1. Introduction

Conventionally, the finite element method (FEM), finite difference method (FDM) or lumped mass method has been widely employed in analyzing the structure’s behavior in civil or mechanical engineering community. These approaches have been well developed and programmed by mathematically analyzing the structural components based on the continuum mechanics. Recently, some advanced finite element models have also been proposed and applied to more accurately model structure’s behavior, e.g., Roy et al. [

1,

2,

3], Uzzaman et al. [

4] and Chen et al. [

5]. These results show that the FEM is able to simulate some complex structural behavior, such as the failure modes of self-drilling screw connections for high strength cold-formed steel, the buckling of gapped built-up cold-formed steel channel sections, etc.

However, there are some inherent defects that have no satisfactory solutions. For example, serious distortion of grids could be observed when solving the large deformation problem using the Lagrangian principle in finite element analysis. It also requires considerable computation resources and time to deal with some non-continuum and geometrically nonlinear issues, which is especially difficult in examining the complex behaviors of a large-scale structure system. The vector form intrinsic finite element (VFIFE) method proposed by E.C. Ting [

6,

7,

8] provides an innovative algorithm for analyzing the complex behaviors of a structure, such as large deformations, large overall motions, fragmentation, etc. The structure’s geometrical shape and motion are described utilizing a set of discrete particles in VFIFE. The interactions between particles are simulated by massless elements. In addition, the trajectory of each particle is divided into several segments (called path elements) in which the particle properties remain unchanged. To deal with the structure’s discontinuous behavior, the properties of each particle can be updated at time steps between path elements. In general, as compared with FEM, the VFIFE method has five significant advantages:

- (1)

According to the discrete model, the particles and elements can be added or removed freely in the analysis process, and thereby the entire process of the collapse or fragmentation of the structure can be well modeled.

- (2)

Inspired by the explicit finite element method, the equation of the motion of each particle is directly formulated by Newton’s second law individually, suggesting that there is no concept of any integrated stiffness matrix. Consequently, this method avoids the issue of ill-conditioned matrices, which can happen in the conventional finite element method.

- (3)

Moreover, in contrast to the explicit finite element method, the VFIFE method adopts a procedure of reversed motion rather than the co-rotational technique [

9,

10] to calculate the pure deformations and internal forces of each element. This treatment avoids the numerical instability of the co-rotational technique in dealing with elements with large deformations.

- (4)

To solve the governing equations, an explicit solution procedure, e.g., a second order central difference time integrator, is employed. The computation cost can be therefore greatly reduced as compared with the implicit time integrator, in which the nonlinear governing equations are solved by a complicated iterative process.

- (5)

Due to the independence of the elements and particles, the VFIFE is specially suitable for parallel computing [

9,

11].

Because of these advantages, the VFIFE method has received intensive attention in the past decade by many scholars. At the very beginning, only a few elements were studied, including planar frame elements [

7], planar 3-node triangular elements and planar 4-node isoparametric elements [

8]. Obviously, they are not sufficient to apply the VFIFE method to analyze the engineering structures. Fortunately, in recent years, many elements have been successfully developed for the VFIFE framework, such as three-dimensional (3D) truss elements [

11], 3D frame elements [

12], 3D fine beam elements [

8,

13], 3-node triangular membrane elements [

14], 4-node quadrilateral elements [

15], 3-node triangular shell elements [

16] and 8-node hexahedral solid elements [

17]. In addition, the VFIFE method has been extended to the analysis of the complex behaviors of structures. The new algorithms of large deflection analysis [

9,

15], elastic-plastic analysis [

13,

18,

19], collapse analysis [

20,

21,

22,

23], crack propagation analysis [

24] and contact analysis [

17,

25,

26] have been successively proposed based on the VFIFE framework.

The continuous development and update of new elements as well as algorithms allow for a wide application of VFIFE in many fields, such as civil engineering [

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37], maritime engineering [

38,

39,

40,

41,

42,

43,

44,

45], mechanical engineering [

17] and biomechanics [

46]. It is confirmed by these literatures that VFIFE has a great potential for the application to civil and infrastructure engineering. However, the most challenging issue is that above-mentioned studies of VFIFE are implemented by self-programmed codes by utilizing MATLAB or FORTRAN language based on a process-oriented framework, which is no scalability and is unsuitable for developing a large-scale and user-friendly software. Besides, the process-oriented framework can hardly meet the requirements of complicated parallel computing. To the authors’ knowledge, there is no software or platform yet available for VFIFE. This is one of the major obstacles for its development and popularization.

On the other hand, structural analysis software such as ANSYS, ABAQUS, ADINA and OpenSees based on FEM or explicit finite element are very mature. These large-scale software have been developed using object-oriented programming technology (OOP), which is currently believed to be the most promising way for designing a new finite element application [

47]. The development of object-oriented engineering software flourished in the 1990s [

48,

49,

50,

51,

52,

53], and some new object-oriented software packages have also been developed to implement new structural analysis algorithms or to extend the capability of existing software [

54,

55,

56,

57]. With the support of abstraction, encapsulation, modularity and code reuse in OOP architecture, object-oriented finite element software, particularly those written in C++ language (such as OpenSees), have shown high performance and still provide for the maintainability and extensibility essential in modern software packages.

