Simulation of Thermal Stress and Fatigue Life Prediction of High Speed Steel Work Roll during Hot Rolling Considering the Initial Residual Stress

Abstract

:1. Introduction

2. FEM Simulations

2.1. FEM Model Description

2.2. Heat Transfer Coefficients of the Work Roll during Hot Rolling

3. Residual Stress in Work Rolls during Heat Treatment

3.1. Generation Mechanism of Residual Stress in the Work Rolls during Heat Treatment

3.2. Residual Stress Distribution in Work Rolls after Heat Treatment

4. Thermal Stress Considering the Initial Residual Stress in the Work Rolls during Hot Rolling

4.1. Generation Mechanism of Thermal Stress in the Work Rolls during Hot Rolling

4.2. Effects of the Initial Work Roll Temperature and Cooling Conditions on Thermal Stress in Work Rolls during Hot Rolling

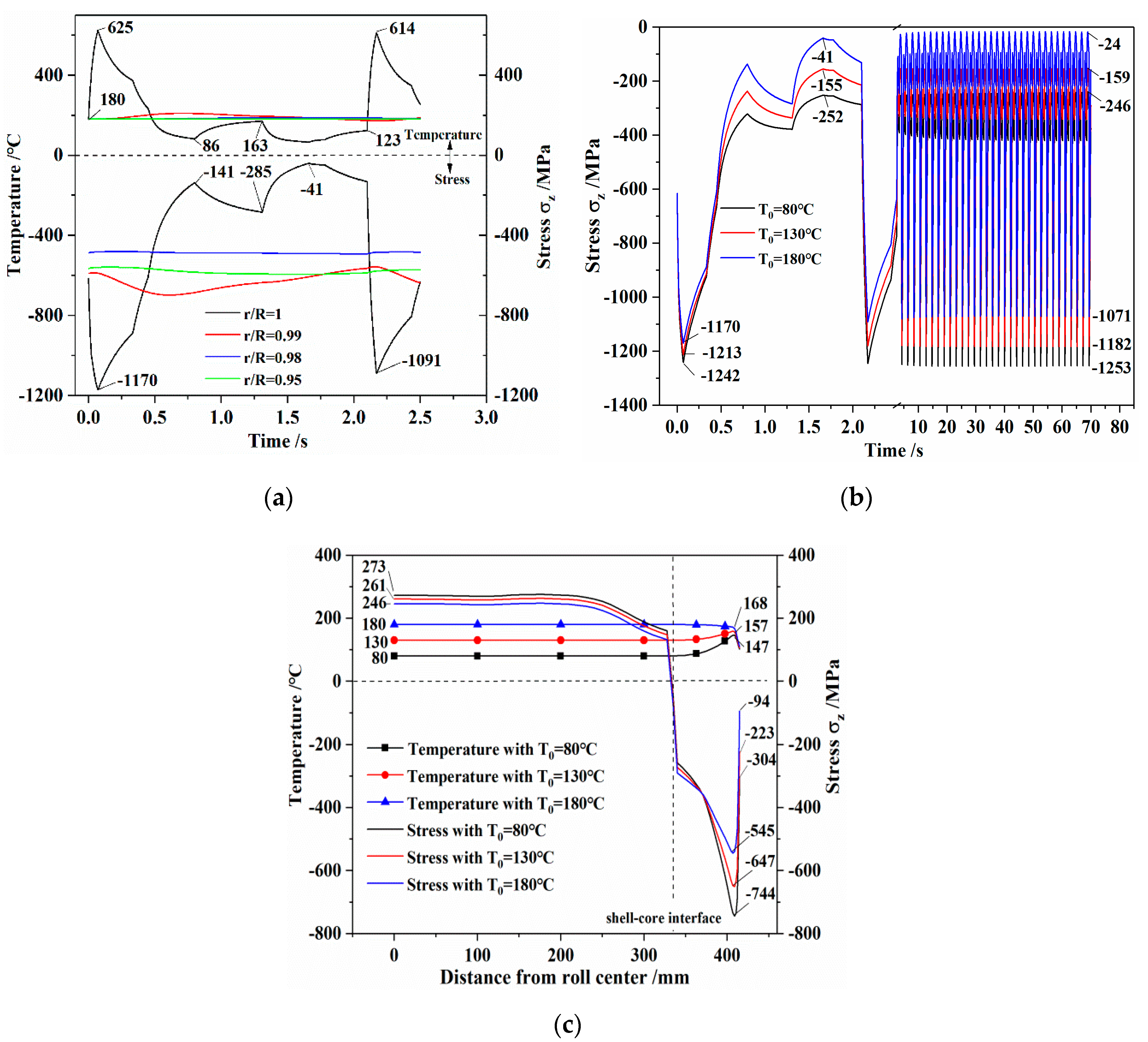

4.2.1. Effect of the Initial Temperature of Work Rolls on Thermal Stress during Hot Rolling

4.2.2. Effect of Cooling Conditions on Thermal Stress during Hot Rolling

5. Prediction of the Thermal Fatigue Life of Work Rolls during Hot Rolling

6. Conclusions

- (1)

- During the quenching process, compressive residual stress appeared at the surface and tensile residual stress appeared at the center, induced by the integrated effects of thermal stress and transformation stress; during the tempering process, the tensile stress decreased uniformly, while the compressive stress was almost unchanged.

- (2)

- During the hot rolling process, stable maximum temperature and compressive stress were reached at the roll surface after 10 revolutions, while the temperature at the subsurface increased gradually with the small variation amplitude.

- (3)

- Considering the initial residual stress, the compressive stress caused plastic deformation at the roll surface in the bite region, while the tensile stress did not appear in the cooling region; the thermal stresses at the shell changed significantly near the surface, while the tensile stresses at the core increased gradually during the whole rolling and reached 367 MPa after rolling of ten strips.

