1. Introduction

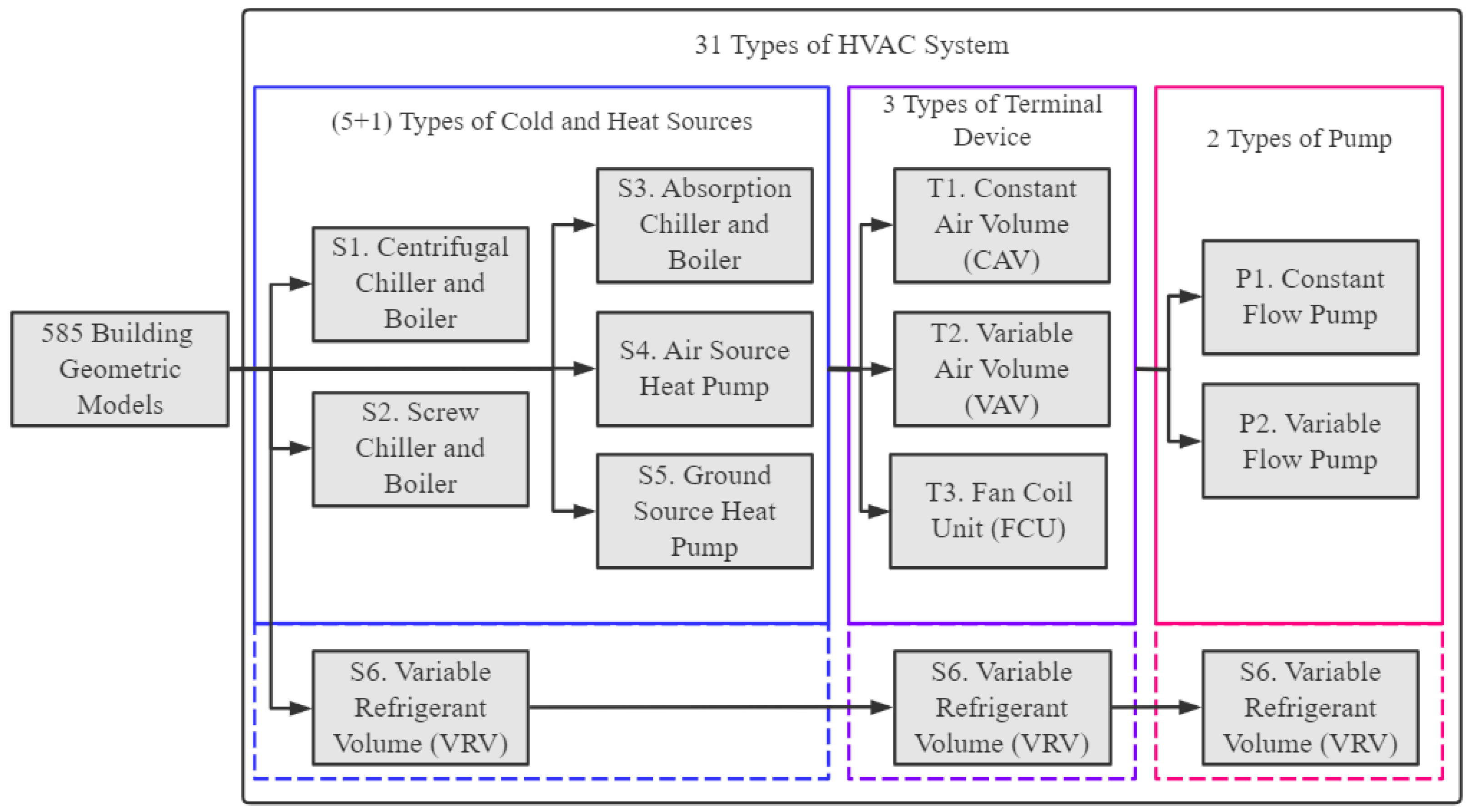

During the pre-design stage for a new HVAC system, the decision makers usually need to compare and evaluate several design alternatives before determining the final design scheme [

