Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

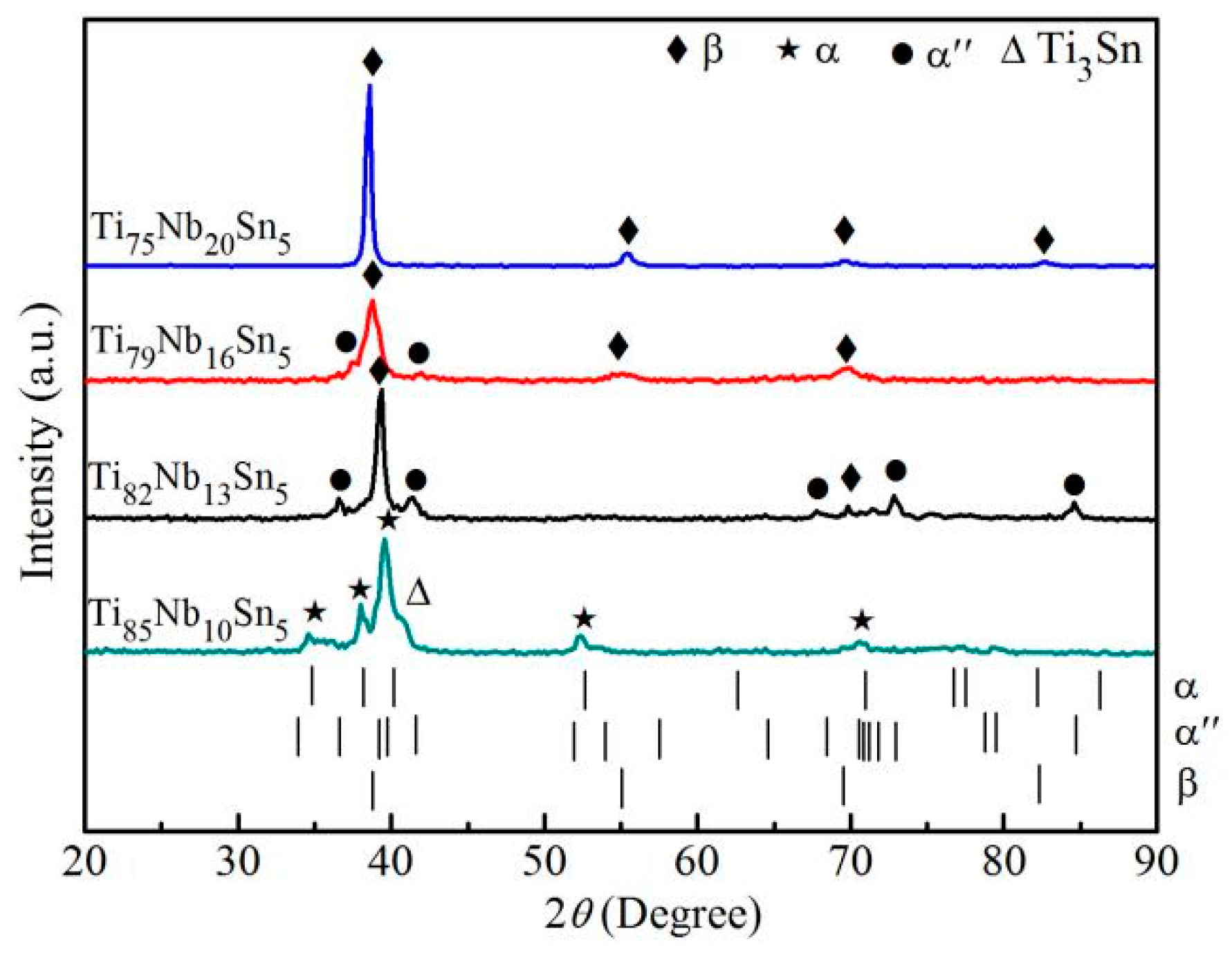

