Model-Based Analysis of Factors Affecting the Burden Layer Structure in the Blast Furnace Shaft

Abstract

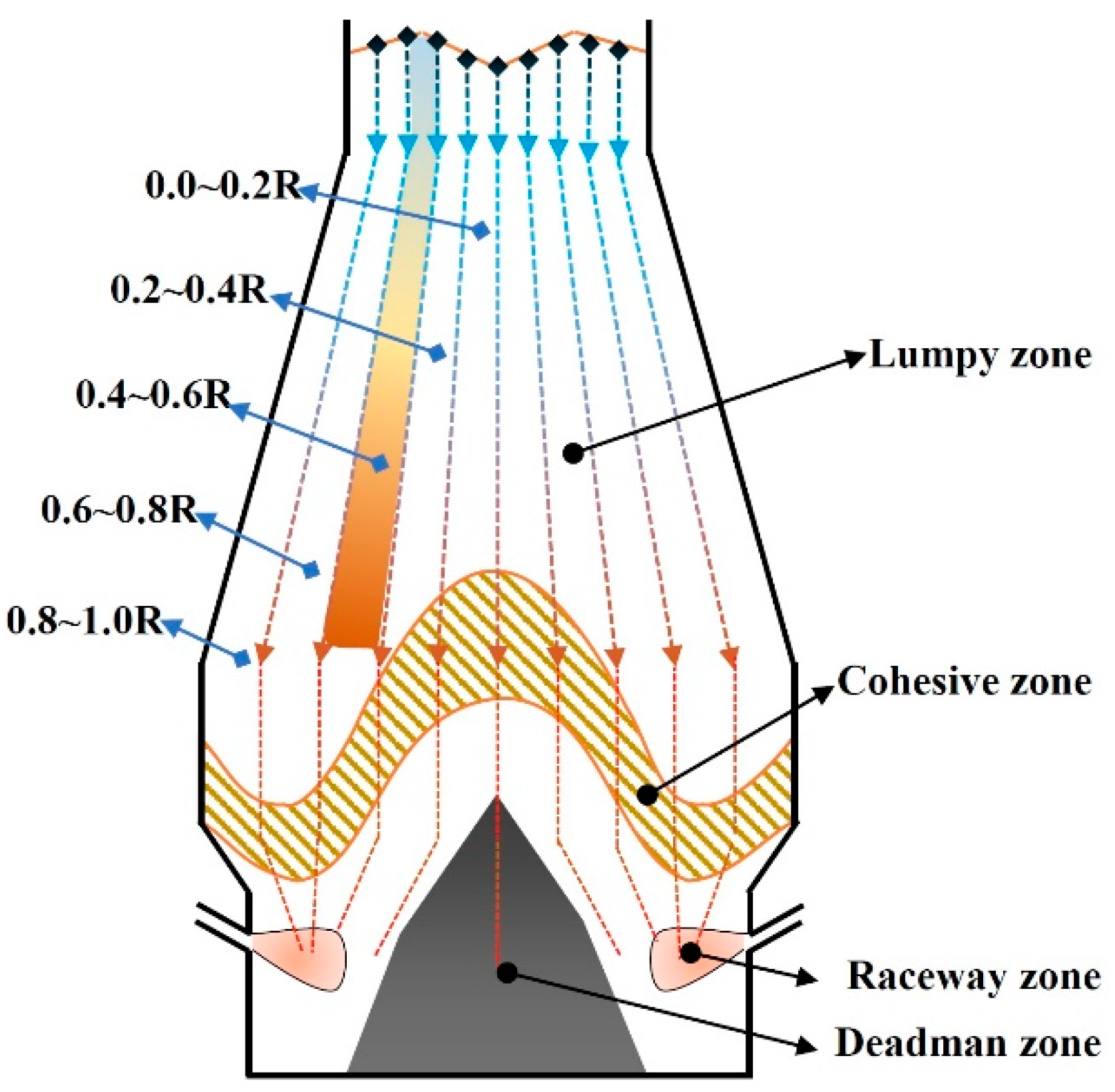

:1. Introduction

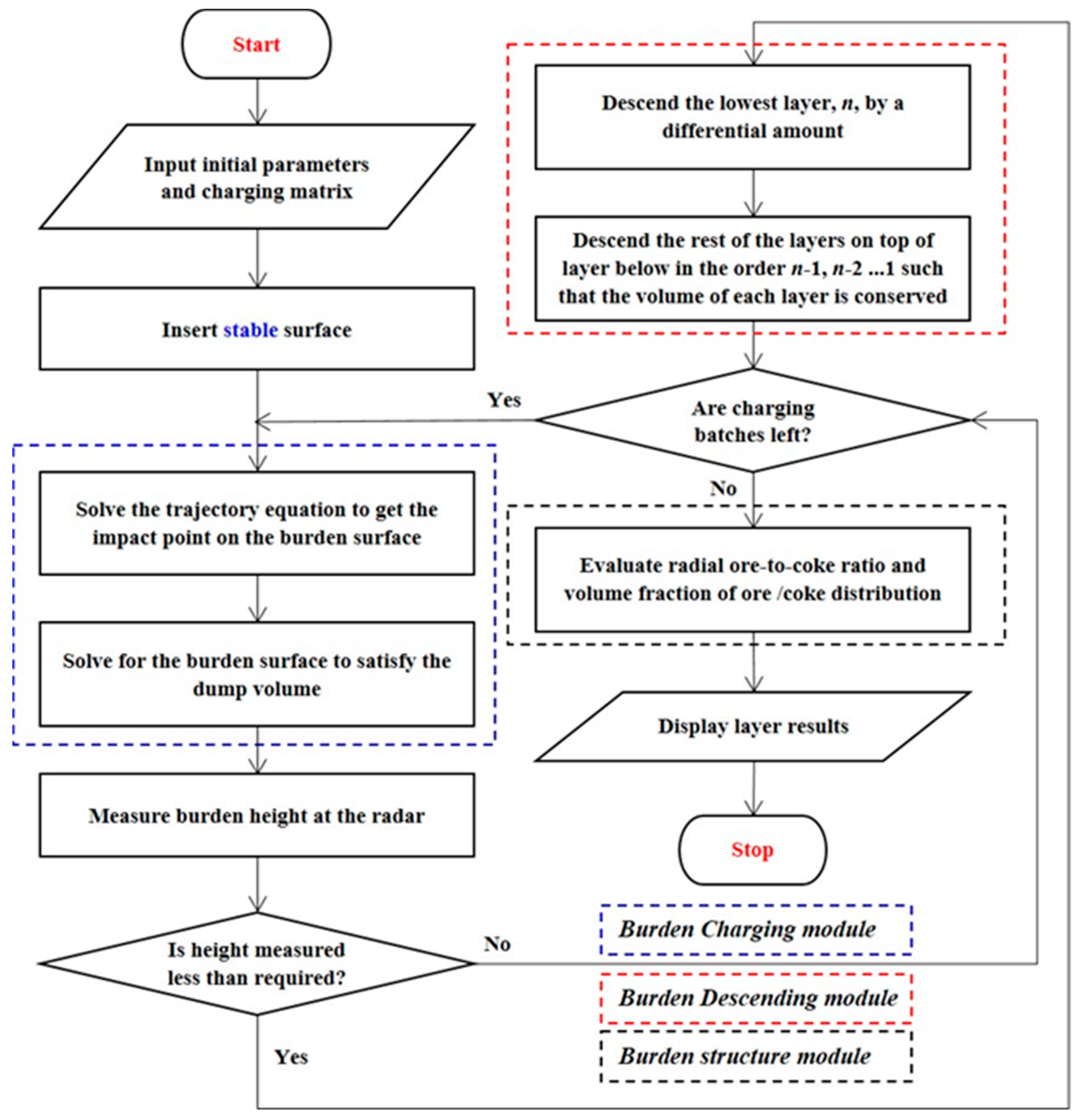

2. Mathematical Model

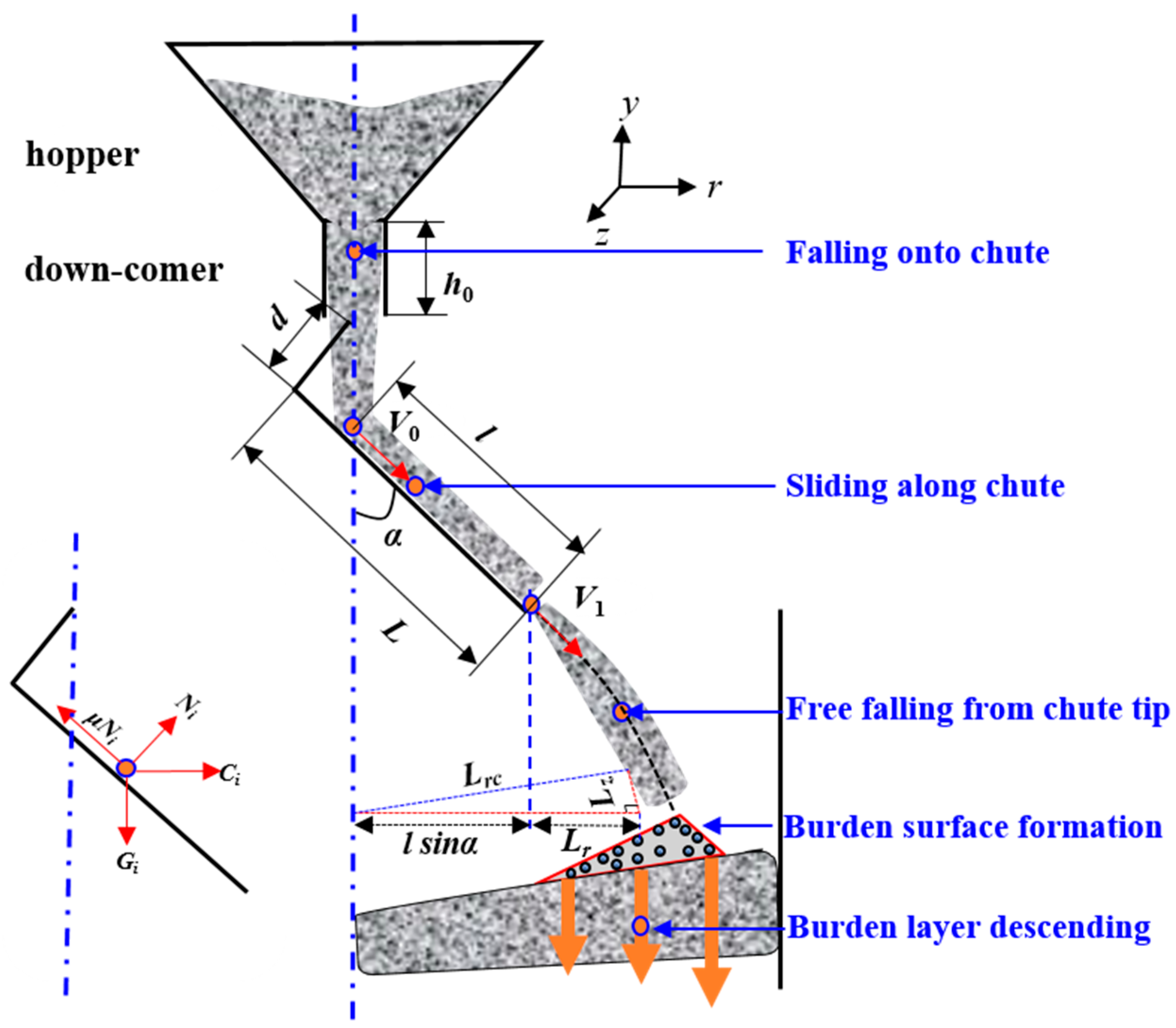

2.1. Free Falling from the Hopper onto the Chute

2.2. Sliding along the Chute

2.3. Free Falling from the Chute Tip

2.4. Burden Surface Formation

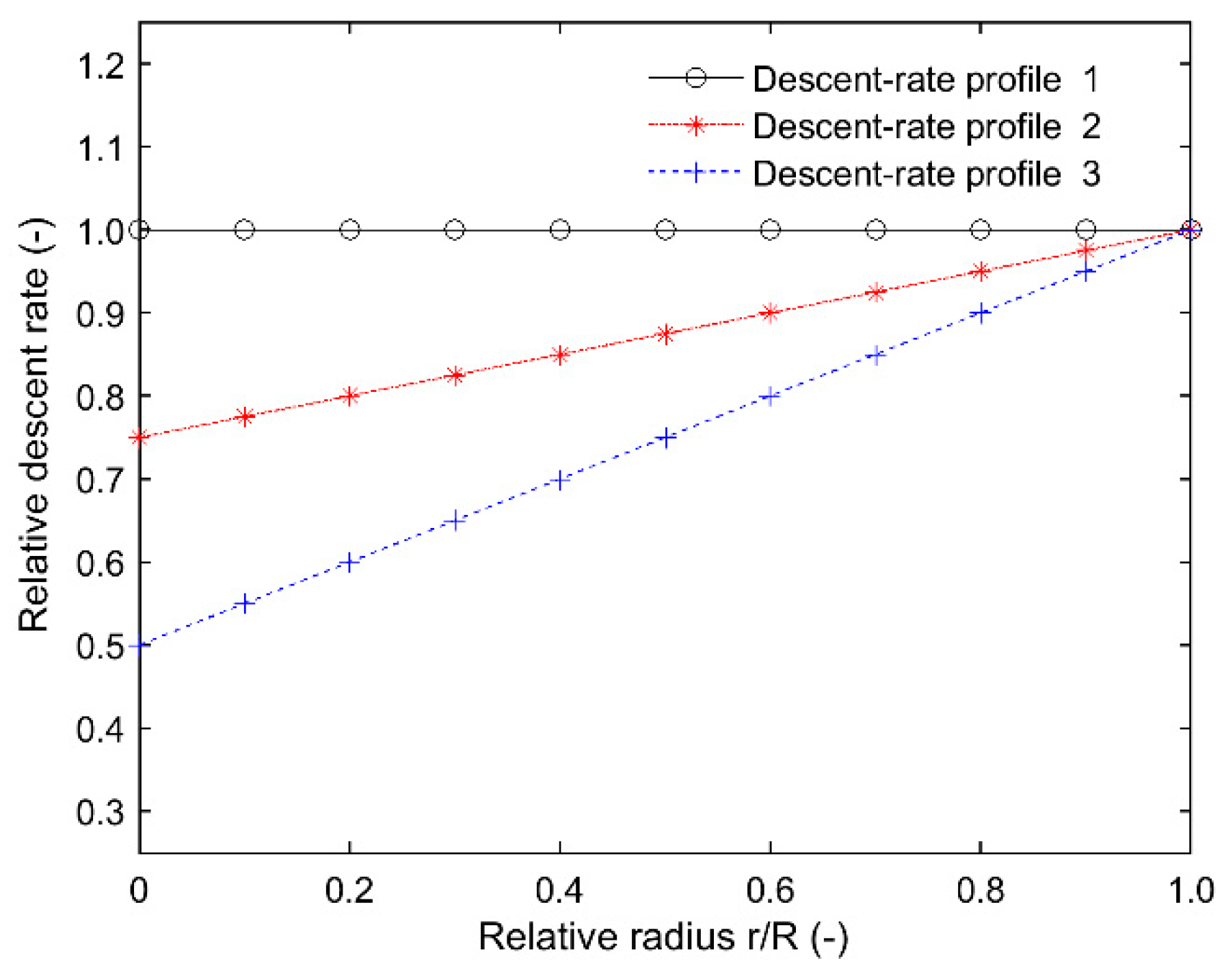

2.5. Burden Layer Descent

3. Results

3.1. Initial and Boundary Conditions

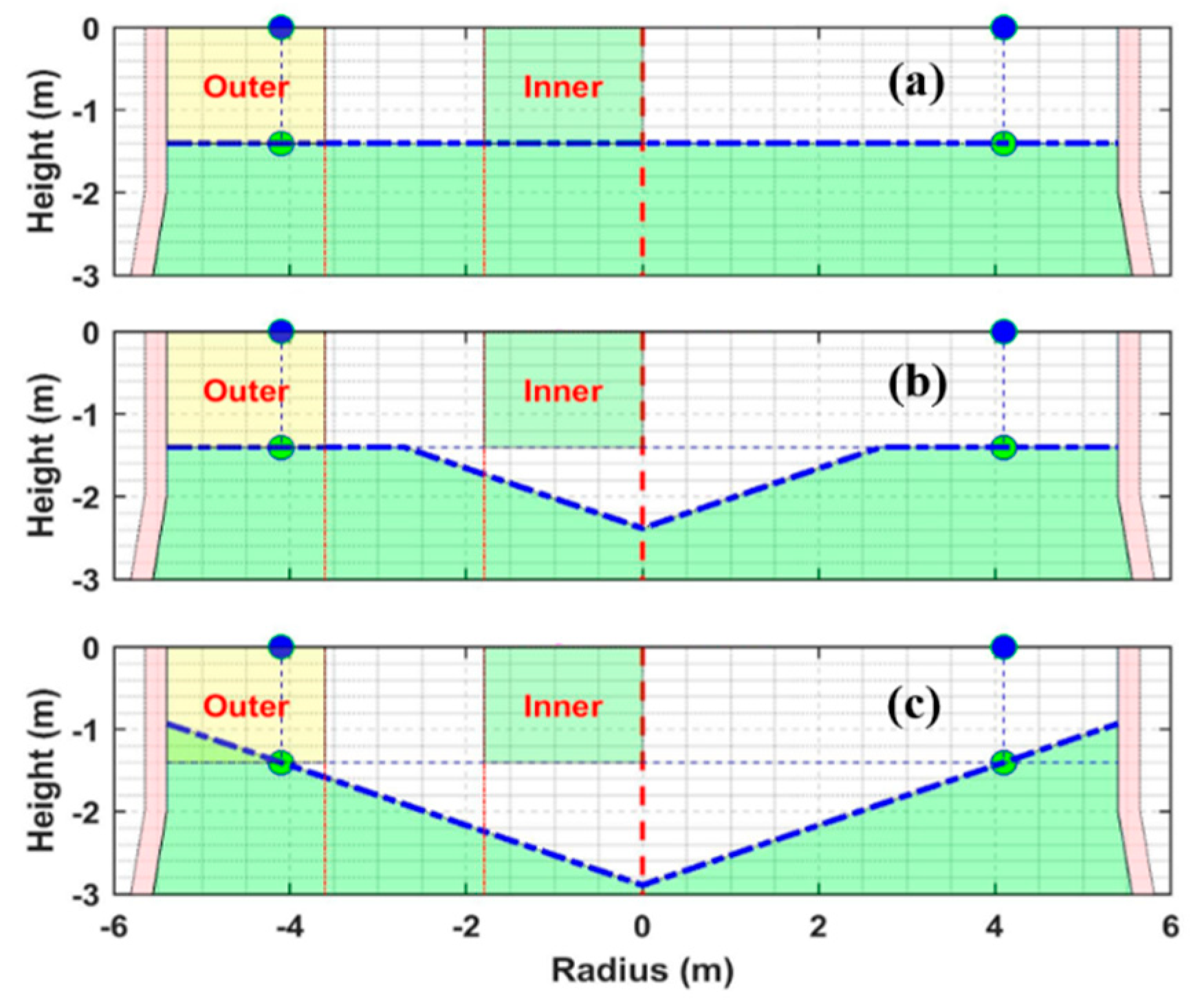

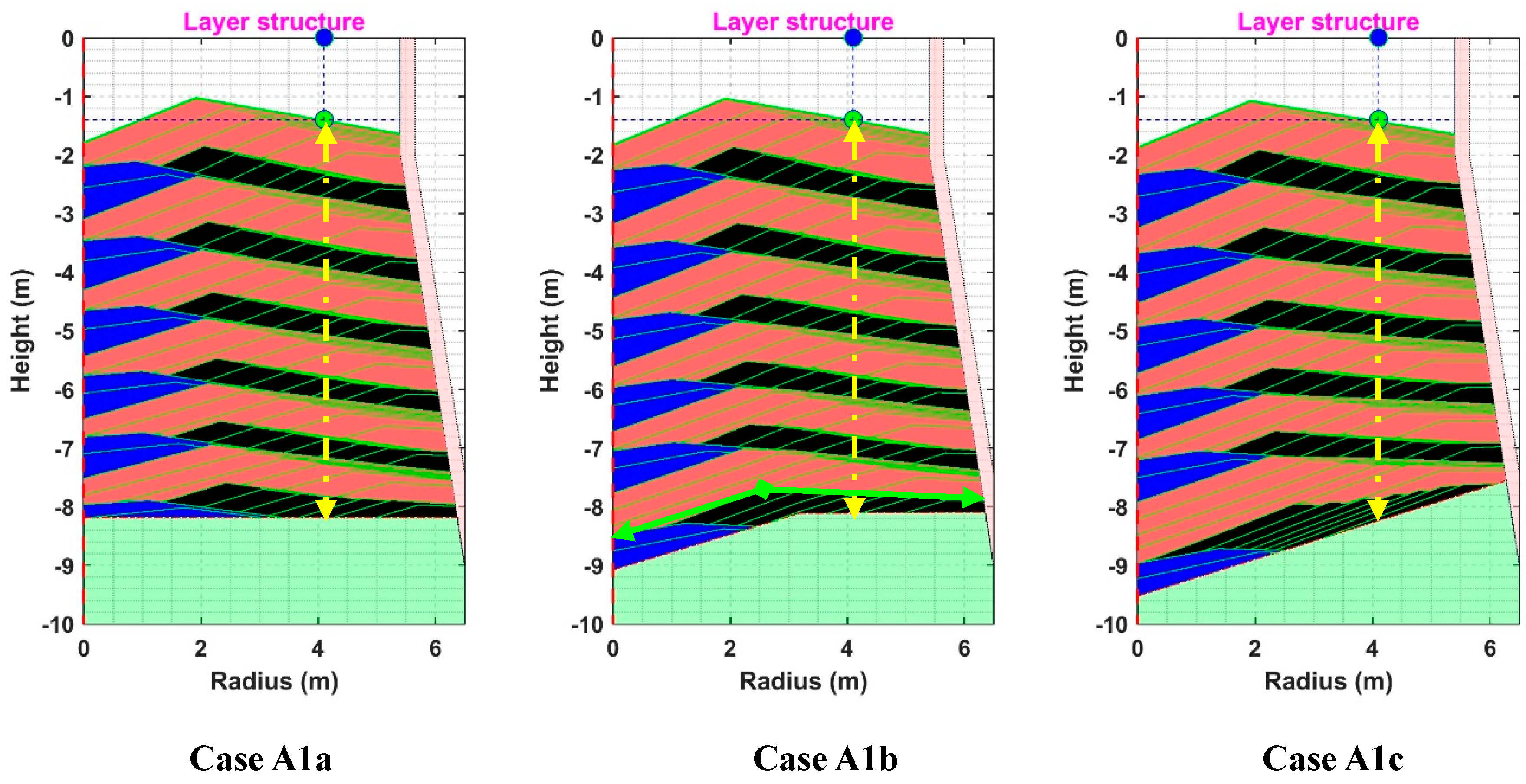

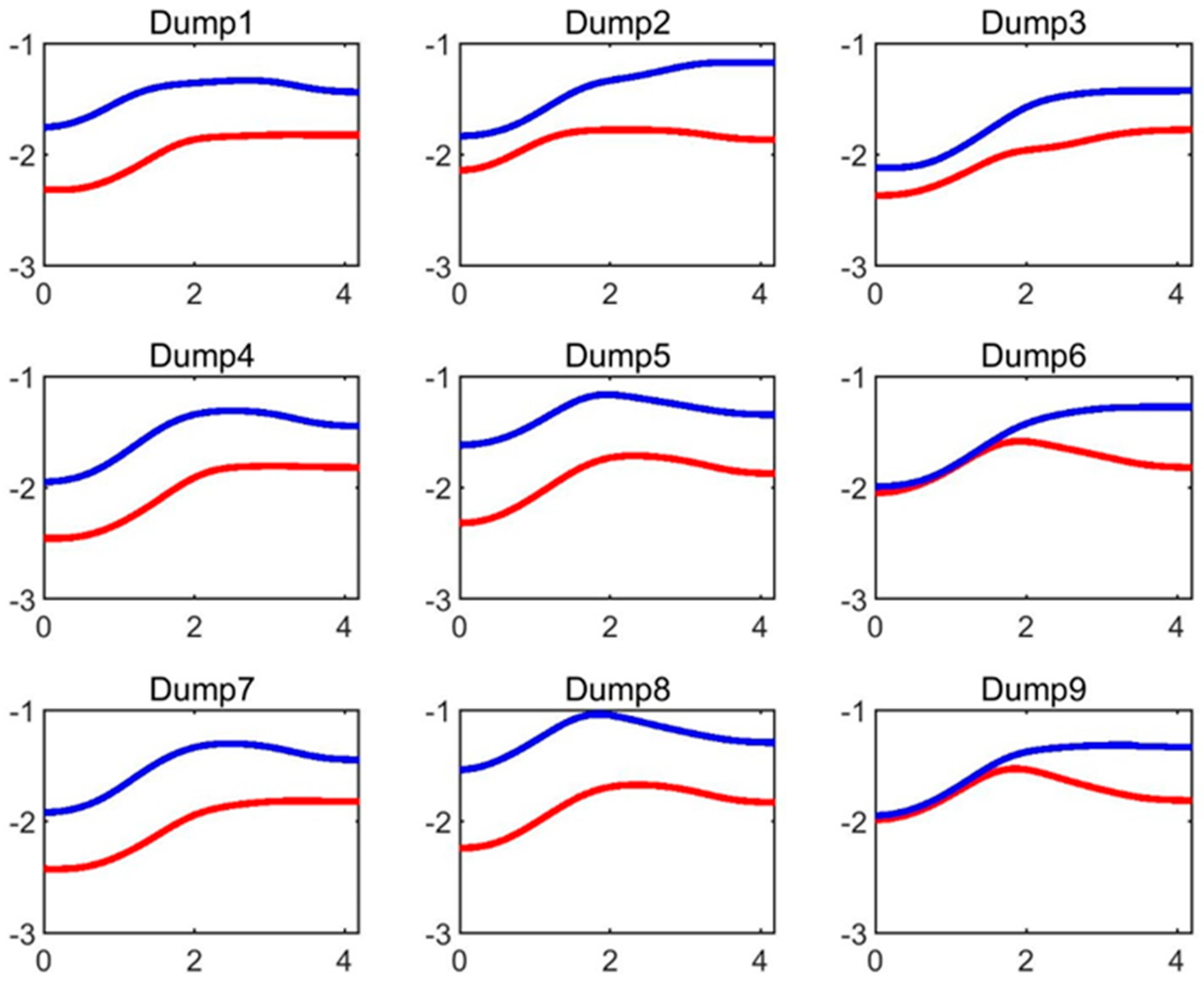

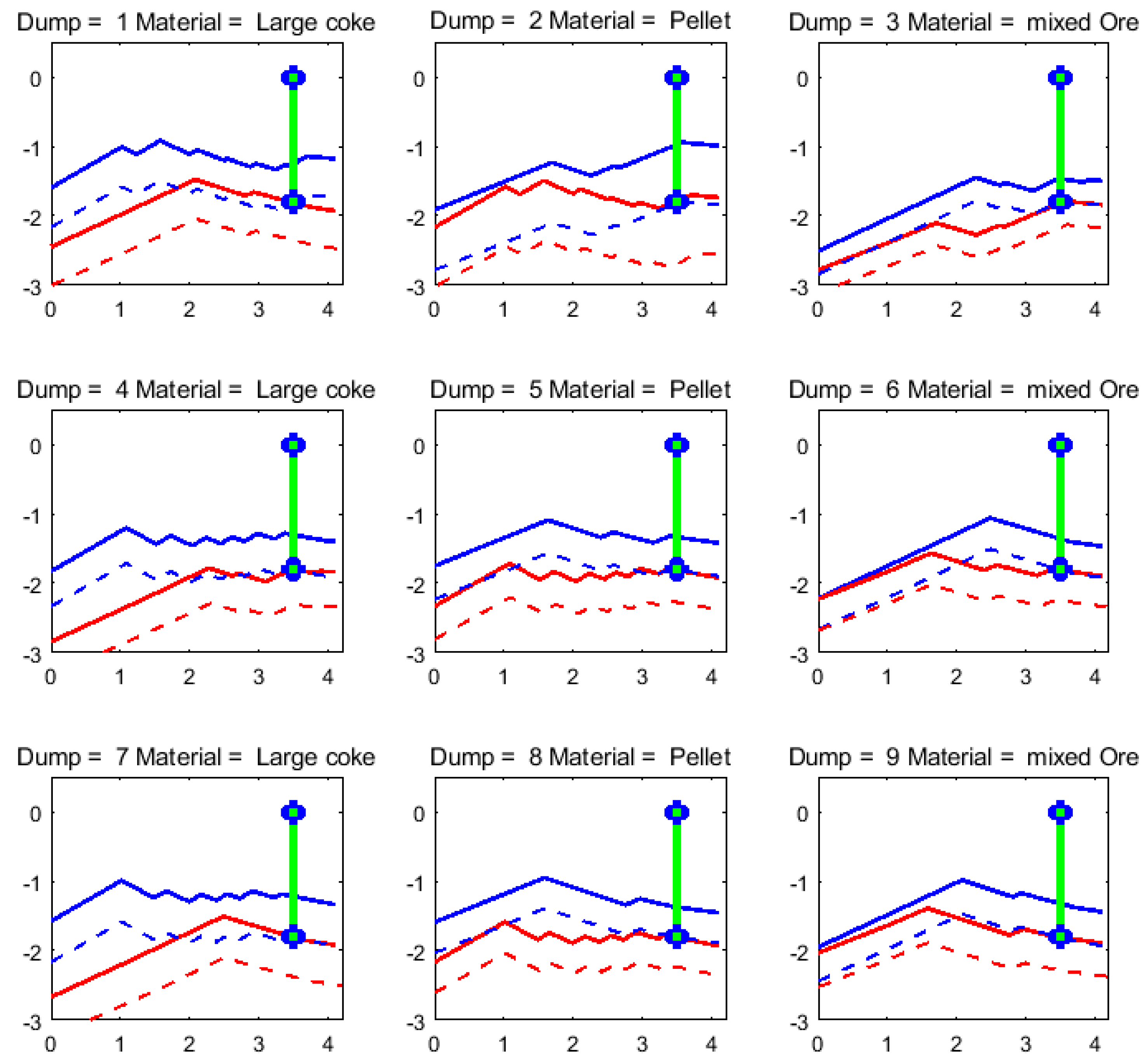

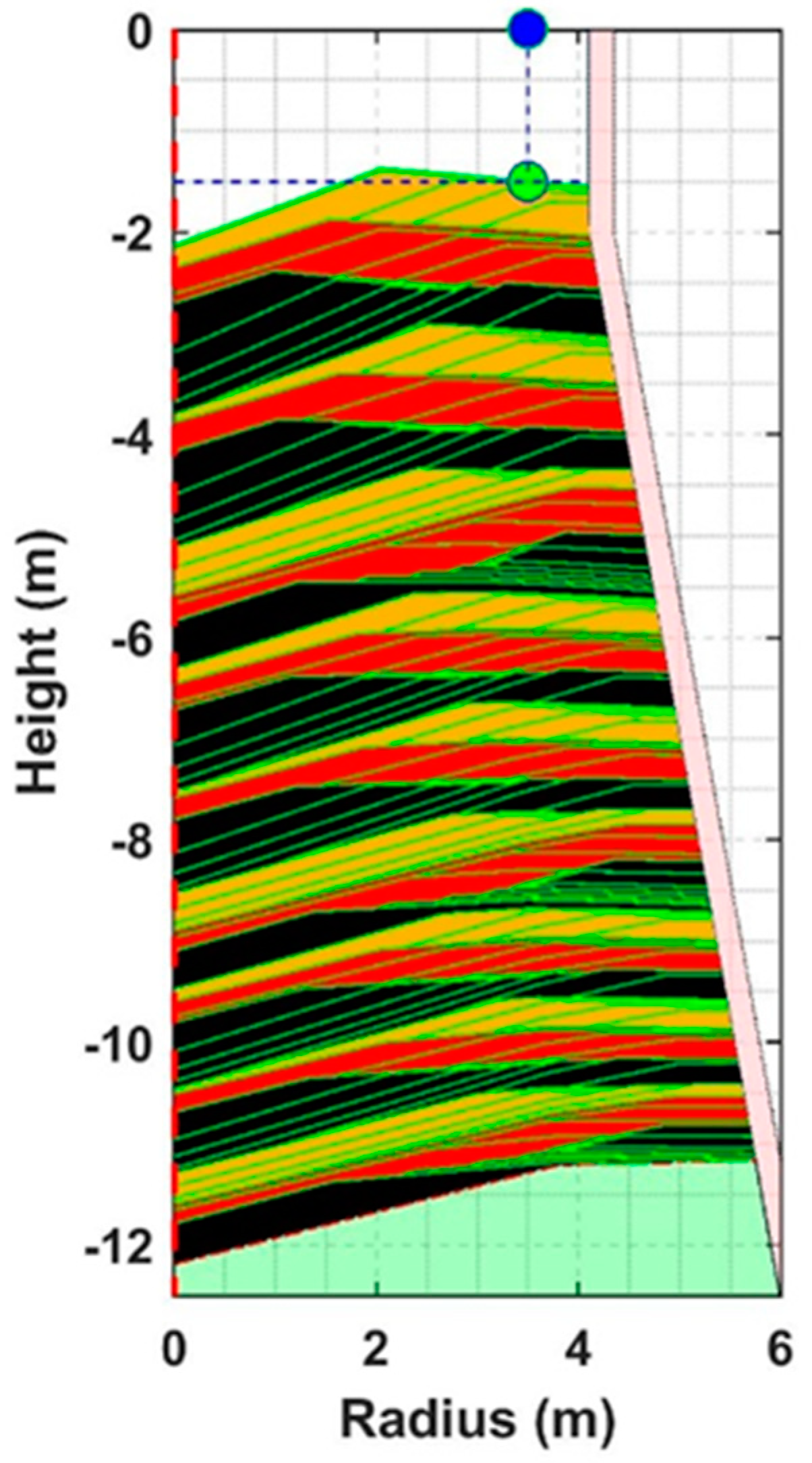

3.2. Effect of Burden Descent-Rate Distribution and Initial Surface

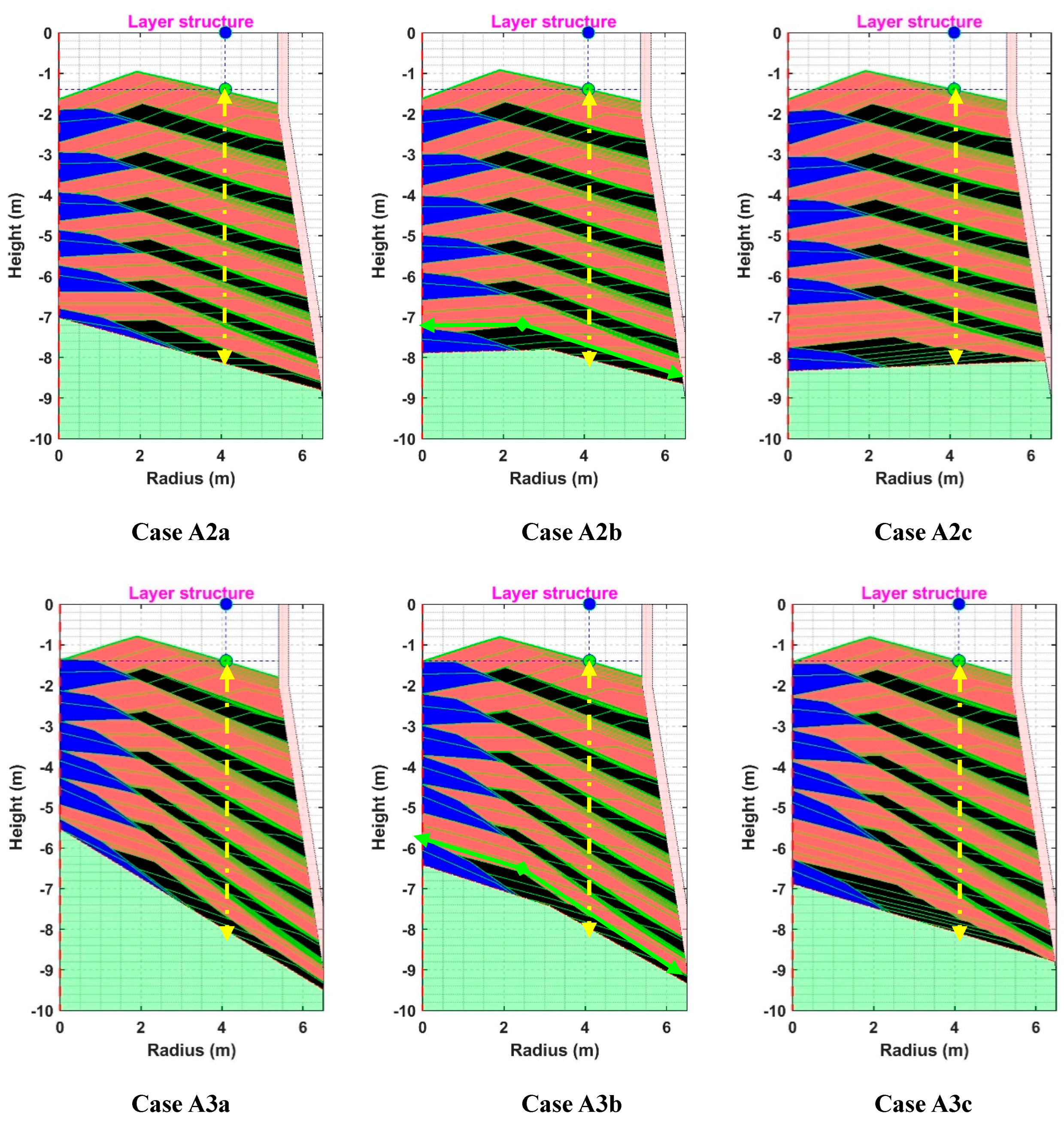

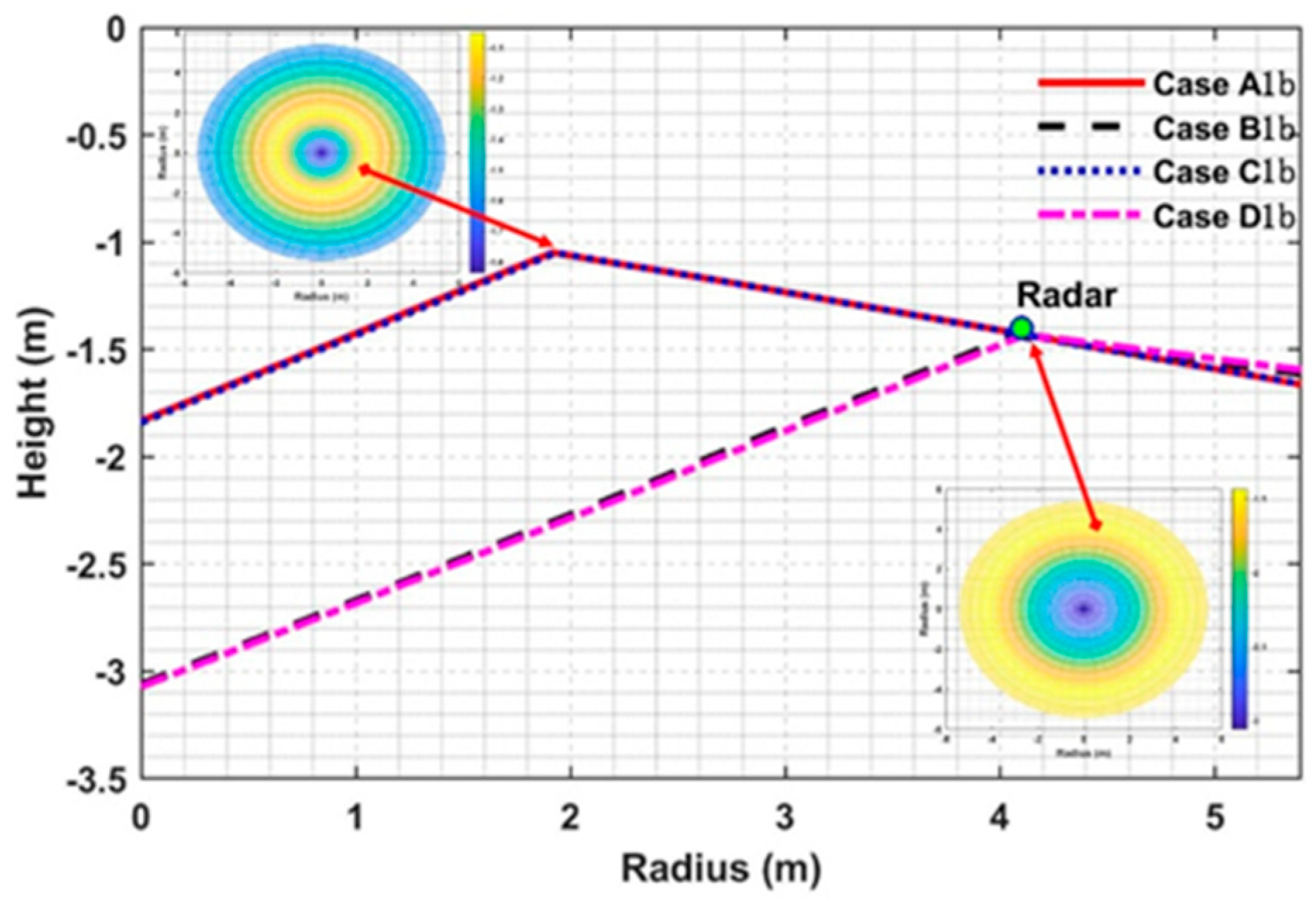

