Structural Aspects of Execution and Thermal Treatment of Welded Joints of Hardox Extreme Steel

Abstract

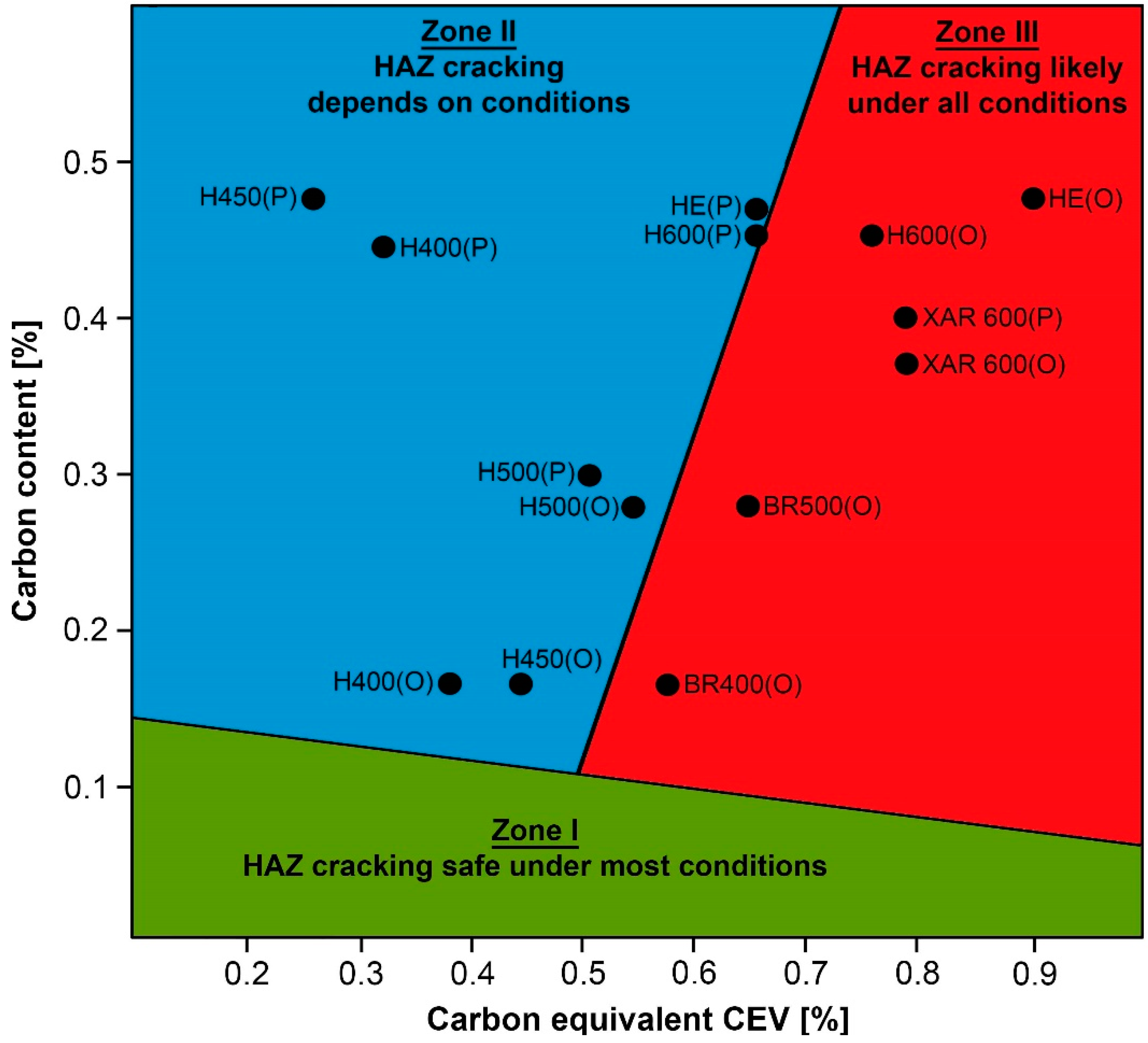

:1. Introduction

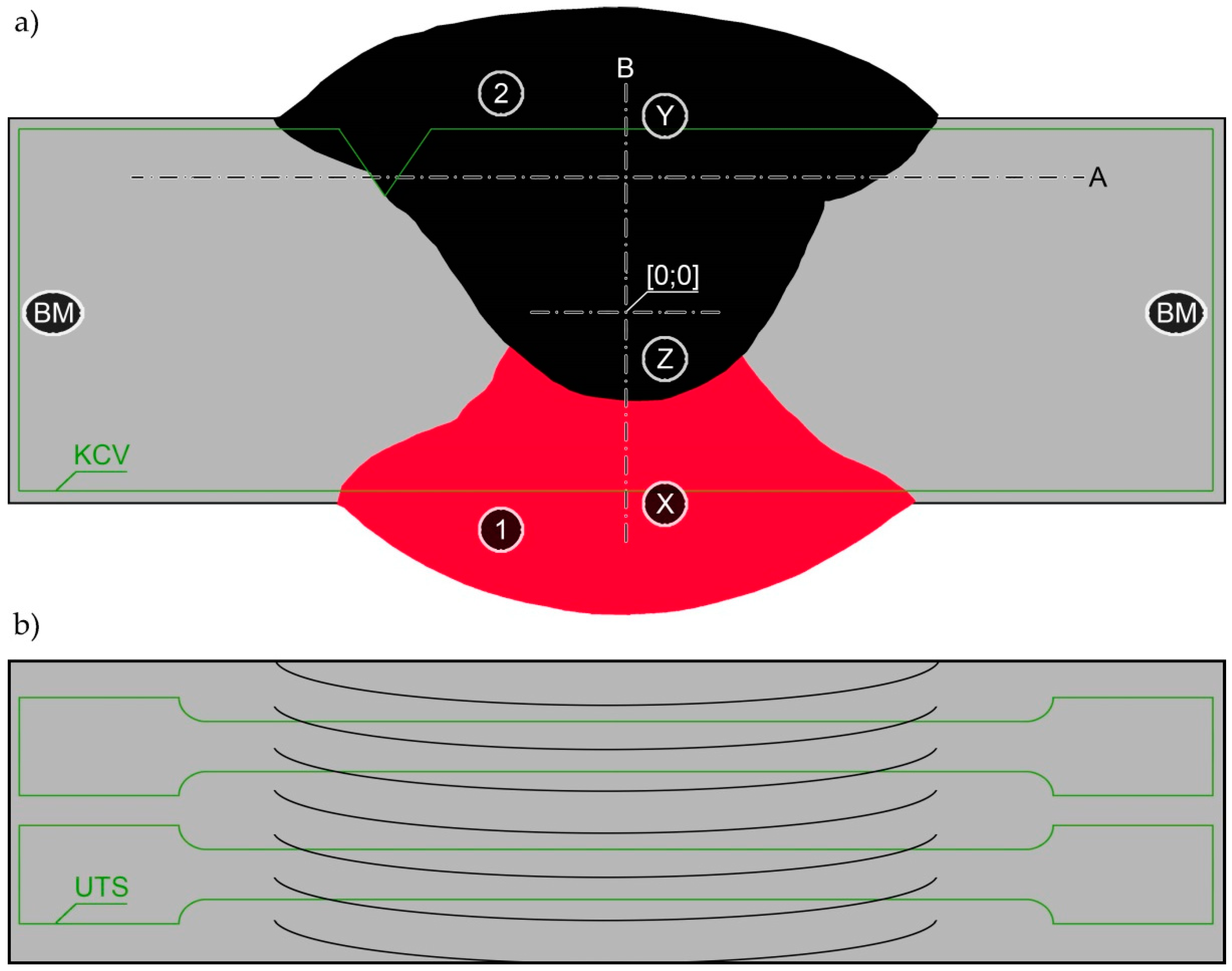

2. Material and Methodology

- -

- weld type: BW (butt weld),

- -

- welding position: PA (flat),

- -

- electrode diameter: 3.0 mm,

- -

- arc voltage (weld layer: 1, 2): 34/35 V,

- -

- amperage (weld layer: 1, 2): 520/640 A,

- -

- polarity: DC(+),

- -

- welding rate (weld layer: 1, 2): 61/63 cm/min,

- -

- electrode wire: OK Autrod 13.43 (S3Ni2.5CrMo acc. to EN ISO 26304),

- -

- flux: OK Flux 10.62,

- -

- preheating: no,

- -

- interpass temperature: ≤100 °C,

- -

- preparation of sheet edges (chamfering): no.

