Prediction of the Weld Qualities Using Surface Appearance Image in Resistance Spot Welding

Abstract

1. Introduction

2. Experiments and Learning Methods

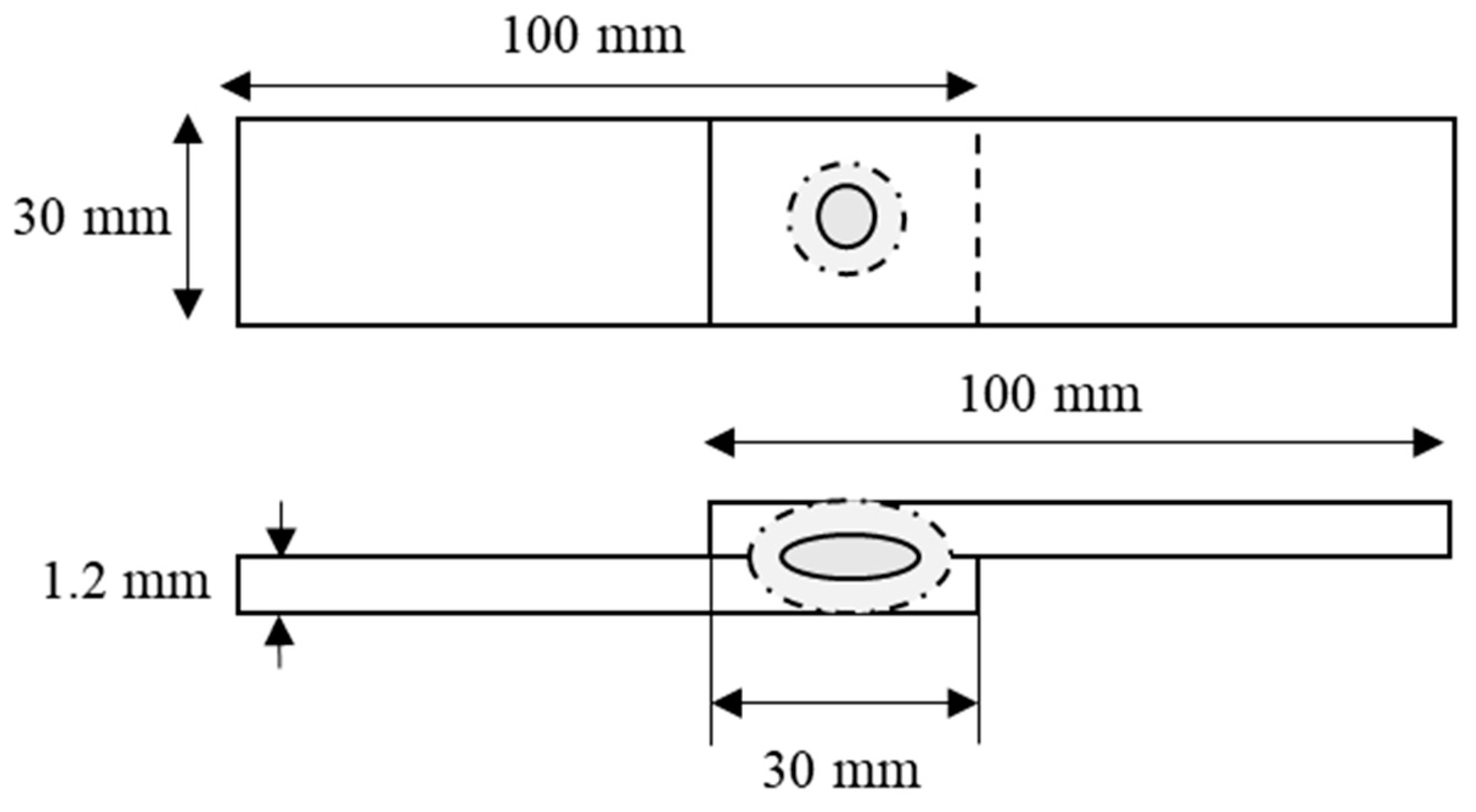

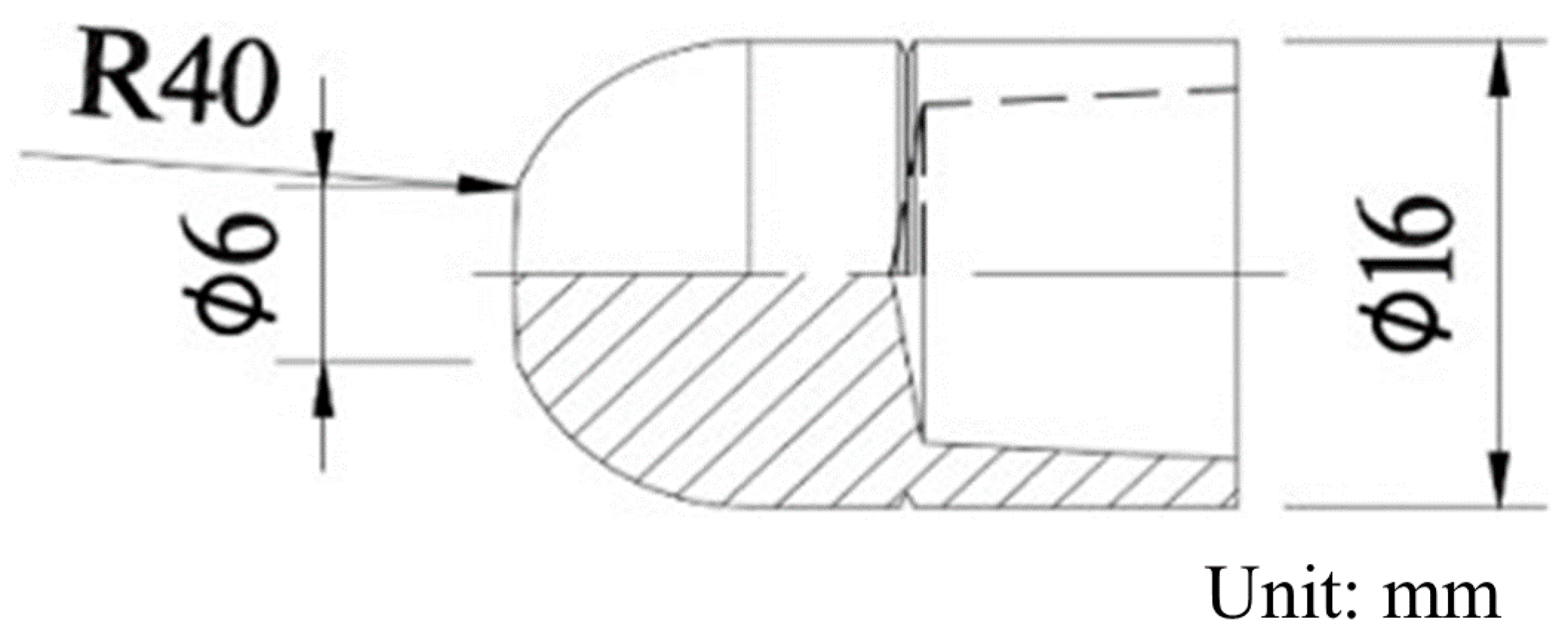

2.1. Materials and Welding Conditions

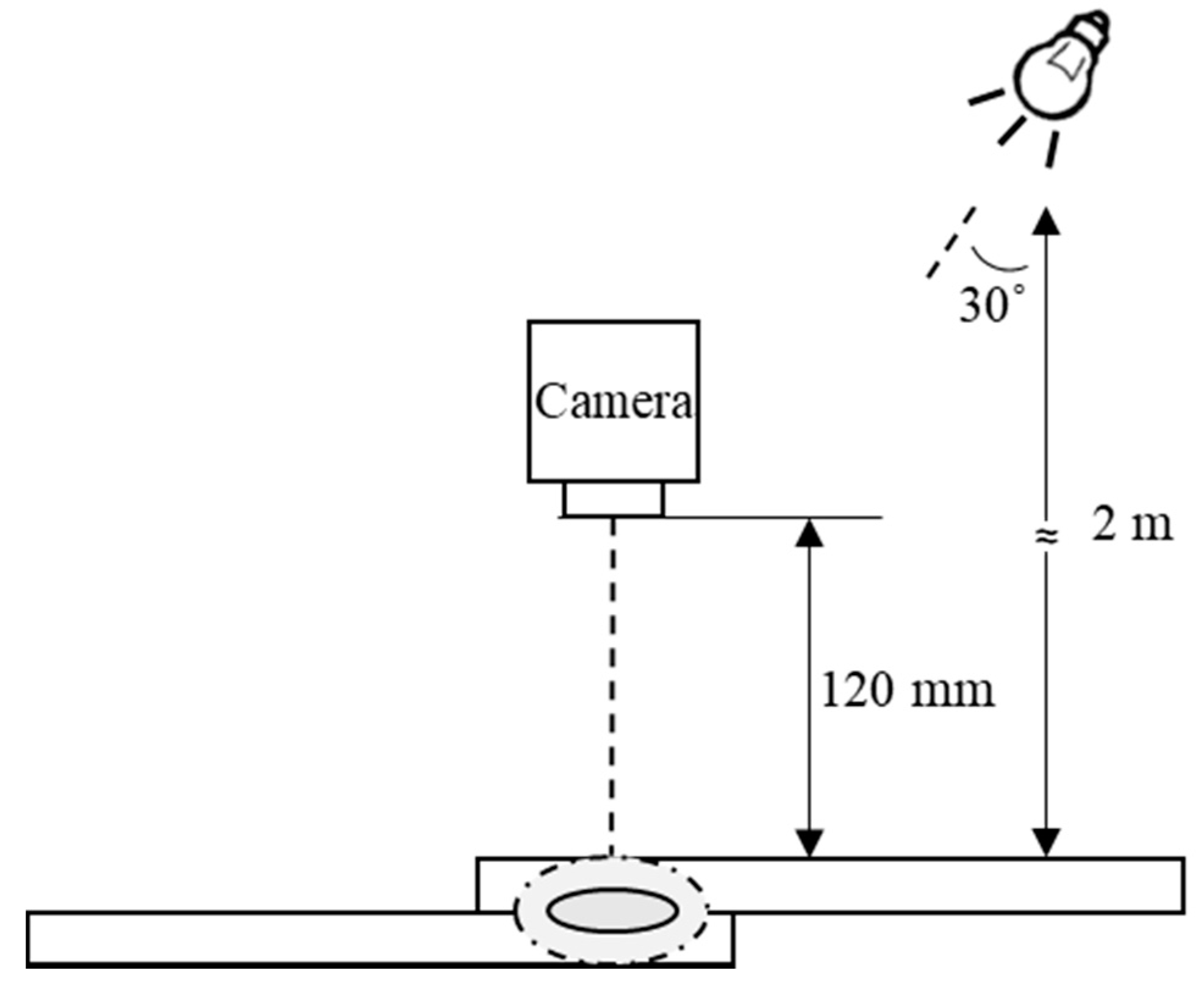

