Risk of Moisture in Diffusionally Open Roofs with Cross-Laminated Timber for Northern Coastal Climates

Abstract

:1. Introduction

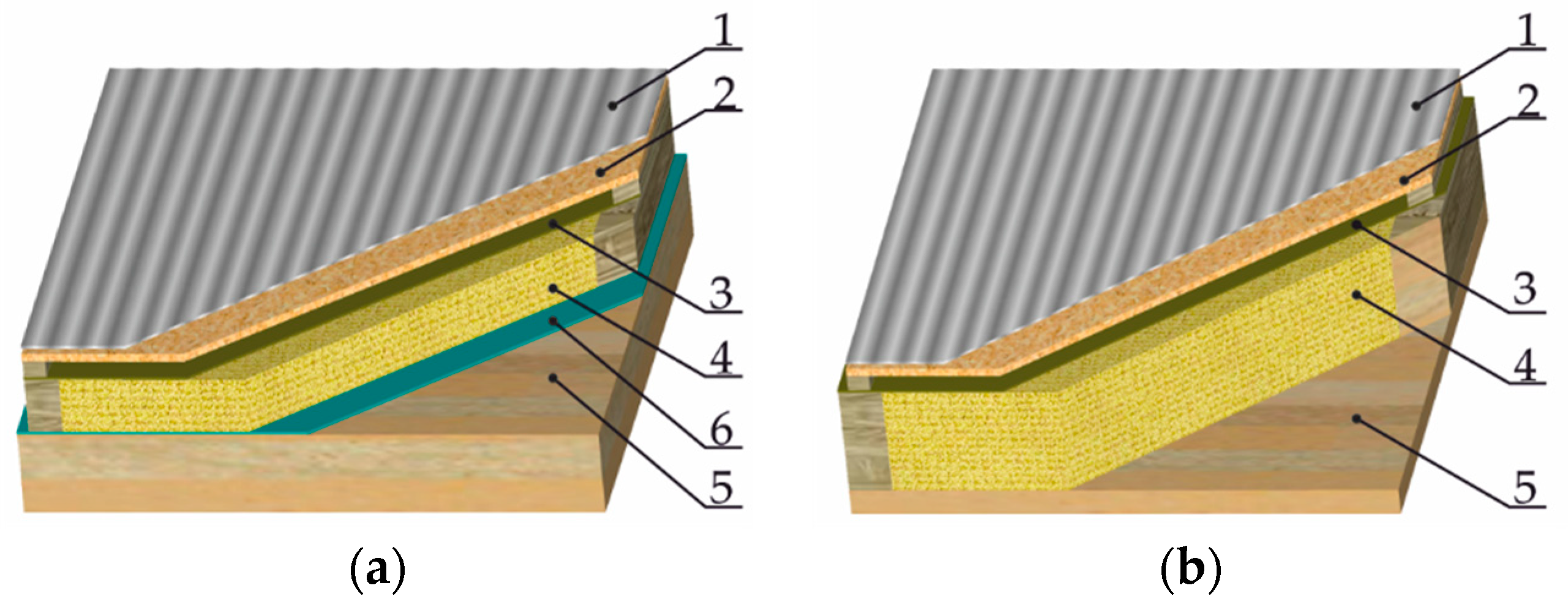

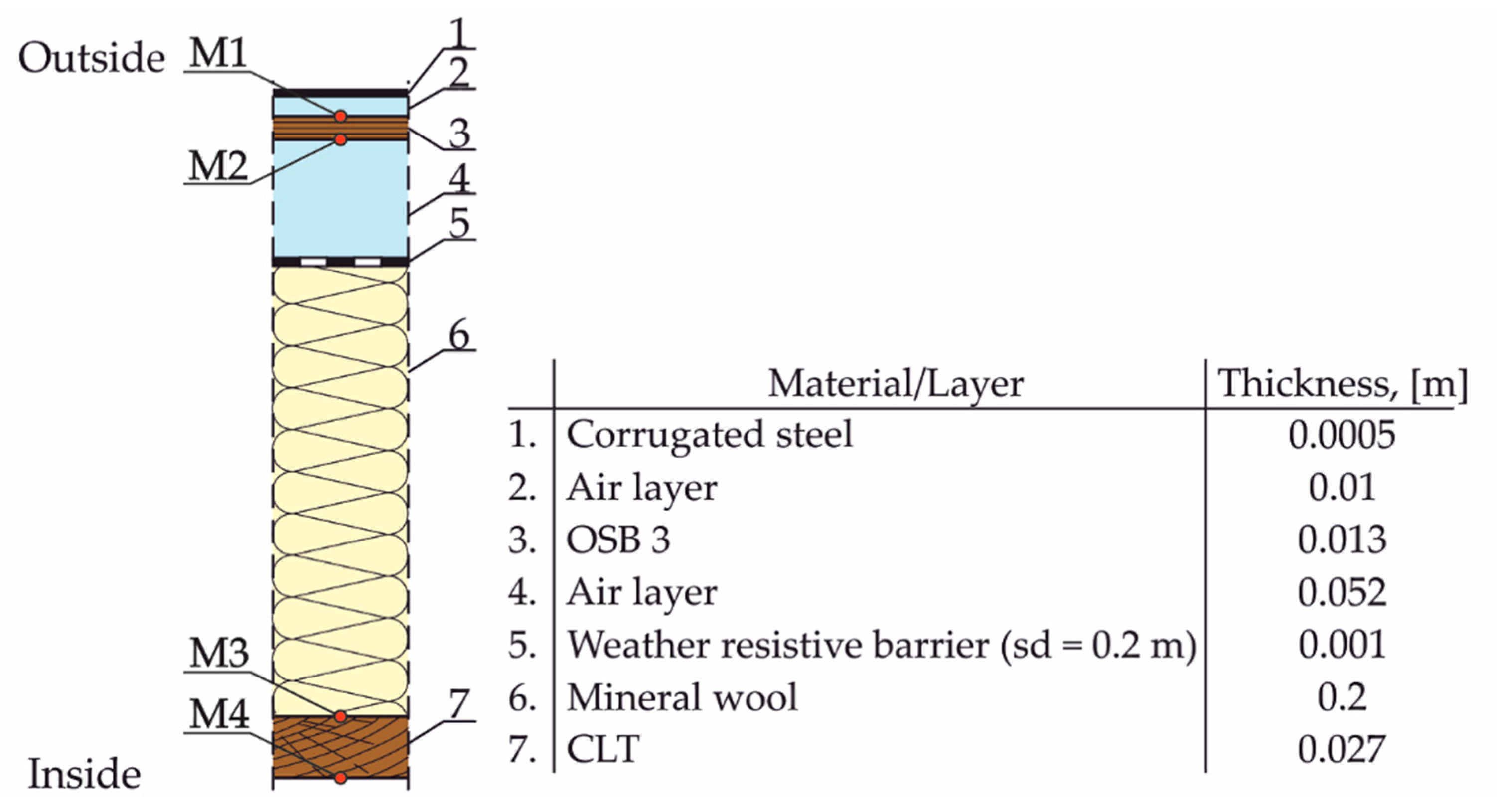

2. Materials and Methods

2.1. Model in WUFI®Plus

2.2. Bounduary Conditions and Assumptions

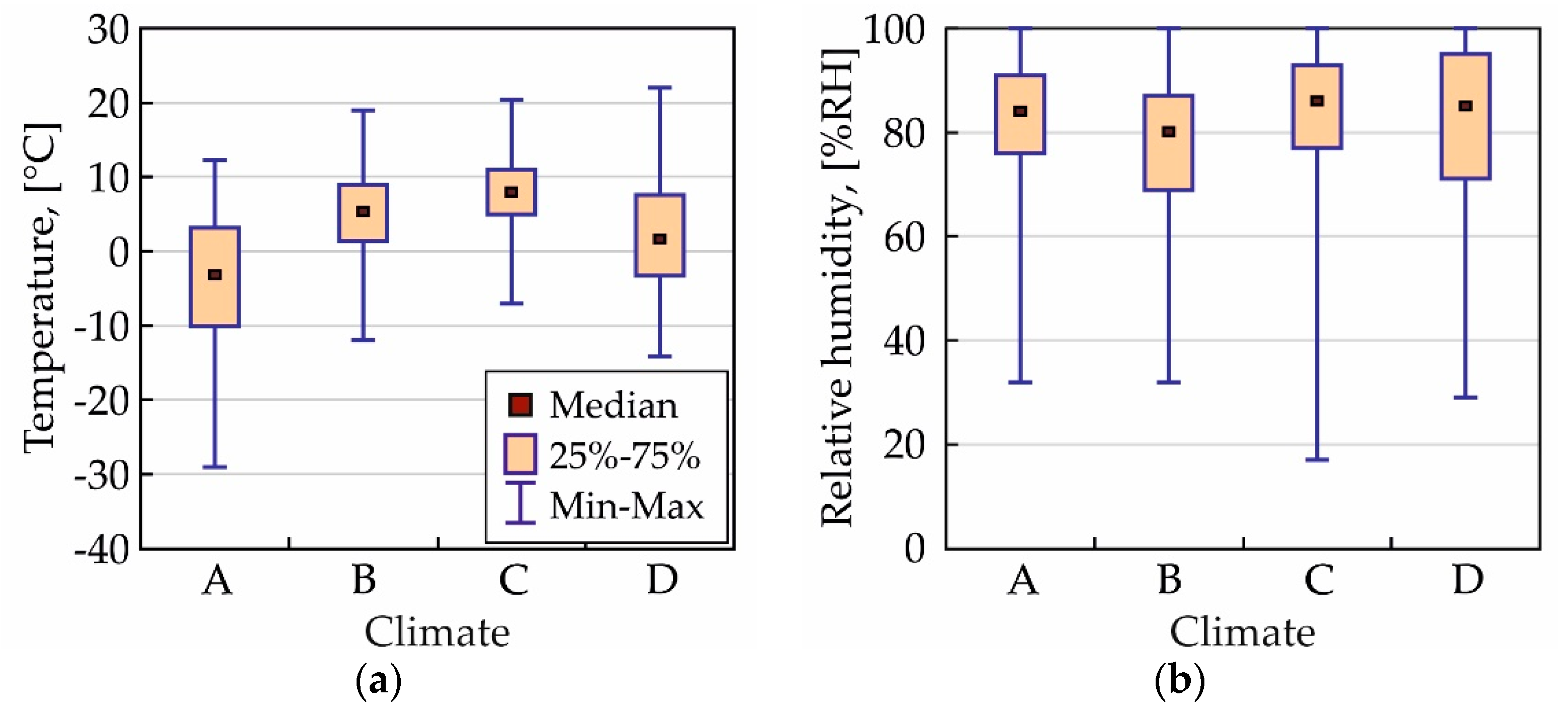

2.2.1. External Climate

2.2.2. Internal Climate

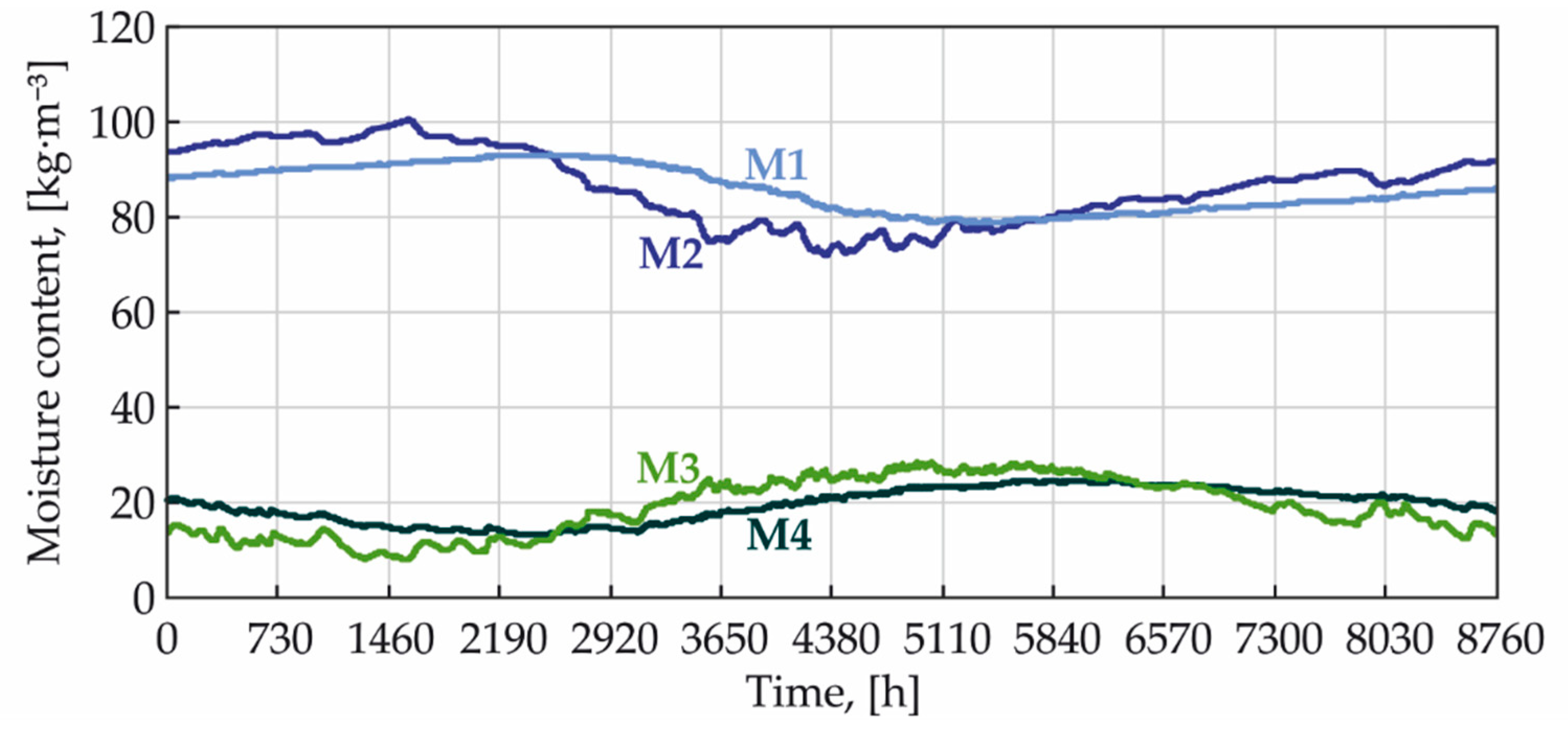

2.2.3. Initial Moisture Content in Wooden Elements

2.2.4. Air Change Rate

2.2.5. Substrate Class for Mold Growth Prediction

3. Results and Discussion

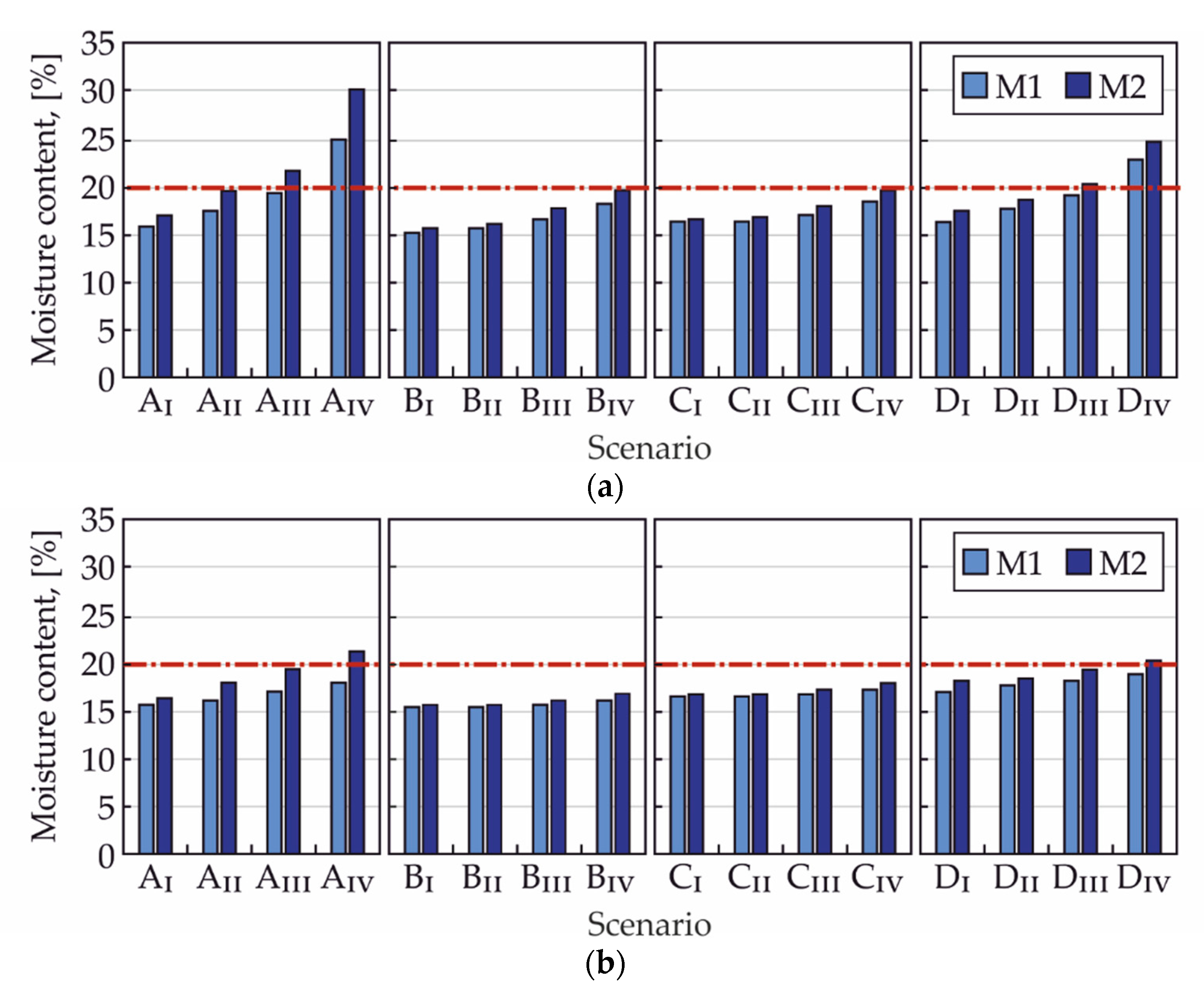

