Building Information Modelling (BIM) to Enhance Occupational Safety in Construction Activities: Research Trends Emerging from One Decade of Studies

Abstract

1. Introduction

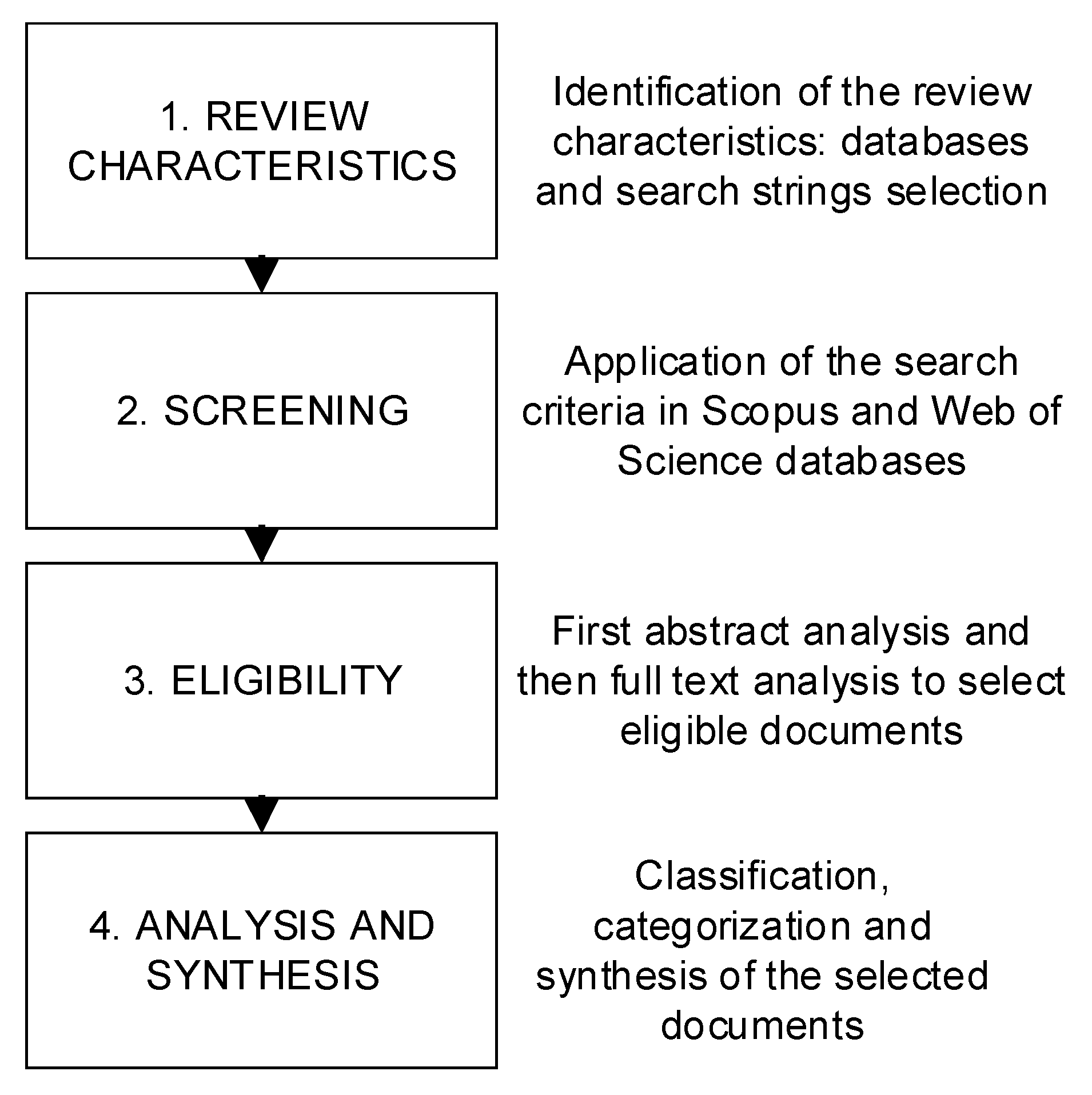

2. Research Methodology

- Identification of the review characteristics (definition of the scope, databases, and search and eligibility criteria);

- Screening of pertinent scientific contributions (application of the search criteria);

- Eligibility evaluation (abstract analysis for inclusion/exclusion);

- Data analysis and synthesis (definition of the type of publication, research categories, and targets by means of the full-text review).

- Definition of the scope. Scientific articles focusing on the use of BIM to improve OHS in the construction industry.

- Databases. Both Scopus and Web of Science databases were used since they are considered some of the most relevant sources of peer-reviewed studies [40].

- Criteria used to carry out the screening. Journal articles published in English between 2010 and 2019 were searched using the following search strings: “TITLE-ABS-KEY ((“building information modelling” OR “building information modeling” OR “BIM”) AND “safety” AND “construction*”)” for Scopus; and “(TS = ((“building information modelling” OR “building information modeling” OR BIM) AND safety AND (construction*)))” for Web of Science.

- Eligibility evaluation. The abstract analysis was performed to evaluate if the inclusion/exclusion of each one of the selected articles considered the scope of the review. Then, a further analysis was carried out analyzing the full text of the selected documents to verify whether they fit with the scope of the review.

- Classification. A first classification of the selected studies was carried out considering the main publication features of each article, i.e., publication year, affiliation country of the first author, and journal. This step can allow the definition of a first overview of research activities on the use of BIM for safety purposes in the last decade.

- Categorization. The selected studies were analyzed based on the type of each article, i.e., empirical or conceptual studies, which is in line with similar examples proposed in literature [39,41,42]. More in detail, such a distinction into empirical and conceptual research was made based on the following criteria: “conceptual study” is referred to those studies that provide theoretical concepts, theoretical models, and frameworks as well as literature reviews. At the same time, “empirical study” pertains to those studies addressing novel technical solutions, surveys among stakeholders, or practical case studies of BIM implementation to improve occupational safety.