In this study, a basic computing platform (called openVFIFE) is proposed and implemented to facilitate the development and application of the VFIFE method as well as the efficient and accurate analyses of complex behaviors for civil structures. It is written in C++ language with the standard template library (STL) using OOP architecture. The mathematical implementation of VFIFE is briefly introduced in

Section 2. Then, the development of the framework and implementation for the openVFIFE platform is described in

Section 3. A series of numerical validations of link as well as beam elements are conducted in

Section 4. Finally, the openVFIFE is applied to perform the nonlinear dynamic and seismic-induced collapse analysis of a transmission tower before being compared with the results achieved by a conventional FEM software, i.e., ANSYS. It is noteworthy that the link and beam elements are implemented in openVFIFE; more work is undergoing in developing the shell and solid elements. Besides, the advanced modeling features such as initial geometric imperfection, semi-rigid of structure connections and bolt slip, which will affect the behavior of the structure [

58,

59], are also under development. It also allows researchers who are interested in this topic to put their creative ideas into this platform and continuously improve the completeness and applicability of the platform.

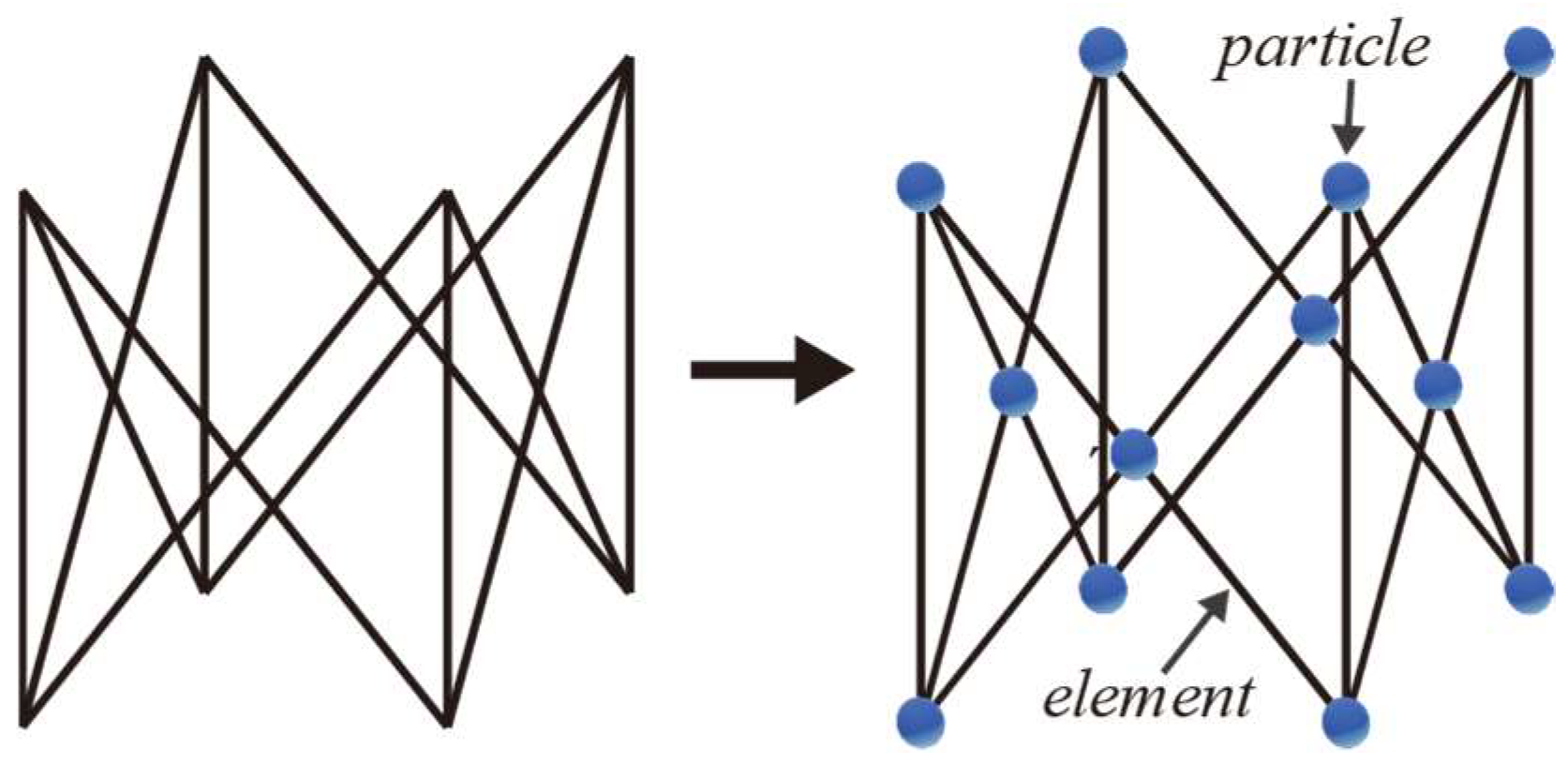

2. Mathematical Implementation of VFIFE

Unlike traditional analytical mechanics, the structure is discretized into a finite number of particles in VFIFE method. These particles are the basic units of the VFIFE. The structure’s geometry and motion are described by the spatial positions and trajectory of the particles, respectively [

