Bond of Ribbed Steel Bar in High-Performance Steel Fiber Reinforced Expanded-Shale Lightweight Concrete

Abstract

:1. Introduction

2. Materials and Methods

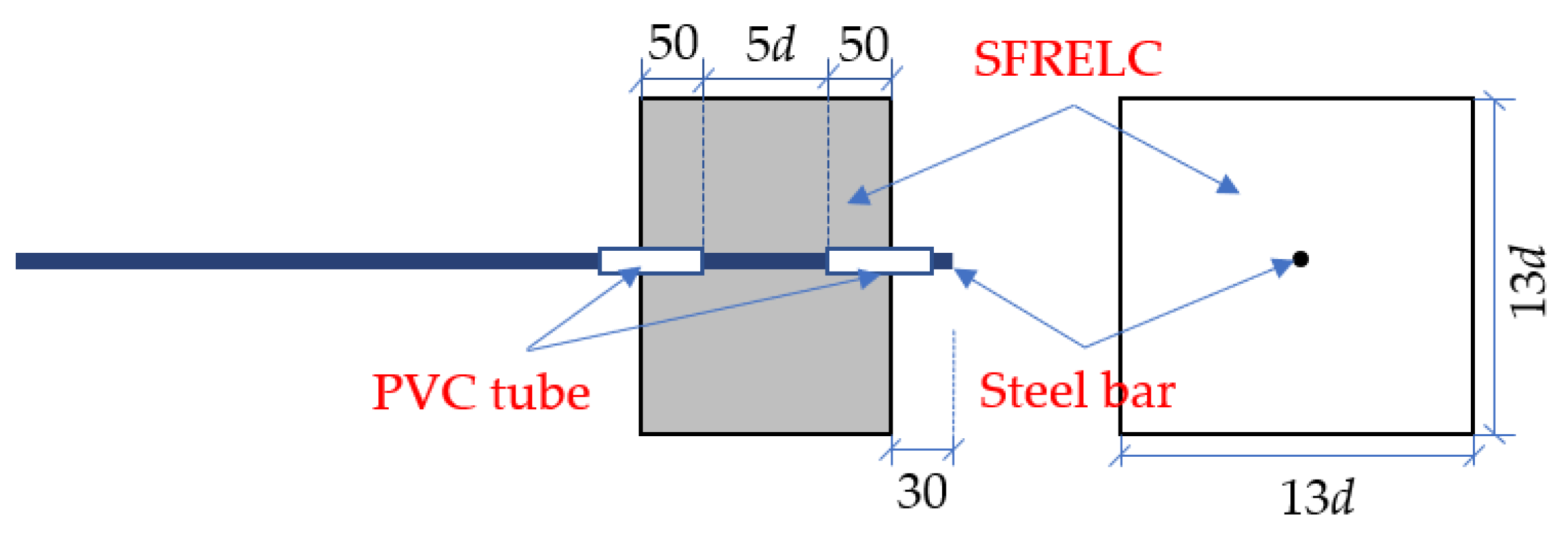

2.1. Specimens

2.2. Materials

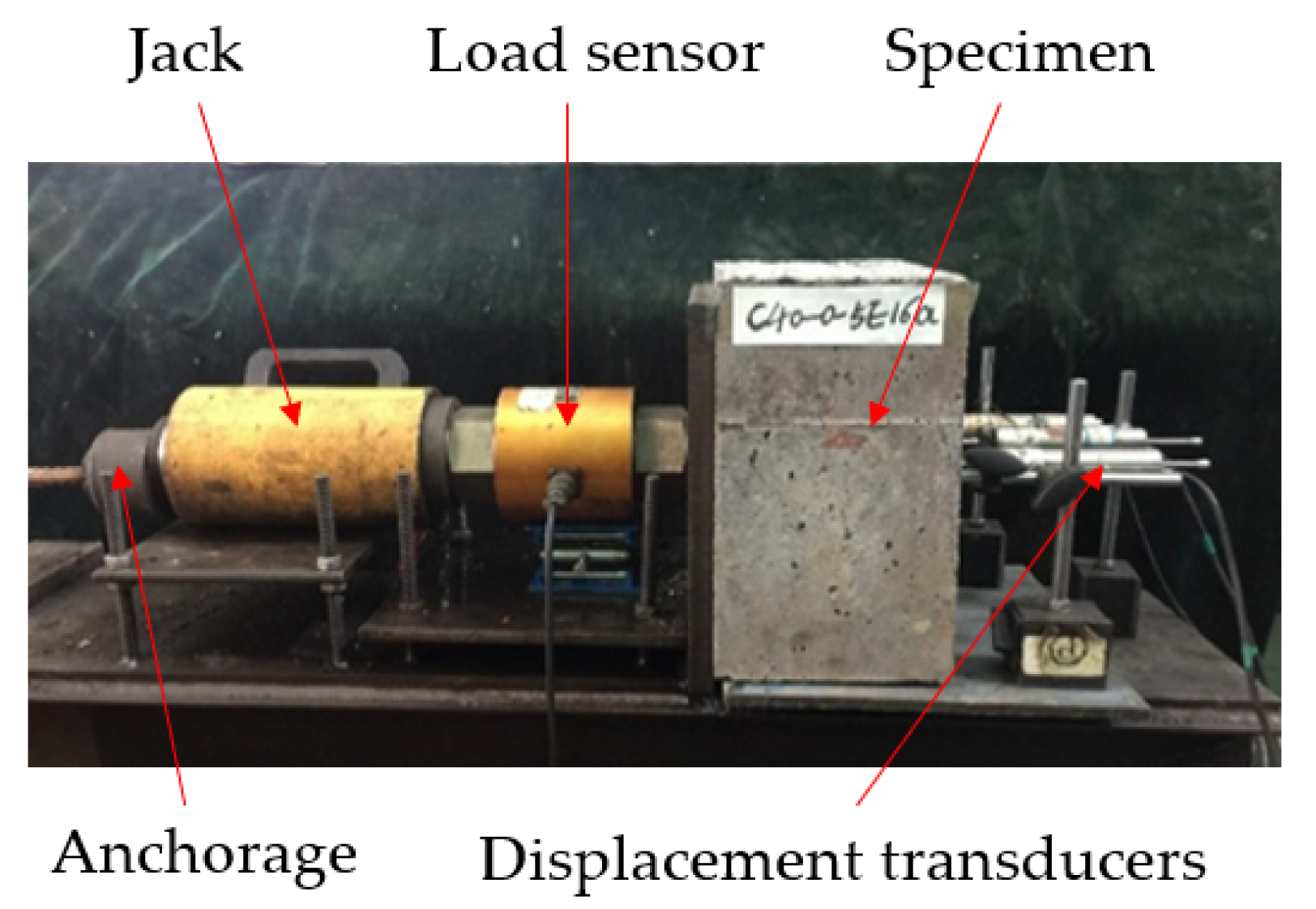

2.3. Pull-Out Test Method

3. Test Results and Analysis

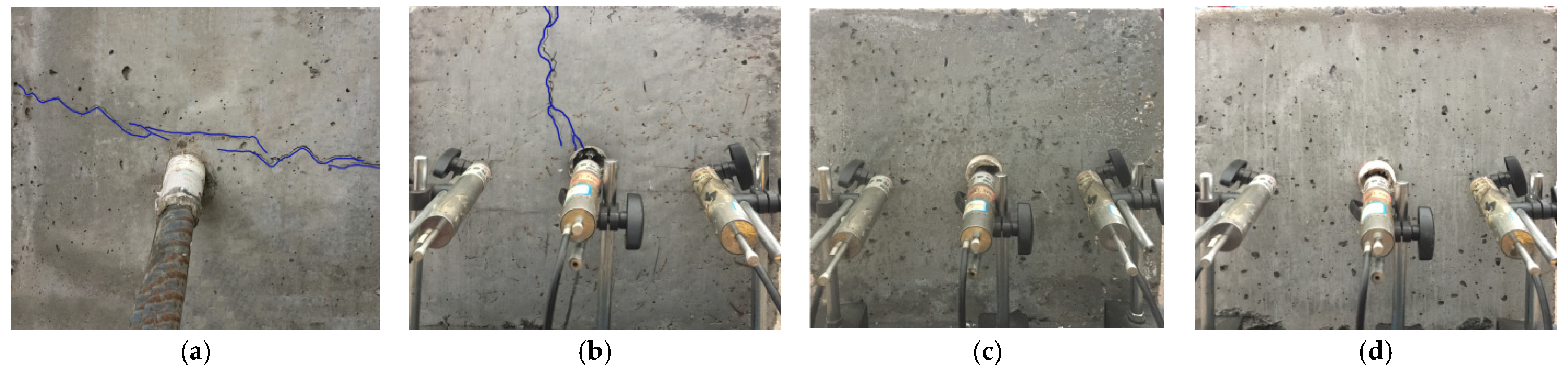

3.1. Failure Mode

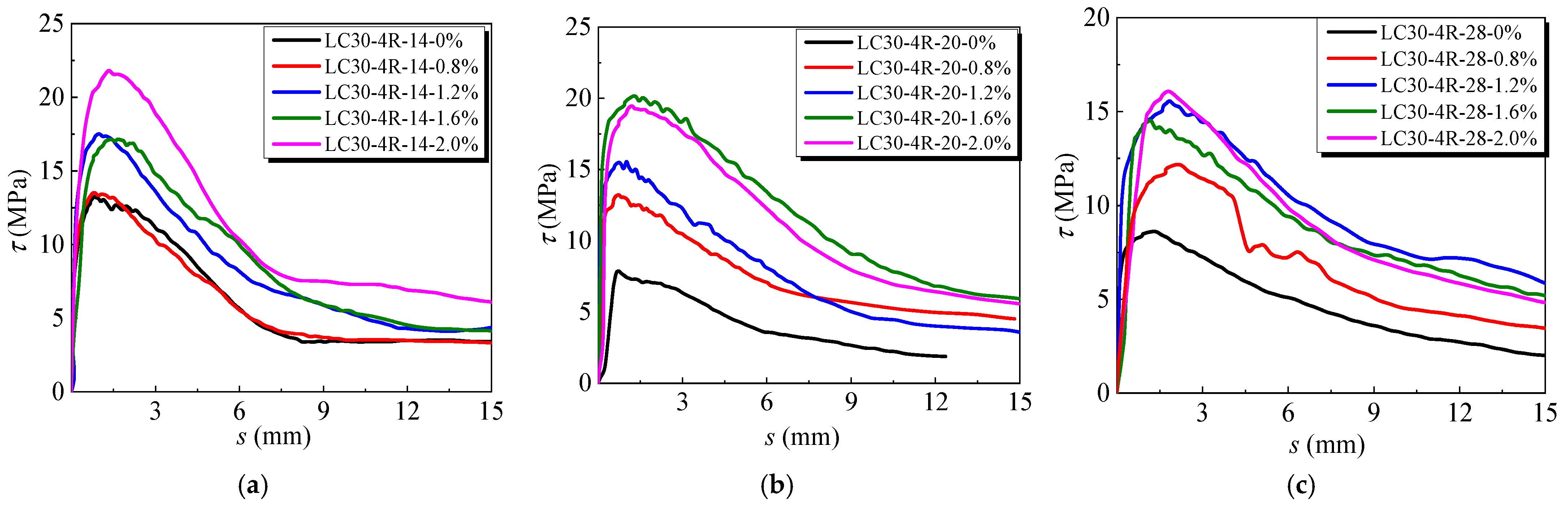

3.2. Bond Stress-Slip Curves

3.3. Bond Stress and Slip at Key Points of Curve

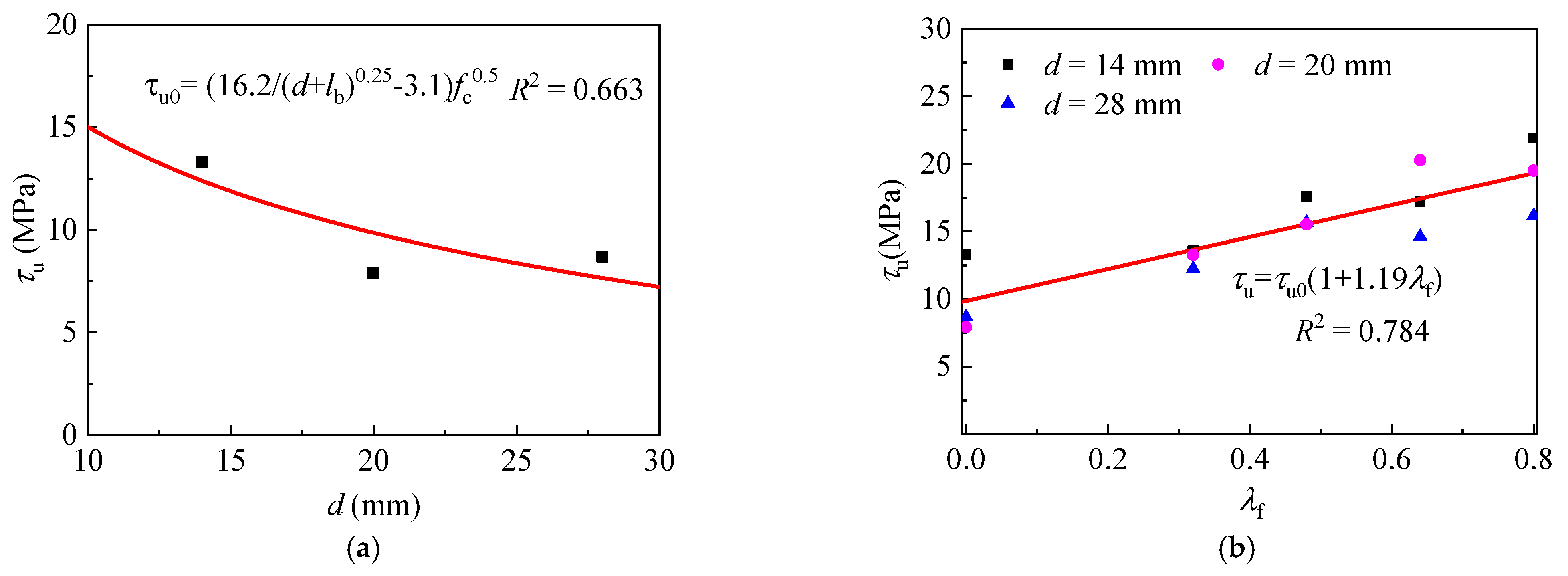

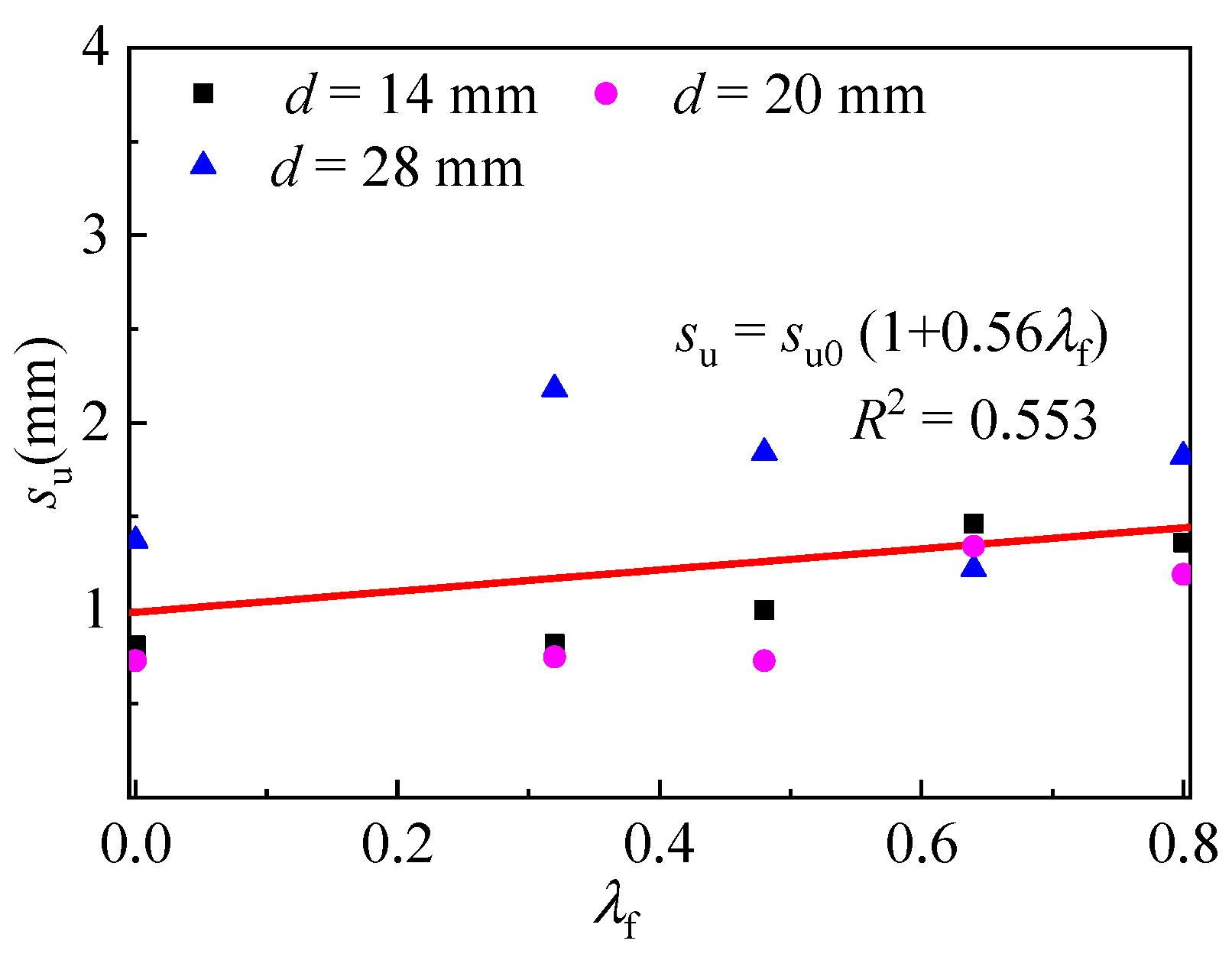

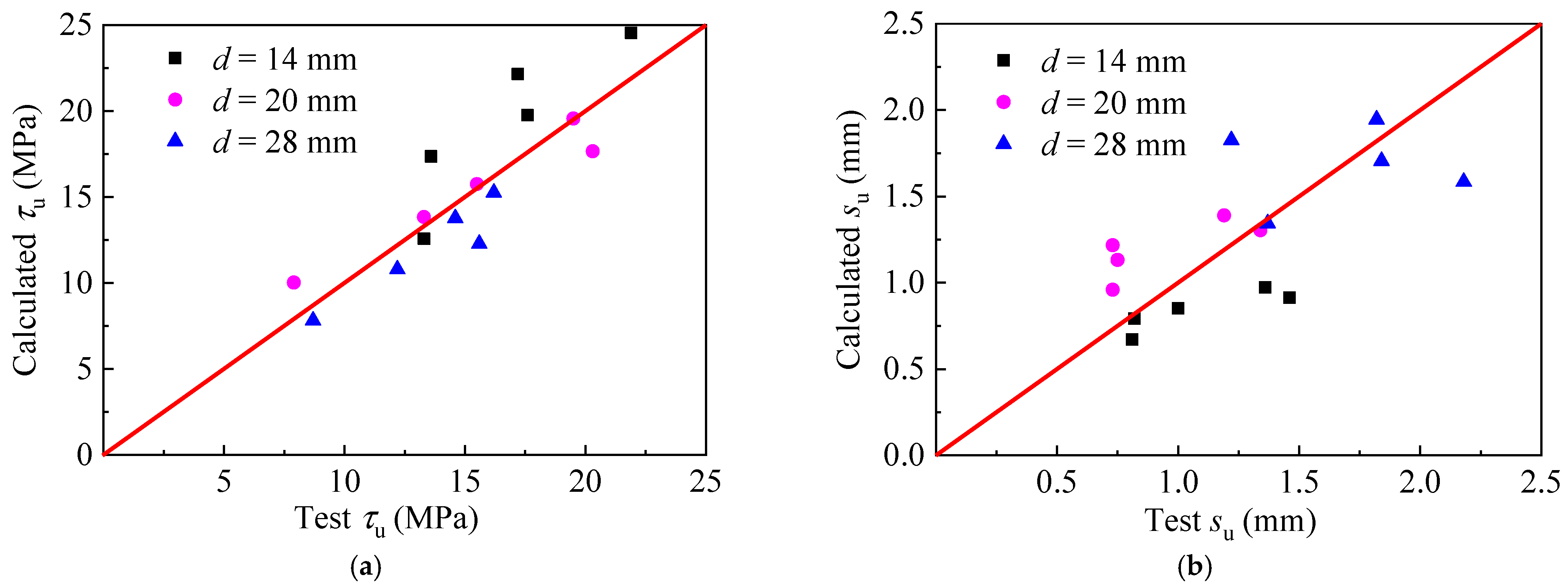

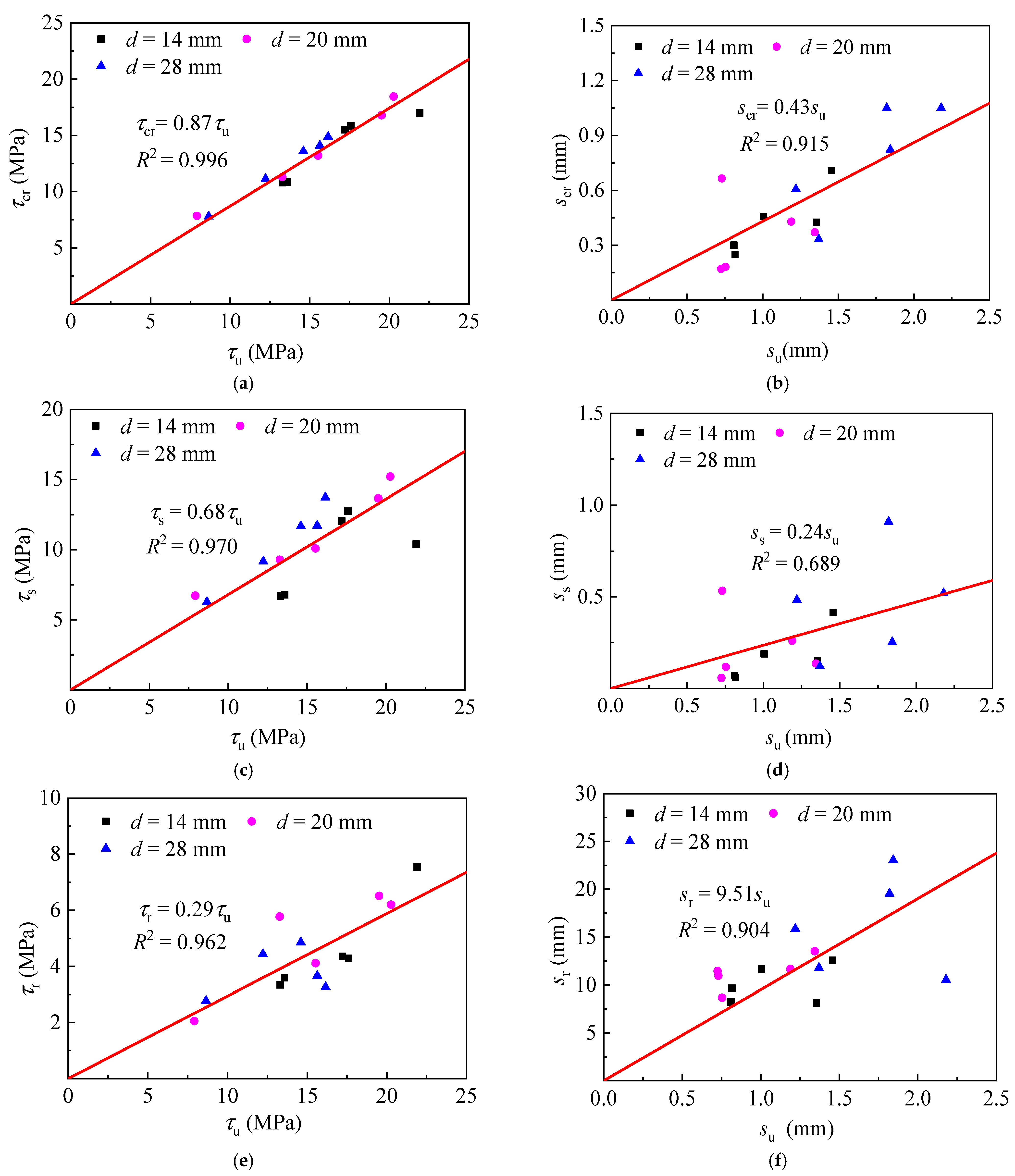

3.4. Prediction of Bond Stress and Slip at Key Points

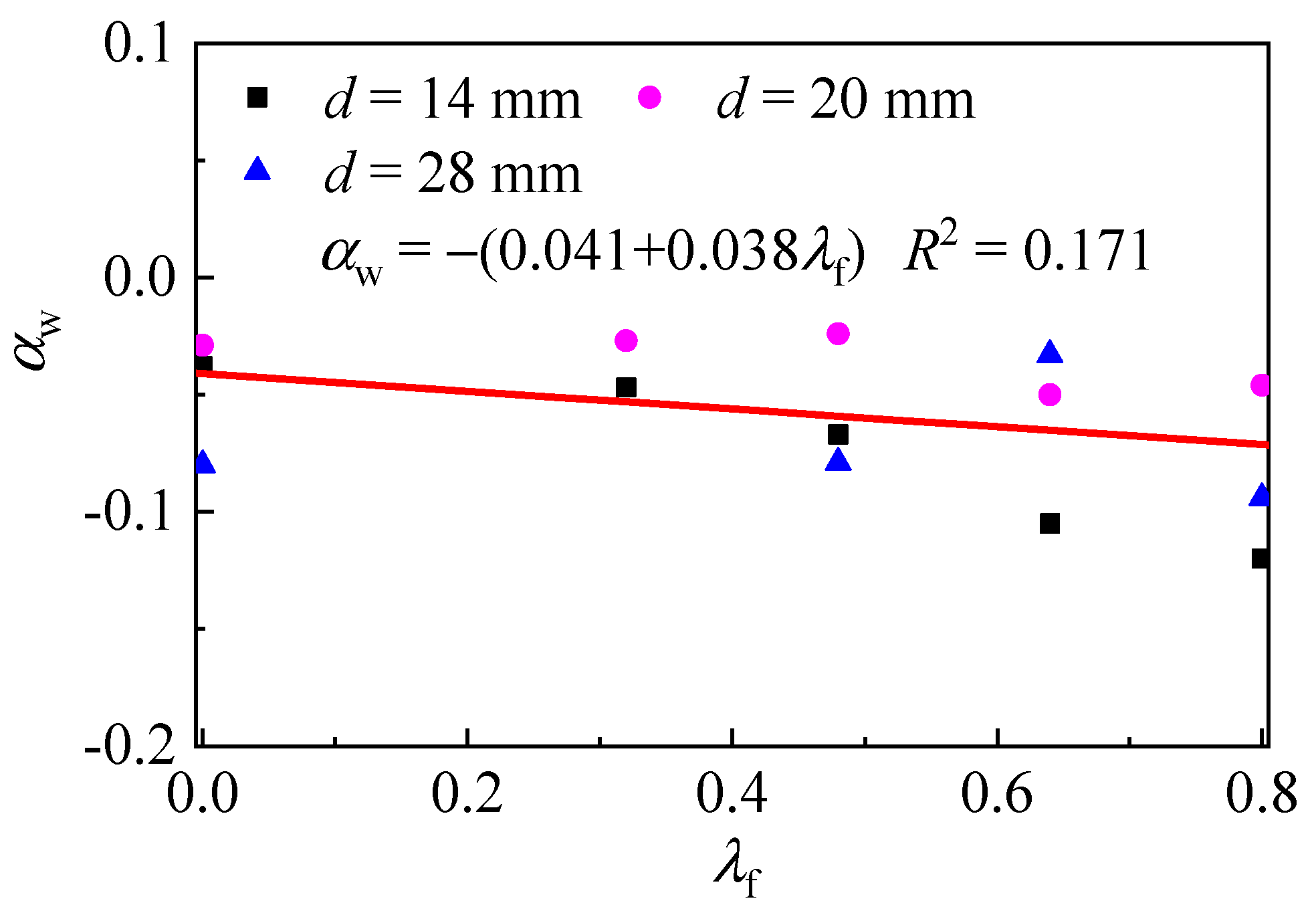

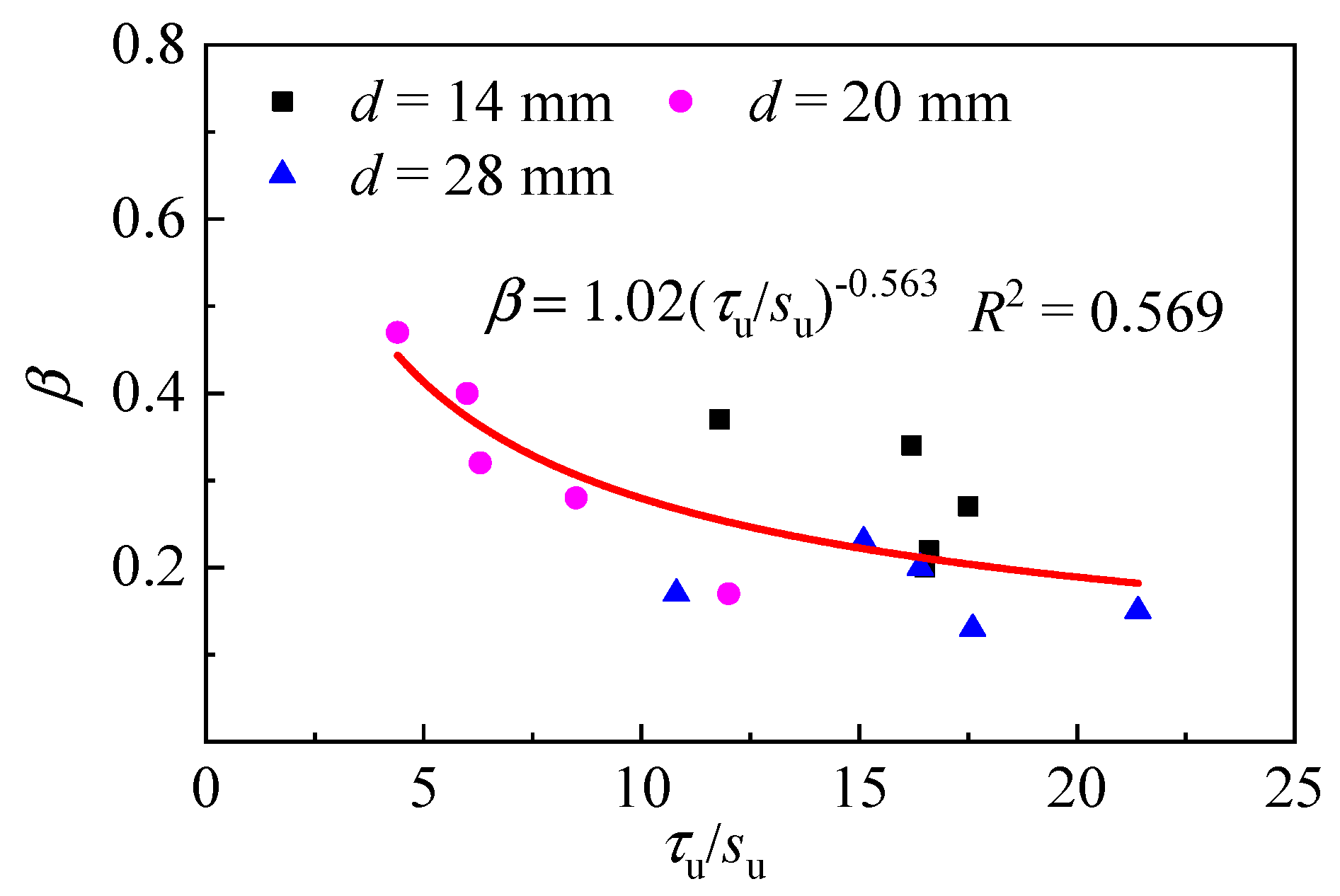

4. Prediction of Bond-Slip Constitutive

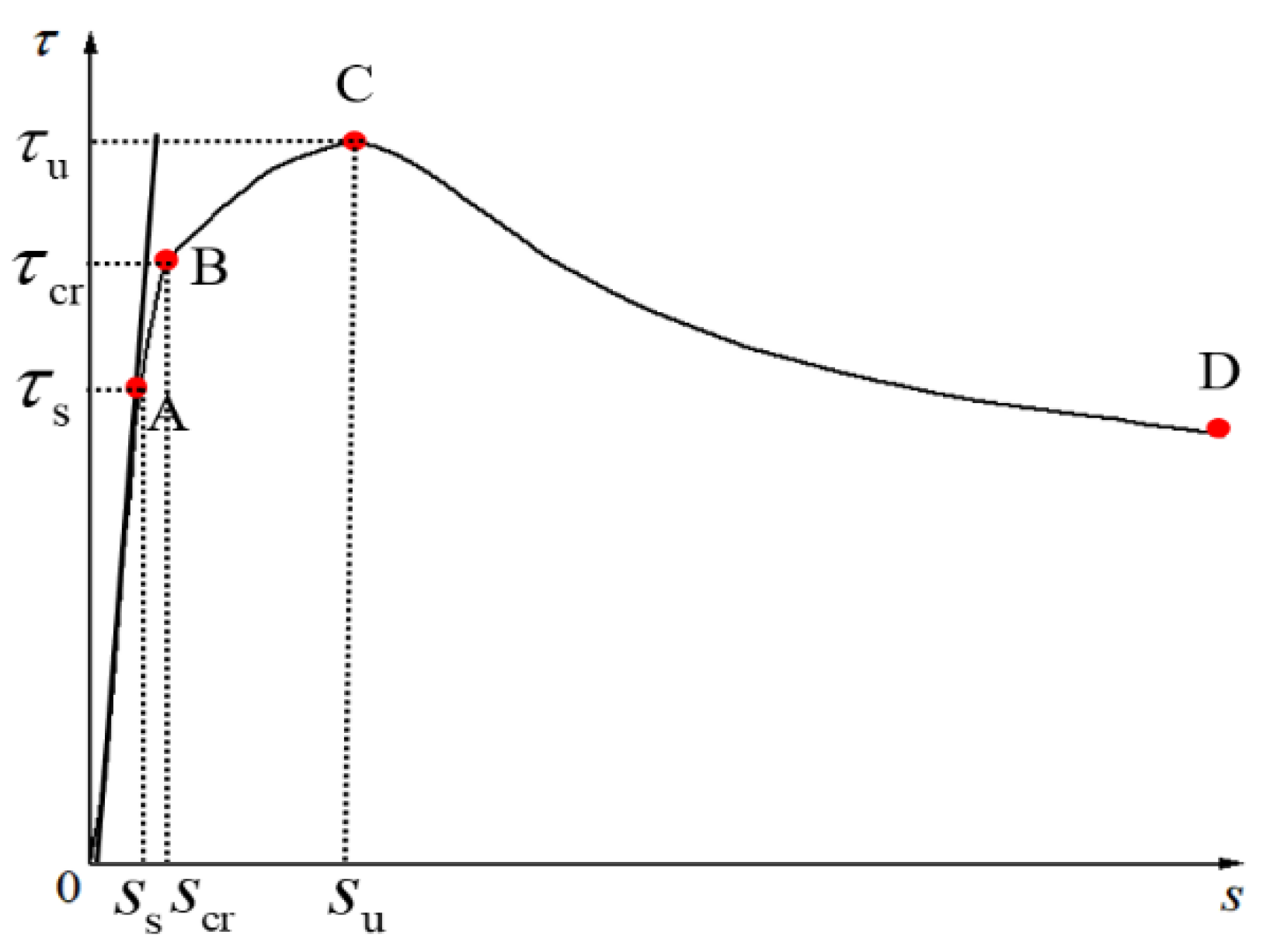

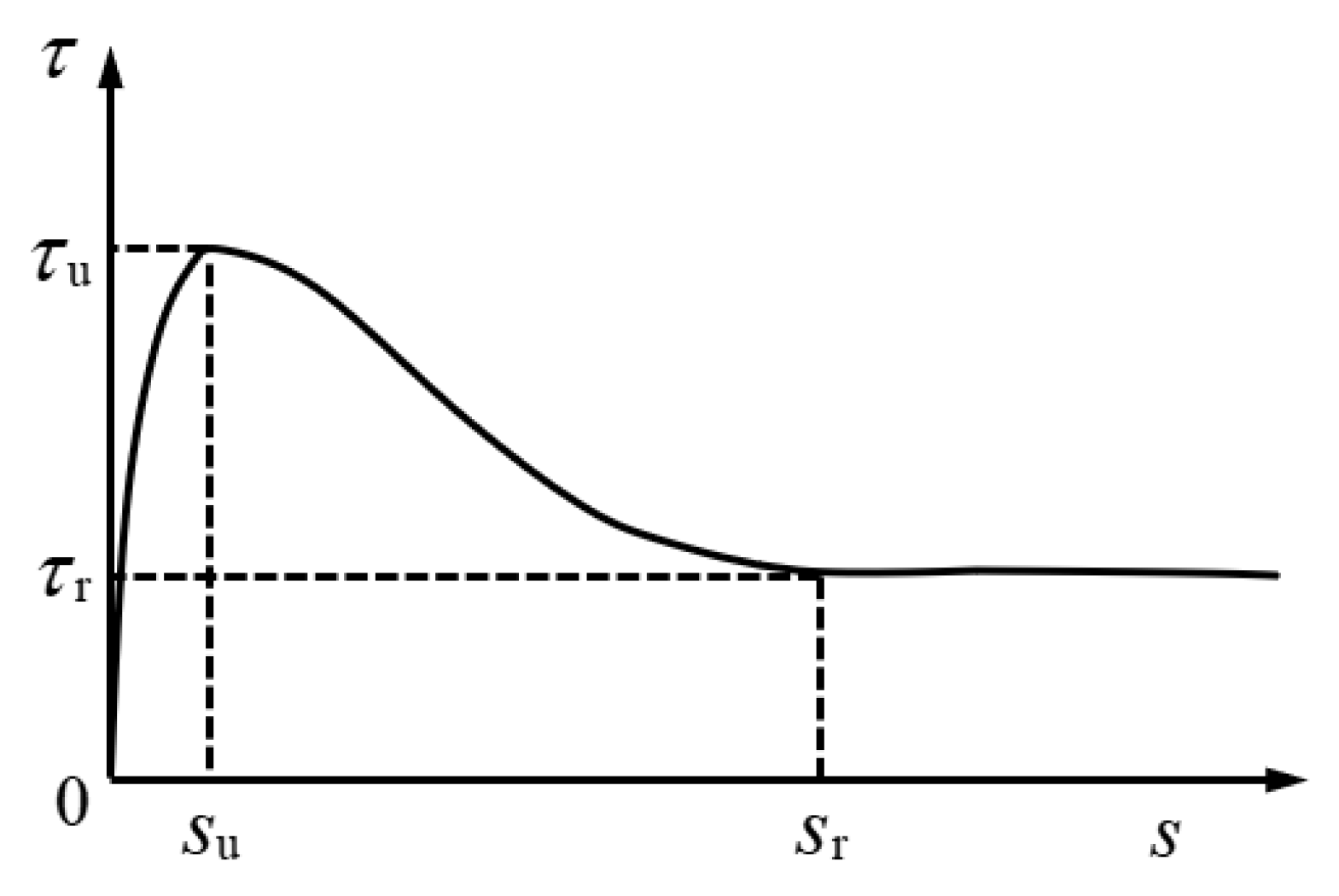

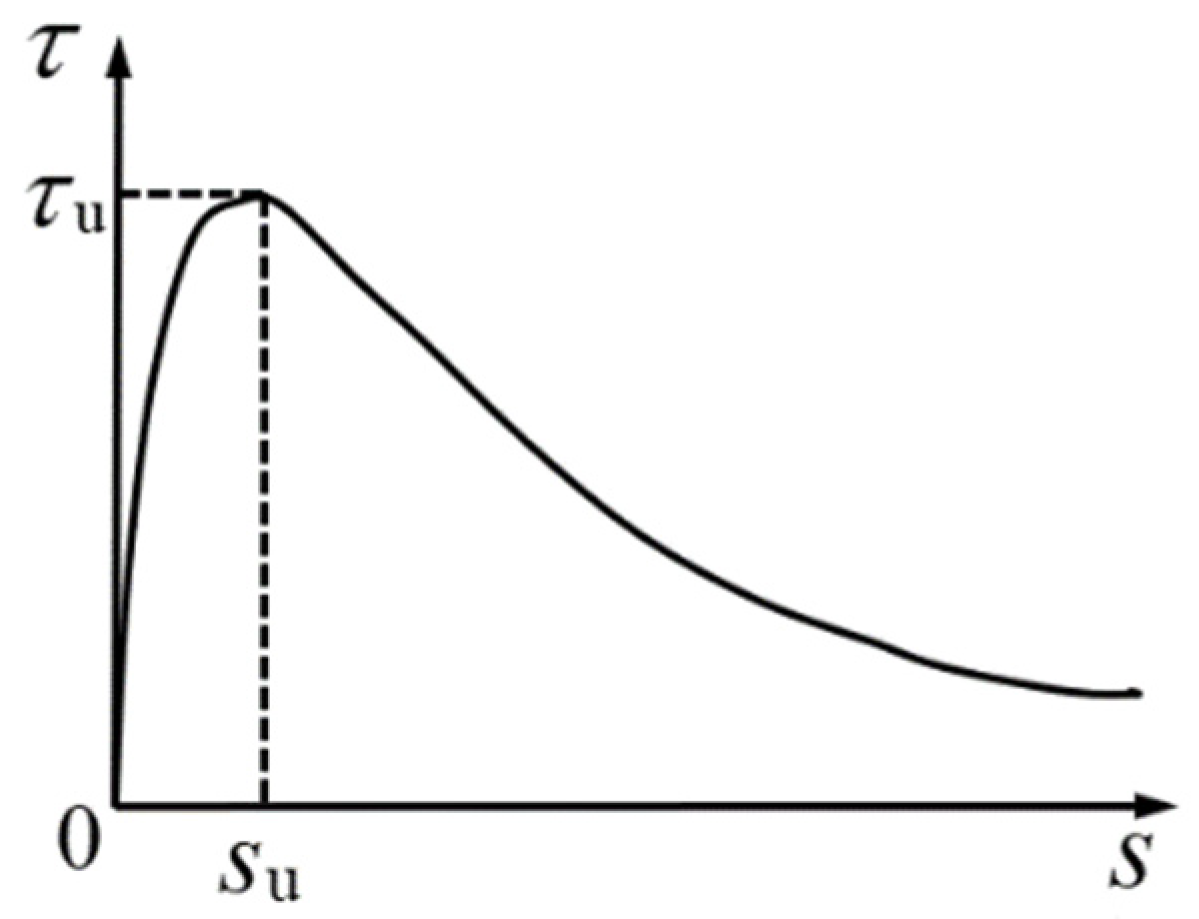

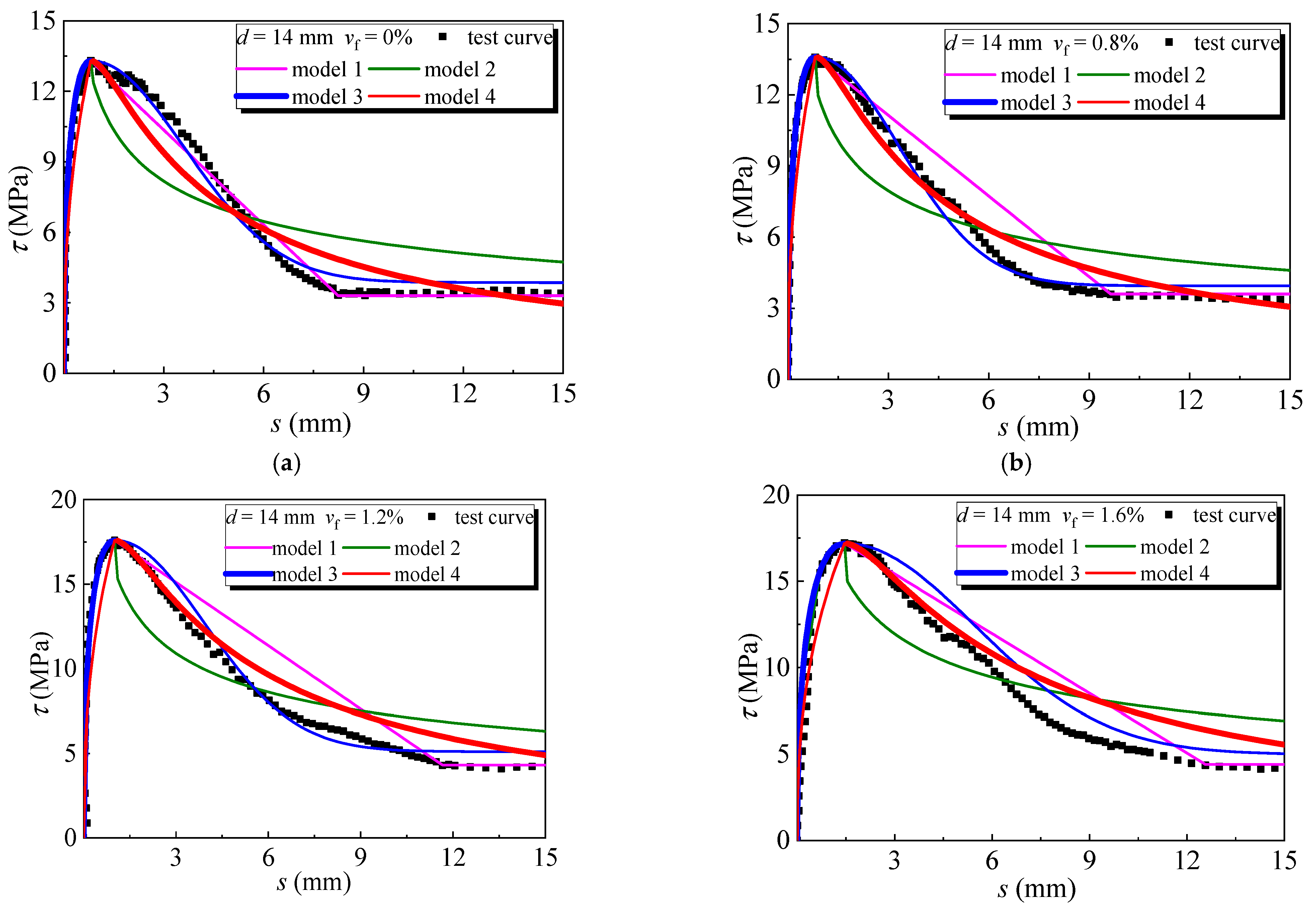