3.1. Phase and Microstructure of Ti–Nb–Sn Alloys

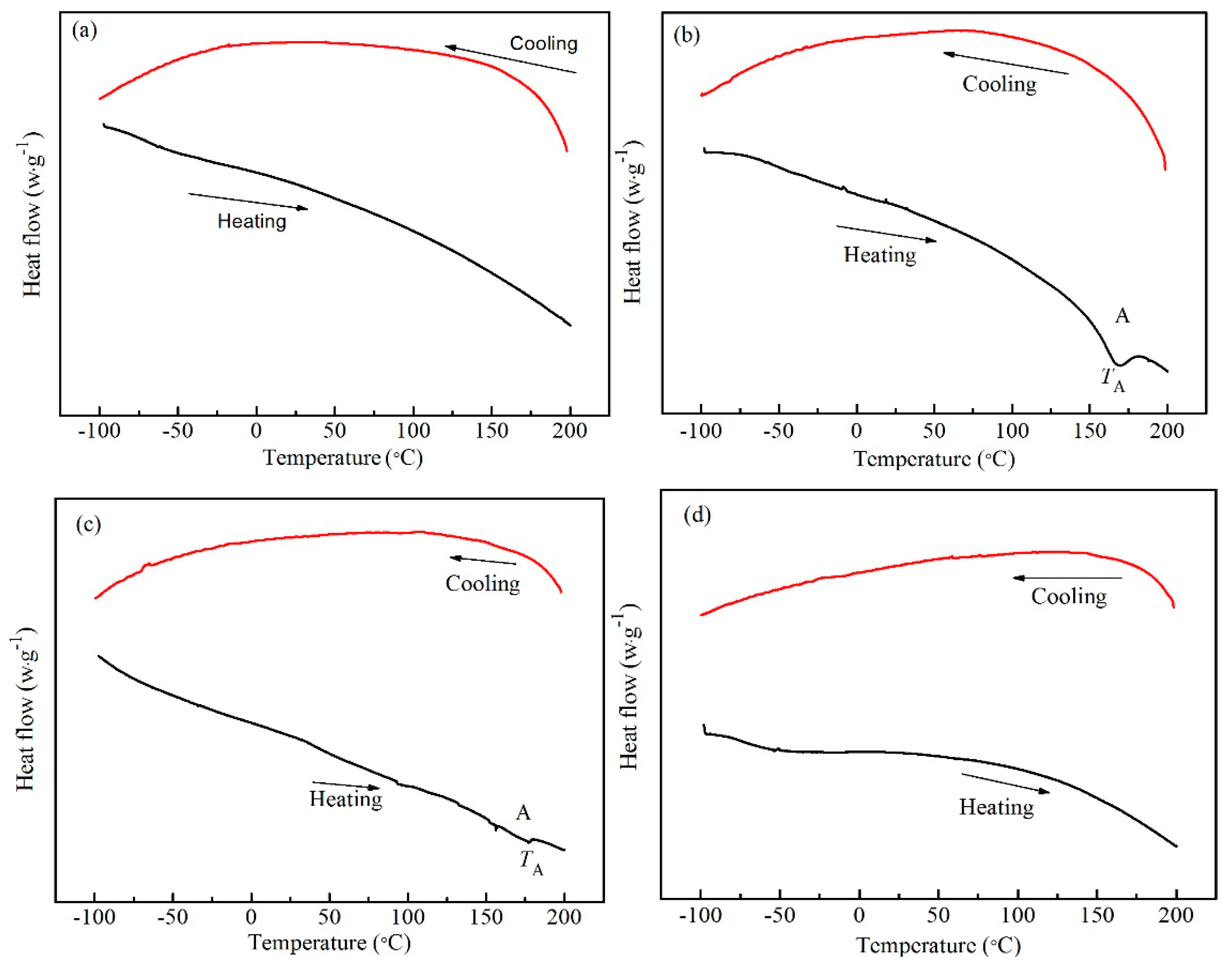