- (4)

- Increasing of the initial roll temperature resulted in a higher temperature but lower compressive thermal stress at the roll surface; the complete cooling condition reduced the roll temperature and compressive thermal stress at the roll surface, while the surface temperature and compressive thermal stress increased significantly in the condition of without water spray cooling and mill stall, as well as the center tensile stress.

- (5)

- The thermal fatigue life of the work roll during hot rolling was calculated to be 35,145 cycles based on the Universal Slopes model and this reduced to 41 cycles and 175 cycles, respectively, according to the 10% rule and 20% rule.

Author Contributions

Funding

Conflicts of Interest

References

- Torres, I.N.; Gilles, G.; Tchuindjang, J.T.; Flores, P.; Lecomte-Beckers, J.J.; Habraken, A.M. FE modeling of the cooling and tempering steps of bimetallic rolling mill rolls. Int. J. Mater. Form. 2017, 10, 287–305. [Google Scholar] [CrossRef]

- Na, D.H.; Moon, C.H.; Lee, Y. Thermal stress evolution of the roll during rolling and idling in hot strip rolling process. J. Therm. Stres. 2014, 37, 981–1001. [Google Scholar] [CrossRef]

- Benasciutti, D. On thermal stress and fatigue life evaluation in work rolls of hot rolling mill. J. Strain Anal. Eng. Des. 2012, 47, 297–312. [Google Scholar] [CrossRef]

- Williams, R.V.; Boxall, M. Roll surface deterioration in in hot strip mills. J. Iron Steel Inst. 1965, 203, 369–377. [Google Scholar]

- Weidlich, F.; Braga, A.P.V.; da Silva Lima, L.G.D.B. The influence of rolling mill process parameters on roll thermal fatigue. Int. J. Adv. Manuf. Technol. 2019, 102, 2159–2171. [Google Scholar] [CrossRef]

