Nickel Laterite Smelting Processes and Some Examples of Recent Possible Modifications to the Conventional Route

Abstract

:1. Introduction

2. Alternative Nickel Laterite Smelting Processes to the Rotary Kiln-Electric Furnace (RKEF) Process

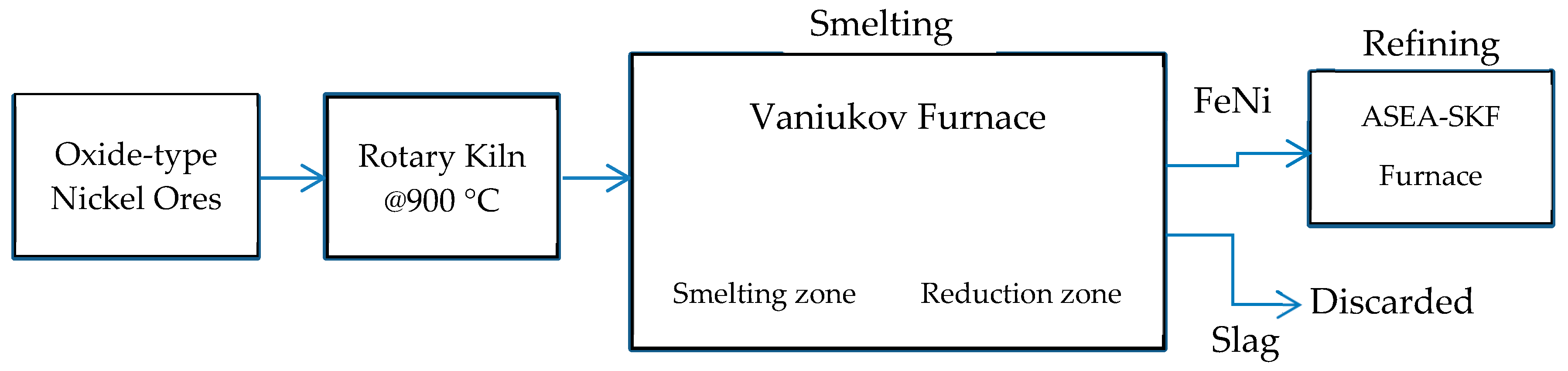

2.1. The Vaniukov Process

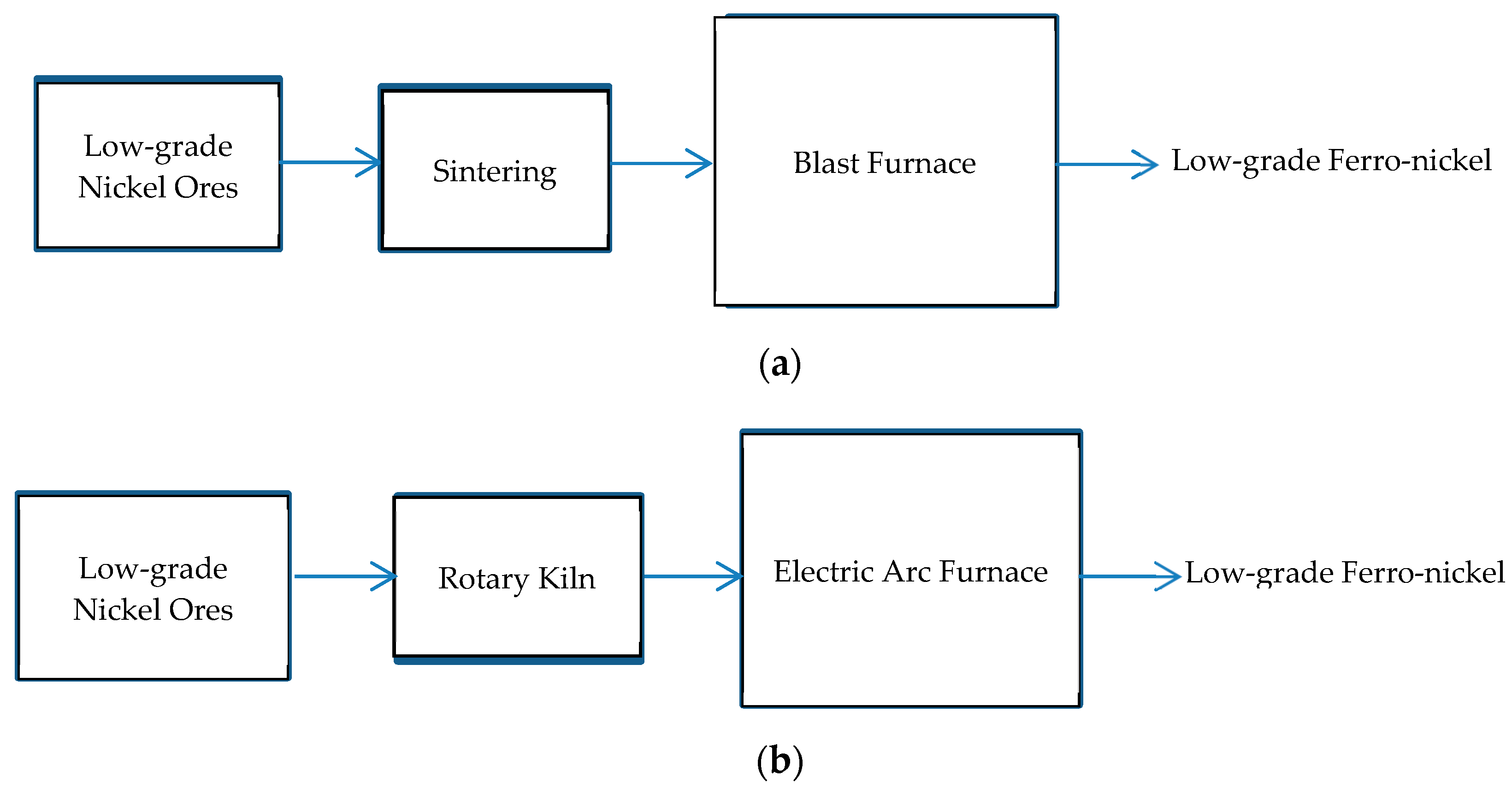

2.2. Low-Grade Ferro-Nickel Production

2.2.1. Low-Grade Ferro-Nickel Production in China

2.2.2. Other Technologies for Low-Grade Ferro-Nickel Production

2.2.3. Modern Low-Grade Ferro-Nickel Production and its Application in Indonesia

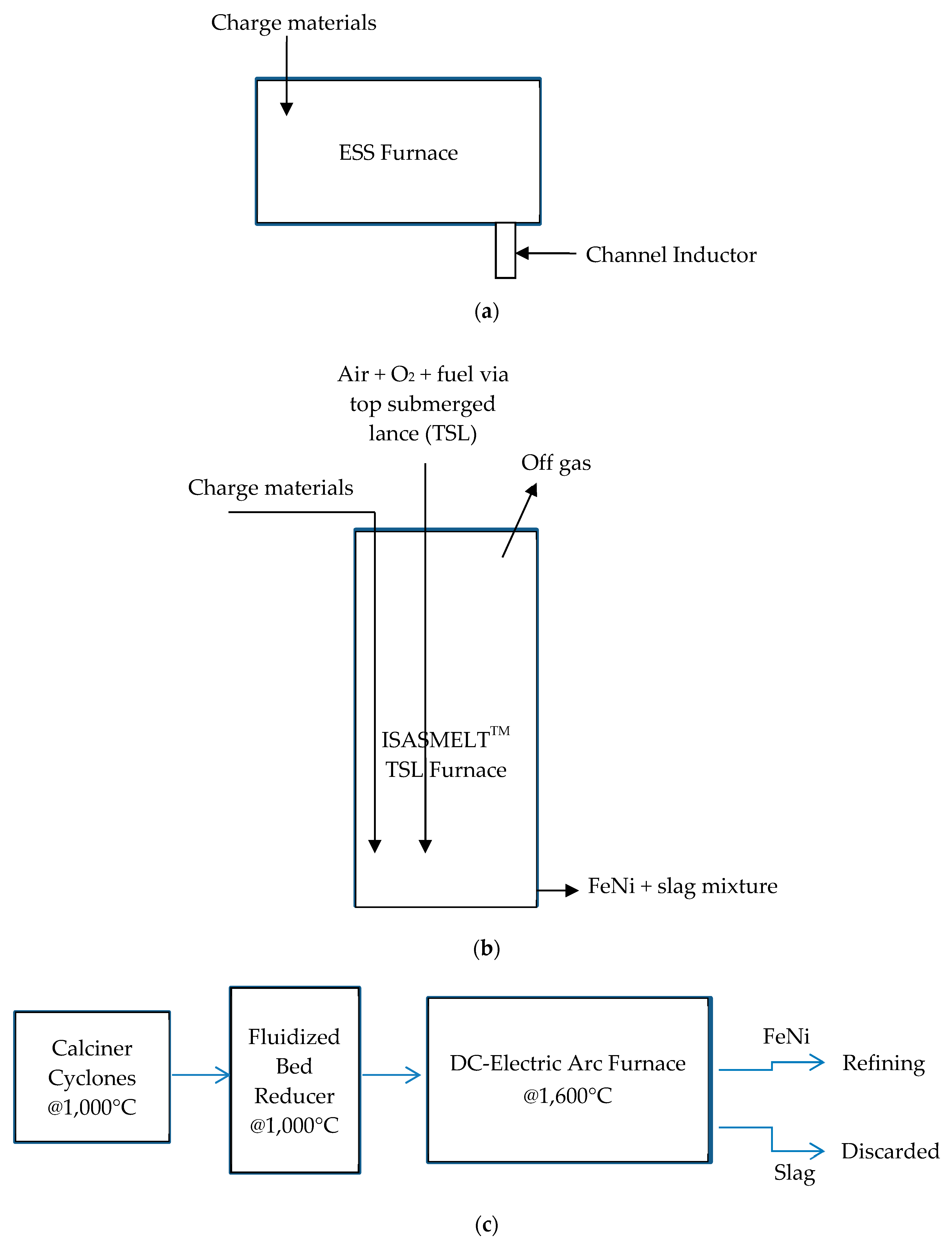

2.3. Envirosteel Smelter Technology

2.4. The ISASMELTTM TSL Process

2.5. Nickel Smelting Technology (NST)

- Transporting the ore.

- Milling and drying.

- Filters (collecting the powdered nickel ore in the gas from the hammer mill flash dryers).

- Calciner cyclones operating at 1000 °C.

- Fluidized bed reducer operating at 1000 °C.

- DC electric furnace operating at 1600 °C.

- The slag is discarded, and ferro-nickel is sent to the refining unit (see Figure 3c).

3. Some Examples of Recent Approaches Related to Conventional Nickel Laterite Smelting Processes

4. Reduction Roasting–Magnetic Separation Method

5. Summary of the Pyrometallurgical Nickel Extraction Processes Outlined in This Study

6. Conclusions

- Major alternative smelting processes to the RKEF process applied for laterites, namely, the Vaniukov process, low-grade ferro-nickel production, ESS technology, the ISASMELTTM TSL process, and NST, were reviewed in detail.

- Examples of recent modifications related to the conventional nickel laterite smelting process were provided.

- Examples of reduction roasting–magnetic separation methods applied to laterites were given. Such methods will probably remain one of the major topics in the treatment of laterites because of their high efficiency and low cost.

