Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels

Abstract

1. Introduction

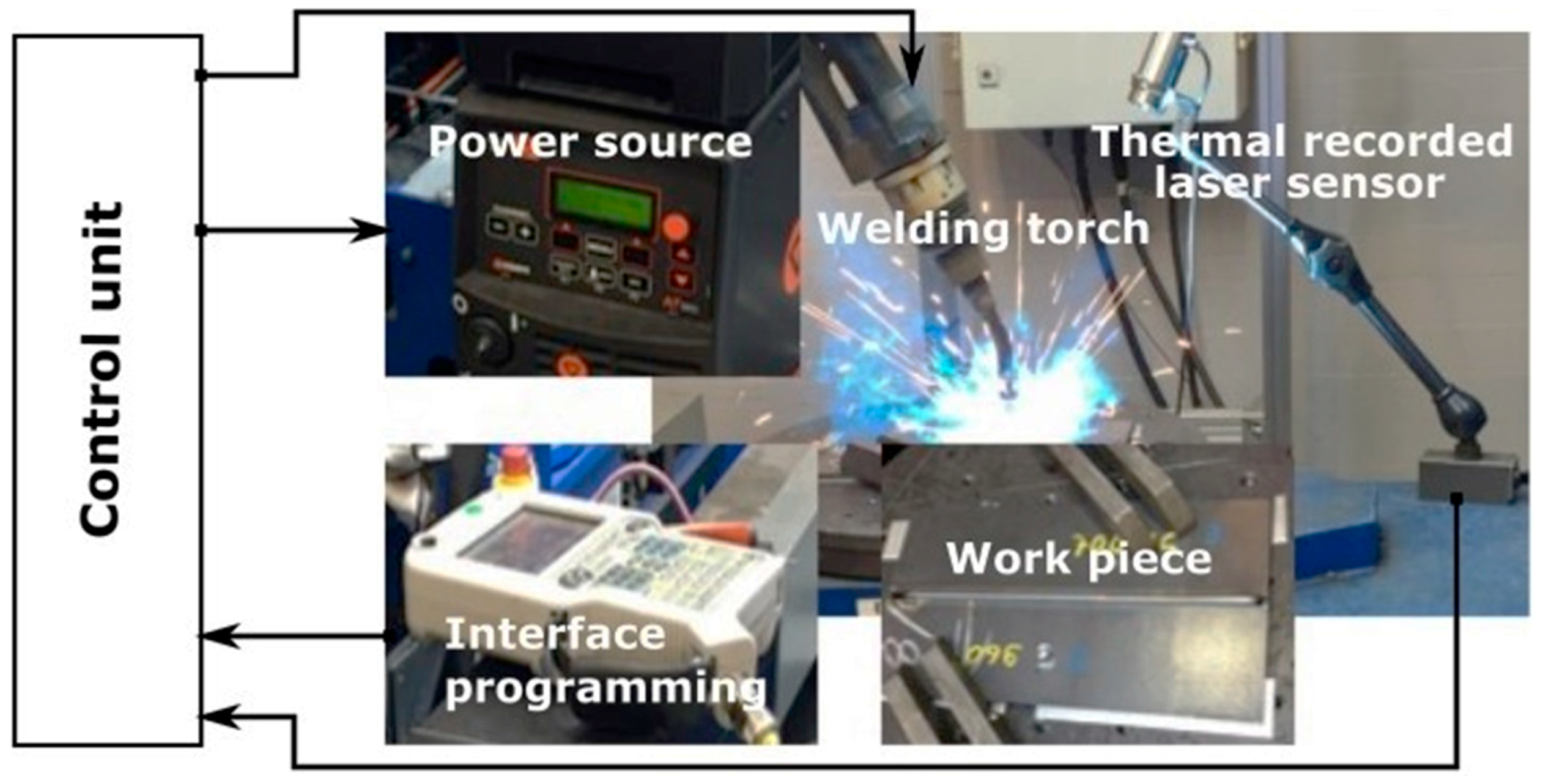

2. Experimental Setup

2.1. Welding Procedure

2.2. Tests of Weld Joints

2.2.1. Conducted Non-Destructive Tests

2.2.2. Conducted Destructive Tests