12]. The structure’s mass, displacement, deformation, boundary conditions, internal force and external force are all determined through each particle. Adjacent particles are connected using a group of standardized elements, such as bar element, beam element, etc. The element is weightless and is only used to calculate the internal force in the particle connected to it. In the time domain, the time trajectory of the particle’s motion is divided into several segments by a series of time points, and the time history of the structure’s motion and deformation is reflected by its displacement, velocity and other state variables at each time point. Assuming that the initial and final time of the analysis is

t0 and

tn, a set of time points

is adopted to divide the time history into several independent fragments. The time interval of each segment is small enough such that the physical properties of the particle remain unchanged in each time segment, while the structure’s discontinuous behavior is dealt with at each time point. This discrete scheme of time and space is called point value description. Based on the above discretization method, a 3D truss system can be discretized into a series of particles and elements, as shown in

Figure 1. In addition, it is worth noting that VFIFE takes the particle as the basic analysis unit. When considering material nonlinearity, firstly, the strain of the element is calculated according to the deformation analysis results of the element, then the stress of the element is obtained directly according to the stress-strain relationship of the material, and then the internal force of the element is obtained by integration. In this process, it is unnecessary to integrate the global mass and stiffness matrix of the structure system. As a result, the inverse operation of the global stiffness matrix, which is time consuming, is avoided. Thus, it is more efficient than FEM, and more conducive to conducting nonlinear behavior analysis of a structure.

VFIFE directly uses the laws of dynamics as a unified criterion to describe various mechanical behaviors. When describing a structure’s physical behavior, each particle is considered to be in a strict dynamic equilibrium state in the process of motion and deformation. At each time step, the motion of any particle in the structure follows Newton’s second law, and its motion equation is:

where

M is the mass matrix,

x is the displacement vector,

is the acceleration vector,

and

are the external and internal forces of the particle and

is the damping force.

To illustrate the procedures of VFIFE, the space bar assemblies, which have only three translational degrees of freedom (DOFs) on the connected particles, are discussed in this paper [

11]. For more information about other types of elements, see [

7,

8,

12,

13,

14,

15,

16,

17,

21]. The mass of a particle connected to a space bar element consists of two parts: the concentrated mass of the particle and the equivalent mass of the space bar element. The mass matrix of the particle can be expressed as:

where

m is the mass of the particle,

m0 is the concentrated mass and

mi is the mass of the

ith bar element.

is the summation of the external forces acting on the particle, which includes the forces directly acting on the particle and the equivalent external forces. The equivalent external forces can be obtained by the principle of virtual work; they have the same form as the results in FEM and are omitted here for brevity.

is the summation of the internal forces applied by the elements connected to the particle. For one space bar element, the internal element force only depends on its pure deformation. In VFIFE, the rigid body displacement and the pure deformation of an element are distinguished by inverse motion. To illustrate this concept, taking the space bar element shown in

Figure 2 as an example, the displacement vector of the end particles

i and

j at time steps

and

are denoted by (

) and (

), respectively. Similar to the updated Lagrangian formulations (UL), the configuration of the element at

is taken as the reference configuration. From

to

, the relative displacement of particles

i and

j are

and

; the angle between elements at

and

can be calculated by:

where

and

are the direction vectors of the elements at

and

, respectively. Let the element at

(denoted as

) translate

and rotate

to

, as shown in

Figure 2a. Then, the pure deformation of element from

to

can be easily derived:

where

and

are the lengths of the element at

and

, respectively. The axial force in the element at time

is:

where

is the axial force in the element at time step

,

E is Young’s modulus and

A is the cross-sectional area of the element. Note that the internal force calculated by Equation (5) is based on the reference configuration. To obtain the actual internal force at time

, element

should be rotated

and translated

to its original configuration. The magnitude of the internal force will remain unchanged during the rotation and translation except for the direction of the internal force. After the forward motion, the internal forces of the element nodes are:

where

and

are the internal forces at nodes

and

, respectively, and

is the magnitude of the element internal force at time step

. Axial forces

and

are applied to the corresponding particles.

Obviously, the VFIFE method is a dynamic analysis method directly based on Newton’s second law. It obtains the dynamic response of a structure by solving the motion Equation of the particles, suggesting that the dynamic analysis is the method’s essential characteristic. However, the energy dissipation of the motion is inevitable due to the effects of damping. The vibration of the real structure will eventually decay to a stable static state. Although different energy dissipation mechanisms result in different trajectories, the structure will converge to a same static stable state as long as the force is unchanged. Therefore, when using VFIFE to solve static problems, the damping force can be assumed arbitrarily. However, when solving dynamic problems, the structure’s real damping parameters should be adopted. To unify the solutions of static and dynamic problems, viscous mass damping is used, and the damping forces are computed from , where is the damping coefficient.

As for the solution of Equation (1), the central difference method is adopted in VFIFE to avoid iteration in the solution procedure. The velocity and acceleration can be approximated as:

where

,

and

are the displacements of an arbitrary particle at steps

,

and

, respectively, and

is the time interval. Substituting Equations (8) and (9) into Equation (1) yields:

where

and

are the external and internal forces at step

i;

and

.

