Effect of Lubrication and Forging Load on Surface Roughness, Residual Stress, and Deformation of Cold Forging Tools

Abstract

1. Introduction

2. Materials and Methods

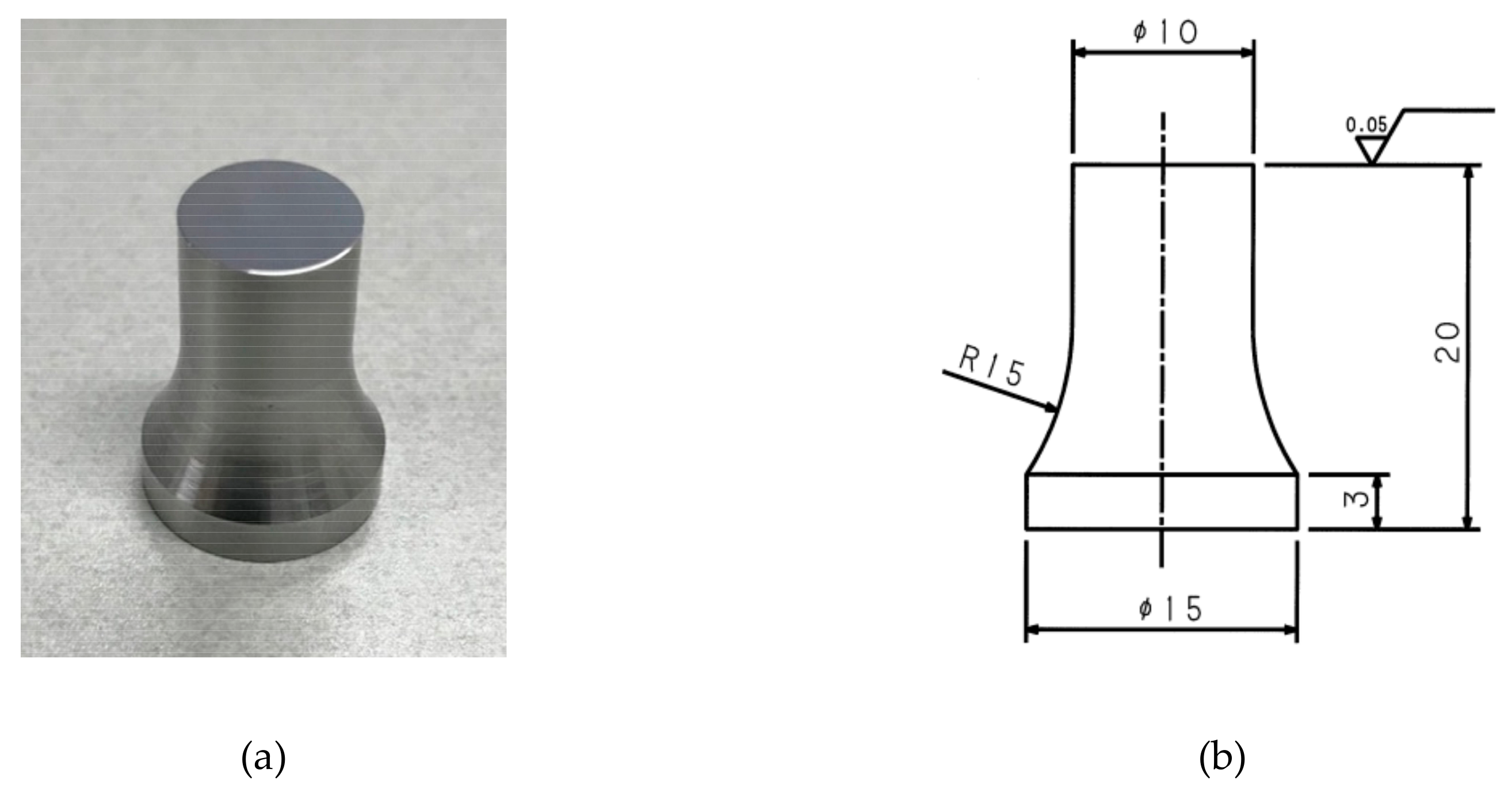

2.1. Materials, Specimen Preparation, and Lubricant

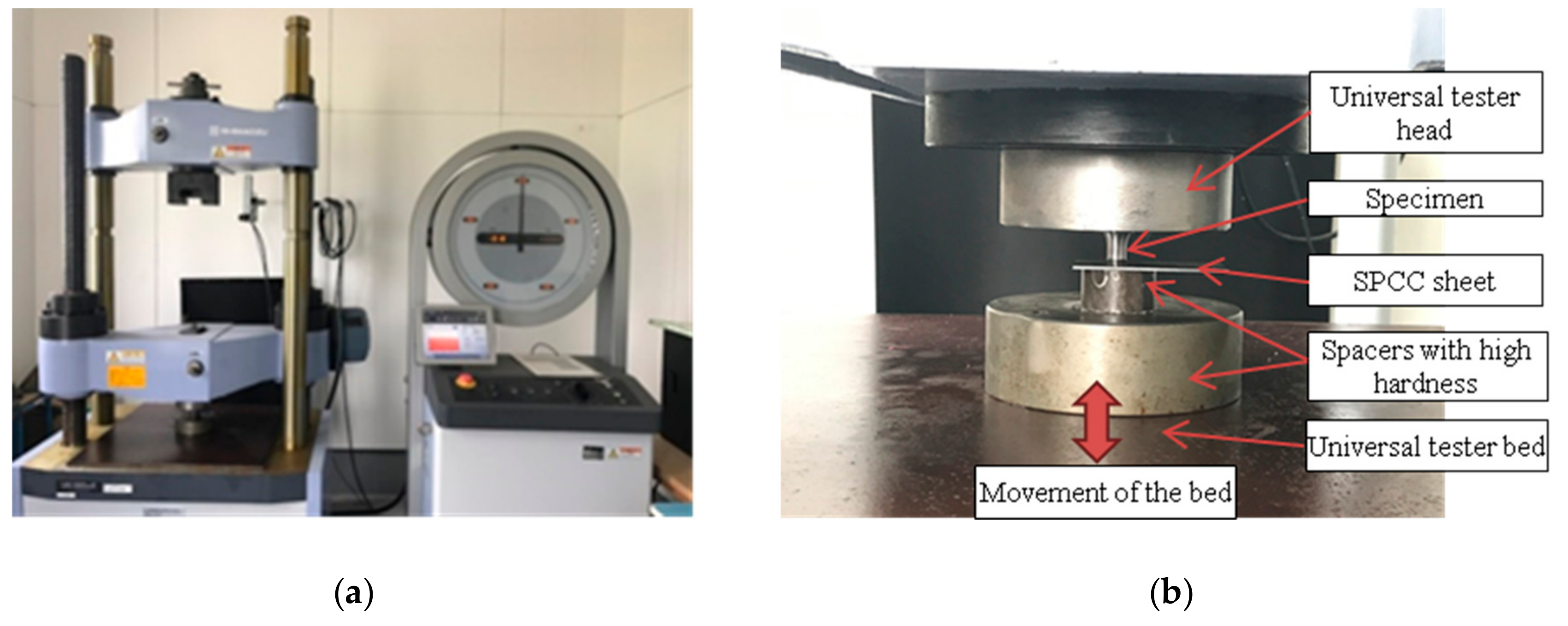

2.2. Experimental Setup

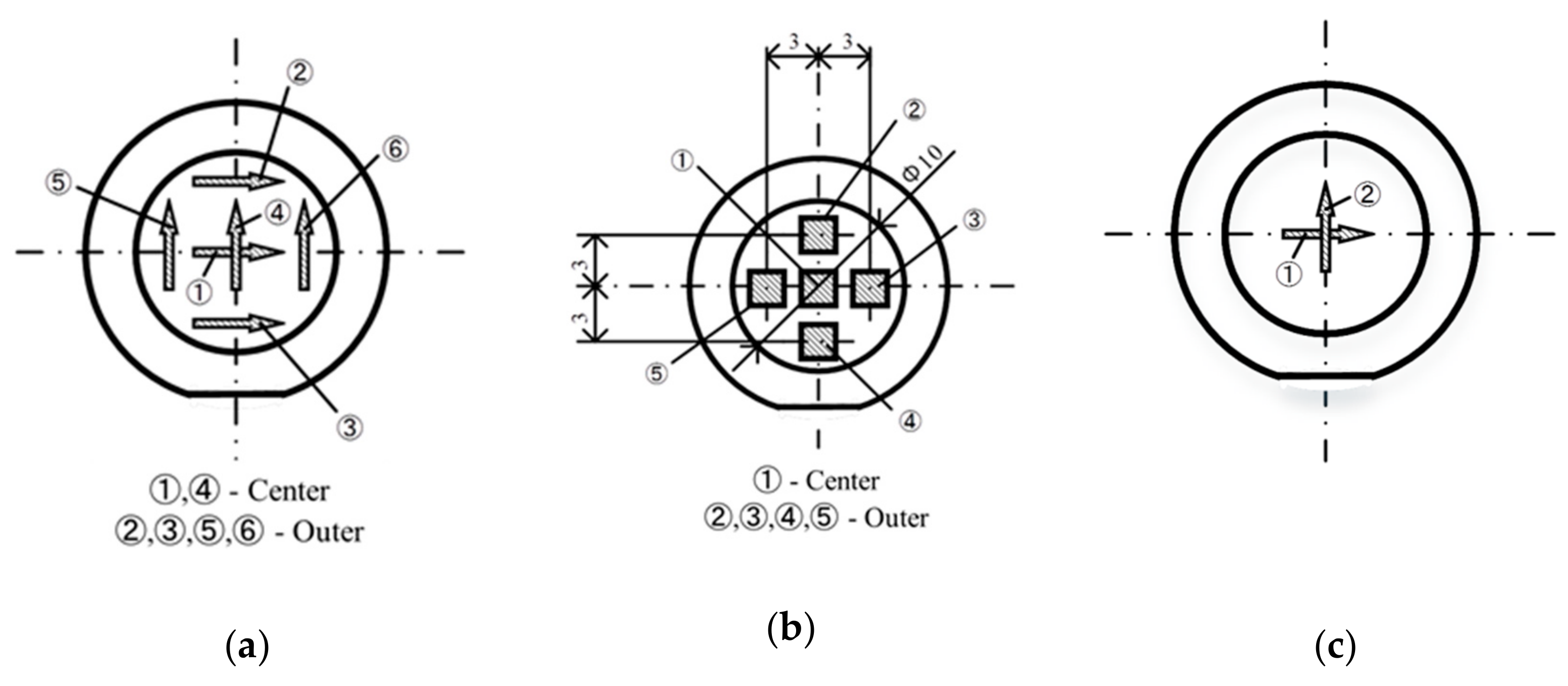

2.3. Measurements

