1. Introduction

The currently dominant model of goods production in the economy is linear. This assumes the acquisition of raw materials, the production of specific goods associated with the simultaneous production of waste, and then the goods produced after their consumption also become waste. This linear, unidirectional model begins to reach its limits due to the limited amount of natural resources. Another disadvantage is the production of large amounts of waste, which are deposited in landfills. Such landfills not only occupy a place, but can also be a source of emissions of harmful substances or radiation.

In order to be able to develop further in a harmonious manner we must follow the example of nature, which continually performs recycling processes [

1,

2]. Thanks to decay processes, which are an important part of its internal cycle, nature is an ideal example of a zero-waste economy. Trying to get at least a little closer to this model, it is worth making attempts to reuse post-production waste, treating it not as waste, but as raw materials of a new era. This is the basic premise of a circular economy, which is currently gaining more and more interest.

The cement and building materials industries offer great opportunities for using different mineral by-products. Materials, such as fly ash, silica fume and blast furnace slag, are commonly used as supplementary cementitious materials (SCMs) [

3], the introduction of which into cement composites gives the possibility to reduce the amount of cement used and, consequently, a reduction of the adverse impacts of cement production on the environment. On the other hand, reduction of the amount of landfilled waste is possible. However, the introduction of SCMs into the concrete changes its chemical composition and rheological properties. In effect, the properties of the final composite are modified depending on the kind of SCM used, its quantity, and physicochemical properties. Therefore, obtaining hardened material with the required properties requires investigation and analysis of the physicochemical processes occurring over time in the system. In some cases, the starting material may require an additional treatment and modification procedure (e.g., chemical or physical activation) [

4,

5,

6,

7], and the composition of the mix should be optimized. It is also important that the final material does not adversely affect its user, so it is necessary to study, e.g., its natural radioactivity.

One such raw material, currently not often used in cement composite contrary to the SCMs mentioned above, is copper slag, which is a by-product from the process of copper extraction by smelting. The residues from the copper smelting process in the form of hot liquid are taken to landfills where they are cooled and then ground. The copper slag thus obtained contains a significant amount of SiO

2 and if it is cooled down quickly enough, this compound takes an amorphous form and exhibits a pozzolanic activity (the ability to react with Ca(OH)

2 in the presence of water to produce hydrated silicate and aluminate phases similar to those that are formed during Portland cement hydration). Additionally, its physical properties are similar to natural sand [

8]. Copper slag obtained directly from smelters is a valued abrasive material used in surface blast-cleaning processes. Due to the morphology of the grains, it is more effective than sand.

Although the ground slag is, in large part (in Poland practically entirely), used as an abradant, after such use some of the material is treated and reused, but most of it is considered to be a waste, which is in major part disposed in landfills or stockpiles. It contains a small amount of corrosion products and corrosion protection coatings [

9] and after the blast cleaning process its granulation is smoother. The fraction content of 0–0.125 mm and 0.125–0.25 mm is much higher than in the initial material. To distinguish between copper slag and the waste material from the blast cleaning procedure, the latter is referred to in the article as waste copper slag.

However, it can be utilised again, and its potential applications are described, amongst others, in [

10,

11]. Due to its composition and physical form, copper slag can be used in the production of concrete as a partial or total substitute for sand [

12,

13,

14,

15] even in lightweight concrete [

16]. In contrast to e.g., fine fractions of recycled concrete aggregate, the material is also suitable for the production of high-quality concrete, without compromising its quality, and some properties even improve in comparison with concrete manufactured with sand [

17,

18]. Copper slag used instead of sand significantly improves the consistency of the mixture without changing the amount of mixing water which results in an increase in the compressive strength [

13,

17,

19]. It is also possible to reduce the water content by about 20% while maintaining the same consistency, thus increasing the compression strength by up to 20%. The material used in the cleaning process does not have these particular advantages, as it deteriorates the consistency of the concrete due to its finer grain size, but it is still very useful in concrete technology. In [

20] the use of blast-cleaning waste as a substitute for sand in concrete with a cement dosage of 300 kg/m

3 and w/c = 0.6 was tested and described. Shrinkage testing of concrete with copper slag as a substitute for sand has shown that such replacement does not have the negative consequences of increased shrinkage [

12].