- Spuzic, S.; Strafford, K.N.; Surbramanian, C.; Savage, G. Wear of hot rolling mill rolls: An overview. Wear 1994, 176, 261–271. [Google Scholar] [CrossRef]

- Szota, P.; Mróz, S.; Dyja, H.; Kawalek, A. 3D FEM modelling and experimental verification of the rolls wear during the bar rolling process. Trans. Tech. Publ. 2012, 706–709, 1533–1538. [Google Scholar] [CrossRef]

- Sano, Y.; Hattori, T.; Haga, M. Characteristics of high-carbon high speed steel rolls for hot strip mill. ISIJ Int. 1992, 32, 1194–1201. [Google Scholar] [CrossRef]

- Ventural, J. Roll Failures Manual: Hot Mill Cast Work Rolls; The European Foundry Association, Roll Section: Düsseldorf, Germany, 2002; pp. 19–20. [Google Scholar]

- Gao, J.H.; Huang, C.Q.; Wang, M.; Huang, J.P. Determination and application of surface temperature field on HSS hot work roll. Mater. Mech. Eng. 2009, 33, 46–49. [Google Scholar]

- Deng, G.Y.; Zhu, H.T.; Tieu, A.K.; Su, L.H.; Reid, M.; Zhang, L.; Wei, P.T.; Zhao, X.; Wang, H.; Zhang, J.; et al. Theoretical and experimental investigation of thermal and oxidation behaviours of a high speed steel work roll during hot rolling. Int. J. Mech. Sci. 2017, 131, 811–826. [Google Scholar] [CrossRef]

- Deng, G.Y.; Zhu, Q.; Tieu, A.K.; Zhu, H.T.; Reid, M.; Saleh, A.A.; Su, L.H.; Ta, T.D.; Zhang, J.; Lu, C.; et al. Evolution of microstructure, temperature and stress in a high speed steel work roll during hot rolling: Experiment and modelling. J. Mater. Process. Technol. 2017, 240, 200–208. [Google Scholar] [CrossRef]

- Dünckelmeyer, M.; Krempaszky, C.; Werner, E.; Hein, G.; Schörkhuber, K. Analytical modeling of thermo-mechanically induced residual stresses of work rolls during hot rolling. Steel Res. Int. 2010, 81, 86–89. [Google Scholar]

- Ryu, J.H.; Ryu, H.B. Effect of thermal fatigue property of hot strip mill work roll materials on the rolled-in defects in the ultra-low carbon steel strips. ISIJ Int. 2007, 43, 1036–1039. [Google Scholar] [CrossRef]

- Mercado-Solis, R.D.; Beynon, J.H. Simulation of thermal fatigue in hot strip mill work rolls. Scand. J. Metall. 2005, 34, 175–191. [Google Scholar] [CrossRef]

- Garzamontesdeoca, N.F. On the damage of a work roll grade high speed steel by thermal cycling. Eng. Failure Anal. 2011, 18, 1576–1583. [Google Scholar] [CrossRef]

- Noda, N.A.; Hu, K.J.; Sano, Y.; Ono, K.; Hosokawa, Y. Residual Stress Simulation for Hot Strip Bimetallic Roll during Quenching. Steel Res. Int. 2016, 87, 1478–1488. [Google Scholar] [CrossRef]

- Noda, N.A.; Hu, K.J.; Sano, Y.; Ono, K.; Hosokawa, Y. Usefulness of non-uniform heating and quenching method for residual stress of bimetallic roll: FEM simulation considering creep behavior. Steel Res. Int. 2017, 88, 1600165. [Google Scholar] [CrossRef]

- Hu, K.; Xia, Y.M.; Zhu, F.X.; Noda, N.A. Evaluation of thermal breakage in bimetallic work roll considering heat treated residual stress combined with thermal stress during hot rolling. Steel Res. Int. 2017, 89, 1700368. [Google Scholar] [CrossRef]