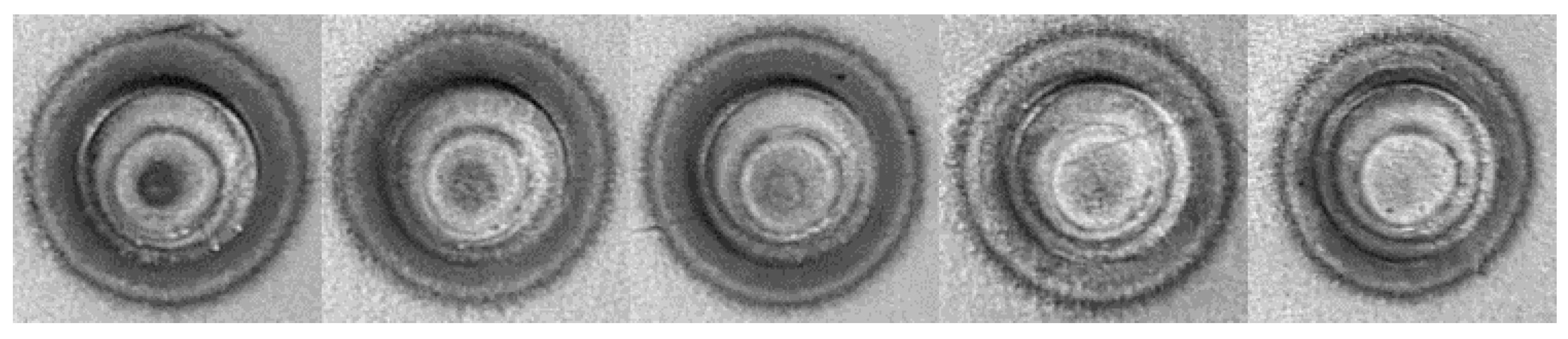

2.2. Weld Surface Appearance Image Processing

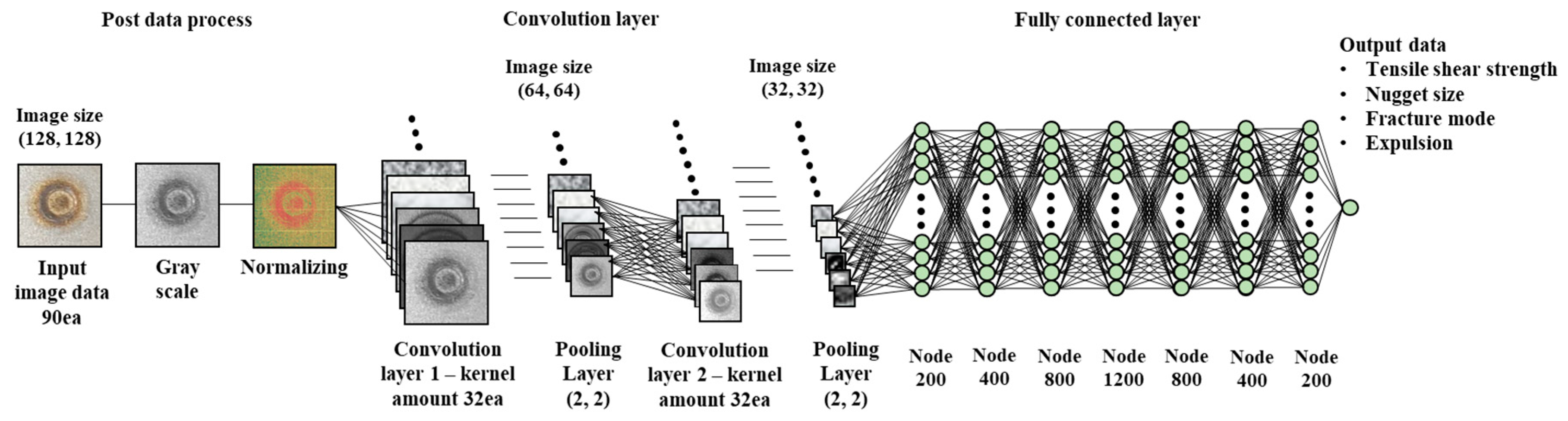

2.3. Convolution Neural Network Algorithm for Prediction of Weld Quality

3. Results and Discussion

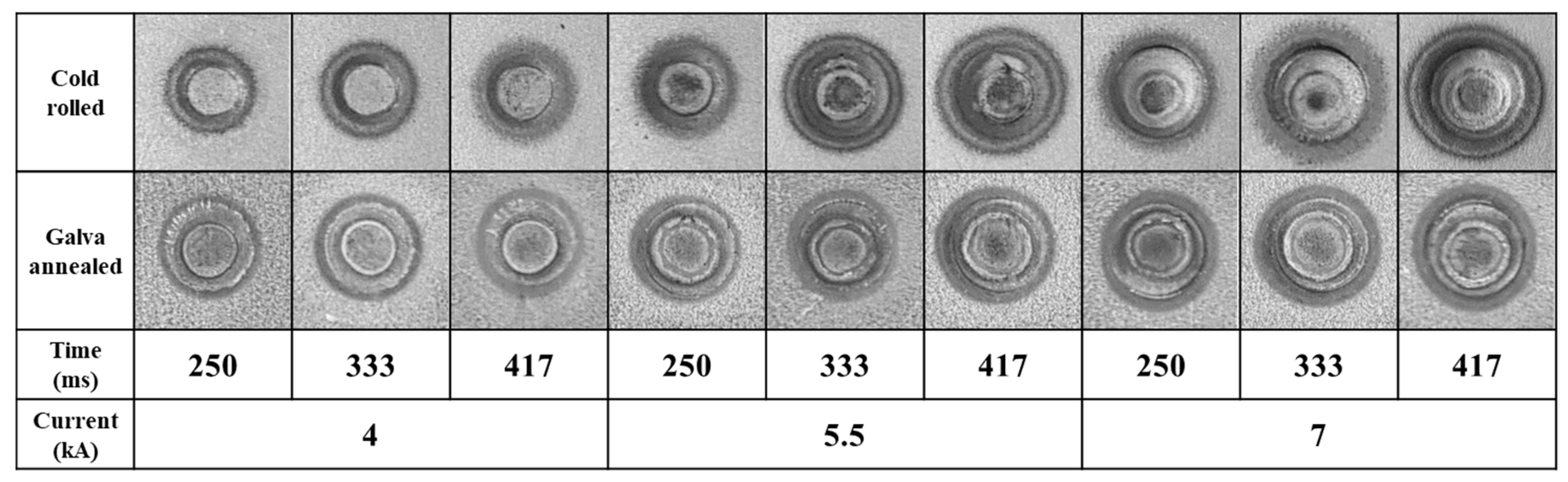

3.1. Result of Welding Experiments for Surface Heat Trace