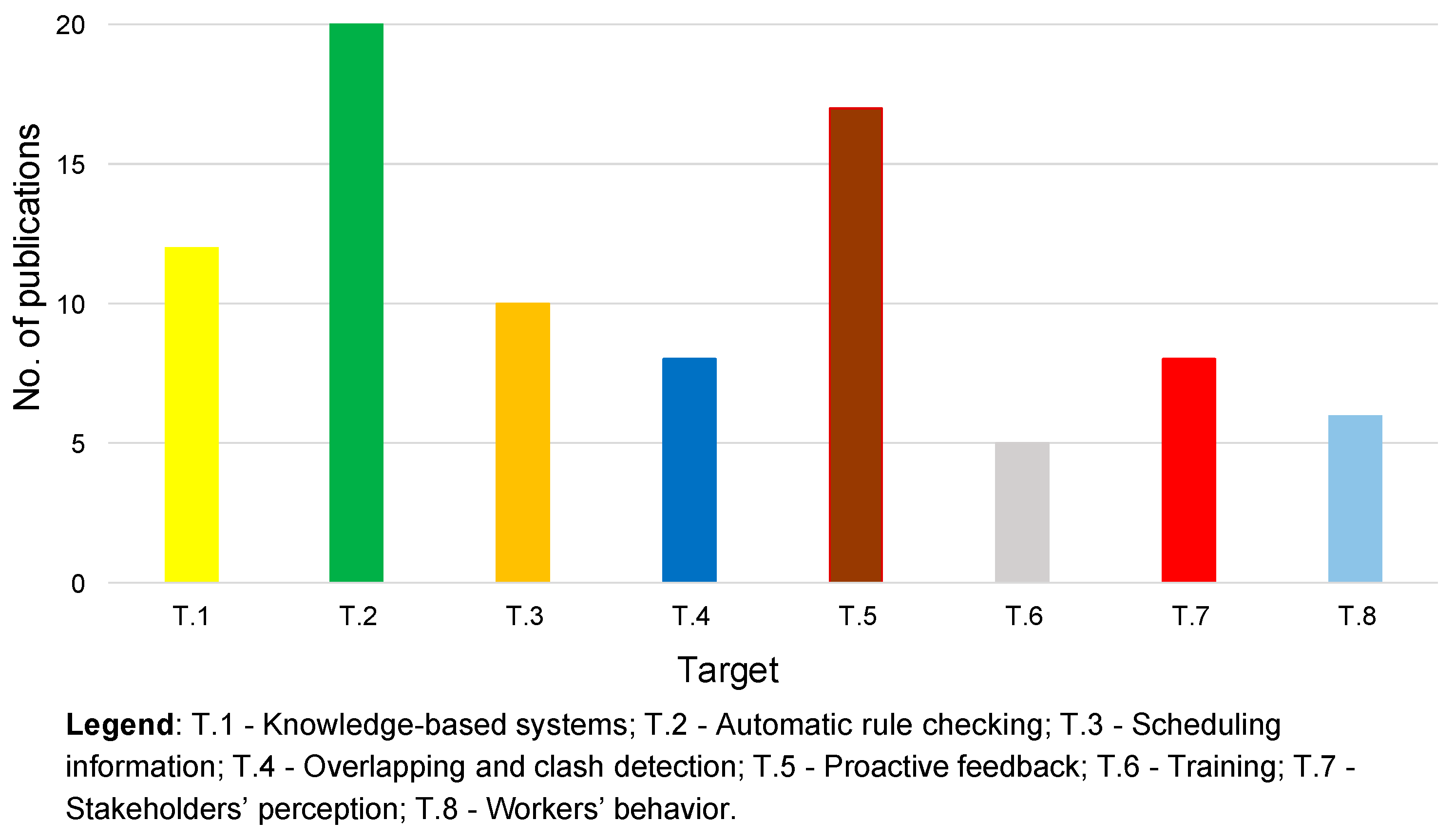

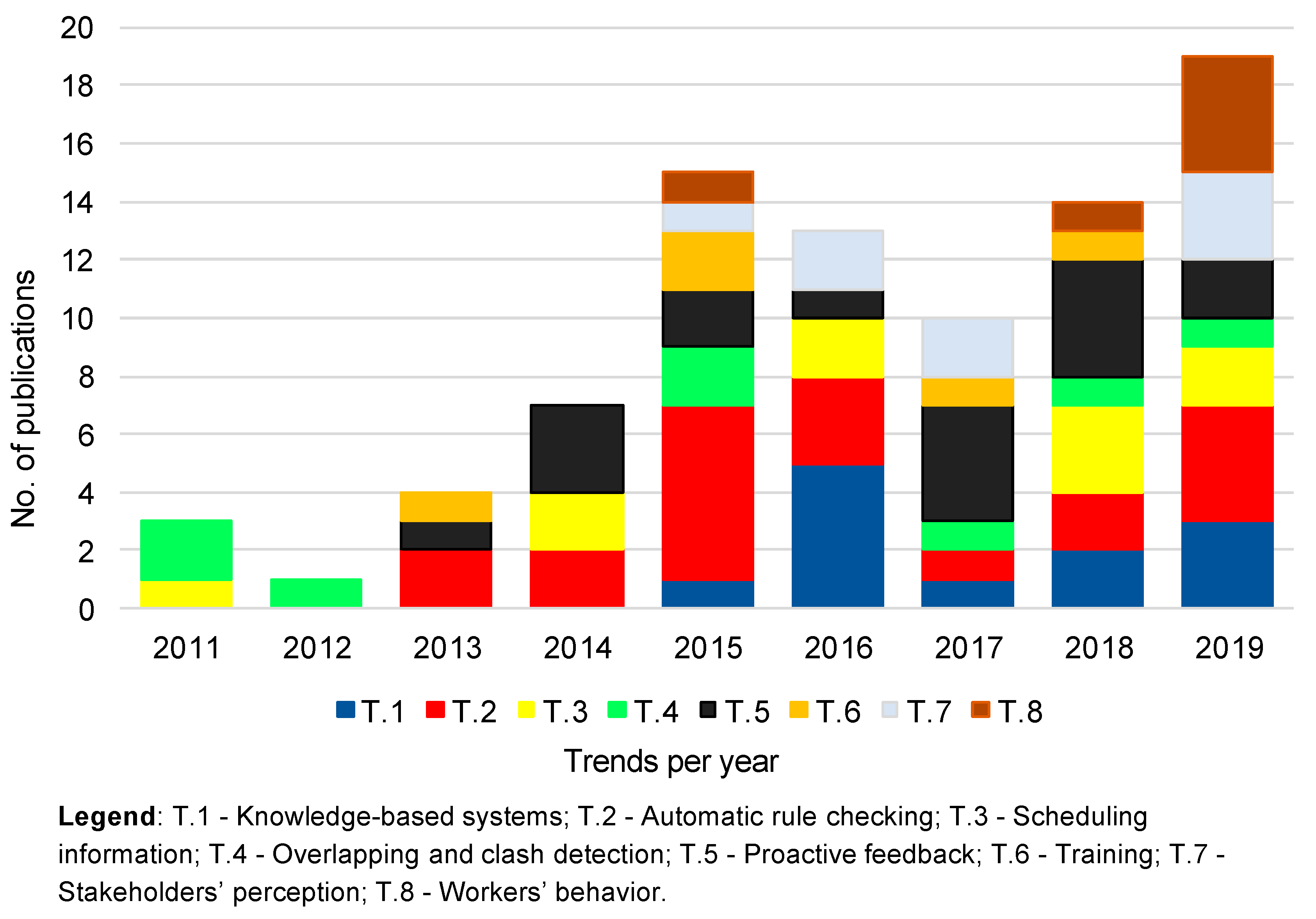

- Research targets. The selected studies were further analyzed with the goal of bringing to light their specific target as well as the means to achieve it. In such a context, the analyses provided by both Zou et al. [29] and Getuli et al. [30] were used as a starting point. Hence, based on these cues, a novel set of research targets emerging from the literature was defined: knowledge-based systems, automatic rule-checking systems, scheduling information, overlaps and clashes resolution, proactive feedback, training, stakeholders’ perception, and workers’ behavior studies. In Table 1, a description of these targets is provided.

