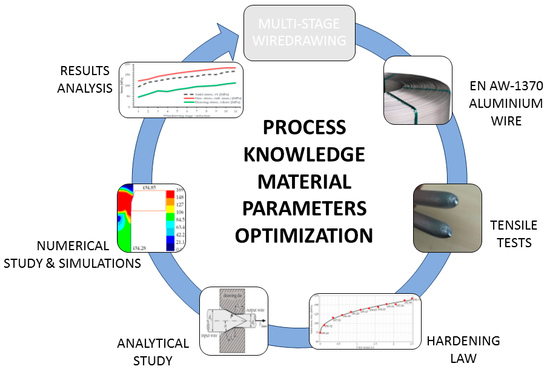

Analysis, Validation and Optimization of the Multi-Stage Sequential Wiredrawing Process of EN AW-1370 Aluminium

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material Object of Study

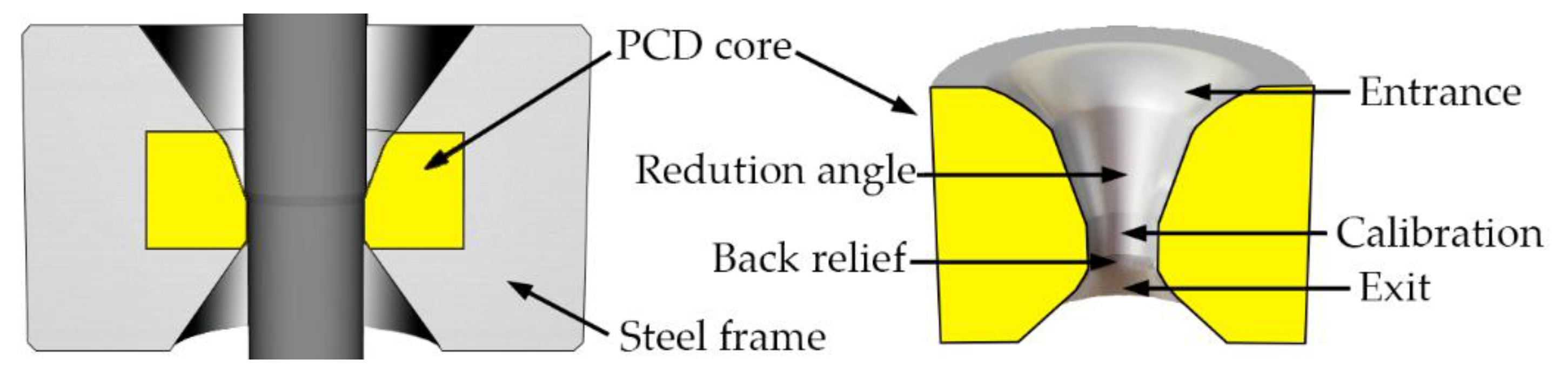

2.2. Equipment, Tooling and Lubrication

2.3. The Finite Element Method Implementation: Deform 2D Software

2.4. Process Design by the Analytical Method: PullWorks Software

3. Results and Discussion

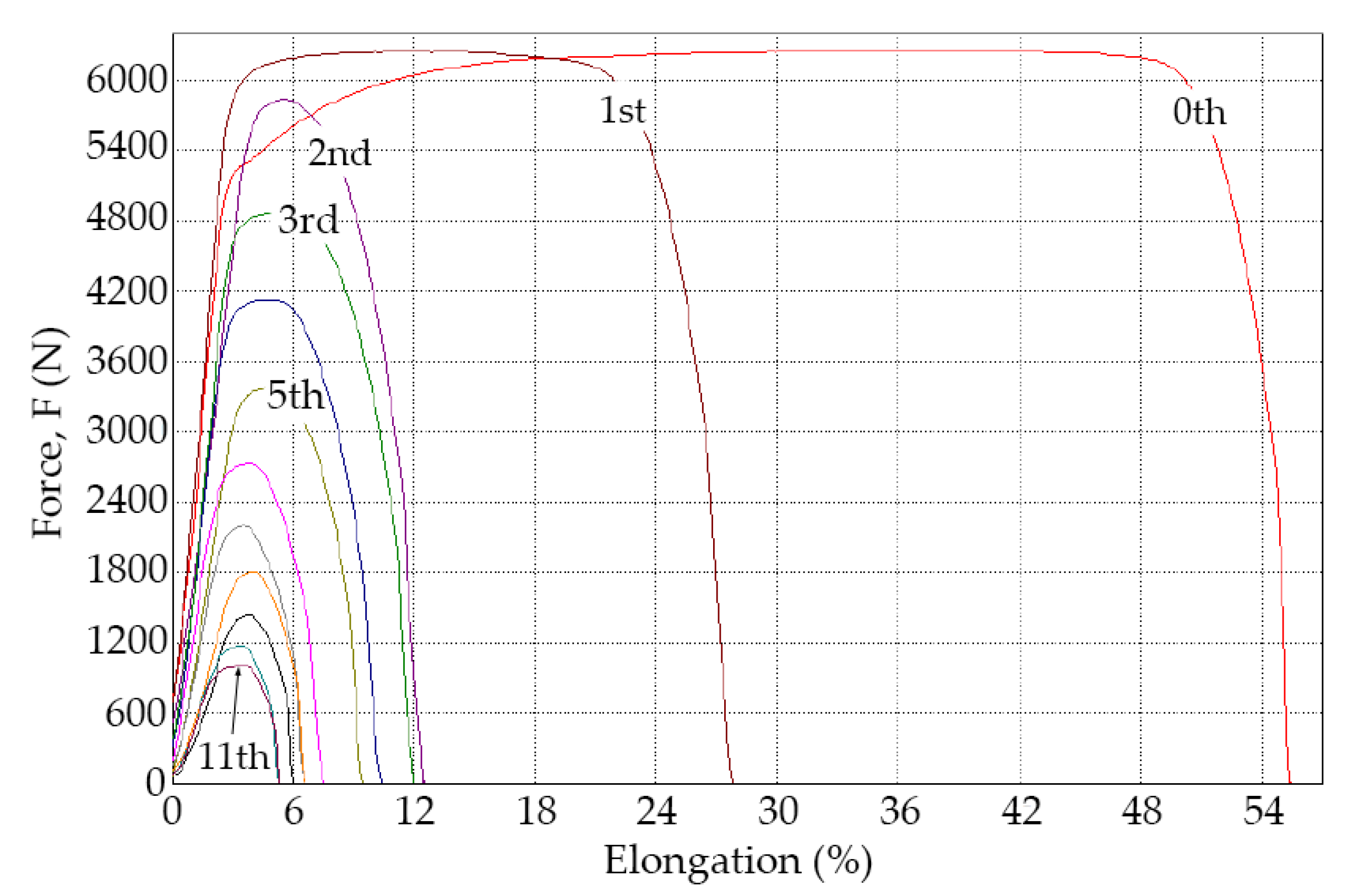

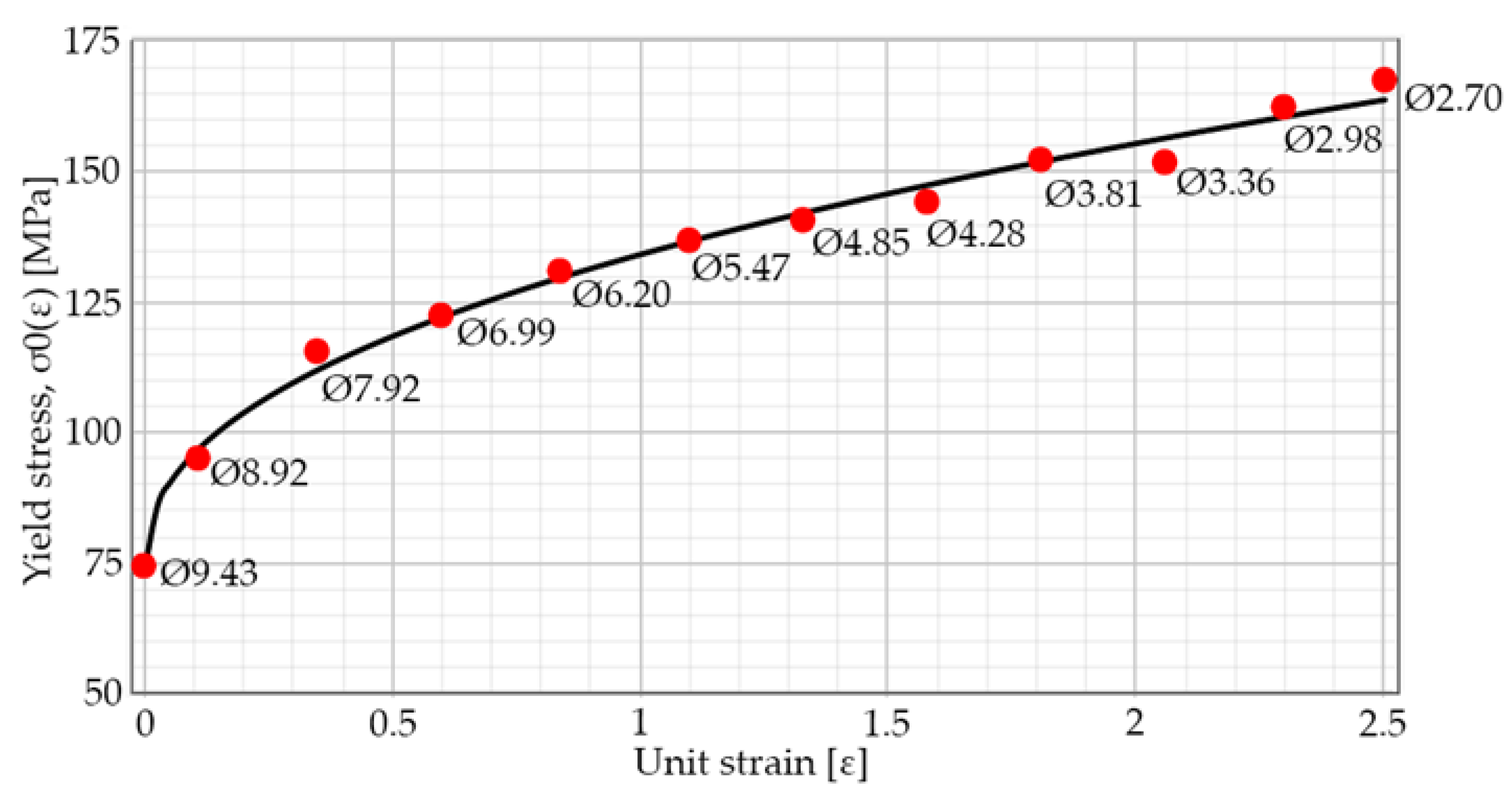

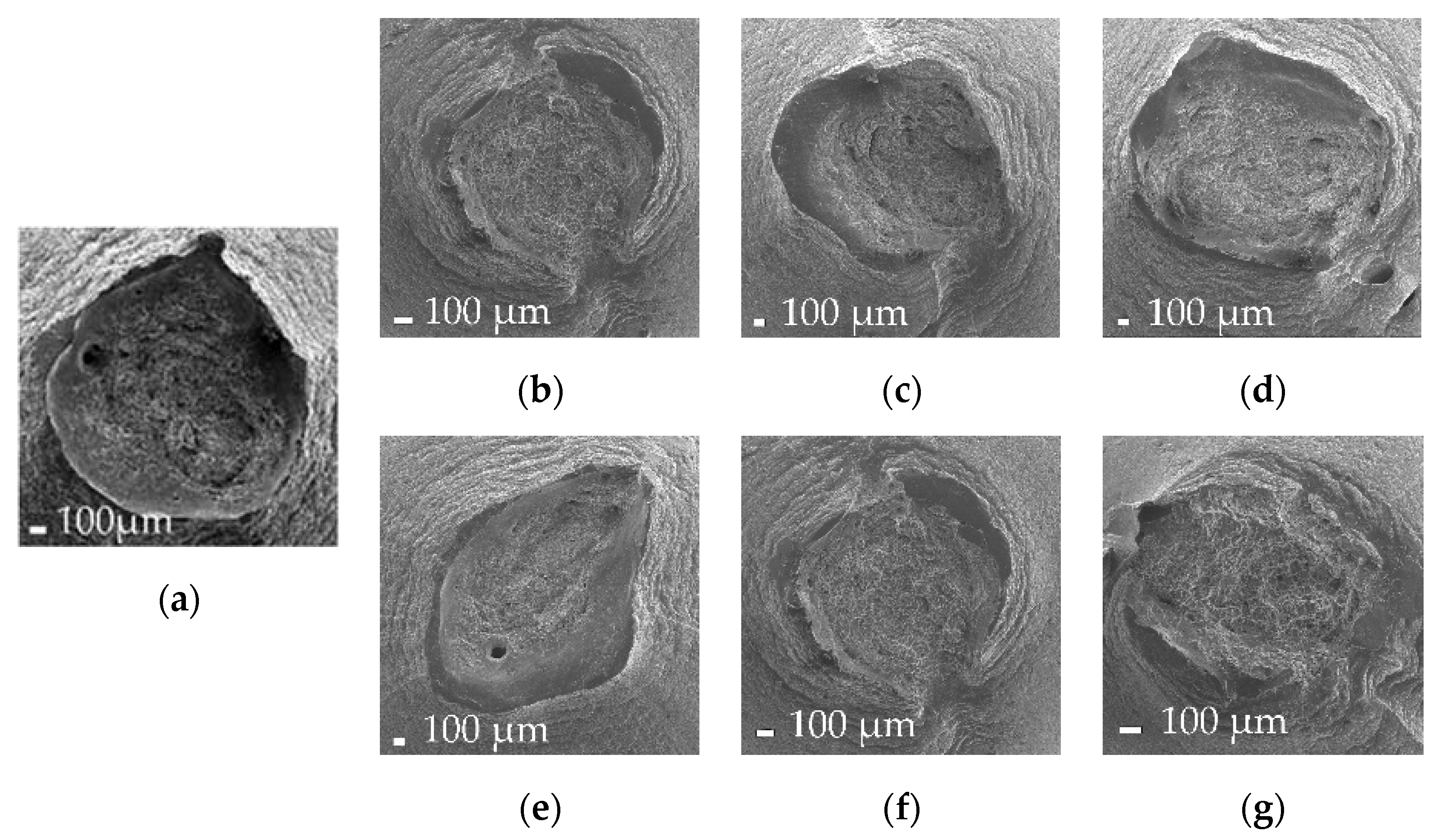

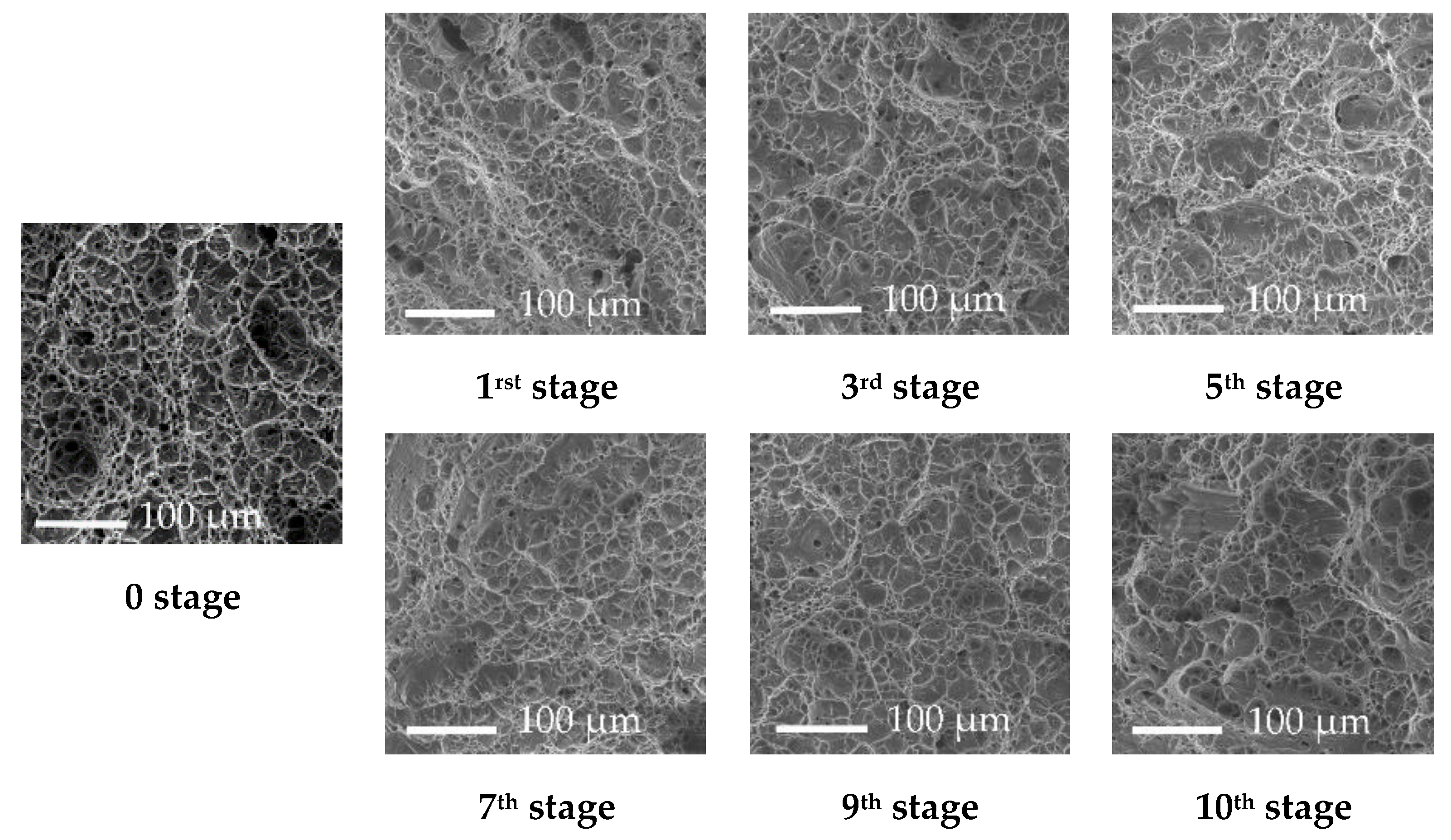

3.1. Strain Hardening Law Definition and Study of the Samples

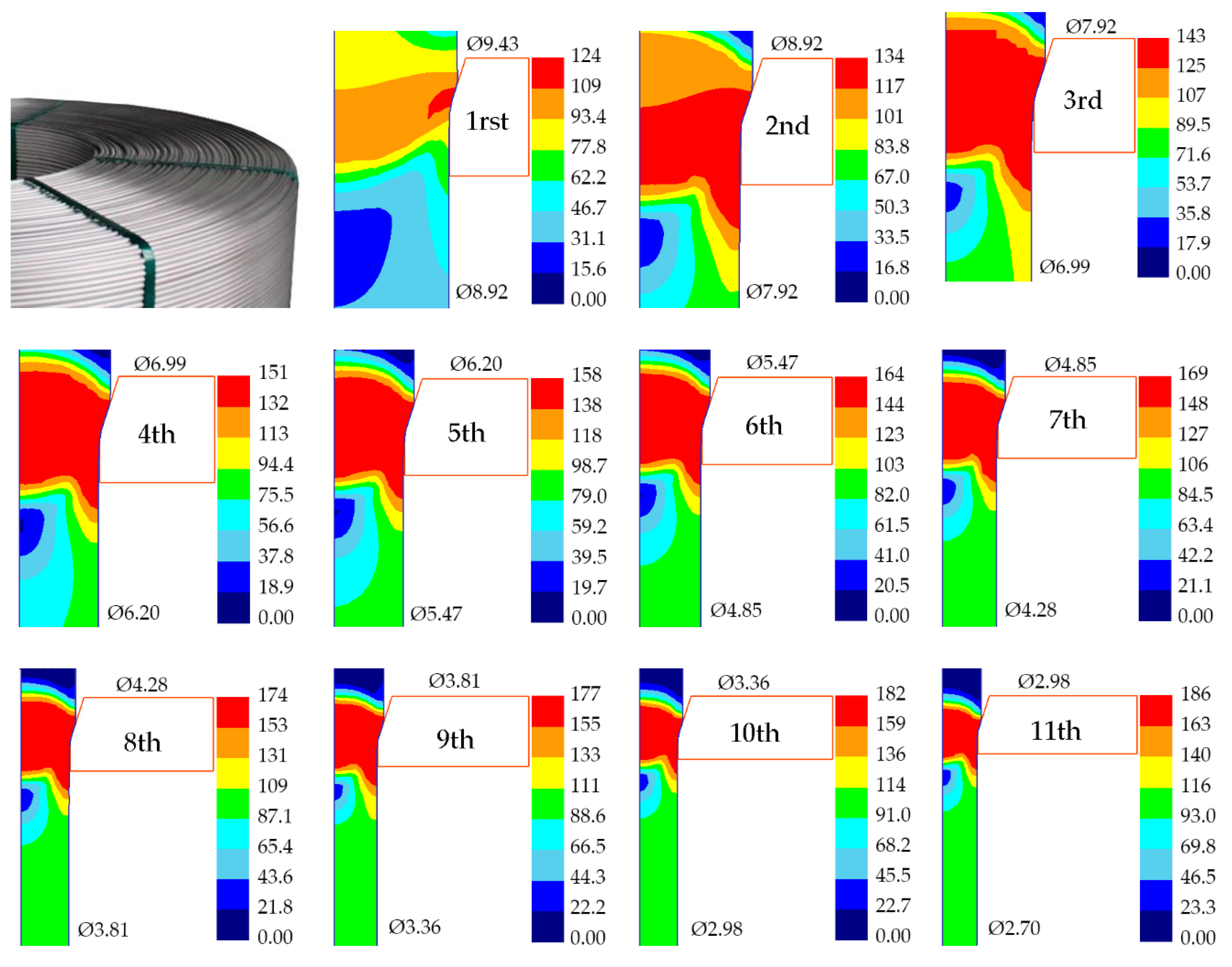

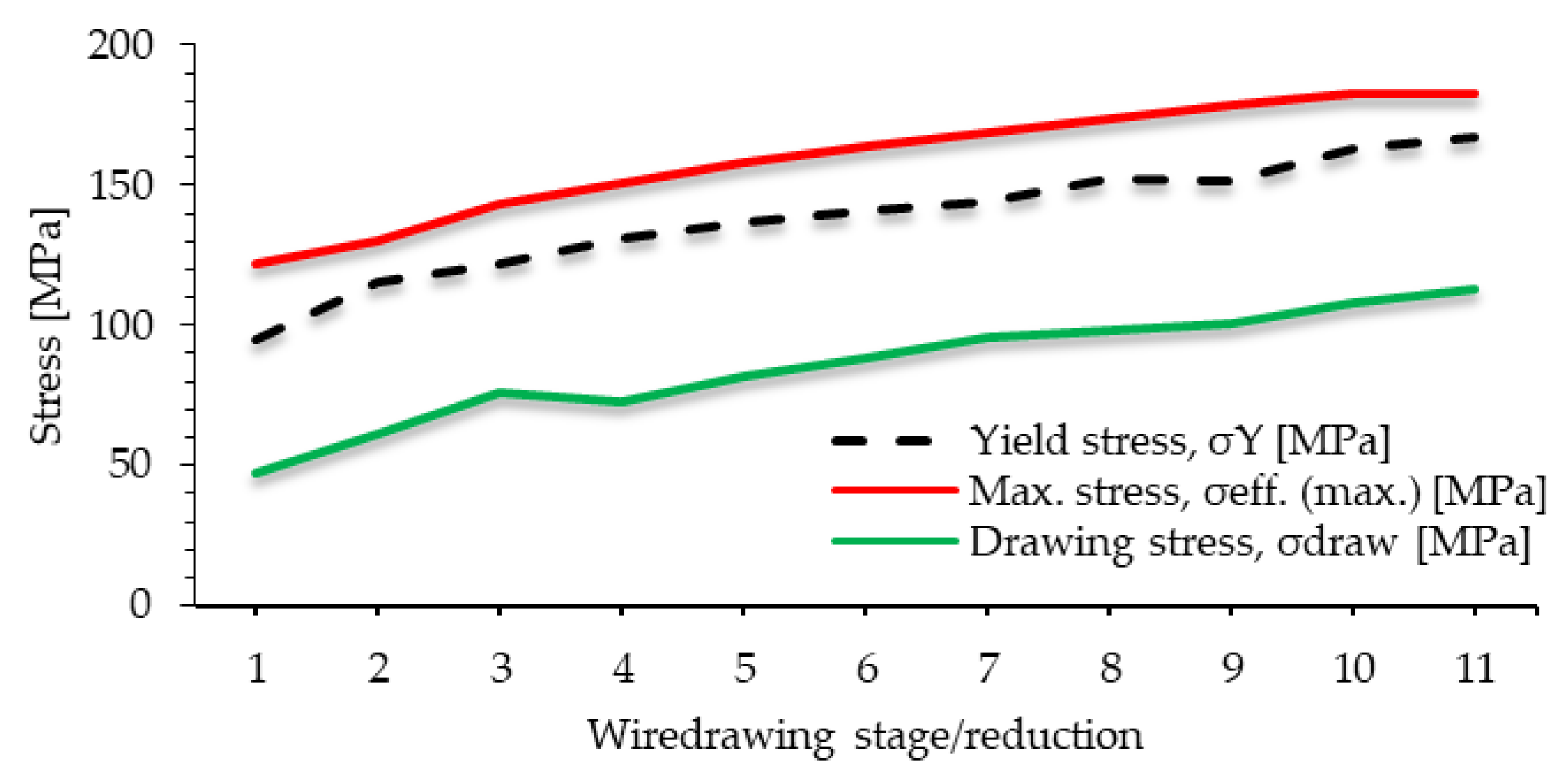

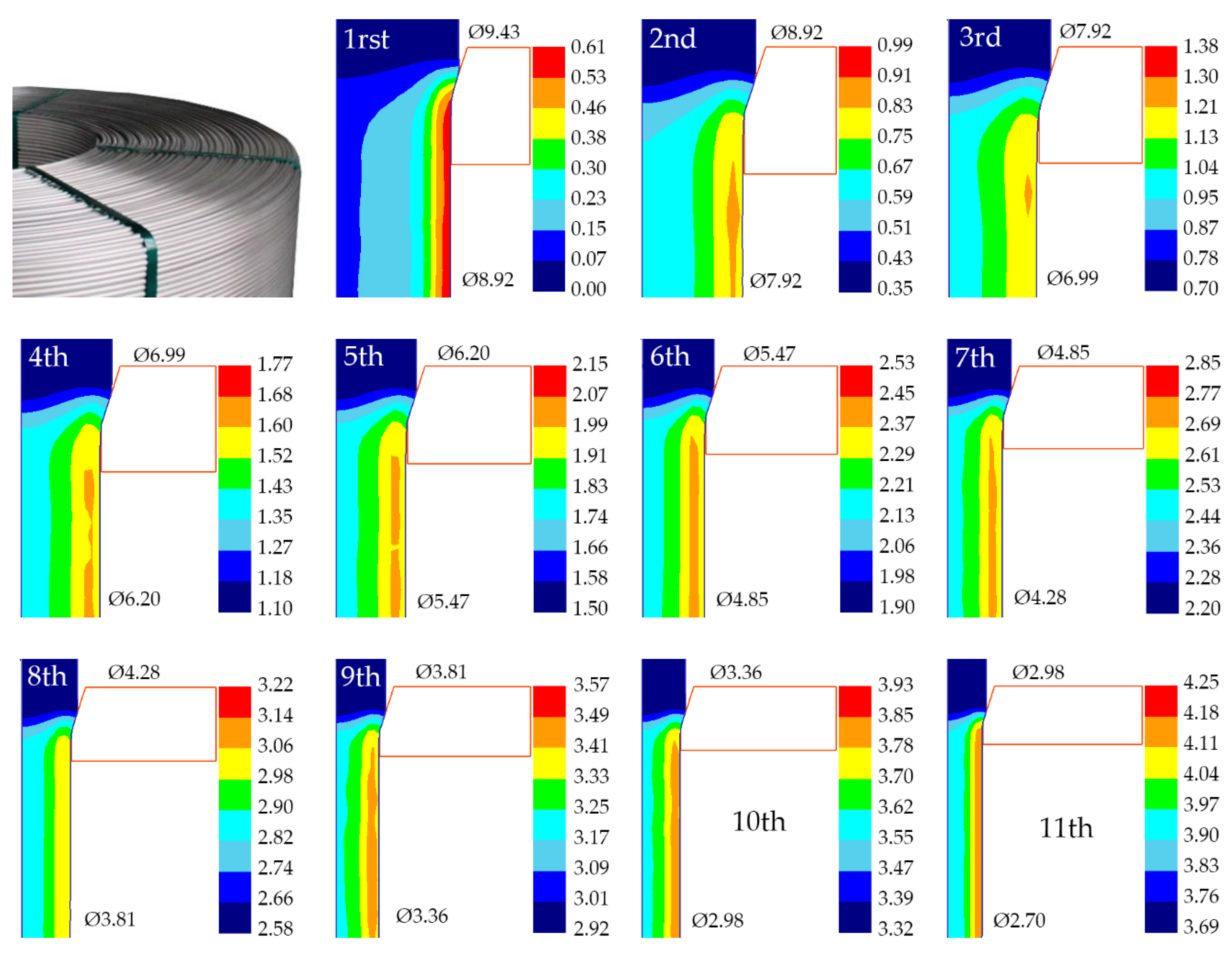

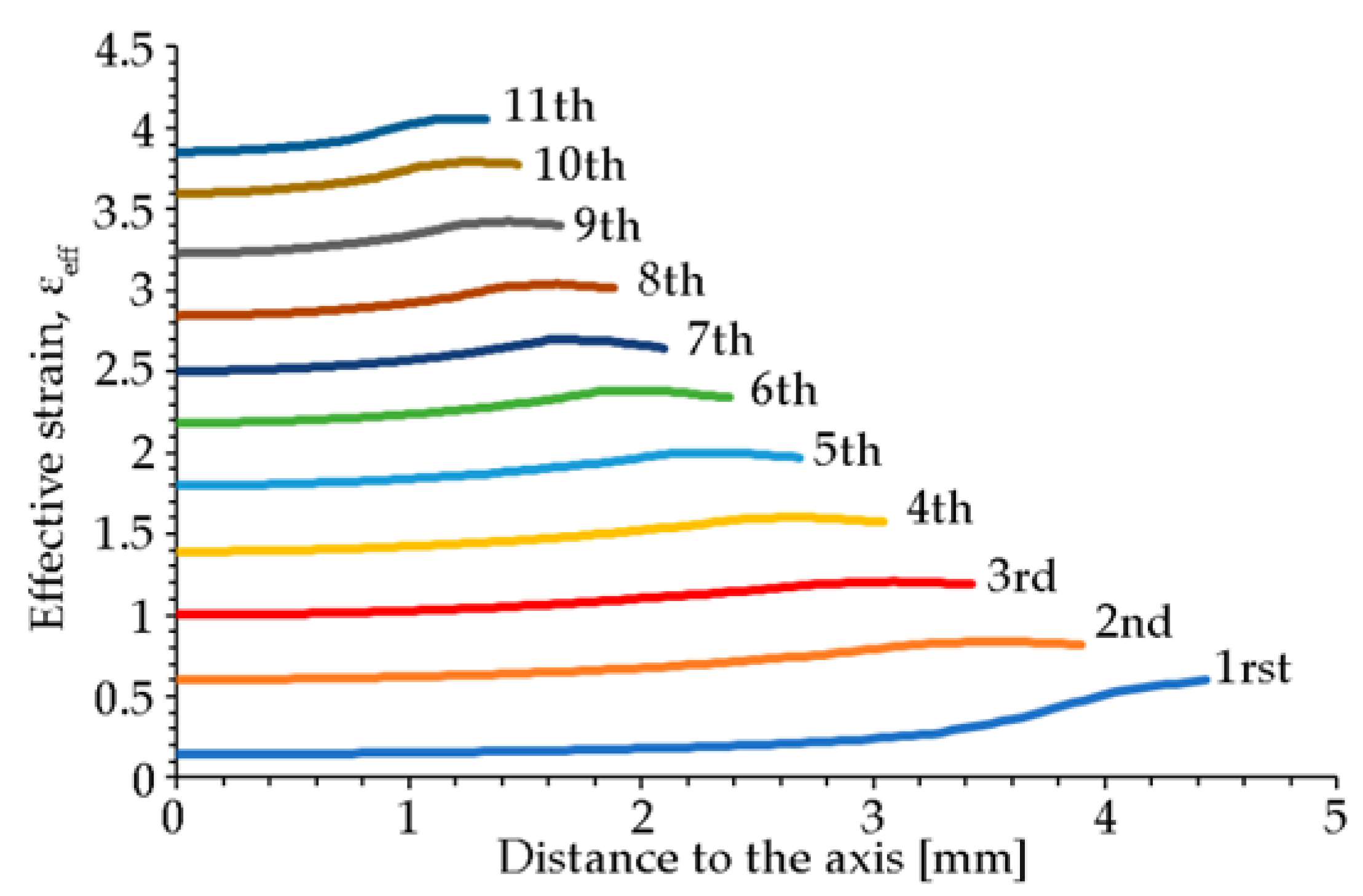

3.2. Simulations by the Finite Element Method

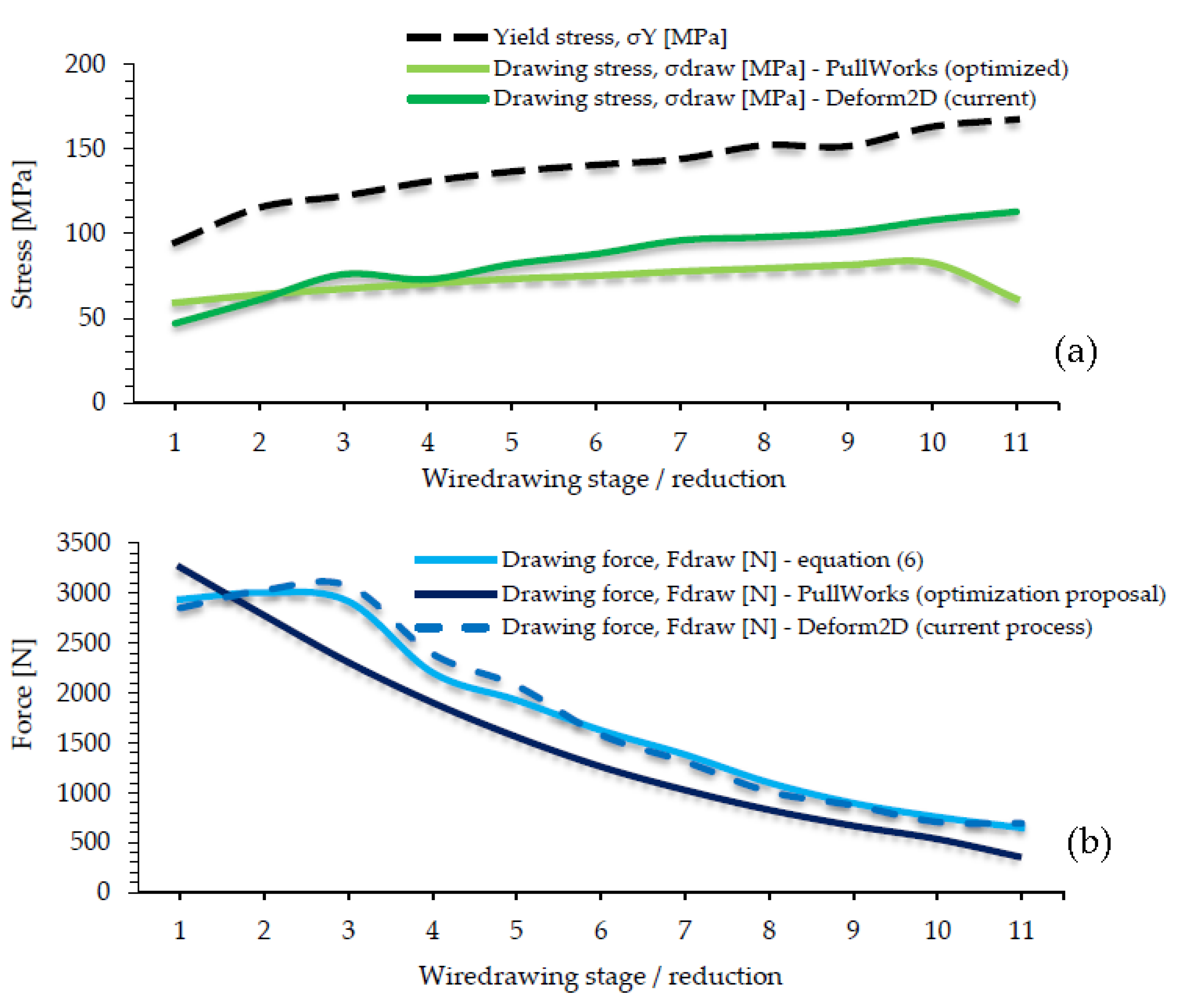

3.3. Proposal for the Optimization of the Industrial Wiredrawing Process Sequence Design

4. Conclusions

- The strain distribution observed in the simulations indicates a greater degree of accumulated strain near the surface of the wire in all the stages of the process. This aspect entails a greater degree of surface hardening by cold deformation and a greater involvement of the residual stresses in this zone in the section of the drawn wire.