3.2. Comparison of Welding Quality Results and Predicted Values According to Welding Conditions

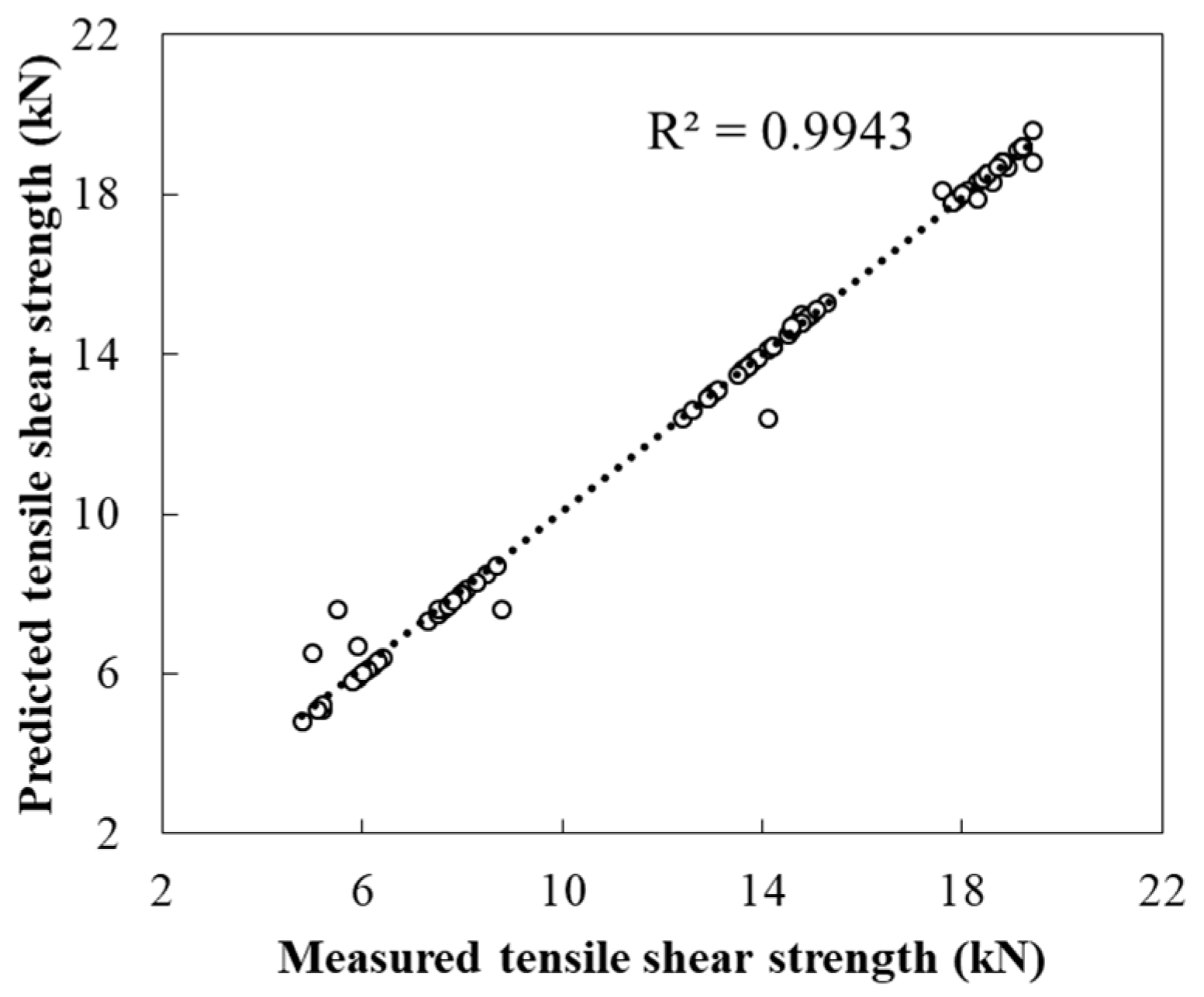

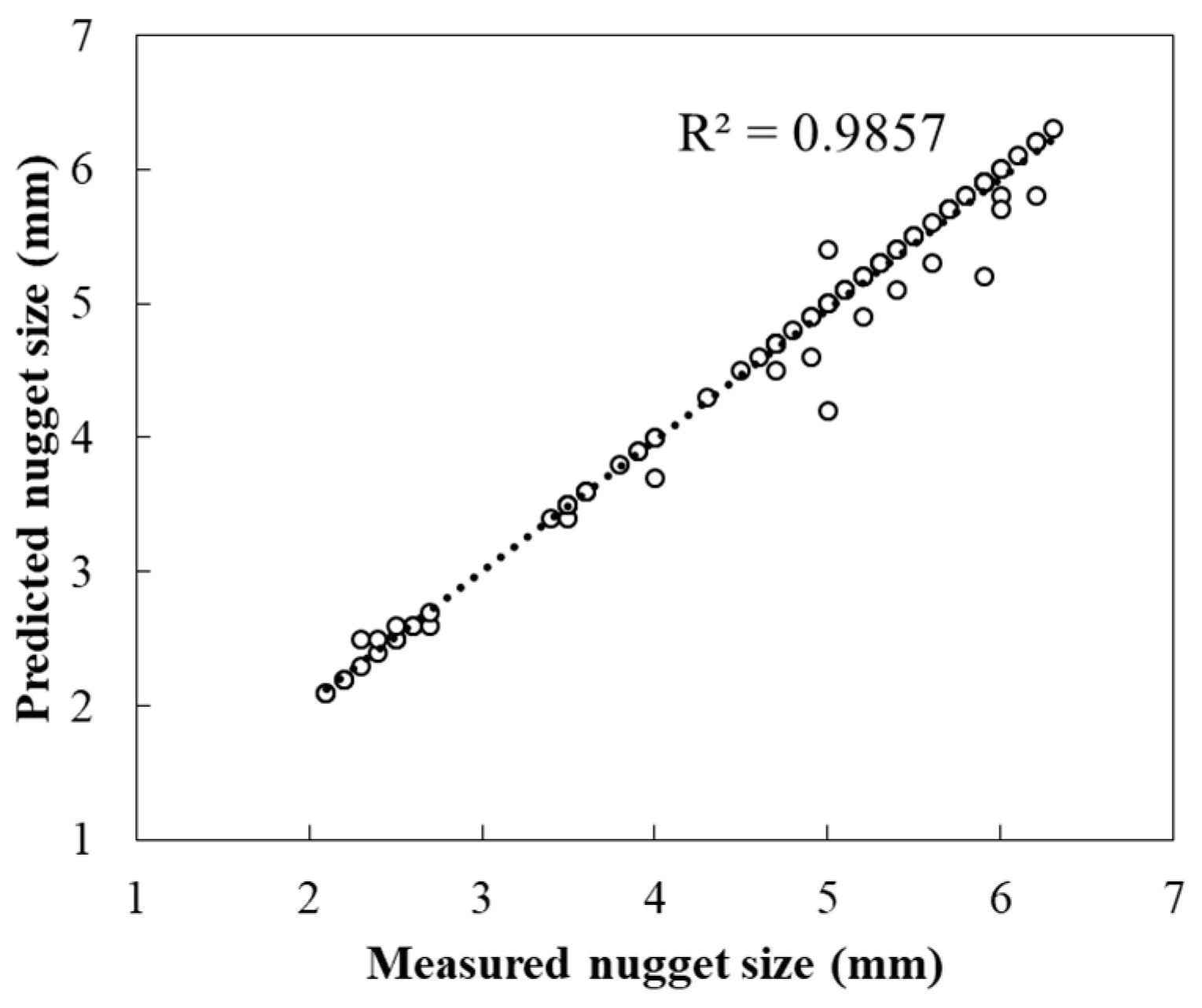

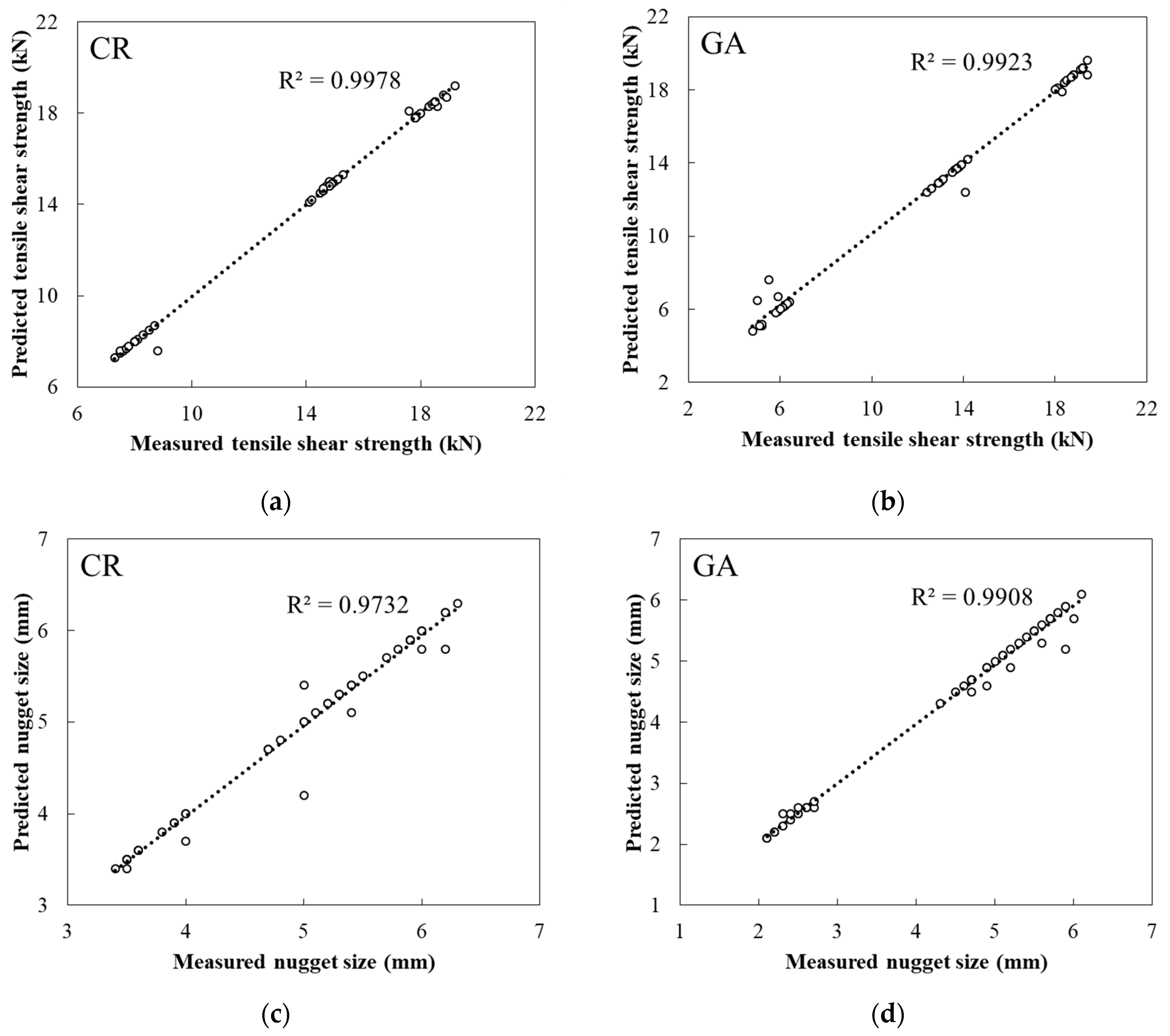

3.3. Neural Network Learning Using CNN

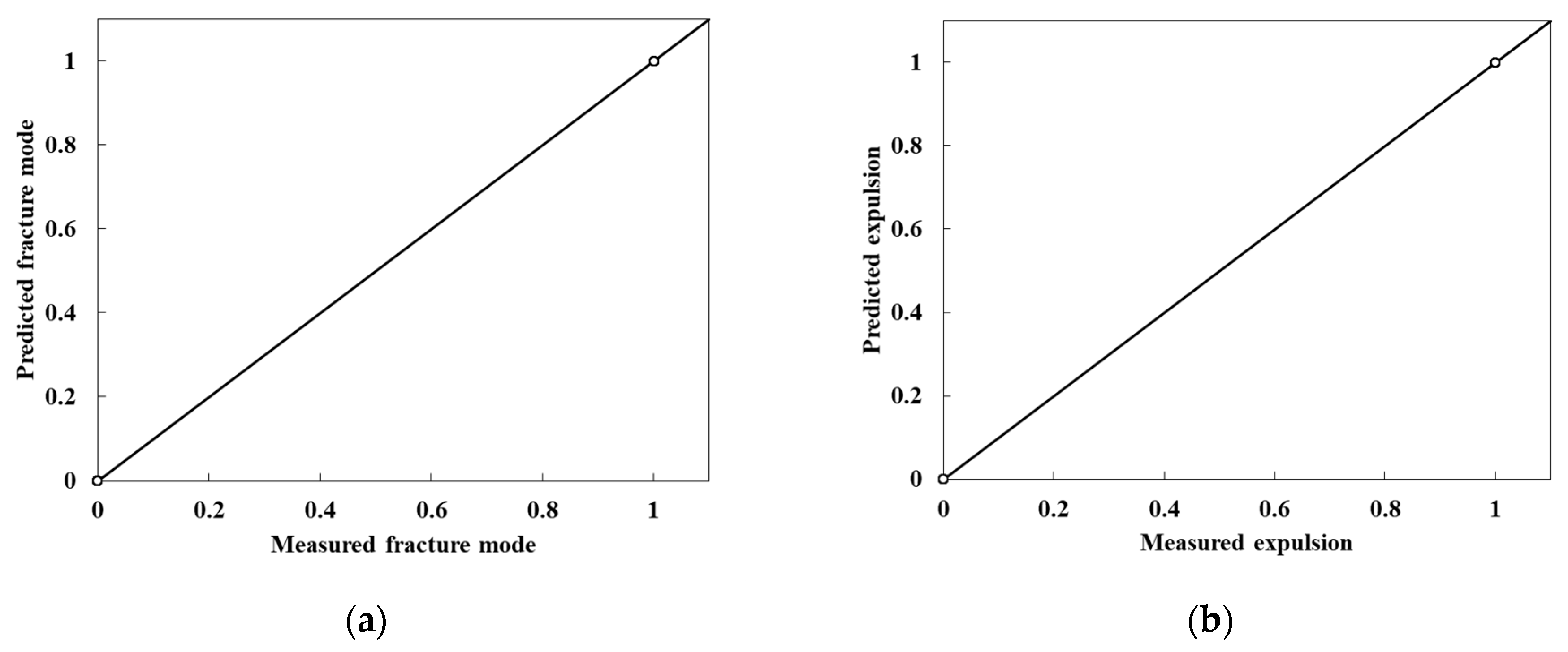