3. Results

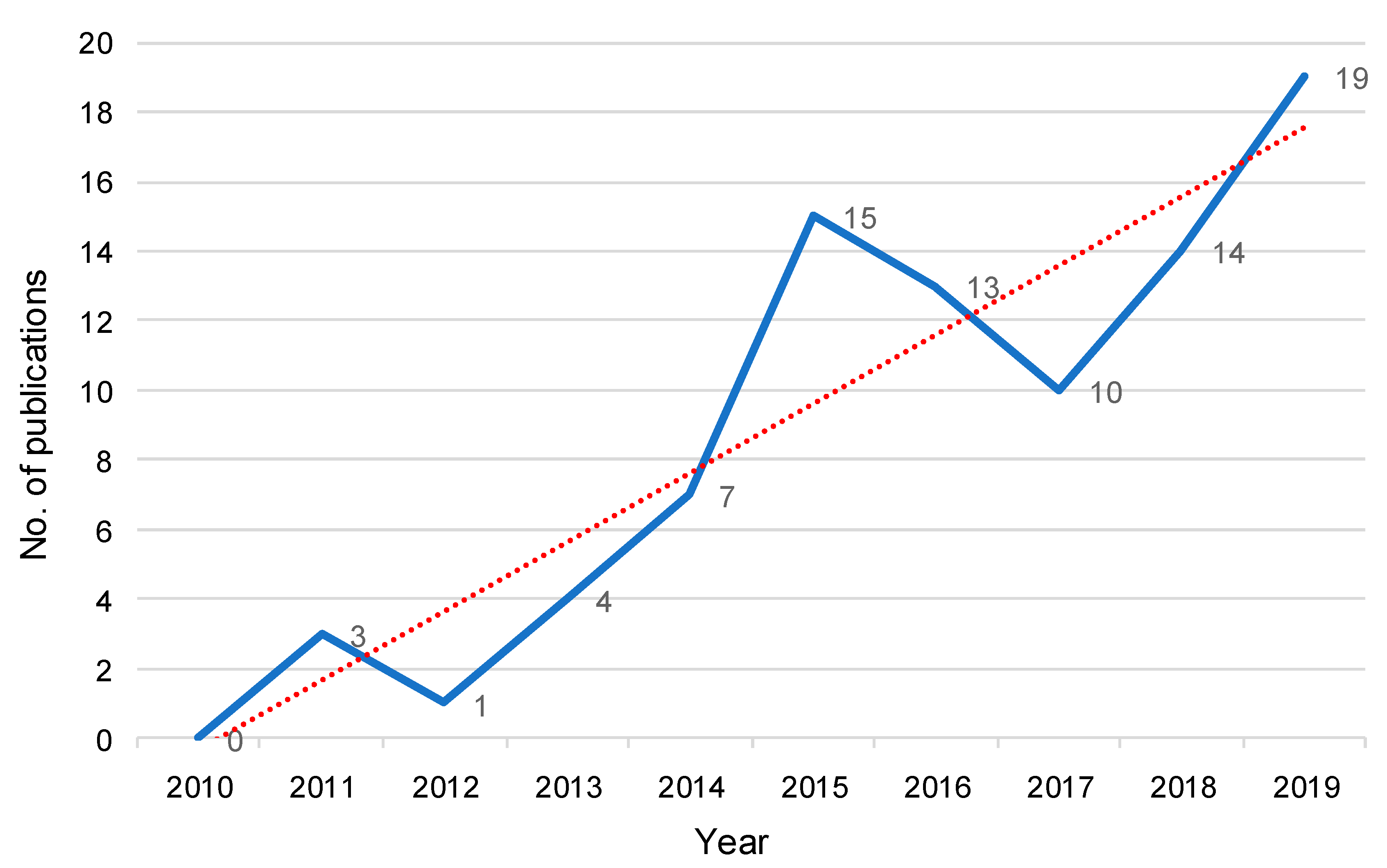

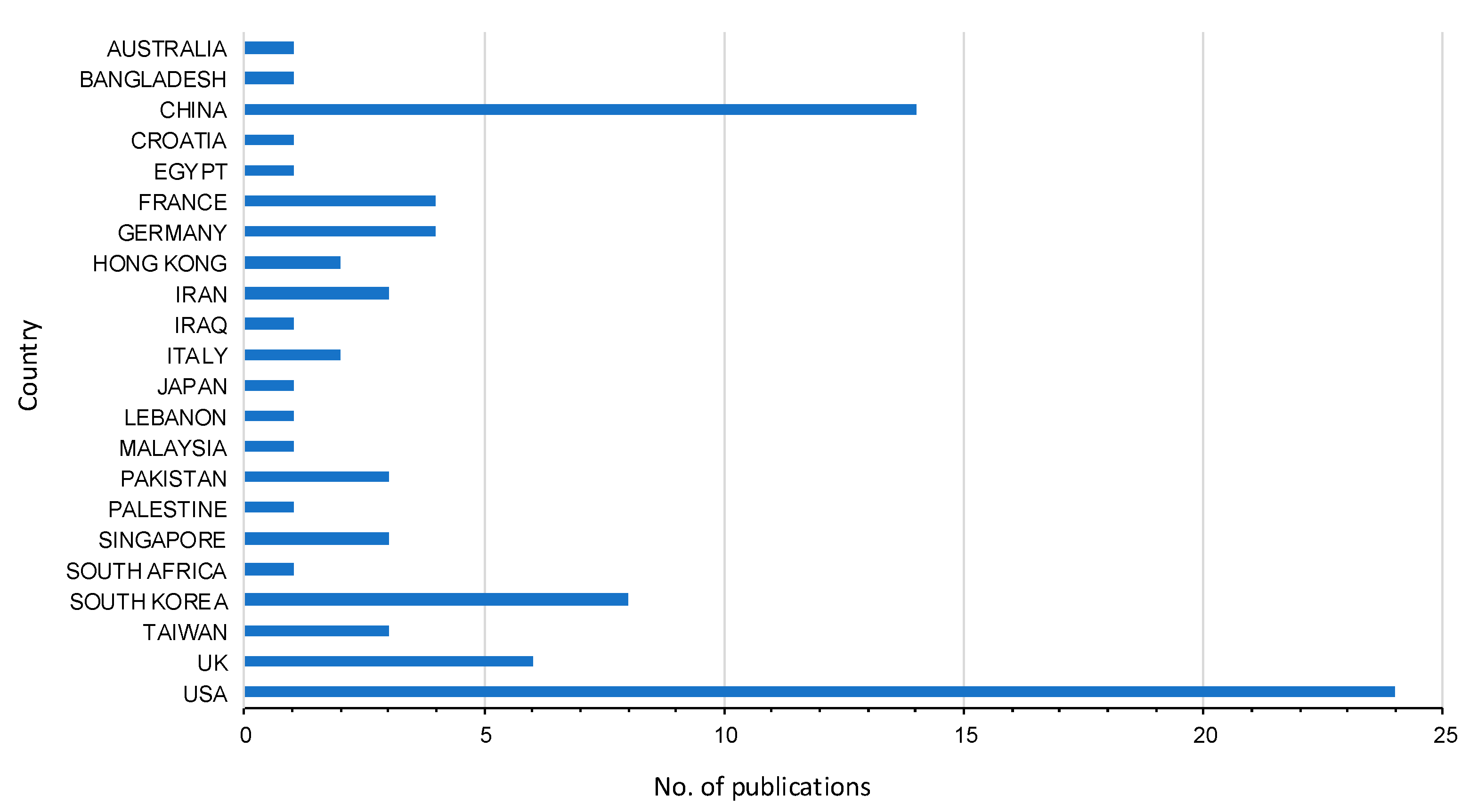

3.1. Classification and Categorization

3.2. Research Targets

3.2.1. Knowledge-Based Systems

3.2.2. Automatic Rule Checking

3.2.3. Scheduling Information

3.2.4. Overlapping and Clash Detection

3.2.5. Proactive Feedback

3.2.6. Training

3.2.7. Stakeholders’ Perception

3.2.8. Workers’ Behaviour

4. Discussion

4.1. Discussion of Results

4.1.1. Knowledge-Based Solutions

4.1.2. Awareness on BIM Applications for Construction Safety

4.1.3. Design for Safety Improvement through BIM Solutions

4.1.4. Transversal Applications of BIM

4.1.5. Dynamic Visualization and Feedback

4.2. Research Insights

- These tools are very important for understanding the dynamics of construction activities and the related hazard types. Hence, they can support safety training and education of workers effectively. In line with Choe and Leite [135], this can also allow safety managers to prepare safety actions more adequately. However, from the analysis, it emerged that the use of BIM for safety training and education has not been investigated sufficiently. Thus, future research directions should focus on these applications of BIM-based tools.

- As highlighted by several studies [26,27,124], the implementation of BIM technologies can enhance safety culture and, hence, safety climate, among all the operators (field workers, managers, and engineers) since they can augment their ability to monitor the safe execution of construction activities as well as respond to external changes and anticipate future incidents. Overall, these applications show a transition of construction safety management from reactive into proactive approaches. Consistent with Chen et al. [136], both the above aspects, awareness and anticipation, represent key factors of resilience in the construction safety context. Accordingly, proactive BIM models can fit with the proactive approach of resilience, which is the core of effective safety management [137]. This aspect is also consistent with the findings of Yap and Lee [138], who underlined the importance of the commitment of the construction personnel and operatives in enhancing safety. Nevertheless, such issues still deserve research efforts.

- The majority of documents proposed conceptual research. Moreover, considering that, in the empirical studies, research relying on surveys is included, few practical applications of BIM-based solutions were observed. This aspect sheds light on the insufficient technology transition from construction safety research into practice. Such a finding confirms research clues suggested by several recent studies [126,139], which asked for more practical applications of Industry 4.0 technologies to enhance construction safety.

- The analysis also highlighted that another knowledge gap is represented by the scarcity of studies aimed at implementing BIM-based tools for quantitative risk analysis to better support safety management [29,103,120]. To reduce such a limitation, it is deemed that further research is needed for developing BIM solutions for a more objective risk assessment.