- The drawing stress (σdraw) never exceeds the value of the yield limit of the deformed metal (σY), so that the drawn wire never undergoes unwanted deformations at its exit from the die. This fact has been confirmed by FEM simulations.

- The experimentally defined hardening law allows to foresee how the value of the yield limit (σY) of EN AW-1370 pure aluminium increases with the applied deformation by wiredrawing. This law, implemented in Deform 2D FEM software, allows to analyse the strain-stress distribution and their evolution in the multi-stage process.

- The analytical methodology, implemented in the PullWorks software application, allowed us to design a new optimized sequence with the same number of stages than the original. This software tool offers a proposed solution that leads to a more uniform value in the drawing stress (σdraw) as a consequence of a progressive increase in the reduction ratio (see Figure 12), as a result of applying a constant delta value in each of the 11 wire-drawing stages.

- It should be noted that both in the application of the numerical method and also in the analytical methodology used to refine the sequence of stages, the possible effect of the temperature variation produced in the deformation zone as a result of the process speed has not been considered. It should be noted that we are in the case of cold forming process conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- UNE-EN 573-3:2014 Aluminio y aleaciones de aluminio. Composición química y Forma de los Productos de forja. Parte 3: Composición química y Forma de los Productos; AENOR: Madrid, Spain, 2014. [Google Scholar]

- Cities, T.S.; Stacey, M. Aluminium: Flexible and Light; Cwningen Press: Warszawa, Poland, 2016; ISBN 978-0-9930162-3-3. [Google Scholar]

- Davis, J.R. Aluminum and Aluminum Alloys. In Alloying: Understanding the Basics; ASM International: Geauga County, OH, USA, 2001; pp. 351–416. ISBN 978-0-87170-744-4. [Google Scholar]

- Knych, T.; Piotr, U.; Marzena, P. The Continuous Casting Technology of the Aluminum Rod Assigned for the Wire for Electrical Purposes. Mater. Sci. Forum. 2011, 690, 87–90. [Google Scholar] [CrossRef]

- Kabayama, L.K.; Taguchi, S.P.; São, U.D.; Usp, P.; Industrial, P.U.; Ai-, G.; Box, P.O.; Sp, L. The Influence of Die Geometry on Stress Distribution by Experimental and FEM Simulation on Electrolytic Copper Wiredrawing. Mater. Res. 2009, 12, 281–285. [Google Scholar] [CrossRef]