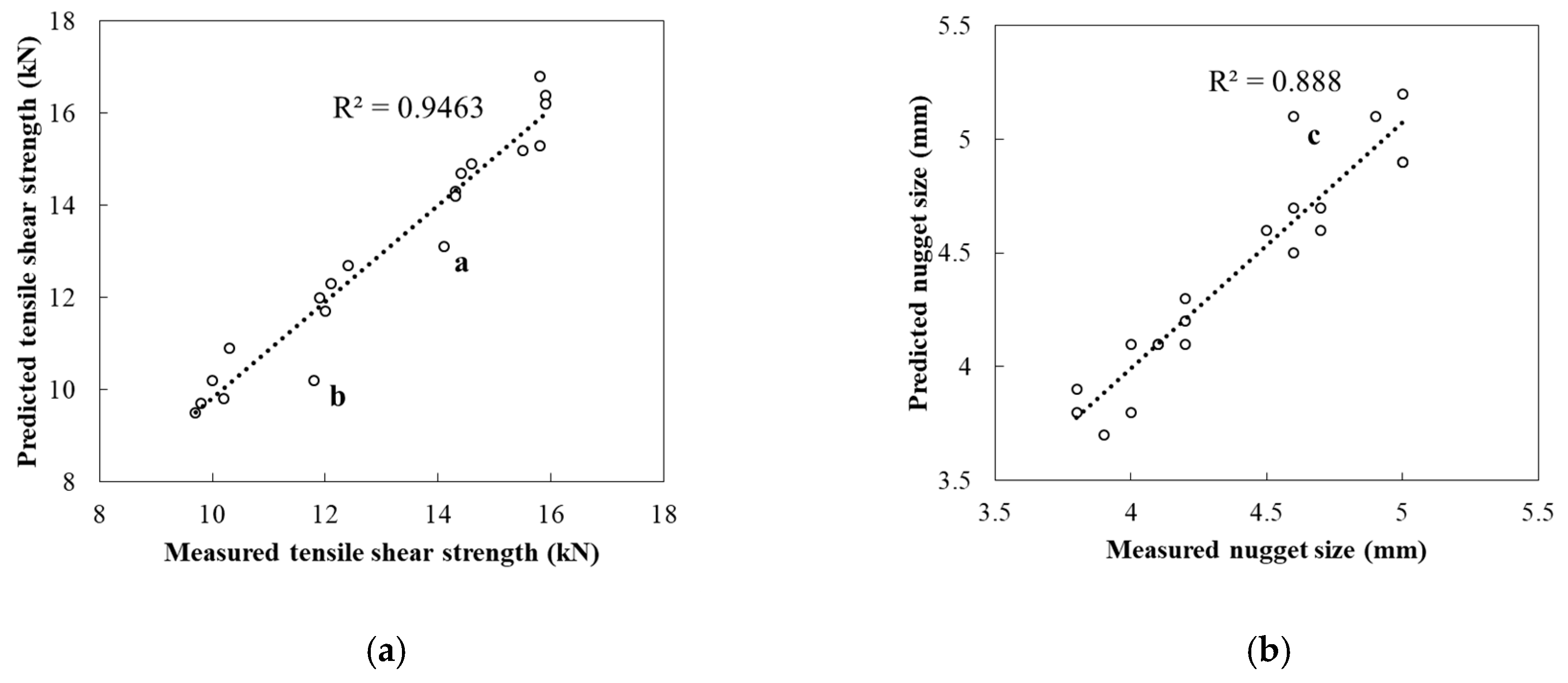

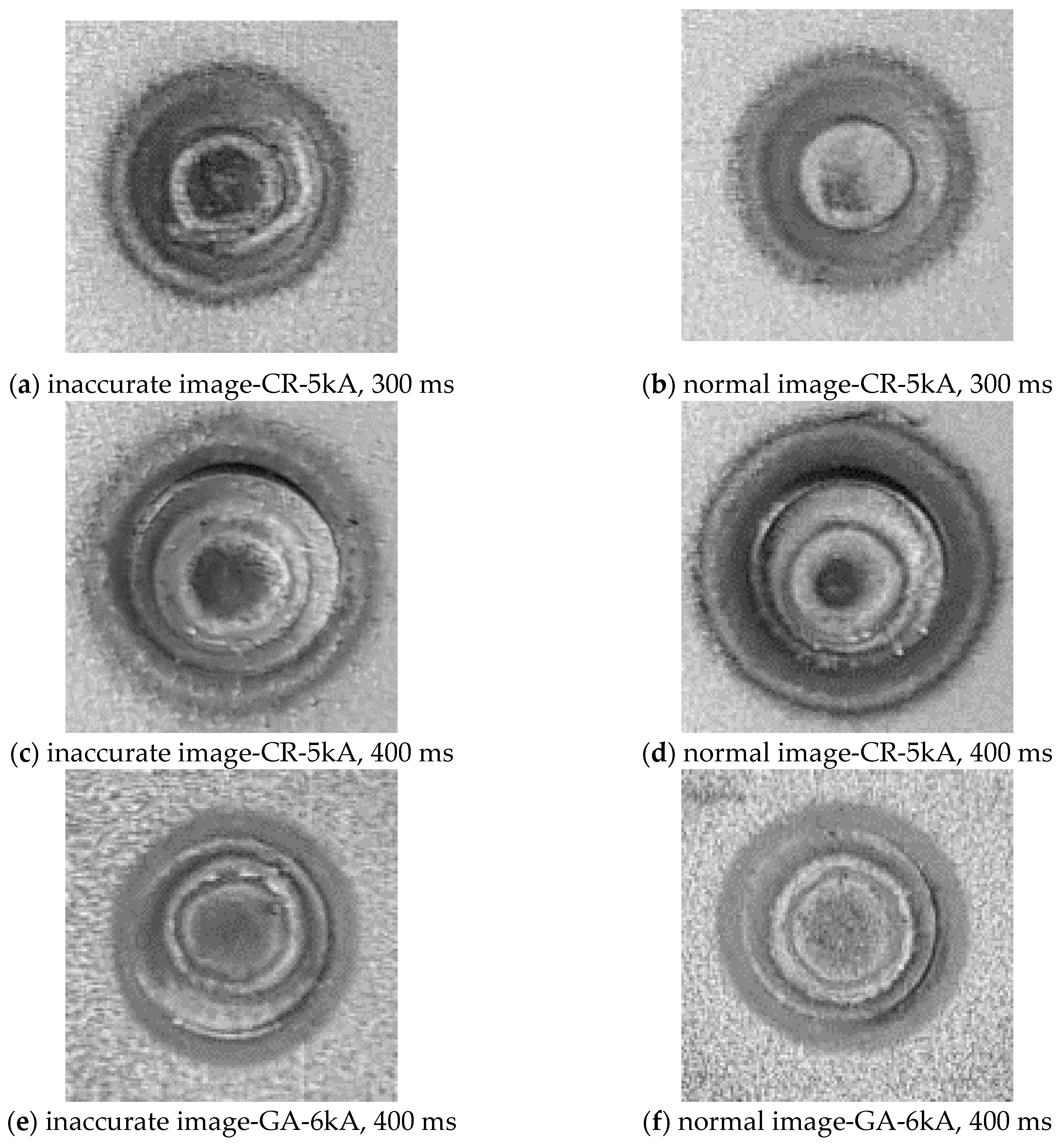

3.4. Verification of Predictive CNN Models

4. Conclusions

- (1)

- In the learning process, the coefficient of determination of tensile shear strength is 0.9943 and the coefficient of determination of nugget diameter is 0.9857. In the verification process, the predicted average error rate of tensile shear strength and nugget diameter are 3.2% and 2.6%, respectively, and the fracture shape and expulsion occurrence are accurately predicted. It has been demonstrated that accurate quality predictions can be made using the image of the welds in resistance spot welding.