- This review indicated that, when analyzing the barriers for implementing BIM solutions for OHS, most studies focused on two major gaps: the need for a higher level of standardization for maximizing the capability of these tools [46,63] and the necessity of a proper training of all the stakeholders interacting with them [55,97,114]. Accordingly, to augment the usability and spreading of OHS BIM solutions, these two research issues are worth further investigation. In fact, while the former can contribute to making BIM-related tools available for small projects, which is in line with the research cues stressed by Olbina et al. [140], the latter is consistent with the suggestions of Cortés-Pérez et al. [128]. Both of them represent key factors in improving safety communications among the construction operators.

- Another remarkable aspect that emerged from the analysis is represented by the possibility of integrating BIM with different types of tools for multipurpose applications. In fact, studies aimed at merging BIM with other technologies such as sensors, GPS, virtual reality tools, etc. are increasing in recent years, especially to develop proactive solutions. Since this ability to combine different technologies can turn “Industry 4.0” into a reality in OHS [141], BIM-based technologies can play a fundamental role for developing “Safety 4.0” in the construction industry. Consequently, this aspect represents a promising research trend to further develop and achieve an integrated construction safety 4.0 environment.

- Furthermore, it is worth pointing out the effort paid to develop BIM-based models for the safety improvement at the design and planning stages of construction operations [15,36,44,65]. In such a context, the development of integrated working procedures, combining technical and safety issues, for a proper movement and positioning of the workforce by means of wearable devices integrated into PPE represent a valuable research stream, which can be extended in other industrial sectors as well as toward different hazard types than the traditional ones.

4.3. Study Limitations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Ref. | Author | Year | Journal | Country | Trend |

|---|---|---|---|---|---|

| [49] | Deng et al. | 2019 | Advances in Civil Engineering | China | T.1 |

| [46] | Ding et al. | 2016 | Safety Science | China | T.1 |

| [54] | Hallowell et al. | 2016 | Construction Innovation | USA | T.1 |

| [47] | Hossain et al. | 2018 | Automation in Construction | Singapore | T.1 |

| [45] | Jin et al. | 2019 | Engineering, Construction, and Architectural Management | USA | T.1 |

| [52] | Kim et al. | 2015 | Journal of Computing in Civil Engineering | South Korea | T.1 |

| [48] | Mihić et al. | 2018 | Tehnicki Vjesnik | Croatia | T.1 |

| [53] | Shen and Marks | 2016 | Journal of Construction Engineering and Management | USA | T.1 |

| [44] | Yuan et al. | 2019 | Automation in Construction | China | T.1 |

| [51] | Zhang et al. | 2016 | Journal of Civil Engineering and Management | China | T.1 |

| [50] | Zou et al. | 2016 | Engineering, Construction, and Architectural Management | U.K. | T.1 |

| [29] | Zou et al. | 2017 | Safety Science | U.K. | T.1 |

| [69] | Hara et al. | 2019 | Advances in Computational Design | Japan | T.2 |

| [58] | Hossain and Ahmed | 2019 | International Journal of Construction Management | Bangladesh | T.2 |

| [68] | Ji and Leite | 2018 | Automation in Construction | USA | T.2 |

| [64] | Khan et al. | 2019 | Advances in Civil Engineering | South Korea | T.2 |

| [70] | Kim and Teizer | 2014 | Advanced Engineering Informatics | USA | T.2 |

| [71] | Kim et al. | 2015 | Journal of computing in Civil engineering | USA | T.2 |

| [72] | Li et al. | 2018 | Automation in Construction | China | T.2 |

| [56] | Lin et al. | 2017 | Engineering, Construction, and Architectural Management | Singapore | T.2 |

| [63] | Luo and Gong | 2015 | Journal of Intelligent and Robotic Systems | China | T.2 |

| [61] | Malekitabar et al. | 2016 | Safety Science | Iran | T.2 |

| [66] | Melzner et al. | 2013 | Construction Management and Economics | Germany | T.2 |

| [57] | Park and Kim | 2015 | International Journal of Architectural Research | South Korea | T.2 |

| [65] | Qi et al. | 2014 | Journal of computing in engineering | China | T.2 |

| [73] | Sadeghi et al. | 2016 | Journal Technology | Iran | T.2 |

| [59] | Schwabe et al. | 2019 | Automation in Construction | Germany | T.2 |

| [55] | Teo et al. | 2016 | Construction Economics and Building | Singapore | T.2 |

| [72] | Wang et al. | 2015 | Automation in Construction | USA | T.2 |

| [60] | Zhang et al. | 2015 | Automation in Construction | USA | T.2 |

| [67] | Zhang et al. | 2015 | Safety Science | USA | T.2 |

| [15] | Zhang et al. | 2013 | Automation in Construction | USA | T.2 |

| [83] | Abed et al. | 2019 | Civil Engineering Journal | IRAQ | T.3 |

| [75] | Kim et al. | 2019 | Applied Sciences | USA | T.3 |

| [74] | Kim et al. | 2016 | Automation in Construction | USA | T.3 |

| [77] | Kim et al. | 2018 | Journal of Management in Engineering | USA | T.3 |

| [78] | Kim et al. | 2018 | Journal of Construction Engineering and Management | USA | T.3 |

| [76] | Kim et al. | 2016 | Automation in Construction | USA | T.3 |

| [82] | Marzouk and Daour | 2018 | Safety Science | Egypt | T.3 |

| [79] | Moon et al. | 2014 | Automation in Construction | South Korea | T.3 |

| [80] | Moon et al. | 2014 | Advanced Engineering Informatics | South Korea | T.3 |

| [81] | Xie et al. | 2011 | Electronic Journal of Information Technology in Construction | USA | T.3 |

| [91] | Al Hattab et al. | 2018 | Construction Innovation | Lebanon | T.4 |

| [87] | Arslan et al. | 2019 | Personal and Ubiquitous Computing | France | T.4 |

| [86] | Hu and Zhang | 2011 | Automation in Construction | China | T.4 |

| [90] | Lee et al. | 2012 | Automation in Construction | South Korea | T.4 |

| [84] | Tixier et al. | 2017 | Automation in Construction | France | T.4 |

| [89] | Yi et al. | 2015 | Journal of Mechanical Engineering Research and Developments | China | T.4 |

| [85] | Zhang and Hu | 2011 | Automation in Construction | China | T.4 |

| [88] | Zhang et al. | 2015 | Automation in Construction | USA | T.4 |

| [104] | Akula et al. | 2013 | Automation in Construction | USA | T.5 |

| [97] | Arslan et al. | 2019 | Automation in Construction | France | T.5 |

| [95] | Arslan et al. | 2014 | Journal of Information Technology in Construction | Pakistan | T.5 |

| [105] | Cheung et al. | 2018 | Sensors | Taiwan | T.5 |

| [92] | Choe and Leite | 2017 | Automation in Construction | South Korea | T.5 |

| [96] | Costin et al. | 2015 | Journal of Information Technology in Construction | USA | T.5 |

| [108] | Forsythe P. | 2014 | Proceedings of Institution of Civil Engineers: Management, Procurement, and Law | Australia | T.5 |

| [103] | Golovina et al. | 2019 | Automation in Construction | Germany | T.5 |

| [102] | Golovina et al. | 2016 | Automation in Construction | Germany | T.5 |

| [99] | Li et al. | 2018 | Safety Science | China | T.5 |

| [100] | Park et al. | 2017 | Journal of Construction Engineering and Management | USA | T.5 |

| [107] | Park et al. | 2017 | Advanced Engineering Informatics | USA | T.5 |

| [94] | Riaz et al. | 2017 | Journal of Engineering, Design, and Technology | Pakistan | T.5 |

| [93] | Riaz et al. | 2014 | Automation in Construction | Pakistan | T.5 |

| [106] | Smaoui et al. | 2018 | Sensors and materials | USA | T.5 |

| [98] | Tagliabue et al. | 2018 | In_bo | Italy | T.5 |

| [101] | Wu et al. | 2015 | Visualization in Engineering | Taiwan | T.5 |

| [110] | Clevenger et al. | 2015 | Advances in Engineering Education | USA | T.6 |