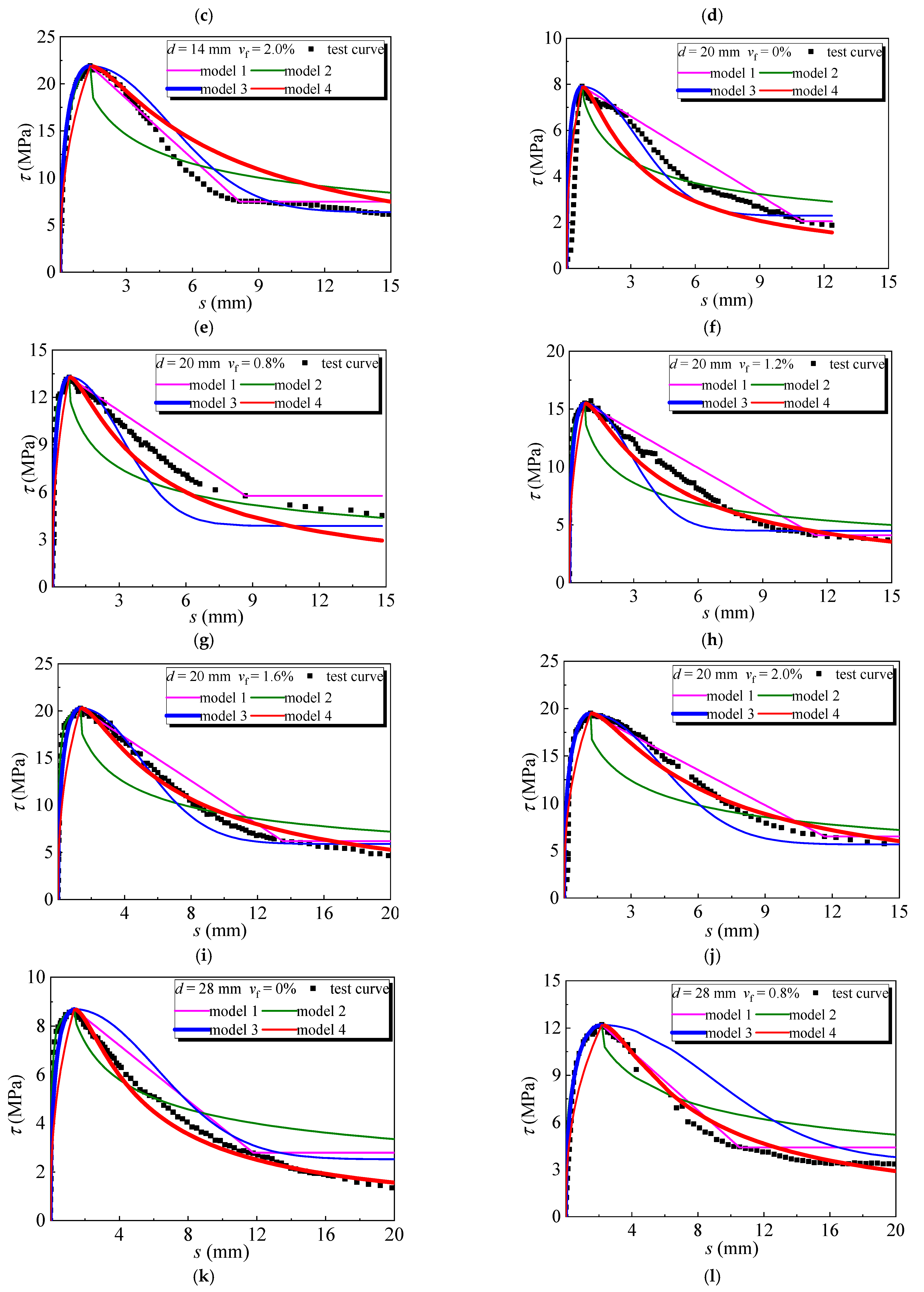

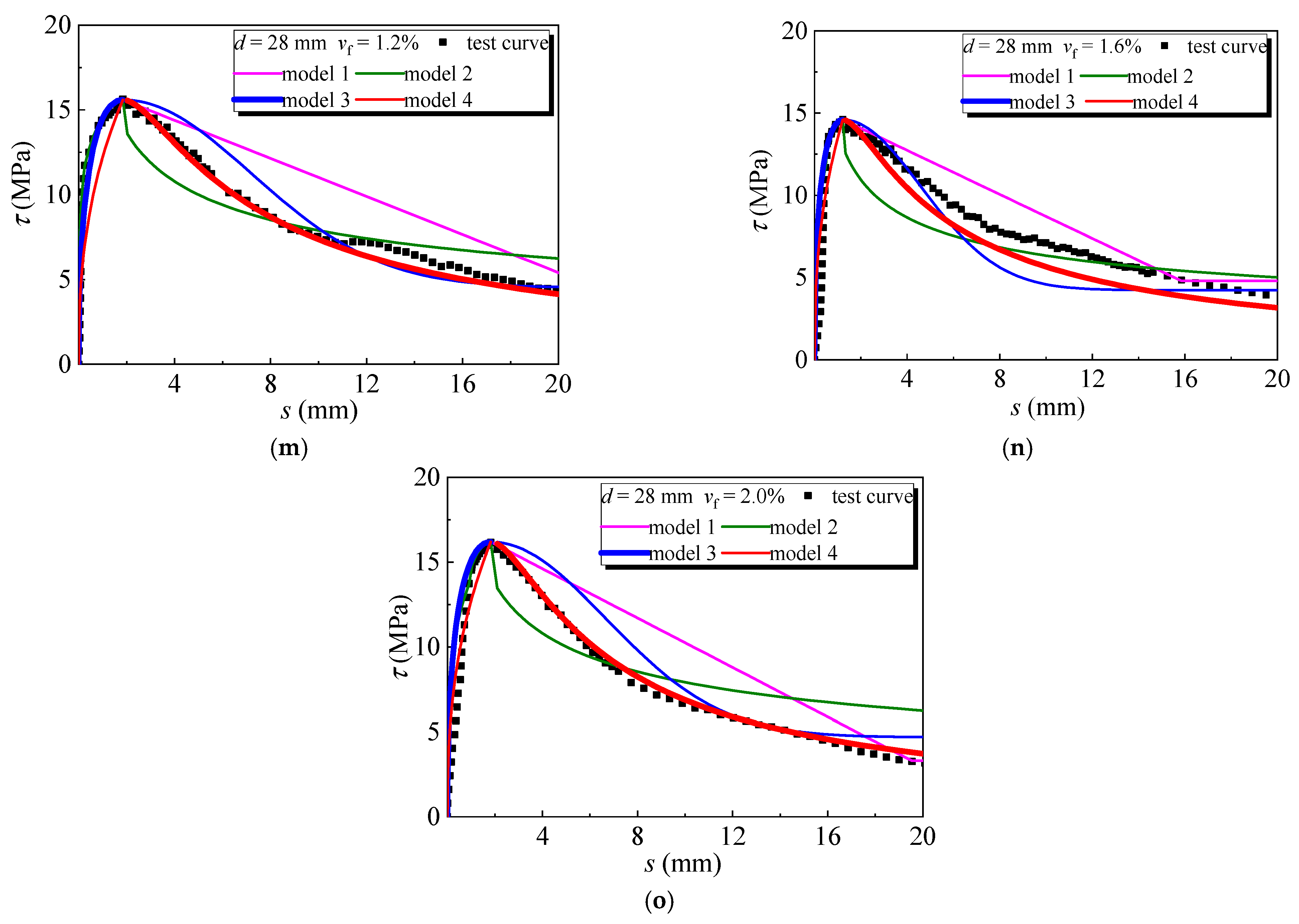

4.1. Constitutive Model

4.2. Comparison with Test Curves

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holschemacher, K.; Ali, A.; Iqbal, S. Bond of reinforcement in lightweight concrete. In Insights and Innovations in Structural Engineering, Mechanics and Computation; Taylor & Francis Group: London, UK, 2016; pp. 1284–1285. [Google Scholar]

- Zhang, D.X.; Yang, W.J. Experimental research on bond behaviors between shale ceramsite lightweight aggregate concrete and bars through pullout tests. J. Mater. Civ. Eng. 2014, 27, 06014030. [Google Scholar] [CrossRef]

- Lachemi, M.; Bae, S.; Hossain, K.M.A.; Sahmaran, M. Steel-concrete bond strength of lightweight self-consolidating concrete. Mater. Struct. 2009, 42, 1015–1023. [Google Scholar] [CrossRef]

- Kaffetzakis, M.I.; Papanicolaou, C.G. Bond behavior of reinforcement in lightweight aggregate self-compacting concrete. Constr. Build. Mater. 2016, 113, 641–652. [Google Scholar] [CrossRef]