1]. In general, a typical centralized HVAC system in commercial buildings can be divided into two main sections: the cooling/heating plant room and the air distribution systems. The plant room contains the main components of cooling/heating (mainly water) production units and distribution such as cooling/heating sources (e.g., chillers, boilers, heat pumps, etc.), chilled water and condenser water pumps, cooling towers and the piping system. The air distribution systems consist of Air Handling Units (AHUs), Fan Coil Units (FCUs), Variable Air Volume (VAV) terminals (without fan) and Fan Powered Boxes (FPBs), air diffusers, and air ducts. High–temperature and low–temperature radiant panels of various types (e.g., radiant cooling ceiling, chilled beam, radiant heating floor, baseboard heating panel, etc.) are also categorized as room terminal units.

For HVAC design, determining the design scheme of the plant room is usually the preliminary task to be completed, since the plant room plays a very important role in the performance of the HVAC system: over 80% of the energy consumption and 40–60% of the initial capital cost of centralized air-conditioning systems come from the equipment in the plant rooms [

2]. In addition, the design of the air distribution system and terminals should be synchronized with the building interior design, thus the design scheme of the terminals is often uncertain in the pre-design stage. Therefore, this paper only focuses on the decision and evaluation of the plant room (except for the piping system, which is also often uncertain in the pre-design stage) of centralized air-conditioning systems.

To determine the most suitable design scheme of the plant room, designers appreciate an easy-to-use and rational method for a comprehensive evaluation of possible optional schemes, which can cover multiple aspects that affect decision making. It is easy to evaluate one individual factor with a single index, e.g., we always use the Seasonal Coefficient of Performance (SCOP) to assess the energy efficiency of the chiller and plant rooms. Another example is the Annual Operation Cost (AOC), which can reflect the economic performance of HVAC plants during the operation period.

However, one single index is far from enough for evaluating the overall performance of a plant room, and integrating multiple indices such as energy efficiency, capital cost, the impact on the indoor and outdoor environment, as well as installation, and maintenance into one comprehensive method is not a simple task. It is difficult to compromise on divergent objectives and the diversity of the investors’ interests. Some studies have employed a Life Cycle Cost (LCC) analysis to convert indices that reflect the performance of the HVAC system during its life cycle into expressions related to capital cost. For example, Badea et al. analyzed the life cycle cost of a passive house to determine the best technical solution during the design period [

3]; and Cui et al. accomplished the optimal design of an HVAC system integrated with a thermal energy storage device based on the maximum life cycle cost savings [

4]. These applications have shown the effectiveness of LCC, but they also reveal a challenge: the difficulty to acquire cost data or models. This problem limits the wide use of LCC analysis in practice, especially in the pre-design stage of a project when detailed data is lacking. Therefore, we think that the LCC analysis method is not suitable for the scenarios in this study.

Another feasible method would be to utilize mathematical approaches developed in operational research to integrate multiple factors. This belongs to the scope of decision theory, and it is an important part of operational research. Based on the mathematical principles in decision theory, the process of decision making or comprehensive evaluation can be expressed by Equation (1) [

5].

This is an example of the Equation:

where

Tj refers to the total score of an evaluation object (in this study, the objects are all alternative design schemes of HVAC systems);

NVj,i refers to the normalized value of each individual index; and

wi refers to the weight factor of this index.

If there are i individual indices for evaluation and j design schemes as the evaluation objects, the normalized values of all indices can form an i × j matrix, the vector of weight factor contains i dimensions corresponding to the number of indices, and the vector of the total score contains j dimensions corresponding to the number of evaluation objects. The core mathematical problem of decision and evaluation is to determine the vector of the weight factor, while the values of all factors should be reasonable, and the decision and evaluation results should be satisfactory. Many researchers have carried out studies on this topic in recent years. We provide a summary on the relevant studies in the next paragraph.