| [30] | Getuli et al. | 2018 | In_bo | Italy | T.6 |

| [112] | Li et al. | 2015 | Automation in Construction | Hong Kong | T.6 |

| [111] | Liu et al. | 2017 | ICIC Express Letters, Part B: Applications | Taiwan | T.6 |

| [109] | Park and Kim | 2013 | Automation in Construction | South Korea | T.6 |

| [27] | Alomari et al. | 2017 | Safety | USA | T.7 |

| [115] | Enshassi et al. | 2016 | International Journal of Construction Management | Palestine | T.7 |

| [118] | Ganah and John | 2017 | Journal of Engineering, Design, and Technology | U.K. | T.7 |

| [26] | Ganah and John | 2015 | Safety and Health at Work | U.K. | T.7 |

| [113] | Marefat et al. | 2019 | Engineering, Construction, and Architectural Management | Iran | T.7 |

| [114] | Swallow and Zulu | 2019 | Frontiers in Built Environment | U.K. | T.7 |

| [117] | Swallow, M., Zulu, S. | 2019 | Journal of Engineering, Design, and Technology | U.K. | T.7 |

| [116] | Zulkifli et al. | 2016 | Journal Technology | Malaysia | T.7 |

| [122] | Arslan et al. | 2019 | Safety Science | France | T.8 |

| [119] | Dong et al. | 2018 | Safety Science | China | T.8 |

| [121] | Lee et al. | 2019 | KSCE Journal of Civil Engineering | China | T.8 |

| [120] | Li et al. | 2015 | Safety Science | Hong Kong | T.8 |

| [124] | Olugboyega and Windapo | 2019 | Frontiers in Built Environment | South Africa | T.8 |

| [123] | Shuang et al. | 2019 | Safety Science | China | T.8 |

References

- Lasi, H.; Fettke, P.; Kemper, H.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- Madsen, D.Ø. The Emergence and Rise of Industry 4.0 viewed through the lens of management fashion theory. Adm. Sci. 2019, 9, 71. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular strategies enabled by the internet of things—A framework and analysis of current practice. Sustainability 2019, 11, 5689. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0: An Innovation Platform for the Built Environment, 1st ed.; Routledge: London, UK, 2020. [Google Scholar] [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers, and Contractors, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Issa, R.R.; Olbina, S. Building Information Modeling: Applications and Practices, 1st ed.; ASCE Book Series; American Society of Civil Engineers: Reston, VA, USA, 2015. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Building Information Models—Information Delivery—Manual—Part 1: Methodology and Format; ISO 29481-1:2016; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Miettinen, R.; Paavola, S. Beyond the BIM utopia: Approaches to the development and implementation of building information modeling. Autom. Constr. 2014, 43, 84–91. [Google Scholar] [CrossRef]

- Marmo, R.; Nicolella, M.; Polverino, F.; Tibaut, A. A Methodology for a performance information model to support facility management. Sustainability 2019, 11, 7007. [Google Scholar] [CrossRef]

- Verghote, A.; Al-Haddad, S.; Goodrum, P.; Van Emelen, S. The effects of information format and spatial cognition on individual wayfinding performance. Buildings 2019, 9, 29. [Google Scholar] [CrossRef]

- Dasovic, B.; Galic, M.; Klansek, U. Active BIM approach to optimize work facilities and tower crane locations on construction sites with repetitive operations. Buildings 2019, 9, 21. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lleshaj, A.; Lombardi, M.; Sciarretta, N.; Di Gravio, G. A BIM-based PSS approach for the management of maintenance operations of building equipment. Buildings 2019, 9, 139. [Google Scholar] [CrossRef]

- Zhang, S.; Teizer, J.; Lee, J.; Eastman, C.M.; Venugopal, M. Building information modeling (BIM) and safety: Automatic safety checking of construction models and schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Issa, R.; Suermann, P.C.; Olbina, S. Use of Building Information Models in Simulations. In Proceedings of the Winter Simulation Conference, Austin, TX, USA, 13–16 December 2009; pp. 2664–2671. [Google Scholar]

- He, Q.; Wang, G.; Luo, L.; Shi, Q.; Xie, J.; Meng, X. Mapping the managerial areas of Building Information Modeling (BIM) using scientometric analysis. Int. J. Proj. Manag. 2017, 35, 670–685. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Pärn, E.A.; Edwards, D.J. Critical success factors for implementing building information modelling (BIM): A longitudinal review. Autom. Constr. 2018, 91, 100–110. [Google Scholar] [CrossRef]

- Eleftheriadis, S.; Mumovic, D.; Greening, P. Life cycle energy efficiency in building structures: A review of current developments and future outlooks based on BIM capabilities. Renew. Sustain. Energ. Rev. 2017, 67, 811–825. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Roelvink, R.; Papadonikolaki, E.; Edwards, D.J.; Pärn, E. Integrating BIM into facility management: Typology matrix of information handover requirements. Int. J. Build. Pathol. Adapt. 2018, 36, 2–14. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, X.; Liu, F.; Wu, D.; Anumba, C. An analysis of BIM web service requirements and design to support energy efficient building lifecycle. Buildings 2016, 6, 20. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of BIM-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M. Identifying and prioritizing the benefits of integrating BIM and sustainability practices in construction projects: A Delphi survey of international experts. Sustain. Cities Soc. 2018, 40, 16–27. [Google Scholar] [CrossRef]

- Ganah, A.; John, G.A. Integrating Building Information Modeling and Health and Safety for Onsite Construction. Saf. Health Work 2015, 6, 39–45. [Google Scholar] [CrossRef]

- Alomari, K.; Gambatese, J.; Anderson, J. Opportunities for using Building Information Modeling to improve worker safety performance. Safety 2017, 3, 7. [Google Scholar] [CrossRef]

- Xiaer, X.; Dib, H.; Yuan, J.; Tang, Y.; Li, Q. Design for safety (DFS) and building information modeling (BIM): A review. In Proceedings of the International Conference on Construction and Real Estate Management, Edmonton, AB, Canada, 29 September–1 October 2016; pp. 69–80. [Google Scholar] [CrossRef]

- Zou, Y.; Kiviniemi, A.; Jones, S.W. A review of risk management through BIM and BIM-related technologies. Saf. Sci. 2017, 97, 88–98. [Google Scholar] [CrossRef]

- Getuli, V.; Giusti, T.; Capone, P.; Sorbi, T.; Bruttini, A. A Project Framework to Introduce Virtual Reality in Construction Health and Safety. In_bo 2018, 9, 166–175. [Google Scholar]

- Martinez-Aires, M.D.; Lopez-Alonso, M.; Martínez-Rojas, M. Building Information Modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- Akram, R.; Thaheem, M.J.; Nasir, A.R.; Ali, T.H.; Khan, S. Exploring the role of building information modeling in construction safety through science mapping. Saf. Sci. 2019, 120, 456–470. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Informetric analysis and review of literature on the role of BIM in sustainable construction. Autom. Constr. 2019, 103, 221–234. [Google Scholar] [CrossRef]

- Vogel, R.; Güttel, W.H. The dynamic capability view in strategic management: A bibliometric review. Int. J. Manag. Rev. 2013, 15, 426–446. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Ge, J.; He, S.X. Digitisation in facilities management: A literature review and future research directions. Autom. Constr. 2018, 92, 312–326. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A science mapping approach based review of construction safety research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The prisma statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Thomé, A.M.T.; Scavarda, L.F.; Scavarda, A.J. Conducting systematic literature review in operations management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Safety Vision of Agricultural tractors: An engineering perspective based on recent studies (2009–2019). Safety 2020, 6, 1. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of web of science and scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Carnevalli, J.A.; Miguel, P.A.C. Review, analysis and classification of the literature on QFD-Types of research, difficulties and benefits. Int. J. Prod. Econ. 2008, 114, 737–754. [Google Scholar] [CrossRef]

- Verbano, C.; Venturini, K. Managing risks in SMEs: A literature review and research agenda. J. Technol. Manag. Innov. 2013, 8, 186–197. [Google Scholar] [CrossRef]

- Vinayak, K.; Kodali, R. Benchmarking the quality function deployment models. BIJ 2013, 20, 825–854. [Google Scholar] [CrossRef]