3. Results and Discussions

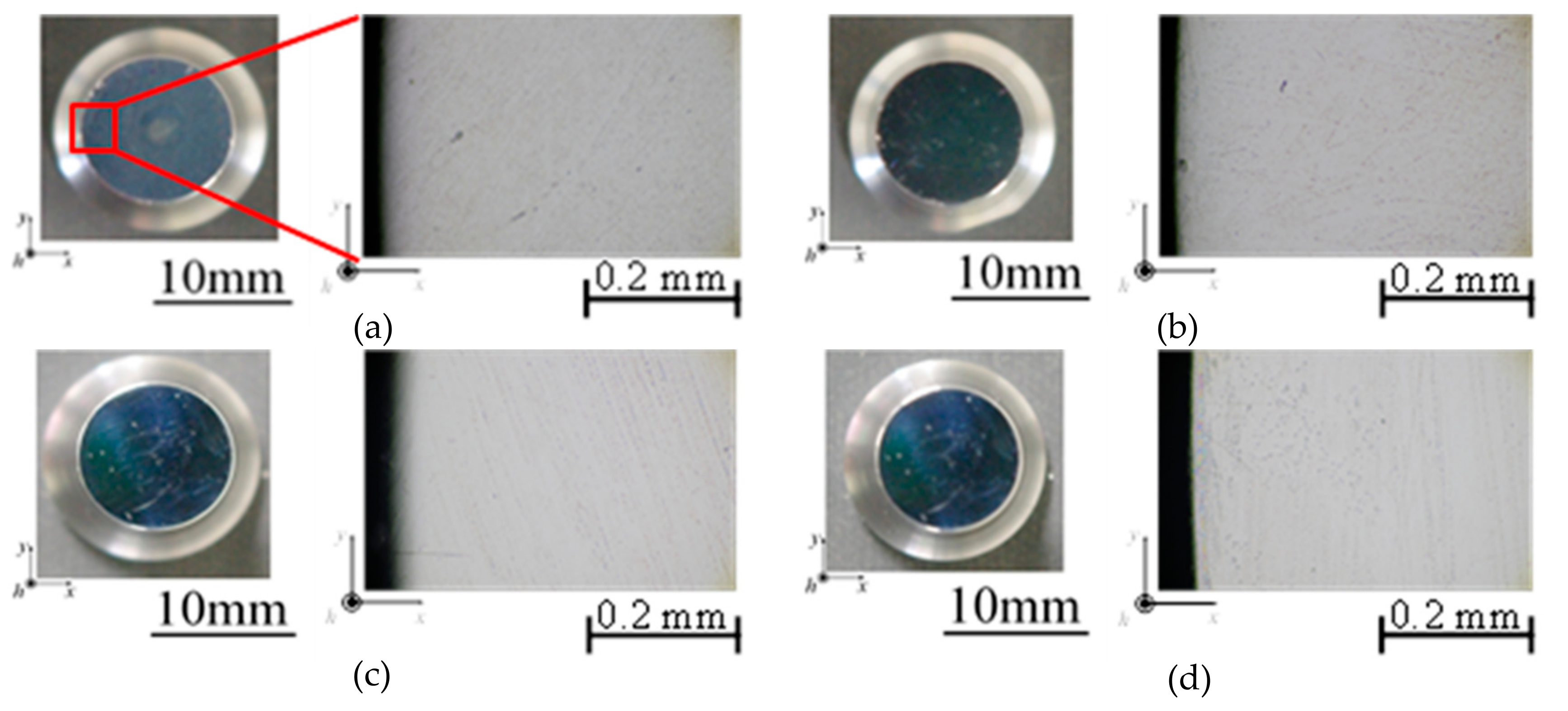

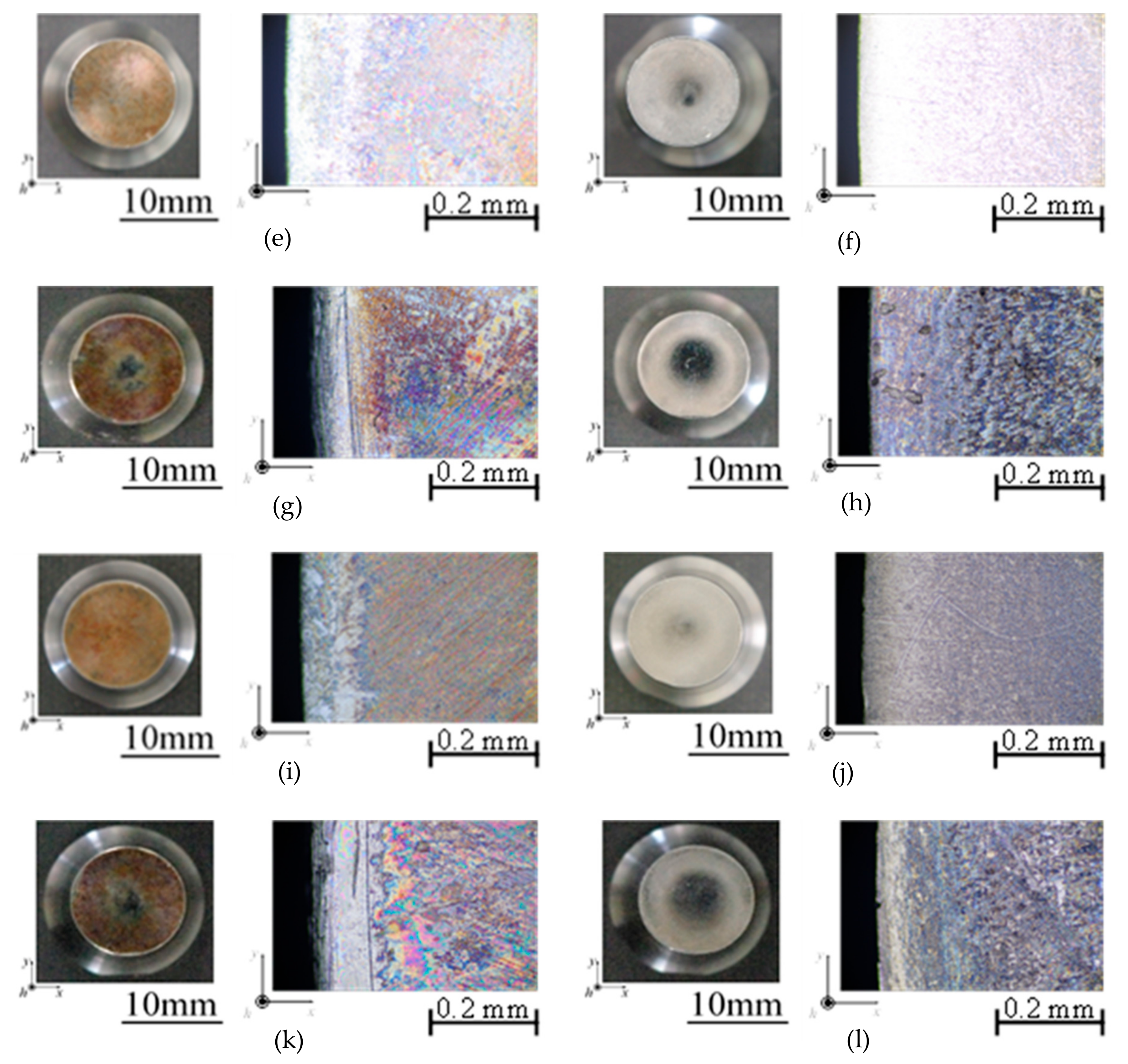

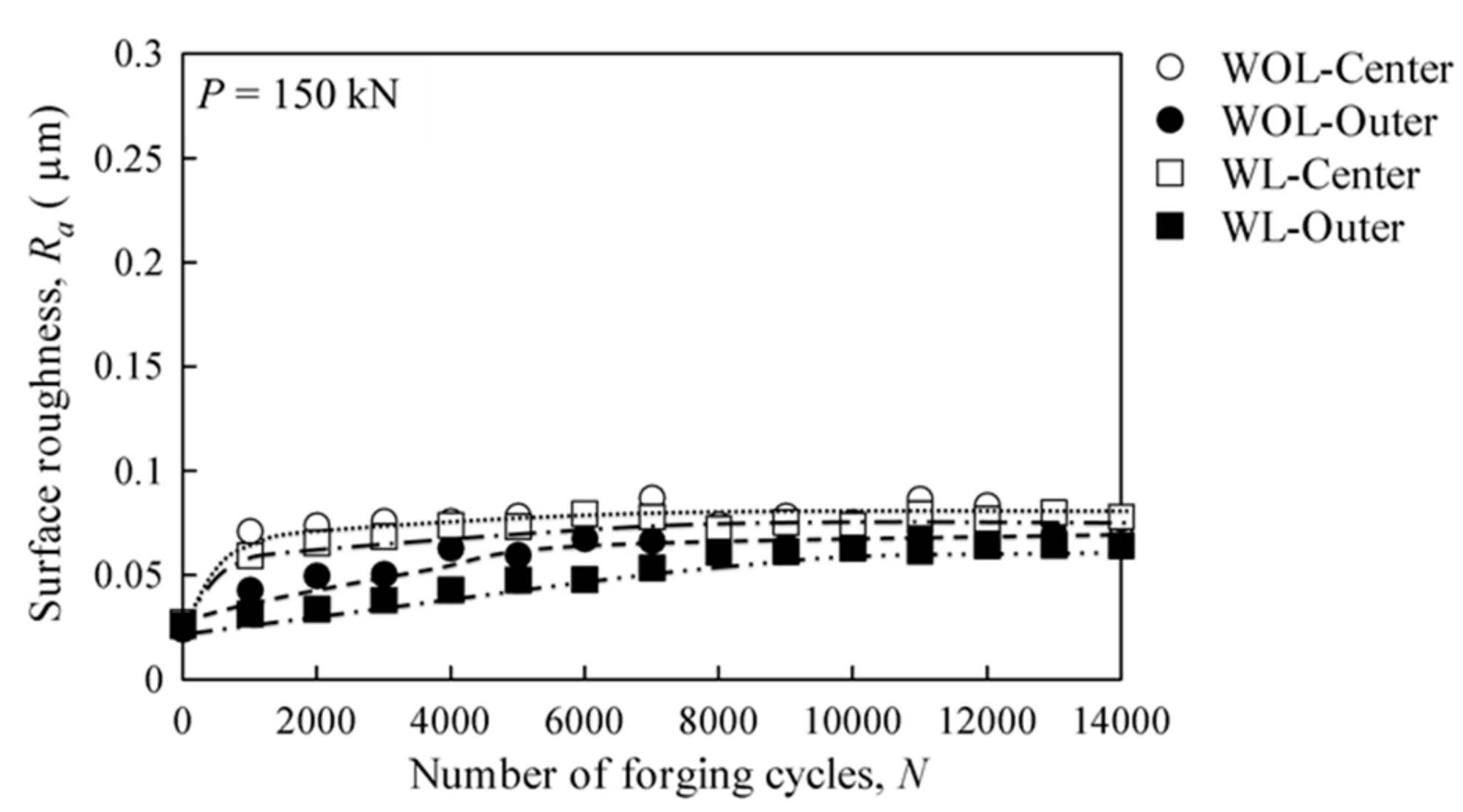

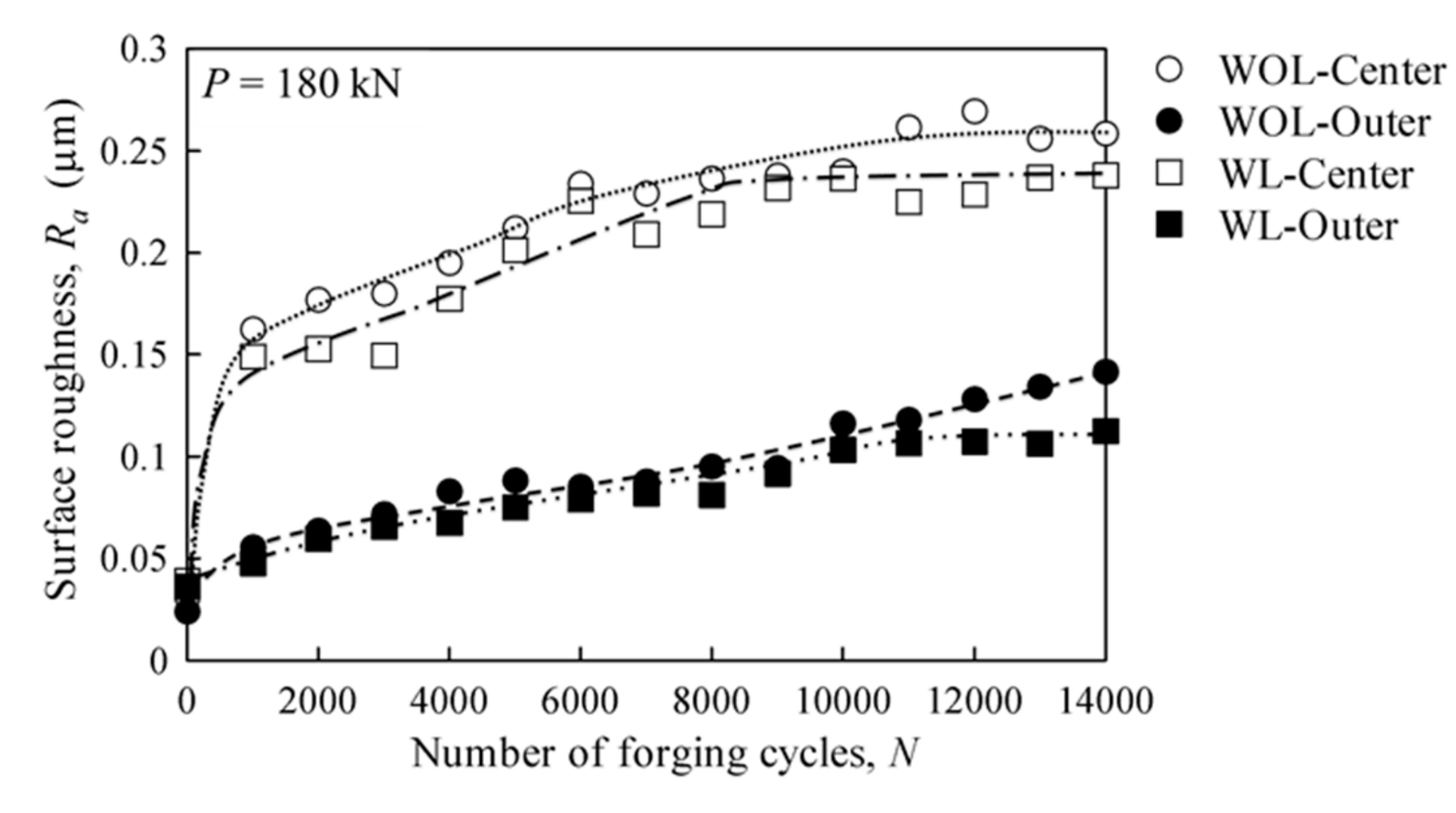

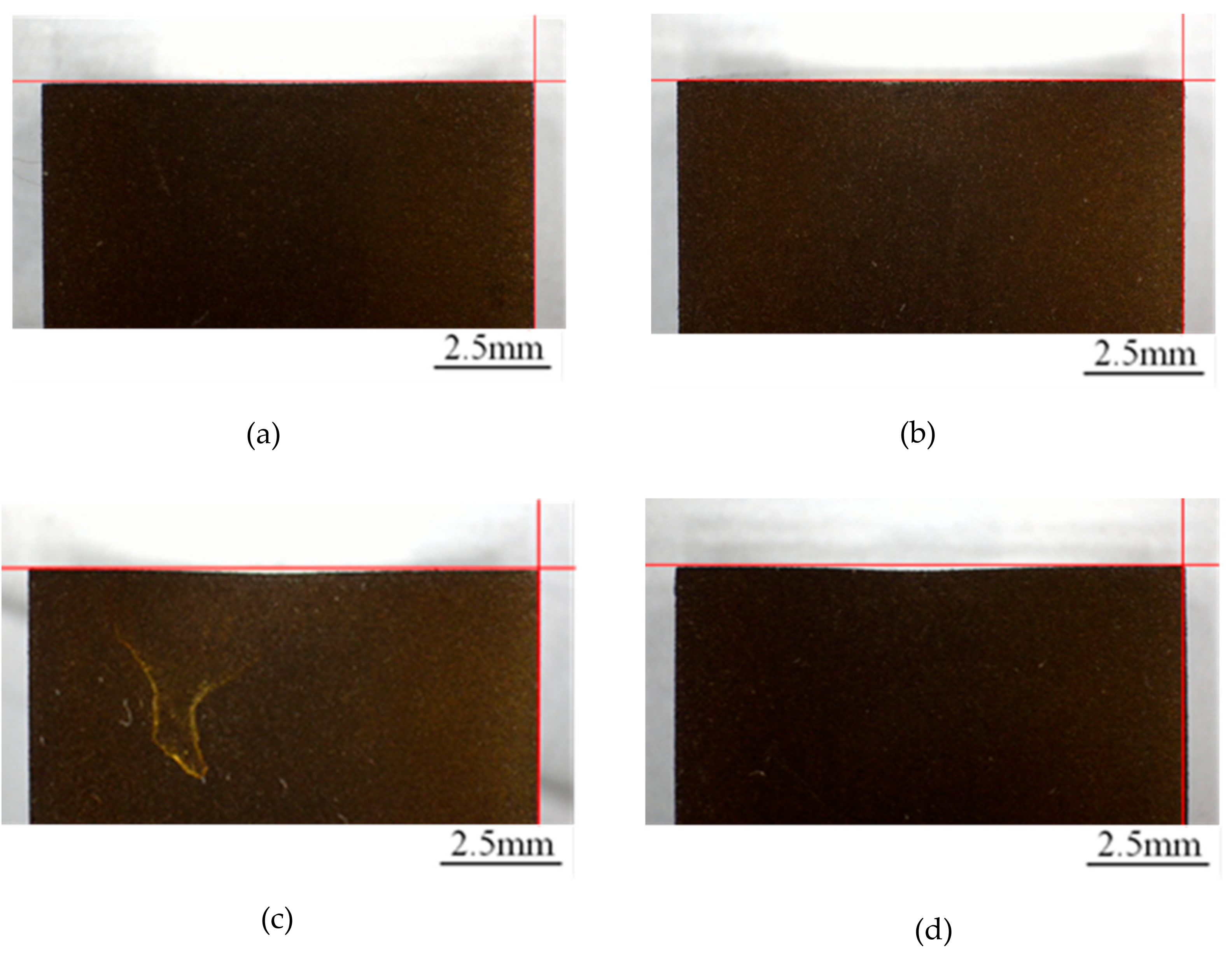

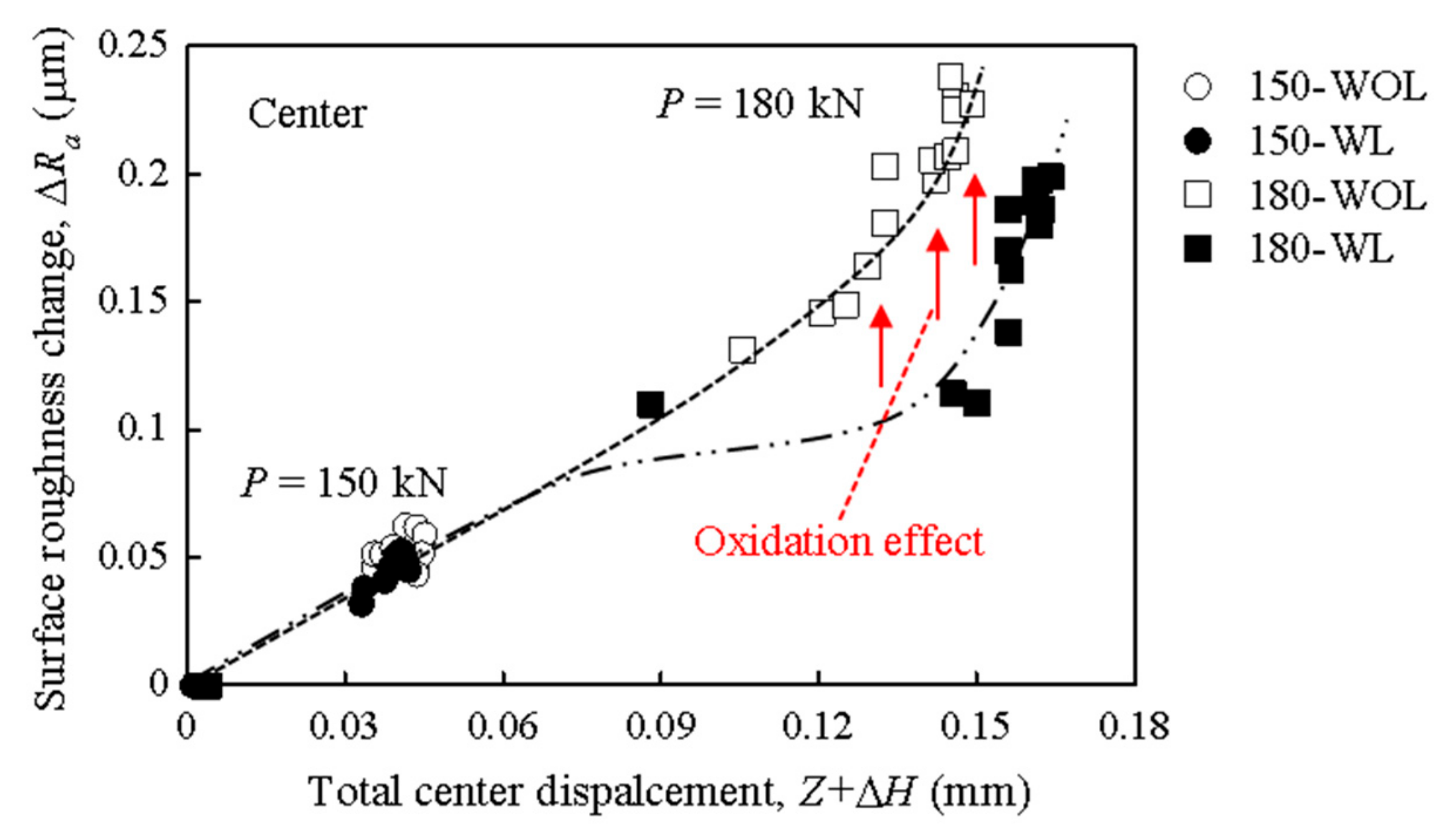

3.1. Working Surface Conditions and Surface Roughness

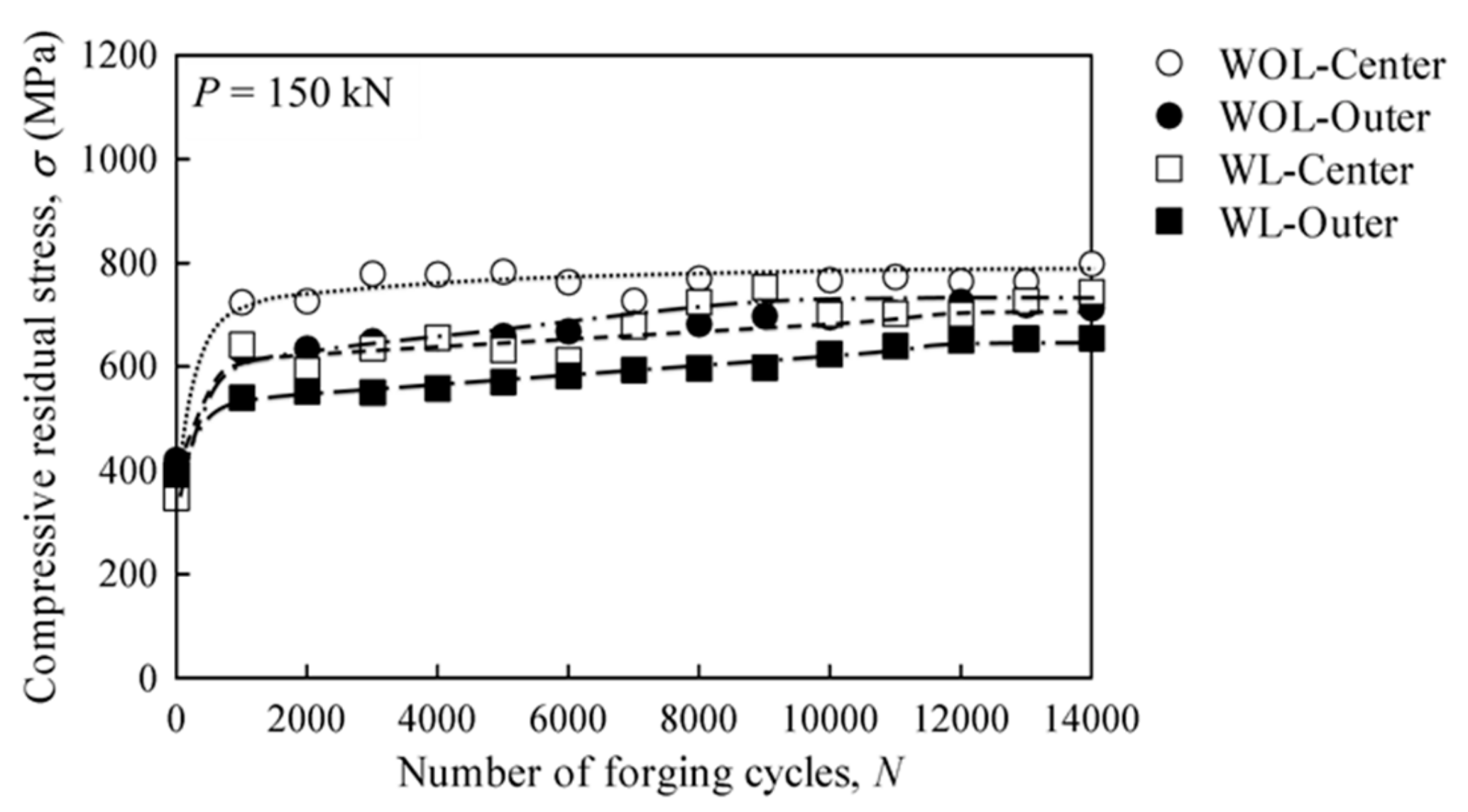