3.3. Effect of Charging Direction

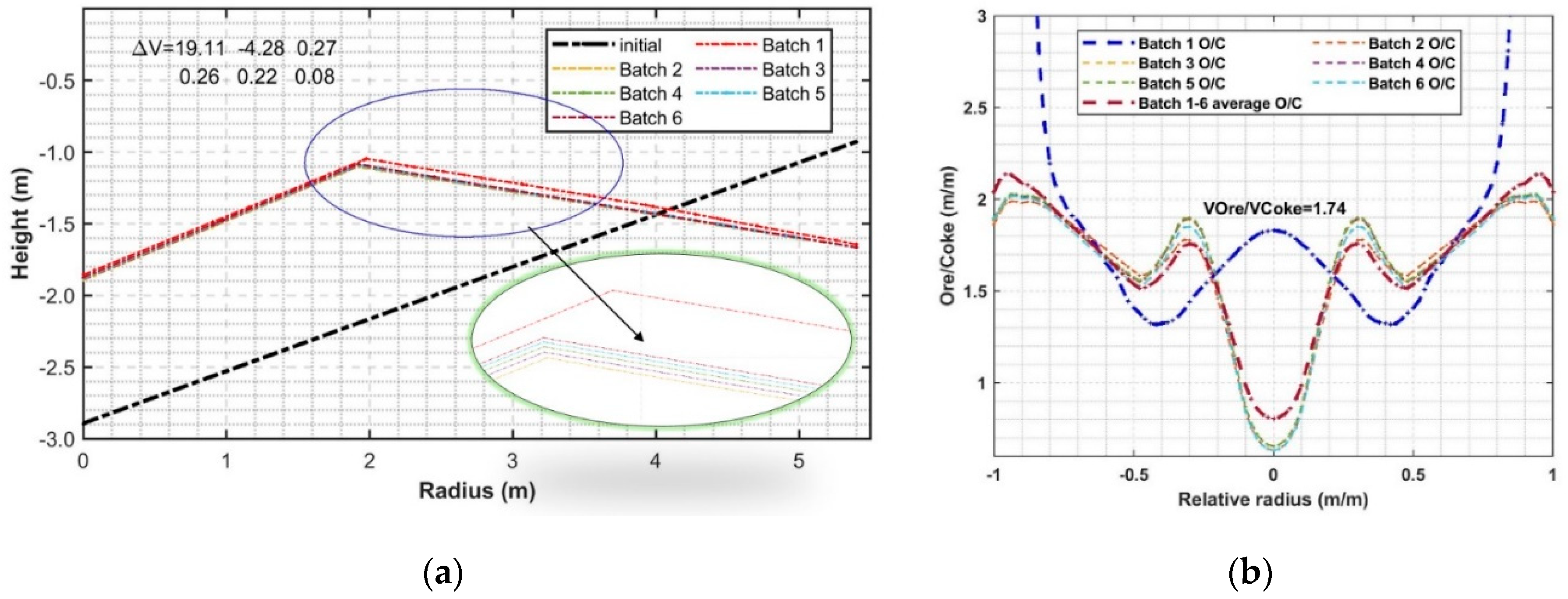

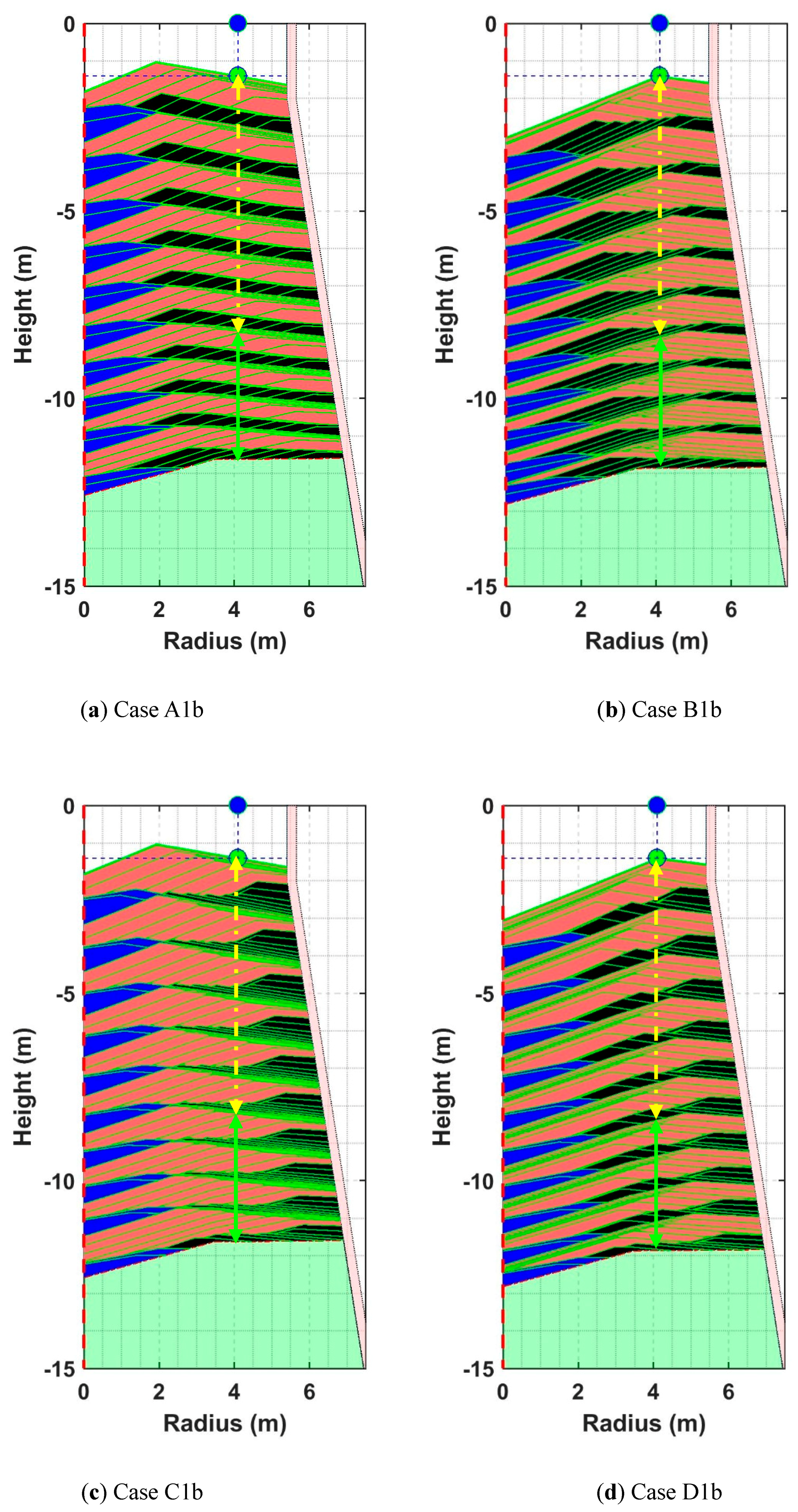

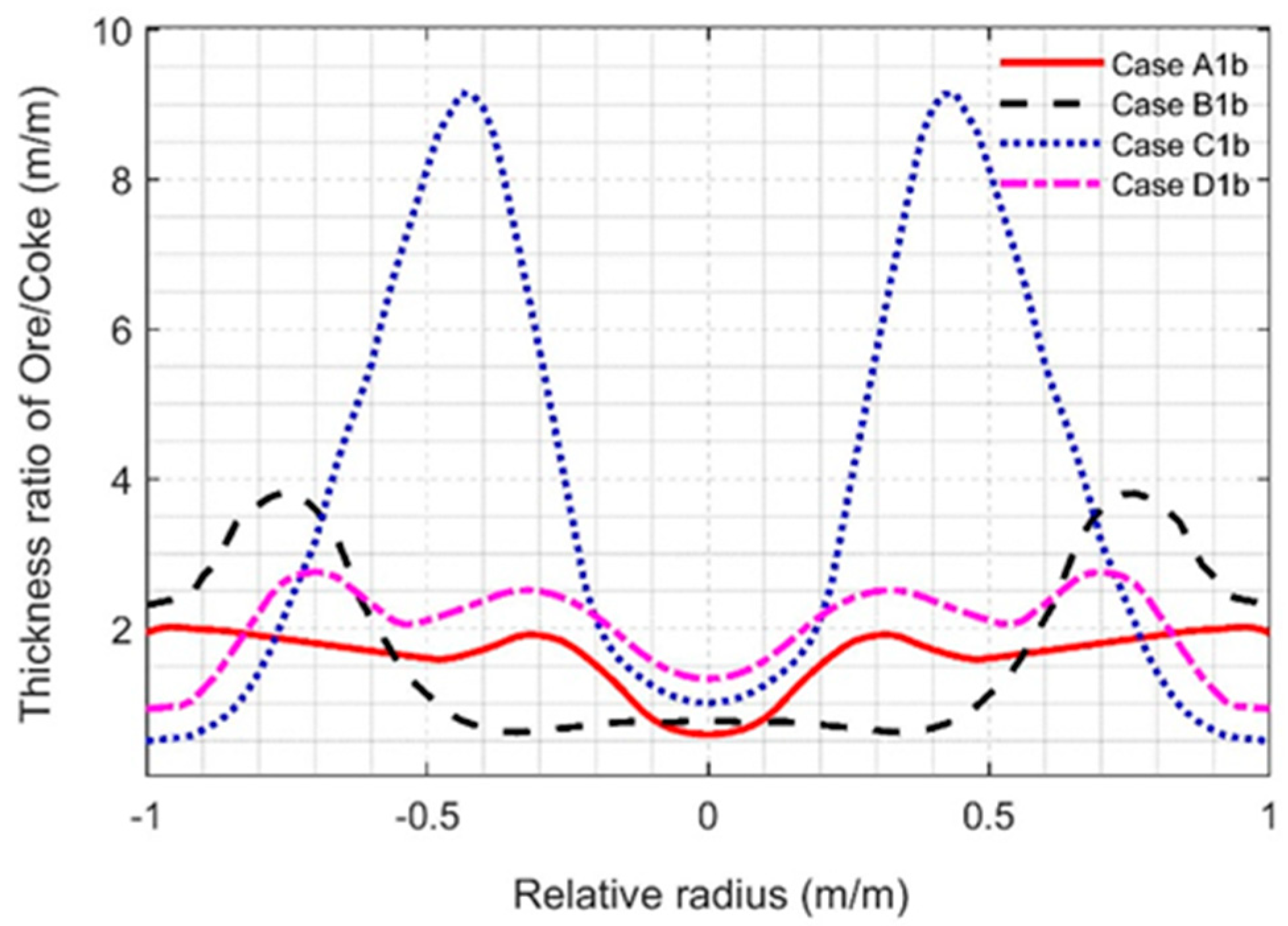

3.4. Validation of the Model

4. Conclusions and Future Perspectives

- Compared with previous versions of the model [12], a sub-model was established for calculating the stable burden top surface using an arbitrary initial surface, which yields information about the conditions in the shaft under a quasi-stationary state. The calculation results showed that the initial burden surface typically affects the results for about five dumps, after which asymptotic behavior of the radial layer distribution will be reached;

- The effect of different radial descent-rate profiles on the arising burden layer structure has been analyzed, and it has been demonstrated that the distribution plays an important role in the internal layers in the shaft, but only marginally affects the radial distribution of the top layers in the throat;