3. Results

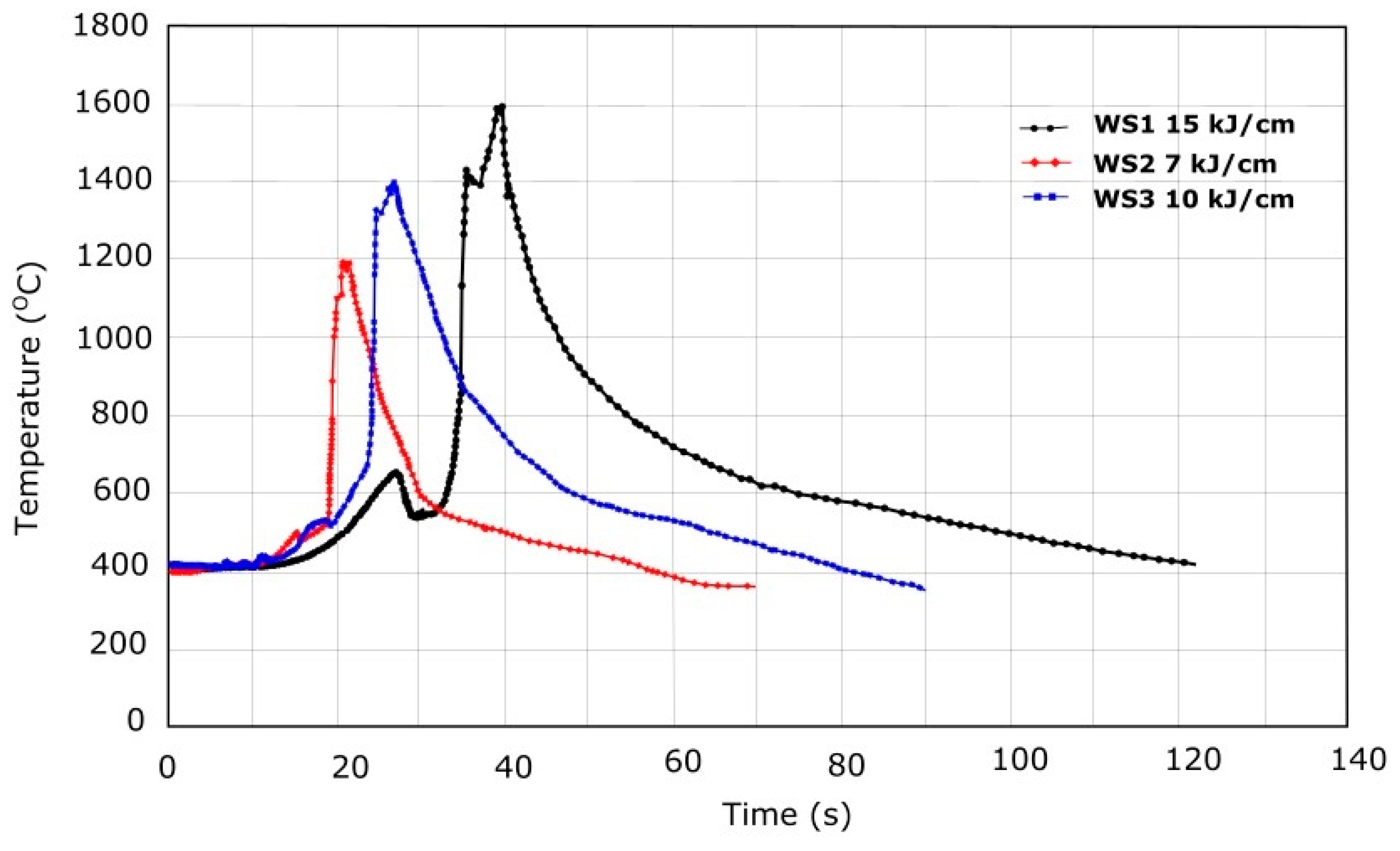

3.1. Thermal Profile

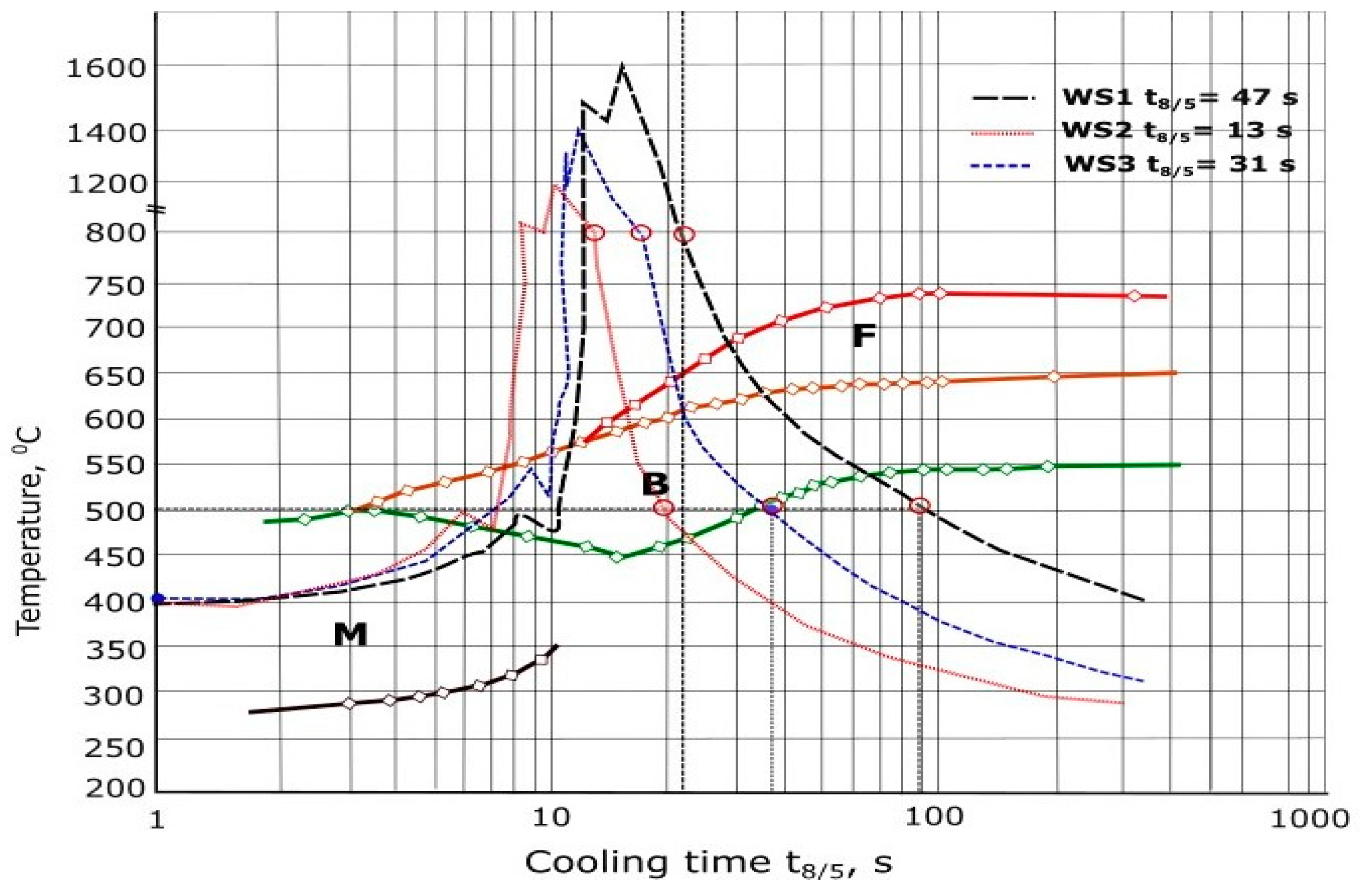

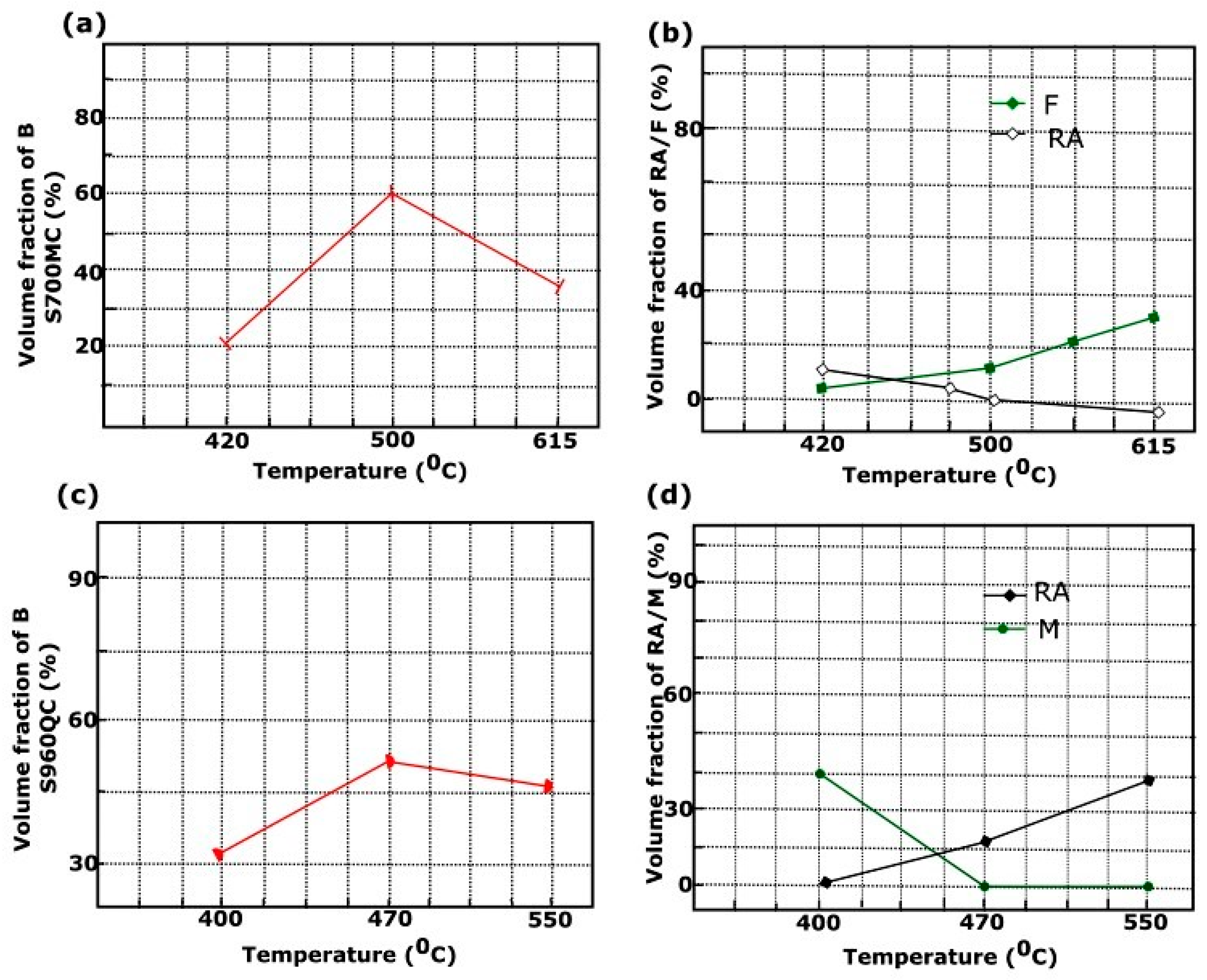

3.2. CCT Diagram of S700MC Steel

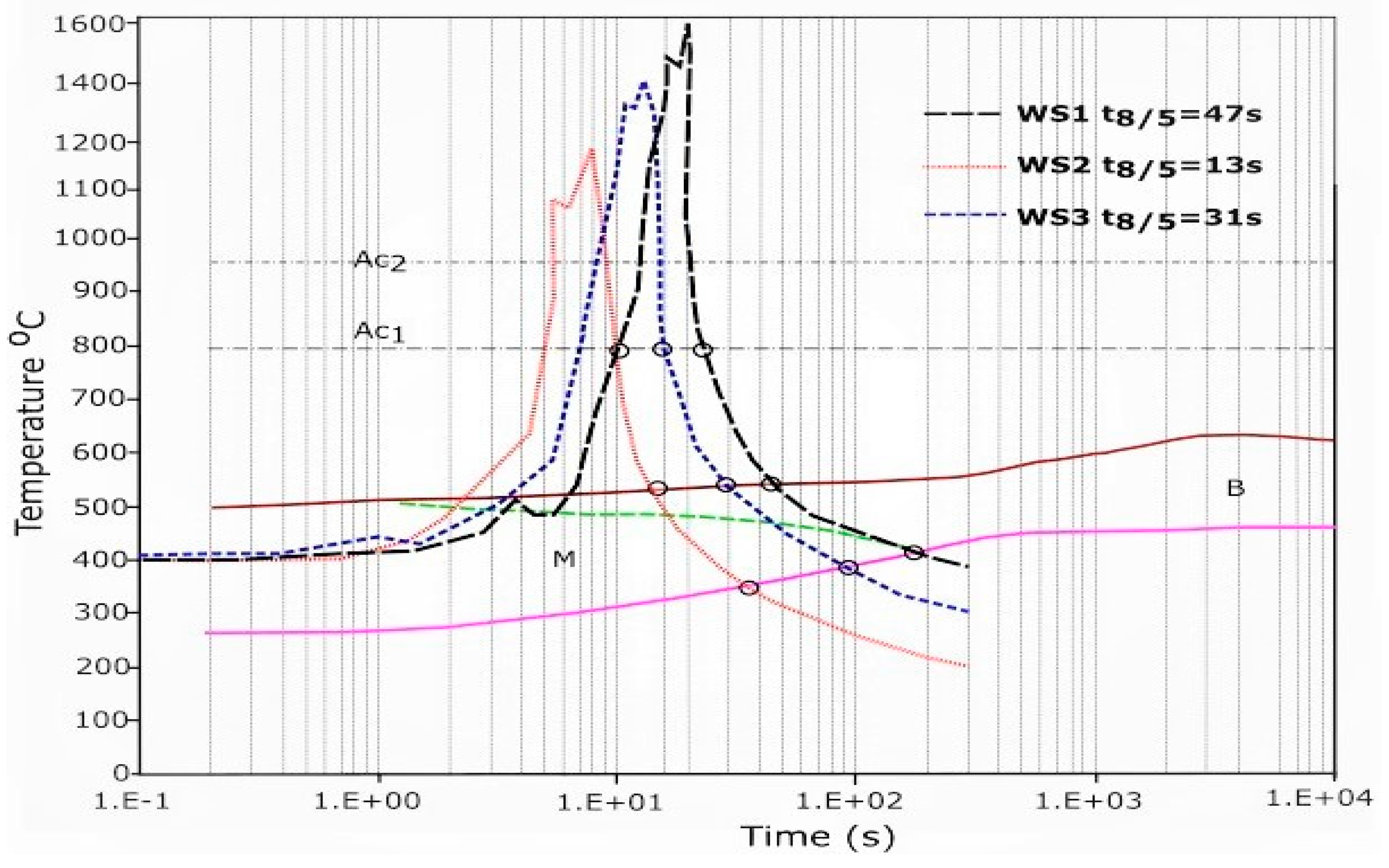