- The treatment of laterites will remain a research hotspot in the field of extractive metallurgy in the near future as the demand for, and production of, stainless steel continues to increase.

Conflicts of Interest

References

- Diaz, C.M.; Landolt, C.A.; Vahed, A.; Warner, A.E.M.; Taylor, J.C. A review of nickel pyrometallurgical operations. JOM 1988, 40, 28–33. [Google Scholar] [CrossRef]

- Udy, M.J.; Udy, M.C. Selective smelting of lateritic ores. JOM 1959, 11, 311–314. [Google Scholar] [CrossRef]

- Diaz, C.M.; Landolt, C.A.; Vahed, A.; Warner, A.E.M.; Taylor, J.C. A Review of Nickel Pyrometallurgical Operations. In Extractive Metallurgy of Nickel and Cobalt, 1st ed.; Tyroler, G.P., Landolt, C.A., Eds.; The Metallurgical Society: Pittsburgh, PA, USA, 1988; pp. 211–239. [Google Scholar]

- Dalvi, A.D.; Bacon, W.G.; Osborne, R.C. The past and the future of nickel laterites. In Proceedings of the International Laterite Nickel Symposium-2004, Charlotte, NC, USA, 14–18 March 2004; Imrie, W.P., Lane, D.M., Eds.; TMS: Warrendale, PA, USA, 2004. [Google Scholar]

- Mudd, G.M. Global trends and environmental issues in nickel mining: Sulfides versus laterites. Ore Geol. Rev. 2010, 38, 9–26. [Google Scholar] [CrossRef]

- Oxley, A.; Smith, M.E.; Caceres, O. Why heap leach nickel laterites? Miner. Eng. 2016, 88, 53–60. [Google Scholar] [CrossRef]

- Tsingshan Indonesia Nickel Operation, Wood Mackenzie, Report Summary. Available online: https://www.woodmac.com/reports/metals-tsingshan-indonesia-nickel-operation-27952638 (accessed on 9 August 2019).

- 2019 PREVIEW: NPI to Extend Its Dominant Role in Nickel Supply. Available online: https://www.fastmarkets.com/article/3848387/2019-preview-npi-to-extend-its-dominant-role-in-nickel-supply (accessed on 9 August 2019).

- Voermann, N.; Gerritsen, T.; Candy, I.; Stober, F.; Matyas, A. Developments in furnace technology for ferro-nickel production. In Proceedings of the Tenth International Ferroalloys Congress, Cape Town, South Africa, 1–4 February 2004; pp. 455–465. [Google Scholar]

- Kotzé, I.J. Pilot plant production of ferro-nickel from nickel oxide ores and dusts in a DC arc furnace. Miner. Eng. 2002, 15, 1017–1022. [Google Scholar] [CrossRef]

- Schlesinger, M.E.; King, M.J.; Sole, K.C.; Davenport, W.G. Extractive Metallurgy of Copper, 5th ed.; Elsevier: Oxford, UK, 2011; pp. 122–124. [Google Scholar]

- Jak, E.; Tsymbulov, L.B. Development of the continuous copper converting using two-zone Vaniukov converter. In Proceedings of the Copper 2010, Vol. 2: Pyrometallurgy I, Hamburg, Germany, 6–10 June 2010; GDMB: Clausthal-Zellerfeld, Germany, 2010; pp. 793–810. [Google Scholar]

- Tsymbulov, L.B.; Knyazev, M.V.; Tsemekhman, L.S. Oxide nickel ores smelting of ferro-nickel in two-zone Vaniukov furnace. Can. Metall. Quart. 2011, 50, 135–144. [Google Scholar] [CrossRef]

- Crundwell, F.K.; Moats, M.S.; Ramachandran, V.; Robinson, T.; Davenport, W.G. Extractive Metallurgy of Nickel, Cobalt and Platinum-Group Metals; Elsevier: Oxford, UK, 2011; pp. pp. 86–91, pp. 452–454. [Google Scholar]