3.2. Phase Transition Temperature of Ti–Nb–Sn Alloys

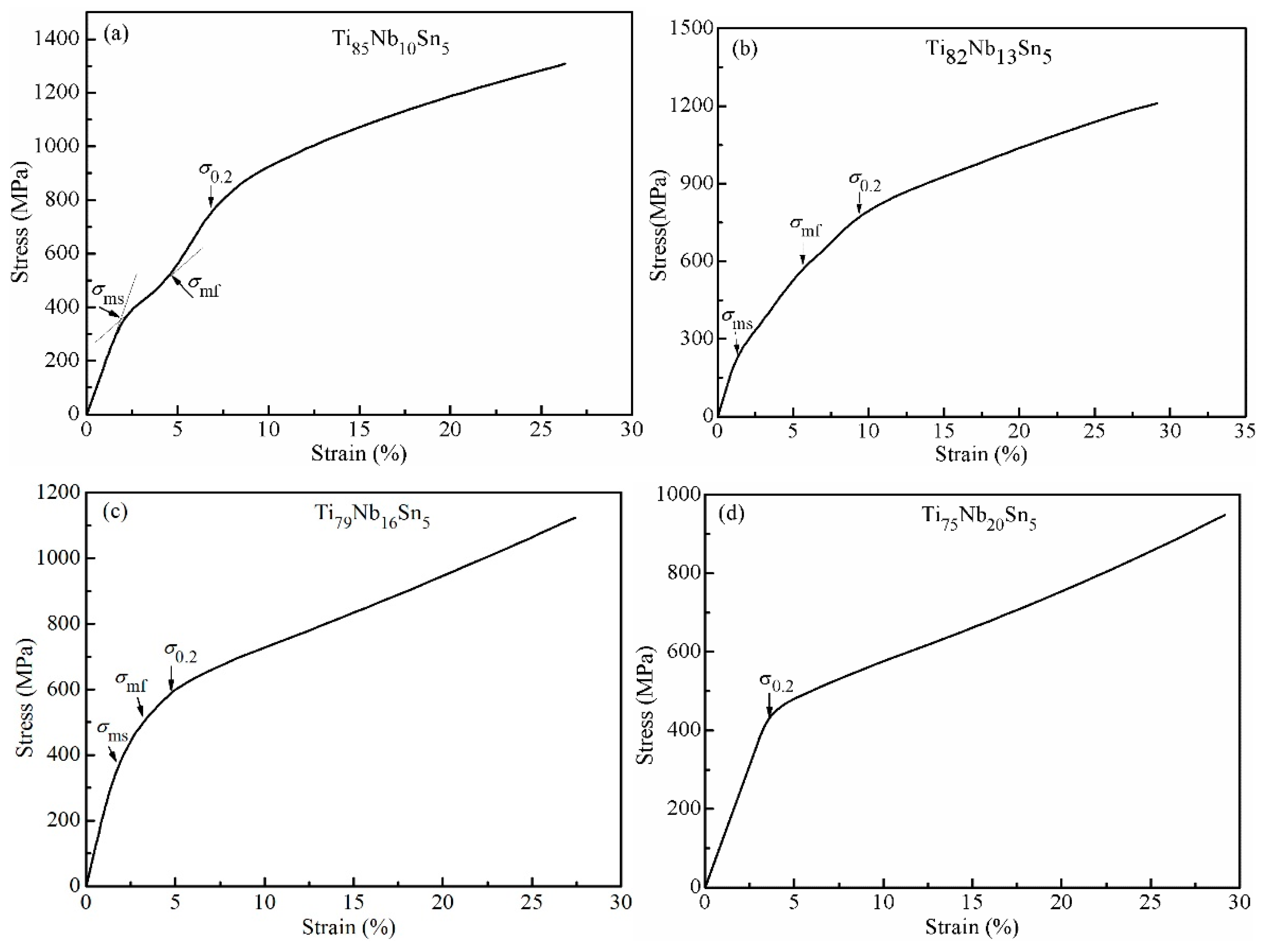

3.3. Mechanical