3.3. CCT Diagram of S960QC Steel

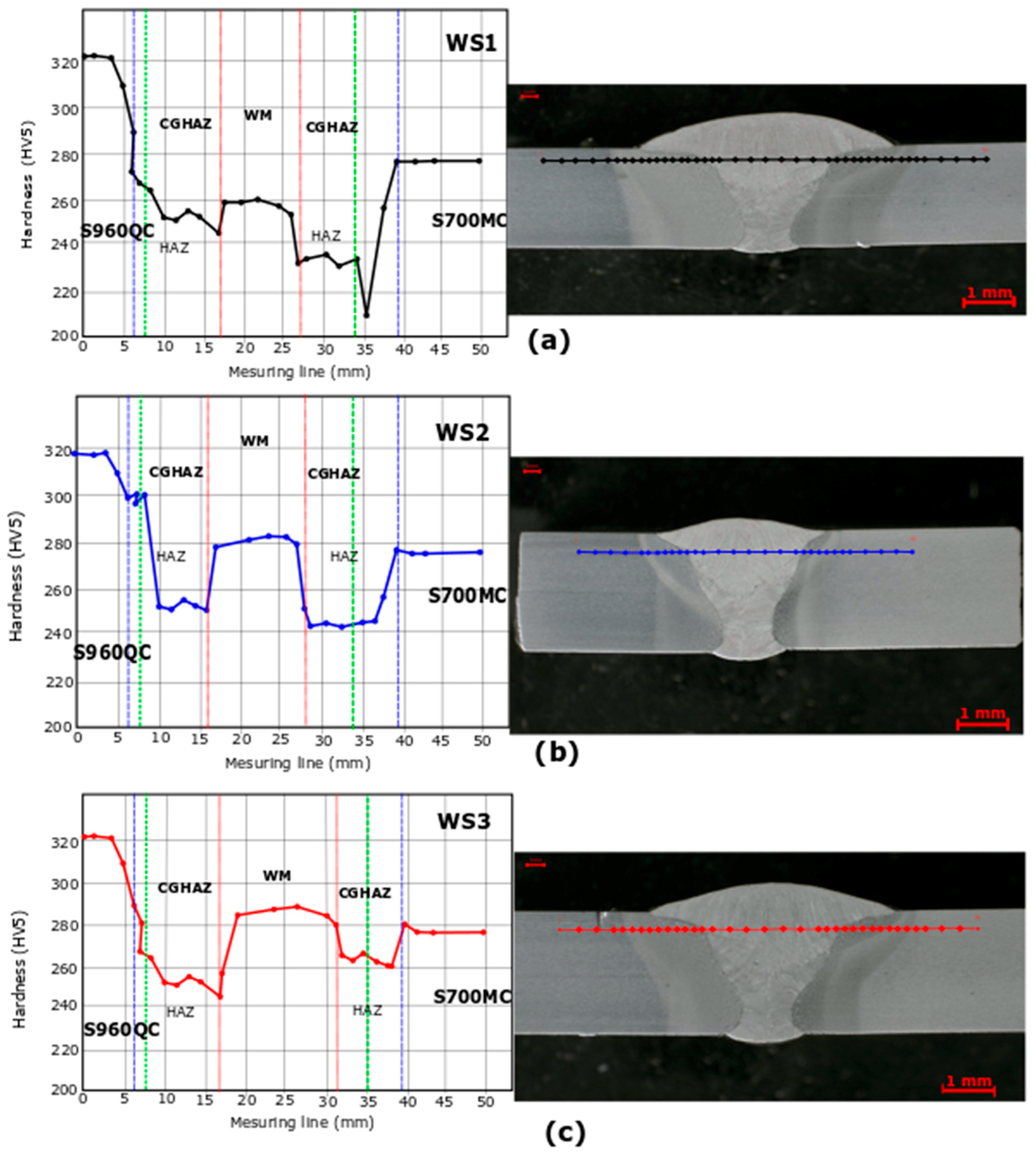

3.4. Hardness Analysis of the Dissimilar Weld Joints

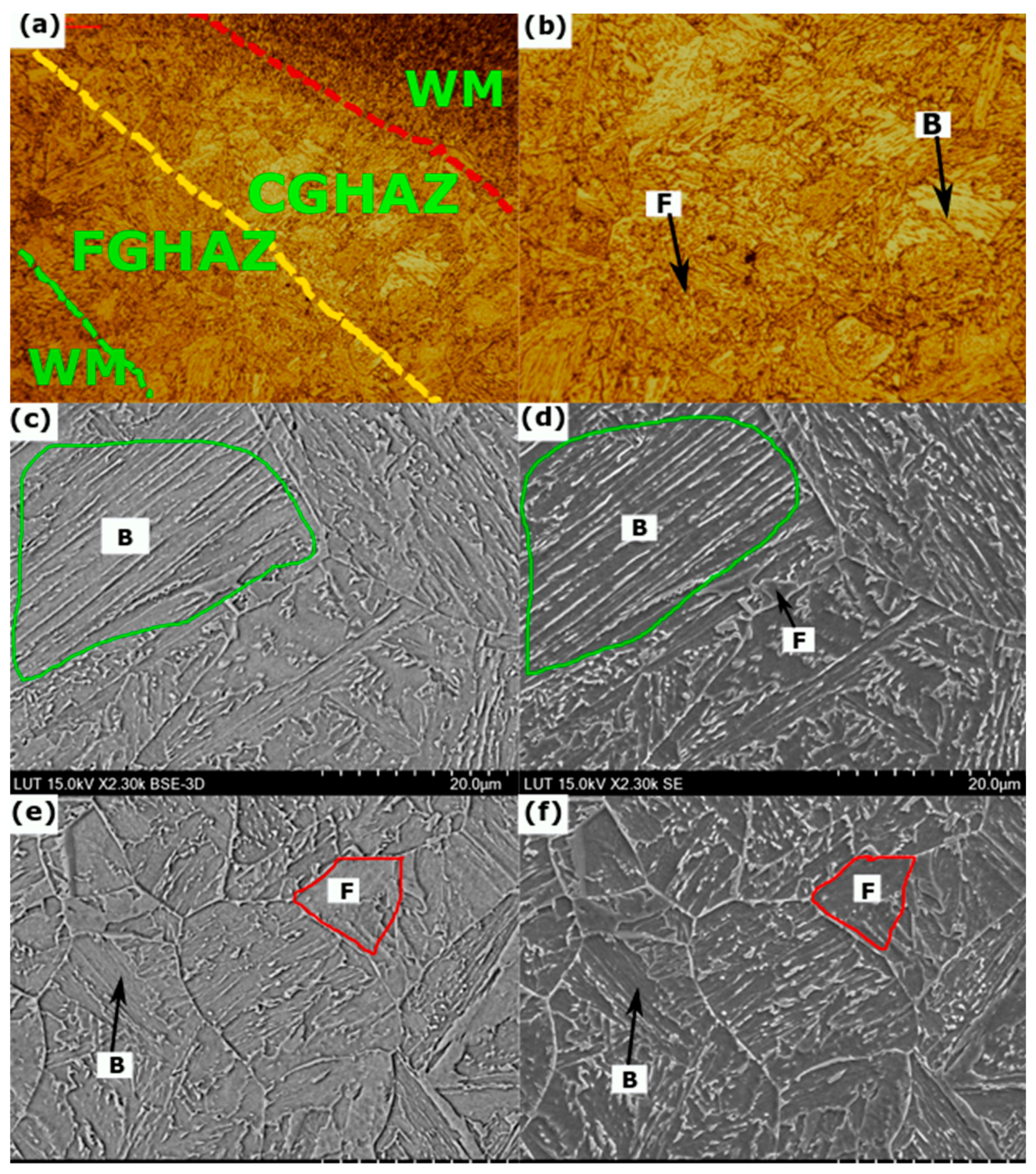

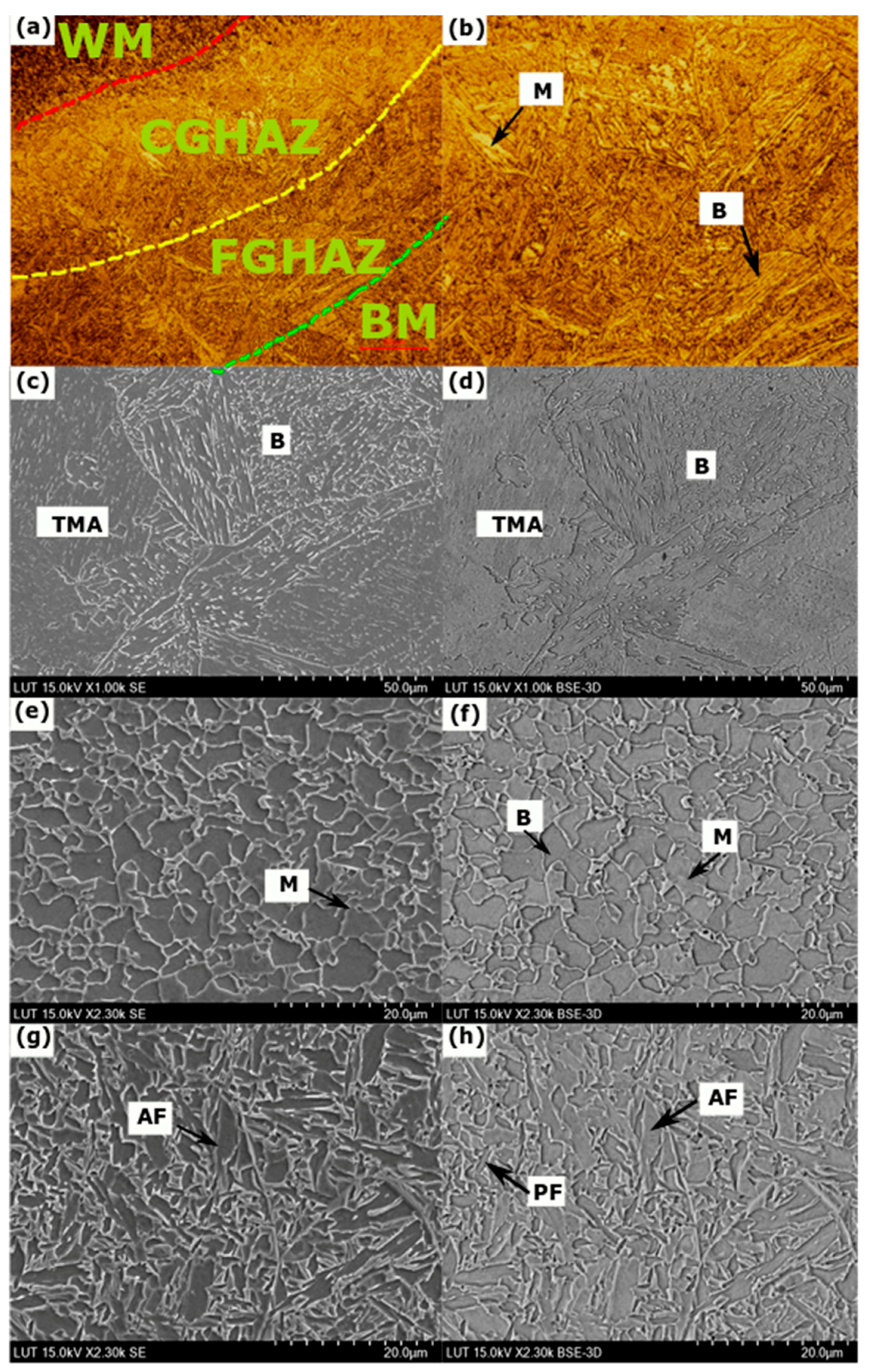

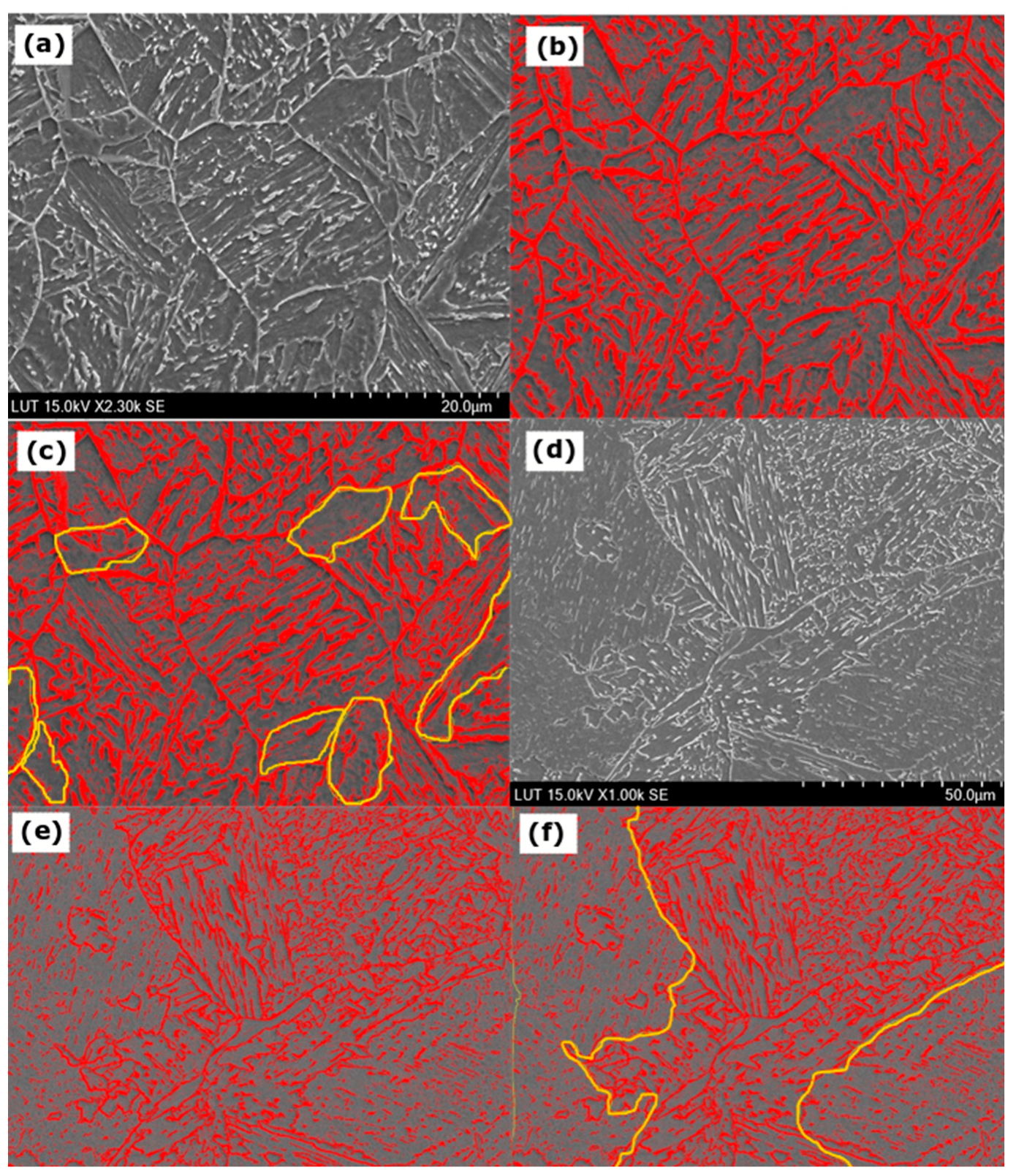