3. Results

3.1. Mechanical Properties

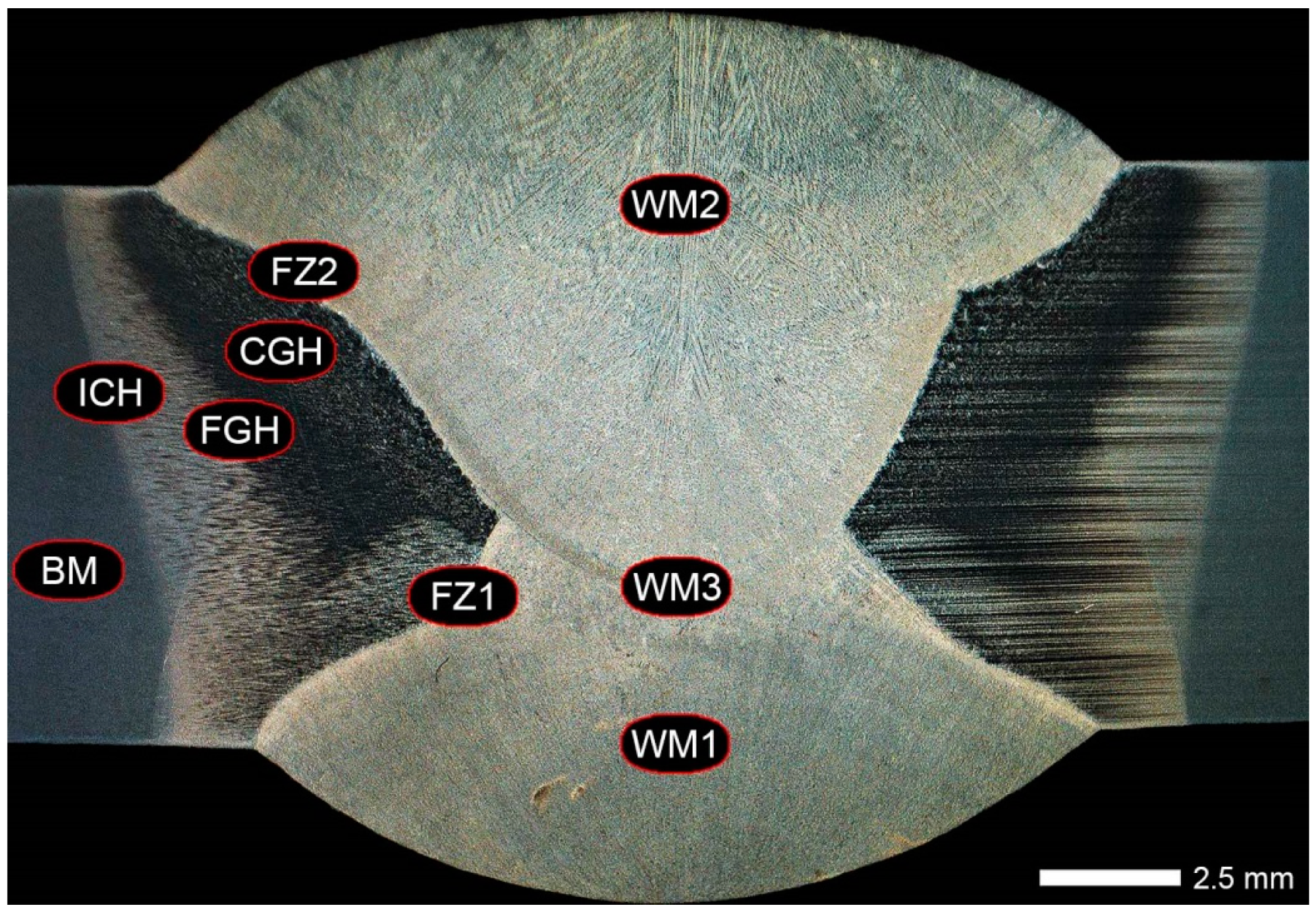

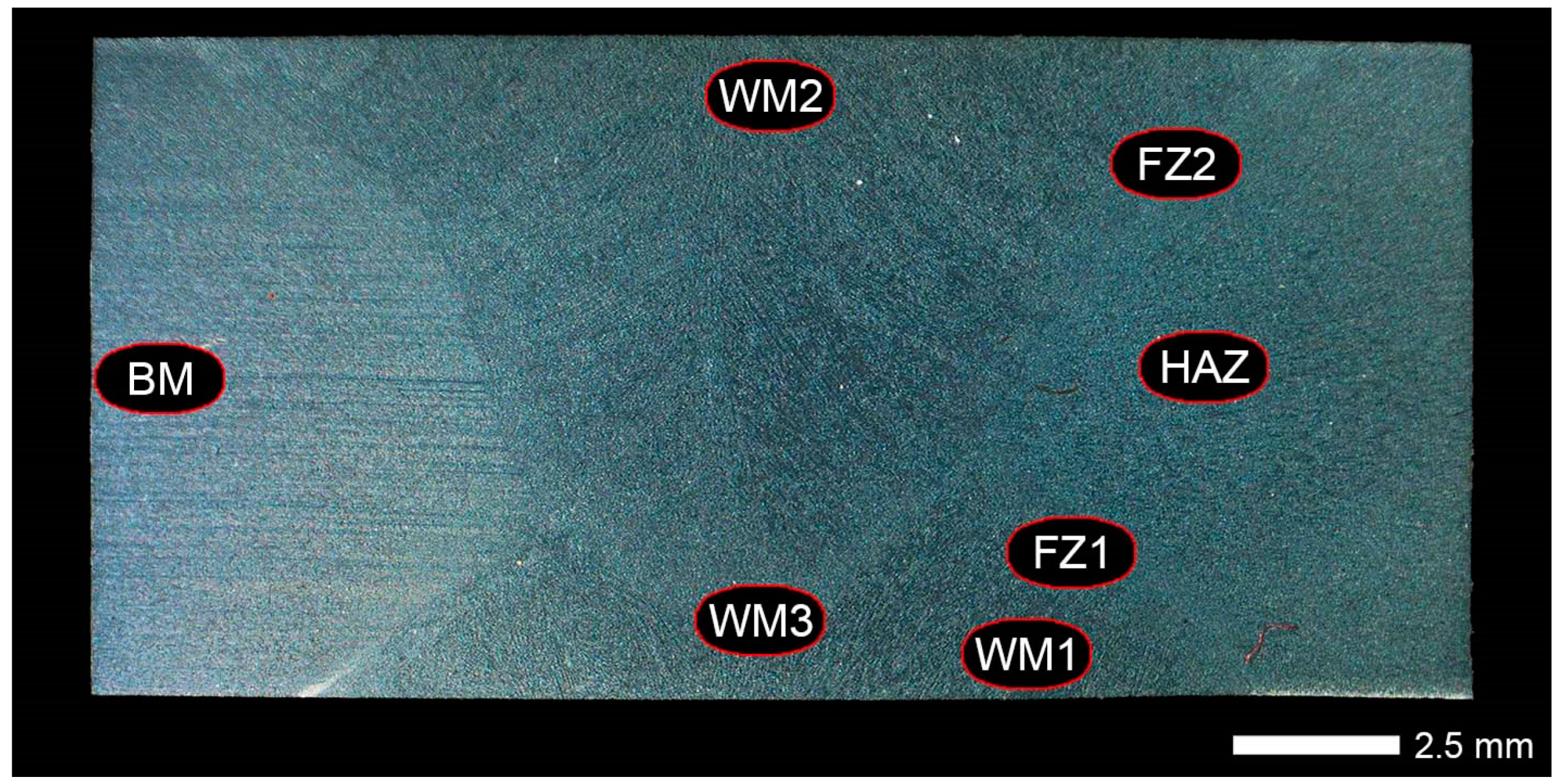

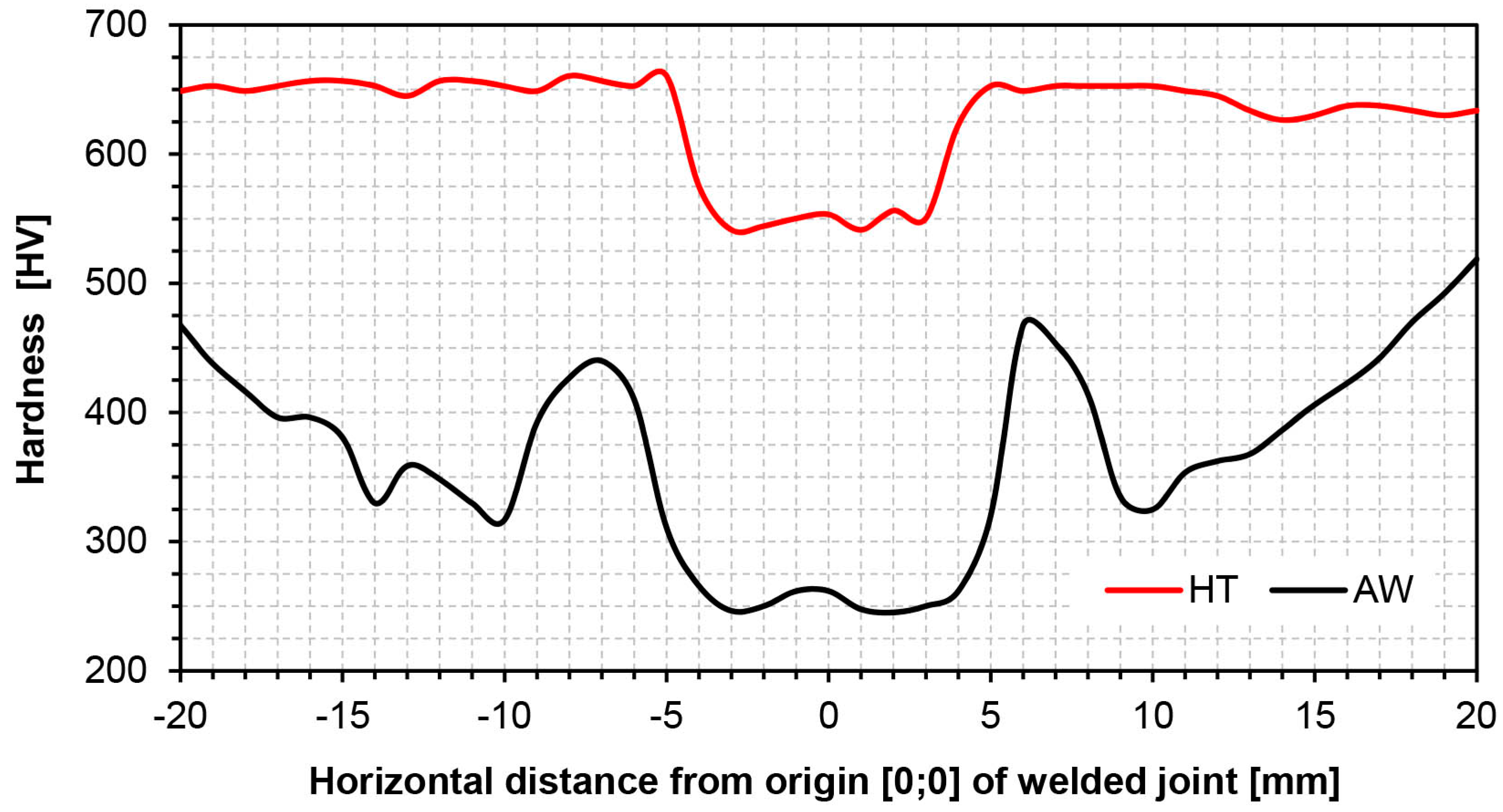

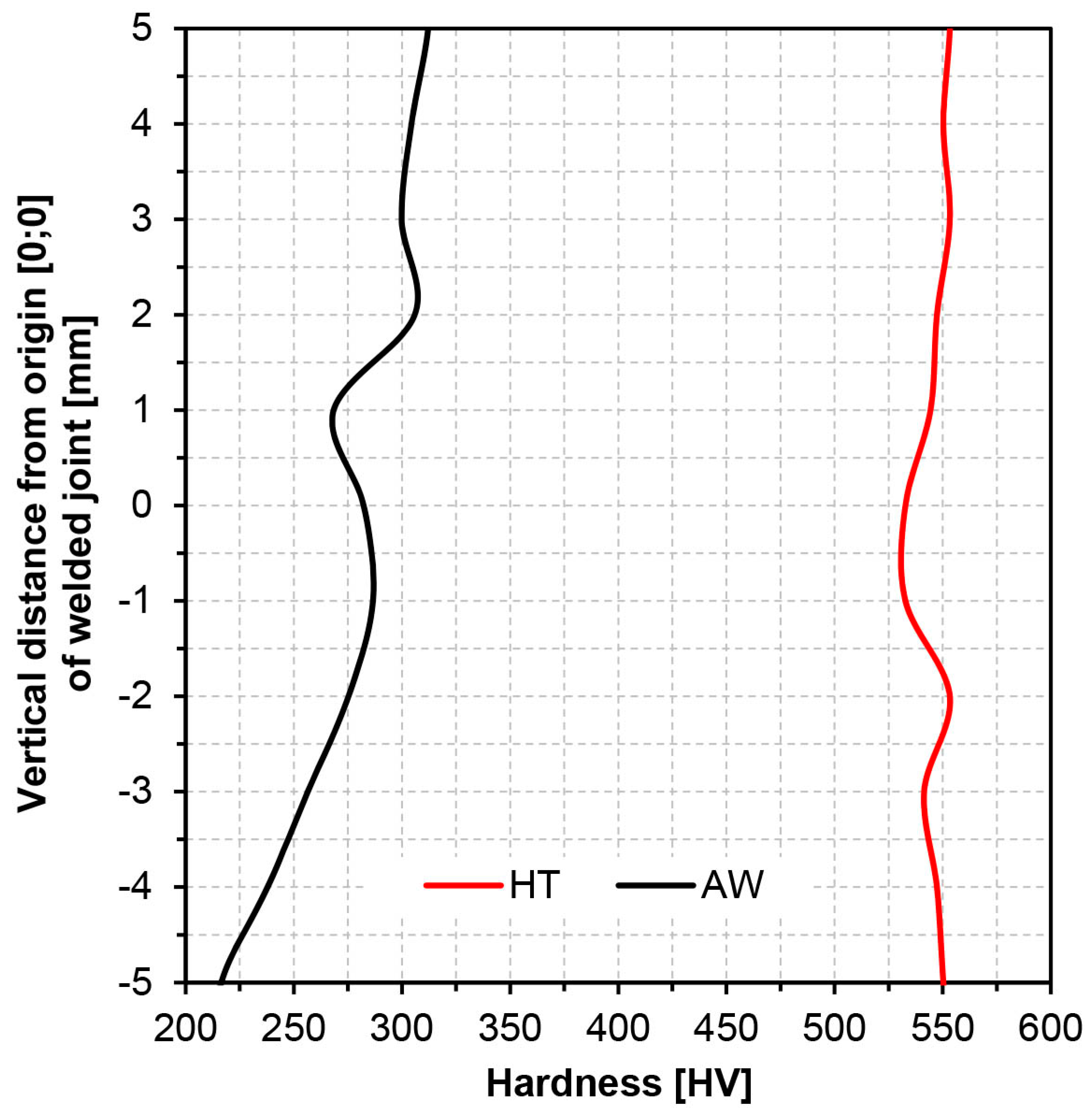

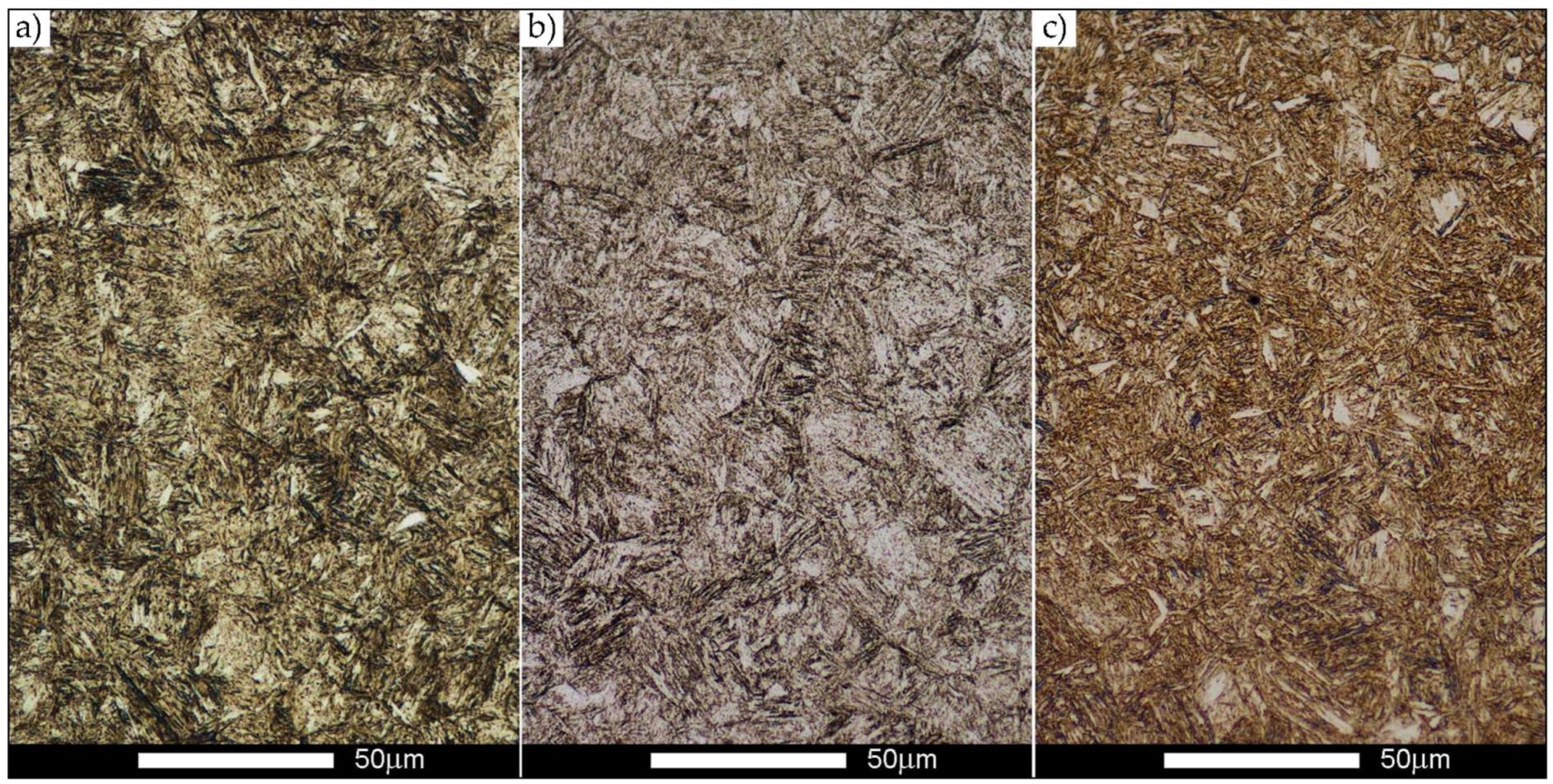

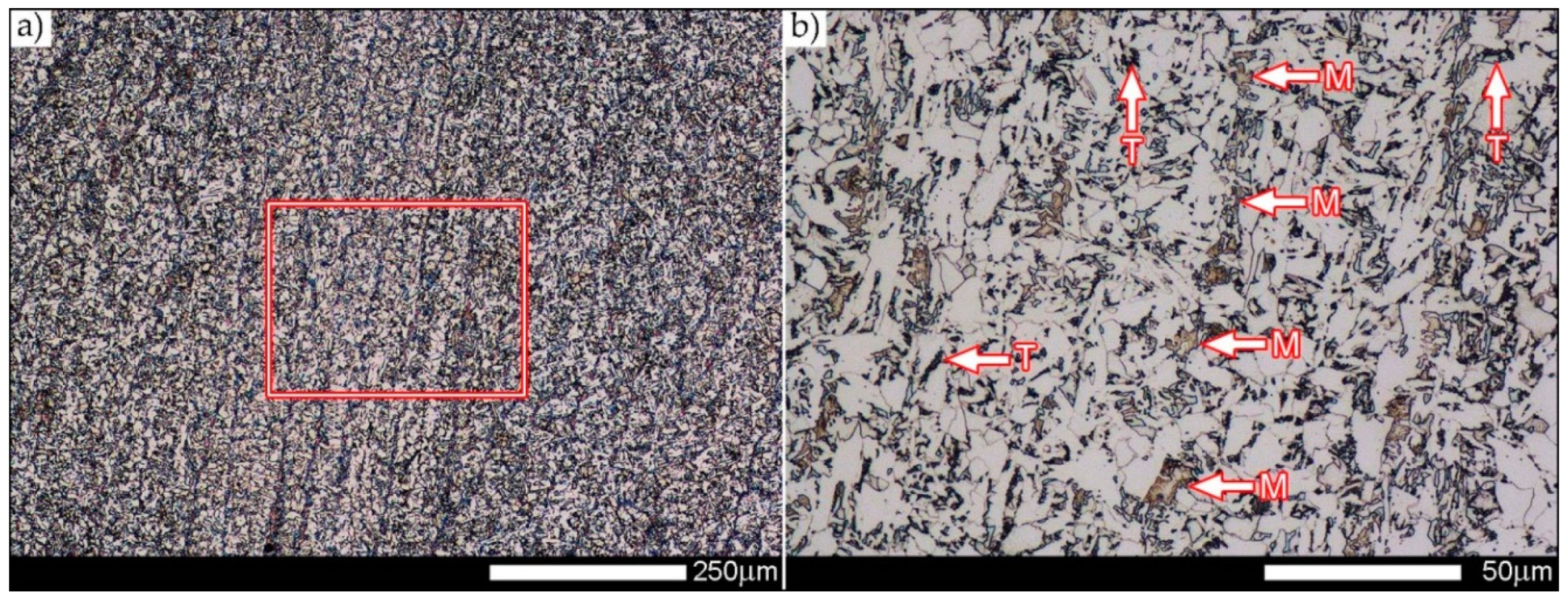

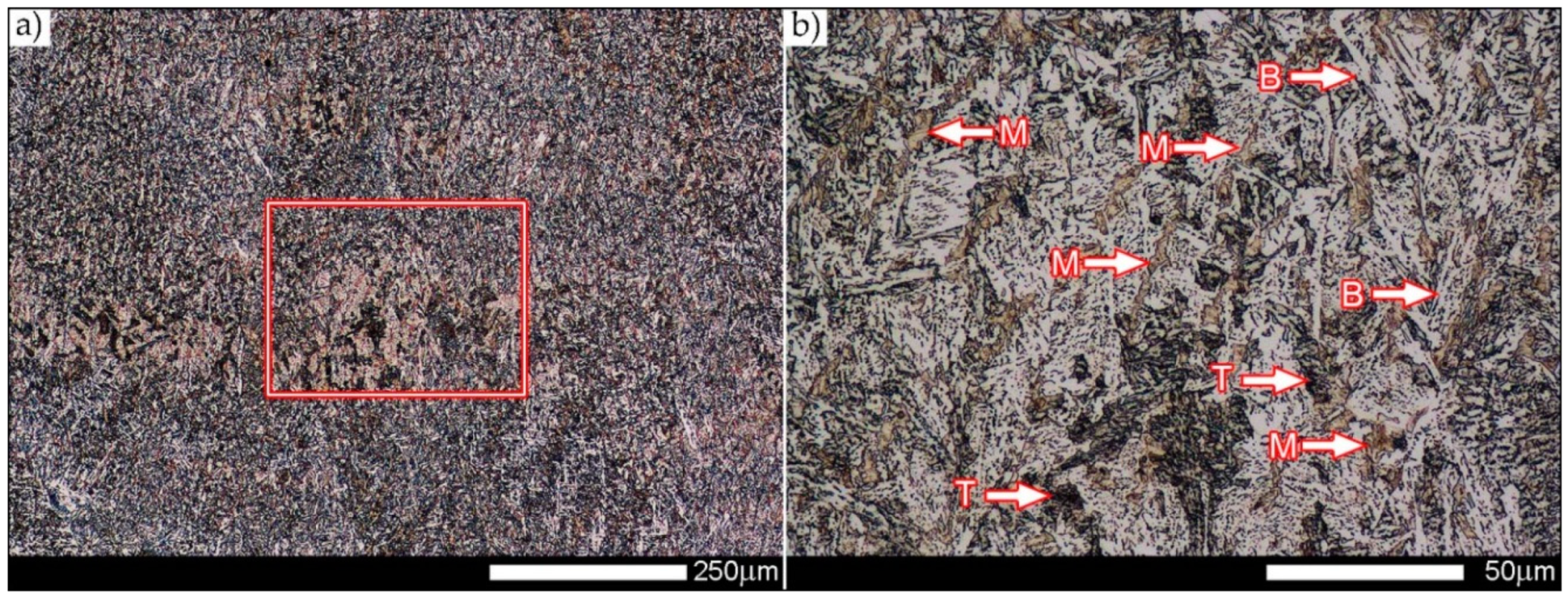

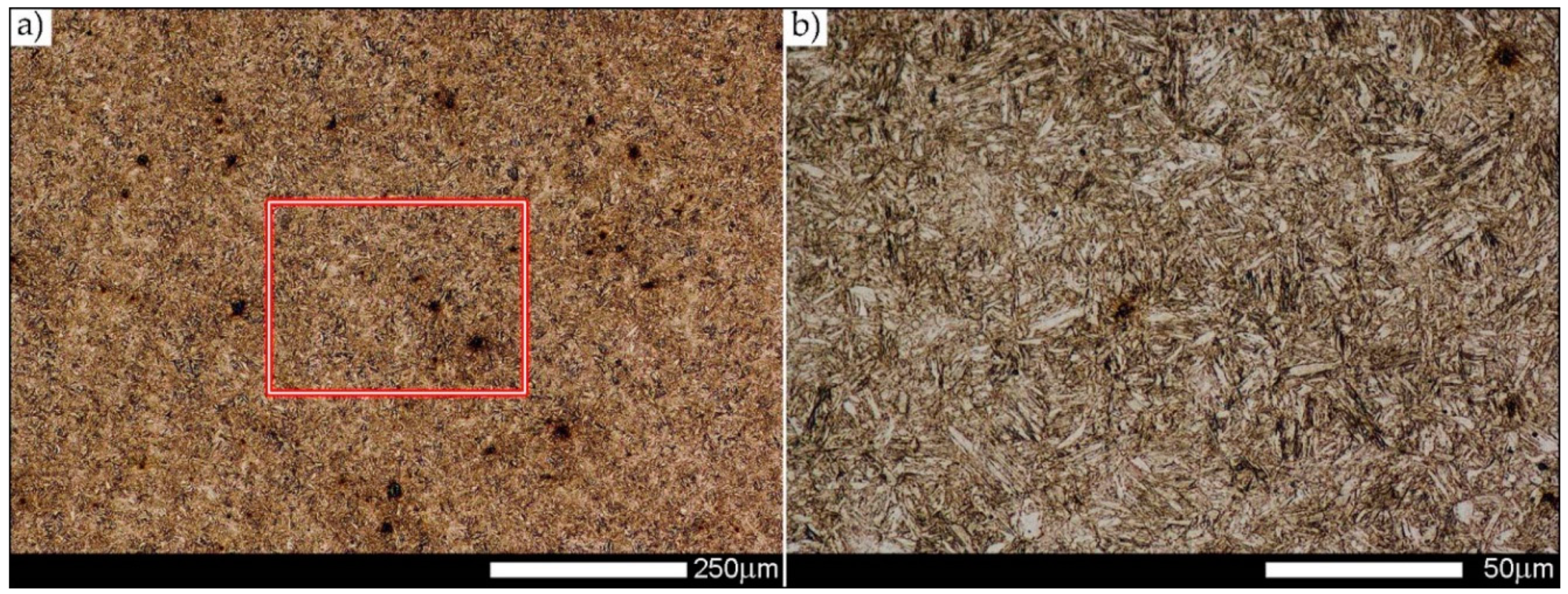

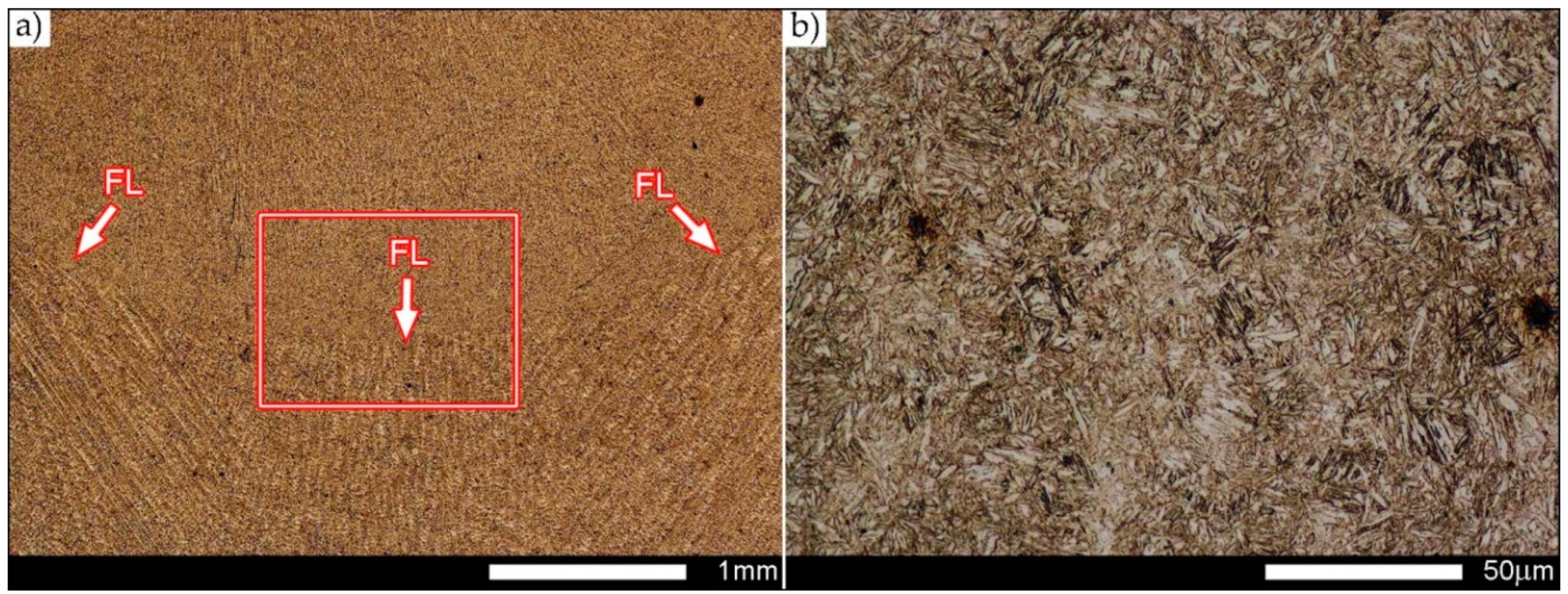

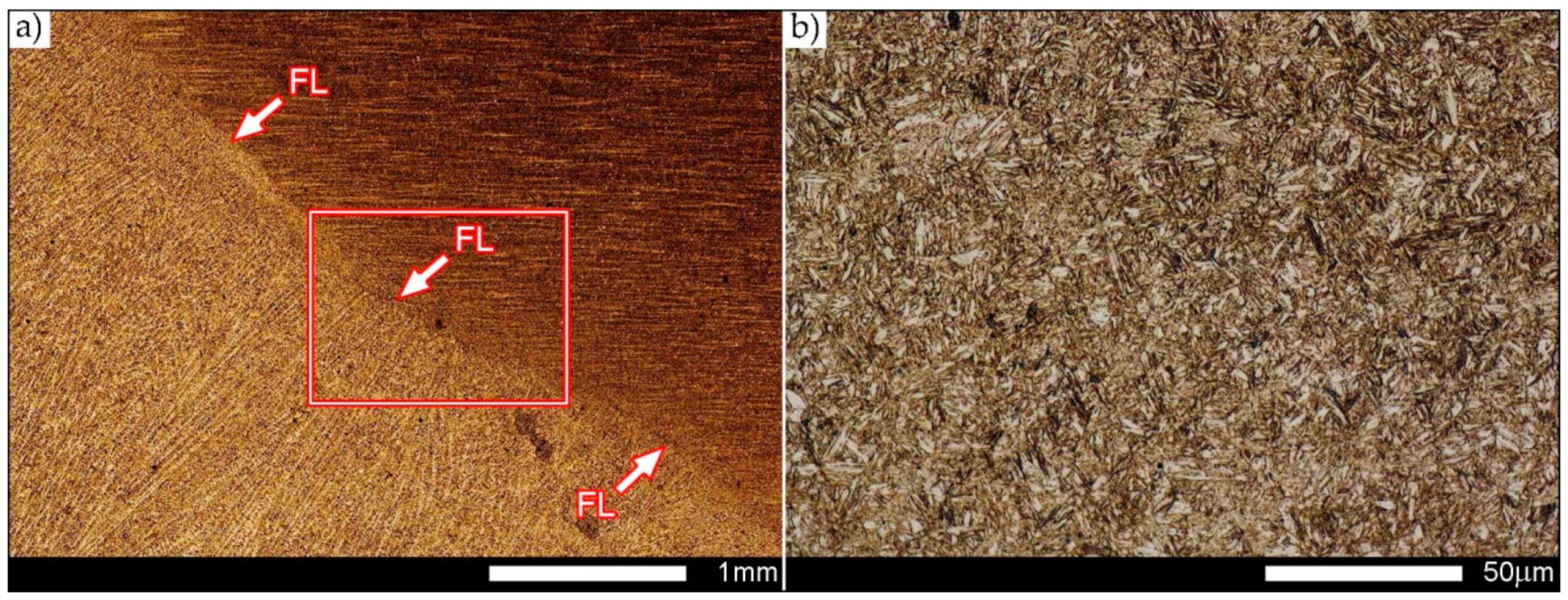

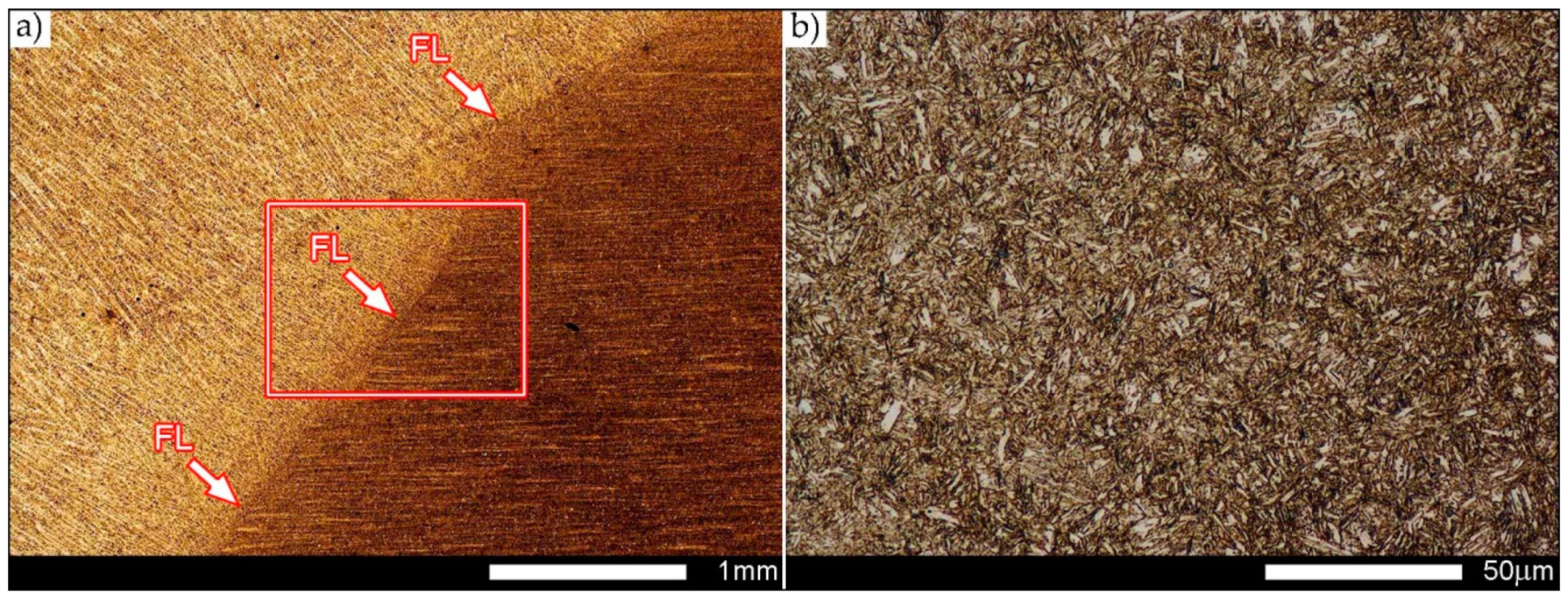

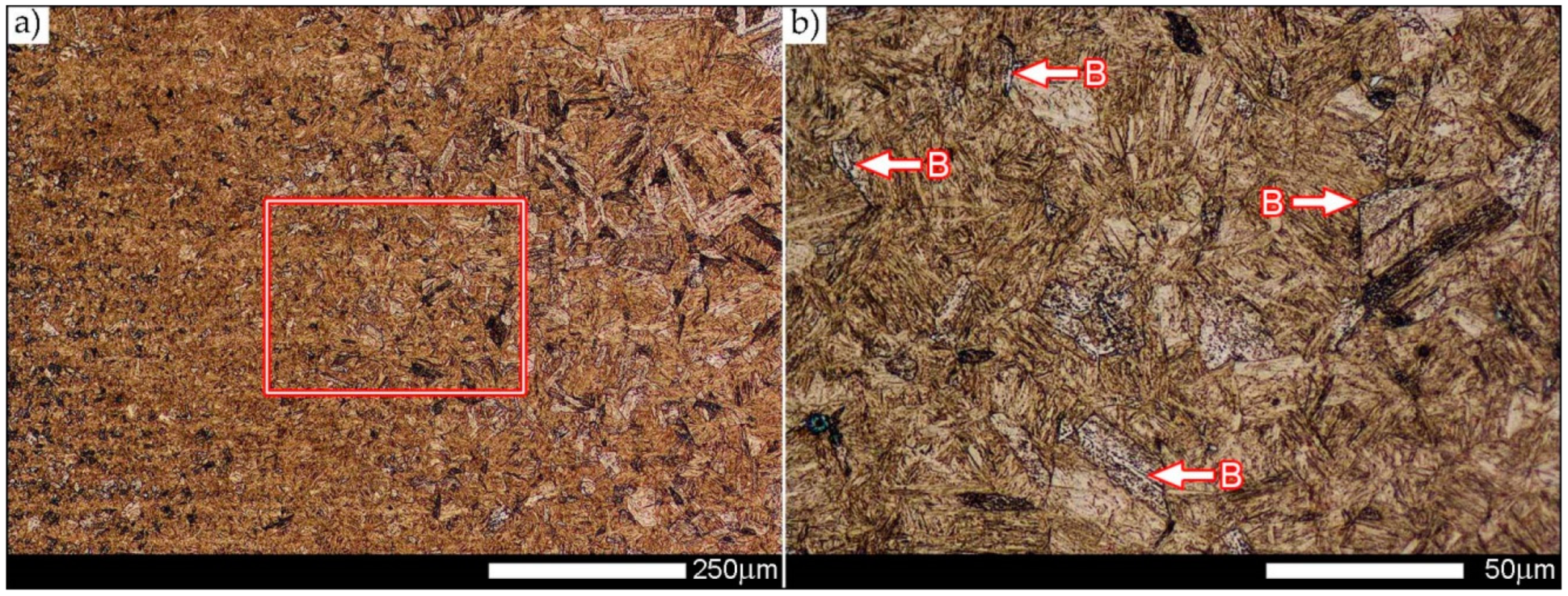

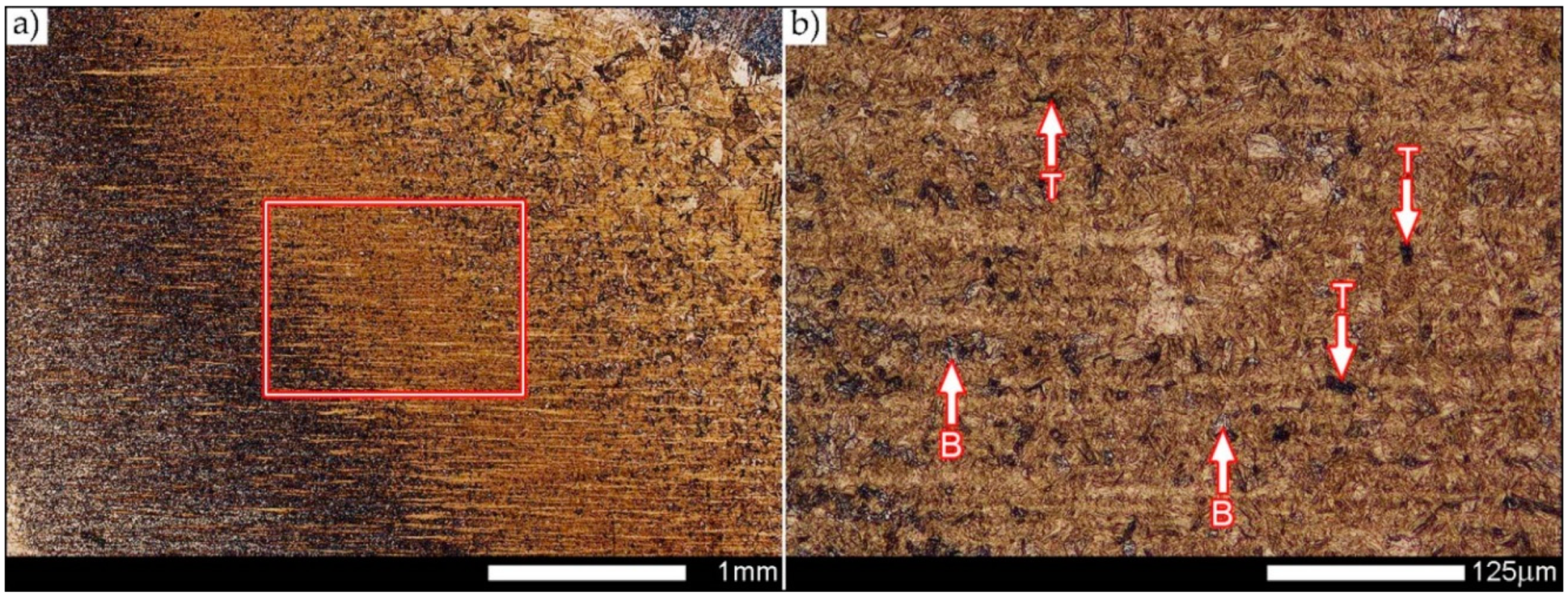

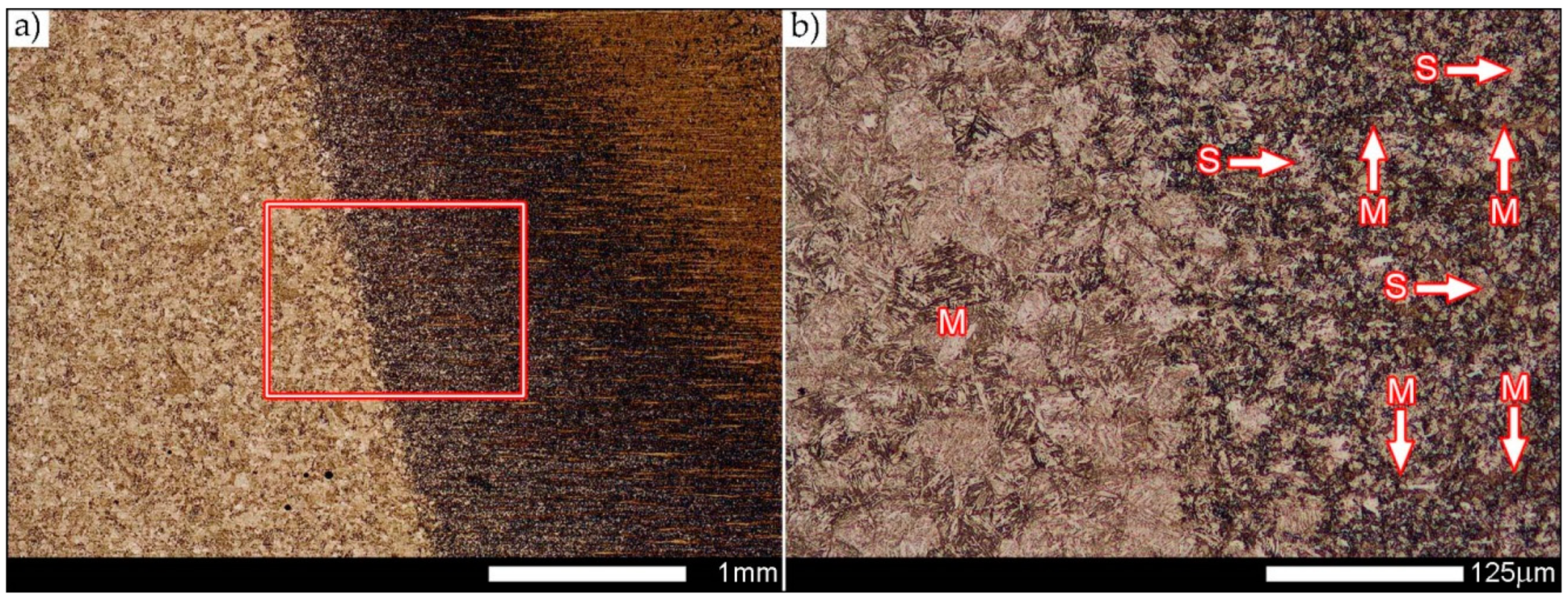

3.2. Results of Microscopic Examinations and Hardness Measurements

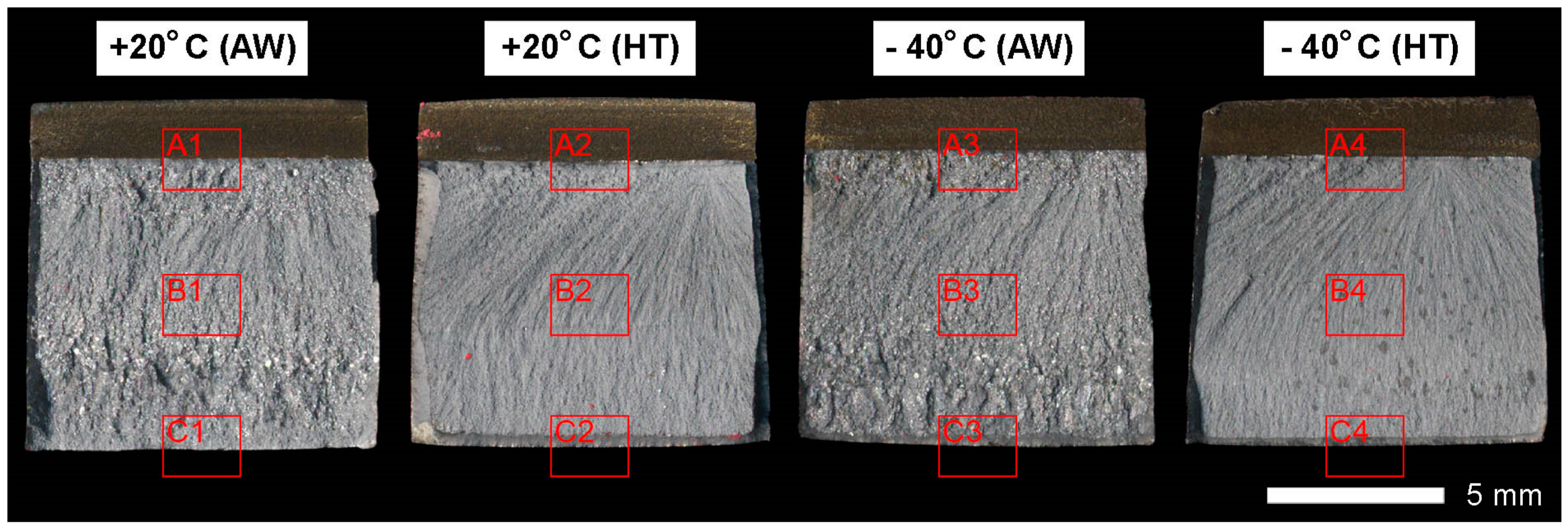

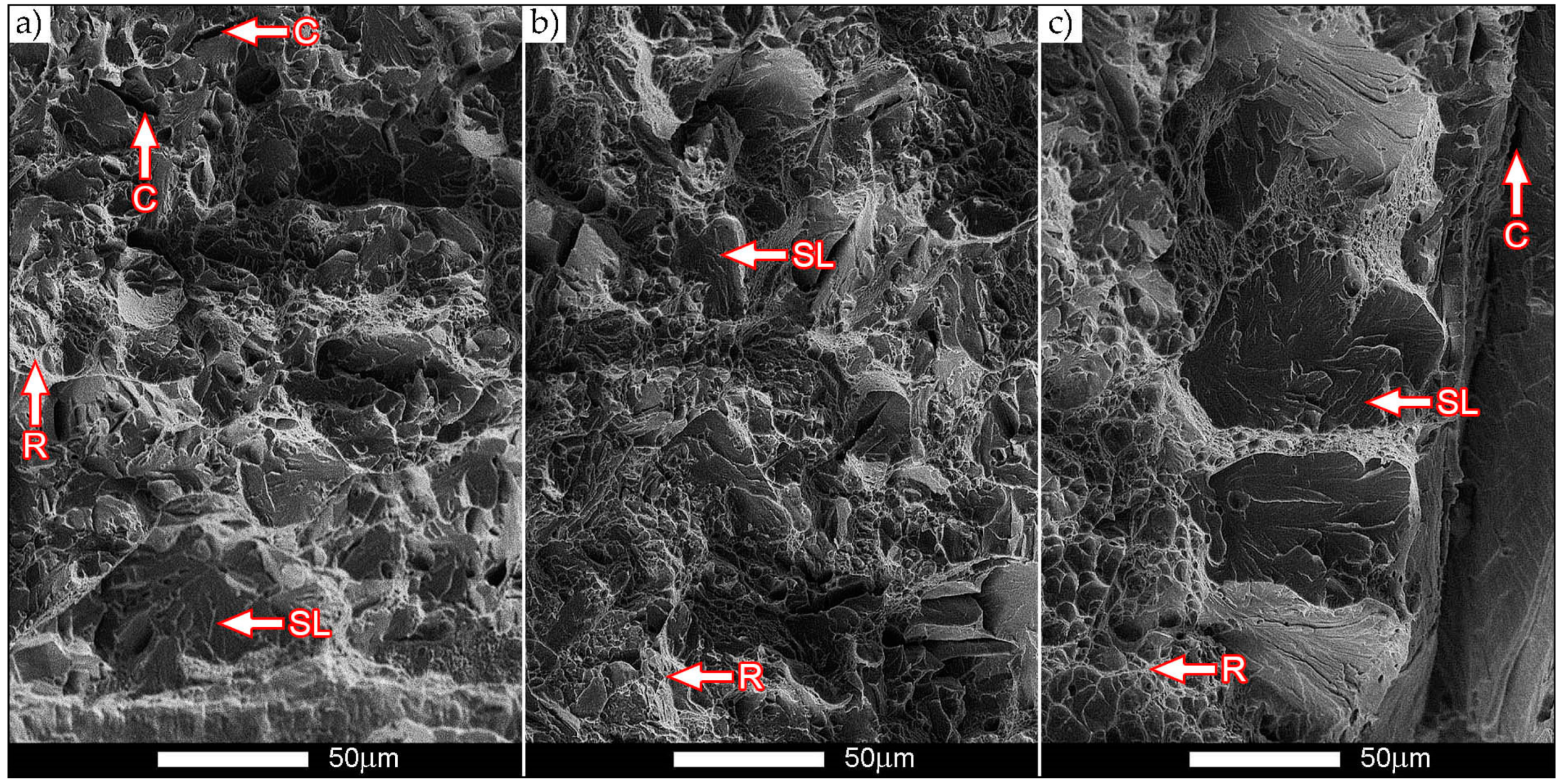

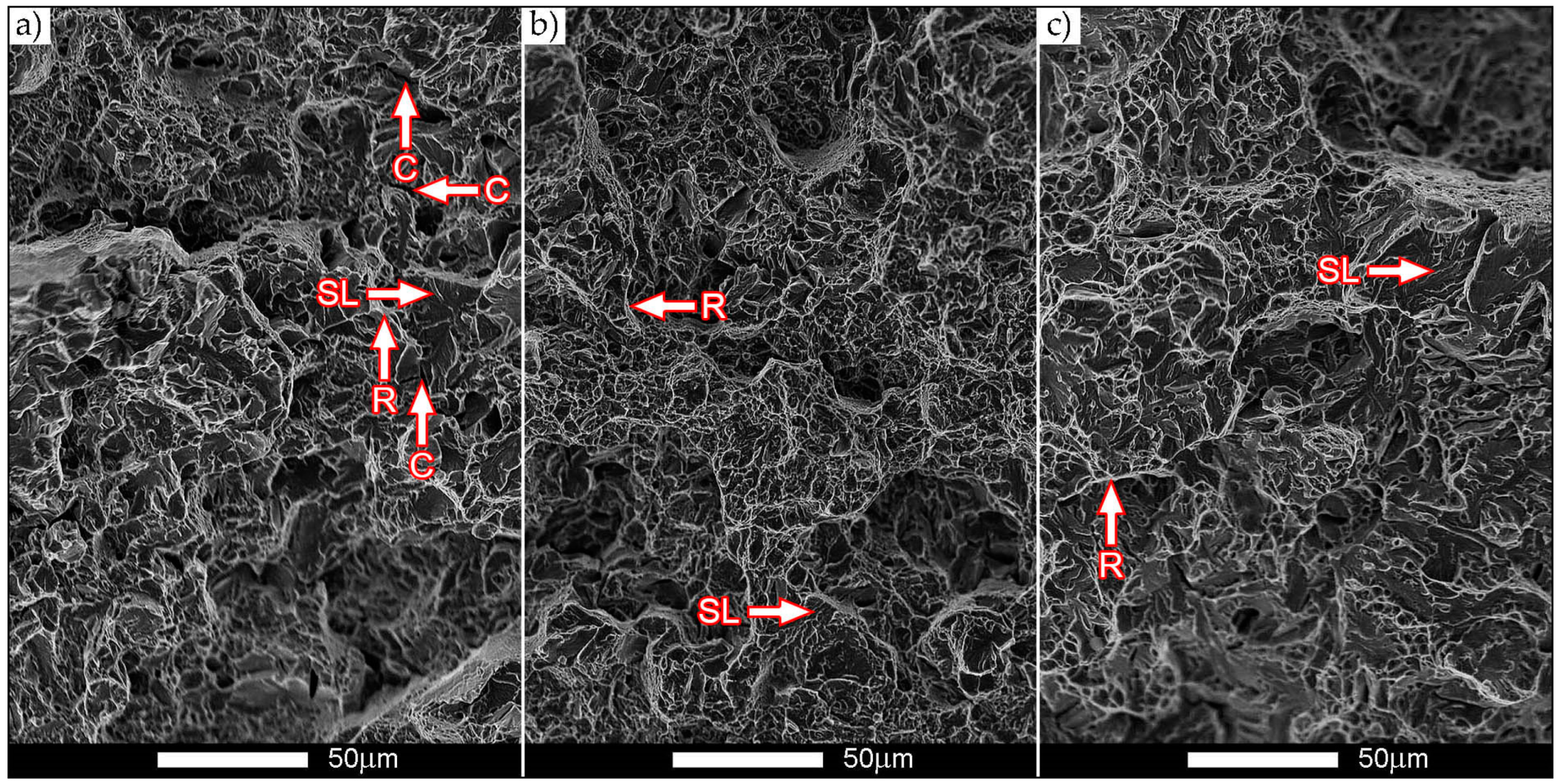

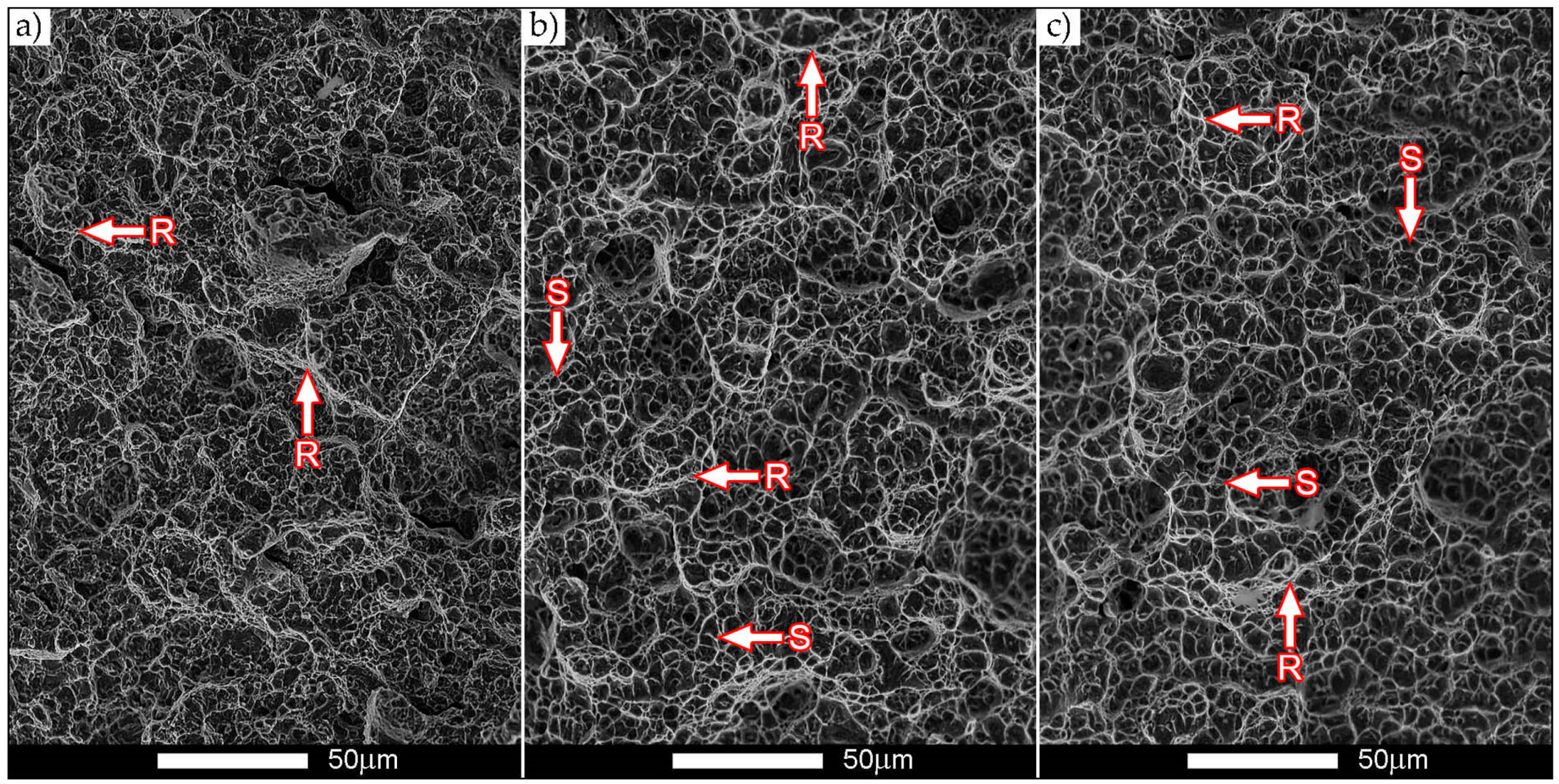

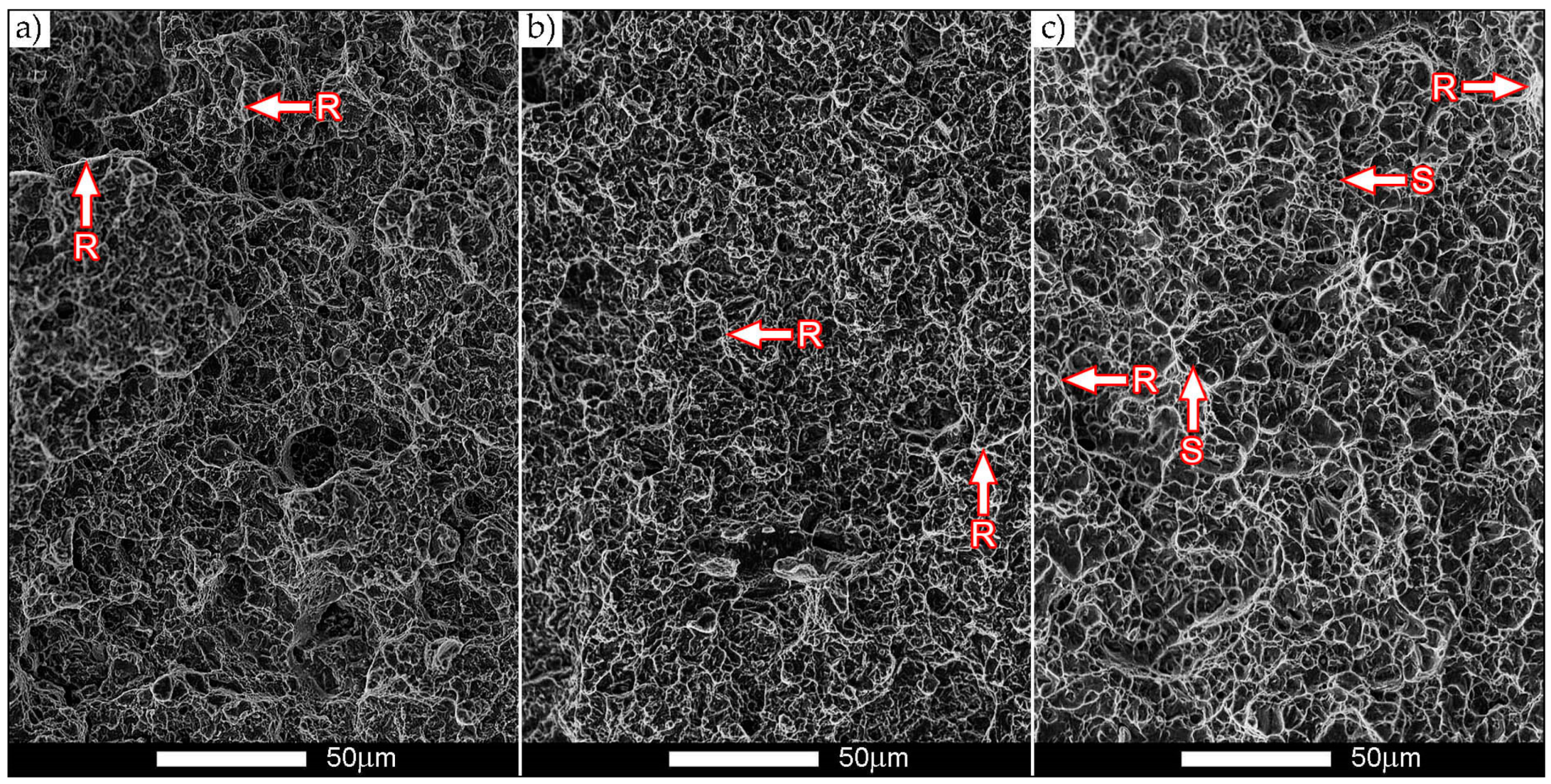

3.3. Results of Fractographic Analysis

4. Summary

- -

- After welding, a highly morphologically diversified microstructure occurs in the entire area of the welded joint that shows, in comparison to the base material, lower hardness levels, tensile strength and impact energy. The obtained and relatively low mechanical properties of the welded joint make it possible to state that welding operations result in lowering the abrasive-wear resistance of the steel Hardox Extreme. The expected drop can occur in both the weld material and the area of base material directly adjacent to the very wide heat-affected zone.