- Vega, G.; Haddi, A.; Imad, A. Investigation of process parameters effect on the copper-wire drawing. Mater. Des. 2009, 30, 3308–3312. [Google Scholar] [CrossRef]

- Rodriguez-Alabanda, O. Metodología para el estudio y diseño tecnológico del proceso secuencial de estirado multi-etapa de alambre y barras de sección circular. Ph.D Thesis, University of Malaga, Malaga, Spain, 2017. Available online: https://riuma.uma.es/xmlui/bitstream/handle/10630/14910/TD_RODRIGUEZ_ALABANDA_Oscar Maquetada.pdf?sequence=1&isAllowed=y (accessed on 15 September 2018).

- Rodriguez-Alabanda, O.; Romero, P.E.; Guerrero-Vaca, G.; Sevilla, L. Software implementation of a new analytical methodology applied to the multi-stage wire drawing process: the case study of the copper wire manufacturing line optimization. Int. J. Adv. Manuf. Technol. 2018, 96, 2077–2089. [Google Scholar] [CrossRef]

- González Rojas, H.A.; Calvet, J.V.; Bubnovich, V.I. A new analytical solution for prediction of forward tension in the drawing process. J. Mater. Process. Technol. 2008, 198, 93–98. [Google Scholar] [CrossRef]

- Zhang, G.-L.; Wang, Z.-W.; Zhang, S.-H.; Cheng, M.; Song, H.-W. A fast optimization approach for multipass wire drawing processes based on the analytical model. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1023–1031. [Google Scholar] [CrossRef]

