Improving Mechanical Properties of 18%Mn TWIP Steels by Cold Rolling and Annealing

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

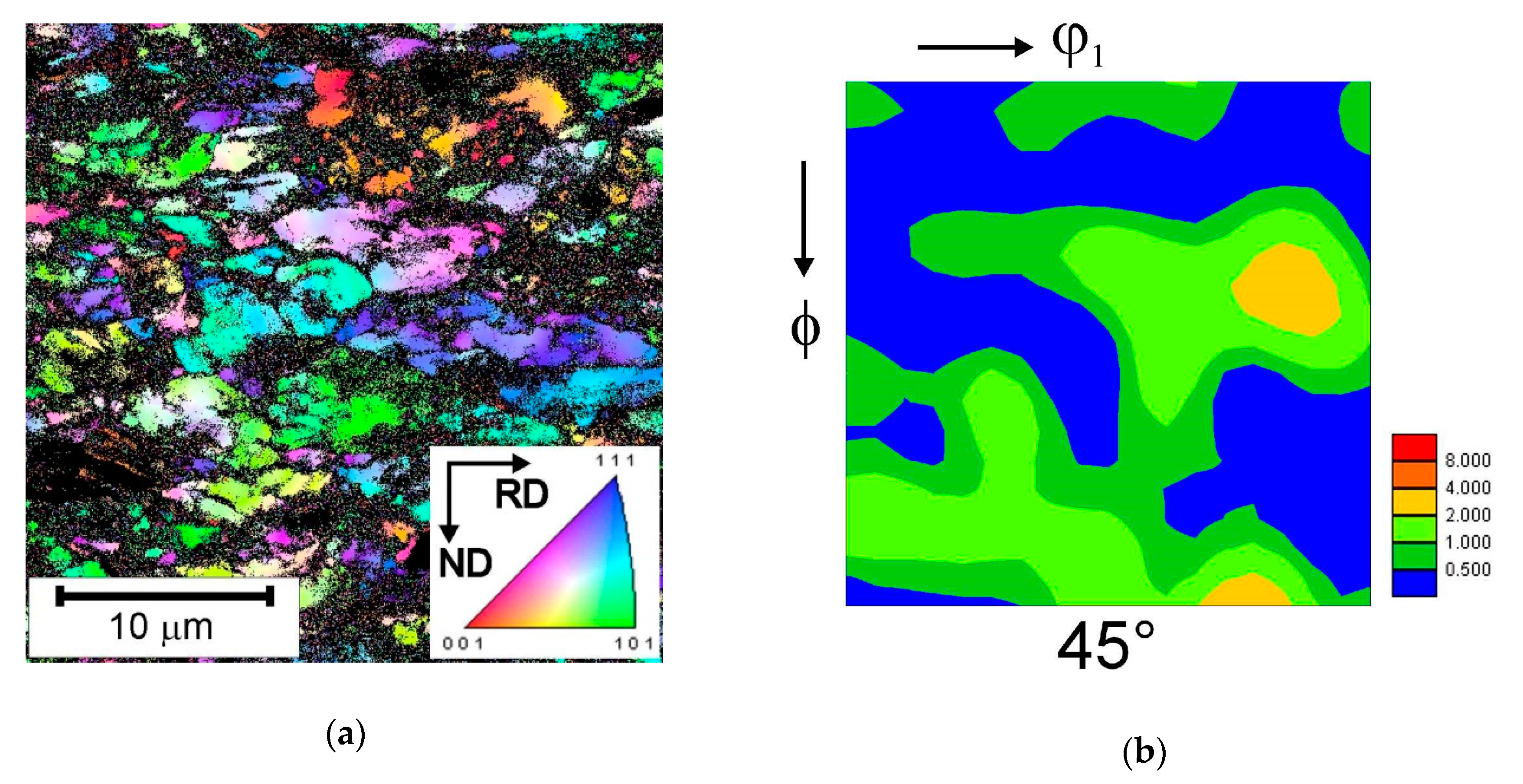

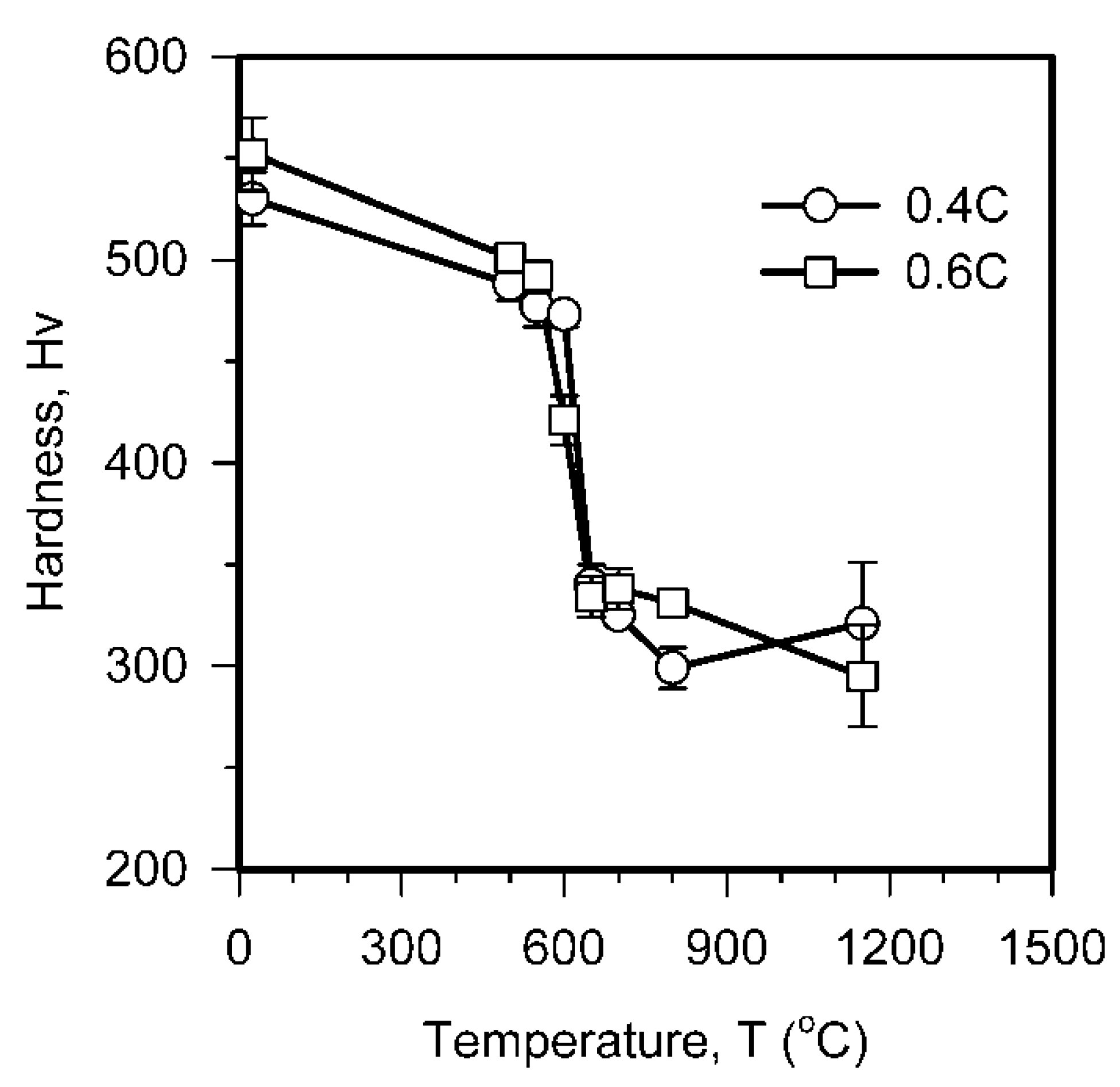

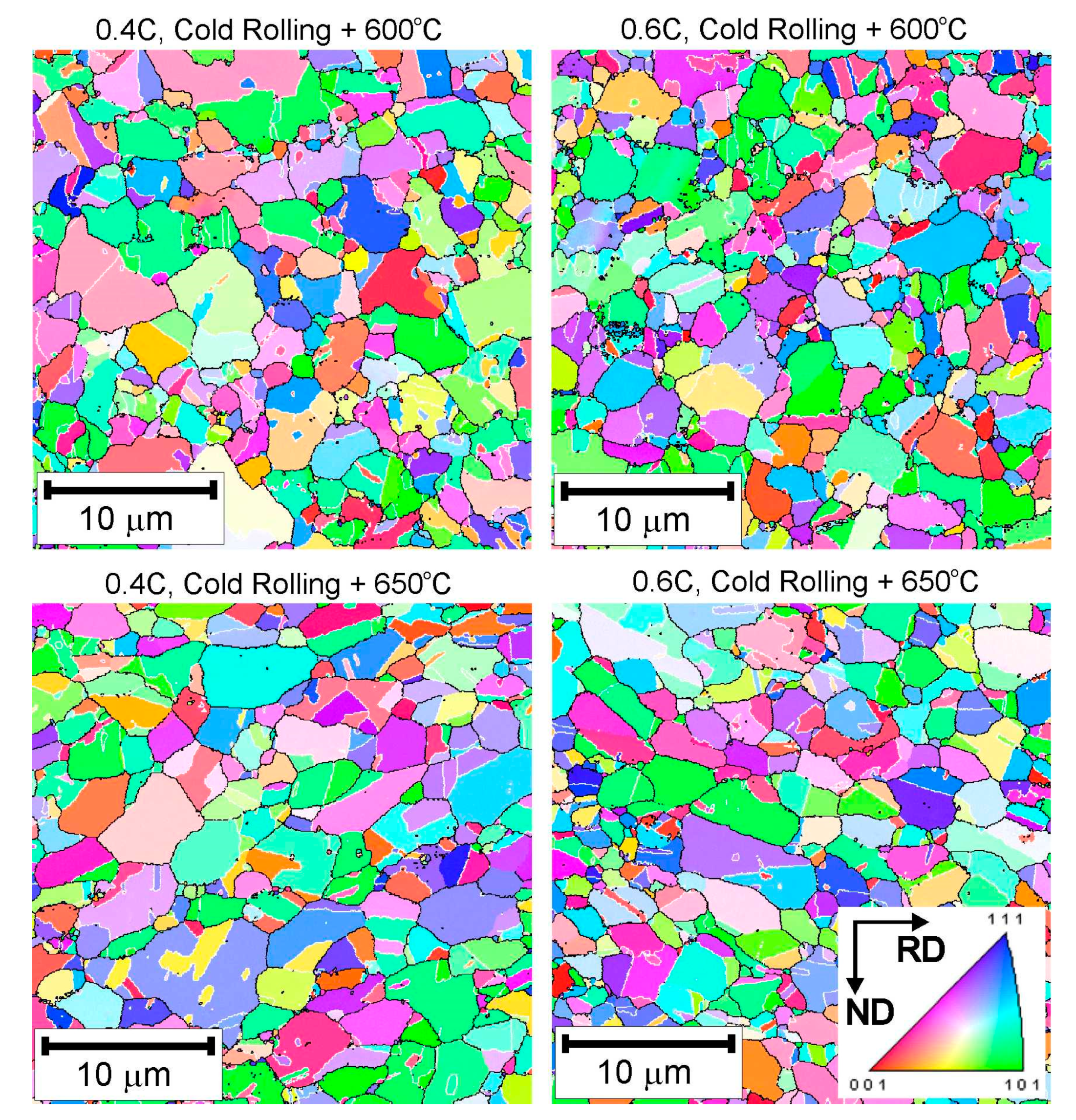