- Al-Shannag, M.J.; Charif, A. Bond behavior of steel bars embedded in concretes made with natural lightweight aggregates. J. King Saud Univ.-Eng. Sci. 2017, 29, 365–372. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Visintin, P.; Goh, S.H.; Jumaat, M.Z. Influence of lightweight aggregate on the bond properties of concrete with various strength grades. Constr. Build. Mater. 2015, 84, 377–386. [Google Scholar] [CrossRef] [Green Version]

- Zhao, M.S.; Zhang, X.Y.; Yan, K.; Fei, T.; Zhao, S.B. Bond performance of ribbed rebar in steel fiber reinforced lightweight-aggregate concrete affected by multi-factors. Civ. Eng. J. 2018, 23, 276–290. [Google Scholar]

- Bogas, J.A.; Gomes, M.G.; Real, S. Bonding of steel reinforcement in structural expanded clay lightweight aggregate concrete: The influence of failure mechanism and concrete composition. Constr. Build. Mater. 2014, 65, 350–359. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Bond properties of lightweight concrete—A review. Constr. Build. Mater. 2016, 112, 478–496. [Google Scholar] [CrossRef]

- Fib Special Activity Group 5. Fib Model Code for Concrete Structures 2010; Case Postale 88, CH-1015; International Federation for Structural Concrete (Fib): Lausanne, Switzerland, 2013. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Code for Design of Concrete Structures; GB50010-2010; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- Li, C.Y.; Zhao, M.L.; Ren, F.C.; Liang, N.; Li, J.; Zhao, M.S. Bond behaviors between full-recycled-aggregate concrete and ribbed steel-bar. Open Civ. Eng. J. 2017, 11, 685–698. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.L.; Shen, W.D.; Wang, H. An experimental study on bond-anchorage properties of bars in concrete. J. Build. Struct. 1994, 15, 26–37. [Google Scholar]

- Zhao, S.B.; Ding, X.X.; Li, C.M.; Li, C.Y. Experimental study of bond properties between ribbed steel bar and concrete with machine-made sand. J. Build. Mater. 2013, 16, 191–202. [Google Scholar] [CrossRef]