- (2)

- Even if the surface treatment of steel is different, it has been proven that good weld quality can be predicted.

- (3)

- In the process of photographing a surface heat trace image, if disturbances that affect the image, such as the focus or lighting of the camera, occur, a large error in the prediction of quality can occur.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hao, M.; Osman, K.A.; Boomer, D.R.; Newton, C.J. Developments in characterization of resistance spot welding of aluminum. Weld. J. 1996, 75, 1–8. [Google Scholar]

- Muhammad, N.; Manurung, Y.H.P.; Hafidzi, M.; Abas, S.K.; Tham, G.; Haruman, E. Optimization and modeling of spot welding parameters with simultaneous multiple response consideration using multi-objective Taguchi method and RSM. J. Mech. Sci. Tech. 2012, 26, 2365–2370. [Google Scholar] [CrossRef]

- Darwish, S.M.; Al-Dekhial, S.D. The response surface approach to spot welding commercial aluminum sheets. Mater. Manuf. Process. 1998, 13, 189–202. [Google Scholar] [CrossRef]

- Choi, S.G.; Hwang, I.; Kang, M.; Hyun, S.; Kim, Y.-M. Optimization of welding parameters in resistance spot welding of 980 MPa grade GA steel sheet using multi-response surface methodology. J. Welding Joining (in Korean) 2018, 36, 63–69. [Google Scholar] [CrossRef]

- Nied, H.A. The finite element modeling of the resistance spot welding process. Weld. J. 1984, 285, 123–132. [Google Scholar]

- Denisov, A.A.; Shakarji, C.M.; Lawford, B.B.; Maev, R.G.; Paille, J.M. Spot weld analysis with 2D ultrasonic arrays. J. Res. Natl. Inst. Stand. Technol. 2004, 109, 233–244. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.I.; Needham, D.J.C. New design of resistance spot welding machine for quality control. Weld. J. 1972, 51, 122–131. [Google Scholar]

- Dickinson, D.W.; Franklin, J.E.; Stanya, A. Characterization of spot welding behavior by dynamic electrical parameter monitoring. Weld. J. 1980, 254, 170–176. [Google Scholar]

- Brown, J.D.; Rodd, M.G.; Williams, N.T. Application of artificial intelligence techniques to resistance spot welding. Ironmak. Steelmak. 1998, 25, 199–204. [Google Scholar]

- Dilthey, U.; Dickersbach, J. Application of neural networks for quality evaluation for resistance spot welds. ISIJ Int. 1999, 39, 1061–1066. [Google Scholar] [CrossRef][Green Version]

- Wan, X.; Wang, Y.; Zhao, D. Quality monitoring based on dynamic resistance and principal component analysis in small scale resistance spot welding process. Int. J. Adv. Manuf. Technol. 2016, 86, 3443–3451. [Google Scholar] [CrossRef]

- Xing, B.; Xiao, Y.; Ain, Q.H.; Cui, H. Quality assessment of resistance spot welding process based on dynamic resistance signal and random forest based. Int. J. Adv. Manuf. Technol. 2018, 94, 327–339. [Google Scholar] [CrossRef]

- Hwang, I.; Yun, H.; Yoon, J.; Kang, M.; Kim, Y.-M. Prediction of resistance spot weld quality of 780 MPa grade steel using adaptive resonance theory artificial neural networks. Metals 2018, 8, 453. [Google Scholar] [CrossRef]

- Ruisz, J.; Biber, J.; Loipetsberger, M. Quality evaluation in resistance spot welding by analysing the weld fingerprint on metal bands by computer vision. Int. J. Adv. Manuf. Technol. 2007, 33, 952–960. [Google Scholar] [CrossRef]

- Simončič, S.; Podržaj, P. Resistance spot weld strength estimation based on electrode tip displacement/velocity curve obtained by image processing. Sci. Technol. Weld. Joi. 2014, 19, 468–475. [Google Scholar] [CrossRef]

| Materials | Chemical composition (wt. %) | Mechanical properties | |||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | Fe | Ultimate Tensile Strength (MPa) | Elongation (%) | Yield Strength (MPa) | |

| GA steel | 0.22 | 1.62 | 2.12 | Bal. | 988 | 15 | 400 |

| CR steel | 0.20 | 1.59 | 2.40 | Bal. | 990 | 15 | 500 |

| Welding Conditions | 980 MPa-Grade GA Steel | 980 MPa-Grade CR Steel |

|---|---|---|

| Welding current (kA) | 4.0, 5.5, 7.0 | |

| Welding time (ms) | 250, 333, 417 | |

| Electrode Force (kgf) | 300 | |

| Convolution Layer 1 | |

| Kernel amount | 32 |

| Kernel size | 4,4 |

| Pooling size | 2,2 |

| Activation function | ReLU |

| Convolution Layer 2 | |

| Kernel amount | 32 |

| Kernel size | 4,4 |

| Pooling size | 2,2 |

| Activation function | ReLU |

| Fully Connected Layer | |

| Node | 200, 400, 800, 1200, 800, 400, 200 |

| Activation function | ReLU |

| Order. | Welding Condition | Measured Result | Predicted Result | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Current (kA) | Time (ms) | Tensile Shear Strength (kN) | Nugget Size (mm) | Fracture Mode | Expulsion | Tensile Shear Strength (kN) | Nugget Size (mm) | Fracture Mode | Expulsion | |