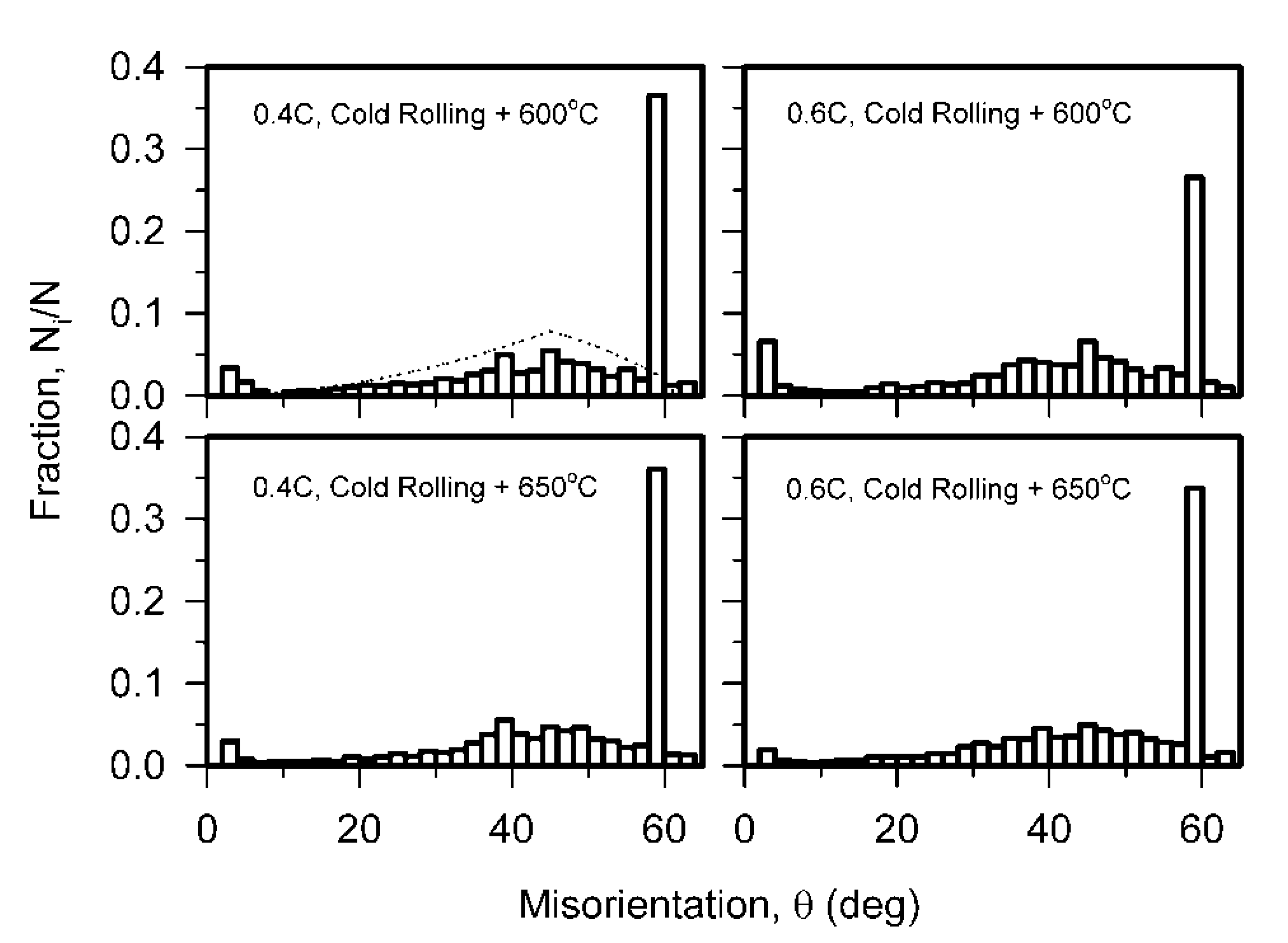

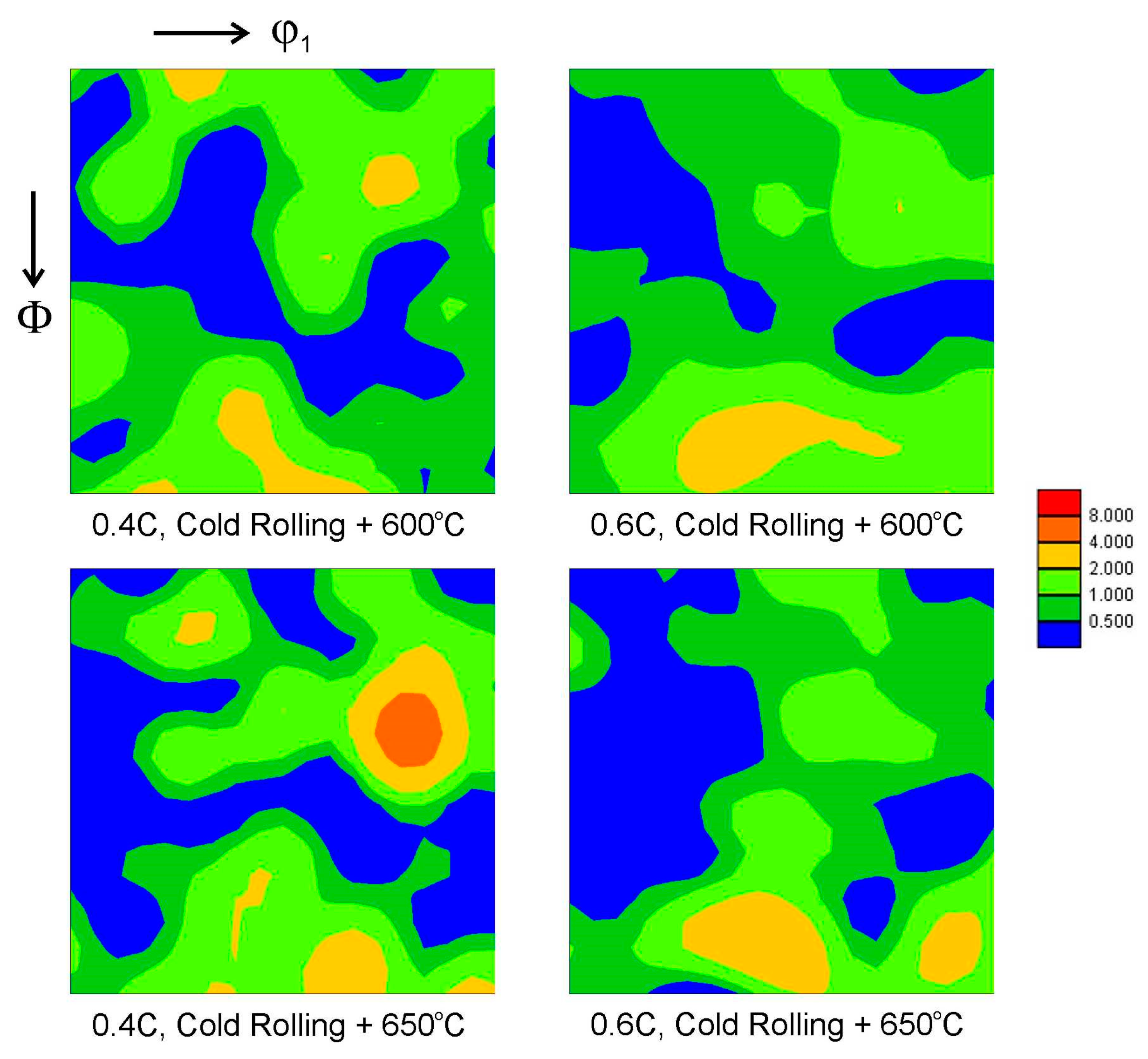

3.1. Annealed Microstructures

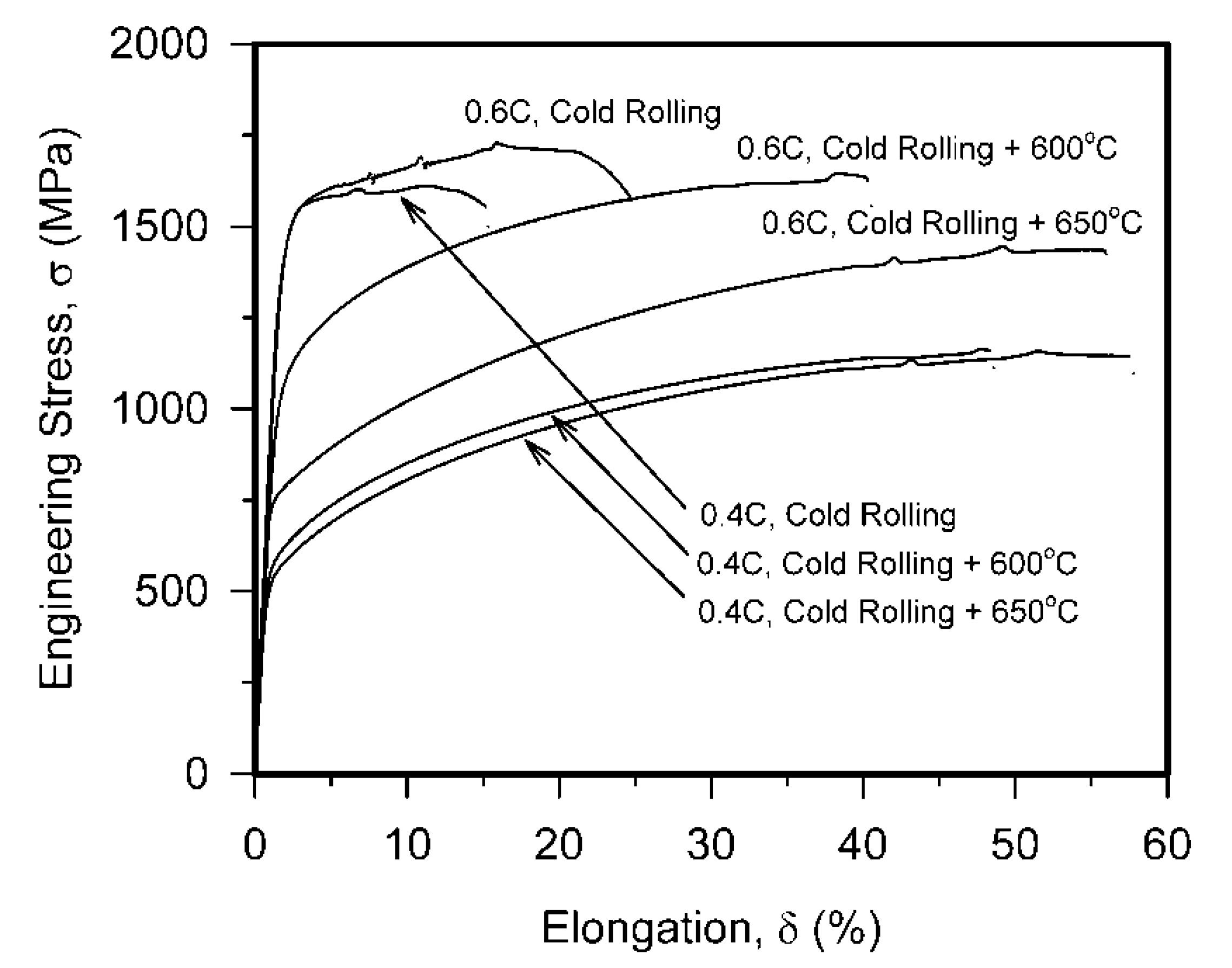

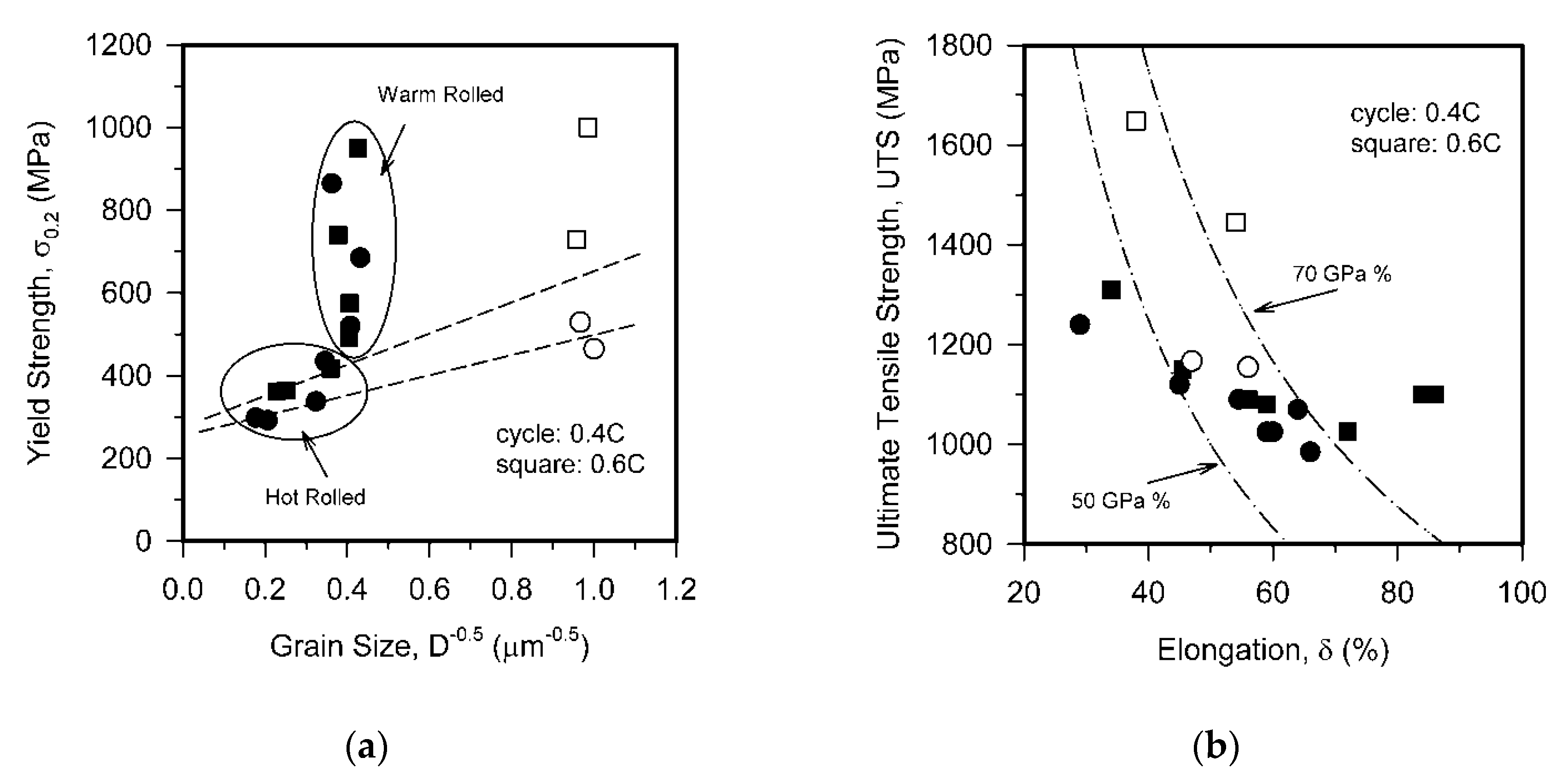

3.2. Tensile Behaviour

