A Novel Turning-Induced-Deformation Based Technique to Process Magnesium Alloys

Abstract

1. Introduction

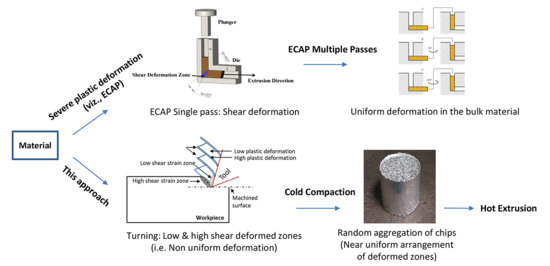

2. Materials and Methods

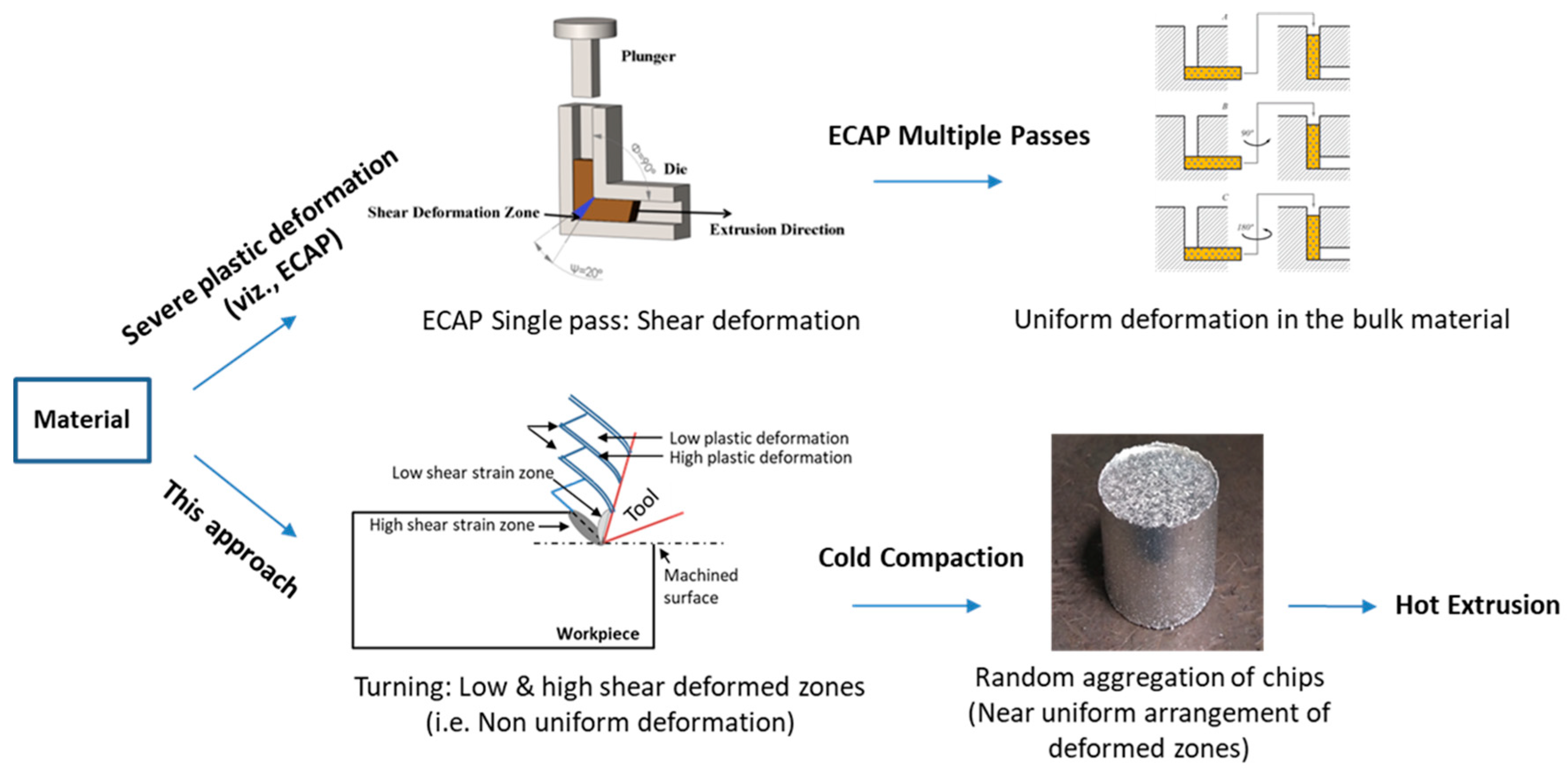

2.1. Processing

2.2. Density and Porosity Measurements

2.3. Microstructure and X-Ray Diffraction

2.4. Mechanical Characterization

3. Results and Discussion

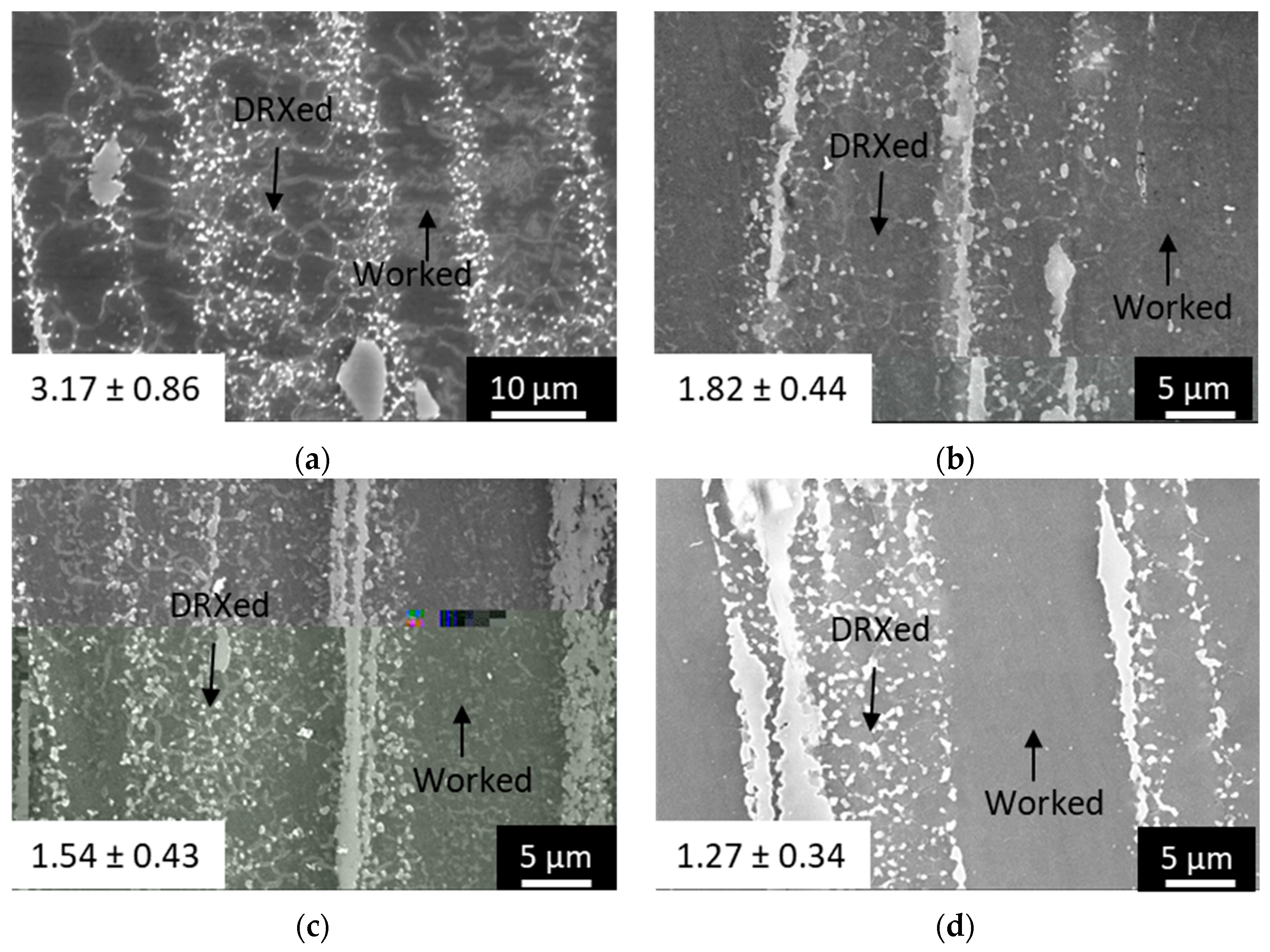

3.1. Plastic Deformation Induced during Turning

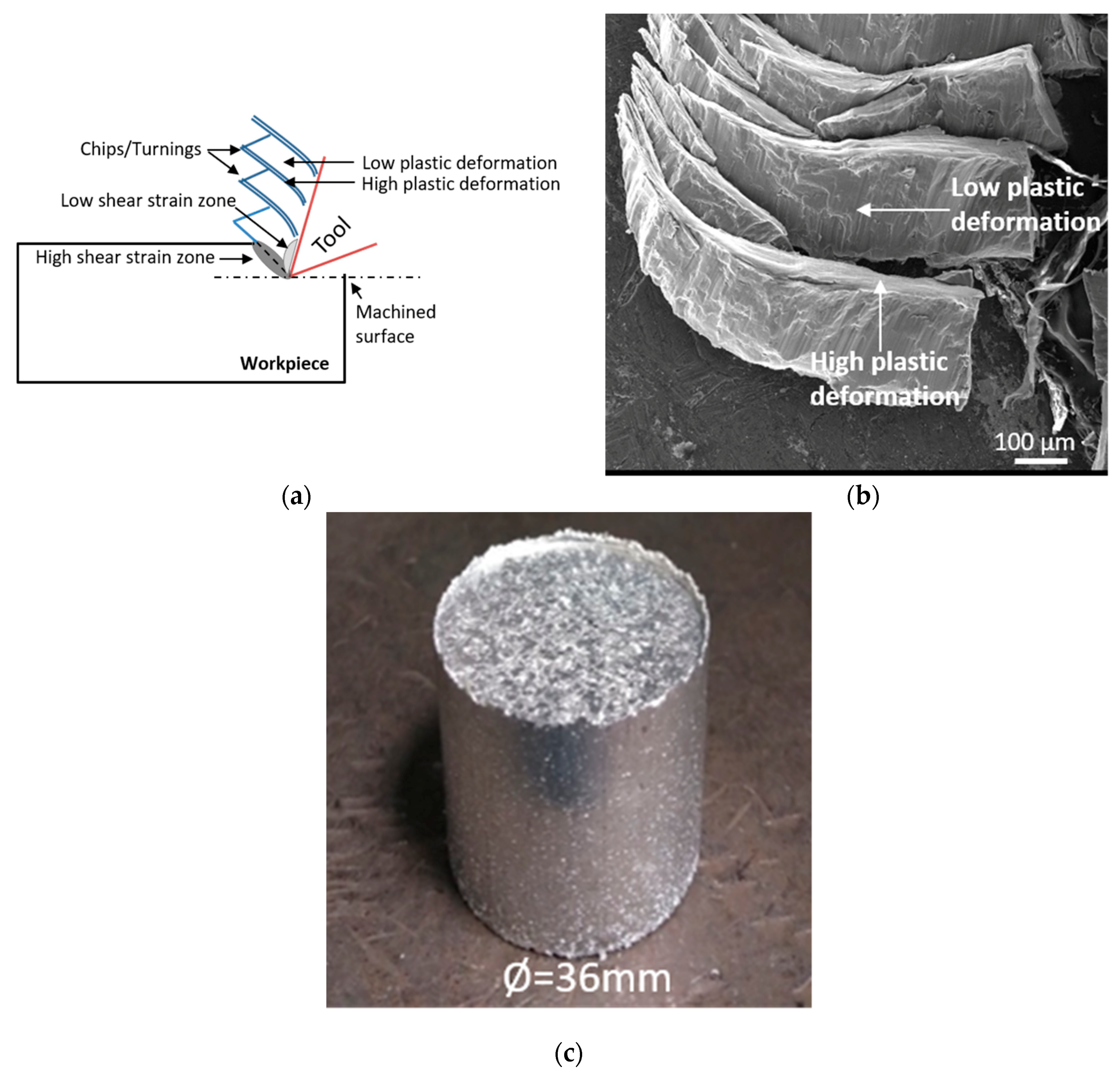