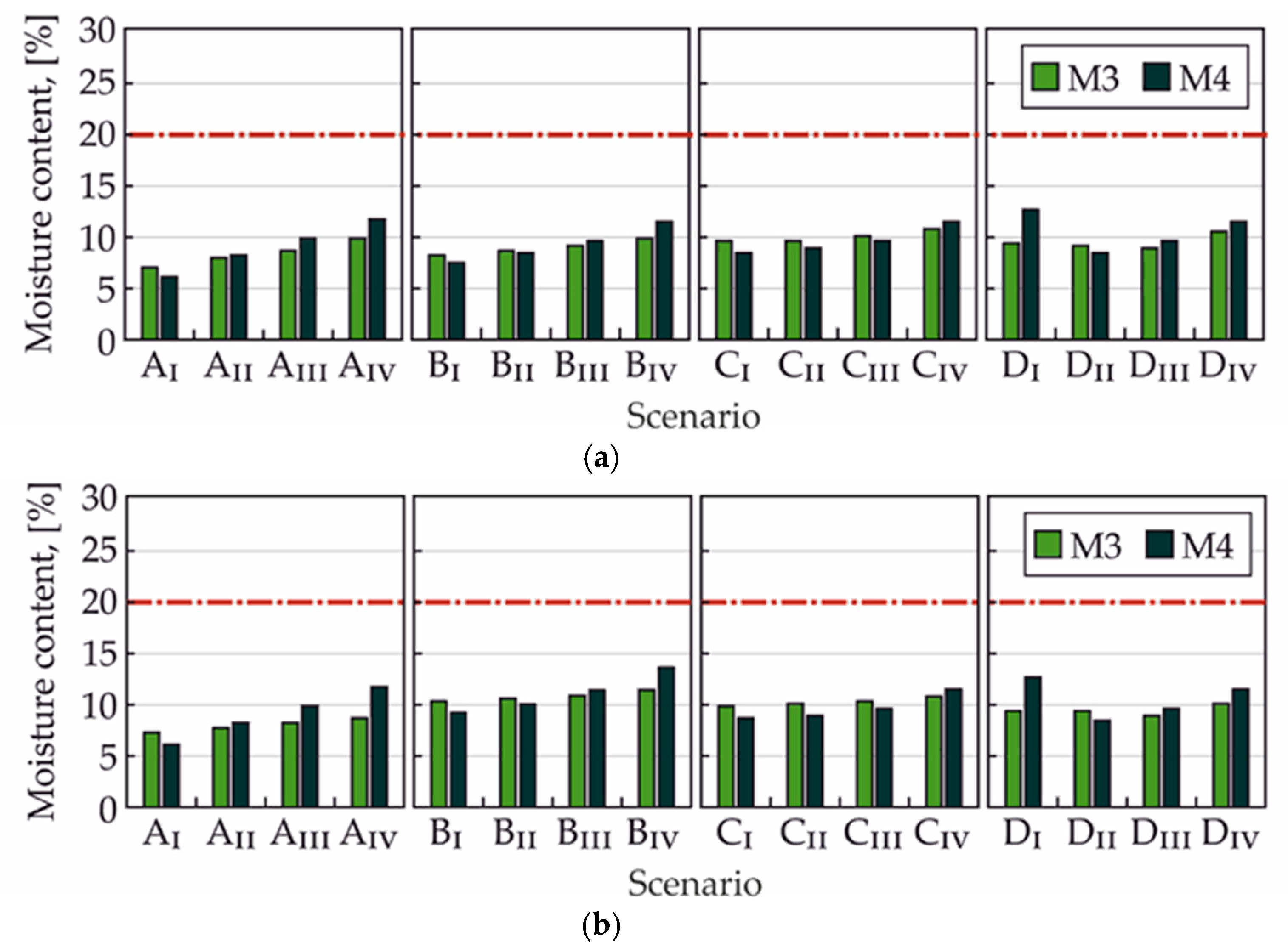

3.1. Impact of Initial Moisture Content

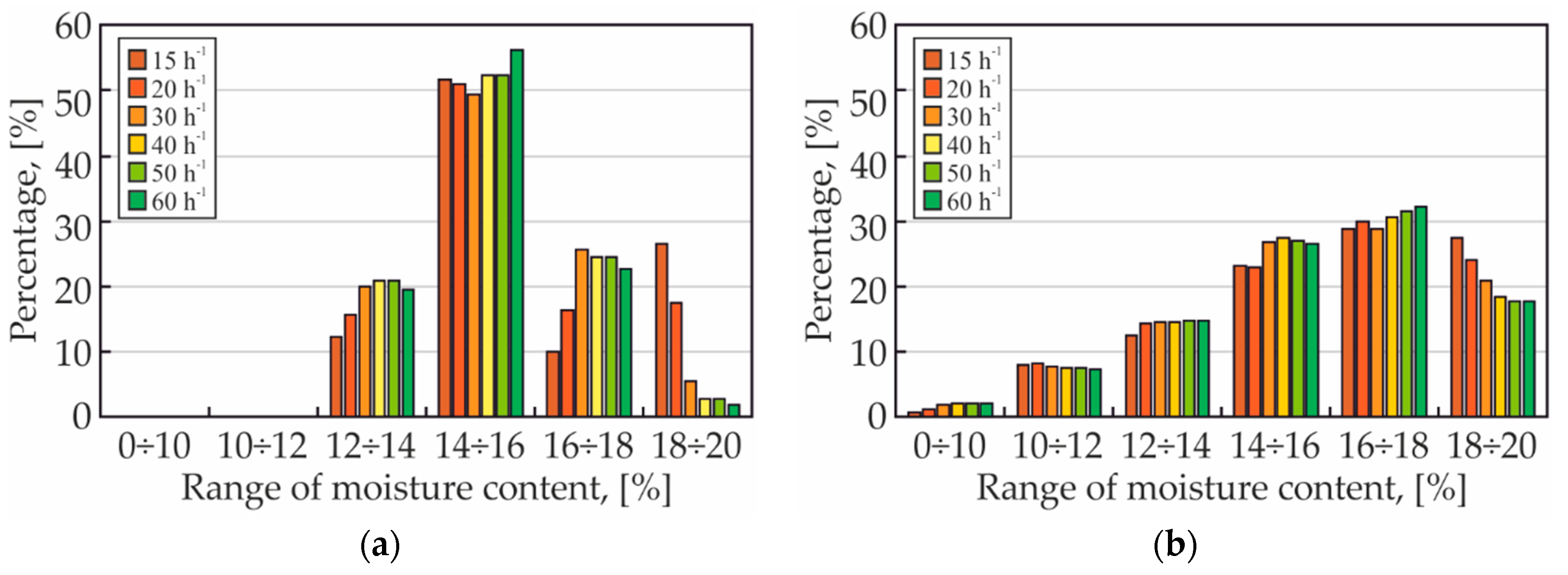

3.2. Impact of Increase in Air Change Rate in Ventilated Cavities

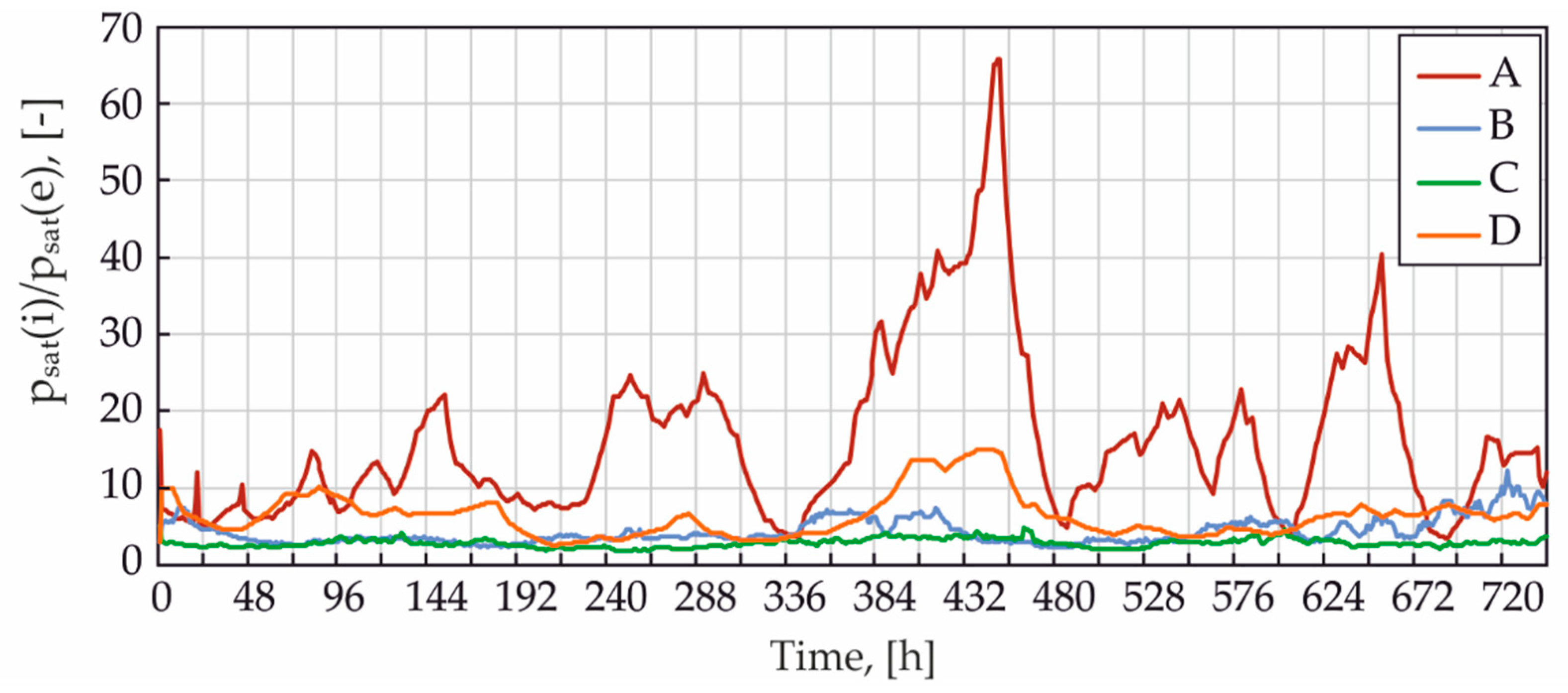

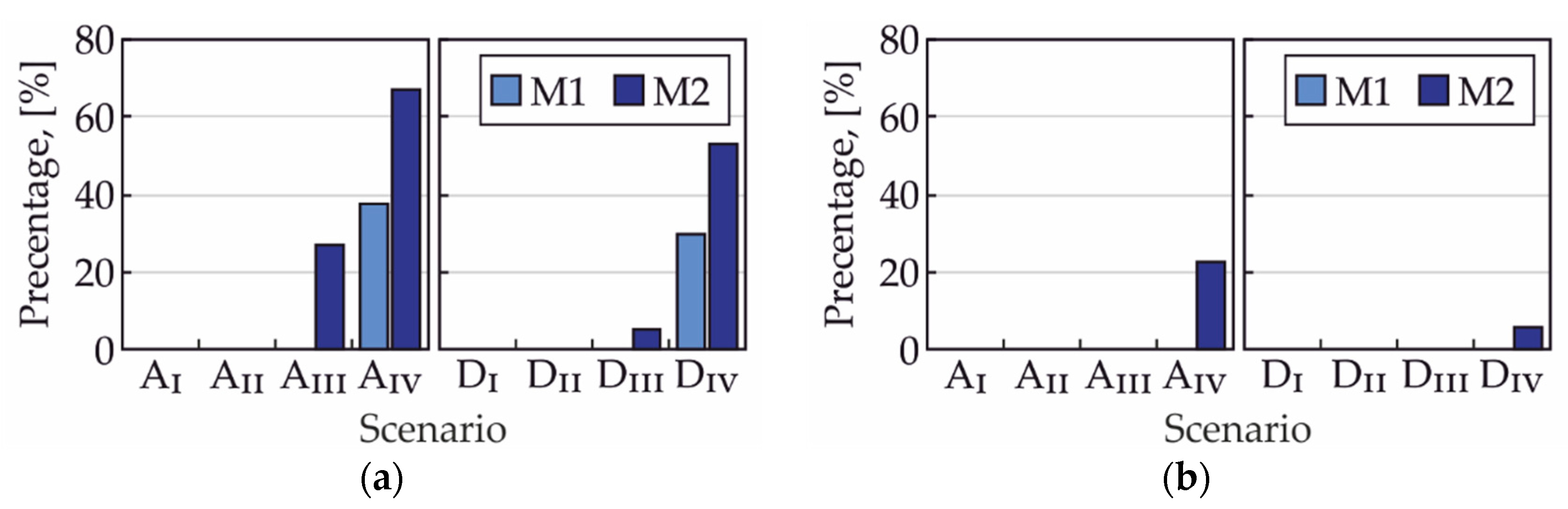

3.3. Risk of Condensation

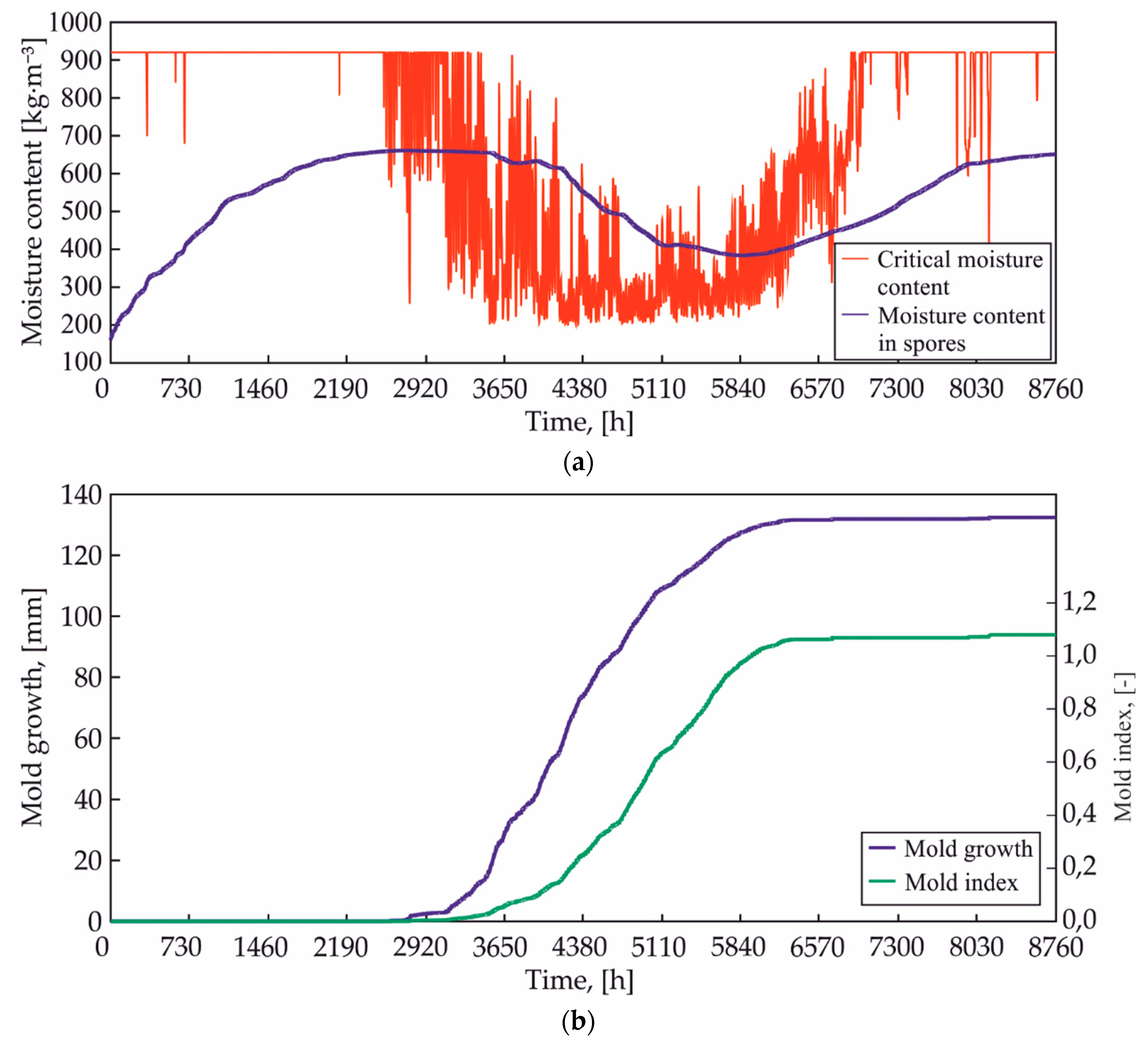

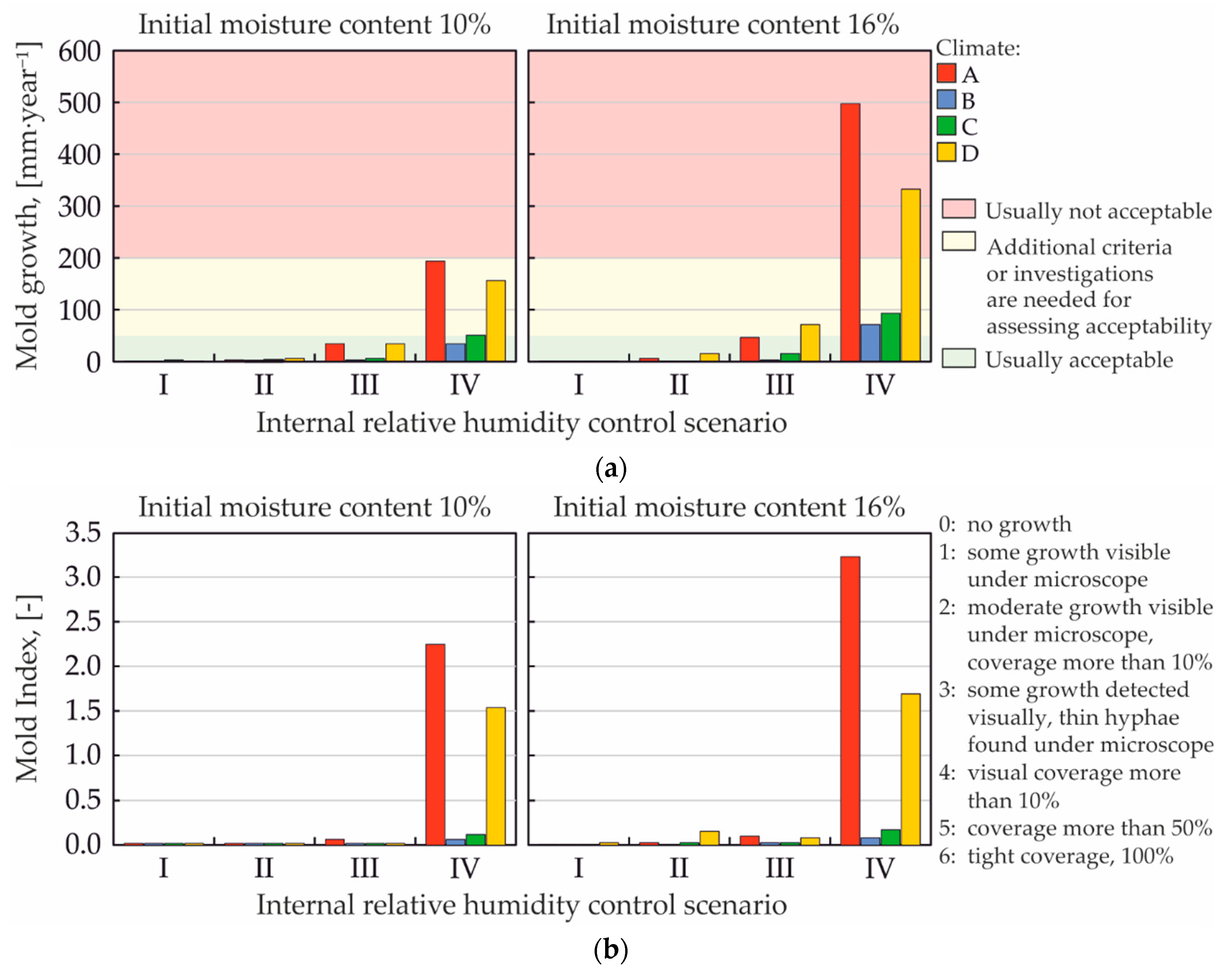

3.4. Mold Growth

3.5. Model Accuracy

4. Conclusions

- No risk of CLT layer moisture was noted (for any calculation variants).

- In the case of OSB for the two coldest climates at low ACH and at internal RH over 50% moisture