3. Framework and Implementation of openVFIFE

As discussed above, the VFIFE frameworks in the existing literature are based on a process-oriented framework for specific problems. This framework is very easy to implement and has high efficiency. However, it has low code reusability, poor scalability and low maintainability. In this paper, based on the aforementioned theory, an object-oriented framework is proposed, as illustrated in

Figure 3. A layered architecture is utilized to design the framework, which is divided into two layers: the controller and the core solver. The controller layer calls the interfaces of the core solver to realize flow control of the analysis procedures. The core solver layer, which consists of particle class (Group A), element library (Group B), material library (Group C) and section library (Group D), is the framework’s foundation. A complex system is divided into several independent modules (also known as modular design) in a layered architecture, which is conducive to simplifying the design and implementation of the program. Based on this layered architecture, the framework proposed here has the following advantages:

Maintainability. The layered architecture and modular design make the framework easy to be understood, easy to be modified and easy to be tested. Thus, it allows users and developers to modify or improve the framework using their own computer system environment. For instance, if the graphic user interface (GUI) is needed, developers only need to add a presentation layer responsible for GUI above the controller layer without changing the rest of the framework.

Extensibility. As shown in

Figure 3, the class hierarchy is reasonably designed, and the abstract interfaces of the top-level abstract base class are elaborately planned as well, which will be explained in the following sections. Therefore, the analysis code can be modified, extended and recompiled in the framework.

Developer-friendliness. The framework proposed here assists researchers in using VFIFE for structural analysis. Hence, it must be developer-friendly. Thus, the framework modules are derived from the basic components of VFIFE, which means that each module has a clear physical meaning. For example, the particle class is developed to simulate the behavior of an actual particle in VFIFE. Thus, the whole framework is easy for developers to understand.

The openVFIFE platform based on this framework has the ability to conduct static and dynamic analysis of truss and frame structures. In addition, the elastoplastic analysis and entire-process simulation of the progressive collapse of a structure can also be conducted by openVFIFE. It should be noted that the platform will be supported for a long time and that more new features such as new elements and algorithms will be continuously implemented.

3.1. Particle Class

The particle is the basis of VFIFE. The structure’s motion and deformation are simulated by the particles’ motion. In addition, the deformation analysis of a structural element also needs position information about particles connected to the element. Therefore, the design of a particle class is the foundation of the whole framework. As discussed in

Section 2, one particle should have the following information: spatial coordinates, displacement, velocity, acceleration, mass and load. A particle has at most six DOFs, including three translational degrees of freedom (translation in x, y and z directions, denoted by

Ux,

Uy and

Uz, respectively) and three rotational degrees of freedom (rotation around x, y and z axes, denoted by

Rotx,

Roty and

Rotz, respectively). When designing the particle class, the particle’s physical quantities should be reflected in all six DOFs. Unlike FEM, the global stiffness matrix and global mass matrix are not required in VFIFE, so the coding sequence and storage order of particles need not be specially designed. However, in order to ensure the uniqueness of particles in the system, it is necessary to assign a unique identifier to each particle. This identifier not only establishes the topological relationship between the structural element and the particle but is also used for the identification of the particle’s output results. Obviously, the particle contains all the information required to solve the governing equation. In order to reduce the frequency of data exchange in the framework and to ensure the system’s efficiency, the computing of the particle’s governing equation should also be conducted at the particle level.

Based on the above conventions, the particle class presented in

Figure 4 is established to represent the VFIFE particles. For convenience, efficiency, the security of storage and the usage of data, the following attributes of particle class are stored by an array container in STL: coordinate, force, mass, display, velocity, acceleration and previous displacement. One particle has 6 DOFs, so each position in the array represents information about a fixed DOF, as shown in

Figure 5. For different problems, the particle’s DOFs are different. For instance, a particle connected with a space bar element has only three translational DOFs (

Ux, Uy, Uz), while a particle connected with a space beam element has all six DOFs. In order to simulate the various combinations of a particle’s DOFs, the

dof_key attribute is designed to control them. This attribute is also stored by the array container, and each position corresponds to a fixed DOF and can only be taken as a Boolean value, as shown in

Figure 5. When the value in the

dof_key[i] (i = 0, 1, …, 5) is correct, the particle has the DOFs corresponding to that position. Correspondingly, three methods,

activateDof(), deactivateDof() and

constraintDof (), are designed to activate, deactivate and constrain the particle’s DOFs. Furthermore, the particle class includes the

solve() method for solving the governing equations. The governing equation is solved by the central difference method, as shown in Equation (10). Once the governing equations are solved, the particle’s spatial position needs to be updated in time, so the

updatePostion() method is designed to achieve this function.

3.2. Material Class and Its Derivations

There are many types of materials involved in practical engineering, such as concrete, steel, wood and so on. In the civil engineering field, the mechanical properties of materials are mainly considered, including density, Young’s modulus, shear modulus, Poisson’s ratio and so on. Obviously, it is unreasonable and difficult to integrate material properties into structural elements. Using a material class to simulate materials in practical engineering can take into account the system’s feasibility and extensibility. Depending on the problem, sometimes only linear elastic materials need to be considered, and sometimes nonlinear materials need to be considered. Thus, the

BaseMaterial class, which serves as an abstract class, is used to specify the necessary mechanical properties of the materials and the interfaces to be called by structural elements. Furthermore, materials with different mechanical properties can be developed according to users’ requirements. The material library shown in

Figure 6 is established to simulate elastic and plastic materials.