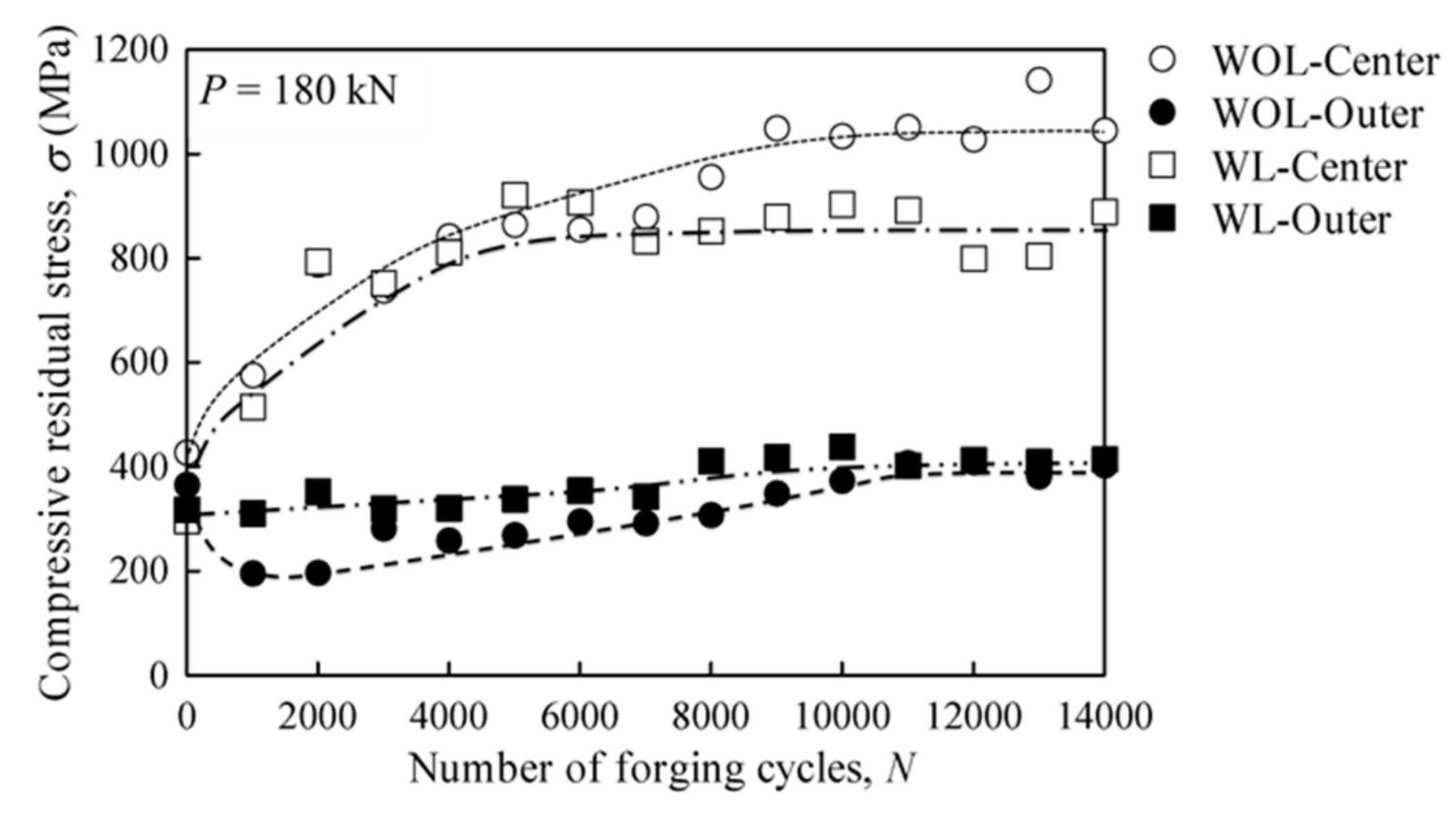

3.2. Residual Stress

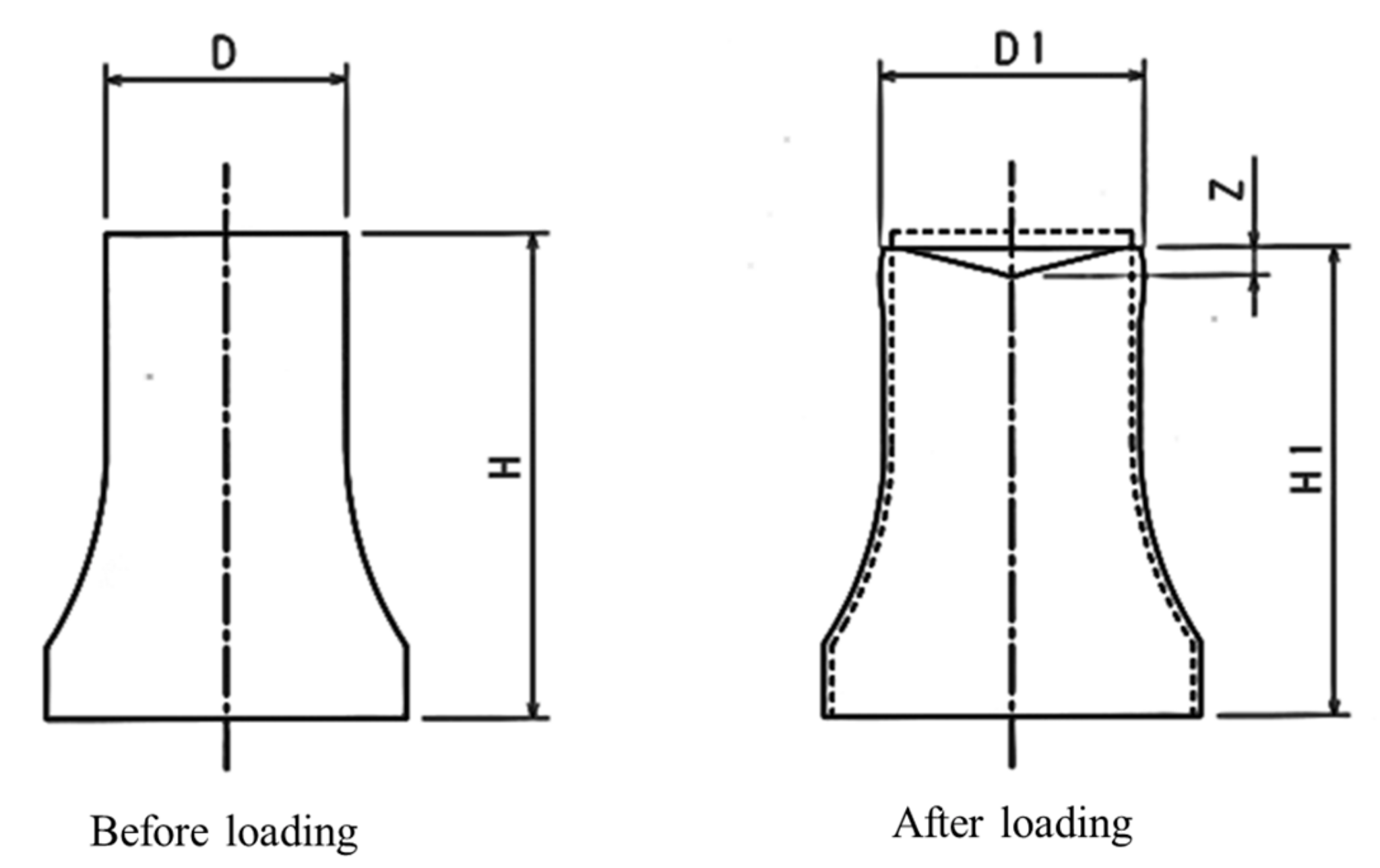

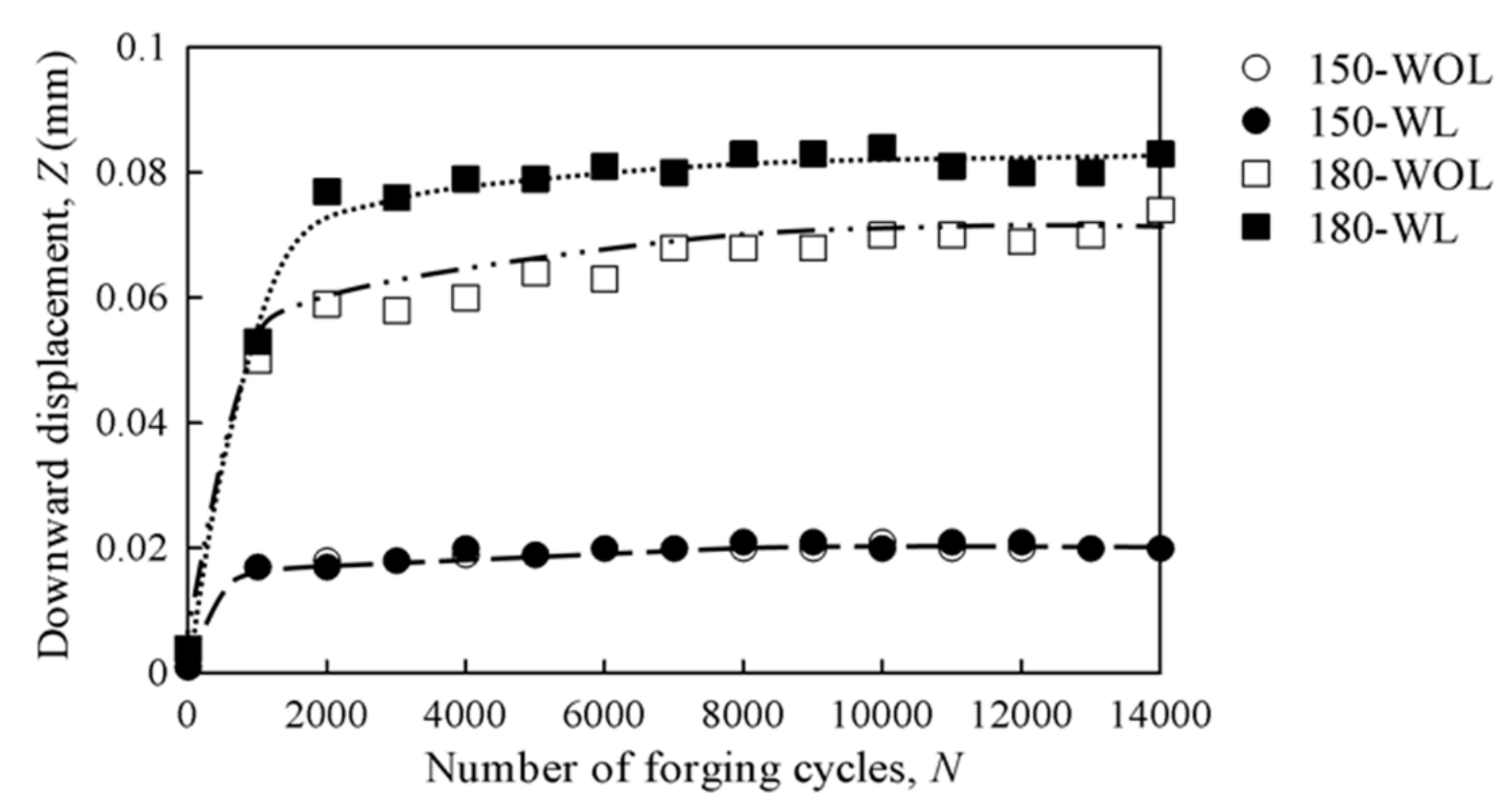

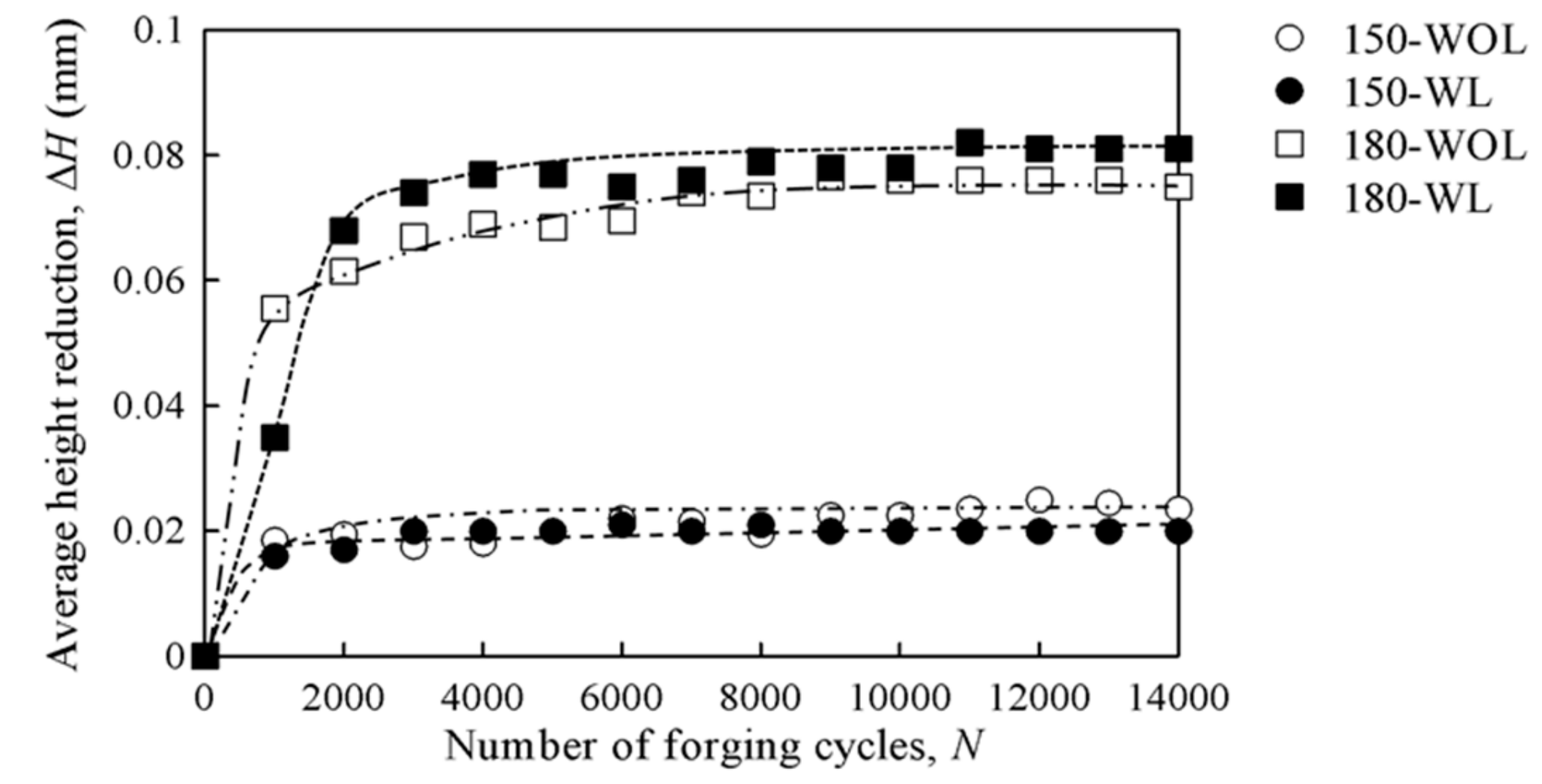

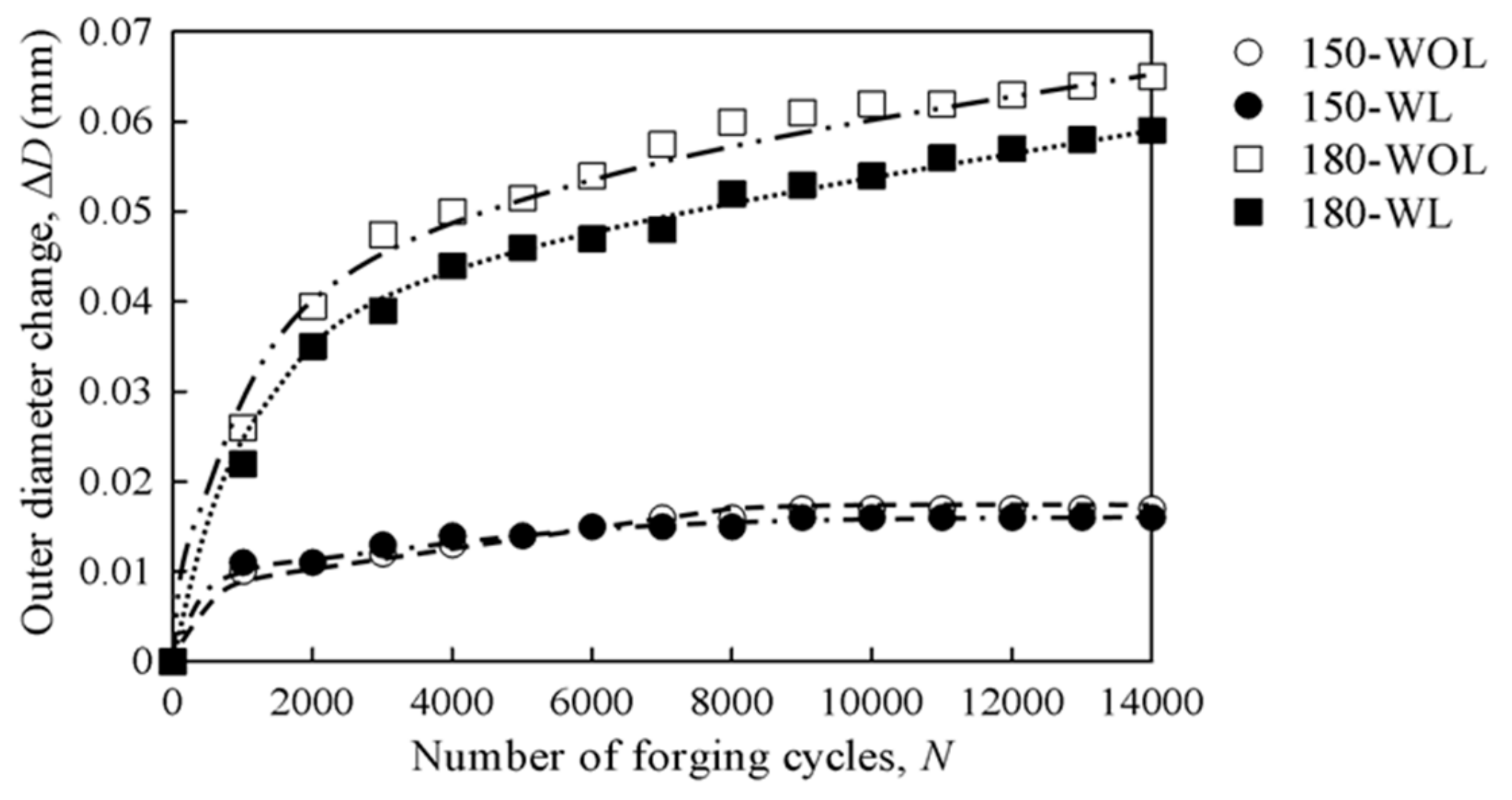

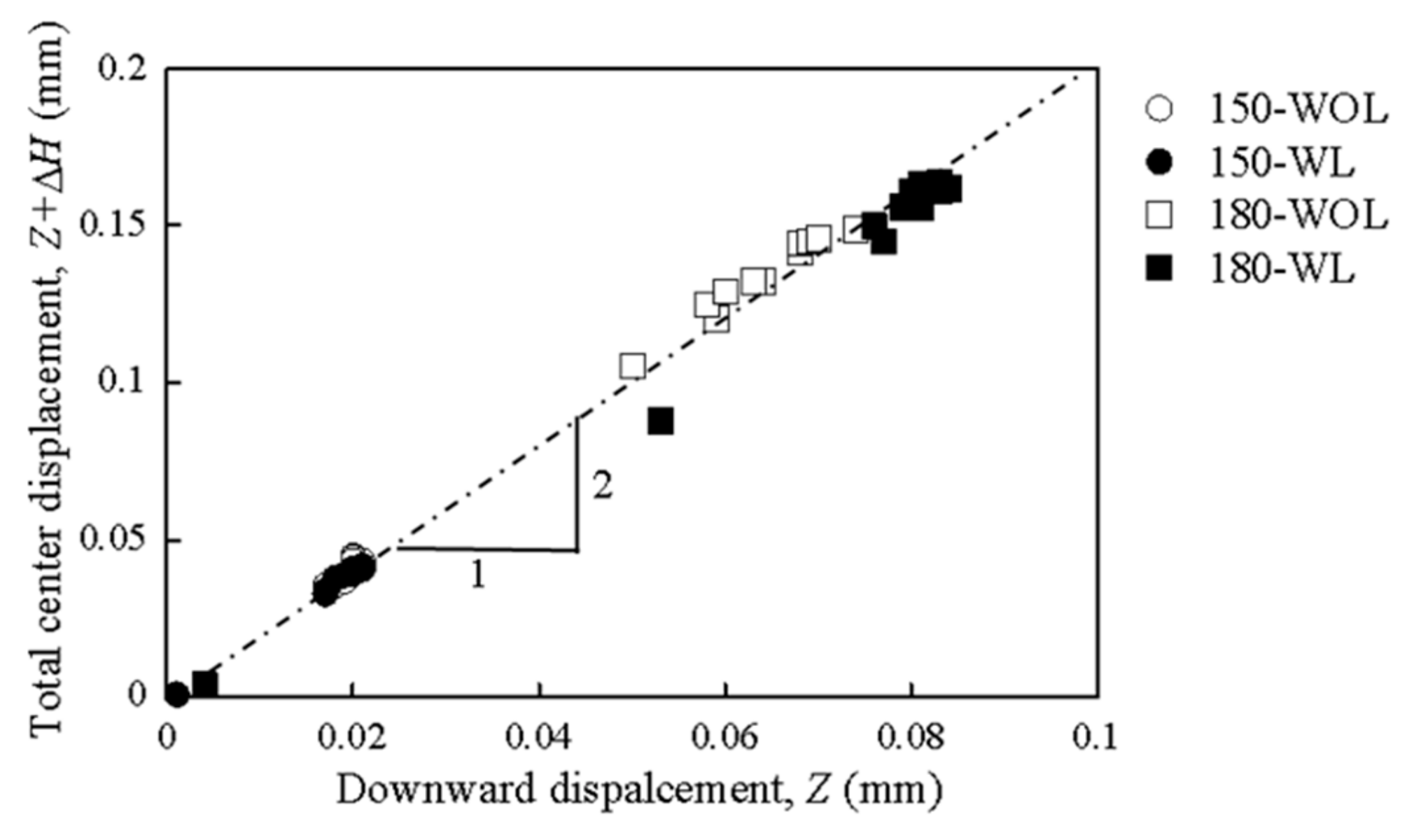

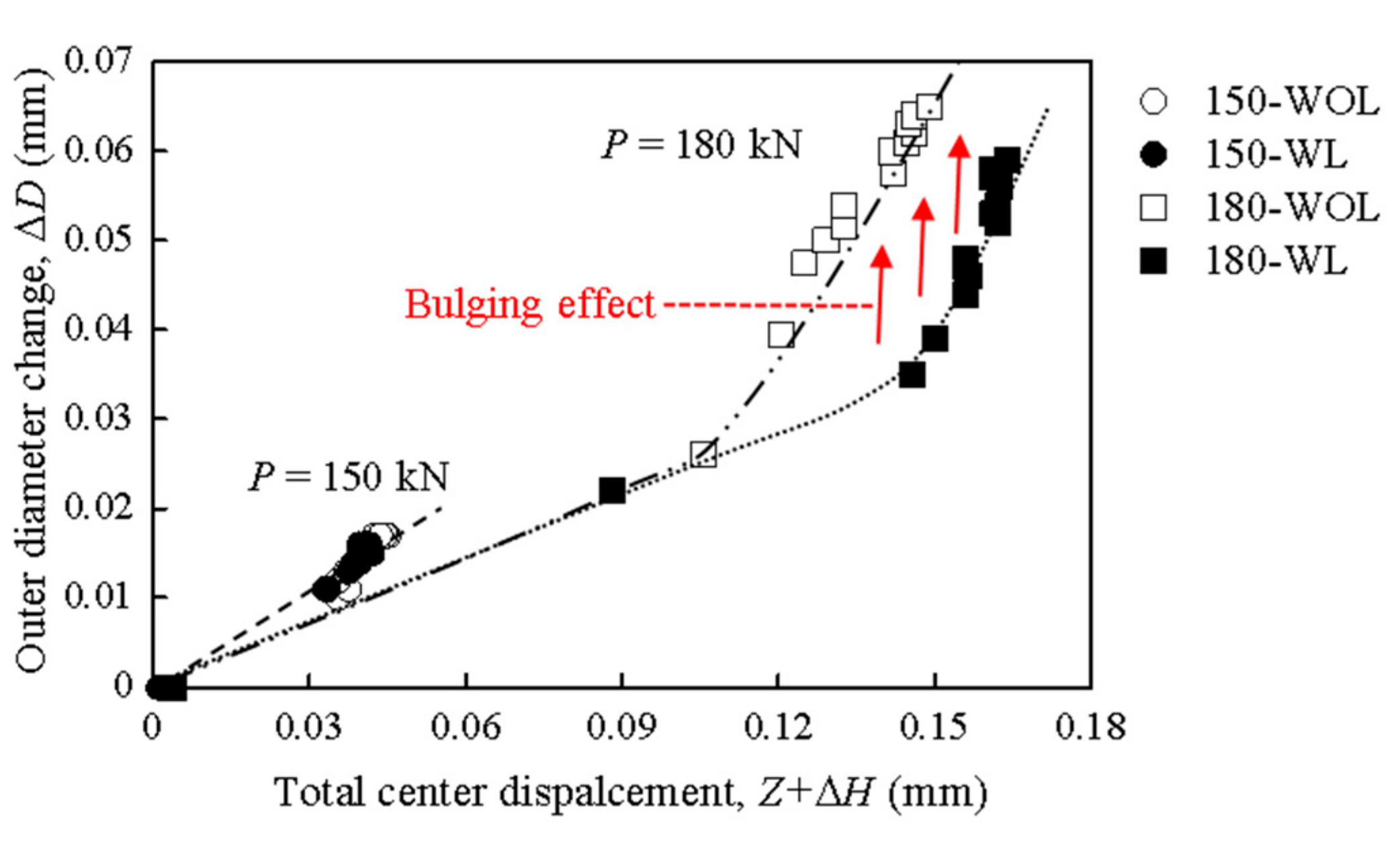

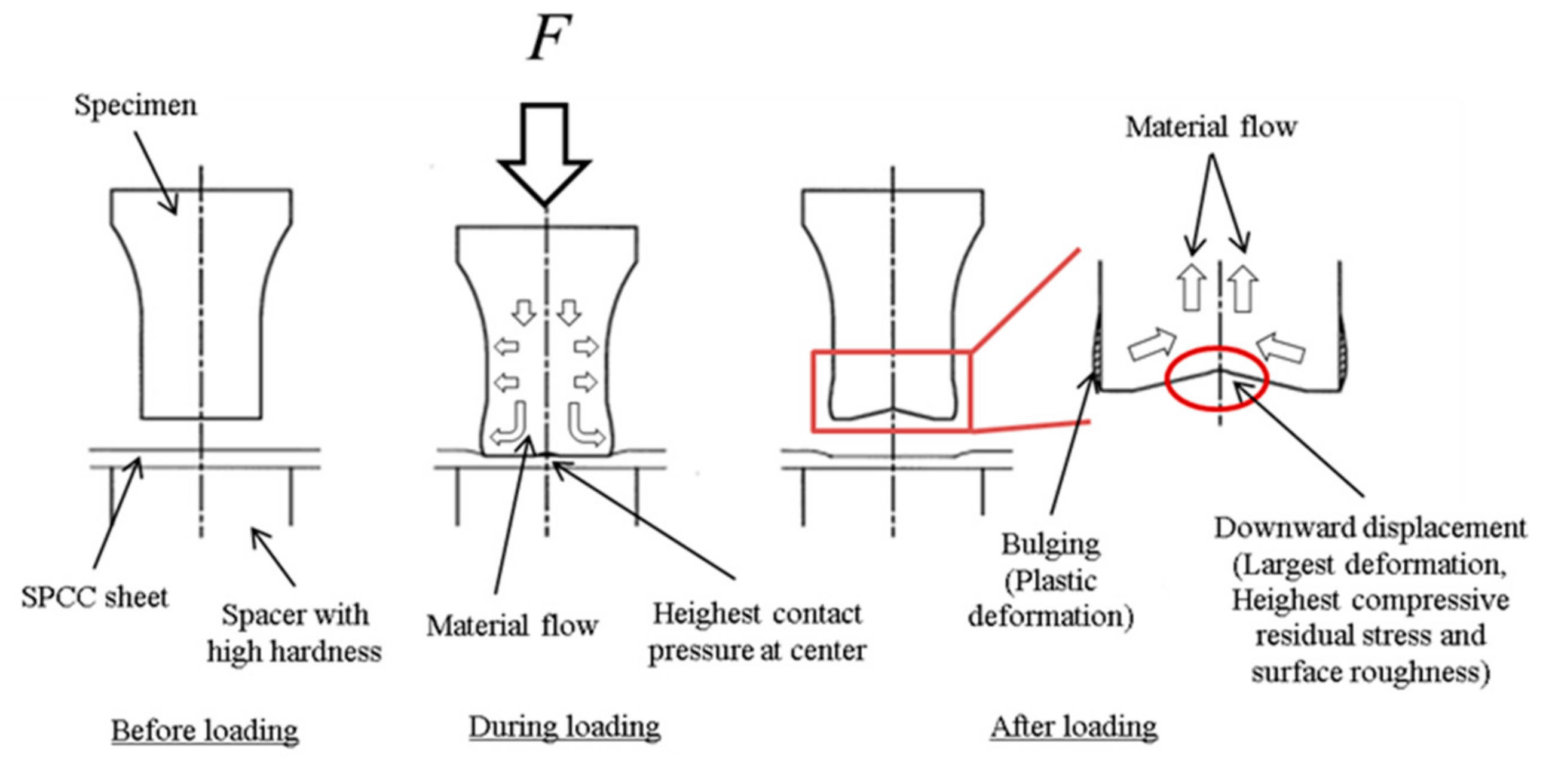

3.3. Deformation of the Specimens