- Yuan, J.F.; Li, X.W.; Xiahou, X.E.; Tymvios, N.; Zhou, Z.P.; Li, Q.M. Accident prevention through design (PtD): Integration of building information modeling and PtD knowledge base. Autom. Constr. 2019, 102, 86–104. [Google Scholar] [CrossRef]

- Jin, Z.; Gambatese, J.; Liu, D.; Dharmapalan, V. Using 4D BIM to assess construction risks during the design phase. Eng. Constr. Archit. Manag. 2019, 26, 2637–2654. [Google Scholar] [CrossRef]

- Ding, L.Y.; Zhong, B.T.; Wu, S.; Luo, H.B. Construction risk knowledge management in BIM using ontology and semantic web technology. Saf. Sci. 2016, 87, 202–213. [Google Scholar] [CrossRef]

- Hossain, M.A.; Abbott, E.L.; Chua, D.K.; Nguyen, T.Q.; Goh, Y.M. Design-for-safety knowledge library for BIM-integrated safety risk reviews. Autom. Constr. 2018, 94, 290–302. [Google Scholar] [CrossRef]

- Mihic, M.; Ceric, A.; Zavrski, I. Developing Construction Hazard Database for Automated Hazard Identification Process. Teh. Vjesn. 2018, 25, 1761–1769. [Google Scholar] [CrossRef]

- Deng, L.; Zhong, M.; Liao, L.; Peng, L.; Lai, S. Research on Safety Management Application of Dangerous Sources in Engineering Construction Based on BIM Technology. Adv. Civ. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Zou, Y.; Kiviniemi, A.; Jones, S.W. Developing a tailored RBS linking to BIM for risk management of bridge projects. Eng. Constr. Archit. Manag. 2016, 23, 727–750. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, X.; Ding, L.; Skibniewski, M.J.; Lu, Y. Bim-based risk identification system in tunnel construction. J. Civ. Eng. Manag. 2016, 22, 529–539. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.S.; Park, M.; Chung, B.; Hwang, S. Information retrieval framework for hazard identification in construction. J. Comput. Civ. Eng. 2015, 29, 04014052. [Google Scholar] [CrossRef]

- Shen, X.; Marks, E. Near-miss information visualization tool in BIM for construction safety. J. Constr. Eng. Manag. 2016, 142, 04015100. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Hardison, D.; Desvignes, M. Information technology and safety: Integrating empirical safety risk data with building information modeling, sensing, and visualization technologies. Constr. Innov. 2016, 16, 323–347. [Google Scholar] [CrossRef]

- Teo, A.L.E.; Ofori, G.; Tjandra, I.K.; Kim, H. Design for safety: Theoretical framework of the safety aspect of BIM system to determine the safety index. Constr. Econ. Build. 2016, 16, 1–18. [Google Scholar] [CrossRef]

- Lin, E.T.A.; Ofori, G.; Tjandra, I.; Kim, H. Framework for productivity and safety enhancement system using BIM in Singapore. Eng. Constr. Archit. Manag. 2017, 24, 1350–1371. [Google Scholar] [CrossRef]

- Park, S.; Kim, I. Bim-based quality control for safety issues in the design and construction phases. Archnet-Ijar 2015, 9, 111–129. [Google Scholar] [CrossRef]

- Hossain, M.M.; Ahmed, S. Developing an automated safety checking system using BIM: A case study in the Bangladeshi construction industry. Int. J. Constr. Manag. 2019, 1–19. [Google Scholar] [CrossRef]

- Schwabe, K.; Teizer, J.; König, M. Applying rule—Based Model—checking to construction site layout planning tasks. Autom. Constr. 2019, 97, 205–219. [Google Scholar] [CrossRef]

- Zhang, S.; Boukamp, F.; Teizer, J. Ontology-based semantic modeling of construction safety knowledge: Towards automated safety planning for job hazard analysis (JHA). Autom. Constr. 2015, 52, 29–41. [Google Scholar] [CrossRef]

- Malekitabar, H.; Ardeshir, A.; Sebt, M.H.; Stouffs, R. Construction safety risk drivers: A BIM approach. Saf. Sci. 2016, 82, 445–455. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.; Liu, P. An automated safety risk recognition mechanism for underground construction at the pre-construction stage based on BIM. Autom. Constr. 2018, 91, 284–292. [Google Scholar] [CrossRef]

- Luo, H.; Gong, P. A BIM-based code compliance checking process of deep foundation construction plans. J. Intell. Robot. Syst. 2015, 79, 549–576. [Google Scholar] [CrossRef]

- Khan, N.; Ali, A.K.; Skibniewski, M.J.; Lee, D.J.; Park, C. Excavation safety modeling approach using BIM and VPL. Adv. Civ. Eng. 2019, 15, 1515808. [Google Scholar] [CrossRef]

- Qi, J.; Issa, R.; Olbina, S.; Hinze, J. Use of building information modeling in design to prevent construction worker falls. J. Comput. Civ. Eng. 2014, 28, A4014008. [Google Scholar] [CrossRef]

- Melzner, J.; Zhang, S.; Teizer, J.; Bargstädt, H. A case study on automated safety compliance checking to assist fall protection design and planning in building information models. Constr. Manag. Econ. 2013, 31, 661–674. [Google Scholar] [CrossRef]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Ji, Y.; Leite, F. Automated tower crane planning: Leveraging 4-dimensional BIM and rule-based checking. Autom. Constr. 2018, 93, 78–90. [Google Scholar] [CrossRef]

- Hara, T.; Shimomura, K.; Hamano, K.; Miyake, S. Automatic design, planning and drawing of scaffolding system for constructions. Adv. Comput. Des. 2019, 4, 179–196. [Google Scholar] [CrossRef]

- Kim, K.; Teizer, J. Automatic design and planning of scaffolding systems using building information modeling. Adv. Eng. Inf. 2014, 28, 66–80. [Google Scholar] [CrossRef]

- Kim, J.; Fischer, M.; Kunz, J.; Levitt, R. Semiautomated scaffolding planning: Development of the feature lexicon for computer application. J. Comput. Civ. Eng. 2015, 29, 04014079. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, S.; Teizer, J. Geotechnical and safety protective equipment planning using range point cloud data and rule checking in building information modeling. Autom. Constr. 2015, 49, 250–261. [Google Scholar] [CrossRef]

- Sadeghi, H.; Mohandes, S.R.; Hamid, A.R.A.; Preece, C.; Hedayati, A.; Singh, B. Reviewing the usefulness of BIM adoption in improving safety environment of construction projects. J. Teknol. 2016, 78, 175186. [Google Scholar] [CrossRef][Green Version]

- Kim, H.; Lee, H.; Park, M.; Chung, B.; Hwang, S. Automated hazardous area identification using laborers’ actual and optimal routes. Autom. Constr. 2016, 65, 21–32. [Google Scholar] [CrossRef]

- Kim, K.; Lee, Y.-C. Automated Generation of Daily Evacuation Paths in 4D BIM. Appl. Sci. 2019, 9, 1789. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y.K.; Zhang, S. Integrating work sequences and temporary structures into safety planning: Automated scaffolding-related safety hazard identification and prevention in BIM. Autom. Constr. 2016, 70, 128–142. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y.K.; Kim, K. BIM-Based Decision-Making Framework for Scaffolding Planning. J. Manag. Eng. 2018, 34, 4018046. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y.; Kim, K. BIM-Driven Automated Decision Support System for Safety Planning of Temporary Structures. J. Constr. Eng. Manag. 2018, 144, 4018072. [Google Scholar] [CrossRef]

- Moon, H.; Kim, H.; Kim, C.; Kang, L. Development of a schedule-workspace interference management system simultaneously considering the overlap level of parallel schedules and workspaces. Autom. Constr. 2014, 39, 93–105. [Google Scholar] [CrossRef]

- Moon, H.; Dawood, N.; Kang, L. Development of workspace conflict visualization system using 4D object of work schedule. Adv. Eng. Inf. 2014, 28, 50–65. [Google Scholar] [CrossRef]