- Noda, N.A.; Sano, Y.; Aridi, M.; Tsuboi, K.; Oda, N. Residual stress differences between uniform and non-uniform heating treatment of bimetallic roll: Effect of creep behavior on residual stress. Metals 2018, 8, 952. [Google Scholar] [CrossRef]

- Devadas, C.; Samarasekera, I.; Hawbolt, E. The thermal and metallurgical state of steel strip during hot rolling: Part I. Characterization of heat transfer. Metall. Trans. A 1991, 22, 307–319. [Google Scholar] [CrossRef]

- Tseng, A.A. Thermal modeling of roll and strip interface in rolling processes: Part 1-review. Numer. Heat Transfer, Part A 1992, 35, 115–133. [Google Scholar] [CrossRef]

- Sun, C.G.; Hwang, S.M.; Yun, C.S.; Chung, J.S. Investigation of thermomechanical behavior of a work roll and of roll life in hot strip rolling. Metall. Mater. Trans. A 1998, 29, 2407–2424. [Google Scholar] [CrossRef] [Green Version]

- Hlady, C.; Brimacombe, J.; Samarasekera, I.; Hawbolt, E. Heat transfer in the hot rolling of metals. Metall. Mater. Trans. B 1995, 26, 1019–1027. [Google Scholar] [CrossRef]

- Shida, S. Empirical formula of flow stress of carbon steels resistance to deformation of carbon steels at elevated temperature. J. Jpn. Soc. Technol. Plast. 1969, 10, 610–617. [Google Scholar]

- Mohanty, A.K.; Tawfek, A.A.; Prasad, B.V.S.S.S. Heat transfer from a rotating cylinder in cross flow. Exp. Therm. Fluid Sci. 1995, 10, 54–61. [Google Scholar] [CrossRef]

- Li, W.G.; Liu, X.H.; Guo, Z.H. Numerical simulation of temperature field and thermal crown of work roll during hot strip rolling. Chin. J. Nonferrous Met. 2012, 22, 3176–3184. (In Chinese) [Google Scholar]

- Stevens, P.G.; Ivens, K.P.; Harper, P. Increasing work roll life by improved roll cooling practice. J. Iron Steel Inst. 1971, 209, 1–11. [Google Scholar]

- Corral, R.L.; Colás, R.; Pérez, A. Modeling the thermal and thermoelastic responses of work rolls used for hot rolling steel strip. J. Mater. Process. Technol. 2004, 153, 886–893. [Google Scholar] [CrossRef]

- Gauthier, J.; Krause, T.W.; Atherton, D.L. Measurement of residual stress in steel using the magnetic Barkhausen noise technique. NDT E Int. 1998, 31, 23–31. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Goodier, J.N. Theory of Elasticity; McGraw-Hill Book Company, Inc.: New York, NY, USA, 1951; pp. 408–409. [Google Scholar]

- Raudenský, M.; Zahradník, R. Minimization of Thermal Cracks of Rolls by Cooling Optimization. In Proceedings of 21st International Conference on Metallurgy and Materials; TANGER Ltd.: Brno, Czech Republic, 2012. [Google Scholar]

- Basquin, O.H. The exponential law of endurance tests. Proc. ASTM 1910, 10, 625–630. [Google Scholar]

- Fatemi, A.; Plaseied, A.; Khosrovaneh, A.K. Application of bi-linear log-log S-N model to strain-controlled fatigue data of aluminum alloys and its effect on life predictions. Int. J. Fatigue 2005, 27, 1040–1050. [Google Scholar] [CrossRef]

- Socie, D.F.; Morrow, J.D. Review of contemporary approaches to fatigue damage Analysis. In Risk and Failure Analysis for Improved Performance and Reliability; Plenum Publication Corp: New York, NY, USA, 1980. [Google Scholar]

- Kim, K.S.; Chen, X.; Han, C.; Lee, H.W. Estimation methods for fatigue properties of steels under axial and torsional loading. Int. J. Fatigue 2002, 24, 783–793. [Google Scholar] [CrossRef]