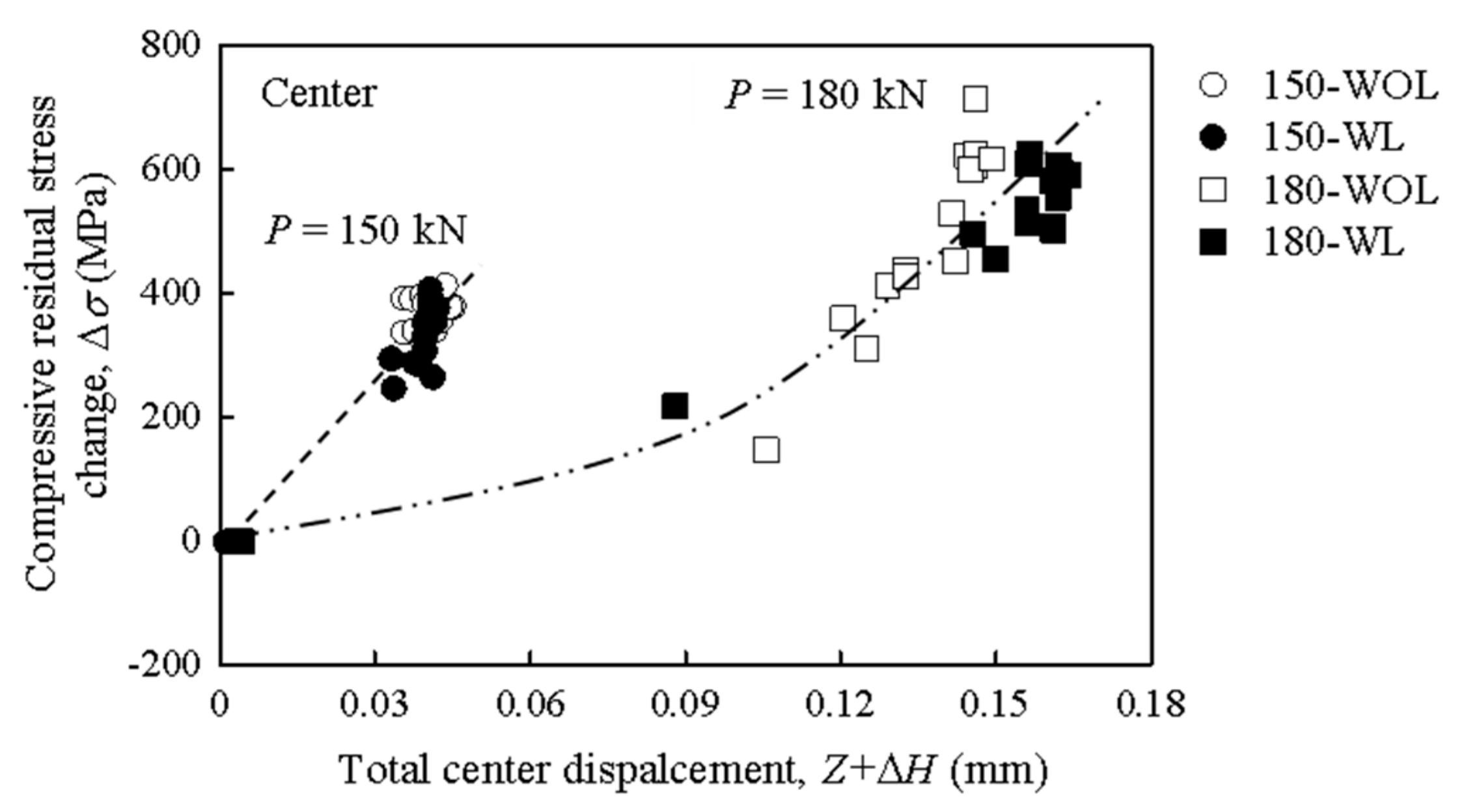

3.4. Interrelation among Evaluated Parameters

4. Conclusions

- The forging conditions greatly influence changes in surface compressive residual stress, surface roughness, and deformation of the forging tools during operation. There is a positive relationship between the forging load and all of the above parameters (surface compressive residual stress, surface roughness, and tool deformation).

- The presence of lubricant during the forging process reduces the increase in surface compressive residual stress and surface roughness of the tool. A uniform distribution of compressive residual stress or surface roughness is not present on the working surface of the tool, for a higher forging load.

- The use of lubricant in forging changes the deformation behavior of the tools and surface condition deterioration. The downward displacement at the center has a positive linear relationship with average height reduction. The presence of lubrication changes the deformation behavior at higher loads.

- The surface roughness change depends on both the forging load and lubrication conditions, but compressive residual stress change largely depends only on forging load.

- The use of lubricant and a moderate forging load will lead to an increase in the tool life, when compared to forging without lubrication (dry forging) at high forging loads. Furthermore, the results of this study can be used in forging tool design and decisions regarding surface treatment conditions, in order to improve the tool life and product quality.

