Plasma Multiwire Technology with Alternating Wire Feed for Tailor-Made Material Properties in Wire and Arc Additive Manufacturing

Abstract

1. Introduction

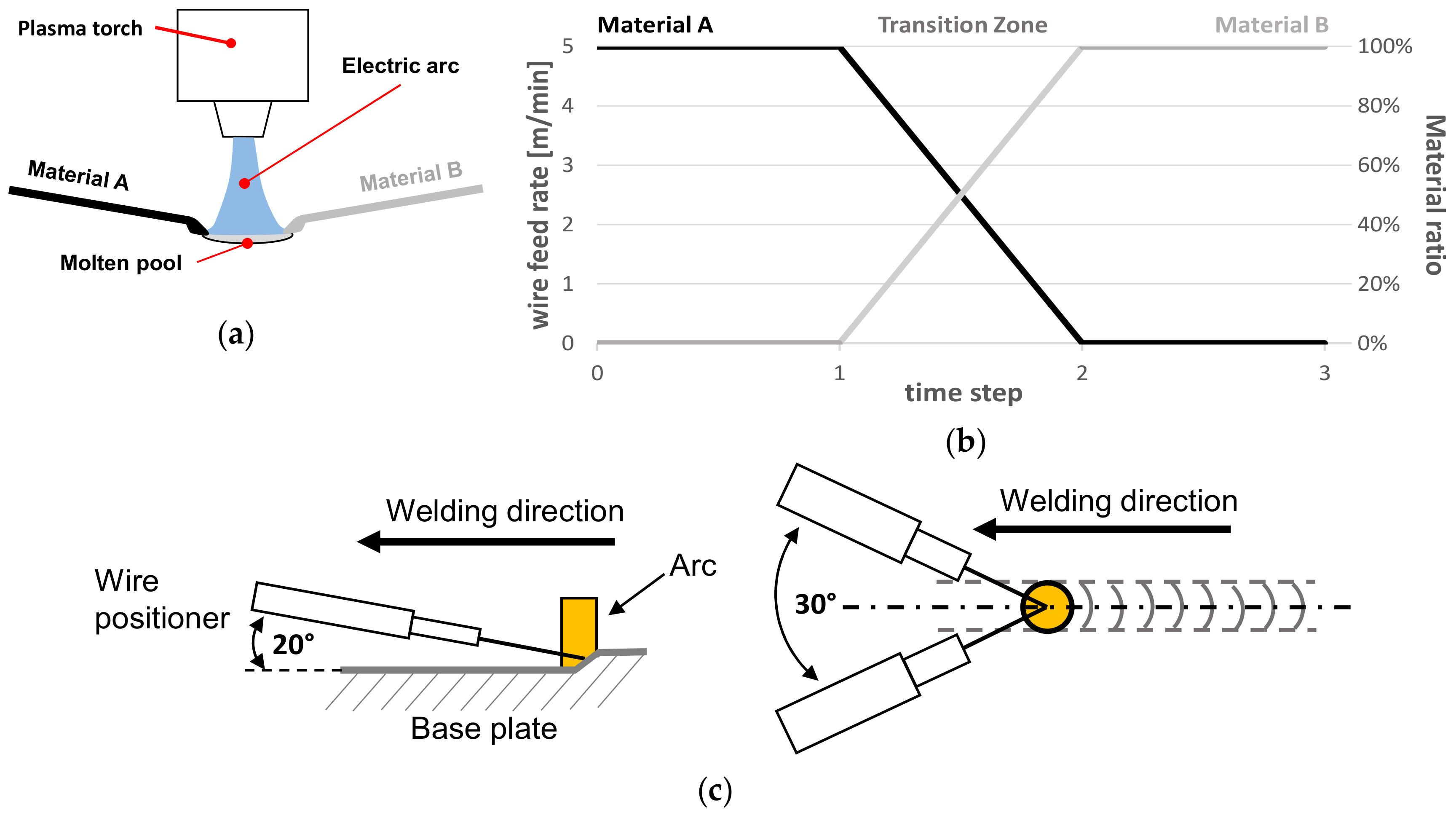

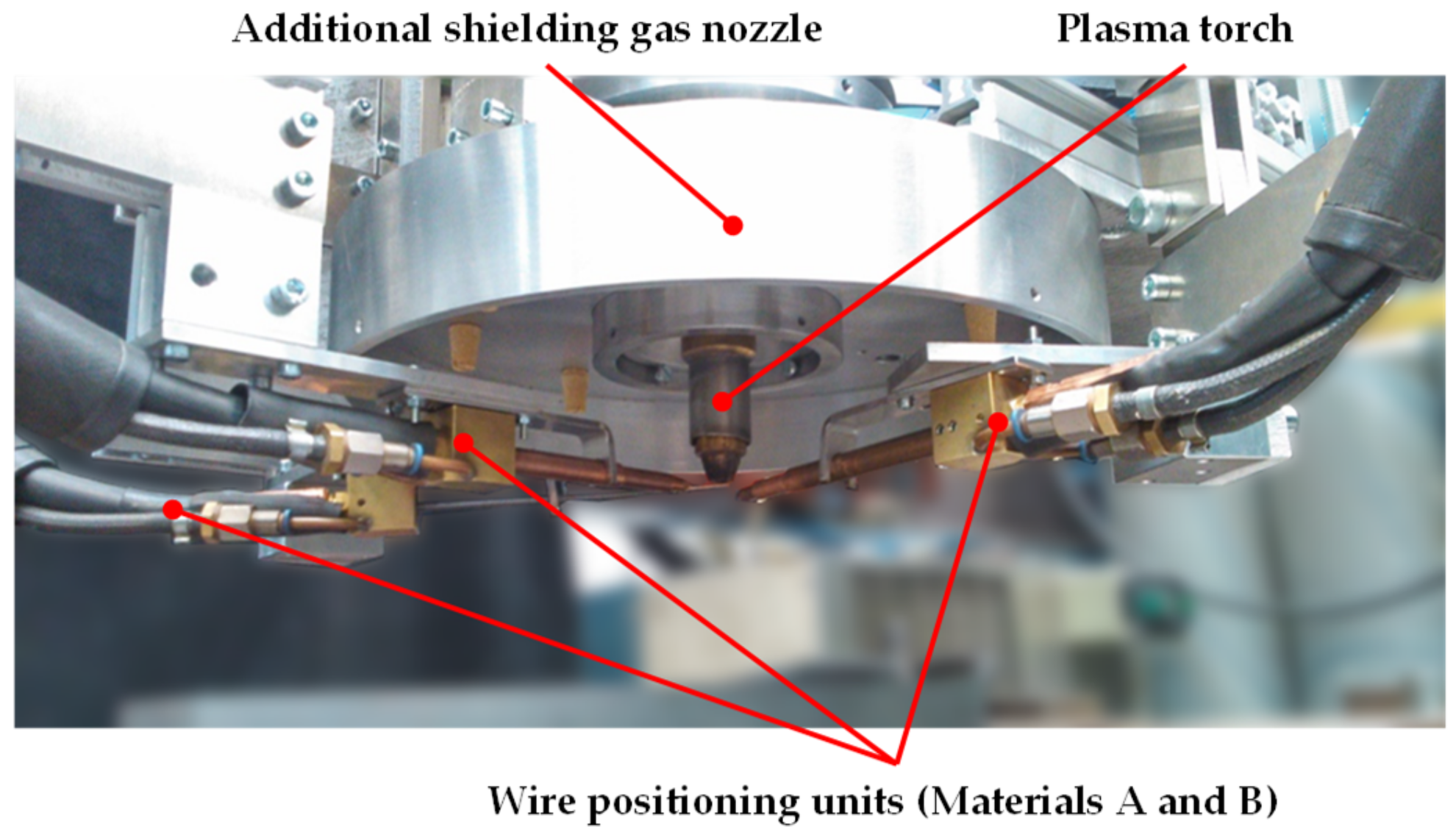

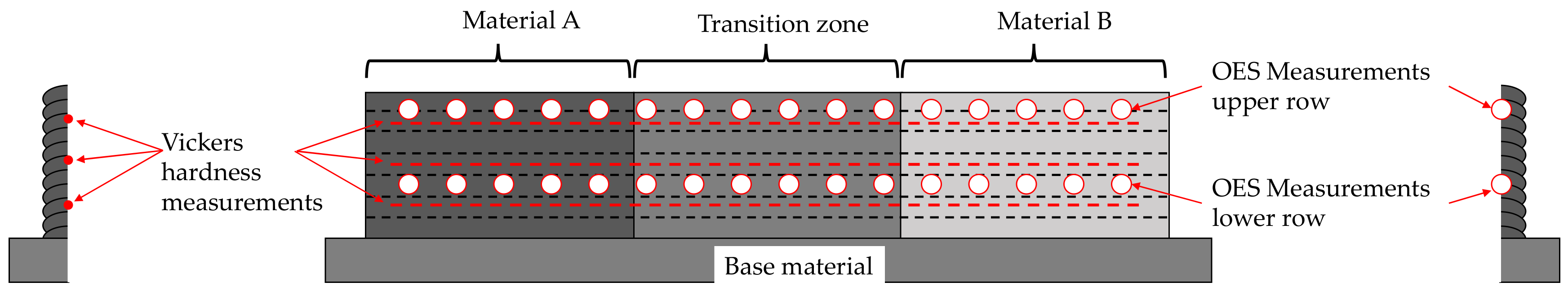

2. Materials and Methods

3. Results

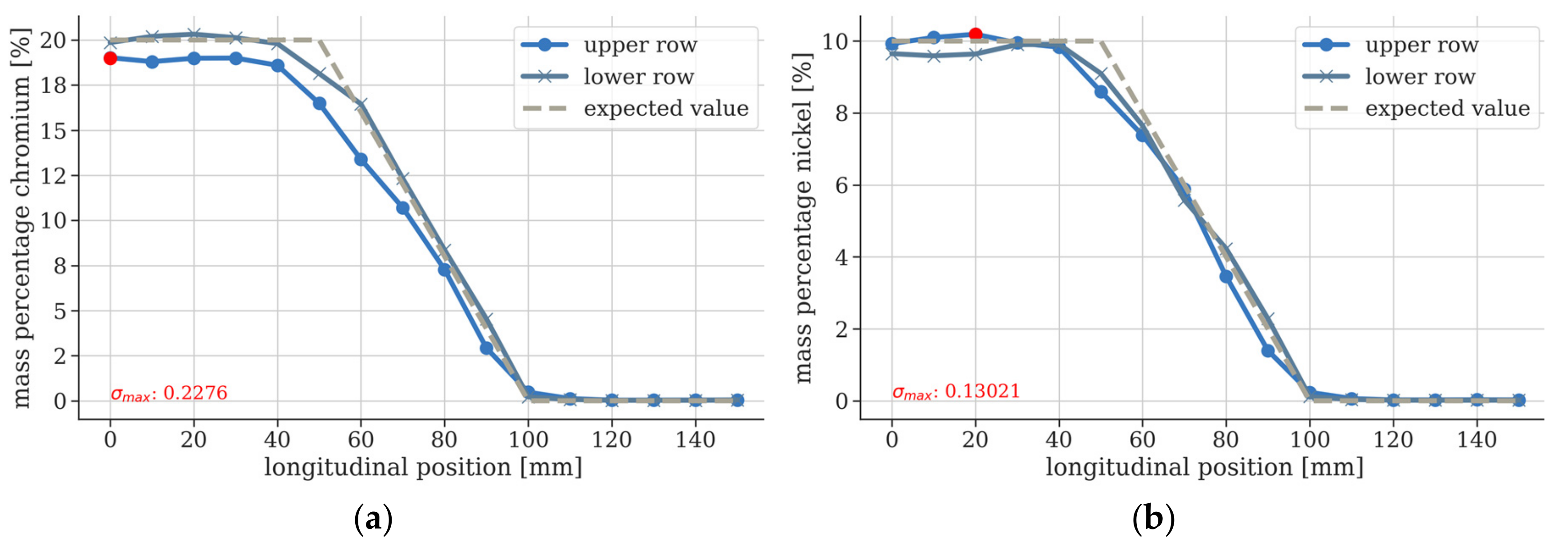

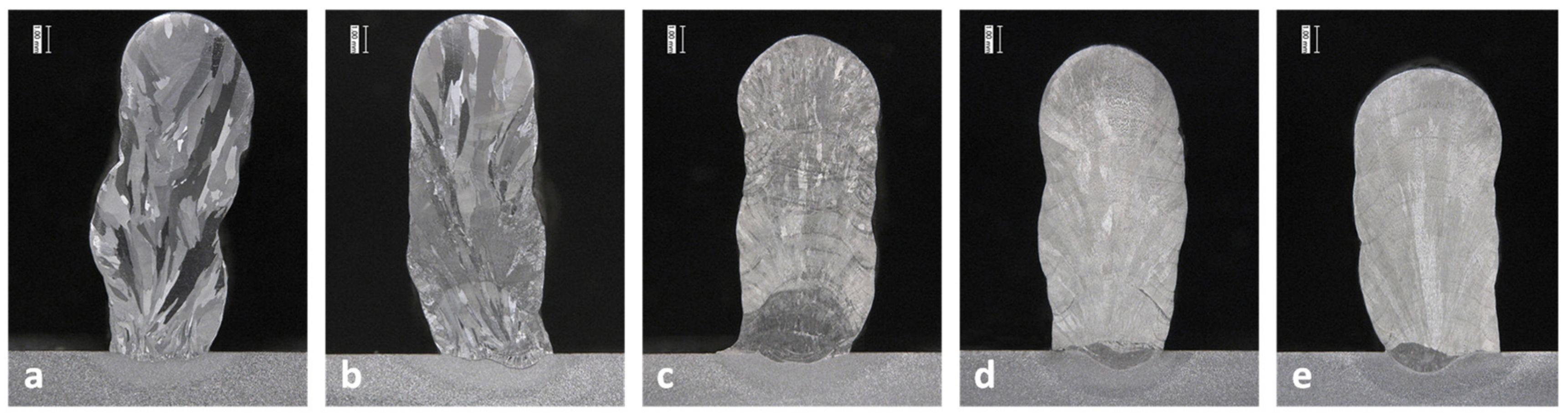

3.1. Material Combination 1: G 19 9 LSi to G 3Si1

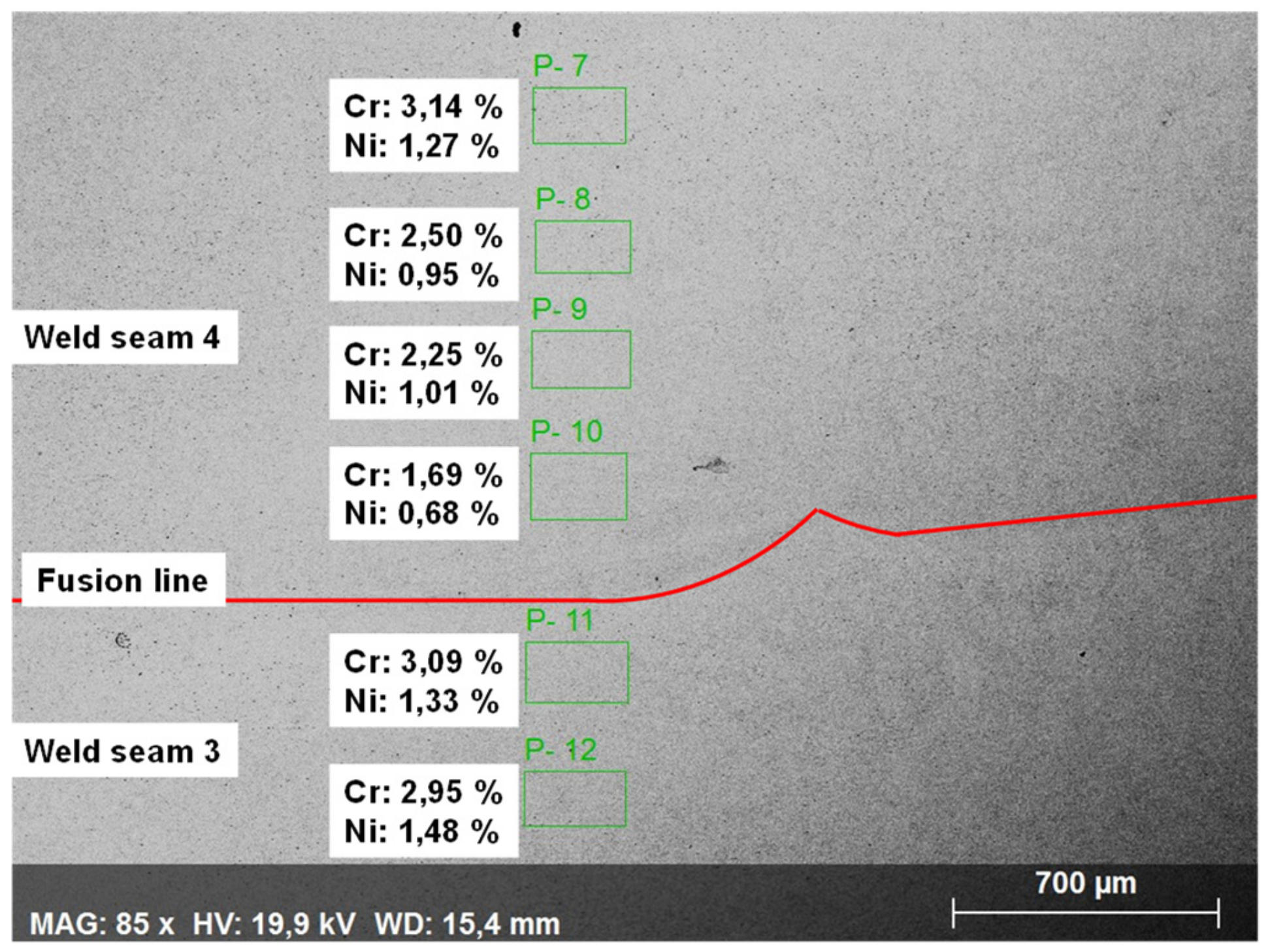

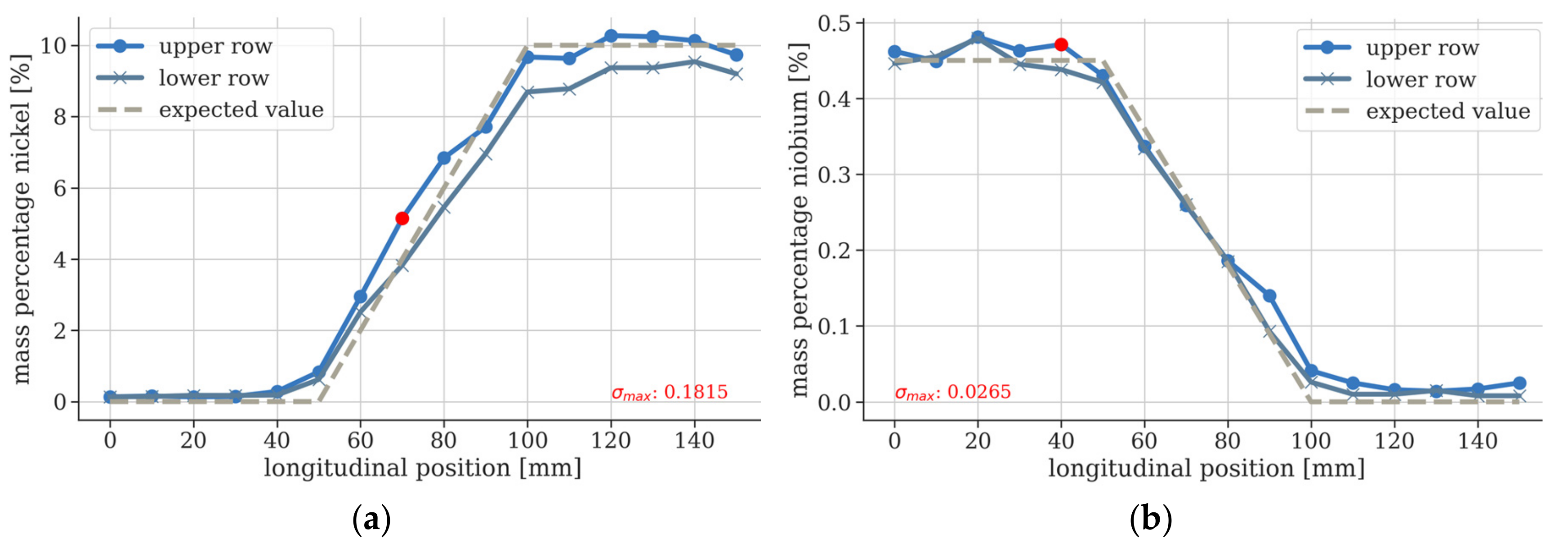

3.2. Material Combination 2: G 18 L Nb to G 19 9 L Si

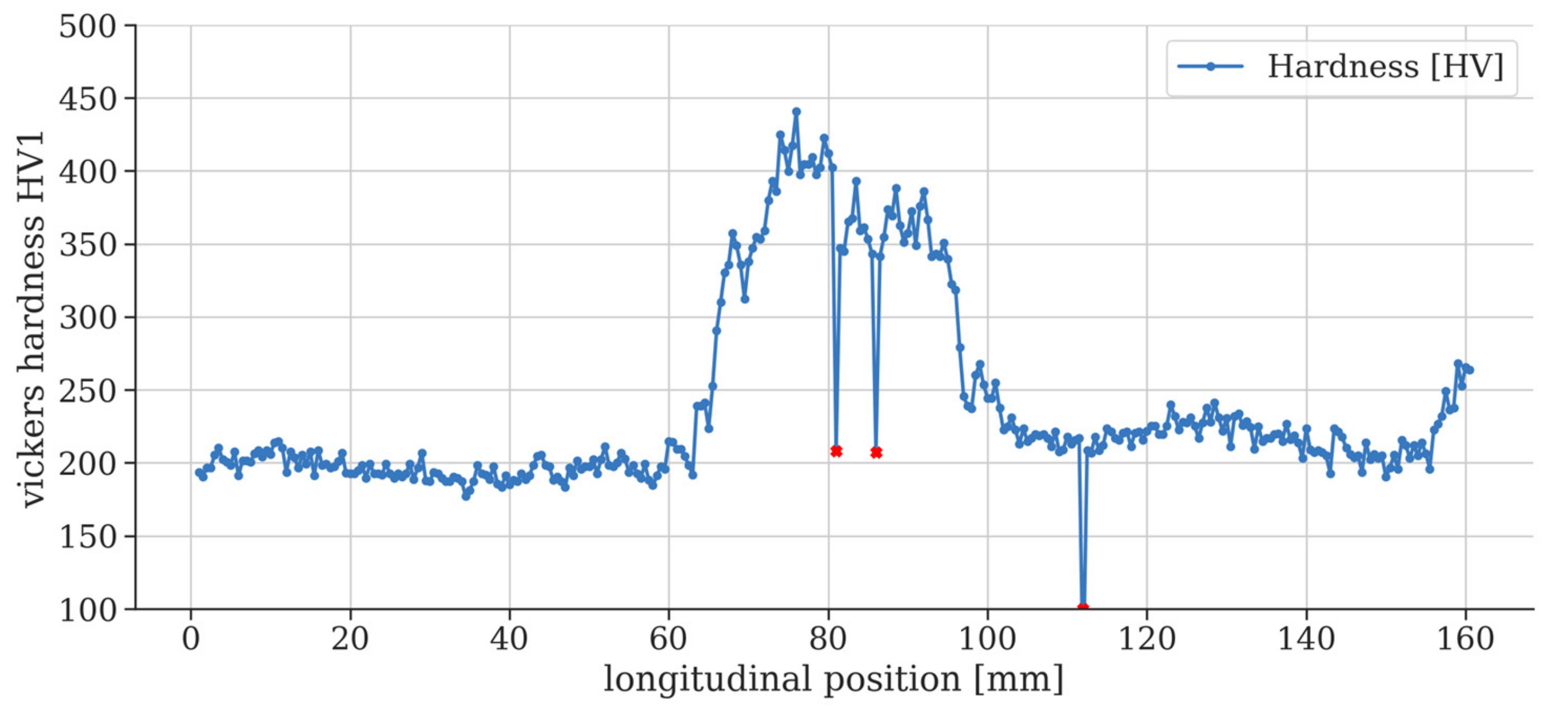

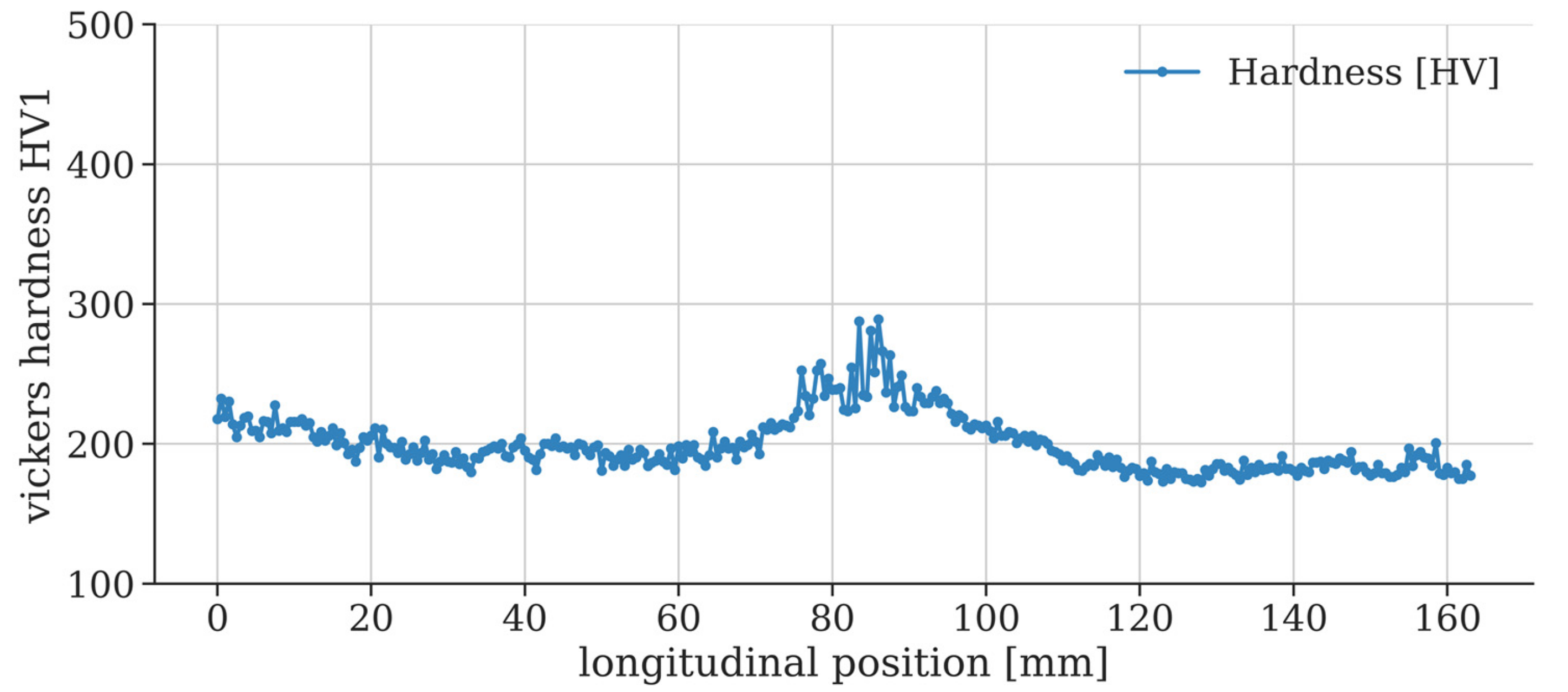