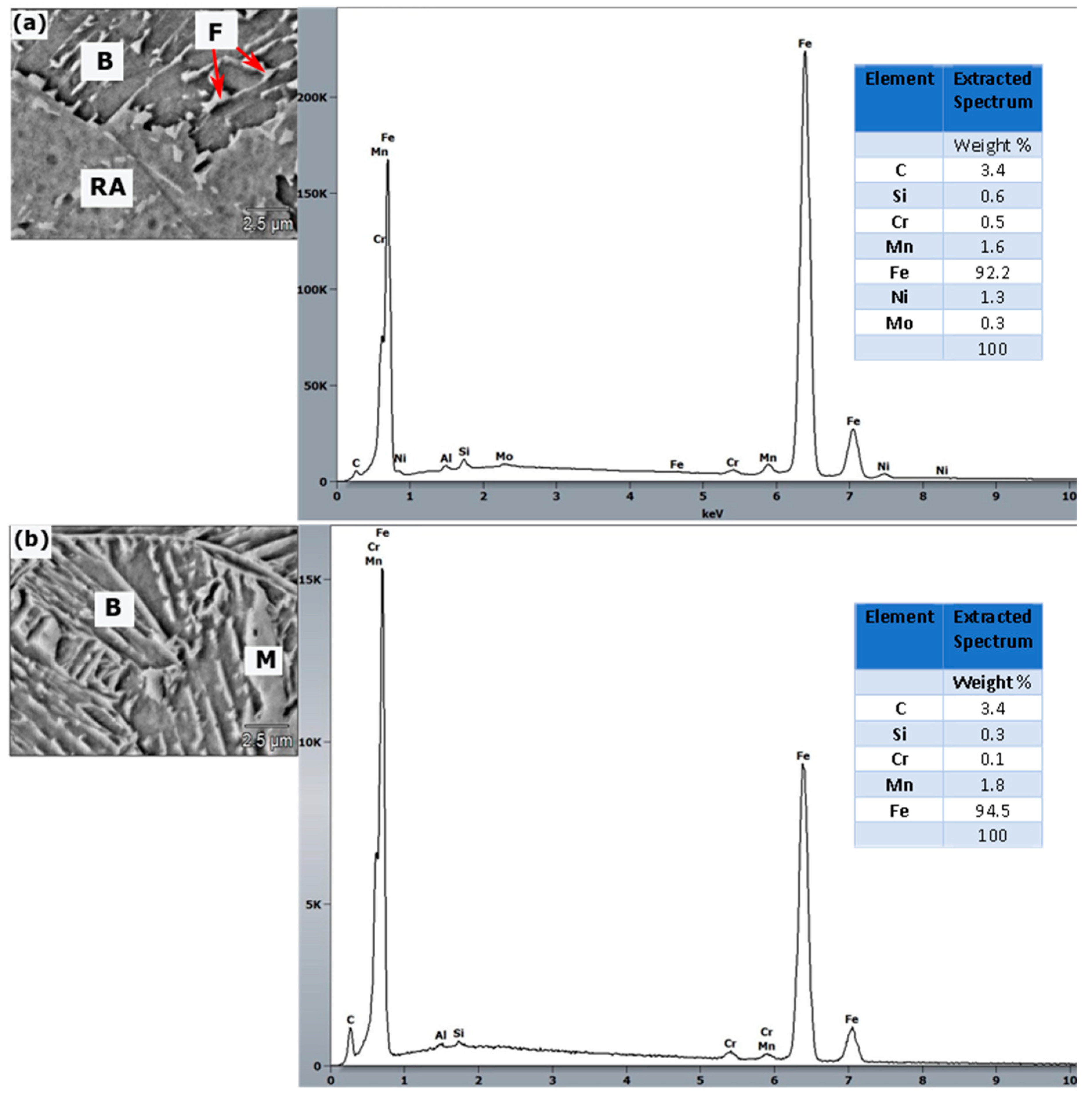

3.5. Effect of the Welding Process on the Microstructure of the Dissimilar Joint

3.5.1. Base Materials

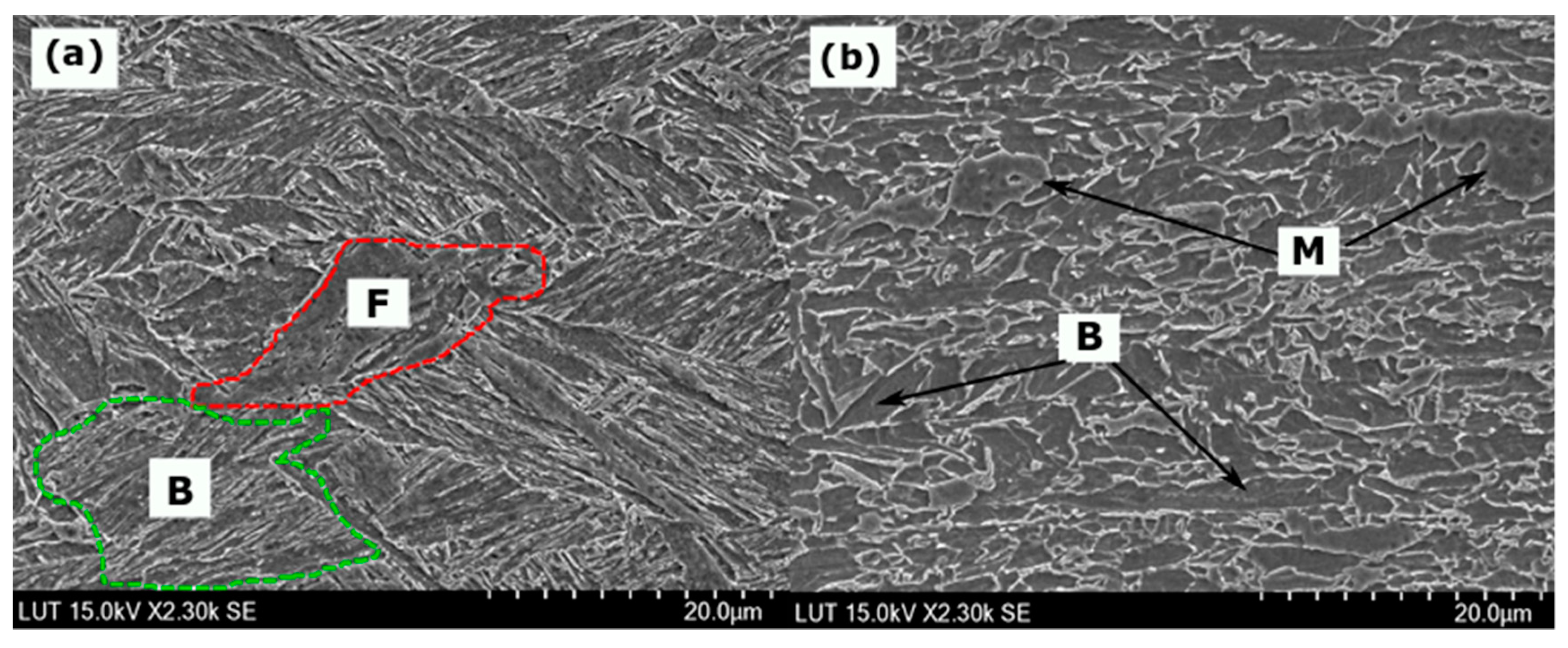

3.5.2. Microstructure Behavior of S700MC HAZ

3.5.3. Microstructure Behavior of S960QC HAZ