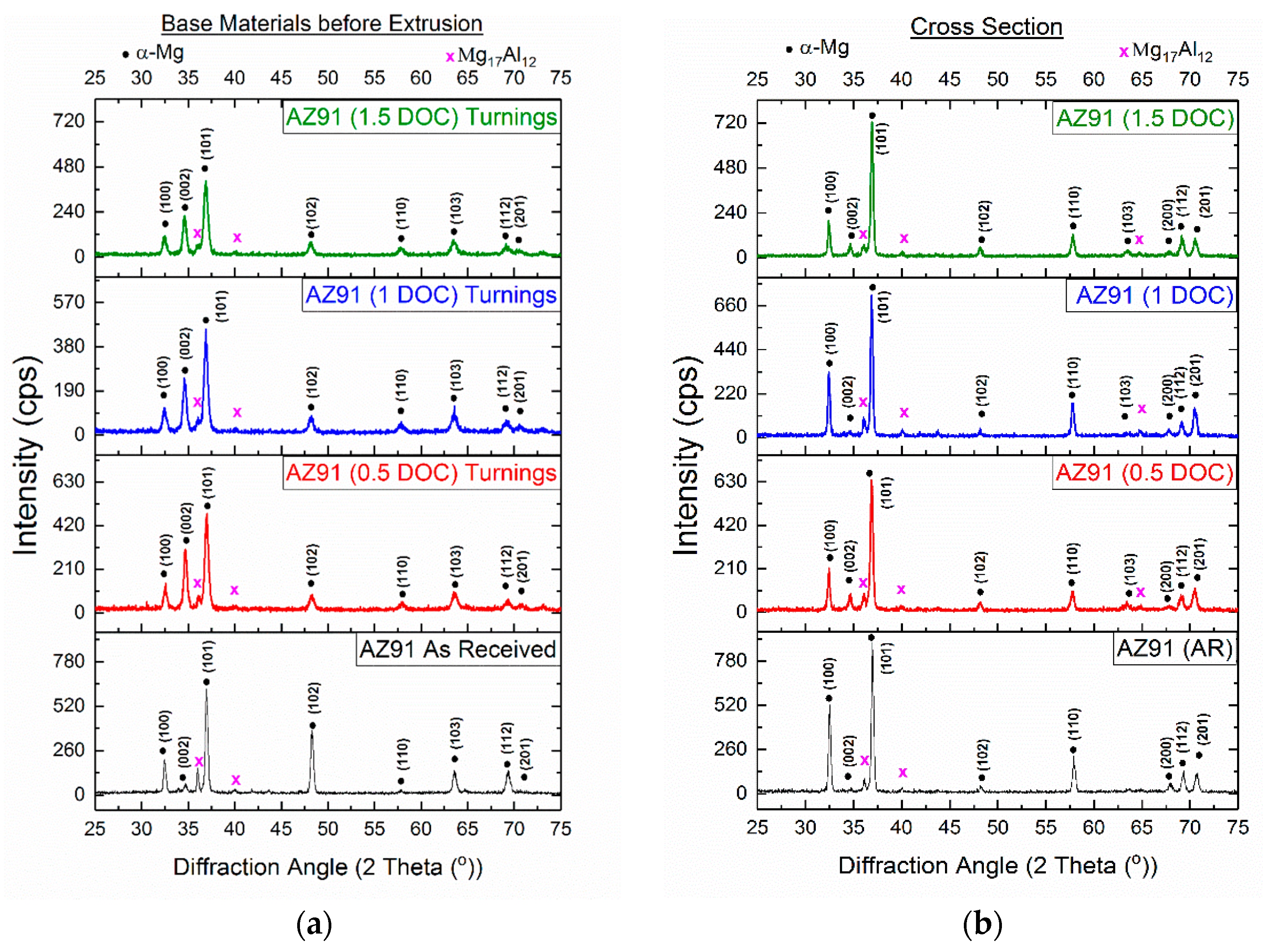

3.2. Effect of Deformation on Microstructural Features

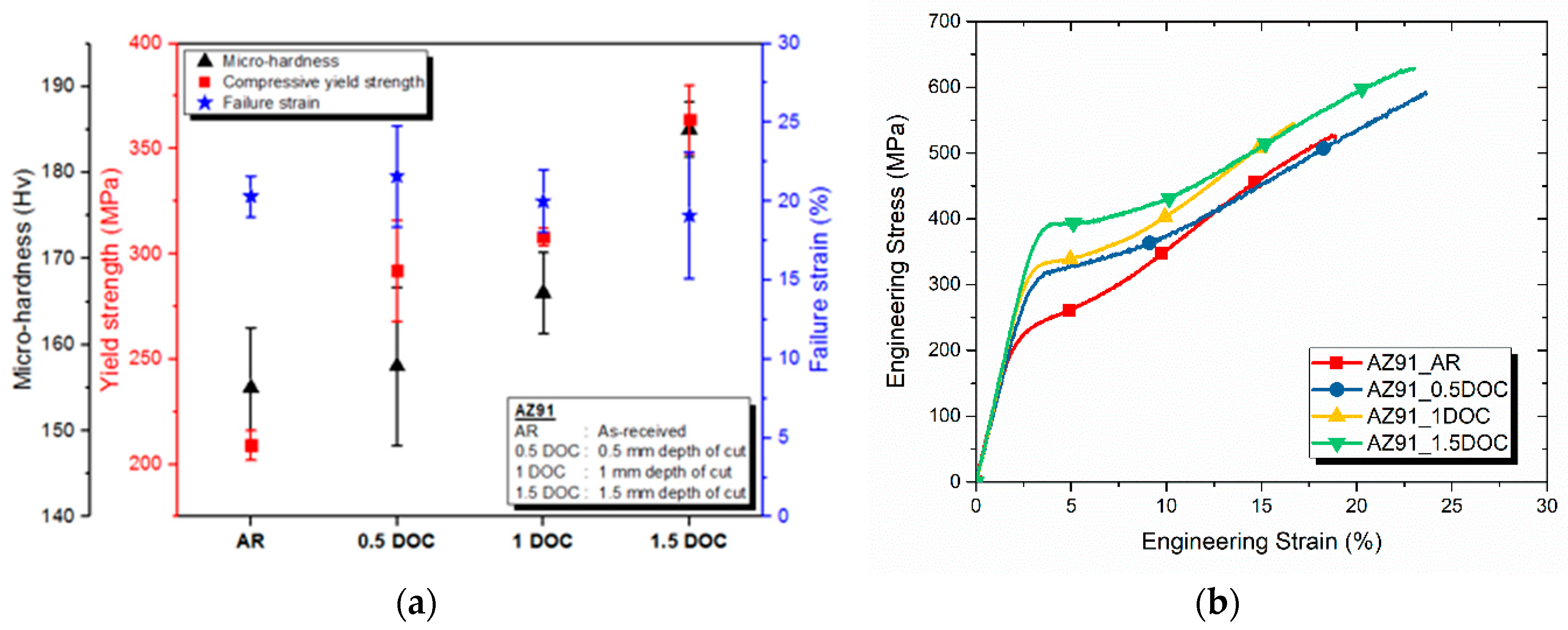

3.3. Effect of Deformation on Mechanical Properties

3.4. Mechanism and Comparison with Conventional Deformation Processes

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tekumalla, S.; Nandigam, Y.; Bibhanshu, N.; Rajashekara, S.; Yang, C.; Suwas, S.; Gupta, M. A strong and deformable in-situ magnesium nanocomposite igniting above 1000 °C. Sci. Rep. 2018, 8, 7038. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.W.; Ding, R.G.; Chiu, Y.L.; Gao, W. Effect of ECAP on microstructure and mechanical properties of cast AZ91 magnesium alloy. J. Phys. Conf. Ser. 2010, 241, 012101. [Google Scholar] [CrossRef]

- Bryła, K.; Dutkiewicz, J.; Litynska-Dobrzynska, L.; Rokhlin, L.L.; Kurtyka, P. Influence of number of ECAP passes on microstructure and mechanical properties of AZ31 magnesium alloy. Arch. Metall. Mater. 2012, 57, 711–717. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Han, J.; Liu, H.; Song, D.; Jiang, J.; Ma, A. High strength and ductility AZ91 magnesium alloy with multi-heterogenous microstructures prepared by high-temperature ECAP and short-time aging. Mater. Sci. Eng. A 2018, 734, 485–490. [Google Scholar] [CrossRef]

- Yuan, Y.; Ma, A.; Jiang, J.; Lu, F.; Jian, W.; Song, D.; Zhu, Y.T. Optimizing the strength and ductility of AZ91 mg alloy by ECAP and subsequent aging. Mater. Sci. Eng. A 2013, 588, 329–334. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.S.J.; Zhilyaev, A.P.; Wang, S.C.; Reed, P.A.S. Superplastic behaviour of AZ91 magnesium alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 637, 1–11. [Google Scholar] [CrossRef]

- Song, B.; Wang, C.; Guo, N.; Pan, H.; Xin, R. Improving tensile and compressive properties of an extruded AZ91 rod by the combined use of torsion deformation and aging treatment. Materials 2017, 10, 280. [Google Scholar] [CrossRef] [PubMed]