- Xie, H.; Shi, W.; Issa, R.R. Using RFID and real-time virtual reality simulation for optimization in steel construction. J. Inf. Technol. Constr. (ITcon.) 2011, 16, 291–308. [Google Scholar]

- Marzouk, M.; Al Daour, I. Planning labor evacuation for construction sites using BIM and agent-based simulation. Saf. Sci. 2018, 109, 174–185. [Google Scholar] [CrossRef]

- Abed, H.R.; Hatem, W.A.; Jasim, N.A. Adopting BIM Technology in Fall Prevention Plans. Civ. Eng. J. 2019, 5, 2270–2281. [Google Scholar] [CrossRef]

- Tixier, A.J.-P.; Hallowell, M.R.; Rajagopalan, B.; Bowman, D. Construction safety clash detection: Identifying safety incompatibilities among fundamental attributes using data mining. Autom. Constr. 2017, 74, 39–54. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Z. BIM-and 4d-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies. Autom. Constr. 2011, 20, 155–166. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, J. BIM-and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 2. Development and site trials. Autom. Construct. 2011, 20, 167–180. [Google Scholar] [CrossRef]

- Arslan, M.; Cruz, C.; Ginhac, D. Semantic enrichment of spatio-temporal trajectories for worker safety on construction sites. Pers. Ubiquitous Comput. 2019, 23, 749–764. [Google Scholar] [CrossRef]

- Zhang, S.; Teizer, J.; Pradhananga, N.; Eastman, C.M. Workforce location tracking to model, visualize and analyze workspace requirements in building information models for construction safety planning. Autom. Constr. 2015, 60, 74–86. [Google Scholar] [CrossRef]

- Yi, S.L.; Zhang, X.; Calvo, M.H. Construction safety management of building project based on BIM. J. Mech. Eng. Res. Dev. 2015, 38, 97–104. [Google Scholar]

- Lee, G.; Cho, J.; Ham, S.; Lee, T.; Lee, G.; Yun, S.H.; Yang, H.J. A BIM-and sensor-based tower crane navigation system for blind lifts. Autom. Constr. 2012, 26, 1–10. [Google Scholar] [CrossRef]

- Al Hattab, M.; Zankoul, E.; Barakat, M.; Hamzeh, F. Crane overlap and operational flexibility: Balancing utilization, duration, and safety. Constr. Innov. 2018. [Google Scholar] [CrossRef]

- Choe, S.; Leite, F. Construction safety planning: Site-specific temporal and spatial information integration. Autom. Constr. 2017, 84, 335–344. [Google Scholar] [CrossRef]

- Riaz, Z.; Arslan, M.; Kiani, A.K.; Azhar, S. CoSMoS: A BIM and wireless sensor based integrated solution for worker safety in confined spaces. Autom. Constr. 2014, 45, 96–106. [Google Scholar] [CrossRef]

- Riaz, Z.; Edwards, D.J.; Parn, E.A.; Shen, C.; Pena-Mora, F. BIM and sensor-based data management system for construction safety monitoring. J. Eng. Des. Technol. 2017, 15, 738–753. [Google Scholar] [CrossRef]

- Arslan, M.; Riaz, Z.; Kiani, A.K. Real-time environmental monitoring, visualization and notification system for construction H&S management. Electron. J. Inf. Tech. Constr. 2014, 19, 72–91. [Google Scholar]

- Costin, A.; Teizer, J.; Schoner, B. RFID and BIM–Enabled worker location tracking to support real-time Building protocol control and data visualization on a large hospital project. J. Inf. Technol. Constr. (ITcon.) 2015, 40, 495–517. [Google Scholar]

- Arslan, M.; Cruz, C.; Ginhac, D. Semantic trajectory insights for worker safety in dynamic environments. Autom. Constr. 2019, 106, 102854. [Google Scholar] [CrossRef]

- Tagliabue, L.C.; Ciribini, A.L.C. A BIM Based IoT Approach to the Construction Site Management. In_bo 2018, 9, 136–145. [Google Scholar]

- Li, M.; Yu, H.; Jin, H.; Liu, P. Methodologies of safety risk control for China’s metro construction based on BIM. Saf. Sci. 2018, 110, 418–426. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.; Cho, Y. Framework of Automated Construction-Safety Monitoring Using Cloud-Enabled BIM and BLE Mobile Tracking Sensors. J. Constr. Eng. Manag. 2017, 143, 05016019. [Google Scholar] [CrossRef]

- Wu, I.C.; Lu, S.R.; Hsiung, B.C. A BIM-based monitoring system for urban deep excavation projects. Visual. Eng. 2015, 3, 2. [Google Scholar] [CrossRef]

- Golovina, O.; Teizer, J.; Pradhananga, N. Heat map generation for predictive safety planning: Preventing struck-by and near miss interactions between workers-on-foot and construction equipment. Autom. Constr. 2016, 71, 99–115. [Google Scholar] [CrossRef]

- Golovina, O.; Perschewski, M.; Teizer, J.; König, M. Algorithm for quantitative analysis of close call events and personalized feedback in construction safety. Autom. Constr. 2019, 99, 206–222. [Google Scholar] [CrossRef]

- Akula, M.; Lipman, R.R.; Franaszek, M.; Saidi, K.S.; Cheok, G.S.; Kamat, V.R. Real-time drill monitoring and control using building information models augmented with 3D imaging data. Autom. Constr. 2013, 36, 1–15. [Google Scholar] [CrossRef]

- Cheung, W.-F.; Lin, T.-H.; Lin, Y.-C. A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies. Sensors 2018, 18, 436. [Google Scholar] [CrossRef]

- Smaoui, N.; Kim, K.; Gnawali, O.; Lee, Y.-J.; Suh, W. Respirable dust monitoring in construction sites and visualization in building information modeling using real-time sensor data. Sens. Mater. 2018, 30, 1775–1786. [Google Scholar] [CrossRef]

- Park, J.; Chen, J.; Cho, Y.K. Self-corrective knowledge-based hybrid tracking system using BIM and multimodal sensors. Adv. Eng. Inform. 2017, 32, 126–138. [Google Scholar] [CrossRef]

- Forsythe, P. Proactive construction safety systems and the human factor. Proc. Inst. Civil Eng. Manag. Procure. Law 2014, 167, 242–252. [Google Scholar] [CrossRef]

- Park, C.-S.; Kim, H.-J. A framework for construction safety management and visualization system. Autom. Constr. 2013, 33, 95–103. [Google Scholar] [CrossRef]

- Clevenger, C.; Lopez del Puerto, C.; Glick, S. Interactive BIM-Enabled Safety Training Piloted in Construction Education. Adv. Eng. Educ. 2015, 4, 1–14. [Google Scholar]

- Liu, K.-T.; Lee, Y.-L.; Shiau, Y.-C.; Lin, C.-C. Examining the layout of scaffolds and decks used in construction projects from the perspective of building information modelling. ICIC Expr. Lett. Part B Appl. 2017, 8, 319–326. [Google Scholar]

- Li, H.; Lu, M.; Chan, G.; Skitmore, M. Proactive training system for safe and efficient precast installation. Autom. Constr. 2015, 49, 163–174. [Google Scholar] [CrossRef]

- Marefat, A.; Toosi, H.; Mahmoudi Hasankhanlo, R. A BIM approach for construction safety: Applications, barriers and solutions. Eng. Constr. Archit. Manag. 2019, 26, 1855–1877. [Google Scholar] [CrossRef]

- Swallow, M.; Zulu, S. Benefits and barriers to the adoption of 4D modeling for site health and safety management. Front. Built Environ. 2019, 4, 86. [Google Scholar] [CrossRef]

- Enshassi, A.; Ayyash, A.; Choudhry, R.M. BIM for construction safety improvement in Gaza strip: Awareness, applications and barriers. Int. J. Constr. Manag. 2016, 16, 249–265. [Google Scholar] [CrossRef]

- Zulkifli, M.H.; Takim, R.; Nawawi, A.H. A proposed initial framework of ASRC system for BIM-based projects in malaysia. J. Teknol. 2016, 78, 61–67. [Google Scholar] [CrossRef]