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High Manganese Austenitic Twinning Induced Plasticity Steels: A Review of the Microstructure Properties Relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and Prediction of Flow Behavior in High-Manganese Twinning Induced Plasticity Steels: Part I. Mechanism Maps and Work-Hardening Behavior. Metall. Mater. Trans. A 2012, 43, 1688–1704. [Google Scholar] [CrossRef]

- Sevsek, S.; Brasche, F.; Haase, C.; Bleck, W. Combined deformation twinning and short-range ordering causes serrated flow in high-manganese steels. Mater. Sci. Eng. A 2019, 746, 434–442. [Google Scholar] [CrossRef]

- Song, W.; Ingendahl, T.; Bleck, W. Control of Strain Hardening Behavior in High-Mn Austenitic Steels. Acta Metall. Sin. Engl. Lett. 2014, 27, 546–556. [Google Scholar] [CrossRef]

- Keeler, S.; Kimchi, M. Advanced High-Strength Steels Application Guidelines V5; WorldAutoSteel: Middletown, OH, USA, 2014. [Google Scholar]

- Nikulin, I.; Sawaguchi, T.; Kushibe, A.; Inoue, Y.; Otsuka, H.; Tsuzaki, K. Effect of strain amplitude on the low-cycle fatigue behavior of a new Fe-15Mn-10Cr-8Ni-4Si seismic damping alloy. Int. J. Fatigue 2016, 88, 132–141. [Google Scholar] [CrossRef]