An important aspect of using waste materials in the production of concrete is their potential harmful impact on the natural environment. In [

21] the authors suggested, that the copper slag is non-toxic and poses no environmental hazard. The slag can be safely considered for use in Portland cement and concrete manufacturing. It should be noted, however, that this material is one of the most intense sources of ionizing radiation among the materials used in construction due to its high content of natural radionuclides [

22,

23,

24,

25]. Of these, particular attention is paid to the content of radium isotopes

226Ra. As a result of its decomposition radon

222Rn is produced, which is a radioactive gas and can be absorbed into the human organism by breathing. There, it undergoes further radioactive decay, resulting in radioactive isotopes of lead and bismuth, which, as solids, accumulate in the body and act as mutagens on its cells [

26]. The use of such a material as a concrete aggregate requires carrying out tests of the natural radioactivity of the concrete produced from it.

Studies on the radioactivity of building materials and waste used in their production are becoming more and more common [

27,

28,

29,

30]. So far, there is not a great deal of data about radon exhalation rate in building materials containing NORM residues [

30]. For example, in [

31] there are only 1100 pieces of data from 14 European countries on radon emanation/exhalation rate. The COST Action TU1301 project is being run: “NORM for Building materials (NORM4BUILDING)” with a view to promoting research into the reuse of waste containing increased concentrations of natural radionuclides (NORM) in customised building materials in the construction sector, while taking into account the impact on both external exposure of building users to gamma radiation and indoor air quality. Models are being developed to better simulate the behaviour of NORM residues in different types of building materials.

In this paper the use of waste copper slag obtained from blast-cleaning as a substitute for part of the sand in concrete with 360 kg/m

3 of 42.5 class cements, and w/c = 0.45 was tested and described. Some researchers pay attention to the large impact of the packing density on many concrete properties [

32,

33,

34,

35], therefore, the concrete mixtures were prepared in two variants which differed from each other in consistency and workability. For each cement type two mixtures with waste copper slag were made. In one, the same dosage of superplasticizer as in the reference series was used. In the second, the amount of superplasticizer was experimentally determined in order to obtain consistency similar to the reference series. It was 420 ± 30 mm in table flow test (near the limit between F2 and F3 class).

According to the requirements of the Polish law [

36] the tests of natural radioactivity of waste copper slag and the concrete were performed. From the results the coefficients f

1 and f

2 were calculated and compared to the limit values which can be found in the relevant regulations. Leachability of hazardous elements (mainly heavy metals) was also assessed.

Optimization of the manufacturing process, the purpose of which is to obtain a material with required properties, needs consideration of many variables, including knowledge of the physicochemical processes occurring during the production process, as well as the impact of raw and final materials on the natural environment and on the user. In this work, the main emphasis was placed on evaluation of the composition of the concrete, taking into account its potential natural radioactivity. To evaluate the concrete studied, the method of multi-criteria EIPI assessment presented in [

37] was applied, in which as the criteria were used: compressive strength, air permeability and sorptivity as parameters determining the durability of concrete, as well as radioactive activity indices f

1 and f

2 used for the evaluation of building materials. Concrete made of traditional fine aggregate (quartz sand) and concrete, in which waste copper slag characterized by higher values of indices f

1 and f

2, used as fine aggregate, were evaluated. Due to the co-existence of both positive (improvement of durability and mechanical properties of concrete) and negative (increase in the intensity of ionizing radiation of the material) effects of the use of waste copper slag, the valuation of the applied material solution encounters objective difficulties. The EIPI method allows this judgement to be reduced to a comparison of the value of one indicator, which significantly simplifies the evaluation.

4. Discussion

4.1. Assumptions and Calculation Method

Optimization of the composition of the concrete mix requires taking into account not only the properties of the final composite, but also the need to limit its broadly understood impact on the environment.

In the calculations using the EIPI method, emissions, consumption of raw materials and rarity of their occurrence were assumed according to the data presented in the article [

37]. The value of PI is evaluated on the basis of the sum of normalized values of selected concrete properties. The compressive strength and sorptivity tested after 28 days were used for calculations. The reference values were adopted at the same level as in [

37], i.e., f

cm = 60 MPa i S = 0.120 cm/h

0.5. As another concrete property, the air permeability k

T, measured with a Torrent apparatus on specimens dried at 65 °C, was included in the evaluation. As a reference value, the limit used for exposure classes XC4, XD1, XD2a, XF1 and, XF2 in Swiss Standard SIA 262 (SIA 262/1 Annex E) [

39], i.e., 2.0 × 10

–16 m

2, was used.