With the development of operational research, mathematicians have developed many evaluation methods, such as the Analytic Hierarchy Process (AHP), fuzzy comprehensive evaluation, Data Envelopment Analysis (DEA), and the entropy weight method. These methods, such as AHP and fuzzy comprehensive evaluation, usually determine the relative importance of different indices according to experts’ previous experience [

6]. Although some studies have achieved acceptable results by using AHP or fuzzy AHP for evaluation and decision making [

7,

8], some scholars still have doubts about AHP because they think that the rigors of a scientific method can be weakened if the judgment criterion is only based on a subjective opinion [

9]. Therefore, mathematicians have begun to utilize the statistical characteristics of the index values to calculate their corresponding weights.

For a complex system with multiple numerical input and output factors, DEA is an applicable technique and its comprehensive performance in converting the inputs into outputs can be evaluated [

10]. For the other general cases, researchers prefer to use information entropy to determine the importance of each variable based on a natural and reasonable inference: “The variable whose data carries more information can be considered more significant,” [

11]. Its basic principle is information theory founded by Shannon in 1948 [

12]. Since then, the entropy weight method for evaluation has been gradually established and proved to be scientific to a certain extent in many applications of actual decision-making problems [

13,

14].

In addition, Rough Set (RS) theory proposed by Pawlak in 1982 is another approach to quantify the importance of factors, especially when there is much vague and uncertain information in the problem [

15]. As a relatively new tool, this method has been successfully applied to some realistic scenarios of comprehensive evaluation in recent years [

16,

17]. In the research field of the evaluation related to buildings, some application cases have been also implemented. For example, Kiluk developed an RS predictor to evaluate the quality of measurement data for fault diagnosis in a district heating system [

18]; Del Giudice et al. proposed a technology based on RS theory for real estate appraisals, and carried out an application of this assessment method in a district of Naples [

19]; Lei et al. combined RS theory and a wavelet neural network to make a comprehensive evaluation of the indoor air quality of buildings [

20]; and Guo et al. used fuzzy-theory-based AHP to assess the performance of an enhanced geothermal system [

21]. Nevertheless, such studies are still not rich enough, and we cannot use the same methods to solve the research problem in this study.

Except for weight factors (the vector of

w in Equation (1)), the matrix of normalized index values (the matrix of

NV in Equation (1)) has to be determined before the evaluation results are provided. Building Performance Simulation (BPS) modeling can be a good method to determine the index matrix. For HVAC plant rooms, the most widely used approach to analyze their performance is to establish a BPS model. According to simulation results from the model developed, the energy performance can then be assessed by indices that can be exported from the outputs of BPS models (e.g., total energy consumption, average energy efficiency of the system, capital cost of energy sources, etc.) [