- Hassan, A.; Hashim, A. Three Dimensional Finite Element Analysis of Wire Drawing Process. Univers. J. Mech. Eng. 2015, 3, 71–82. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Afolalu, S.A. Experimental and Theoretical Investigation of Tensile Stress Distribution During Aluminium Wire Drawing. Eur. Sci. J. 2015, 11, 86–102. [Google Scholar]

- Luis, C.J.; León, J.; Luri, R. Comparison between finite element method and analytical methods for studying wire drawing processes. J. Mater. Process. Technol. 2005, 164–165, 1218–1225. [Google Scholar] [CrossRef]

- Teja, C.S.N.; Murty, G.; Reddy, P.S. Finite Element Analysis of Wire Drawing Process with different die contours. Int. J. Sci. Eng. Adv. Technol. 2016, 4, 134–143. [Google Scholar]

- Rojas, E.L.; Celentano, D.J.; Artigas, A.A.; Monsalve, A.G. Simulación experimental y numérica de un proceso de trefilado húmedo de un alambre de acero al carbono. Ingeniare 2008, 16, 188–194. [Google Scholar] [CrossRef]

- Moharana, B.; Kushwaha, B.K.; Polytechnic, B.B.A.G.; Karad, D.P. FEM analysis of stress Predication of Aluminum wire rod in Drawing Operation. Int. Res. J. Eng. Technol. 2017, 4, 982–992. [Google Scholar]

- Zottis, J.; Soares Diehl, C.A.T.; Rocha A da, S. Evaluation of experimentally observed asymmetric distributions of hardness, strain and residual stress in cold drawn bars by FEM-simulation. J. Mater. Res. Technol. 2018, 7, 469–478. [Google Scholar] [CrossRef]