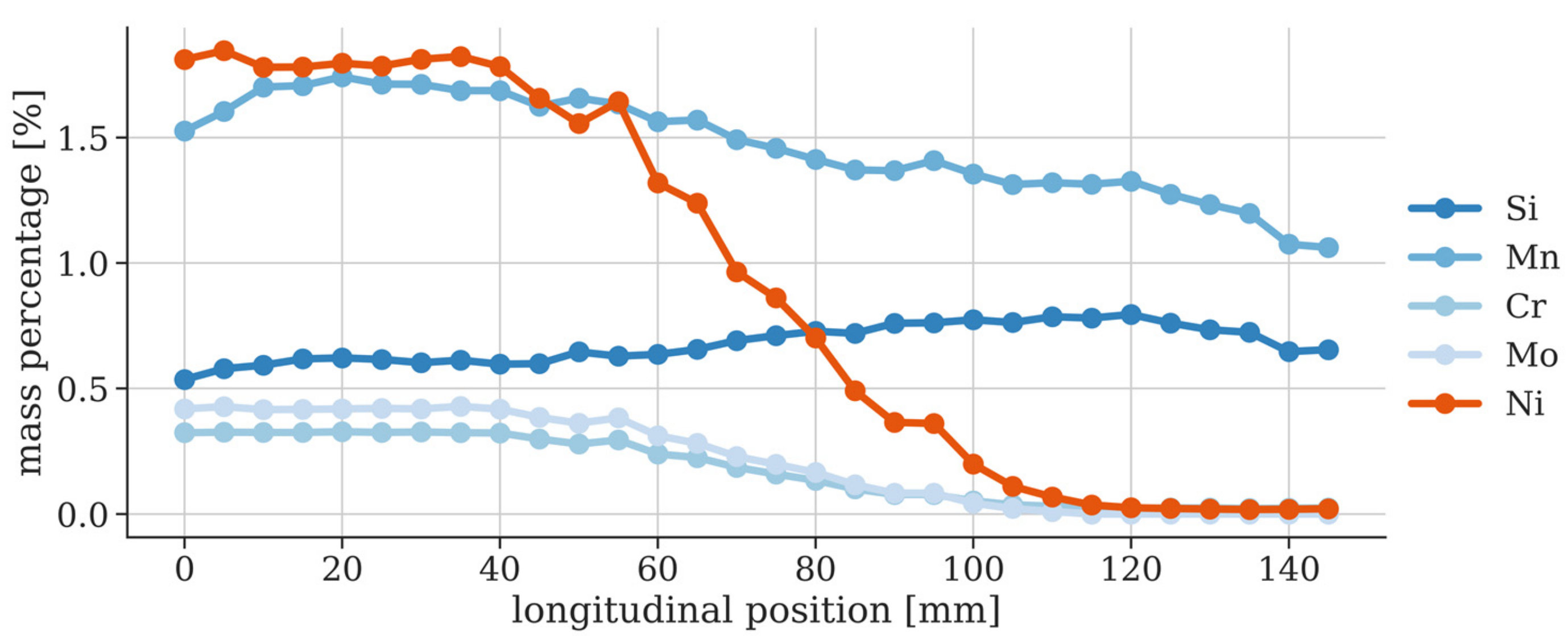

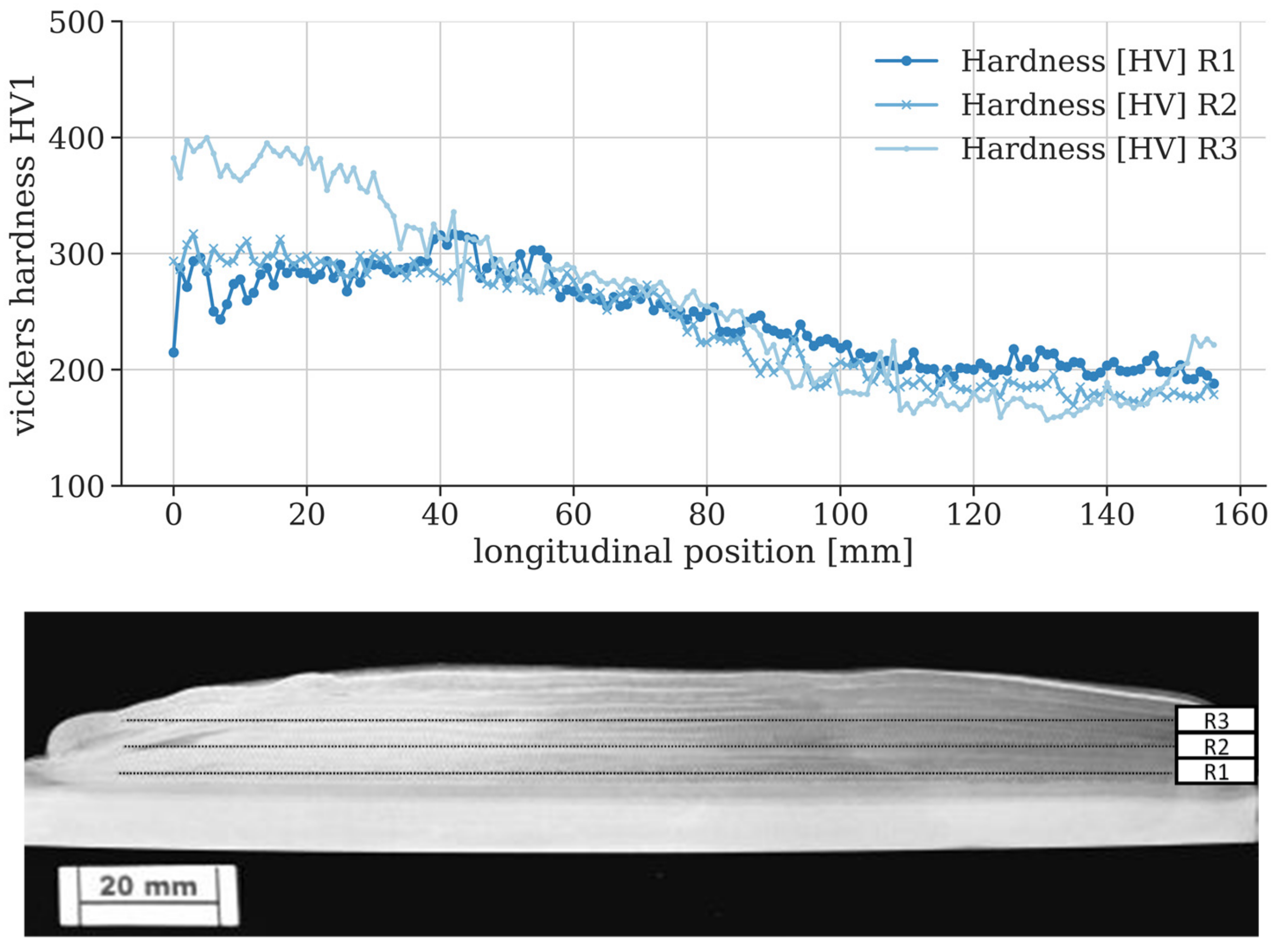

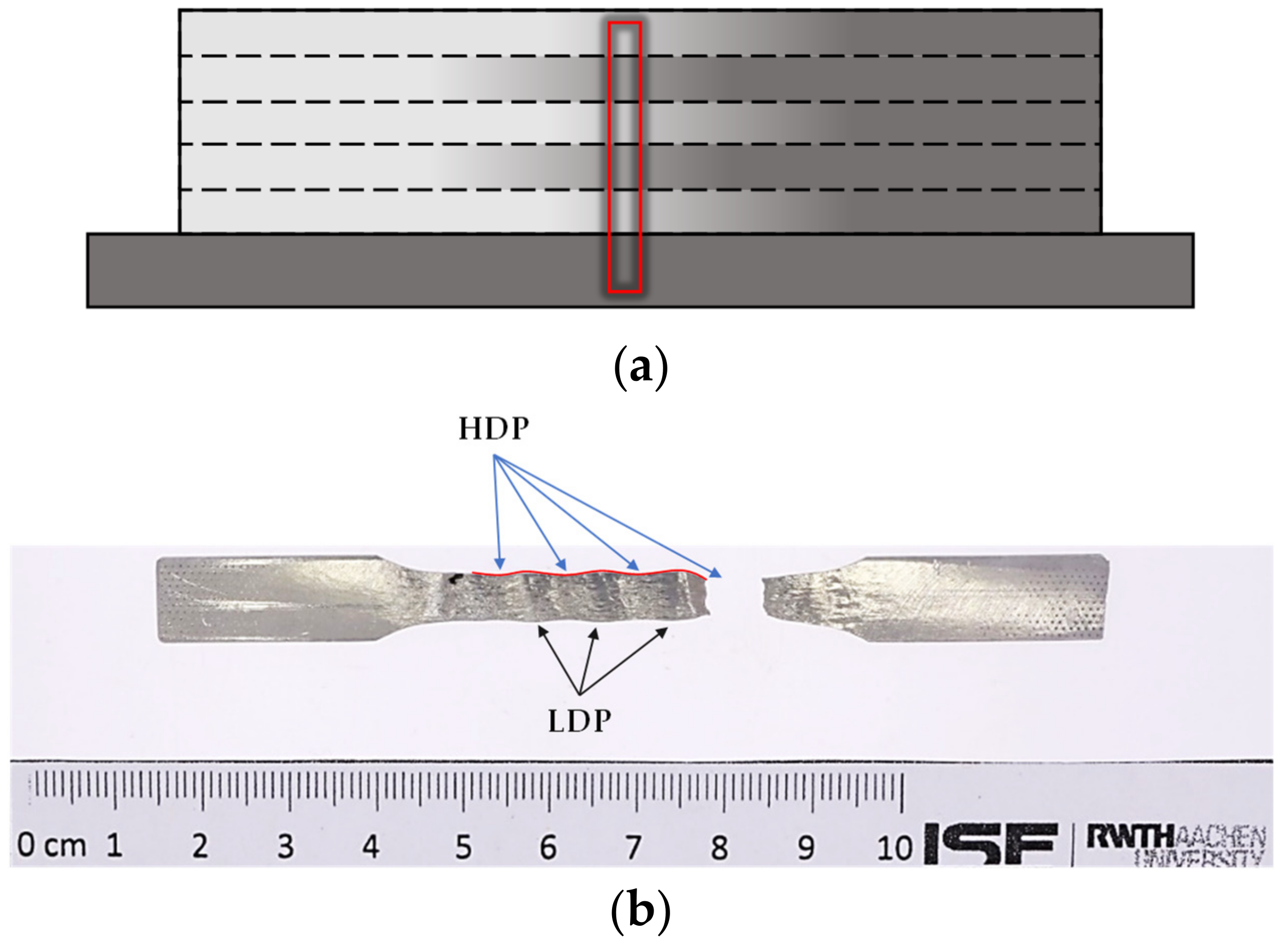

3.3. Material Combination 3: G Mn4Ni2CrMo to G 3Si1

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mahmoud, D.; Elbestawi, M. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Yan, L.; Chen, X.; Zhang, Y.; Newkirk, J.W.; Liou, F. Fabrication of Functionally Graded Ti and γ-TiAl by Laser Metal Deposition. JOM 2017, 69, 2756–2761. [Google Scholar] [CrossRef]

- Demirhan, P.A.; Taskin, V. Levy solution for bending analysis of functionally graded sandwich plates based on four variable plate theory. Compos. Struct. 2017, 177, 80–95. [Google Scholar] [CrossRef]