Equation (3), which contains the abovementioned concrete parameters, was used to calculate PI without taking into account radioactivity. The relevant quotients from normalization are multiplied by the respective weighting coefficients, whose values were taken as:

wfcm = 0.4,

wkT = 0.3 and

wS = 0.3 in the present study. The sum of the weighting coefficients should be equal to unity so that a concrete mix with reference values of selected properties will give a PI value of 1:

In the further concrete assessment, the values of indicators f

1 and f

2 were taken into account in the PI calculations. In their case, the reference values were adopted according to the Ordinance mentioned above, i.e., f

1 = 2 and f

2 = 400 Bq/kg. To calculate so extended PI values Equation (4) was used:

The higher values of PI the analysed concrete achieves, the more desirable engineering properties it possesses. The weighting coefficients in Equation (4), were assumed in a few variants which are presented and described in the next subsection.

The value of EI is calculated according to Equation (5) as the square root of the sum of the normalized total emission of CO

2 and the normalized total raw materials usage both multiplied by weights that sum to one:

To normalize the values of total emission of CO

2 (EM) and usage of raw materials (RM), which have to be calculated first, they are divided by the reference values. The reference values in this study were assumed as in [

37] and equal approximately 490 kg of CO

2 emission and 2000 kg/m

3 of raw materials usage per cubic metre of concrete. The weighting coefficients were assumed as:

wEM = 0.5 and

wRM = 0.5.

A lower EI value means that analysed concrete is more environmentally friendly. Results of the calculations the EI for analysed concrete mixtures are presented in

Table 8 and repeated in

Table 9.

A comprehensive evaluation of concrete, taking into account both its ecological impact (EI) and engineering performance (PI), is expressed by Gross Ecological and Performance Indicator (GEPI), which is calculated using Equation (6):

When designing a concrete mix in practice, a low GEPI is aimed for concrete with favourable concurrent EI and PI, while a high GEPI should be avoided.

It should be stressed very clearly here that the comparison of different variants of the designed concrete mixtures using the EIPI method in engineering practice will be only reasonable, if all the technical parameters of the concrete obtained from the designed concrete mixtures, taken into account in the PI calculations, meet the specified limit requirements defined by the construction designer or the relevant regulations or standards.