content exceeded critical values. According to the authors, for rooms with a relative humidity exceeding 50%, the use of diffusionally open structures is not advisable. Nevertheless, it is possible to use more moisture-resistant OSB4 instead of OSB3 or to increase the area of inlet openings for ventilated spaces, so that in all weather conditions the ACH exceeds 15 h−1 (this solution requires calculations as to whether it is possible to increase the ventilated space for structural reasons). As a last resort, the partition can be sealed with a vapor barrier.

- Increasing the ACH above 15 h−1 caused the MC to fall below the critical value. Further increase in ACH (up to 40 h−1) caused a further decrease in recorded MC values. Above 40 h−1 no more changes were noted.

- It is critical to control the moisture content of wood delivered to the construction site and to avoid its moisture during construction. Increasing the initial moisture content of wooden elements to the maximum permissible for coastal climates resulted in a significant increase in MC above the permissible values.

- For subpolar/subarctic climates with an initial moisture content of wooden construction elements of 10%, the predicted mold growth exceeds 100 mm · year−1. This indicates necessity of additional criteria or further investigations are needed for assessing acceptability. MI = 1.5–2.25 allows to state that there is a moderate risk of mold growth. Increasing the initial MC for these climates may result in an increased risk of mold growth above an acceptable value (>300 mm · year−1).

Author Contributions

Funding

Conflicts of Interest

References

- Wei, P.; Wang, B.J.; Li, H.; Wang, L.; Peng, S.; Zhang, L. A comparative study of compression behaviors of cross-laminated timber and glued-laminated timber columns. Constr. Build. Mater. 2019, 222, 86–95. [Google Scholar] [CrossRef]

- Hafnes, A.; Schäfer, S. Environmental aspects of material efficiency versus carbon storage in timber buildings. Eur. J. Wood Wood Prod. 2018, 76, 1045–1059. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Fink, G.; Kohler, J.; Brandner, R. Application of European design principles to cross laminated timber. Eng. Struct. 2018, 171, 934–943. [Google Scholar] [CrossRef]

- Viau, C.; Doudak, G. Behaviour and modeling of cross-laminated timber panels with boundary connections subjected to blast loads. Eng. Struct. 2019, 197, 109404. [Google Scholar] [CrossRef]

- Bomberg, M.T.; Brown, W.C. Building envelope and environmental control: Part 1—Heat, air and moisture interactions. Constr. Can. 1993, 35, 15–18. [Google Scholar]

- Tye, R.P. Relevant moisture properties of building construction materials. In Moisture Control in Buildings; Trechsel, H.R., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1994. [Google Scholar]

- EN 14298: 2017. Sawn Timber. Assessment of Drying Quality; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Loffer, L. Acceptable Moisture Levels in Wood—Knowing the Moisture Content. Available online: http://www.wagnermeters.com/moisture-meters/wood-info/acceptable-moisture-levels-wood (accessed on 12 October 2019).