- Sarathchandra, D.T.; Subbu, S.K.; Venkaiah, N. Functionally graded materials and processing techniques: An art of review. Mater. Today: Proc. 2018, 5, 21328–21334. [Google Scholar] [CrossRef]

- Rostek, T.; Homberg, W. Locally Graded Steel Materials for Self-Sharpening Cutting Blades. Procedia Eng. 2017, 207, 2185–2190. [Google Scholar] [CrossRef]

- Chen, Y.; Liou, F. Additive Manufacturing of Metal Functionally Graded Materials: A Review. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium 2018, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Reichardt, A. Additive Manufacturing of Metal-based Functionally Graded Materials. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2017. [Google Scholar]

- Zhang, Y.; Wei, Z.; Shi, L.; Xi, M. Characterization of laser powder deposited Ti–TiC composites and functional gradient materials. J. Mater. Process. Technol. 2008, 206, 438–444. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; Zhang, W.; DebRoy, T. Residual stresses and distortion in additively manufactured compositionally graded and dissimilar joints. Comput. Mater. Sci. 2018, 143, 325–337. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Konovalov, S.V. Additive Manufacturing Based on Welding Arc: A low-Cost Method. J. Surf. Invest. 2017, 11, 1317–1328. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc Welding Processes for Additive Manufacturing: A Review. Transactions on Intelligent Welding Manufacturing; Springer: Singapore, 2018; pp. 3–24. ISBN 978-981-10-5354-2. [Google Scholar]

- Dilthey, U.; Berger, C.; Million, K.; Datta, R.; Zimmermann, H.; Stein, L. Future prospects of shape welding. Weld. Cutting 2006, 3, 164–172. [Google Scholar]

- Piehl, K.H. Formgebendes Schweissen von Schwerkomponenten. Thyssen, Technische Berichte 1989, 21, 53–71. [Google Scholar]

- Chen, X.; Su, C.; Wang, Y.; Siddiquee, A.N.; Sergey, K.; Jayalakshmi, S.; Singh, R.A. Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System. J. Surf. Invest. 2018, 12, 1278–1284, ISSN 1027-4510. [Google Scholar] [CrossRef]