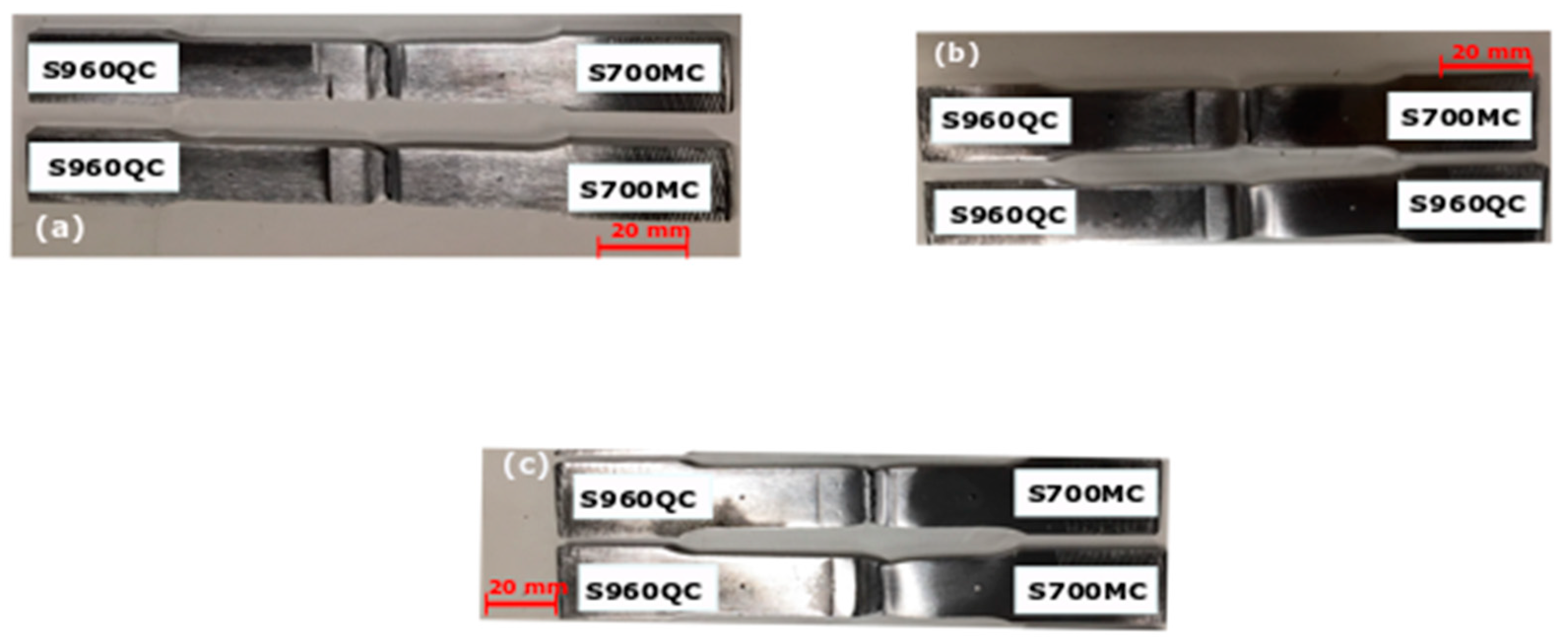

3.6. Tensile Test Analysis

4. Conclusions

- Experimental analysis of the heat effects in welding dissimilar S700MC/S960QC using an undermatched filler wire enabled measurement of the hardness behavior of the weld joint and evaluation of the formation of B, F, M, and RA in the HAZ region of both BMs. The same reference samples were used to evaluate the volume fraction of microstructure formations at the end of the transformation and to evaluate the mechanical behavior in the HAZ.