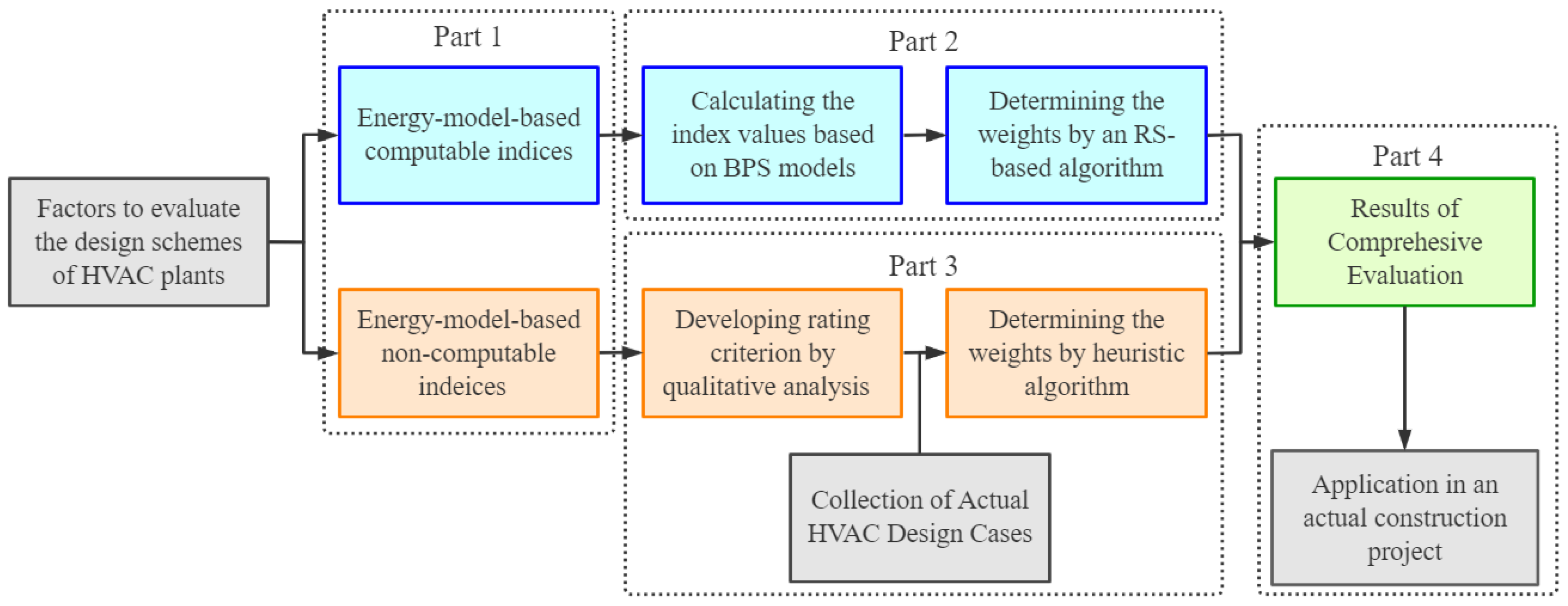

22]. However, other aspects such as initial investment costs, difficulty of installation and maintenance that cannot be output by BPS models also have significant effects on the final decision-making process [

23]. Since the information about the building and the HVAC equipment is usually insufficient for a detailed analysis during the pre-design stage, decision makers often make judgments based on experts’ previous experience when considering these aspects. To obtain a more accurate evaluation result, this paper covers two parts: for the former category that is denoted as computable index (based on BPS models), a database of BPS models is used as a foundation to compute the values and then determine the weights through an RS-based approach; and for the latter part that is denoted as non-computable index (based on BPS models), a technique based on heuristic optimization is developed to codify experts’ experience into compiled information, which makes the detailed analysis of those non-computable indices feasible.

The main goal of this paper is to establish an integrative evaluation method that contains multiple relevant indices to provide a comprehensive and reasonable assessment for the plant room of centralized HVAC systems in commercial buildings, which is different from the current common method of using only a single index for evaluation. In the new evaluation method, the theory of decision science is applied to a practical issue: comprehensively evaluating the performance of an HVAC plant room, which is a complicated decision-making process that requires a substantial number of working hours. In this process, BPS models and experience information are both utilized to obtain the final results through a new approach developed in this study, thus improving the design quality and reducing the design costs.