Author Contributions

Funding

Conflicts of Interest

References

- Merklein, M.; Andreas, K.; Engel, U. Influence of machining process on residual stresses in the surface of cemented carbides. Procedia Eng. 2011, 19, 252–257. [Google Scholar] [CrossRef]

- Geiger, M.; Arbak, M.; Engel, U. Material adapted tool design in cold forging exemplified by powder metallurgical tool steels and industrial ceramics. Prod. Eng. 2008, 2, 409–415. [Google Scholar] [CrossRef]

- Ku, T.W.; Kang, B.S. Hardness-controlled tool fabrication and application to cold forging of inner race with skewed ball grooves. Int. J. Adv. Manuf. Technol. 2014, 74, 1337–1354. [Google Scholar] [CrossRef]

- Jarfors, A.E.; Castagne, S.J.; Danno, A.; Zhang, X. Tool wear and life span variations in cold forming operations and their implications in micro forming. Technologies 2017, 5, 3. [Google Scholar] [CrossRef]

- Abdullah, A.B.; Samad, Z. Cold forging die design: Recent advanced and future trends. J. Appl. Sci. 2007, 7, 868–876. [Google Scholar]

- Kramer, P.; Groche, P. Friction measurement under consideration of contact conditions and type of lubricant in bulk metal forming. Lubricants 2019, 7, 12. [Google Scholar] [CrossRef]

- Caminaga, C.; Neves, F.O.; Gentile, F.C.; Button, S.T. Study of alternative lubricants to the cold extrusion of steel shafts. J. Mater. Process. Technol. 2007, 182, 432–439. [Google Scholar] [CrossRef]

- Gariety, M.; Ngaile, G.; Altan, T. Evaluation of new cold forging lubricants without zinc phosphate precoat. Int. J. Mach. Tools Manuf. 2007, 47, 673–681. [Google Scholar] [CrossRef]

- Vollertsen, F.; Schmidt, F. Dry metal forming: Definition, chances and challenges. Int. J. Precis. Eng. Manuf. Technol. 2014, 1, 59–62. [Google Scholar] [CrossRef]

- Martinez Krahmer, D.; Hameed, S.; Sánchez Egea, A.J.; Pérez, D.; Canales, J.; López de Lacalle, L.N. Wear and MnS layer adhesion in uncoated cutting tools when dry and wet turning free-cutting steels. Metals 2019, 9, 556. [Google Scholar] [CrossRef]

- Herrmann, M.; Schenck, C.; Kuhfuss, B. Graded structured tools for dry rotary swaging. Dry Met. Form. 2018, 4, 18–24. [Google Scholar]

- Hafis, S.M.; Ridzuan, M.J.M.; Rahayu, A.; Mohamed, A.R.; Farahana, R.N.; Syahrullail, S. Minimum quantity lubrication in cold work drawing process: Effects on forming load and surface roughness. Procedia Eng. 2013, 68, 639–646. [Google Scholar] [CrossRef][Green Version]

- Andreas, K.; Merklein, M. Influence of surface integrity on the tribological performance of cold forging tools. Procedia CIRP 2014, 13, 61–66. [Google Scholar] [CrossRef][Green Version]

- Mckelvey, S.A.; Fatemi, A. Effect of forging surface on fatigue behavior of steels: A literature review. In Proceedings of the 28th Forging Industry Technical Conference, Chicago, IL, USA, 5–7 April 2011. [Google Scholar]

- Souza, T.; Pereira, M.; de Souza, R. Effect of Roughness on the Wear of Cold Forming Tools; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Syahrullail, S.; Azwadi, C.S.N.; Abdul Kadir, M.R.; Shafie, N.E.A. The effect of tool surface roughness in cold work extrusion. J. Appl. Sci. 2011, 11, 367–372. [Google Scholar]

- Martinez Krahmer, D.; Polvorosa, R.; López de Lacalle, L.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1555. [Google Scholar] [CrossRef]

- Kloos, K.H. Residual stresses, definition and causes of generation. Z. Werkstofftech. 1979, 10, 293–302. [Google Scholar] [CrossRef]

- Czan, A.; Holubjak, J.; Daniš, I.; Martinček, J.; Mikloš, M.; Čep, R.; Hatala, M.; Malotova, Š. Analysis of residual stress in subsurface layers after precision hard machining of forging tools. MATEC Web Conf. 2018, 157, 01005. [Google Scholar] [CrossRef][Green Version]

- Del Pozo, D.; López de Lacalle, L.N.; López, J.M.; Hernandez, A. Prediction of press/ die deformation for an accurate manufacturing of drawing dies. Int. J. Adv. Manuf. Technol. 2008, 37, 649–656. [Google Scholar] [CrossRef]

- Rosochowski, A. Die compensation procedure to negate die deflection and component springback. J. Mater. Process. Technol. 2001, 115, 187–191. [Google Scholar] [CrossRef]

- Jurči, P.; Dlouhý, I.; Priknerová, P.; Mrštný, Z. Effect of sub-zero treatment temperatures on hardness, flexural strength, and fracture toughness of vanadis 6 ledeburiticdie steel. Metals 2018, 8, 1047. [Google Scholar] [CrossRef]

- Chang, S.H.; Lee, S.C.; Tang, T.P. Effect of shot peening treatment on forging die life. Mater. Trans. 2008, 49, 619–623. [Google Scholar] [CrossRef]

- Harada, Y.; Fukauara, K.; Kohamada, S. Effects of microshotpeening on surface characteristics of high-speed tool steel. J. Mater. Process. Technol. 2008, 201, 319–324. [Google Scholar] [CrossRef]

- Popp, U.; Engel, U. Microtexturing of cold forging tools - Influence on tool life. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2006, 220, 27–33. [Google Scholar] [CrossRef]

- Krajewski, M.; Brzozka, K.; Lin, W.S.; Lin, H.M.; Tokarczyk, M.; Borysiuk, J.; Kowalskia, G.; Wasik, D. High temperature oxidation of iron-iron oxide core-shell nanowires composed of iron nanoparticles. Phys. Chem. Chem. Phys. 2016, 18, 3900–3909. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi, H.M.; Furey, M.J.; Kajdas, C. Surface temperatures and fretting corrosion of steel under conditions of fretting contact. Wear 1993, 162, 357–369. [Google Scholar] [CrossRef]

- Labašová, E. Measurement of Changes of the Surface Roughness in Sliding Area. Am. Int. J. Contemp. Res. 2013, 3, 1–2. [Google Scholar]

- Herai, T.; Ejima, M.; Yoshida, K.; Miyauchi, K.; Ike, H. Frictional surface damage and its mechanism in metal sheets. Sci. Pap. Inst. Phys. Chem. Res. 1978, 72, 1–13. [Google Scholar]

- Osakada, K.; Matsumoto, R. Fundamental study of dry metal forming with coated tools. CIRP Ann. Manuf. Technol. 2000, 49, 161–164. [Google Scholar] [CrossRef]

- Jianga, D.; Annéa, G.; Vleugelsa, J.; Vanmeensela, K.; Eeraertsb, W.; Liub, W.; Lauwersb, B.; Biesta, O.V. Residual stresses in hardmetals caused by grinding and EDM machining and their influence on the flexural strength, Powder Metallurgical High Performance Materials. In Proceedings of the 16th International Plansee Seminar, Reutte, Austria, 30 May 2005; Volume 2, pp. 1075–1085. [Google Scholar]

- Williams, J.A.; Dwyer-Joyce, R.S. Modern Tribology Handbook (Principles of Tribology); CRC Press: Boca Raton, FL, USA, 2001; Volume 1. [Google Scholar]

- Natori, M.; Song, S.; Sugimoto, K. The effects of fine particle peening on surface residual stress of a TRIP-aided bainiticferrite steel. J. Soc. Mater. Sci. 2014, 63, 662–668. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Goodier, J.N. Theory of Elasticity, 1st ed.; McGraw-Hill Book Company: New York, NY, USA, 1951. [Google Scholar]

- Malayappan, S.; Narayanasamy, R. An experimental analysis of upset forging of aluminum cylindrical billets considering the dissimilar frictional conditions at flat die surfaces. Int. J. Adv. Manuf. Technol. 2004, 23, 636–643. [Google Scholar] [CrossRef]

- Barrau, O.; Boher, C.; Vergne, C.; Rezai-Aria, F.; Gras, R. Investigations of friction and wear mechanisms of hot forging tool steels. In Proceedings of the 6th International Conference on Tooloing, Karlstad, Sweden, 10–13 September 2002. [Google Scholar]

| C | Si | Mn | Cr | Mo | V | W | P, S |

|---|---|---|---|---|---|---|---|

| 0.80–0.88 | ≤0.45 | ≤0.40 | 3.80–4.50 | 4.70–5.20 | 1.70–2.10 | 5.90–6.70 | ≤0.03 |

| Parameter | Value |

|---|---|

| Density (15 °C) | 891.8 kg/m3 |

| Viscosity (40 °C) | 77.82 mm2/s |

| Flash point (C.O.C) | 240 °C |

| Copper corrosion (100 °C × 1 h) | 1 |

| Parameter | Ra | σ | Z | ΔH | ΔD |

|---|---|---|---|---|---|

| Increase in load | ⇈ | ⇈ | ⇈ | ⇈ | ⇈ |

| Presence of lubrication | ↓ | ↓ | ↑ | ↑ | ↓ |

| Parameter | Ra | σ | Z | ΔH | ΔD |

|---|---|---|---|---|---|

| Tool life | ↓ | ↑ | ↓ | ↓ | ↓ |

| Forged part accuracy | ↓ | - | ↓ | ↓ | ↓ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karunathilaka, N.; Tada, N.; Uemori, T.; Hanamitsu, R.; Fujii, M.; Omiya, Y.; Kawano, M. Effect of Lubrication and Forging Load on Surface Roughness, Residual Stress, and Deformation of Cold Forging Tools. Metals 2019, 9, 783. https://doi.org/10.3390/met9070783

Karunathilaka N, Tada N, Uemori T, Hanamitsu R, Fujii M, Omiya Y, Kawano M. Effect of Lubrication and Forging Load on Surface Roughness, Residual Stress, and Deformation of Cold Forging Tools. Metals. 2019; 9(7):783. https://doi.org/10.3390/met9070783

Chicago/Turabian StyleKarunathilaka, Nuwan, Naoya Tada, Takeshi Uemori, Ryota Hanamitsu, Masahiro Fujii, Yuya Omiya, and Masahiro Kawano. 2019. "Effect of Lubrication and Forging Load on Surface Roughness, Residual Stress, and Deformation of Cold Forging Tools" Metals 9, no. 7: 783. https://doi.org/10.3390/met9070783

APA StyleKarunathilaka, N., Tada, N., Uemori, T., Hanamitsu, R., Fujii, M., Omiya, Y., & Kawano, M. (2019). Effect of Lubrication and Forging Load on Surface Roughness, Residual Stress, and Deformation of Cold Forging Tools. Metals, 9(7), 783. https://doi.org/10.3390/met9070783