- Milenin, A.; Kustra, P. Numerical and Experimental Analysis of Wire Drawing for Hardly Deformable Biocompatible Magnesium Alloys/Numeryczna I Doswiadczalna Analiza Ciagnienia Drutu Z Trudno Odkształcalnych Biozgodnych Stopów Magnezu. Arch. Metall. Mater. 2013, 58, 55–62. [Google Scholar] [CrossRef]

- Camacho, A.M.; Domingo, R.; Rubio, E.; González, C. Analysis of the influence of back-pull in drawing process by the finite element method. J. Mater. Process. Technol. 2005, 164–165, 1167–1174. [Google Scholar] [CrossRef]

- Valverg, H. Applied Metal Forming including FEM Analysis; Cambridge University Press: New York, NY, USA, 2010; ISBN 13 978-0-511-72943-0. [Google Scholar]

- Luksza, J.; Majta, J.; Burdek, M.; Ruminski, M. Modelling and measurements of mechanical behaviour in multi-pass drawing process. J. Mater. Process. Technol. 1998, 80–81, 398–405. [Google Scholar] [CrossRef]

- Fluhrer, J. Deform2D, Version 8.1; User’s Manual; Scientific Forming Technologies Corporation: Columbus, OH, USA, 2004. [Google Scholar]

- Rodriguez-Alabanda, O. PullWorks Software Download Website. Available online: http://www.uco.es/grupos/prinia/oscar-rodriguez-alabanda/ (accessed on 11 July 2018).