The abstract base class

BaseMaterial is formed by abstracting the commonness of all materials and includes the following main attributes: material number id, material type type, elastic modulus E, shear modulus G and Poisson’s ratio nu. The

BaseMaterial class also provides a virtual method

Eq() to return the material’s equivalent tangent modulus. The

LinearElastic class inherits from

BaseMaterial and is used to simulate all linear elastic materials. Two abstract classes,

UniaxialPlastic and

NdPlastic, are also derived from

BaseMaterial and are used to represent plastic materials under uniaxial stress-strain status and plastic materials under complex stress-strain status, respectively. The material properties of plastic materials are related to the loading state and plastic strain/stress history. Therefore, the

isYield() and

isLoad() methods are designed to determine whether the material yields and whether it is loaded or unloaded after yielding, respectively, as shown in the

UniaixalPlastic class diagram in

Figure 6. Furthermore, the material’s subsequent yield strength needs to be updated according to its hardening criterion after yielding. Therefore, the method of

updateYiledFunc() is designed to simulate the material’s hardening. The method involves four attributes: back stress alpha, hardening parameter kappa, mixed hardening paramePleaster

m and plastic stress history

plastic_stress.

Table 1 shows the pseudo-code of the

Eq() function for plastic material. Depending on the

UniaxialPlastic class, two kinds of commonly used plastic material models, ideal elastoplastic model (

UniIdeal class) and bilinear elastoplastic model (

UniBilinear class), are realized in this paper.

It is obvious that the inheritance mechanism in OOP increases the reusability of codes and is very convenient for programming. The base class BaseMaterial provides a common interface through virtual methods, and the dynamic polymorphism for computing an equivalent tangent modulus by a common instruction is achieved. This mechanism makes it possible to develop a universal solver for VFIFE and also to expand new features for users.

3.3. Section Class and Its Derivations

In truss structure analysis, the element’s stiffness matrix depends on its cross-section characteristics. As in the material library, the section should not be integrated into the element class. It is necessary to design an abstract base class to specify the section characteristics (including area, static moment, moment of inertia, etc.) and the interfaces for calculating them. In the engineering practice, there are various structure members with different sections, so it is unrealistic to establish a derived class for each section. Therefore, it is necessary to design a user-defined section class to simulate the situation where the section properties are given directly. In this way, the section characteristic parameters of an irregular section calculated by other software can be directly used.

Figure 7 shows a UML diagram of the section library. The abstract base class

BaseSection has the following properties: section number

id, area

A, moments of inertia

Iyy and

Izz and polar moment of inertia

Iyz. Correspondingly, the

BaseSection class also provides virtual methods

calcArea(), calcIyy(), calcIzz() and

calcIyz(). In fact, besides the above properties, the section should also have other attributes, such as static moment and shear center, which are not given in this paper due to limited space. The

CustomSection,

Ctube and

AngleSteel classes are inherited from

BaseSection and are used to simulate sections with arbitrary parameters, circular tube sections and angle sections, respectively. As stated above, there are many cross-sections of beam and column members in engineering. This paper only provides concrete realization of a few common ones. However, with object-oriented programming, users can easily develop custom section types based on the abstract base class

BaseSection.

3.4. Element Class and Its Derivations

In VFIFE, a structural element is used to reflect the internal force response of the structural system under external load, and the internal force in the element is also a part of the external force acting on the particles. When analyzing the internal force in a structural element, it is necessary to first obtain the motion information about the particle connected to it. Deformation analysis according to the particle’s displacement is then carried out to obtain the element’s rigid body motion and pure deformation. Once the pure deformation is obtained, the internal element force can be computed by taking the material and section properties into consideration. Finally, the internal element force is applied to the particles connected to the element as the external force on the particles. The complete procedures are listed in

Table 2. It is natural to associate element object with particle object, material object and section object in the framework’s design.

On the other hand, according to the type and scale of the problem, a structural system can be discretized into truss elements (bar and/or beam elements), plane elements, shell elements, solid elements, etc. Obviously, there are many differences among these elements in both geometric modeling and mechanical analysis: (1) a bar element usually contains only two nodes, a plane triangular element can contain three or six nodes, and a shell element and a solid element need at least eight nodes; (2) a truss element must specify element cross-section information, while other elements do not; (3) the material properties that can be considered for each element are different; for example, a bar element cannot reasonably reflect the characteristics of anisotropic materials, while a solid element can fully consider all the mechanical characteristics of anisotropic materials; (4) the rules for establishing the local coordinate systems of elements are not the same; for example, a beam element needs to predetermine its principal axis direction; (5) the stress-strain state of each element is different. In object-oriented programming, the commonness of the above elements is abstracted to form a base element class

BaseElement. Besides the basic properties of elements such as particle, material and section, this base class also specifies the methods that elements must have, such as calculating element mass and internal force, as shown in

Figure 8.

The abstract base class BaseElement has the following main attributes: element number id, particle objects container particles, material object material, section object section, element mass mass, stress stress, strain strain and direction vector of element local coordinate system ex, ey, ez. The BaseElement class also provides virtual methods setParticleMass(), setParticleMass() and setParticleForce(), which are used to set the DOFs, mass and internal forces in the particles connected to the element, respectively. The virtual method calcOrientVector() is designed to update the element’s local coordinate system. On this basis, the virtual method calcElementForce() is designed to calculate the internal element force.