- -

- The additional thermal treatments carried-out after welding make it possible to favorably modify the structure in the entire welded joint and wide heat-affected zone, to obtain the structures similar to those of Hardox Extreme steel in the as-delivered condition from the manufacturer’s plant.

- -

- The obtained average hardness level of the welded joint after welding, amounting to only 17 J/cm2 at +20 °C, clearly indicates susceptibility of this steel to brittle cracking. From practical point of view, it excludes application of welding techniques for joining Hardox Extreme sheets (irrespective of the relatively very high average tensile strength Rm = 1278 MPa obtained) with no additional heat treatment operations. The above statement is additionally confirmed by the performed fractographic analysis.

- -

- Examination results of heat-treated welded joints of Hardox Extreme steel indicate a possibility of restoring structural, mechanical, and impact properties “degraded” as a result of welding to the level corresponding to the base material. In the case of tensile strength, the obtained result Rm = 1831 MPa makes a good reason for undertaking the problems of welding and heat treatment of the considered steel. An additional justification of this question is also obtained through heat treatment of other mechanical properties that are much better than those existing in the as-welded condition. In spite of a significant increase of the Rm value (and also of the yield point, not cited in the reference), a nearly 12% increase percentage reduction of area reaching Z = 29.1% (Table 5) was noted, as well as an increase of impact strength at ambient temperature to KCV = 27 J/cm2. It is worth noting that the brittleness threshold of constructional materials is accepted as impact strength of 35 J/cm2 [30], which results from maintaining at least 50% share of ductile fracture. Therefore, the obtained impact strength value after heat treatment and results of fractographic analysis make it possible to conclude that there was an occurrence of a favorable “shift” of plastic properties of the welded joint beyond the accepted brittleness threshold.

Funding

Acknowledgments

Conflicts of Interest

References

- SSAB Data Sheet Hardox. Available online: https://www.ssab.com/products/brands/hardox (accessed on 11 August 2019).

- Ilsenburger Grobblech GmbH Data Sheet Brinar 400. Available online: https://www.ilsenburger-grobblech.de/fileadmin/mediadb/ilg/infocenter/downloads/werkstoffblaetter/eng/abrasion_resistant_brinar400.pdf (accessed on 11 August 2019).