- Ding, D.; Shen, C.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N.; van Duin, S. Towards an automated robotic arc-welding-based additive manufacturing system from CAD to finished part. Comput.-Aided Des. 2016, 73, 66–75. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kovacevic, R. Automated torch path planning using polygon subdivision for solid freeform fabrication based on welding. J. Manuf. Syst. 2004, 23, 278–291. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Almeida, P.S.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Norsk Titanium—Companywebsite. Available online: http://www.norsktitanium.com/ (accessed on 2 July 2019).

- Appleyard, D. Welding Pelton Runners. Available online: https://www.hydroworld.com/articles/print/volume-20/issue-4/articles/turbines-mechanical-components/welding-pelton-runners.html (accessed on 2 July 2019).

- Fischer, G. Additives Fertigungsverfahren mit Draht als Basismaterial. Available online: https://www.springerprofessional.de/additives-fertigungsverfahren-mit-draht-als-basismaterial/15282886 (accessed on 2 July 2019).

- Wegener, V. Ramlab—Unternehmenswebsite. Available online: https://ramlab.com/ (accessed on 2 July 2019).

- Jackson, B. Huisman’s 3D printed WAAM hook lifts 80,000 kg load. Available online: https://3dprintingindustry.com/news/huismans-3d-printed-waam-hook-lifts-80000-kg-load-127564/ (accessed on 2 July 2019).