Furthermore,

StructElement,

PlaneElement and

SolidElement are inherited from the

BaseElement class and are used to specify the basic characteristics of truss element, plane element and solid element, respectively. Thus, they also serve as abstract classes. One specific element class can be derived from the above three abstract classes according to its own characteristics. The inheritance relationship of the element class implemented in this paper is shown in

Figure 3 Group B.

Link2D, Link3D, Beam2D and Beam3D classes are derived from StructElement class. Link2D element is a 2D bar element that can simulate truss, connecting rod and spring. Each particle of Link2D element has 2 DOFs (Ux and Uy). Link3D is a 3D bar element with similar performance to Link2D, but each of its particles has 3 DOFs (Ux, Uy and Uz). Link2DLD and Link3DLD elements are developed based on Link2D and Link3D elements, respectively, and can consider both geometric nonlinearity and material nonlinearity. Beam2D element is a 2D frame element that can bear axial tension, compression and bending. Each particle of Beam2D element has 3 DOFs (Ux, Uy and Rotz). Beam3D element is a 3D frame element that can bear axial tension, compression and bending. Each particle of Beam3D element has 6 DOFs (Ux, Uy, Uz, Rotx, Roty and Rotz). Both Beam2D and Beam3D elements can consider geometric nonlinearity, but they cannot accurately consider material nonlinearity.

3.5. StructSystem Class

The structural system can be modeled and analyzed utilizing the particle class, material library, section library and element library. However, it has not been unified, and the function of organizing and outputting the results has not been implemented. In order to solve these problems,

StructSystem class is designed to manage the particle objects, material objects, section objects and element objects involved in the analysis procedures, as shown in

Figure 9. This class is responsible for the creation and destruction of the objects of classes of the core solver, as well as the addition, deletion, checking and modification of each object. At the same time, the

StructSystem class is responsible for the output of model information (including particle coordinates, element information and constraint information) and calculation results (including particle motion information and element internal force). The

StructSystem class is also the middle layer for users to interact with the core solver of VFIFE. The specific solving process is open to users after being encapsulated by the

StructSystem class. This design can not only reduce the cost of users but also increase the security of the whole system.

The StructSystem class has the following properties: number id, working directory workdir, job name jobname, container for Particle objects particles, container for BaseSection objects sections, container for BaseMaterial objects materials, container for BaseElement objects elements and constraint information constraints. The above containers are mainly used to store and manage all kinds of objects in the whole system. In order to facilitate interaction between the user and the kernel, the StructSystem class provides the following methods: setExtetnalForce(), setInternalForce(), autoTimeStep(), solve(), saveResult() and relaseContainers(). Among them, the setExtetnalForce() method is used to apply external load; the setInternalForce() method is used to calculate the internal forces in the elements and apply them to the particle; the autoTimeStep() method is used to achieve automatic time step size; the solve() method calls the particle solver program to solve the governing equation; the saveResult() method is used to save the calculation results; and the relaseContainers() is used to release the contents in the StructSystem class to avoid memory leak.

4. Numerical Validation

As mentioned before, six types of elements are implemented in openVFIFE currently, including Link2D, Link3D, Link2DLD, Link3DLD, Beam2D and Beam3D. Link2DLD and Link3DLD inherit from Link2D and Link3D, respectively. The accuracy and reliability ofLink2DLD, Link3DLD, Beam2D and Beam3D are validated in this section. In addition, the performance of openVFIFE in large deformation analysis, elastic-plastic analysis and dynamic nonlinear analysis is also examined. For example, applications presented in this section demonstrate the aforementioned multiple capabilities of the platform, including the elastoplastic analysis of a planar truss (example 1), stability analysis of a 24-member shallow dome (example 2), large deformation analysis of a planar cantilever beam (example 3) and dynamic analysis of a space curved beam (example 4).