4.2. Results Analysis and Discution

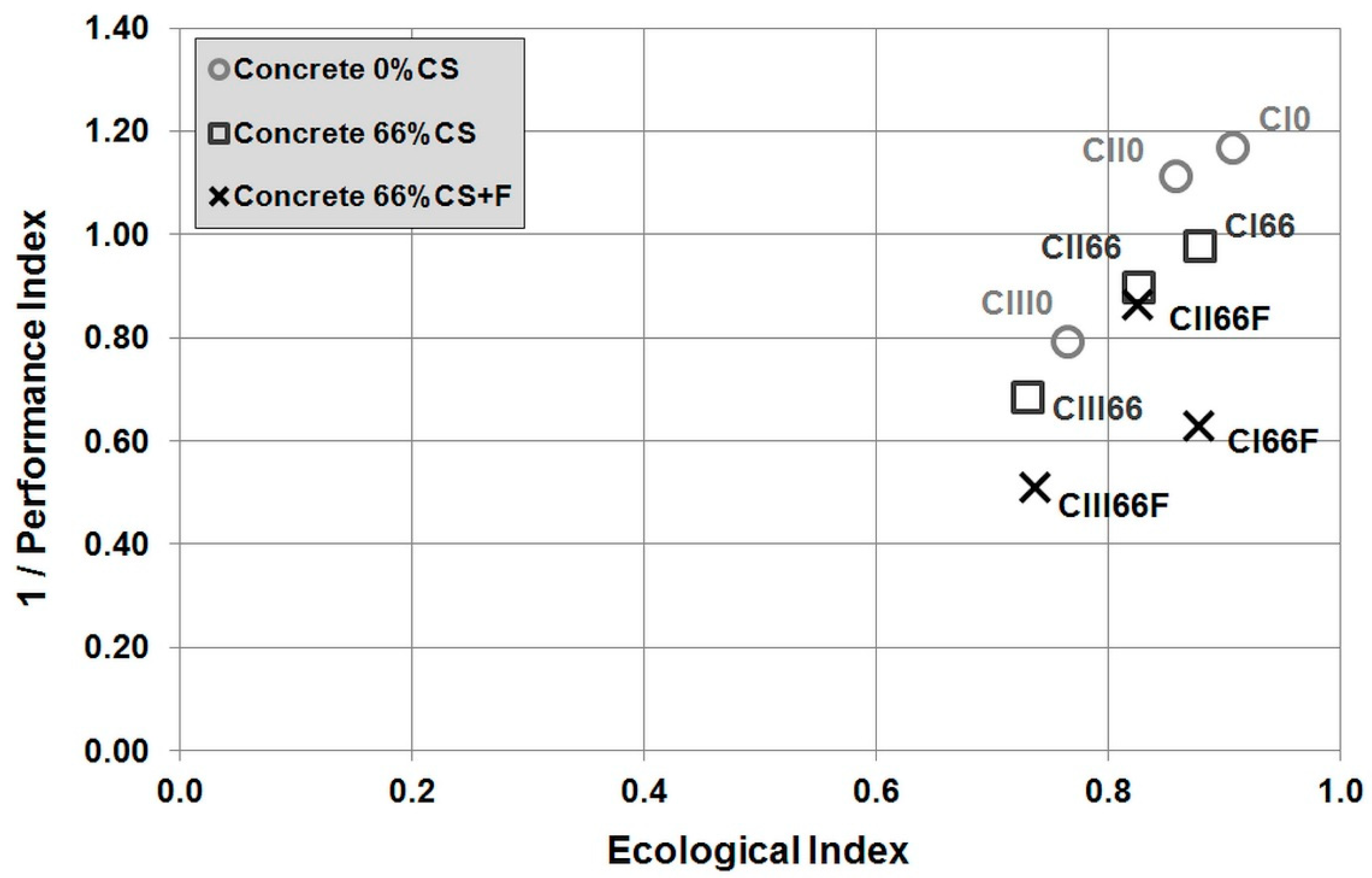

The results of calculations conducted without taking into account the influence of radioactive nuclide content on the PI value are presented in

Figure 1. The PI and EI values calculated under this assumption are presented in

Table 8 together with the GEPI values calculated on their basis. Series with CEM III cement are characterized by the most favourable EI value due to lower clinker content than in other cements, resulting in a lower consumption of natural resources and a lower carbon dioxide emission. The highest PI values were achieved by the CI66F and CIII66F series. This is mainly due to higher tightness than in other series, which consists of the lowest values of sorptivity and one of the lowest values of air permeability. The overall assessment based on GEPI values indicates as the best series CIII66F (GEPI = 0.897) and CIII66 (GEPI = 1.001). The CI0 series (GEPI = 1.480) and CI66 series (GEPI = 1.314) were the least favourable from the point of view of the complete score.

In the next stage of the assessment, the impact of the radioactive nuclides contained in the concrete was also taken into account. This was done by using Equation (4) in the calculations of PI values. Four variants differing in the values of weights for the components of the formula taking into account indicators f

1 and f

2 were used in the calculations. Their influence on PI value was differentiated by assigning to them in the calculations a sum of weights equal to 0.3 (variants S) or 0.7 (variants B). Additional differentiation was based on taking equal weight values (variants S1 and B1) and assigning about twice as much weight to the f

2 indicator in relation to the f

1 indicator (variants S2 and B2). The list of adopted values of weights is presented in

Table 9 and the obtained GEPI results are presented in

Table 10.