- Cunext Copper Industries, S.L. Declaración Ambiental (Environmental Statement). 2016. Available online: http://www.cunext.com/wp-content/uploads/2016/01/DM-17-2014-con-sello_espanol_ingles.pdf. (accessed on 24 July 2017).

- Cunext Copper Industries, S.L. Productos. Available online: https://www.cunext.com/origen-y-aplicaciones/ (accessed on 1 June 2018).

- Attaway, S.W. The Mechanics of Friction in Rope Rescue; International Technical Rescue Symposium: Fort Collins, CO, USA, 1999; pp. 1–16. [Google Scholar]

- Nuruzzaman, D.M.; Chowdhury, M.A. Friction Coefficient and Wear Rate of Copper and Aluminum Sliding against Mild Steel. Int. Trans. J. Eng. Manag. Appl. Sci. Technol. 2013, 4, 29–40. [Google Scholar]

- Arkles, B. Polytetrafluoroethylene and Fluorinated Ethylene-Propylene Grease Lubricants. Lubr. Eng. 2015, 30, 136–143. [Google Scholar]

- Maschinenfabrik Niehoff GmbH MSM 86 Rod Breakdown Machine MSM 86. Available online: https://www.niehoff-gmbh.info/images/downloads/produktprospekte/05a_MSM 86_e.pdf (accessed on 13 September 2019).

- Van der Putten, C. Drawing Die Wizard. Available online: http://www.estevesgroup.com/es/services/drawing-die-wizard-software/overview/index.php (accessed on 1 June 2018).

- Wistreich, B.J.G.; Eng, M.S.; Member, A. Investigation of the Mechanics of Wire Drawing. Proc. Inst. Mech. Eng. 1955, 169, 654–678. [Google Scholar] [CrossRef]

- Wright, R.N. Mechanical analysis and die design. Wire, J. Int. 1979, 12, 60–61. [Google Scholar]

- Wright, R.N. Wire Technology: Process Engineering and Metallurgy, 2nd ed.; Elsevier Inc.: Burlington, VT, USA, 2011; ISBN 978-0123820921. [Google Scholar]

- Jindal, H.; Jindal, A. Dies Management in Wire Drawing Industry. Available online: http://www.wirecable.in/2015/04/dies-management-in-wire-drawing-industry/ (accessed on 11 September 2019).

- Baker, G.; Wright, R.N. Friction Coefficients in Laboratory Simulation of Magnet Wire Drawing. Wire, J. Int. 1992, 25, 67–72. [Google Scholar]

- Evans, W.; Avitzur, B. Measurement of Friction in Drawing, Extrusion, and Rolling. J. Lubr. Technol. 1968, 90, 72–80. [Google Scholar] [CrossRef]

- Faverjon, P. Influence of Minimum Quantity Lubrication on Friction Coefficient and Work-Material Adhesion During Machining of Cast Aluminum With Various Cutting Tool Substrates Made of Polycrystalline Diamond, High Speed Steel, and Carbides. J. Tribol. 2013, 135, 1–8. [Google Scholar] [CrossRef]

- UNE-EN ISO 6892-1:2009 Materiales metálicos. Ensayo de Tracción. Parte 1: Método de Ensayo a Temperatura Ambiente; AENOR: Madrid, Spain, 2010. [Google Scholar]

- Scientific Forming Technologies Corporation. Deform Product Brochure. Available online: https://www.deform.com/products/deform-3d/ (accessed on 3 July 2018).

- Rubio, E.M.; Camacho, A.M.; Sevilla, L.; Sebastián, M.A. Calculation of the forward tension in drawing processes. J. Mater. Process. Technol. 2005, 162–163, 551–557. [Google Scholar] [CrossRef]

- Adamczyk, J.; Suliga, M.; Pilarczyk, J.W.; Burdek, M. The Influence of Die Approach and Bearing Part of Die on Mechanical-Technological Properties of High Carbon Steel Wires. Arch. Metall. Mater. 2012, 57, 12–14. [Google Scholar] [CrossRef]

- Salcedo, D.; Luis, C.J.; León, J.; Luri, R.; Puertas, I.; Pérez, I. Analysis of residual stresses in wire drawing processes. In Proceedings of the 14th International Research/Expert Conference “Trends in the Development of Machinery and Associated Technology” TMT 2010, Mediterranean Cruises, 11–18 September 2010; Ekinović, S., Uctug, Y., Vivancos, J., Eds.; University of Zenica: Zenica, Bosnia and Herzegovina, 2010; pp. 69–72. [Google Scholar]

| EN AW-1370 | Chemical Composition (%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ga | V + Ti | B | Other | Al | |

| Standard | <0.10 | <0.25 | <0.02 | <0.01 | <0.02 | <0.01 | - | <0.04 | <0.03 | <0.02 | <0.02 | <0.10 | rest |

| Measured | 0.03 | 0.24 | 0.10 | - | - | - | - | - | - | - | - | - | 99.62 |

| Diameter (mm) | Maximum Force Fmáx. (N) | Breaking Stress σuts (MPa) | Yield Stress σY(0) (MPa) |

|---|---|---|---|

| 9.50 | 6250.38 | 89.44 | 74.23 |

| Parameters | Wiredrawing Stages | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage Number (i) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Output Diameter, df (mm) | 9.43 | 8.92 | 7.92 | 6.99 | 6.20 | 5.47 | 4.85 | 4.28 | 3.81 | 3.36 | 2.98 | 2.70 |

| Reduction Rate, r | - | 0.118 | 0.211 | 0.221 | 0.213 | 0.221 | 0.213 | 0.221 | 0.207 | 0.222 | 0.213 | 0.179 |

| Acum. Reduction, rac. | - | 0.118 | 0.305 | 0.458 | 0.574 | 0.668 | 0.739 | 0.797 | 0.839 | 0.875 | 0.901 | 0.919 |

| Elongation, (%) | - | 13.43 | 26.85 | 28.38 | 27.11 | 28.47 | 27.20 | 28.41 | 26.19 | 28.58 | 27.13 | 21.82 |

| Die Semi-Angle, α (°) | - | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| Calibration Length, Lc (mm) | - | 2.67 | 2.37 | 2.10 | 1.86 | 1.64 | 1.45 | 1.28 | 1.14 | 1.00 | 0.89 | 0.81 |