- Song, L.; Qu, F.L.; Liu, G.R.; Zhao, S.B. Bond properties of steel bar in concrete under water environment. Materials 2019, 12, 3517. [Google Scholar] [CrossRef] [Green Version]

- Wu, X. Mechanical Properties of Self-Compacting Lightweight Concrete. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M.; Ipek, S. Effect of steel fiber addition and aspect ratio on bond strength of cold-bonded fly ash lightweight aggregate concretes. Constr. Build. Mater. 2013, 47, 358–365. [Google Scholar] [CrossRef]

- Ali, A.; Iqbal, S.; Holschemacher, K.; Bier, A.T. Effect of fibers on bond performance of lightweight reinforced concrete. Period. Polytech. Civ. Eng. 2016, 60, 97–102. [Google Scholar] [CrossRef] [Green Version]

- Mo, K.H.; Goh, S.H.; Alengaram, U.J.; Visintin, P.; Jumaat, M.Z. Mechanical, toughness, bond and durability-related properties of lightweight concrete reinforced with steel fibers. Mater. Struct. 2017, 50, 46. [Google Scholar] [CrossRef]

- Li, F.L.; Yu, Y.N.; Yu, K.F.; Chen, J.Q. Experimental study on bond properties of plain steel-bar with SFRLAC. J. Hebei Univer. Technol. 2014, 43, 93–96. [Google Scholar]

- Zhao, M.L.; Zhao, M.S.; Chen, M.H.; Li, J.; Law, D. An experimental study on strength and toughness of steel fiber reinforced expanded-shale lightweight concrete. Constr. Build. Mater. 2018, 183, 493–501. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhao, M.L.; Geng, H.B.; Fu, H.; Zhang, X.Y.; Li, X.K. Shear performance of steel fiber reinforced expanded-shale lightweight concrete beams with varying of shear-span to depth ratio and stirrups. Case Study Constr. Mater. 2021, 14, e00550. [Google Scholar]

- Li, C.Y.; Zhao, M.S.; Yang, J.L.; Xu, W.X.; Zhang, X.Y. Shear testing of reinforced hybrid composite beams made of SFRELC and partial higher-strength conventional concrete. Case Study Constr. Mater. 2021, 15, e00721. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision of the People’s Republic of China. Metallic Materials-Tensile Testing—Part 1: Method of Test at Room Temperature; GB/T 228-2010; China Standard Press: Beijing, China, 2010. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Lightweight Aggregate and Its Test Methods—Part 2: Test Methods for Lightweight Aggregates; GB/T 17431.2-2010; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Standard for Application of Lightweight Aggregate Concrete; JGJ/T12-2019; China Building Industry Press: Beijing, China, 2019. [Google Scholar]

- Ding, X.X.; Zhao, M.L.; Li, J.; Shang, P.R.; Li, C.Y. Mix proportion design of self-compacting SFRC with manufactured sand based on the packing test of steel fiber-aggregates skeleton. Materials 2020, 13, 2833. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Performance on Ordinary Fresh Concrete; GB/T50080-2016; China Building Industry Press: Beijing, China, 2016. [Google Scholar]

- Zhao, S.B.; Zhao, M.S.; Zhang, X.Y.; Peng, Z.J.; Huang, T.H. Study on complete stress-strain curves of steel fiber reinforced lightweight-aggregate concrete under uniaxial compression. J. Build. Struct. 2019, 40, 181–190. [Google Scholar]