- Kusakin, P.S.; Kaibyshev, R.O. High-Mn twinning-induced plasticity steels: Microstructure and mechanical properties. Rev. Adv. Mater. Sci. 2016, 44, 326–360. [Google Scholar]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Kusakin, P.; Tsuzaki, K.; Molodov, D.A.; Kaibyshev, R.; Belyakov, A. Advanced thermomechanical processing for a high-Mn austenitic steel. Metall. Mater. Trans. A 2016, 47, 5704–5708. [Google Scholar] [CrossRef]

- Torganchuk, V.; Belyakov, A.; Kaibyshev, R. Effect of rolling temperature on microstructure and mechanical properties of 18%Mn TWIP/TRIP steels. Mater. Sci. Eng. A 2017, A708, 110–117. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Saha, R.; Ueji, R.; Tsuji, N. Fully recrystallized nanostructure fabricated without severe plastic deformation in high-Mn austenitic steel. Scripta Mater. 2013, 68, 813–816. [Google Scholar] [CrossRef]

- Hirsch, J.; Lucke, K. Mechanism of deformation and development of rolling texture in polycrystalline f.c.c. metal—I. Description of rolling texture development in homogeneous CuZn alloys. Acta Metall. Mater. 1988, 36, 2863–2882. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Belyakov, A.; Kaibyshev, R.; Haase, C.; Molodov, D.A. Effect of cold rolling on recrystallization and tensile behavior of a high-Mn steel. Mater. Charact. 2016, 112, 180–187. [Google Scholar] [CrossRef]

- Mahajan, S. Critique of mechanisms of formation of deformation, annealing and growth twins: Face-centered cubic metals and alloys. Scripta Mater. 2013, 68, 95–99. [Google Scholar] [CrossRef]

- Mackenzie, J.K. Second Paper on the Statistics Associated with the Random Disorientation of Cubes. Biometrika 1958, 45, 229–240. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Oxford, UK, 2004; pp. 215–268. ISBN 0-08-044164-5. [Google Scholar]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. R. Soc. Lond. Ser. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

| Steel Processing | Grain Size, μm | Fraction of Σ3 CSL Boundaries | Fraction of Low-Angle Boundaries |

|---|---|---|---|

| Fe-0.4C-18Mn Cold Rolling + 600 °C | 1.07 | 0.40 | 0.06 |

| Fe-0.4C-18Mn Cold Rolling + 650 °C | 1.10 | 0.39 | 0.07 |

| Fe-0.6C-18Mn Cold Rolling + 600 °C | 1.03 | 0.29 | 0.10 |

| Fe-0.6C-18Mn Cold Rolling + 650 °C | 1.09 | 0.37 | 0.05 |

| Steel Processing | σ0.2, MPa | UTS, MPa | δ, % |

|---|---|---|---|

| Fe-0.4C-18Mn Cold Rolling + 600 °C | 530 | 1165 | 45 |

| Fe-0.4C-18Mn Cold Rolling + 650 °C | 465 | 1155 | 55 |

| Fe-0.6C-18Mn Cold Rolling + 600 °C | 1000 | 1650 | 40 |

| Fe-0.6C-18Mn Cold Rolling + 650 °C | 730 | 1445 | 55 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torganchuk, V.; Belyakov, A.; Kaibyshev, R. Improving Mechanical Properties of 18%Mn TWIP Steels by Cold Rolling and Annealing. Metals 2019, 9, 776. https://doi.org/10.3390/met9070776

Torganchuk V, Belyakov A, Kaibyshev R. Improving Mechanical Properties of 18%Mn TWIP Steels by Cold Rolling and Annealing. Metals. 2019; 9(7):776. https://doi.org/10.3390/met9070776

Chicago/Turabian StyleTorganchuk, Vladimir, Andrey Belyakov, and Rustam Kaibyshev. 2019. "Improving Mechanical Properties of 18%Mn TWIP Steels by Cold Rolling and Annealing" Metals 9, no. 7: 776. https://doi.org/10.3390/met9070776

APA StyleTorganchuk, V., Belyakov, A., & Kaibyshev, R. (2019). Improving Mechanical Properties of 18%Mn TWIP Steels by Cold Rolling and Annealing. Metals, 9(7), 776. https://doi.org/10.3390/met9070776