- The charging direction, i.e., the direction in which the chute moves (center to wall, or wall to center) when the rings of a dump are distributed on the burden surface plays a key role. This strong effect is due to the material overlapping, which becomes accentuated in a large BF with large dump sizes, where each dump is split into several rings. By changing the direction, fundamentally different layer distributions can be obtained.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| a | descent-rate coefficient at furnace center | - |

| b | slope coefficient of descent rate from furnace center to furnace wall | - |

| C | centrifugal force | N |

| d | pivot of distance from center | m |

| f | frictional force | N |

| F | net force | N |

| g | gravitational acceleration constant | m2/s |

| G | gravity force | N |

| h0 | height of down-comer | m |

| k1 | collision correction coefficient | - |

| k2 | buoyancy correction coefficient | - |

| l | effective length of the chute | m |

| l | chute direction | m |

| L | length of the chute | m |

| m | mass of the particle | k |

| N | counteracting force | N |

| R | throat radius | m |

| t | time of particle movement in free board | s |

| u | descent rate along the vertical direction | - |

| V0 | exit velocity along the direction of chute | m/s |

| V1 | velocity at the end of chute | m/s |

| α | chute angle in the vertical direction | rad |

| ω | rotation speed of the chute | rad/s |

| μ | friction factor between material and chute | - |

| β | repose angle | rad |

Subscript

| i | ore or coke | - |

| rc | center to particle stream (cf. Figure 1) | |

| in | inner repose angle | - |

| min | minimum | - |

| max | maximum | - |

| out | outer repose angle | - |