- Ilsenburger Grobblech GmbH Data Sheet Brinar 500. Available online: https://www.ilsenburger-grobblech.de/fileadmin/mediadb/ilg/infocenter/downloads/werkstoffblaetter/eng/abrasion_resistant_brinar500.pdf (accessed on 11 August 2019).

- Stal-Hurt Data Sheet Hardox. Available online: https://www.stal-hurt.com/ (accessed on 5 April 2019).

- ThyssenKrupp Steel Europe Data sheet XAR 600. Available online: https://www.flinkenberg.fi/wp-content/uploads/DATASHEET-XAR600.pdf (accessed on 5 April 2019).

- Bugłacki, H.; Smajdor, M. Mechanical Properties of Abrasion-Resistant Hardox 400 Steel and Their Welded Joints. Adv. Mater. Sci. 2003, 4, 5–8. [Google Scholar]

- Magdalena, M.; Robert, U.; Otakar, B. The impact of welding wire on the mechanical properties of welded joints. Mater. Eng. Mater. Inžinierstvo 2014, 21, 122–128. [Google Scholar]

- Eva, B.; Harold, M.; Pavol, R. Welding of High Strength Materials Used in the Manufacture of Special Equipment. Univ. Rev. 2014, 8, 51–61. [Google Scholar]

- Uzunali, U.Y.; Cuvalci, H. The effects of post weld heat treatment on the mechanical properties of tempered martensite and high strength steel welded joints. In Proceedings of the 2015 World Congress on Advances in Structural Engineering and Mechanics (ASEM15), Incheon, Korea, 25–29 August 2015. [Google Scholar]