- Swallow, M.; Zulu, S. Student’s awareness and perception of the value of BIM and 4D for site health and safety management. J. Eng. Des. Technol. 2019, 18, 414–430. [Google Scholar] [CrossRef]

- Ganah, A.A.; John, G.A. BIM and project planning integration for on-site safety induction. J. Eng. Des. Technol. 2017, 15, 341–354. [Google Scholar] [CrossRef]

- Dong, S.; Li, H.; Yin, Q. Building information modeling in combination with real time location systems and sensors for safety performance enhancement. Saf. Sci. 2018, 102, 226–237. [Google Scholar] [CrossRef]

- Li, H.; Lu, M.; Hsu, S.C.; Gray, M.; Huang, T. Proactive behavior-based safety management for construction safety improvement. Saf. Sci. 2015, 75, 107–117. [Google Scholar] [CrossRef]

- Lee, P.C.; Wei, J.; Ting, H.I.; Lo, T.P.; Long, D.; Chang, L.M. Dynamic analysis of construction safety risk and visual tracking of key factors based on behavior-based safety and building information modeling. KSCE J. Civ. Eng. 2019, 23, 4155–4167. [Google Scholar] [CrossRef]

- Arslan, M.; Cruz, C.; Ginhac, D. Visualizing intrusions in dynamic building environments for worker safety. Saf. Sci. 2019, 120, 428–446. [Google Scholar] [CrossRef]

- Shuang, D.; Heng, L.; Skitmore, M.; Qin, Y. An experimental study of intrusion behaviors on construction sites: The role of age and gender. Saf. Sci. 2019, 115, 425–434. [Google Scholar] [CrossRef]

- Olugboyega, O.; Windapo, A. Building information modelling–enabled construction safety culture and maturity model: A grounded theory approach. Front. Built Environ. 2019, 5, 35. [Google Scholar] [CrossRef]

- Fargnoli, M.; De Minicis, M.; Di Gravio, G. Knowledge Management integration in Occupational Health and Safety systems in the construction industry. Int. J. Prod. Dev. 2011, 14, 165–185. [Google Scholar] [CrossRef]

- Yu, D.; Yang, J. Knowledge management research in the construction industry: A review. J. Knowl. Econ. 2018, 9, 782–803. [Google Scholar] [CrossRef]

- Deepak, M.D.; Mahesh, G. Developing a knowledge-based safety culture instrument for construction industry: Reliability and validity assessment in Indian context. Eng. Constr. Architect. Manag. 2019, 26, 2597–2613. [Google Scholar] [CrossRef]

- Cortés-Pérez, J.P.; Cortés-Pérez, A.; Prieto-Muriel, P. BIM-integrated management of occupational hazards in building construction and maintenance. Autom. Constr. 2020, 113, 103115. [Google Scholar] [CrossRef]

- Lombardi, M.; Fargnoli, M.; Parise, G. Risk Profiling from the European Statistics on Accidents at Work (ESAW) Accident’s Databases: A case study in construction sites. Int. J. Environ. Res. Public Health 2019, 16, 4748. [Google Scholar] [CrossRef]

- Nnaji, C.; Karakhan, A.A. Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers. J. Build. Eng. 2020, 29, 101212. [Google Scholar] [CrossRef]

- Aneziris, O.N.; Topali, E.; Papazoglou, I.A. Occupational risk of building construction. Reliab. Eng. Syst. Saf. 2012, 105, 36–46. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Preliminary Human Safety Assessment (PHSA) for the improvement of the behavioral aspects of safety climate in the construction industry. Buildings 2019, 9, 69. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Guadagno, F. Hazard Function Deployment: A QFD based tool for the assessment of working tasks—A practical study in the construction industry. Int. J. Occup. Saf. Ergon. 2020, 26, 348–369. [Google Scholar] [CrossRef] [PubMed]

- Shafique, M.; Rafiq, M. An overview of construction occupational accidents in Hong Kong: A recent trend and future perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef]

- Choe, S.; Leite, F. Assessing safety risk among different construction trades: Quantitative approach. J. Constr. Eng. Manag. 2017, 143, 04016133. [Google Scholar] [CrossRef]

- Chen, Y.; McCabe, B.; Hyatt, D. A resilience safety climate model predicting construction safety performance. Saf. Sci. 2018, 109, 434–445. [Google Scholar] [CrossRef]

- Carmeli, A.; Friedman, Y.; Tishler, A. Cultivating a resilient top management team: The importance of relational connections and strategic decision comprehensiveness. Saf. Sci. 2013, 51, 148–159. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lee, W.K. Analysing the underlying factors affecting safety performance in building construction. Prod. Plan. Control. 2019, 1–16. [Google Scholar] [CrossRef]

- Swuste, P.; Groeneweg, J.; Van Gulijk, C.; Zwaard, W.; Lemkowitz, S.; Oostendorp, Y. The future of safety science. Saf. Sci. 2020, 125, 104593. [Google Scholar] [CrossRef]

- Olbina, S.; Elliott, J.W. Contributing Project Characteristics and Realized Benefits of Successful BIM Implementation: A Comparison of Complex and Simple Buildings. Buildings 2019, 9, 175. [Google Scholar] [CrossRef]

- Barata, J.; da Cunha, P.R. Safety Is the New Black: The Increasing Role of Wearables in Occupational Health and Safety in Construction. In Business Information Systems, BIS 2019; Abramowicz, W., Corchuelo, R., Eds.; Springer: Basel, Switzerland, 2019; Volume 353, pp. 526–537. [Google Scholar] [CrossRef]

- Kitchenham, B.; Brereton, O.P.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic literature reviews in software engineering—A systematic literature review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

- Enya, A.; Pillay, M.; Dempsey, S. A Systematic Review on High Reliability Organisational Theory as a Safety Management Strategy in Construction. Safety 2018, 4, 6. [Google Scholar] [CrossRef]

| Code | Target | Description |

|---|---|---|

| T.1 | Knowledge-based systems | BIM provides information to knowledge management systems, supporting decision making for risk assessment and management, especially by identifying safety risks during the planning and design phases. |

| T.2 | Automatic rule checking | Codified safety rules are implemented in a BIM-based platform, which allows designers to verify the conformity of both object configurations (e.g., spaces, distances, and dimensions) and processes (e.g., construction sequences and tasks). |

| T.3 | Scheduling information | Studies focusing on the use of BIM-based models to augment dynamic visualization of safety procedures. |

| T.4 | Overlapping and clash detection | BIM models can allow designers to detect space conflicts (e.g., workspaces, equipment), task overlaps, and site congestions. |

| T.5 | Proactive feedback | The combination of BIM with proactive technologies can allow real-time warnings and feedback: tracking the dynamic position of materials, workers, and equipment, and monitoring the presence of hazards and obstacles. |

| T.6 | Training | Studies addressing the use of BIM models and the related technologies that can be used for education and training purposes (e.g., training of workers, students, and safety managers). |

| T.7 | Stakeholders’ perception | Surveys on the use of BIM to improve safety in construction activities by highlighting the benefits of and barriers to its use. |

| T.8 | Workers’ behavior | BIM based/compliant tracking systems to recognize the behavior of workers. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fargnoli, M.; Lombardi, M. Building Information Modelling (BIM) to Enhance Occupational Safety in Construction Activities: Research Trends Emerging from One Decade of Studies. Buildings 2020, 10, 98. https://doi.org/10.3390/buildings10060098

Fargnoli M, Lombardi M. Building Information Modelling (BIM) to Enhance Occupational Safety in Construction Activities: Research Trends Emerging from One Decade of Studies. Buildings. 2020; 10(6):98. https://doi.org/10.3390/buildings10060098

Chicago/Turabian StyleFargnoli, Mario, and Mara Lombardi. 2020. "Building Information Modelling (BIM) to Enhance Occupational Safety in Construction Activities: Research Trends Emerging from One Decade of Studies" Buildings 10, no. 6: 98. https://doi.org/10.3390/buildings10060098

APA StyleFargnoli, M., & Lombardi, M. (2020). Building Information Modelling (BIM) to Enhance Occupational Safety in Construction Activities: Research Trends Emerging from One Decade of Studies. Buildings, 10(6), 98. https://doi.org/10.3390/buildings10060098