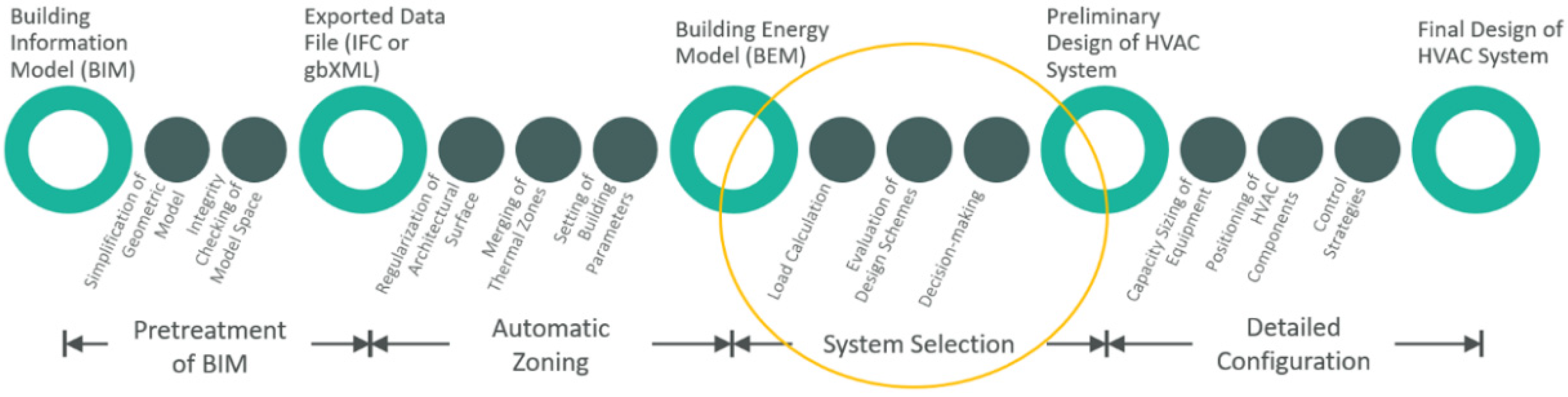

This new method will also be a helpful supporting tool for decision making in HVAC design and construction projects to enhance the quality of the design process and also to reduce the costs of the design work. For example, the method provides a unified standard for discussion between parties before the decision-making process in a construction project for a commercial building (especially when the decision maker of one party is not a professional in building energy system design); and for the “Automatic design of an HVAC system” (as illustrated in

Figure 1). The work flow of this new concept can be divided into four tasks: pretreatment of BIM (Building Information Model), automatic zoning, system selection, and detailed configuration. Some researchers in recent years have emphasized the importance of the task of system selection, which means they want to generate the appropriate design scheme of an HVAC system automatically (as highlighted by the yellow circle in

Figure 1) [

24]. The current project will support this idea by programming the method for a BIM software plug-in such as Revit.

Generally, this paper proposes a novel idea to realize a complicated decision-making process in the design of air-conditioning system plants: selecting the most applicable design schemes of the plants in the building. In the traditional workflow, this process is usually completed manually by professionals. From the perspective of engineering application, it is extremely appreciable for the designers because this evaluation method is actually equivalent to quantifying the fuzzy information (the experience of these designers for the decision making) into a set of compiled rules. Meanwhile, this study also makes an innovative contribution to the research field of the evaluation of HVAC systems: the approach to determine the weight factors— “a hybrid method of RS theory and heuristic algorithm”. Especially in the application of heuristic algorithm, this paper presents a totally new technology to transfer the task of determining the combination of the weights into a global optimization problem, which makes it possible to extract experiment information from the constructed design cases. This provides a good reference for the researchers who are interested in similar topics. They can apply the same idea to realize the integrated evaluation for more components and systems in buildings, so as to improve the design quality and reduce the costs during the whole process of architectural design.