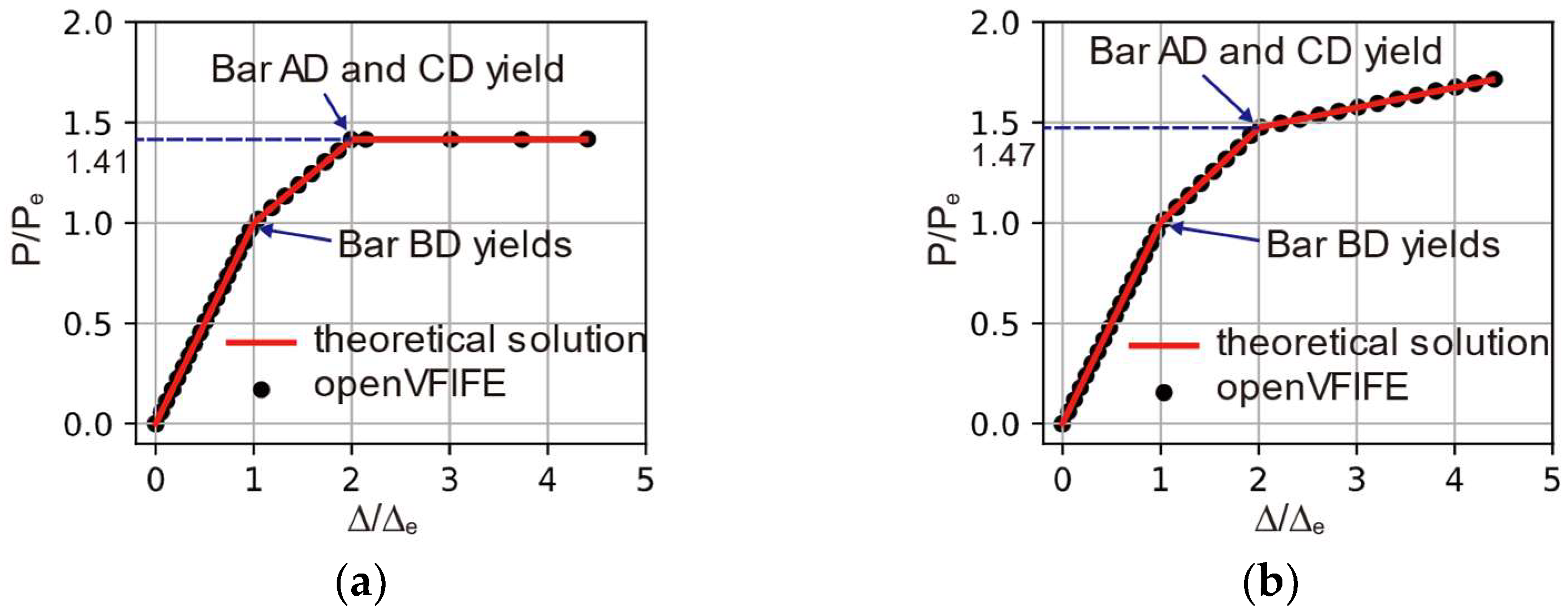

4.1. Example 1: Link2DLD Element

In example 1, a planar three-bar truss subjected to a load P in the y direction is analyzed, as shown in

Figure 10. The cross-sectional area (

A) of bars is 1 m

2; the length (

L) of BD bar is 1 m; and

. Two different plastic material models are considered: an ideal elastic-plastic model and an elastic linear hardening model, as shown in

Figure 10. The density (

) of the bars is 7850 kg/m

3; Young’s modulus

E is 206 Gpa in the elastic state; the tangent modulus

Et is 20.6 Gpa in the plastic state; and the yield stress

is 235 Mpa.

If the ideal elastic-plastic model is adopted, the displacement of node

D can be expressed as:

where

,

, and

.

If the elastic linear hardening model is adopted, the displacement of node

D can be expressed as:

where

,

, and

.

A numerical analysis of the truss is conducted using the proposed framework. The truss is simulated using three

Link2DLD elements, which consider material nonlinearity and geometric nonlinearity simultaneously. The time increment

is taken as 10

−5 s to ensure the stability of central difference, and the total analysis time t is 100 s. The load

P is applied slowly with

. The damping coefficient

is taken as 1.0. The dimensionless results of the numerical analysis and the theoretical solution are presented in

Figure 11.

As shown in

Figure 11, in the planar 3-bar system, BD bar always yields first, and then AD bar and CD bar yield together. For the ideal elastic-plastic model, the truss’s bearing capacity remains unchanged after all three bars have yielded. However, in the numerical analysis, the load is continuously increasing, which leads to a slightly larger numerical result at this stage. For the elastic linear hardening model, the numerical result is consistent with the theoretical result, even when all three bars have yielded. All in all, the openVFIFE results are in good agreement with the theoretical solution for both material models, which proves the feasibility and correctness of the

Link2DLD element and openVFIFE. This example also shows that the VFIFE method is suitable for the elastoplastic analysis of a structure.

4.2. Example 2: Link3DLD Element

To illustrate the capability of VFIFE in geometric nonlinear analysis, and to test the

Link3DLD element, a 24-member shallow dome (as shown in

Figure 12) is analyzed by openVFIFE. The topological relationship between elements and particles as well as the size information are depicted in

Figure 12. The density of the bars is 20 lb/in

3; Young’s modulus

E is 10

6 ksi; and the cross-sectional area (

A) of the bars is 0.1 in

2. A concentrated force

P is imposed on node 1 in the z direction, as shown in

Figure 12.

The dome is simulated by 13 particles located in the joints and 24

Link3DLD elements. To capture the structure’s buckling process, two loading schemes are adopted here: the displacement-controlled method (DCM) and the load-controlled method (LCM). The computing parameters of openVFIFE are listed in

Table 3. The buckling analysis is also conducted using FEM for comparison purpose. The arc-length method is adopted to capture the complete buckling process, which can provide a benchmark of DCM in openVFIFE. The LCM in FEM is also conducted using same computing parameters as openVFIFE.