- Heat input of 7 kJ/cm resulted in a faster cooling rate (33 °C/s), which slightly decreased the average hardness in the HAZ of both materials. In the FGHAZ of S700MC, it was observed that there was a decrease in hardness of 11% to 245 HV5 versus 270 HV5 for the BM. In the S960QC steel, the lowest hardness was found in the FGHAZ, which decreased by 22% to 268 HV5 versus 320 HV5 for the BM. In the FGHAZ, using the whole sample, the hardness of both steels underwent a decrease of 15% for S700MC and 20% for S960QC.

- When considering the microstructures obtained with a cooling rate of 21 °C/s, the B–F constituent formed at the interface of S700MC austenite grains and some lath B morphology was observed. For S960QC, the formation of B, M, and RA was observed during the transformation. In the microstructure with a carbon content of 0.09% (S960QC), the highest volume fractions of RA (18%), bainite (55%), and M (27%) were observed.

- In the microstructure of S700MC with a carbon content of 0.056%, the highest volume fractions of B (60%), F (approximately 35%), and RA (5%) resulted in the composition of 1.3 Ni, 0.4 Mo, 1.6 Mn in the CGHAZ. Application of a heat input of 10 kJ/cm resulted in the best combination of alloy elements, which led to a slight increase in the hardness to 260 HV5 and a slight increase in the strength of the welded joint.

- The tensile strength of GMA welded dissimilar S700MC and S960QC steel specimens had different values compared to the strength of the BM, and all the welded specimens failed in the HAZ of the S700MC side. The elongation of the specimens differed from that of the BM for all the studied cooling rates. The average elongation indicated a 17% decrease when compared to the BM.

- The best combination of hardness and strength was achieved by choosing a cooling rate of 21 °C/s, which achieved an equilibrium of B, F, and M in the dissimilar S700MC/S960QC weld, reducing the formation of proeutectoid grain boundary carbide.

- To improve the hardening ability and strength of the dissimilar S700MC/S960QC welded samples using GMA welding, an increase in the number of alloy elements in the filler wire, such as Ni, Cr, and Mo, is required.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mvola, B.; Kah, P.; Martikainen, J.; Suoranta, R. Dissimilar high-strength steels: Fusion welded joints, mismatches, and challenges. Rev. Adv. Mater. Sci. 2016, 44, 146–159. [Google Scholar]

- Monika, K.; Bala, M.; Nanda, K.; Prahalada, R. The Effect of Heat input on the Mechanical Properties of MIG welded Dissimilar Joint. Inter. J. Eng. Res. Tech. 2013, 2, 1406–1413. [Google Scholar]

- Sarizam, M.; Yu-Ichi, K. Effect of cooling rate invariant selection during bainite transformation in heat affected zone of Cr-Mo steel. J. Eng. Appl. Sci. 2015, 10, 9481–9486. [Google Scholar]

- Laitinen, R. Improvement of Weld HAZ touGhness at Low Heat Input by Controlling the Distribution of M-A Constituents. Ph.D. Dissertation, Acta Universitatis Ouluensis, Oulu, Finland, 2006. [Google Scholar]

- Tadashi, F.; Shin-ya, A.; Goro, M. Anisotropic Ferrite Growth and Substructure Formation du Bainite Transformation in Fe-9Ni-C alloys: In-Situ Measurement. Mat. Trans. 2018, 59, 214–223. [Google Scholar]

- Njock Bayock, F.; Kah, P.; Mvola, B.; Pavel, L. Experimental review of the thermal analysis of dissimilar high-strength steel. Rev. Adv. Mater. Sci. 2019, 58, 38–49. [Google Scholar] [CrossRef]

- Wei, G.; Lin, L.; Shiyun, D.; Dave, C.; Alan, T. Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel. Opt. Lasers Eng. 2017, 91, 1–15. [Google Scholar]

- Gaspar, M.; Balogh, A. GMAW experiments for advanced (Q+T) high strength steels. Prod. Pro. Syst. 2013, 6, 9–24. [Google Scholar]

- Karkhin, V.; Michailov, V.; Petrov, P. Principles of Welding; St.Petersburg Polytechnic University Publishing: St. Petersburg, Russia, 2016. [Google Scholar]

- Porter, D.; Laukkanen, A.; Nevasmaa, P.; Rahka, K.; Wallin, K. Performance of TMCP steel for mechanical properties after cold forming and post-forming heat treatment. Int. J. Press. Vessel Pip. 2004, 81, 867–877. [Google Scholar] [CrossRef]

- Siltanen, J.; Tihinen, S. Position welding of 960 MPa ultra-high-strength steel. J. Laser Appl. 2012. [Google Scholar] [CrossRef]

- Ndiwe, B.; Mvola, B.; Kah, P.; Njock Bayock, F. Effect of consumable filler wire composition to mismatches of high-Mn steels welded joints. In Proceedings of the International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017. [Google Scholar]

- Schneide, R.C.; Ernst, W.; Schnitzer, R.; Staufer, H.; Vallant, R.; Enzinger, N. Welding of S960MC with undermatching filler material. Weld. World 2018, 62, 801–809. [Google Scholar] [CrossRef]

- Gorka, J. Assessment of Steel Subjected to the Thermomechanical Control Process with Respect to Weldability. Metals 2018, 8, 169. [Google Scholar] [CrossRef]

- Gorka, J. Analysis of simulated welding thermal cycles S700MC using thermal imaging camera. Adv. Mater. Res. 2014, 837, 375–380. [Google Scholar] [CrossRef]

- Gorka, J. Microstructure and properties of the high-temperature (HAZ) of thermo-mechanically treated S700MC high-yield-strength steel. Mat. Tehnol. 2016, 50, 617–621. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mat. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Njock Bayock, F.; Kah, P.; Layus, P.; Karkhin, V. Numerical and experimental investigation of the heat input effect on the mechanical properties and microstructure of dissimilar weld joints of 690-MPa QT and TMCP steel. Metals 2019, 9, 355. [Google Scholar] [CrossRef]

- Talas, S. The assessment of carbon equivalent formulas in predicting the properties of steel weld metals. Mater. Des. 2010, 31, 2649–2653. [Google Scholar] [CrossRef]

- Changfei, W.; Zhaodong, W.; Xiangtao, D.; Guodong, W.; Raja, D. Effect of heat input on the microstructure and mechanical properties of low alloy ultra-high strength structural steel welded joint. Steel Res. Int. 2018, 89, 1–9. [Google Scholar]

- Gyasi, E.; Kah, P. Structure integrity analysis of the usability of high strength steel (HSS). Rev. Adv. Mater. Sci. 2016, 2, 39–52. [Google Scholar]

- Sadeghan, M.; Shamanian, M.; Shafyei, A. Effect of heat input on microstructure and mechanical properties of dissimilar joints between super duplex stainless steel and high strength steel. Mat. Des. 2014, 60, 678–684. [Google Scholar] [CrossRef]

- Zhuangfei, W.; Minghao, S.; Shuai, T.; Guodong, W. Effect of heat input and M-A constituent on microstructure evolution and mechanical properties of heat affected zone in low carbon steel. J. Wuhan Univ. Tech. Mat. Sci. Educ. 2017, 32, 1163–1170. [Google Scholar]