| r | horizontal (radial) direction | - |

| y | vertical (altitudinal) direction | - |

| z | rotation (tangential) direction | - |

References

- Zhou, C.Q. Minimization of Blast Furnace Fuel Rate by Optimizing Burden and Gas Distribution; Technical Report: Project No. DE-FG36-07GO17041; Purdue University: Hammond, IN, USA, 2012. [Google Scholar]

- Huang, D.; Andrade, M.; White, D.; Maude, J. Blast Furnace Above-Burden Infrared Camera. Iron Steel Tech. 2017, 14, 44–56. [Google Scholar]

- Kuang, S.B.; Li, Z.Y.; Yu, A.B. Review of modeling and simulation of blast furnace. Steel Res. Int. 2018, 89, 1700071. [Google Scholar] [CrossRef]

- Yang, Y.L.; Yin, Y.X.; Wunsch, D.; Zhang, S.; Chen, X.Z.; Li, X.L.; Cheng, S.S.; Wu, M.; Liu, K.Z. Development of Blast Furnace Burden Distribution Process Modeling and Control. ISIJ Int. 2017, 57, 1350–1363. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.Y.; Kuang, S.B.; Liu, S.D.; Gan, J.Q.; Yu, A.B.; Li, Y.T.; Mao, X.M. Numerical investigation of burden distribution in ironmaking blast furnace. Powder Technol. 2019, 353, 385–397. [Google Scholar] [CrossRef]

- Nishio, H.; Ariyama, T. Analysis on Formation Processes of Burden Distribution in Blast Furnace. Tetsu-to-Hagane. 1982, 68, 2330–2337. [Google Scholar] [CrossRef] [Green Version]

- Kajiwara, Y.; Jimbo, T.; Sakai, T. Development of a simulation model for burden distribution at blast furnace top. Trans. ISIJ. 1983, 23, 1045–1052. [Google Scholar] [CrossRef]

- Hattori, M.; Iino, B.; Shimomura, A.; Tsukiji, H.; Ariyama, T. Development of burden distribution simulation model for bell-less top in a large blast furnace and its application. ISIJ Int. 1993, 33, 1070–1077. [Google Scholar] [CrossRef]

- Radhakrishnan, V.R.; Ram, K.M. Mathematical model for predictive control of the bell-less top charging system of a blast furnace. J. Proc. Control. 2001, 11, 565–586. [Google Scholar] [CrossRef]

- Saxén, H.; Hinnelä, J. Model for Burden Distribution Tracking in the Blast Furnace. Min. Process Extr. Metall. Rev. 2004, 25, 1–27. [Google Scholar] [CrossRef]

- Park, J.I.; Jung, H.J.; Jo, M.K.; Oh, H.S.; Han, J.-W. Mathematical Modeling of the Burden Distribution in the Blast Furnace Shaft. Met. Mater. Int. 2011, 17, 485–496. [Google Scholar] [CrossRef]

- Mitra, T.; Saxén, H. Model for Fast Evaluation of Charging Programs in the Blast Furnace. Metall. Mater. Trans. B 2014, 45, 2382–2394. [Google Scholar] [CrossRef]

- Fu, D. Numerical Simulation of Ironmaking Blast Furnace Shaft. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Li, H.F.; You, Y.; Zhou, H.; Luo, Z.G.; Zou, Z.S. Study on Burden Pile Profile Prediction Model for COREX-3000 Melter Gasifier. J. Chongqing Univ. 2015, 38, 39–44. (In Chinese) [Google Scholar]