- Pękalski, G.; Haimann, K.; Konat, Ł.; Koniarek, K.; Krugła, M.; Mroczkowski, L.; Orłowski, J.; Oskwarek, M.; Ptak, T.; Szymczak, H. Material Testing of Hardox 400 and Hardox 500; Wrocław Univertsity of Science and Technology Report SPR: Wrocław, Poland, 2005. (In Polish) [Google Scholar]

- Konat, Ł. Structures and Properties of Hardox Steels and their Application Possibilities in Conditions of Abrasive Wear and Dynamic Loads. Ph.D. Thesis, Wroclaw University of Technology, Wroclaw, Poland, 2007. (In Polish). [Google Scholar]

- Dudziński, W.; Konat, Ł.; Pękalski, G. Modern constructional steels. In Maintenance Strategy of Surface Mining Machines and Facilities with High Degree of Technical Degradation; Dudek, D., Ed.; Publishing House of Wroclaw University of Technology: Wroclaw, Poland, 2013; pp. 346–366. (In Polish) [Google Scholar]

- Dudziński, W.; Konat, Ł.; Pękalski, G. Structural and strength characteristics of wear-resistant martensitic steels. Arch. Foundry Eng. 2008, 8, 21–26. [Google Scholar]

- Cegiel, L.; Konat, Ł.; Pawłowski, T.; Pękalski, G. Hardox Steels New generations of construction materials for surface mining machinery. Brown Coal 2006, 3, 24–29. (In Polish) [Google Scholar]