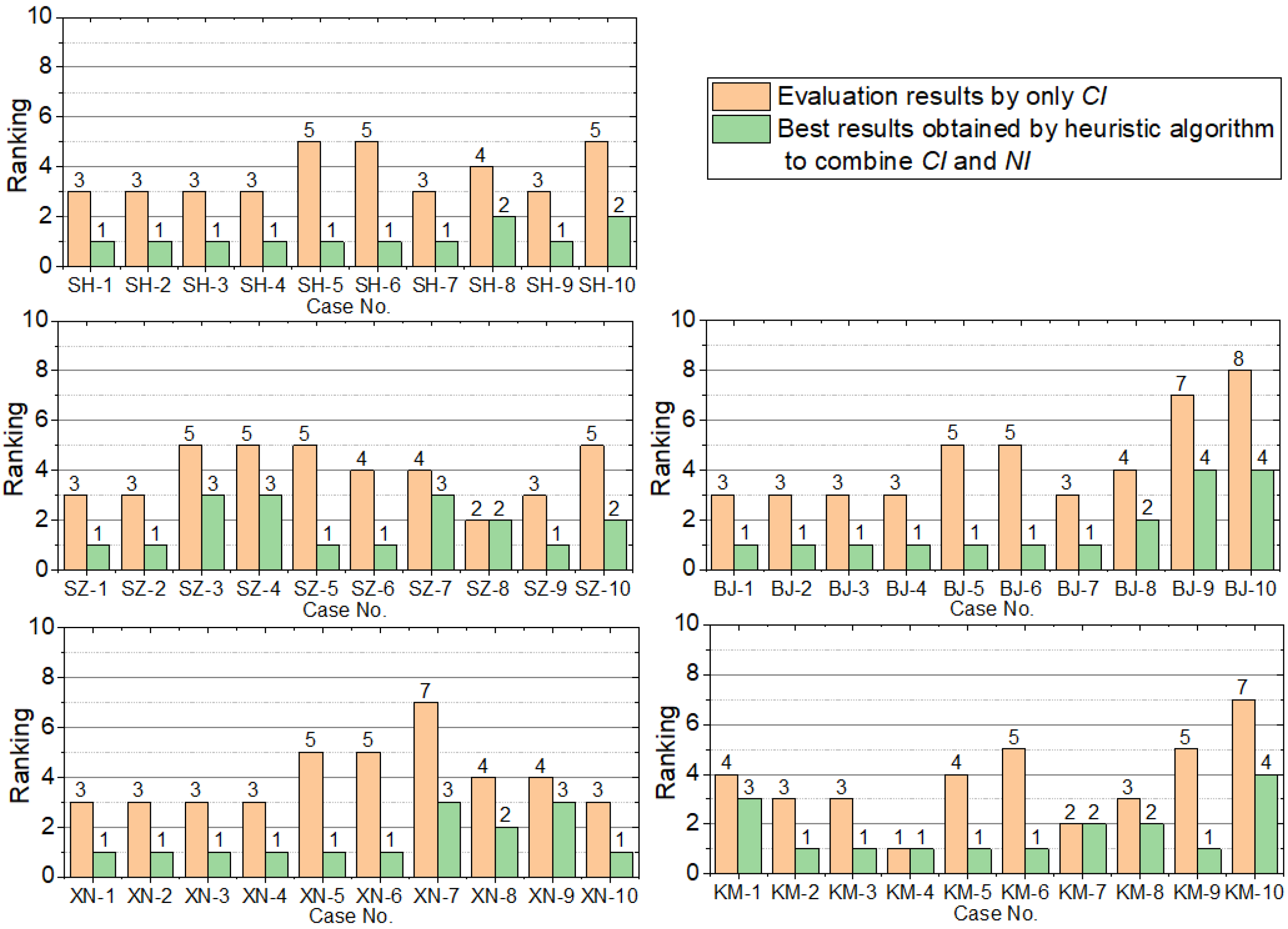

4. Application in an Actual Case

In this section, an actual construction project for a commercial building with a centralized air-conditioning system is taken as an example to show how to apply this method in practice. The example building is a sports center in the suburb of Shanghai, which contains a court, a gym, a swimming pool, as well as shopping and office areas. This case includes two design scenarios from the view of the operating schedule, the building should be divided into two large thermal zones: the core zone that contains the court, gym, swimming pool, and shopping area (the total floor area is 9845 m2) and the office zone (the total floor area is 4890 m2), which means two separate HVAC systems are required for each zone to ensure that these zones with different schedules can operate independently. In this project, the decision makers have decided to adopt different system types for the different zones: an air source heat pump for the core zone and a VRV air-conditioning system for the office zone. To test the rationality of the new evaluation method, the consistency between the evaluation results and the decisions in reality will be checked in this section. We assume that the designers have made a reasonable decision in this actual project, so the finally carried-out design option is regarded as the best design scheme. If the new evaluation method also gives this design scheme a high score, the evaluation results can be considered reasonable.