- Manson, S.S. Thermal Stress and Low-Cycle Fatigue; McGraw-Hill: New York, NY, USA, 1966. [Google Scholar]

- Manson, S.S.; Haiford, G.R. Fatigue and Durability of Structural Materials; ASM International: Materials Park, OH, USA, 2006. [Google Scholar]

- Manson, S.S. A simple procedure for estimating high-temperature low-cycle fatigue. Exp. Mech. 1968, 8, 349–355. [Google Scholar] [CrossRef]

- Novak, J.S.; Benasciutti, D.; De Bona, F. Thermo-mechanical finite element simulation and fatigue life assessment of a copper mould for continuous casting of steel. Procedia Eng. 2015, 133, 688–697. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P | S | Ni | Cr | Mo | Co | V | W | Mg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HSS | 1–3 | <2 | <1.5 | <5 | 2–7 | <10 | <10 | 3–10 | <20 | <10 | ||

| DCI | 2.5–4 | 1.5–3.1 | - | <0.1 | <0.1 | 0.4–5 | 0.01–1.5 | 0.1–1 | - | - | - | 0.02–0.08 |

| Property | HSS | DCI |

|---|---|---|

| Young’s modulus/GPa | 233 | 173 |

| Poisson’s ratio | 0.3 | 0.3 |

| Density/kg m−3 | 7600 | 7300 |

| Thermal expansion coefficient/K−1 | 12.6 × 10−6 | 13.0 × 10−6 |

| Thermal conductivity/W (m K)−1 | 20.2 | 23.4 |

| Specific heat/J (kg K)−1 | 461 | 460 |

| Tensile strength/MPa | 1280 | 415 |

| Parameters | Surface Region | Value |

|---|---|---|

| Velocity of the work roll/m·s−1 Rolling pressure [kN] | - | 1.2419990 |

| Roll diameter/mm | - | 830 |

| Rolling reduction | - | 43.6% |

| Initial work roll temperature/°C | - | 30 |

| Entry strip temperature/°C | - | 1030 |

| Air/water temperature/°C | - | 30 |

| Entry strip temperature/°C | - | 1030 |

| Entry strip width/mm | - | 1040 |

| Water pressure/MPa | - | 1.47 |

| Water flow/L·min−1 | - | 2500 |

| Heat transfer coefficient/W (m2·K)−1 | Bite region | 45,000 |

| Wiper cooling | 14,600 | |

| Water cooling | 32,600 | |

| Air cooling | 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, K.; Zhu, F.; Chen, J.; Noda, N.-A.; Han, W.; Sano, Y. Simulation of Thermal Stress and Fatigue Life Prediction of High Speed Steel Work Roll during Hot Rolling Considering the Initial Residual Stress. Metals 2019, 9, 966. https://doi.org/10.3390/met9090966

Hu K, Zhu F, Chen J, Noda N-A, Han W, Sano Y. Simulation of Thermal Stress and Fatigue Life Prediction of High Speed Steel Work Roll during Hot Rolling Considering the Initial Residual Stress. Metals. 2019; 9(9):966. https://doi.org/10.3390/met9090966

Chicago/Turabian StyleHu, Kejun, Fuxian Zhu, Jufang Chen, Nao-Aki Noda, Wenqin Han, and Yoshikazu Sano. 2019. "Simulation of Thermal Stress and Fatigue Life Prediction of High Speed Steel Work Roll during Hot Rolling Considering the Initial Residual Stress" Metals 9, no. 9: 966. https://doi.org/10.3390/met9090966

APA StyleHu, K., Zhu, F., Chen, J., Noda, N.-A., Han, W., & Sano, Y. (2019). Simulation of Thermal Stress and Fatigue Life Prediction of High Speed Steel Work Roll during Hot Rolling Considering the Initial Residual Stress. Metals, 9(9), 966. https://doi.org/10.3390/met9090966