- Tsymbulov, L.B.; Kongoli, F. New method of laterite ore processing: Smelting in two-zone Vaniukov furnace to ferro-nickel. In Proceedings of the Sustainable Industrial Processing Summit, Cancum, Mexico, 29 June–4 July 2014; pp. 319–320. [Google Scholar]

- Rao, M.; Li, G.; Jiang, T.; Luo, J.; Zhang, Y.; Fan, X. Carbothermic reduction of nickeliferous laterite ores for nickel pig iron production in China: A review. JOM 2013, 65, 1573–1583. [Google Scholar] [CrossRef]

- SMM Exclusive, China’s Basic Metal Production Data Released in May. Available online: https://news.metal.com/newscontent/100936321/%5Bsmm-exclusive%5D-chinas-basic-metal-production-data-released-in-may/ (accessed on 9 August 2019).

- Dong, X. Technology and development of nickel pig iron blast furnace. Presented at the 2017 SEAISI Conference & Exhibition, Singapore, 22–25 May 2017; Available online: http://seaisi.org/seaisi2017/file/file/full-paper/Session8B%20Paper2.pdf (accessed on 15 July 2019).

- GLENCORE. Report: The Realities of the Nickel Market. November 2013. Available online: https://www.glencore.com/dam/jcr:38f0e145-d7e9-4104-a5dd-3bcc0119ff4d/Glencore-the-realities-of-the-Nickel-market-November-201311.pdf (accessed on 15 July 2019).

- Nickel Pig Iron Market Contributes to Indonesian Nickel Mining Growth. Available online: https://m.miningweekly.com/article/nickel-pig-iron-market-contributes-to-indonesian-nickel-mining-growth-2019-04-19 (accessed on 15 July 2019).

- Andika, R.; Astuti, W.; Syafriadi; Nurjaman, F. Effect of flux addition and reductant type in smelting process of Indonesian limonite ore in electric arc furnace. In Proceedings of the 2nd Mineral Processing and Technology International Conference, Serpong, Indonesia, 1–2 November 2018; IOP Publishing: Bristol, UK, 2019. [Google Scholar] [CrossRef]

- Manning, C.P.; Fruehan, R.J. Emerging technologies for iron and steelmaking. JOM 2001, 53, 20–23. [Google Scholar] [CrossRef]

- Erasmus, L.J.; Fourie, L.J. ESS Smelting technology enabling FeNi smelting from limonite. In Proceedings of the Fourteenth International Ferroalloys Congress, Kiev, Ukraine, 31 May–4 June 2015; pp. 210–218. [Google Scholar]

- Fourie, L.J.; Erasmus, L.J. A ferro-nickel product and a process for its production. Patent No: WO 2015/015468 A1, 5 February 2015. [Google Scholar]

- Erasmus, L.J.; Fourie, L.J. ESS Smelting technology. JOM 2017, 69, 325–333. [Google Scholar] [CrossRef]

- Bakker, M.L.; Nikolic, S.; Mackey, P.J. ISASMELTTM TSL-Applications for nickel. Miner. Eng. 2011, 24, 610–619. [Google Scholar] [CrossRef]

- King, M.G.; Zuliani, P.; Schonewille, R.; Mason, P. Technology development for processing Koniambo laterites. In Proceedings of the ALTA 2005 Nickel/Cobalt Conference, Perth, Australia, 16–18 May 2005. [Google Scholar]

- Koniambo Nickel Sas. Available online: https://smsp.nc/en/koniambo-nickel-sas-eng/ (accessed on 15 July 2019).