| 1 | CR | 4 | 250 | 7.3 | 3.6 | 0 | 0 | 7.3 | 3.6 | 0 | 0 |

| 2 | CR | 4 | 250 | 7.6 | 3.5 | 0 | 0 | 7.6 | 3.5 | 0 | 0 |

| 3 | CR | 4 | 250 | 7.5 | 3.5 | 0 | 0 | 7.5 | 3.5 | 0 | 0 |

| 4 | CR | 4 | 250 | 7.6 | 3.4 | 0 | 0 | 7.6 | 3.4 | 0 | 0 |

| 5 | CR | 4 | 250 | 7.5 | 3.5 | 0 | 0 | 7.6 | 3.4 | 0 | 0 |

| 6 | CR | 4 | 333 | 7.7 | 3.8 | 0 | 0 | 7.7 | 3.8 | 0 | 0 |

| 7 | CR | 4 | 333 | 8.1 | 3.6 | 0 | 0 | 8.1 | 3.6 | 0 | 0 |

| 8 | CR | 4 | 333 | 8.5 | 3.5 | 0 | 0 | 8.5 | 3.5 | 0 | 0 |

| 9 | CR | 4 | 333 | 8 | 3.5 | 0 | 0 | 8 | 3.5 | 0 | 0 |

| 10 | CR | 4 | 333 | 8 | 3.6 | 0 | 0 | 8 | 3.6 | 0 | 0 |

| 11 | CR | 4 | 417 | 8 | 3.9 | 0 | 0 | 8 | 3.9 | 0 | 0 |

| 12 | CR | 4 | 417 | 7.8 | 3.9 | 0 | 0 | 7.8 | 3.9 | 0 | 0 |

| 13 | CR | 4 | 417 | 8.3 | 4 | 0 | 0 | 8.3 | 4 | 0 | 0 |

| 14 | CR | 4 | 417 | 8.7 | 4 | 0 | 0 | 8.7 | 4 | 0 | 0 |

| 15 | CR | 4 | 417 | 8.8 | 4 | 0 | 0 | 7.6 | 3.7 | 0 | 0 |

| 16 | CR | 5.5 | 250 | 14.1 | 5 | 0 | 0 | 14.1 | 5 | 0 | 0 |

| 17 | CR | 5.5 | 250 | 14.9 | 4.8 | 0 | 0 | 14.9 | 4.8 | 0 | 0 |

| 18 | CR | 5.5 | 250 | 14.2 | 4.7 | 0 | 0 | 14.2 | 4.7 | 0 | 0 |

| 19 | CR | 5.5 | 250 | 14.5 | 4.7 | 0 | 0 | 14.5 | 4.7 | 0 | 0 |

| 20 | CR | 5.5 | 250 | 14.8 | 5 | 0 | 0 | 9.4 | 4.2 | 0 | 0 |

| 21 | CR | 5.5 | 333 | 14.6 | 5 | 0 | 0 | 14.6 | 5 | 0 | 0 |

| 22 | CR | 5.5 | 333 | 14.8 | 5.1 | 0 | 0 | 14.8 | 5.1 | 0 | 0 |

| 23 | CR | 5.5 | 333 | 15 | 5.2 | 0 | 0 | 15 | 5.2 | 0 | 0 |

| 24 | CR | 5.5 | 333 | 14.9 | 5.3 | 0 | 0 | 14.9 | 5.3 | 0 | 0 |

| 25 | CR | 5.5 | 333 | 14.7 | 5 | 0 | 0 | 14.8 | 5.4 | 0 | 0 |

| 26 | CR | 5.5 | 417 | 14.6 | 5.2 | 0 | 0 | 14.6 | 5.2 | 0 | 0 |

| 27 | CR | 5.5 | 417 | 15.3 | 5.4 | 0 | 0 | 15.3 | 5.4 | 0 | 0 |

| 28 | CR | 5.5 | 417 | 15.1 | 5.4 | 0 | 0 | 15.1 | 5.4 | 0 | 0 |

| 29 | CR | 5.5 | 417 | 14.8 | 5.3 | 0 | 0 | 14.8 | 5.3 | 0 | 0 |

| 30 | CR | 5.5 | 417 | 14.6 | 5.4 | 0 | 0 | 14.7 | 5.1 | 0 | 0 |

| 31 | CR | 7 | 250 | 17.8 | 5.9 | 1 | 1 | 17.8 | 5.9 | 1 | 1 |

| 32 | CR | 7 | 250 | 17.9 | 5.8 | 1 | 1 | 17.9 | 5.8 | 1 | 1 |

| 33 | CR | 7 | 250 | 17.8 | 5.5 | 1 | 1 | 17.8 | 5.5 | 1 | 1 |

| 34 | CR | 7 | 250 | 18 | 5.7 | 1 | 1 | 18 | 5.7 | 1 | 1 |

| 35 | CR | 7 | 250 | 17.6 | 5.9 | 1 | 1 | 18.1 | 5.9 | 1 | 1 |

| 36 | CR | 7 | 333 | 18.5 | 6 | 1 | 1 | 18.5 | 6 | 1 | 1 |

| 37 | CR | 7 | 333 | 18.5 | 6 | 1 | 1 | 18.5 | 6 | 1 | 1 |

| 38 | CR | 7 | 333 | 18.8 | 5.9 | 1 | 1 | 18.8 | 5.9 | 1 | 1 |

| 39 | CR | 7 | 333 | 18.3 | 5.9 | 1 | 1 | 18.3 | 5.9 | 1 | 1 |

| 40 | CR | 7 | 333 | 18.6 | 6.2 | 1 | 1 | 18.3 | 5.8 | 1 | 1 |

| 41 | CR | 7 | 417 | 18.4 | 6.2 | 1 | 1 | 18.4 | 6.2 | 1 | 1 |

| 42 | CR | 7 | 417 | 18.5 | 6.3 | 1 | 1 | 18.5 | 6.3 | 1 | 1 |

| 43 | CR | 7 | 417 | 17.8 | 5.9 | 1 | 1 | 17.8 | 5.9 | 1 | 1 |

| 44 | CR | 7 | 417 | 19.2 | 6.2 | 1 | 1 | 19.2 | 6.2 | 1 | 1 |

| 45 | CR | 7 | 417 | 18.9 | 6 | 1 | 1 | 14.7 | 5.8 | 1 | 1 |

| 46 | GA | 4 | 250 | 5.2 | 2.1 | 0 | 0 | 5.1 | 2.1 | 0 | 0 |

| 47 | GA | 4 | 250 | 5.2 | 2.2 | 0 | 0 | 5.2 | 2.2 | 0 | 0 |

| 48 | GA | 4 | 250 | 5.1 | 2.1 | 0 | 0 | 5.1 | 2.1 | 0 | 0 |

| 49 | GA | 4 | 250 | 4.8 | 2.2 | 0 | 0 | 4.8 | 2.2 | 0 | 0 |

| 50 | GA | 4 | 250 | 5 | 2.3 | 0 | 0 | 6.5 | 2.5 | 0 | 0 |

| 51 | GA | 4 | 333 | 6.4 | 2.4 | 0 | 0 | 6.4 | 2.4 | 0 | 0 |

| 52 | GA | 4 | 333 | 6.2 | 2.5 | 0 | 0 | 6.2 | 2.5 | 0 | 0 |

| 53 | GA | 4 | 333 | 6.3 | 2.5 | 0 | 0 | 6.3 | 2.5 | 0 | 0 |

| 54 | GA | 4 | 333 | 6.1 | 2.7 | 0 | 0 | 6.1 | 2.6 | 0 | 0 |

| 55 | GA | 4 | 333 | 5.9 | 2.4 | 0 | 0 | 6.7 | 2.5 | 0 | 0 |

| 56 | GA | 4 | 417 | 5.9 | 2.6 | 0 | 0 | 5.9 | 2.6 | 0 | 0 |

| 57 | GA | 4 | 417 | 5.9 | 2.3 | 0 | 0 | 5.9 | 2.3 | 0 | 0 |

| 58 | GA | 4 | 417 | 5.8 | 2.6 | 0 | 0 | 5.8 | 2.6 | 0 | 0 |

| 59 | GA | 4 | 417 | 6 | 2.7 | 0 | 0 | 6 | 2.7 | 0 | 0 |

| 60 | GA | 4 | 417 | 5.5 | 2.5 | 0 | 0 | 7.6 | 2.6 | 0 | 0 |

| 61 | GA | 5.5 | 250 | 12.4 | 4.6 | 0 | 0 | 12.4 | 4.6 | 0 | 0 |

| 62 | GA | 5.5 | 250 | 12.6 | 4.7 | 0 | 0 | 12.6 | 4.7 | 0 | 0 |

| 63 | GA | 5.5 | 250 | 13 | 4.5 | 0 | 0 | 13 | 4.5 | 0 | 0 |

| 64 | GA | 5.5 | 250 | 13.1 | 4.3 | 0 | 0 | 13.1 | 4.3 | 0 | 0 |

| 65 | GA | 5.5 | 250 | 12.9 | 4.7 | 0 | 0 | 12.9 | 4.5 | 0 | 0 |

| 66 | GA | 5.5 | 333 | 13.7 | 4.9 | 0 | 0 | 13.7 | 4.9 | 0 | 0 |

| 67 | GA | 5.5 | 333 | 13.8 | 4.9 | 0 | 0 | 13.8 | 4.9 | 0 | 0 |