- Zhao, M.S.; Zhang, B.X.; Shang, P.R.; Fu, Y.; Zhang, X.Y.; Zhao, S.B. Complete stress–strain curves of self-compacting steel fiber reinforced expanded-shale lightweight concrete under uniaxial compression. Materials 2019, 12, 2979. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Steel Fiber Reinforced Concrete; JG/T 472-2015; China Building Industry Press: Beijing, China, 2015. [Google Scholar]

- General Administration of Quality Supervision of the People’s Republic of China. Standard for Test Method of Concrete Structures; GB/T 50152-2012; China Standard Press: Beijing, China, 2012. [Google Scholar]

- Kim, D.; Kim, M.S.; Yun, G.Y.; Lee, Y.H. Bond strength of steel ribbed rebars embedded in artificial lightweight aggregate concrete. J. Adhesion Sci. Technol. 2013, 27, 490–507. [Google Scholar] [CrossRef]

| Grade | Diameter d (mm) | Transverse Rib (mm) | Longitudinal Rib (mm) | Yield Strength fy (MPa) | Ultimate Tensile Strength fst (MPa) | Elongation After Fracture δ (%) | ||

|---|---|---|---|---|---|---|---|---|

| Height | Width | Height | Width | |||||

| HRB400 | 14 | 1.4 | 0.8 | 1.8 | 1.8 | 453 | 629 | 22.7 |

| 20 | 1.7 | 1.2 | 2.1 | 2.0 | 473 | 630 | 20.4 | |

| 28 | 2.2 | 1.7 | 2.7 | 3.0 | 496 | 656 | 18.4 | |

| Water Requirement of Normal Consistency (%) | Setting Time (min) | Compressive Strength (MPa) | Tensile Strength (MPa) | |||

|---|---|---|---|---|---|---|

| Initial | Final | 3d | 28d | 3d | 28d | |

| 28.5 | 142 | 229 | 26.1 | 49.4 | 4.97 | 8.64 |

| Density (kg/m3) | Specific Surface (m2/kg) | Water Demand Ratio (%) | Moisture Content (%) | Ignition Loss (%) |

|---|---|---|---|---|

| 2342 | 406 | 84 | 0.1 | 2.6 |

| Aggregates | Particle Size (mm) | Fineness Modulus | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Compacting Density (kg/m3) | 1 h Water Absorption (%) | Cylinder Compressive Strength (MPa) |

|---|---|---|---|---|---|---|---|

| Sand | 0–2 | 3.2 | 1851 | 1068 | — | 8.48 | — |

| expanded-shale | 2–16 | — | 1653 | 896 | 932 | 6.04 | 7.1 |

| Trials | Dosage of Raw Materials (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Expanded—Shale | Ceramsite Sand | Water | Additional Water | Superplasticizer | Steel Fiber | |

| LC30-0 | 496 | 124 | 538 | 473 | 192 | 73 | 2.7 | — |

| LC30-0.8 | 496 | 124 | 525 | 473 | 192 | 72 | 3.2 | 62.8 |

| LC30-1.2 | 496 | 124 | 518 | 473 | 192 | 71 | 3.5 | 94.2 |

| LC30-1.6 | 496 | 124 | 511 | 473 | 192 | 71 | 3.7 | 125.6 |

| LC30-2.0 | 496 | 124 | 505 | 473 | 192 | 71 | 3.7 | 157 |

| Trials | Slump (mm) | fcu (MPa) | fc (MPa) | Ec (GPa) | fst (MPa) | ρd (kg/m3) |

|---|---|---|---|---|---|---|

| LC30-0 | 208 | 38.2 | 31.2 | 19.5 | 1.87 | 1622 |

| LC30-0.8 | 173 | 41.2 | 31.8 | 19.1 | 2.66 | 1716 |

| LC30-1.2 | 165 | 43.6 | 33.8 | 19.2 | 2.85 | 1732 |

| LC30-1.6 | 94 | 45.4 | 37.8 | 18.0 | 3.25 | 1767 |

| LC30-2.0 | 62 | 55.1 | 43.1 | 17.0 | 4.19 | 1800 |

| Trials | fc (MPa) | fst (MPa) | d (mm) | vf (%) | τs (MPa) | ss (mm) | τcr (MPa) | scr (mm) | τu (MPa) | su (mm) | τr (MPa) | sr (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LC30-4R-14-0% | 31.2 | 1.87 | 14 | 0 | 6.7 | 0.07 | 10.8 | 0.30 | 13.3 | 0.81 | 3.3 | 8.24 |

| LC30-4R-14-0.8% | 31.8 | 2.66 | 14 | 0.8 | 6.8 | 0.06 | 10.9 | 0.25 | 13.6 | 0.82 | 3.6 | 9.64 |

| LC30-4R-14-1.2% | 33.8 | 2.85 | 14 | 1.2 | 12.8 | 0.19 | 15.8 | 0.46 | 17.6 | 1.00 | 4.3 | 11.66 |

| LC30-4R-14-1.6% | 37.8 | 3.25 | 14 | 1.6 | 12.0 | 0.41 | 15.5 | 0.71 | 17.2 | 1.46 | 4.4 | 12.57 |

| LC30-4R-14-2.0% | 43.1 | 4.19 | 14 | 2.0 | 10.4 | 0.15 | 17.0 | 0.42 | 21.9 | 1.36 | 7.5 | 8.13 |

| LC30-4R-20-0% | 31.2 | 1.87 | 20 | 0 | 6.7 | 0.53 | 7.8 | 0.66 | 7.9 | 0.73 | 2.1 | 10.97 |

| LC30-4R-20-0.8% | 31.8 | 2.66 | 20 | 0.8 | 9.3 | 0.12 | 11.3 | 0.18 | 13.3 | 0.75 | 5.8 | 8.67 |

| LC30-4R-20-1.2% | 33.8 | 2.85 | 20 | 1.2 | 10.1 | 0.06 | 13.2 | 0.17 | 15.5 | 0.73 | 4.1 | 11.44 |

| LC30-4R-20-1.6% | 37.8 | 3.25 | 20 | 1.6 | 15.2 | 0.14 | 18.5 | 0.37 | 20.3 | 1.34 | 6.2 | 13.53 |

| LC30-4R-20-2.0% | 43.1 | 4.19 | 20 | 2.0 | 13.7 | 0.26 | 16.8 | 0.43 | 19.5 | 1.19 | 6.5 | 11.65 |

| LC30-4R-28-0% | 31.2 | 1.87 | 28 | 0 | 6.3 | 0.12 | 7.8 | 0.33 | 8.7 | 1.37 | 2.8 | 11.78 |

| LC30-4R-28-0.8% | 31.8 | 2.66 | 28 | 0.8 | 9.2 | 0.52 | 11.1 | 1.05 | 12.2 | 2.18 | 4.4 | 10.53 |

| LC30-4R-28-1.2% | 33.8 | 2.85 | 28 | 1.2 | 11.7 | 0.25 | 14.1 | 0.82 | 15.6 | 1.84 | 3.7 | 23.04 |

| LC30-4R-28-1.6% | 37.8 | 3.25 | 28 | 1.6 | 11.7 | 0.48 | 13.6 | 0.61 | 14.6 | 1.22 | 4.8 | 15.85 |

| LC30-4R-28-2.0% | 43.1 | 4.19 | 28 | 2.0 | 13.7 | 0.91 | 14.9 | 1.05 | 16.2 | 1.82 | 3.3 | 19.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, M.; Liu, G.; Liu, L.; Zhang, Y.; Shi, K.; Zhao, S. Bond of Ribbed Steel Bar in High-Performance Steel Fiber Reinforced Expanded-Shale Lightweight Concrete. Buildings 2021, 11, 582. https://doi.org/10.3390/buildings11120582

Zhao M, Liu G, Liu L, Zhang Y, Shi K, Zhao S. Bond of Ribbed Steel Bar in High-Performance Steel Fiber Reinforced Expanded-Shale Lightweight Concrete. Buildings. 2021; 11(12):582. https://doi.org/10.3390/buildings11120582

Chicago/Turabian StyleZhao, Mingshuang, Guirong Liu, Lingli Liu, Yanyan Zhang, Kang Shi, and Shunbo Zhao. 2021. "Bond of Ribbed Steel Bar in High-Performance Steel Fiber Reinforced Expanded-Shale Lightweight Concrete" Buildings 11, no. 12: 582. https://doi.org/10.3390/buildings11120582

APA StyleZhao, M., Liu, G., Liu, L., Zhang, Y., Shi, K., & Zhao, S. (2021). Bond of Ribbed Steel Bar in High-Performance Steel Fiber Reinforced Expanded-Shale Lightweight Concrete. Buildings, 11(12), 582. https://doi.org/10.3390/buildings11120582