- Ghadbeigi, H.; Bradbury, S.R.; Pinna, C.; Yates, J.R. Determination of micro-scale plastic strain caused by orthogonal cutting. Int. J. Mach. Tools Manuf. 2008, 48, 228–235. [Google Scholar] [CrossRef]

- Sinha, N. Ta202a: Introduction to Manufacturing Processes; Department of Mechanical Engineering, IIT Kanpur: Kanpur, India, 2017. [Google Scholar]

- Xiong, B.; Zhang, X.; Li, F.; Hu, H.; Liu, C. Recycling of aluminum A380 machining chips. In Light Metals 2015; Hyland, M., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 1011–1015. [Google Scholar]

- Guo, Y.B.; Salahshoor, M. Process mechanics and surface integrity by high-speed dry milling of biodegradable magnesium–calcium implant alloys. CIRP Ann. 2010, 59, 151–154. [Google Scholar] [CrossRef]

- ASM International. Machining of magnesium and magnesium alloys. In Machining; ASM International: Materials Park, OH, USA, 1989; Volume 16. [Google Scholar]

- Wan, B.; Chen, W.; Lu, T.; Liu, F.; Jiang, Z.; Mao, M. Review of solid state recycling of aluminum chips. Resour. Conserv. Recycl. 2017, 125, 37–47. [Google Scholar] [CrossRef]

- Hu, M.-L.; Ji, Z.-S.; Chen, X.-Y.; Wang, Q.-D.; Ding, W.-J. Solid-state recycling of AZ91D magnesium alloy chips. Trans. Nonferrous Met. Soc. China 2012, 22, s68–s73. [Google Scholar] [CrossRef]

- Rios, P.R.; Siciliano, F., Jr.; Sandim, H.R.Z.; Plaut, R.L.; Padilha, A.F. Nucleation and growth during recrystallization. Mater. Res. 2005, 8, 225–238. [Google Scholar] [CrossRef]

- Yang, W.; Tekumalla, S.; Gupta, M. Cumulative effect of strength enhancer—lanthanum and ductility enhancer—cerium on mechanical response of magnesium. Metals 2017, 7, 241. [Google Scholar] [CrossRef]

- Chen, Y.; Tekumalla, S.; Guo, Y.B.; Shabadi, R.; Shim, V.P.W.; Gupta, M. The dynamic compressive response of a high-strength magnesium alloy and its nanocomposite. Mater. Sci. Eng. A 2017, 702, 65–72. [Google Scholar] [CrossRef]

- Tekumalla, S.; Shabadi, R.; Yang, C.; Seetharaman, S.; Gupta, M. Strengthening due to the in-situ evolution of ß1′ Mg-Zn rich phase in a ZnO nanoparticles introduced Mg-Y alloy. Scr. Mater. 2017, 133, 29–32. [Google Scholar] [CrossRef]

| Composition | Experimental Density (g/cm3) | Theoretical Density (g/cm3) | Porosity (%) |

|---|---|---|---|

| AZ91_AR | 1.816 | 1.835 | 1.06 |

| AZ91_0.5 DOC | 1.815 | 1.835 | 1.10 |

| AZ91_1 DOC | 1.812 | 1.835 | 1.27 |

| AZ91_1.5 DOC | 1.817 | 1.835 | 1.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tekumalla, S.; Ajjarapu, M.; Gupta, M. A Novel Turning-Induced-Deformation Based Technique to Process Magnesium Alloys. Metals 2019, 9, 841. https://doi.org/10.3390/met9080841

Tekumalla S, Ajjarapu M, Gupta M. A Novel Turning-Induced-Deformation Based Technique to Process Magnesium Alloys. Metals. 2019; 9(8):841. https://doi.org/10.3390/met9080841

Chicago/Turabian StyleTekumalla, Sravya, Manasa Ajjarapu, and Manoj Gupta. 2019. "A Novel Turning-Induced-Deformation Based Technique to Process Magnesium Alloys" Metals 9, no. 8: 841. https://doi.org/10.3390/met9080841

APA StyleTekumalla, S., Ajjarapu, M., & Gupta, M. (2019). A Novel Turning-Induced-Deformation Based Technique to Process Magnesium Alloys. Metals, 9(8), 841. https://doi.org/10.3390/met9080841