- Ali, Y.; Steinerstauch, D.; Günther, K.; Henckell, P.; Bergmann, J.P. Additive Fertigung von 3D-Verbundstrukturen mittels MSG-Schweißen. DVS Ber. 2016, 327, 75–80. [Google Scholar]

- Ding, D.; Pan, Z.; van Duin, S.; Li, H.; Shen, C. Fabricating Superior NiAl Bronze Components through Wire Arc Additive Manufacturing. Materials 2016, 9, 652. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Ding, D.; Li, H. Influences of deposition current and interpass temperature to the Fe3Al-based iron aluminide fabricated using wire-arc additive manufacturing process. Int. J. Adv. Manuf. Technol. 2017, 88, 2009–2018. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Dong, B.; Li, H. In-depth study of the mechanical properties for Fe 3 Al based iron aluminide fabricated using the wire-arc additive manufacturing process. Mater. Sci. Eng. A 2016, 669, 118–126. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Hoye, N.; Li, H.; Pan, Z. Characterization of In situ Alloyed and Additively Manufactured Titanium Aluminides. Metall. Mater. Trans. B 2014, 45, 2299–2303. [Google Scholar] [CrossRef]

- Henckell, P.; Ali, Y.; Metz, A.; Bergmann, J.P.; Reimann, J. In Situ Production of Titanium Aluminides during Wire Arc Additive Manufacturing with Hot-Wire Assisted GMAW Process. Metals 2019, 9, 578. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Roberts, J.; Li, H. Fabrication of Fe-FeAl Functionally Graded Material Using the Wire-Arc Additive Manufacturing Process. Metall. Mater. Trans. B 2016, 47, 763–772. [Google Scholar] [CrossRef]

- Brentrup, G.J.; DuPont, J.N. Fabrication and characterization of graded transition joints for welding dissimilar alloys. Weld. J. 2013, 92, 72–79. [Google Scholar]

- Rodriguez, J.; Hoefer, K.; Haelsig, A.; Mayr, P. Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals 2019, 9, 620. [Google Scholar] [CrossRef]

- Reisgen, U.; Sharma, R.; Oster, L.; Zanders, E. Plasma-Mehrdraht-Schweißen zum Herstellen gradierter Strukturen. In Proceedings of the DVS CONGRESS, Friedrichshafen, Germany, 16–17 September 2018; pp. 109–114. (In German). [Google Scholar]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Feldmann, M.; Kühne, R.; Citarelli, S.; Reisgen, U.; Sharma, R.; Oster, L. 3D-Drucken im Stahlbau mit dem automatisierten Wire Arc Additive Manufacturing. Stahlbau 2019, 88, 203–213. [Google Scholar] [CrossRef]

- Van Bolderen, G. Exploration of Stability of 3D-Printed Steel Members: A study to buckling behaviour of wire and arc additively manufactured stainless steel tubular columns. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, December 2017. [Google Scholar]

- Reisgen, U.; Stein, L. Fundamentals of Joining Technology—Welding, Brazing and Adhesive Bonding; DVS Media: Düsseldorf, Germany, 2016; (English edition). [Google Scholar]

- Kitano, H.; Nakamura, T. Distortion reduction of parts made by wire and arc additive manufacturing technique using low transformation temperature welding materials. Q.J. Jpn. Weld. Soc. 2018, 36, 31–38. [Google Scholar] [CrossRef]

- Reisgen, U.; Olschok, S.; Gach, S. Nutzung von Low-Transformation-Temperature-Werkstoffen (LTT) zur Eigenspannungsreduzierung im Elektronenstrahlschweißprozess. Materialwiss. Werkstofftech. 2016, 47, 589–599. [Google Scholar] [CrossRef]

| Material | C | Mn | Si | S | P | Ni | Cr | Nb | Mo |

|---|---|---|---|---|---|---|---|---|---|

| G 3Si1 | 0.088 | 1.348 | 0.936 | 0.023 | 0.011 | 0.018 | 0.024 | - | - |

| G 19 9 L Si | 0.015 | 1.610 | 0.756 | <0.010 | 0.024 | 9.680 | 19.610 | - | 0.171 |

| G 18 L Nb | 0.023 | 0.461 | 0.414 | 0.003 | 0.029 | 0.165 | 18.740 | 0.675 | 0.040 |

| G Mn4Ni2CrMo | 0.246 | 1.467 | 0.953 | 0.017 | 0.021 | 2.069 | 0.417 | 0.011 | 0.576 |

| Material Combination | Material A | Material B | Use Case |

|---|---|---|---|

| Combination 1 | G 3Si1 | G 19 9 L Si | General process behavior |

| Combination 2 | G 18 L Nb | G 19 9 L Si | α-γ-transition elements |

| Combination 3 | G 3Si1 | G Mn4Ni2CrMo | Local high-strength zones |

| Welding Parameter | Combination 1 | Combination 2 | Combination 3 |

|---|---|---|---|

| Welding current | 110–165 A | 135–170 A | 155–175 A |

| Welding speed | 20 cm /min | 30 cm/min | 20 cm/min |

| Maximum wire feed speed | 3.5 m/min | 3.5 m/min | 3 m/min |

| Plasma gas (EN ISO 14175) | Ar + 5% H2 (R1) | Ar + 5% H2 (R1) | Ar (I1) |

| Shielding gas (EN ISO 14175) | Ar (I1) | Ar + 2.5% CO2 (M12) | Ar + 2.5% CO2 (M12) |

| Interlayer temperature | 50 °C | 40 °C | 75 °C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reisgen, U.; Sharma, R.; Oster, L. Plasma Multiwire Technology with Alternating Wire Feed for Tailor-Made Material Properties in Wire and Arc Additive Manufacturing. Metals 2019, 9, 745. https://doi.org/10.3390/met9070745

Reisgen U, Sharma R, Oster L. Plasma Multiwire Technology with Alternating Wire Feed for Tailor-Made Material Properties in Wire and Arc Additive Manufacturing. Metals. 2019; 9(7):745. https://doi.org/10.3390/met9070745

Chicago/Turabian StyleReisgen, Uwe, Rahul Sharma, and Lukas Oster. 2019. "Plasma Multiwire Technology with Alternating Wire Feed for Tailor-Made Material Properties in Wire and Arc Additive Manufacturing" Metals 9, no. 7: 745. https://doi.org/10.3390/met9070745

APA StyleReisgen, U., Sharma, R., & Oster, L. (2019). Plasma Multiwire Technology with Alternating Wire Feed for Tailor-Made Material Properties in Wire and Arc Additive Manufacturing. Metals, 9(7), 745. https://doi.org/10.3390/met9070745