| 68 | GA | 5.5 | 333 | 13.9 | 4.7 | 0 | 0 | 13.9 | 4.7 | 0 | 0 |

| 69 | GA | 5.5 | 333 | 13.6 | 4.7 | 0 | 0 | 13.6 | 4.7 | 0 | 0 |

| 70 | GA | 5.5 | 333 | 14.1 | 4.9 | 0 | 0 | 12.4 | 4.6 | 0 | 0 |

| 71 | GA | 5.5 | 417 | 12.9 | 5 | 0 | 0 | 12.9 | 5 | 0 | 0 |

| 72 | GA | 5.5 | 417 | 13.6 | 5.1 | 0 | 0 | 13.6 | 5.1 | 0 | 0 |

| 73 | GA | 5.5 | 417 | 13.7 | 5.2 | 0 | 0 | 13.7 | 5.2 | 0 | 0 |

| 74 | GA | 5.5 | 417 | 13.5 | 5.1 | 0 | 0 | 13.5 | 5.1 | 0 | 0 |

| 75 | GA | 5.5 | 417 | 14.2 | 5.2 | 0 | 0 | 14.2 | 4.9 | 0 | 0 |

| 76 | GA | 7 | 250 | 18.4 | 5.4 | 0 | 0 | 18.4 | 5.4 | 0 | 0 |

| 77 | GA | 7 | 250 | 18.1 | 5.6 | 0 | 0 | 18.1 | 5.6 | 0 | 0 |

| 78 | GA | 7 | 250 | 18 | 5.5 | 0 | 0 | 18 | 5.5 | 0 | 0 |

| 79 | GA | 7 | 250 | 18.5 | 5.3 | 0 | 0 | 18.5 | 5.3 | 0 | 0 |

| 80 | GA | 7 | 250 | 18.3 | 5.6 | 0 | 0 | 17.9 | 5.3 | 0 | 0 |

| 81 | GA | 7 | 333 | 18.8 | 5.8 | 0 | 0 | 18.8 | 5.8 | 0 | 0 |

| 82 | GA | 7 | 333 | 18.8 | 5.7 | 0 | 0 | 18.8 | 5.7 | 0 | 0 |

| 83 | GA | 7 | 333 | 18.8 | 5.7 | 0 | 0 | 18.8 | 5.7 | 0 | 0 |

| 84 | GA | 7 | 333 | 19.2 | 5.5 | 0 | 0 | 19.2 | 5.5 | 0 | 0 |

| 85 | GA | 7 | 333 | 19.4 | 5.9 | 0 | 0 | 15.1 | 5.2 | 0 | 0 |

| 86 | GA | 7 | 417 | 18.7 | 5.9 | 0 | 0 | 18.7 | 5.9 | 0 | 0 |

| 87 | GA | 7 | 417 | 19.1 | 6.1 | 0 | 0 | 19.1 | 6.1 | 0 | 0 |

| 88 | GA | 7 | 417 | 19.2 | 5.9 | 0 | 0 | 19.2 | 5.9 | 0 | 0 |

| 89 | GA | 7 | 417 | 19.2 | 5.7 | 0 | 0 | 19.2 | 5.7 | 0 | 0 |

| 90 | GA | 7 | 417 | 19.4 | 6 | 0 | 0 | 18.8 | 5.7 | 0 | 0 |

| Welding Conditions of verification test | 980 MPa-Grade GA Steel | 980 MPa-Grade CR Steel |

|---|---|---|

| Welding current (kA) | 6 | 5 |

| Welding time (ms) | 300, 400 | 300, 400 |

| Electrode Force (kgf) | 300 | |

| Order. | Welding Condition | Measured Result | Predicted Result | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Current (kA) | Time (ms) | Tensile Shear Strength (kN) | Nugget Size (mm) | Fracture Mode | Expulsion | Tensile Shear Strength (kN) | Nugget Size (mm) | Fracture Mode | Expulsion | |

| 1 | CR | 5 | 300 | 12.1 | 3.9 | 0 | 0 | 12.3 | 3.7 | 0 | 0 |

| 2 | CR | 5 | 300 | 12.4 | 4.0 | 0 | 0 | 12.7 | 3.8 | 0 | 0 |

| 3 | CR | 5 | 300 | 11.8 | 4.0 | 0 | 0 | 10.2 | 4.1 | 0 | 0 |

| 4 | CR | 5 | 300 | 11.9 | 3.8 | 0 | 0 | 12.0 | 3.8 | 0 | 0 |

| 5 | CR | 5 | 300 | 12.0 | 3.8 | 0 | 0 | 11.7 | 3.9 | 0 | 0 |

| 6 | CR | 5 | 400 | 15.5 | 4.2 | 0 | 0 | 15.2 | 4.1 | 0 | 0 |

| 7 | CR | 5 | 400 | 15.9 | 4.2 | 0 | 0 | 16.4 | 4.2 | 0 | 0 |

| 8 | CR | 5 | 400 | 15.9 | 4.1 | 0 | 0 | 16.2 | 4.1 | 0 | 0 |

| 9 | CR | 5 | 400 | 15.8 | 4.1 | 0 | 0 | 15.3 | 4.1 | 0 | 0 |

| 10 | CR | 5 | 400 | 15.8 | 4.2 | 0 | 0 | 16.8 | 4.3 | 0 | 0 |

| 11 | GA | 6 | 300 | 9.7 | 4.5 | 0 | 0 | 9.5 | 4.6 | 0 | 0 |

| 12 | GA | 6 | 300 | 9.8 | 4.6 | 0 | 0 | 9.7 | 4.5 | 0 | 0 |

| 13 | GA | 6 | 300 | 10.3 | 4.7 | 0 | 0 | 10.9 | 4.7 | 0 | 0 |

| 14 | GA | 6 | 300 | 10.2 | 4.6 | 0 | 0 | 9.8 | 4.7 | 0 | 0 |

| 15 | GA | 6 | 300 | 10.0 | 4.7 | 0 | 0 | 10.2 | 4.6 | 0 | 0 |

| 16 | GA | 6 | 400 | 14.1 | 5.0 | 0 | 0 | 13.1 | 5.2 | 0 | 0 |

| 17 | GA | 6 | 400 | 14.6 | 4.9 | 0 | 0 | 14.9 | 5.1 | 0 | 0 |

| 18 | GA | 6 | 400 | 14.3 | 4.6 | 0 | 0 | 14.3 | 5.1 | 0 | 0 |

| 19 | GA | 6 | 400 | 14.3 | 5.0 | 0 | 0 | 14.2 | 4.9 | 0 | 0 |

| 20 | GA | 6 | 400 | 14.4 | 5.0 | 0 | 0 | 14.7 | 4.9 | 0 | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-G.; Hwang, I.; Kim, Y.-M.; Kang, B.; Kang, M. Prediction of the Weld Qualities Using Surface Appearance Image in Resistance Spot Welding. Metals 2019, 9, 831. https://doi.org/10.3390/met9080831

Choi S-G, Hwang I, Kim Y-M, Kang B, Kang M. Prediction of the Weld Qualities Using Surface Appearance Image in Resistance Spot Welding. Metals. 2019; 9(8):831. https://doi.org/10.3390/met9080831

Chicago/Turabian StyleChoi, Sang-Gyu, Insung Hwang, Young-Min Kim, Bongyong Kang, and Munjin Kang. 2019. "Prediction of the Weld Qualities Using Surface Appearance Image in Resistance Spot Welding" Metals 9, no. 8: 831. https://doi.org/10.3390/met9080831

APA StyleChoi, S.-G., Hwang, I., Kim, Y.-M., Kang, B., & Kang, M. (2019). Prediction of the Weld Qualities Using Surface Appearance Image in Resistance Spot Welding. Metals, 9(8), 831. https://doi.org/10.3390/met9080831