- Eccleston, E.; Schonewille, R.; Letarte, F.; Gardner, E. Fluidized bed reduction of nickel laterite at Koniambo nickel. In Proceedings of the Nickel-Cobalt 2017 (4th International Conference), Vancouver, BC, Canada, 27–30 August 2017. [Google Scholar]

- Reinecke, I.J.; Lagendijk, H. A twin-cathode DC arc smelting test at Mintek to demonstrate the feasibility of smelting FeNi from calcine prepared from siliceous laterite ores from Kazakhstan for Oriel Resources PLC. In Proceedings of the INFACON XI Congress, New Delhi, India, 18–21 February 2007; pp. 781–797. [Google Scholar]

- Solar, M.J.; Mostaghel, S. Smelting of difficult laterite ores. Miner. Process. Extr. M. 2015, 124, 35–46. [Google Scholar] [CrossRef]

- Liu, P.; Li, B.; Cheung, S.C.P.; Wu, W. Material and energy flows in rotary kiln-electric furnace smelting of ferro-nickel alloy with energy saving. Appl. Therm. Eng. 2016, 109, 542–559. [Google Scholar] [CrossRef]

- Ma, X.; Cui, Z.; Zhao, B. Efficient utilization of nickel laterite to produce master alloy. JOM 2016, 68, 3006–3014. [Google Scholar] [CrossRef]

- Park, H.S.; Ha, M.C.; Kim, M.S.; Heo, J.H.; Park, J.H. Novel design of ferro-nickel smelting slag by utilizing red mud as a fluxing agent: Thermochemical computations and experimental confirmation. CALPHAD 2017, 56, 185–195. [Google Scholar] [CrossRef]

- Sakkas, K.; Nomikos, P.; Sofianos, A.; Panias, D. Utilization of FeNi-slag for the production of inorganic polymeric materials for construction or for passive fire protection. Waste Biomass Valori. 2014, 5, 403–410. [Google Scholar] [CrossRef]

- Gu, F.; Peng, Z.; Zhang, Y.; Tang, H.; Ye, L.; Tian, W.; Liang, G.; Lee, J.; Rao, M.; Li, G.; et al. Valorization of ferro-nickel slag into refractory materials: Effect of sintering temperature. JOM 2019, 71, 1024–1032. [Google Scholar] [CrossRef]

- Dong, J.; Wei, Y.; Zhou, S.; Li, B.; Yang, Y.; McLean, A. The effects of additives on extraction of Ni, Fe and Co from nickel laterite ores. JOM 2018, 70, 2365–2377. [Google Scholar] [CrossRef]

- Dong, J.; Wei, Y.; Lu, C.; Zhou, S.; Li, B.; Ding, Z.; Wang, C.; Ma, B. Influence of calcium chloride addition on coal-based reduction roasting of low-nickel garnierite ore. Mater. Trans. 2017, 58, 1161–1168. [Google Scholar] [CrossRef]

- Liu, W.; Li, X.; Hu, Q.; Wang, Z.; Gu, K.; Li, J.; Zhang, L. Pretreatment study on chloridizing segregation and magnetic separation of low-grade nickel laterites. Trans. Nonferr. Metal. Soc. 2010, 20, 82–86. [Google Scholar] [CrossRef]

- Lu, J.; Liu, S.; Shangguan, J.; Du, W.; Pan, F.; Yang, S. The effect of sodium sulphate on the hydrogen reduction process of nickel laterite ore. Miner. Eng. 2013, 49, 154–164. [Google Scholar] [CrossRef]

- Li, G.; Shi, T.; Rao, M.; Jiang, T.; Zhang, Y. Beneficiation of nickeliferous laterite by reduction roasting in the presence of sodium sulfate. Miner. Eng. 2012, 32, 19–26. [Google Scholar] [CrossRef]

- Yi, L.; Huang, Z.; Peng, H.; Jiang, T. Experimental study on reduction roasting and separation of nickeliferous laterite by microwave heating. In Proceedings of the TMS Annual Meeting & Exhibition 2011, 27 February–3 March 2011, San Diego, CA, USA; 2011. [Google Scholar] [CrossRef]