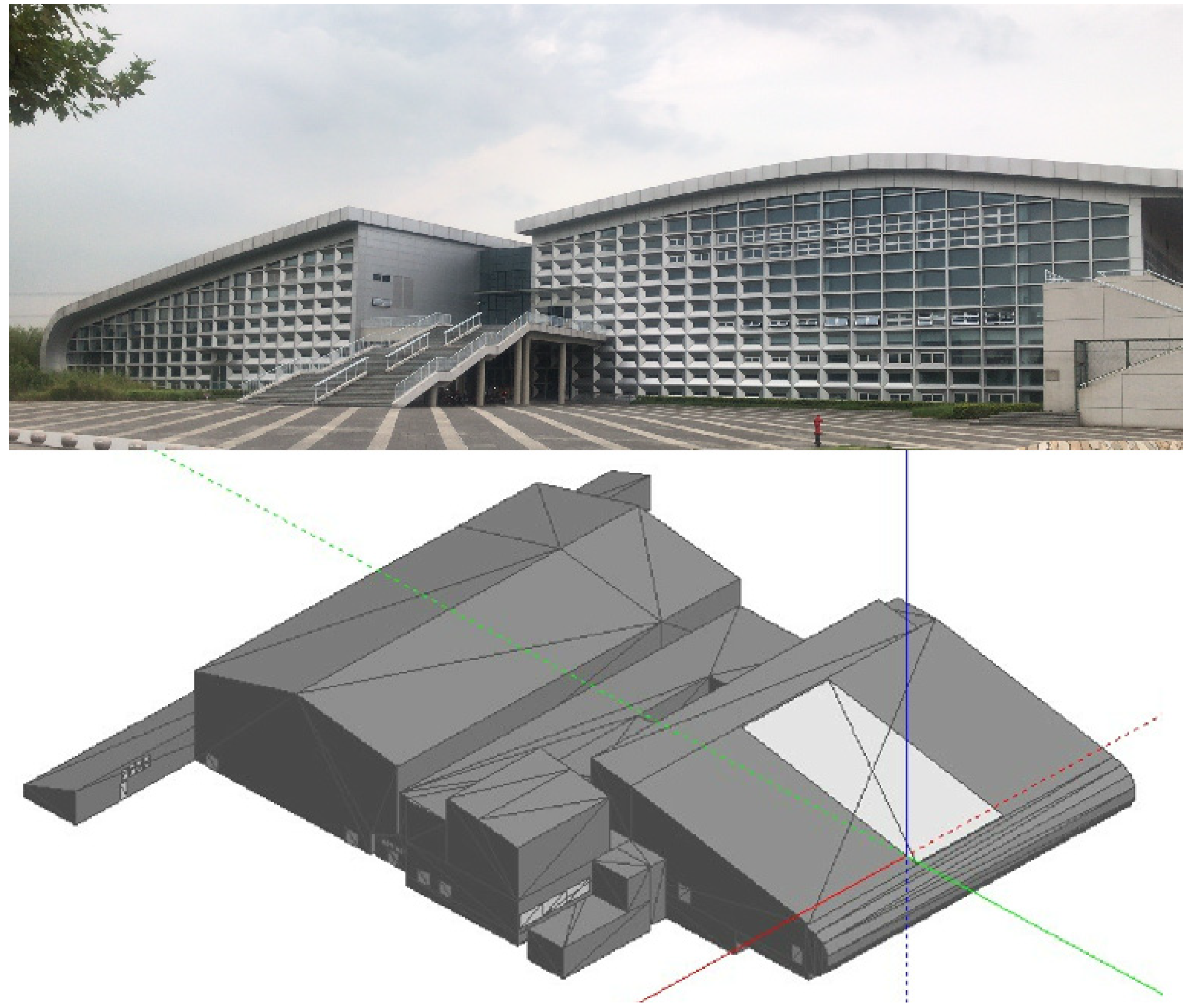

In the design stage, the designers had already built up the original BPS model of the case building in DesignBuilder (

Figure 8). This model can be used as the foundation for further computation analysis.

Table 9 lists the settings of the model parameters, and

Table 10 lists the characteristics of the cooling and heating loads of the building as the outputs of the original model. By changing the settings of the type of HVAC plant room in the model, modelers can build up multiple options for models of the buildings with different design schemes. The number of models is equal to how many design schemes are regarded as a final option plan. The outputs of these models are used to compute the values of indices, and then they are weighted and summed up to generate the total rating score for each design scheme. The total score of the option design chosen in the final plan in reality can be also obtained. If the design scheme that is selected by experts in the practical case gains a fairly high total score, it can be considered that the decision made by the new evaluation method is consistent with the experience information.

The total scores of the optional design schemes for both scenarios are listed in

Table 11. In this table, all the design options are sorted according to their total scores, so the rankings of the final adopted designs (in red) can be easily determined. According to the evaluation results, the design scheme actually adopted in the core area (air source heat pump with variable flow pumps, S4 + P2) ranks 3rd; and the design scheme in the office area (VRV air-conditioning system, S6) ranks 1st. Besides, it can be seen that there are some design schemes whose total scores are zero according to the evaluation results in both of the two indoor scenarios. The zero total score means that

CM, the Boolean variable in Equation (14), takes the value of zero in the evaluation of these design schemes. According to the definition,