- Pękalski, G.; Konat, Ł.; Oskwarek, M. Macro- and microstructural properties of welded joints of Hardox 400 and Hardox 500 steels. In Proceedings of the XIX Scientific Conference on Development Problems of Working Machines, Zakopane, Poland, 23–26 January 2006. [Google Scholar]

- Frydman, S.; Konat, Ł.; Pękalski, G. Structure and hardness changes in welded joints of Hardox steels. Arch. Civ. Mech. Eng. 2008, 8, 15–27. [Google Scholar] [CrossRef]

- Konat, Ł.; Białobrzeska, B.; Białek, P. Effect of Welding Process on Microstructural and Mechanical Characteristics of Hardox 600 Steel. Metals 2017, 7, 349. [Google Scholar] [CrossRef]

- Pawlak, K.; Białobrzeska, B.; Konat, Ł. The influence of austenitizing temperature on prior austenite grain size and resistance to abrasion wear of selected low-alloy boron steel. Arch. Civ. Mech. Eng. 2016, 16, 913–926. [Google Scholar] [CrossRef]

- Łętkowska, B. Influence of Heat Treatment on Structure and Selected Properties of B27 and 28MCB5 Steels. Ph.D. Thesis, Wroclaw University of Technology, Wroclaw, Poland, 2013. (In Polish). [Google Scholar]

- Konat, Ł.; Pękalski, G. Structures and selected properties of Hardox steels in the context of their use in surface mining machinery construction. In Proceedings of the XV International Symposium on Mine Planning Equipment Selection (MPES 2006), Torino, Italy, 20–22 September 2006. [Google Scholar]