- Wang, X.; Sun, T.; Chen, C.; Hu, T. Current studies of treating processes for nickel laterite ores. Adv. Com. Sci. Res. 2017, 70, 139–152. [Google Scholar]

- Warner, A.E.M.; Diaz, C.M.; Dalvi, A.D.; Mackey, P.J.; Tarasov, A.V. JOM world nonferrous smelter survey-Part III: Nickel: Laterite. JOM 2006, 58, 11–20. [Google Scholar] [CrossRef]

- Solar, M.Y.; Candy, I.; Wasmund, B. Selection of optimum ferronickel grade for smelting nickel laterites. CIM Bul. 2008, 101, 1–8. [Google Scholar]

- Von Kruger, P.; Silva, C.A.; Vieira, C.B.; Araujo, F.G.S.; Seshadri, V. Relevant aspects related to production of iron nickel alloys (pig iron containing nickel) in mini blast furnaces. In Proceedings of the Twelfth International Ferroalloys Congress, Helsinki, Finland, 6–9 June 2010; pp. 671–680. [Google Scholar]

- Bekem Metals, Inc. U.S. Securities and Exchange Commision, Annual Report. 2008. Available online: https://www.sec.gov/Archives/edgar/data/1223550/000103883809000101/k123108.htm (accessed on 15 August 2019).

| Processes → Performances ↓ | The RKEF Process 2 | Low-grade Ferro-Nickel Production Process 3 | The ESS Process 4 | The Vaniukov Process 5 | Reduction Roasting–Magnetic Separation Process 6 |

|---|---|---|---|---|---|

| Ore Ni composition (%) | 1.1–2.5 | BF/SAF: ~1 | 1.5 | 0.90 | (0.82–1.91) Avg.: 1.31 |

| Crude Alloy Composition | Ni: ~25 Co: 0.60 Fe: Balance | Ni: <15 Co: 0.60 Fe: Balance | Ni: 15 C: 0.30 Si: 0.07 Fe: 84.6 | Ni: 15 Co: 0.80 Fe: Balance | Ni: 9 Fe: Balance |

| Crude Alloy Ni grade (%) | ~25 | BF: 2–5 SAF: 10-15 | 15 | ~15 | ~9 |

| Crude Alloy Ni recovery (%) | 90–95 | BF/SAF: ~80 | 91 | ~92.5 | ~90 |

| Refined Alloy Composition | Ni: ~28 Co: 0.60 C: 0.05 Si < 0.5 S < 0.06 P < 0.03 | Decarburization can be applied for low-C low-grade FeNi production. | NA | Ni ≥20 C: 0.07 Si: 0.5 Cr: 0.06 | - |

| Refined Alloy Ni grade (%) | ~28 | <15 | NA | ≥20 | - |

| Refined Alloy Ni recovery (%) | 90–95 | NA | NA | >90 | - |

| Energy requirement | 502 kWh/t of calcine | BF: ~750 $/t alloy 7 | 189 kWh/t of limonite | 6132 $ per 1 ton of nickel 8 | NA |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keskinkilic, E. Nickel Laterite Smelting Processes and Some Examples of Recent Possible Modifications to the Conventional Route. Metals 2019, 9, 974. https://doi.org/10.3390/met9090974

Keskinkilic E. Nickel Laterite Smelting Processes and Some Examples of Recent Possible Modifications to the Conventional Route. Metals. 2019; 9(9):974. https://doi.org/10.3390/met9090974

Chicago/Turabian StyleKeskinkilic, Ender. 2019. "Nickel Laterite Smelting Processes and Some Examples of Recent Possible Modifications to the Conventional Route" Metals 9, no. 9: 974. https://doi.org/10.3390/met9090974

APA StyleKeskinkilic, E. (2019). Nickel Laterite Smelting Processes and Some Examples of Recent Possible Modifications to the Conventional Route. Metals, 9(9), 974. https://doi.org/10.3390/met9090974