Properties of Ti–Nb–Sn Alloys

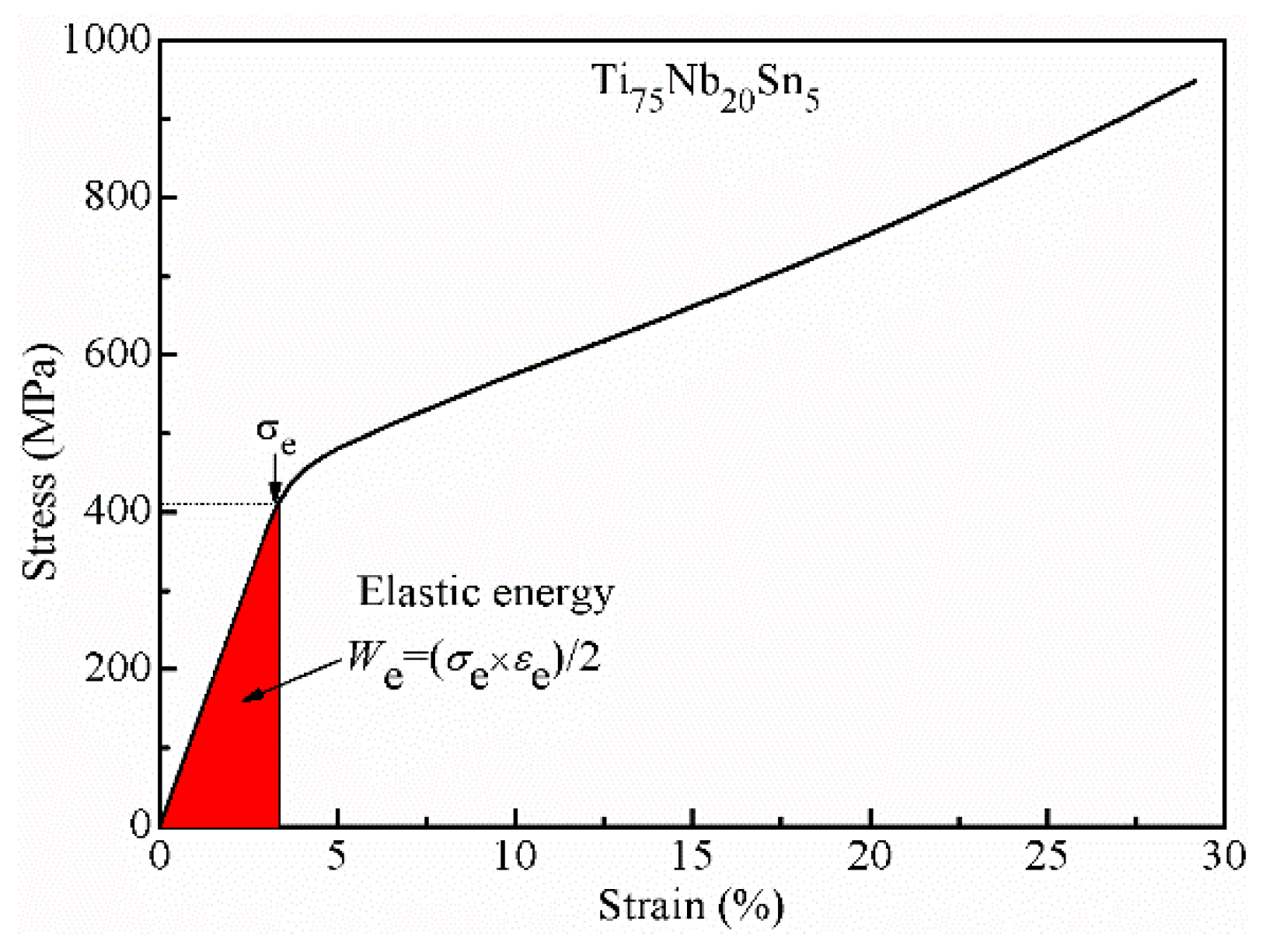

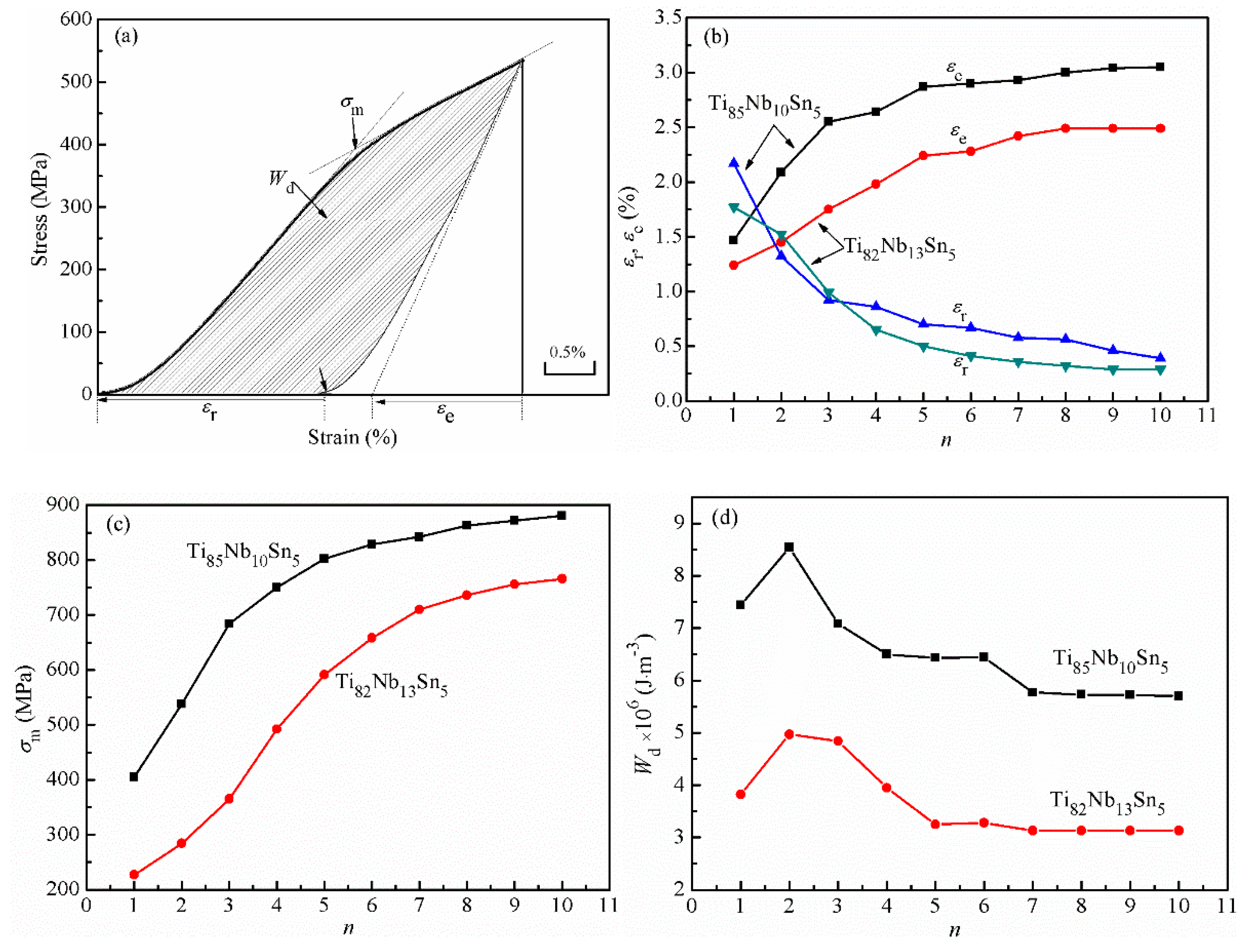