- Hinnelä, J.; Saxén, H. Neural network model of burden layer formation dynamics in the blast furnace. ISIJ Int. 2001, 41, 142–150. [Google Scholar] [CrossRef]

- Su, X.L.; Zhang, S.; Yin, Y.X.; Liu, Y.N.; Xiao, W.D. Data-driven prediction model for adjusting burden distribution matrix of blast furnace based on improved multilayer extreme learning machine. Soft Comput. 2018, 22, 3575–3589. [Google Scholar] [CrossRef]

- Li, Y.J.; Zhang, S.; Zhang, J.; Yin, Y.X.; Xiao, W.D.; Zhang, Z.Q. Data-driven multi-objective optimization for burden surface in blast furnace with feedback compensation. IEEE Trans. Ind. Inform 2019, in press. [Google Scholar] [CrossRef]

- Saxén, H.; Nikus, M.; Hinnela, J. Burden Distribution Estimation in the Blast Furnace from Stockrod and Probe Signals. Steel Res. Int. 1998, 69, 406–410. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Zhu, H.P.; Yu, A.B.; Wright, B.; Pinson, D.; Zulli, P. Discrete Particle Simulation of Solid Flow in a Model Blast Furnace. ISIJ Int. 2005, 45, 1828–1837. [Google Scholar] [CrossRef] [Green Version]

- Mio, H.; Kadowaki, M.; Matsuzaki, S.; Kunitomo, K. Development of particle flow simulator in charging process of blast furnace by discrete element method. Min. Eng. 2012, 33, 27–33. [Google Scholar] [CrossRef]

- Li, H.F.; Luo, Z.G.; Zou, Z.S.; Sun, J.J.; Han, L.H.; Di, Z.X. Mathematical Simulation of Burden Distribution in COREX Melter Gasifier by Discrete Element Method. J. Iron Steel Res. Int. 2012, 19, 36–42. [Google Scholar] [CrossRef]

- Liu, S.D.; Zhou, Z.Y.; Dong, K.J.; Yu, A.B.; Pinson, D.; Tsalapatis, J. Numerical investigation of burden distribution in a blast furnace. Steel Res. Int. 2015, 86, 651–661. [Google Scholar] [CrossRef]

- Mitra, T.; Saxén, H. Discrete Element Simulation of Charging and Mixed Layer Formation in the Ironmaking Blast Furnace. Comput. Part. Mech. 2016, 3, 541–555. [Google Scholar] [CrossRef]

- Fu, D.; Chen, Y.; Zhou, C.Q. Mathematical Modeling of Blast Furnace Burden Distribution with Non-uniform Descending Speed. Appl. Math. Model. 2015, 39, 7554–7567. [Google Scholar] [CrossRef]

- Mitra, T.; Saxén, H. Evolution of Charging Programs for Achieving Required Gas Temperature Profile in a Blast Furnace. Mater. Manuf. Process. 2015, 30, 474–487. [Google Scholar] [CrossRef]

- Liu, Y.C. Burden Distribution Law in Blast Furnace, 3rd ed.; Metallurgical Industry Press: Beijing, China,, 2005; pp. 25–30. (In Chinese) [Google Scholar]

- Ichida, M.; Nishihara, K.; Tamura, K.; Sugata, M.; Ono, H. Influence of Ore/Coke Distribution on Descending and Melting Behavior of Burden in Blast Furnace. ISIJ Int. 1991, 31, 505–514. [Google Scholar] [CrossRef]

- Ichida, M.; Takao, M.; Kunitomo, K.; Matsuzaki, S.; Deno, T.; Nishihara, K. Radial Distribution of Burden Descent Velocity near Burden Surface in Blast Furnace. ISIJ Int. 1996, 35, 493–502. [Google Scholar] [CrossRef]

- Lu, Y.X.; Jiang, Z.Y.; Zhang, X.R.; Wang, J.S.; Zhang, X.X. Vertical Section Observation of the Solid Flow in a Blast Furnace with a Cutting Method. Metals 2019, 9, 127. [Google Scholar] [CrossRef]

- Zhou, P.; Shi, P.Y.; Song, Y.P.; Tang, K.L.; Fu, D.; Zhou, C.Q. Evaluation of Burden Descent Model for Burden Distribution in Blast Furnace. J. Iron Steel Res. Int. 2016, 23, 765–771. [Google Scholar] [CrossRef]

- Fu, D.; Huang, F.; Tian, F.; Zhou, C.Q. Burden Descending and Redistribution in a Blast Furnace. In Proceedings of the AISTech 2010, Iron & Steel Technology Conference, Pittsburgh, PA, USA, 3–6 May 2010; Association for Iron and Steel Technology: Warrendale, PA, USA, 2010; Volume 1, pp. 693–700. [Google Scholar]

| Material | Mass/ton | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | Color |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Center Coke | 2.62 | - | 1 | 1 | - | - | - | - | - | - | - | - | |

| Large Coke | 21.0 | - | - | - | - | 2 | 2 | 2 | 2 | 2 | 3 | 3 | |

| Mixed Ore (Sinter and Pellet and Lump Ore) | 136.0 | - | - | - | - | 2 | 2 | 2 | 2 | 3 | 3 | - |

| Initial Burden Surface | a | b | c | |

|---|---|---|---|---|

| Descent-Rate Profile | ||||

| 1 | Case A1a | Case A1b | Case A1c | |

| 2 | Case A2a | Case A2b | Case A2c | |

| 3 | Case A3a | Case A3b | Case A3c | |

| Material | Center Coke | Coke | Mixed Ore | |

|---|---|---|---|---|

| Case | ||||

| Case A1b | W → C | W → C | W → C | |

| Case B1b | W → C | W → C | C → W | |

| Case C1b | C → W | C → W | W → C | |

| Case D1b | C → W | C → W | C → W | |

| Material | Mass/Ton | Direction | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | Color |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Coke | 15.5 | C → W | - | - | 5.5 | 1.3 | 1.3 | 1.3 | 1.3 | 2.6 | 2.2 | - | - | |

| 2. Pellets | 60.4 | C → W | - | - | - | 16.3 | - | 15.2 | - | 14.5 | 14.4 | - | - | |

| 3. Pellets and Coke | 40.7 | W → C | - | - | - | 9.1 | 9.9 | - | 10.6 | 11.1 | - | - | ||

| 4. Coke | 15.6 | W → C | - | - | 1.3 | 1.8 | 1.8 | 1.7 | 1.7 | 3.5 | 3.8 | - | - | |

| 5. Pellets | 60.2 | W → C | - | - | - | 14.2 | - | 14.7 | - | 15.2 | 16.1 | - | - | |

| 6. Pellets and Coke | 40.9 | W → C | - | - | - | - | 11.0 | 10.3 | 10.3 | 9.3 | - | - | ||

| 7. Coke | 15.5 | W → C | - | - | 1.3 | 1.8 | 1.7 | 1.7 | 1.8 | 3.4 | 3.8 | - | - | |

| 8. Pellets | 60.4 | W → C | - | - | - | 11.4 | 11.5 | - | 12.3 | 12.1 | 13.1 | - | - | |

| 9. Pellets and Coke | 40.7 | W → C | - | - | - | 11.3 | - | 10.0 | 10.1 | 9.3 | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Saxén, H.; Liu, W.; Zou, Z.; Shao, L. Model-Based Analysis of Factors Affecting the Burden Layer Structure in the Blast Furnace Shaft. Metals 2019, 9, 1003. https://doi.org/10.3390/met9091003

Li H, Saxén H, Liu W, Zou Z, Shao L. Model-Based Analysis of Factors Affecting the Burden Layer Structure in the Blast Furnace Shaft. Metals. 2019; 9(9):1003. https://doi.org/10.3390/met9091003

Chicago/Turabian StyleLi, Haifeng, Henrik Saxén, Weiqiang Liu, Zongshu Zou, and Lei Shao. 2019. "Model-Based Analysis of Factors Affecting the Burden Layer Structure in the Blast Furnace Shaft" Metals 9, no. 9: 1003. https://doi.org/10.3390/met9091003

APA StyleLi, H., Saxén, H., Liu, W., Zou, Z., & Shao, L. (2019). Model-Based Analysis of Factors Affecting the Burden Layer Structure in the Blast Furnace Shaft. Metals, 9(9), 1003. https://doi.org/10.3390/met9091003