- Gülzow, A.; Richter, K.; Steiger, R. Influence of wood moisture content on bending and shear stiffness of cross laminated timber panels. Eur. J. Wood Wood Prod. 2011, 69, 193–197. [Google Scholar] [CrossRef] [Green Version]

- Moisture Properties of Wood. Available online: https://www.woodproducts.fi/content/moisture-properties-wood (accessed on 1 October 2019).

- Viitanen, H.; Ritschkoff, A.C. Mould Growth in Pine and Spruce Sapwood in Relation to Air Humidity and Temperature; Swedish University of Agricultural Sciences: Uppsal, Swedish, 1991. [Google Scholar]

- Stankiewicz, H. Zabezpieczenie Budowli Przed Wilgocią, Wodą Gruntową I Korozją (Protection of Buildings Against Moisture, Ground Water and Corrosion); Arkady: Warszawa, Poland, 1984. [Google Scholar]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of and Inside Building Components. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2001. [Google Scholar]

- Sedlbauer, K.; Krus, M.; Breuer, K. Mould Growth Prediction with a New Biohygrothermal Method and its Application in Practice Materials. In Proceedings of the IX Polska Konferencja Naukowo-Techniczna Fizyka Budowli w Teorii i Praktyce, Lodz, Poland, 10–13 June 2003. Available online: https://docplayer.net/92192580-Mould-growth-prediction-with-a-new-biohygrothermal-method-and-its-application-in-practice.html (accessed on 11 November 2019).

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhof, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Alev, U.; Kalamees, T. Avoiding mould growth in an interiorly insulated log wall. Build. Environ. 2016, 105, 104–115. [Google Scholar] [CrossRef]

- Goto, Y.; Wakili, K.G.; Ostermeyer, Y.; Frank, T.; Ando, N.; Wallbaum, H. Preliminary investigation of a vapor-open envelope tailored for subtropical climate. Build. Environ. 2011, 46, 719–728. [Google Scholar] [CrossRef]

- Häglund, M. Moisture content penetration in wood elements under varying boundary conditions. Wood Sci. Technol. 2007, 41, 477. [Google Scholar] [CrossRef]

- Hameury, S. Moisture buffering capacity of heavy timber structures directly exposed to an indoor climate: A numerical study. Build. Environ. 2005, 40, 1400–1412. [Google Scholar] [CrossRef]

- Kalamees, T.; Vinha, J. Hygrothermal calculations and laboratory tests on timber-framed structures. Build. Environ. 2003, 38, 689–697. [Google Scholar] [CrossRef]

- McClung, R.; Ge, H.; Straube, J.; Wang, J. Hygrothermal performance of cross-laminated timber wall assemblies with built-in moisture: Field measurements and simulation. Build. Environ. 2014, 71, 95–110. [Google Scholar] [CrossRef]

- Öberg, J.; Wiege, E. Moisture Risks with CLT-Panels Subjected to Outdoor Climate during Construction-Focus on Mould and Wetting Processes. Bachelor’s Thesis, KTH Royal Institute of Technology Stockholm, Stockholm, Sweden, June 2018. [Google Scholar]

- Setter, L.; Smoorenburg, E.; Wijesuriya, S.; Taberes-Velasco, P.C. Energy and hygrothermal performance of cross laminated timber single-family homes subjected to constant and variable electric rates. J. Build. Eng. 2019, 25, 100784. [Google Scholar] [CrossRef]

- Climate.OneBuilding. Available online: http://climate.onebuilding.org/WMO_Region_6_Europe/default.html (accessed on 11 November 2019).

- European Committee for Standardization. Energy Performance of Buildings. Ventilation for Buildings. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; European Committee for Standardization: Brussels, Belgium, 2019; EN 16798-1:2019. [Google Scholar]

- Patoka, K. Wentylacja Dachów I Stropodachów. Poradnik (Ventilation of Roofs and Flat Roofs. Guide); Dom Wydawniczy MEDIUM: Warsaw, Poland, 2019; ISBN 978-83-926815-6-4. [Google Scholar]

- German Institute for Standardization. Klimabedingter Feuchteschutz; Anforderungen, Berechnungsverfahren und Hinweise für Planung und Ausführung (Climate-Related Moisture Protection; Requirements, Calculation Methods and Notes for Planning and Execution); German Institute for Standardization: Berlin, Germany, 1996; DIN 4108-3: 1996. [Google Scholar]

- Künzel, H.M.; Karagiozis, A.N.; Kehrer, M. Assessing the Benefits of Cavity Ventilation by Hygrothermal Simulation. 2018. Available online: https://wufi.de/literatur/K%C3%BCnzel,%20Karagiozis%20et%20al%202008%20-%20Assessing%20the%20benefits%20of%20cavity.pdf (accessed on 11 November 2019).

| Indoor Air Relative Humidity Scenarios | Climates | |||

|---|---|---|---|---|

| Greenland | Iceland | Scotland | Norway | |

| (A) | (B) | (C) | (D) | |

| Free floating (I) | AI | BI | CI | DI |

| RHmin = 40% (II) | AII | BII | CII | DII |

| RHmin = 50% (III) | AIII | BIII | CIII | DIII |

| RHmin = 60% (IV) | AIV | BIV | CIV | DIV |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadłowska-Sałęga, A.; Wąs, K. Risk of Moisture in Diffusionally Open Roofs with Cross-Laminated Timber for Northern Coastal Climates. Buildings 2020, 10, 10. https://doi.org/10.3390/buildings10010010

Sadłowska-Sałęga A, Wąs K. Risk of Moisture in Diffusionally Open Roofs with Cross-Laminated Timber for Northern Coastal Climates. Buildings. 2020; 10(1):10. https://doi.org/10.3390/buildings10010010

Chicago/Turabian StyleSadłowska-Sałęga, Agnieszka, and Krzysztof Wąs. 2020. "Risk of Moisture in Diffusionally Open Roofs with Cross-Laminated Timber for Northern Coastal Climates" Buildings 10, no. 1: 10. https://doi.org/10.3390/buildings10010010

APA StyleSadłowska-Sałęga, A., & Wąs, K. (2020). Risk of Moisture in Diffusionally Open Roofs with Cross-Laminated Timber for Northern Coastal Climates. Buildings, 10(1), 10. https://doi.org/10.3390/buildings10010010