zeng, S.; Ng, W.C. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Maqsoom, A.; Hashmi, A.A.Q.; Zeeshan, M.; Arshad, Q.; Nawaz, A.; Zeeshan, B.U.A.; Salahuddin, H. A system dynamics-based economic performance simulation of construction waste reduction management: Effective application of prefabrication. Environ. Eng. Manag. J. 2019, 18, 2363–2376. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Shan, M.; Hwang, B.-G. Green building rating systems: Global reviews of practices and research efforts. Sustain. Cities Soc. 2018, 39, 172–180. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Strategies for minimizing construction and demolition wastes in Malaysia. Resour. Conserv. Recycl. 2017, 120, 219–229. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L. Application of low waste technologies for design and construction: A case study in Hong Kong. Renew. Sustain. Energy Rev. 2012, 16, 2973–2979. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Ng, L.H. Comparison of low-waste building technologies adopted in public and private housing projects in Hong Kong. Eng. Constr. Archit. Manag. 2003, 10, 88–98. [Google Scholar] [CrossRef]

- Peres, S.; Loureiro, E.; Santos, H.; Silva, F.V.E.; Gusmao, A. The production of gaseous biofuels using biomass waste from construction sites in Recife, Brazil. Processes 2020, 8, 457. [Google Scholar] [CrossRef]

- Hong, Y.; Wu, Y.R. Acidolysis as a biorefinery approach to producing advanced bioenergy from macroalgal biomass: A state-of-the-art review. Bioresour. Technol. 2020, 318, 124080. [Google Scholar] [CrossRef]

- Shanmugam, S.; Ngo, H.H.; Wu, Y.R. Advanced CRISPR/Cas-based genome editing tools for microbial biofuels production: A review. Renew. Energy 2020, 149, 1107–1119. [Google Scholar] [CrossRef]

| Group | No. | Factor | Influential Stakeholder |

|---|---|---|---|

| Regulatory environment | 1 | Sufficient legislation and regulations | Governments |

| 2 | Enforcement of regulations | Governments | |

| 3 | Financial incentives | Governments | |

| 4 | Landfill levies | Governments | |

| 5 | Fines and penalties | Governments | |

| Government and public supervision | 6 | Government supervision | Governments |

| 7 | Public participation in supervision | Governments, the public | |

| 8 | Availability of the C&D waste statistics | Governments, experts | |

| Advances in technologies | 9 | Application of information and communication technologies | Experts, governments, contractors, recycling companies |

| 10 | Maturity of the technologies to treat waste | Experts, governments, contractors, recycling companies | |

| Recycling market | 11 | Availability of local waste recycling facilities | Recycling companies |

| 12 | Supplies of recyclable waste to recycling facilities | Contractors | |

| 13 | Specifications, technical or quality standards for recycled products | Governments | |

| 14 | Demand for recycled products | Contractors, the public, designers | |

| 15 | Cost of recycling products | Governments, recycling companies | |

| Knowledge, awareness, attitude, and behaviour of stakeholders | 16 | Knowledge and skills of staff | Contractors, clients, designers |

| 17 | Awareness and attitude of clients | Clients | |

| 18 | Awareness, attitude and behaviour of designers | Designers | |

| 19 | Awareness, attitude and behaviour of contractors | Contractors | |

| 20 | Awareness and attitude of the public | The public | |

| 21 | Training and education | Experts, governments, contractors, recycling companies | |

| 22 | Top management support | Clients, contractors, designers | |

| 23 | Organizational WM policies | Clients, contractors, designers | |

| 24 | Supportive organizational culture | Clients, contractors, designers | |

| Project-specific factors | 25 | Communication, collaboration and coordination among project participants | Clients, contractors, designers |

| 26 | Selecting contractors with C&D WM capability | Clients | |

| 27 | Effective contract management | Clients, contractors, designers | |

| 28 | Formal waste management plans | Contractors | |

| 29 | Site conditions for on-site waste treatment | Contractors | |

| 30 | Effective site planning | Contractors | |

| 31 | Effective material management | Contractors | |

| 32 | Regular site inspection | Contractors | |

| 33 | Incentives for workers | Contractors | |

| 34 | Rework minimization | Contractors, designers | |

| 35 | Adoption of low-waste methods in design and construction | Contractors, designers, experts |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X. Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review. Buildings 2021, 11, 149. https://doi.org/10.3390/buildings11040149

Zhao X. Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review. Buildings. 2021; 11(4):149. https://doi.org/10.3390/buildings11040149

Chicago/Turabian StyleZhao, Xianbo. 2021. "Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review" Buildings 11, no. 4: 149. https://doi.org/10.3390/buildings11040149

APA StyleZhao, X. (2021). Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review. Buildings, 11(4), 149. https://doi.org/10.3390/buildings11040149