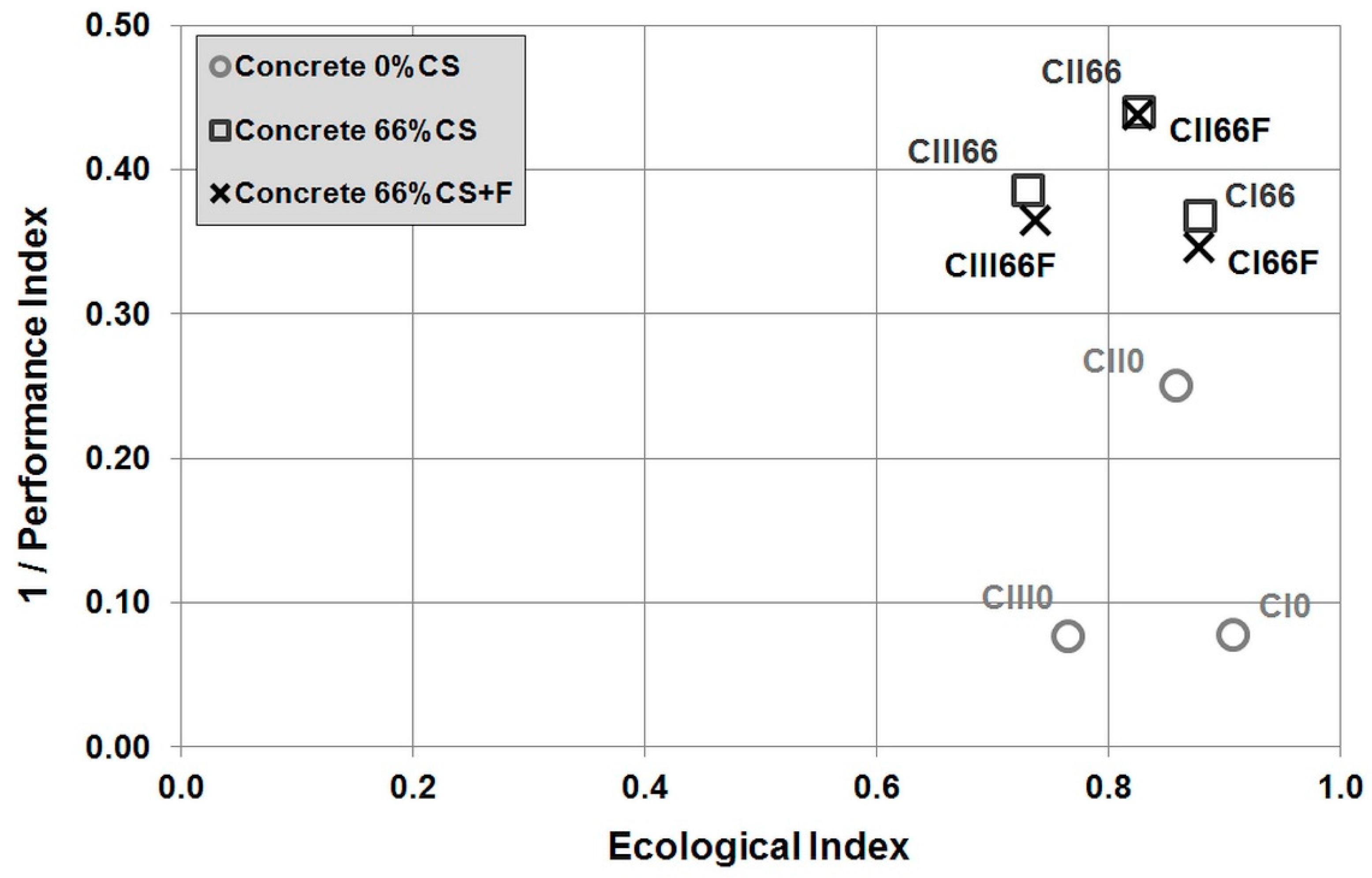

The analysis of the obtained results showed a clear but small variation in the calculated PI values obtained in the individual variants. Regardless of the adopted variant, the mutual proportions of GEPI values obtained in the case of individual series remained very close to each other. Therefore, it was found pointless to present in detail the results of EI and PI calculations of all variants and to visualize them in the figures. Only the results of calculations obtained in variant B2 were selected, in which the influence of natural radioactivity of concrete on the result of PI calculations was the greatest. The results obtained in this variant are presented in

Table 11 and

Figure 2.

As can be seen, the weight variation in the adopted variants had the greatest impact on the GEPI values for CEM II cement concrete, regardless of the type of fine aggregate and plasticiser used, and for waste copper slag, regardless of the type of cement. However, this variation, understood as the difference between the highest and the lowest GEPI value, reaches a maximum of less than 12%.

The significantly lower natural radioactivity of concrete with CEM I and CEM III without the use of waste copper slag caused PI in these two series to be high, several times higher than in series with the same type of cement and waste. It is also about three times higher than that of CII0 series, in which cement with increased natural radioactivity due to fly ash content is used. CIII0 concrete (GEPI = 0.768) proved to be the best with such established assessment criteria. Despite increased natural radioactivity, mixtures with the waste and blast furnace slag cement were ranked in the next two places (GEPI = 0.822 and GEPI = 0.826). The worst results were obtained in the case of the series with CEM I cement and waste copper slag (GEPI = 0.953 and GEPI = 0.944). This allows us to state that the use of waste copper slag improves the performance of concrete so much that it reduces the negative impact of increased radioactivity in the assessment performed by the EIPI method.

It should be taken into account that when PI is calculated on the basis of other parameters (selected properties, reference values, weights), it is not possible to directly compare PI and GEPI results obtained in the calculation of the different variants. The comparisons make sense between the different concrete mixes assessed on the basis of the criteria adopted for the specific variant and adapted to the requirements of the specific conditions of concrete exploitation and, for example, the limitations related to natural radioactivity. The variant calculations of the impact of natural radioactivity of concrete on the PI value presented in the paper were aimed at analysing various variants of the differentiation of the weights and their impact on the final assessment of the concrete.

Despite favourable results of the calculations of GEPI values due to the relatively high natural radioactivity of waste copper slag, however, within acceptable limits, the authors do not recommend the use of concrete with this material for the construction of buildings intended for permanent human presence. This type of concrete materials can be used, e.g., for erecting farm buildings or road pavements (bottom layer) and structures (bridges, overpasses, etc.).