Figure 13 and

Figure 14 show load-deflection curves using DCM and LCM, respectively. As can be seen in

Figure 13, the load-deflection curves of node 1 obtained by openVFIFE and FEM are quite close, while there is a slight discrepancy for node 2, especially in the z direction. The bearing capacity of the dome increases with the increase of the displacement of node 1 at the small deformation stage. When the dome is instable, the bearing capacity continues to decline. Until the dome stabilizes again, the bearing capacity of the structure can be improved. As shown in

Figure 14, the complete instability path can be obtained using DCM. The LCM fails to reproduce the descending portion of the load-deflection curve. Instead, the load remains unchanged after buckling, then increases in the post-buckling position. When the structure is about to buckle, the results calculated by openVFIFE are more consistent with the results using DCM, while the results of FEM are slightly larger. It is obvious that the results of openVFIFE are quite close to FEM, indicating that openVFIFE is suitable for the buckling analysis of a structure.

4.3. Example 3: Beam2D Element

The large deformation analysis of a planar cantilever beam subjected to a bending moment at its free end is shown in

Figure 15. Young’s modulus

is

, density

is

, beam length (

) is

, cross-section area (

) is

and moment of inertia (

of the cross-section is

. The beam’s deformation is related to the bending moment acting on the free end, as expressed by:

where

is the curvature.

The cantilever beam is discretized into 21 particles and 20

Beam2D elements. The time step

is taken as

to meet the stability of central difference, the analysis time

is 100 s and the damping coefficient

is taken as 1.0. The numerical computing results by openVFIFE are compared with the theoretical solution, as shown in

Figure 16.

It is obvious that the numerical simulation results yeilded by applying openVFIFE are in good agreement with the theoretical results, as can be seen in

Figure 16. The numerical solutions remain highly accurate even when the beam is curled by 3 laps, i.e.,

. It provides sufficient evidence to prove the accuracy of the

Beam2D element and also verifies the capability of the geometrically nonlinear analysis of openVFIFE.

4.4. Example 4: Beam3D Element

Example 4 illustrates the application of

Beam3D element in dynamic time history analysis. A space curved beam (

AB) is located in the

plane. End

A is fixed, and end

B is free, as shown in

Figure 17. The center angle of the curved beam is 45°, with the radius of R = 100 in. The cross-section of the beam is a rectangle (width w= depth h = 1 in). Young’s modulus

E is

, shear modulus

G is

and density

is

. A concentrated load (

) perpendicular to the

plane is suddenly applied at the free end of the curve beam, and the duration is 0.3 s. The curved beam is simulated by 21 particles and 20 Beam3D elements. The time step

is taken as

to meet the stability of central difference, the analysis time

t is 0.3 s and the damping coefficient

is taken as 0.

According to Chan’s study [

60], the curved beam will vibrate under a suddenly applied load P. As shown in

Figure 18, the openVFIFE results are compared with those of Chan’s study in which FEM was adopted. As can be seen, the openVFIFE results show reasonable agreements with the FEM results, especially in the

z direction. This further validates that the

Beam3D element as well as openVFIFE is effective in analyzing the dynamic nonlinear problems of space frames.

The above four examples verify the accuracy of the four structural elements (Link2DLD, Link3DLD, Beam2D and Beam3D) constructed in the present study. They also prove the ability of openVFIFE in structural behavior analysis, including but not limited to the following aspects: (1) static and dynamic analysis of structures; (2) nonlinear analysis of structures, including geometrical nonlinearity and material nonlinearity; (3) structural stability analysis.

6. Conclusions

VFIFE is a new structural analysis method that has significant advantages in the large deformation analysis, nonlinear dynamic analysis, discontinuous behavior analysis, etc., of a structure. It has therefore been widely used in civil engineering, marine engineering and mechanical engineering. To provide a general VFIFE analysis platform for researchers and engineers, an object-oriented general structural analysis platform (openVFIFE) based on VFIFE is developed in this paper. This platform is structured by a layered architecture with two layers: the controller and the core solver. In the core solver, four modules including particle class, element library, material library and section library are developed to implement the computing tasks of VFIFE. In the controller, a StructSystem class is achieved to manage objects created in the core solver and encapsulate the core solver. Six types of elements are implemented, including planar bar element (Link2D), space bar element (Link3D), flexibility planar bar element (Link2DLD), flexibility space bar element (Link3DLD), planar frame element (Beam2D) and space frame element (Beam3D). Three material models are achieved, including linear elastic material (LinearElastic), ideal elastoplastic material (UniIdeal) and bilinear elastoplastic material (UniBlinear). To validate the reliability and efficiency of the platform, a series of numerical examples are conducted. Furthermore, to extend the applications of VFIFE, the nonlinear dynamic and collapse process of a transmission tower under earthquake load are studied using openVFIFE.

Based on the numerical results presented in this paper, the following conclusions can be drawn:

The accuracy of elements and material models in openVFIFE are verified by four numerical examples. The capacity of the platform in large deformation analysis, elastic-plastic analysis and nonlinear dynamic analysis is also confirmed by these numerical examples.

Benefiting from the explicit solution strategy and the well-designed object-oriented framework, the proposed platform is much more efficient than ANSYS in nonlinear dynamic analysis. Its operation speed is about 6–10 times faster than ANSYS.

In addition, the entire-process collapse of the transmission tower under earthquake loads has been successfully simulated by the openVFIFE. Firstly, the cross-arm of the tower destroys, and then the whole tower tilts under a strong earthquake, which is consistent with the failure modes observed in real cases. The study lays the foundation for further investigation of the collapse mechanism, failure modes and their control of the transmission towers.