CM is the correction factor to screen out those optional schemes that is inapplicable due to the difficulty to obtain the equipment with appropriate capacity on the market. Therefore, this evaluation method can easily exclude some types of HVAC plants from being the decision-making result. For example, the evaluation results show that the total scores of these two design schemes, S1 + P1 and S1 + P2, are zero in the scenario of the core area. Through the load prediction, the total capacity of the cooling system in this scenario can be calculated: 1226.69 kW. According to the rules introduced in

Section 2.3.2, the plant design schemes with the centrifugal chiller cooling source are not appropriate for this building. Finally, this makes the total scores of these schemes zero.

Generally speaking, the design schemes chosen by the professional decision makers of the application case also obtained relatively high scores in the comprehensive evaluation. For the scenario of the office area, the system type of HVAC plant with the highest evaluation score was used in reality. For the scenario of the core area, a screw chiller with a constant or variable flow pump (S2 + P1, S2 + P2) seems to be a better design for the HVAC plant room according to the evaluation result; however, in reality the designers still selected an air source heat pump system as the cooling and heating source. In summary, the results obtained by the evaluation method are basically consistent with the judgment of experts, which can explain the rationality of the comprehensive evaluation method proposed in this paper to some extent.

For the slight mismatch in the evaluation of the design schemes for the core area of the sports center, we infer that the decision makers of the project considered the following factor: there is a constant-temperature swimming pool in the core area of this sports center, and the designers choose the heat pumps to provide hot water for both the HVAC system and the swimming pool. In Shanghai, the energy efficiency of the heat pump to produce domestic heat can be significantly higher than boilers. Thus, for those design schemes of HVAC plants that are not normal (the core area is just an example, in which the designers hope the plants can meet the requirements of air-conditioning and water supply), the evaluation results of this method can be a reference but the final decision-making process still needs to be verified by experts.