- Radaj, D. Heat Effects of Welding; Springer: Berlin, Germany, 1992. [Google Scholar]

- Tasalloti, H.; Kah, P.; Martikainen, J. Effect of heat input on dissimilar welds of ultra-high-strength steel and duplex stainless steel: Microstructural and compositional analysis. Mat. Charact. 2017, 123, 29–41. [Google Scholar] [CrossRef]

- Yan, S.; Liu, X.; Liang, T.; Chen, J.; Zhao, Y. Effect of micro-alloying elements on microstructure and mechanical properties in C-Mn-Si Quenching and Partitioning (Q&P) steels. Steel Res. Int. 2019, 90, 1–10. [Google Scholar]

- ISO. Standard Test Methods for Micro Indentation Hardness of Materials; ISO 6507-1:2018; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- ISO. International Standard Test Methods for Tensile Testing of Metallic Materials; ISO 6892-1: 2016; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. Non-Destructive Testing of Weld-Visual Testing of Fusion-Welded Joint; ISO 17637–2017; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Poorhaydari, K.; Patchett, B.; Ivey, D. Estimation of cooling rate in the welding of plates with intermediate thickness. Wel. J. 2005, 84, 149–155. [Google Scholar]

- Xiuzhi, Y.; Lichao, Z.; Yusheng, S.; Shengfu, Y.; Chunfa, D. Effective microstructure unit in control of impact toughness in CGHAZ for high strength bridge steel. J. Wuhan Univ. Tech. Mat. Sci. Educ. 2018, 33, 177–184. [Google Scholar]

- Hamada, M. Control of strength and toughness at the heat affected zone. Weld. Inter. 2003, 17, 265–270. [Google Scholar] [CrossRef]

- Guo, W.; Li, L. Laser welding of high strength steels (S960 and S700) with medium thickness. J. Laser Appl. 2016, 28, 1–10. [Google Scholar] [CrossRef]

- Hochhauser, F.; Ernest, W.; Rauch, R.; Vallant, R.; Enzinger, N. Influence of the soft zone on the strength of welded modern HSLA steels. Weld. World 2006, 56, 77–85. [Google Scholar] [CrossRef]

- In, K.; Hyunbin, N.; Myungjin, L.; Daegeun, N.; Yeong-do, P.; Namhyun, K. Effect of Martensite-Austenite constituent on low-temperature toughness in YS 500 MPa Grade Steel Welds. Metals 2018, 8, 1–11. [Google Scholar]

- ASTM. Standard Practice for Radiographic Examination of Weldments Using X-Ray Film; ASTM E1032–19; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Tian, J.; Xu, G.; Zhou, M.; Hu, H. Refined bainite microstructure and mechanical properties of high-strength low-carbon bainitic steel treated by austempering below and above Ms. Steel Res. Int. 2018, 89, 1–10. [Google Scholar] [CrossRef]

- Ali, M.; Porter, D.; Kömi, J.; Eissa, M.; El Faramawy, H.; Mattar, T. Effect of cooling rate and composition on microstructure and mechanical properties of ultrahigh-strength steels. J. Iron Steel Res. Int. 2019. [Google Scholar] [CrossRef]

| Welded Samples | Pass 1 | Pass 2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Welding Speed (cm/min) | Heat Input Q (kJ/cm) | Current (A) | Voltage (V) | Welding Speed (cm/min) | Q (kJ/cm) | |

| WS1 | 215 | 25.3 | 37.3 | 7 | 211 | 26.7 | 18 | 15 |

| WS2 | 215 | 25.3 | 37.3 | 7 | 203 | 26.6 | 37.5 | 7 |

| WS3 | 215 | 25.3 | 37.3 | 7 | 208 | 26.7 | 24 | 10 |

| Chemical Composition, wt % | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials | С | Si | Mn | Al | B | Nb | Ti | V | Сu | Cr | Ni | Mo | N | P | S | CE |

| S700MC | 0.056 | 0.16 | 1.18 | 0.027 | 0.002 | 0.044 | 0.12 | 0.006 | 0.02 | 0.062 | 0.066 | 0.0150 | 0.005 | 0.01 | 0.005 | 0.38 |

| S960QC | 0.09 | 0.21 | 1.05 | 0.03 | 0.002 | 0.003 | 0.032 | 0.008 | 0.025 | 0.82 | 0.04 | 0.04 | - | 0.01 | 0.004 | 0.49 |

| Filler wire | 0.08 | 0.60 | 1.40 | - | - | - | 0.05 | - | ≤0.30 | 0.30 | 2.50 | 0.45 | - | - | - | 0.45 |

| Mechanical Properties | ||||||||||||||||

| Materials | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation A5, % | Hardness HV5 | ||||||||||||

| S700MC | 768 | 822 | 12 | 280 | ||||||||||||

| S960QC | 960 | 1000 | 18 | 320 | ||||||||||||

| Filler wire | 780 | 830 | 17 | 270 | ||||||||||||

| Weld Heat Input | Cooling Time (t8/5) | Cooling Rate (R500) |

|---|---|---|

| WS1 (15 kJ/cm) | 47 s | 10 °C/s |

| WS2 (7 kJ/cm) | 13 s | 33 °C/s |

| WS3 (10 kJ/cm) | 31 s | 21 °C/s |

| Sample | Dimensions (mm) | So (mm2) | Fe (kN) | YS (MPa) | TS Fm (kN) | UTS (MPa) | Lo (mm) | Lu (mm) | A5% | Place of Rupture |

|---|---|---|---|---|---|---|---|---|---|---|

| 1A | 24.9 × 8 | 199.2 | 138 | 692.8 | 153.2 | 769.1 | 79 | 83.8 | 6.1 | HAZ S700MC |

| 1B | 24.6 × 8 | 196.8 | 139 | 706.3 | 151.6 | 770.3 | 79.2 | 84.9 | 7.2 | HAZ S700MC |

| Av. | - | - | - | 699.5 | - | 769.7 | - | - | 6.6 | - |

| 2A | 24.7 × 8 | 197.6 | 150 | 759.1 | 161.6 | 817.8 | 79.4 | 87.4 | 10 | HAZ S700MC |

| 2B | 24.9 × 8 | 199.2 | 150 | 753.0 | 162 | 813.3 | 79.6 | 87.4 | 9.8 | HAZ S700MC |

| Av. | - | - | - | 756.1 | - | 815.5 | - | - | 9.9 | - |

| 3A | 24.8 × 8 | 198.4 | 142 | 715.7 | 157.6 | 794.4 | 79.6 | 85.3 | 7.2 | HAZ S700MC |

| 3B | 25 × 8 | 200 | 140 | 700 | 166.3 | 823 | 79.7 | 85 | 6.6 | HAZ S700MC |

| Av. | - | - | - | 707.9 | - | 808.7 | - | - | 6.9 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Njock Bayock, F.; Kah, P.; Mvola, B.; Layus, P. Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels. Metals 2019, 9, 883. https://doi.org/10.3390/met9080883

Njock Bayock F, Kah P, Mvola B, Layus P. Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels. Metals. 2019; 9(8):883. https://doi.org/10.3390/met9080883

Chicago/Turabian StyleNjock Bayock, Francois, Paul Kah, Belinga Mvola, and Pavel Layus. 2019. "Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels" Metals 9, no. 8: 883. https://doi.org/10.3390/met9080883

APA StyleNjock Bayock, F., Kah, P., Mvola, B., & Layus, P. (2019). Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels. Metals, 9(8), 883. https://doi.org/10.3390/met9080883