| Reduction Zone Contact, (%) | - | 13 | 22 | 21 | 18 | 28 | 30 | 28 | 32 | 41 | 35 | 26 |

| Die Shape Factor, Delta Δ | - | 9.81 | 5.20 | 4.95 | 5.15 | 4.94 | 5.14 | 4.95 | 5.31 | 4.92 | 5.15 | 6.26 |

| Parameters | Wiredrawing Stages | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage Number (i) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Drawing Speed (mm.s−1) | - | 915 | 1161 | 1490 | 1894 | 2435 | 3096 | 3977 | 5017 | 6455 | 8206 | 10000 |

| Meas. Diameter, df (mm) | 9.43 | 8.92 | 7.92 | 6.99 | 6.20 | 5.47 | 4.85 | 4.28 | 3.81 | 3.36 | 2.98 | 2.70 |

| Output Area, A (mm2) | 69.89 | 62.51 | 49.25 | 38.37 | 30.19 | 23.49 | 18.47 | 14.38 | 11.40 | 8.86 | 6.97 | 5.72 |

| % Area Reduction | - | 10.56 | 21.20 | 22.13 | 21.28 | 22.08 | 21.28 | 22.32 | 20.72 | 22.13 | 21.27 | 17.76 |

| % Acc. Area Reduction | - | 11.83 | 30.50 | 45.86 | 57.40 | 66.85 | 73.94 | 79.71 | 83.91 | 87.50 | 90.16 | 91.93 |

| Unit Strain, ε | - | 0.11 | 0.23 | 0.25 | 0.24 | 0.25 | 0.24 | 0.25 | 0.23 | 0.25 | 0.24 | 0.20 |

| Acc. Unit Strain, εacc | - | 0.11 | 0.35 | 0.60 | 0.84 | 1.1 | 1.33 | 1.58 | 1.81 | 2.06 | 2.30 | 2.50 |

| Breaking Force, F (N) | 6250 | 6242 | 5834 | 4860 | 4119 | 3371 | 2726 | 2191 | 1806 | 1430 | 1170 | 998 |

| Breaking Stress, σmáx (MPa) | 89.4 | 99.8 | 118.4 | 126.7 | 136.4 | 143.3 | 147.2 | 152.3 | 158.3 | 161.0 | 167.3 | 173.5 |

| Yield Stress, σY (MPa) | 74.2 | 94.86 | 115.4 | 122.3 | 130.8 | 136.7 | 140.6 | 144.1 | 152.2 | 151.7 | 163.2 | 167.5 |

| Parameters | Wiredrawing Stages | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage Number (i) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Output Diameter, df (mm) | 9.50 | 8.92 | 7.92 | 6.99 | 6.20 | 5.47 | 4.85 | 4.28 | 3.81 | 3.36 | 2.98 | 2.70 |

| (1) Yield Stress, σY (MPa) | 74.2 | 94.86 | 115.4 | 122.3 | 130.8 | 136.7 | 140.6 | 144.1 | 152.2 | 151.7 | 163.2 | 167.5 |

| (2) Max. Stress, σeff. (max.) (MPa) | - | 122 | 130 | 143 | 151 | 158 | 164 | 169 | 174 | 179 | 183 | 183 |

| (2) Drawing Stress, Draw σ (MPa) | - | 47 | 61 | 76 | 73 | 82 | 88 | 96 | 98 | 101 | 108 | 113 |

| (2) Drawing Force, Fe (N) | - | 2850 | 3030 | 3070 | 2390 | 2070 | 1580 | 1310 | 1010 | 872 | 706 | 693 |

| (3) Drawing Force, Fe (N) | - | 2937 | 3005 | 2916 | 2203 | 1926 | 1625 | 1381 | 1100 | 895 | 756 | 647 |

| Variable | Value |

|---|---|

| Input Diameter, d0 (mm) | 9.43 |

| Output Diameter, df (mm) | 2.70 |

| Die Semi-Angle, α (°) | 18 |

| Bearing Length, Lc (mm) | 0.3∙df |

| Delta Factor, Δ | 5.20 |

| Friction Dies-Wire, μ1 | 0.20 |

| Initial Yield Limit, σY (MPa) | 74.20 |

| Initial Breaking Limit, σUTS (MPa) | 89.43 |

| Strain Hardening Coefficient, n | 0.44 |

| Deformation Resistance Coefficient, C | 59.804 |

| Production Velocity, vf (m sec−1) | 10 |

| Pass nr | d0 (mm) | df (mm) | V0 (m/s) | Vf (m/s) | σdraw (MPa) | σY (MPa) | Fdraw (N) | P (W) |

|---|---|---|---|---|---|---|---|---|

| 1 | 9.43 | 8.37 | 1.934 | 2.185 | 59.21 | 106.11 | 3257.96 | 3391.54 |

| 2 | 8.37 | 7.43 | 2.185 | 2.773 | 64.00 | 117.42 | 2775.30 | 3666.17 |

| 3 | 7.43 | 6.60 | 2.773 | 3.514 | 67.40 | 125.85 | 2305.80 | 3859.91 |

| 4 | 6.60 | 5.86 | 3.514 | 4.458 | 70.53 | 132.87 | 1902.28 | 4038.55 |

| 5 | 5.86 | 5.20 | 4.458 | 5.662 | 73.32 | 138.97 | 1557.09 | 4197.91 |

| 6 | 5.20 | 4.62 | 5.662 | 7.172 | 75.20 | 144.33 | 1260.45 | 4304.45 |

| 7 | 4.62 | 4.10 | 7.172 | 9.107 | 77.70 | 149.31 | 1025.93 | 4449.47 |

| 8 | 4.10 | 3.64 | 9.107 | 11.554 | 79.50 | 153.84 | 827.26 | 4551.61 |

| 9 | 3.64 | 3.23 | 11.554 | 14.674 | 81.50 | 158.10 | 667.78 | 4666.44 |

| 10 | 3.23 | 2.87 | 14.674 | 18.586 | 82.67 | 162.04 | 534.86 | 4733.50 |

| 11 | 2.87 | 2.70 | 18.586 | 21 | 61.51 | 165.86 | 352.21 | 3522.11 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Alabanda, Ó.; Romero, P.E.; Molero, E.; Guerrero-Vaca, G. Analysis, Validation and Optimization of the Multi-Stage Sequential Wiredrawing Process of EN AW-1370 Aluminium. Metals 2019, 9, 1021. https://doi.org/10.3390/met9091021

Rodríguez-Alabanda Ó, Romero PE, Molero E, Guerrero-Vaca G. Analysis, Validation and Optimization of the Multi-Stage Sequential Wiredrawing Process of EN AW-1370 Aluminium. Metals. 2019; 9(9):1021. https://doi.org/10.3390/met9091021

Chicago/Turabian StyleRodríguez-Alabanda, Óscar, Pablo E. Romero, Esther Molero, and Guillermo Guerrero-Vaca. 2019. "Analysis, Validation and Optimization of the Multi-Stage Sequential Wiredrawing Process of EN AW-1370 Aluminium" Metals 9, no. 9: 1021. https://doi.org/10.3390/met9091021

APA StyleRodríguez-Alabanda, Ó., Romero, P. E., Molero, E., & Guerrero-Vaca, G. (2019). Analysis, Validation and Optimization of the Multi-Stage Sequential Wiredrawing Process of EN AW-1370 Aluminium. Metals, 9(9), 1021. https://doi.org/10.3390/met9091021