3.4. Elastic Energy of Ti–Nb–Sn Alloys

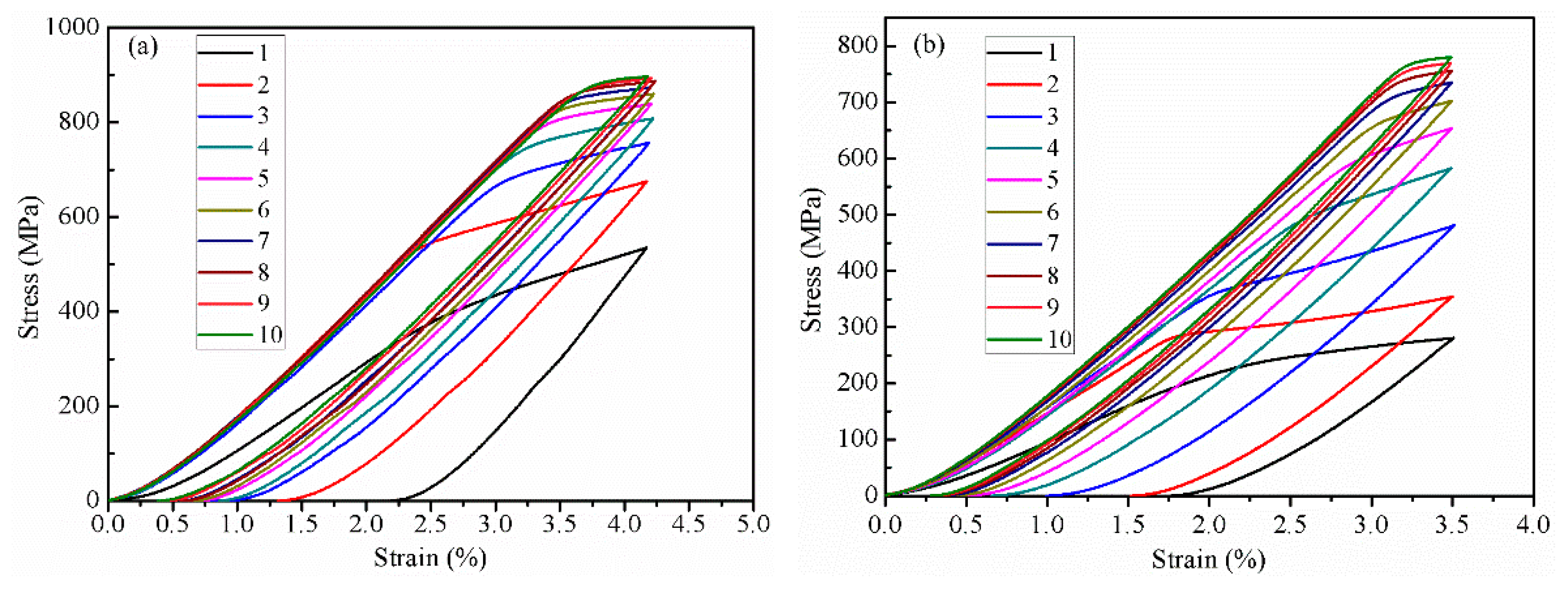