- Frydman, S.; Konat, Ł.; Łętkowska, B.; Pękalski, G. Impact resistance and fractography of low-alloy martensitic steels. Arch. Foundry Eng. 2008, 8, 89–94. [Google Scholar]

- Dudziński, W.; Konat, Ł.; Pękalska, L.; Pękalski, G. Structures and properties of Hardox 400 and Hardox 500 steels. Mater. Eng. 2006, 3, 139–142. (In Polish) [Google Scholar]

- Dudziński, W.; Konat, Ł.; Białobrzeska, B. Fractographic analysis of selected boron steels subjected to impact testing. Arch. Met. Mater. 2015, 60, 2373–2378. [Google Scholar] [CrossRef]

- Dudziński, W.; Białobrzeska, B.; Konat, Ł. Comparative analysis of structural and mechanical properties of selected low-alloy boron-containing abrasive-wear resistant steels. In Polish Metallurgy in the Years 2011–2014; Świątkowski, K., Ed.; Akapit: Kraków, Poland, 2014; pp. 871–888. (In Polish) [Google Scholar]

- Białobrzeska, B.; Konat, Ł.; Jasiński, R. The influence of austenite grain size on the mechanical properties of low-alloy steel with boron. Metals 2017, 7, 26. [Google Scholar] [CrossRef]

- Białobrzeska, B.; Konat, Ł.; Jasiński, R. Fractographic Analysis of Brinar 400 and Brinar 500 Steels in Impact Testing. Scanning 2018, 2018, 17. [Google Scholar] [CrossRef] [PubMed]

- Graville, B.A. Cold Cracking in welds in HSLA steels, welding of HSLA (Microalloyed) structural steels. In Proceedings of the AIM/ASM Conference, Rome, Italy, 9–12 November 1976. [Google Scholar]

- ESAB. Welding Consumables; ESAB: Gothenburg, Swedish, 2012; p. H17. [Google Scholar]

- Maciejny, A. Brittleness of Metals; Publishing House Śląsk: Katowice, Poland, 1973. (In Polish) [Google Scholar]

- Wyrzykowski, J.W.; Pleszakow, E.; Sieniawski, J. Deformation and Cracking of Metals; WNT: Warszawa, Poland, 1999. (In Polish) [Google Scholar]

| Grade of Steel | Rp0.2 | Rm | A5 | KCV−40 | HBW |

|---|---|---|---|---|---|

| [MPa] | [MPa] | [%] | [J/cm2] | ||

| Hardox 400 | 1100 | 1250 | 10 | 56 | 370–430 |

| Hardox 450 | 1200 | 1400 | 10 | 50 | 425–475 |

| Hardox 500 | 1400 | 1550 | 10 | 46 | 470–530 |

| Hardox 600 | 1650 | 2000 | 7 | 25 | 570–640 |

| Hardox Extreme | NA | NA | NA | NA | 650–700 |

| Brinar 400 | 900 | 1200 | 12 | 25 (−20 °C) | 340–440 |

| Brinar 500 | 1350 | 1500 | 8 | 25 (−20 °C) | 480 |

| XAR 600 | 1700 | 2000 | 8 | 25 (−20 °C) | >550 |

| Element | Hardox | Brinar | XAR 600 | |||||

|---|---|---|---|---|---|---|---|---|

| 400 | 450 | 500 | 600 | Extreme | 400 | 500 | ||

| Selected Element [wt%] | ||||||||

| C | 0.32 | 0.26 | 0.30 | 0.45 | 0.47 | 0.18 | 0.28 | 0.40 |

| Mn | 1.60 | 1.60 | 1.60 | 1.40 | 1.40 | 2.00 | 1.50 | 1.50 |

| Si | 0.70 | 0.70 | 0.70 | 0.70 | 0.50 | 0.50 | 0.80 | 0.80 |

| P | 0.025 | 0.025 | 0.020 | 0.015 | 0.015 | 0.015 | 0.020 | 0.025 |

| S | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.005 | 0.005 | 0.010 |

| Cr | 2.40 | 1.40 | 1.50 | 1.20 | 1.20 | 1.55 | 1.50 | 1.50 |

| Ni | 1.50 | 1.50 | 1.50 | 2.50 | 2.50 | NA | NA | 1.50 |

| Mo | 0.60 | 0.60 | 0.60 | 0.70 | 0.80 | 0.60 | 0.40 | 0.50 |

| B | 0.004 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | NA | 0.005 |

| # [mm] | 8–20 | 10–19.9 | 4–13 | 6–35 | 8–19 | ≤80 | ≤60 | 15 |

| CEVT | 0.44 | 0.48 | 0.51 | 0.66 | 0.66 | NA | NA | 0.79 |

| CETT | 0.28 | 0.36 | 0.37 | 0.55 | 0.55 | NA | NA | 0.53 |

| Element | Hardox Steels | Brinar Steels | XAR 600 | |||||

|---|---|---|---|---|---|---|---|---|

| 400 | 450 | 500 | 600 | Extreme | 400 | 500 | ||

| Selected Element [wt%] | ||||||||

| C | 0.17 | 0.17 | 0.28 | 0.45 | 0.48 | 0.17 | 0.28 | 0.37 |

| Mn | 1.00 | 1.00 | 0.69 | 0.51 | 0.52 | 1.14 | 0.95 | 0.85 |

| Si | 0.37 | 0.32 | 0.26 | 0.16 | 0.16 | 0.22 | 0.66 | 0.19 |

| P | 0.010 | 0.010 | 0.011 | 0.012 | 0.010 | 0.008 | 0.012 | 0.014 |

| S | 0.002 | 0.000 | 0.001 | 0.002 | 0.001 | 0.000 | 0.000 | 0.001 |

| Cr | 0.22 | 0.45 | 0.66 | 0.33 | 0.89 | 0.60 | 0.84 | 0.83 |

| Ni | 0.05 | 0.05 | 0.08 | 1.98 | 1.96 | 0.38 | 0.01 | 1.21 |

| Mo | 0.01 | 0.08 | 0.03 | 0.14 | 0.13 | 0.30 | 0.20 | 0.15 |

| V | 0.004 | 0.005 | 0.010 | 0.009 | 0.008 | 0.039 | 0.006 | 0.002 |

| Cu | 0.006 | 0.018 | 0.016 | 0.016 | 0.021 | 0.010 | 0.008 | 0.030 |

| Al | 0.035 | 0.032 | 0.050 | 0.031 | 0.034 | 0.073 | 0.039 | 0.097 |

| Ti | 0.020 | 0.016 | 0.005 | 0.006 | 0.006 | 0.009 | 0.012 | 0.003 |

| Nb | 0.010 | 0.000 | 0.000 | 0.005 | 0.001 | 0.043 | 0.023 | 0.009 |

| Co | 0.010 | 0.016 | 0.017 | 0.026 | 0.022 | 0.001 | 0.005 | 0.005 |

| B | 0.0016 | 0.0014 | 0.0016 | 0.0026 | 0.0025 | 0.0023 | 0.0008 | 0.0021 |

| # [mm] | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 15 |

| CEV | 0.38 | 0.44 | 0.54 | 0.76 | 0.90 | 0.58 | 0.65 | 0.79 |

| CET | 0.28 | 0.30 | 0.39 | 0.58 | 0.64 | 0.36 | 0.43 | 0.54 |

| Weld Metal | C | Mn | Si | Cr | Ni | Mo | Rp0.2 | Rm | A4 | KCV−40 |

|---|---|---|---|---|---|---|---|---|---|---|

| Chemical Composition [%] | [MPa] | [%] | [J/cm2] | |||||||

| OK Autrod 13.43 + OK Flux 10.62 | 0.11 | 1.50 | 0.25 | 0.60 | 2.20 | 0.50 | 700 | 800 | 21 | 94 |

| Specimen | Heat Treatment Parameters | Rm | Z | KCV+20 | KCV−40 | ||||

|---|---|---|---|---|---|---|---|---|---|

| [MPa] | [%] | [J/cm2] | |||||||

| UTS-1 | No treatment | 1329 | 1278 | 26.0 | 17.4 | --- | |||

| UTS-2 | 1263 | 16.3 | |||||||

| UTS-3 | 1242 | 10.1 | |||||||

| KCV-1 | --- | 18.7 | 17 | --- | |||||

| KCV-2 | 16.4 | ||||||||

| KCV-3 | 16.6 | ||||||||

| KCV-4 | --- | 14.3 | 18 | ||||||

| KCV-5 | 12.7 | ||||||||

| KCV-6 | 26.1 | ||||||||

| UTS-25 | Normalization: 800 °C/1h/Air + Quenching: 850 °C/20′/Oil + Tempering: 100 °C/20h/Air | 1831 | 1831 | 30.6 | 29.1 | --- | |||

| UTS-26 | 1823 | 31.6 | |||||||

| UTS-28 | 1839 | 25.2 | |||||||

| KCV-7 | --- | 27.1 | 27 | --- | |||||

| KCV-8 | 27.9 | ||||||||

| KCV-9 | 25.9 | ||||||||

| KCV-10 | --- | 21.6 | 19 | ||||||

| KCV-11 | 17.1 | ||||||||

| KCV-12 | 19.0 | ||||||||

| Element | X | Y | Z | OK 13.43 + OK Flux 10.62 | Hardox Extreme |

|---|---|---|---|---|---|

| Chemical Composition [wt%] | |||||

| C | 0.31 | 0.32 | 0.31 | 0.10 | 0.48 |

| Mn | 0.81 | 0.82 | 0.81 | 1.22 | 0.52 |

| Si | 0.23 | 0.23 | 0.23 | 0.30 | 0.16 |

| P | 0.013 | 0.013 | 0.014 | 0.020 | 0.010 |

| S | 0.002 | 0.002 | 0.002 | 0.002 | 0.001 |

| Cr | 0.81 | 0.82 | 0.81 | 0.50 | 0.89 |

| Ni | 2.06 | 2.08 | 2.07 | 1.65 | 1.96 |

| Mo | 0.23 | 0.23 | 0.22 | 0.31 | 0.13 |

| V | 0.009 | 0.009 | 0.010 | 0.009 | 0.008 |

| Cu | 0.040 | 0.038 | 0.041 | 0.105 | 0.021 |

| Al | 0.020 | 0.021 | 0.020 | 0.013 | 0.034 |

| Ti | 0.004 | 0.004 | 0.005 | 0.003 | 0.006 |

| Nb | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 |

| Co | 0.017 | 0.016 | 0.018 | 0.006 | 0.022 |

| B | 0.0021 | 0.0021 | 0.0021 | 0.0014 | 0.0025 |

| CEV | 0.79 | 0.80 | 0.80 | 0.59 | 0.90 |

| CET | 0.51 | 0.51 | 0.51 | 0.33 | 0.64 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konat, Ł. Structural Aspects of Execution and Thermal Treatment of Welded Joints of Hardox Extreme Steel. Metals 2019, 9, 915. https://doi.org/10.3390/met9090915

Konat Ł. Structural Aspects of Execution and Thermal Treatment of Welded Joints of Hardox Extreme Steel. Metals. 2019; 9(9):915. https://doi.org/10.3390/met9090915

Chicago/Turabian StyleKonat, Łukasz. 2019. "Structural Aspects of Execution and Thermal Treatment of Welded Joints of Hardox Extreme Steel" Metals 9, no. 9: 915. https://doi.org/10.3390/met9090915