3.5. Cyclic Loading Stress-Strain Curves of Ti–Nb–Sn Alloys

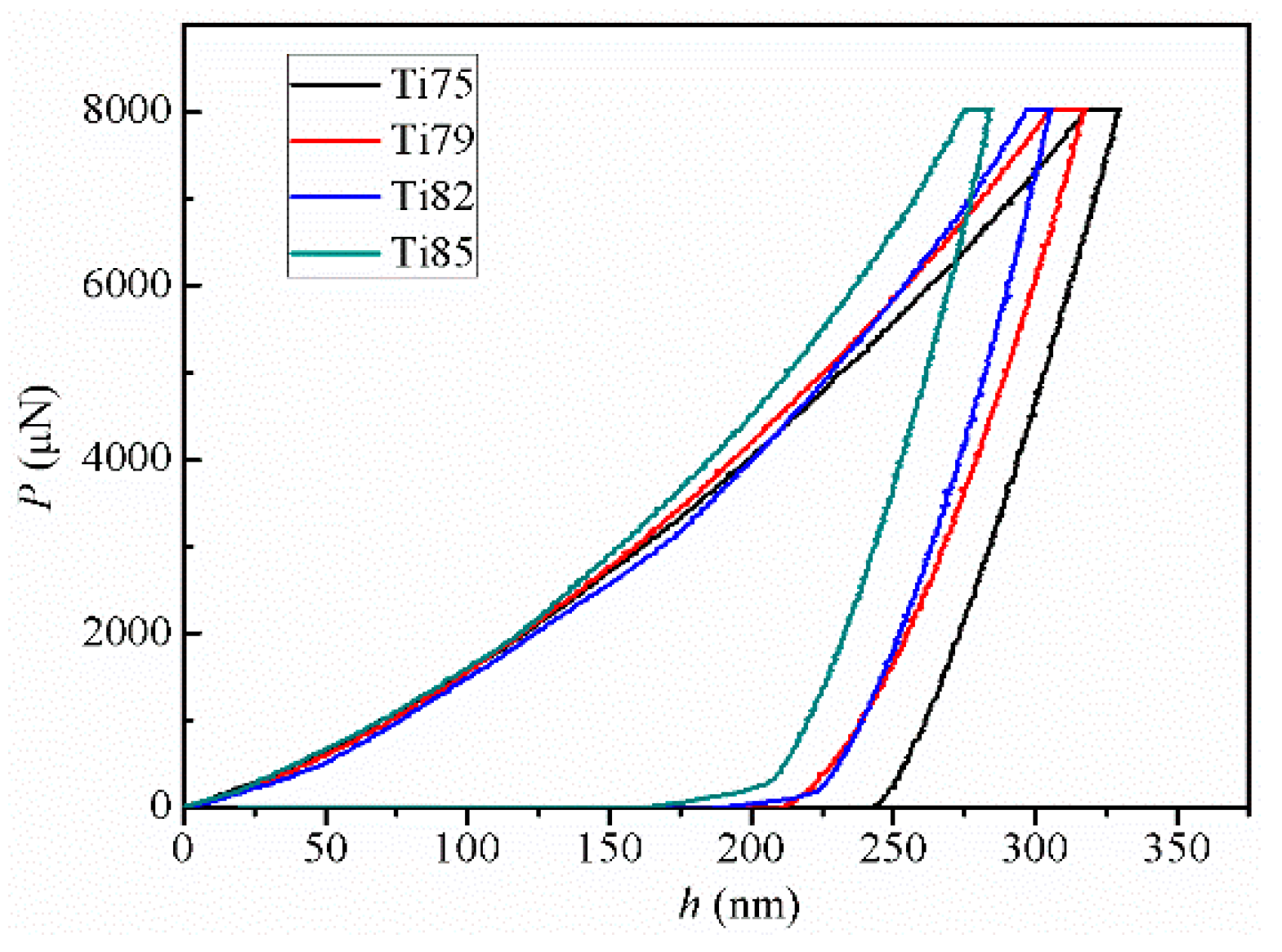

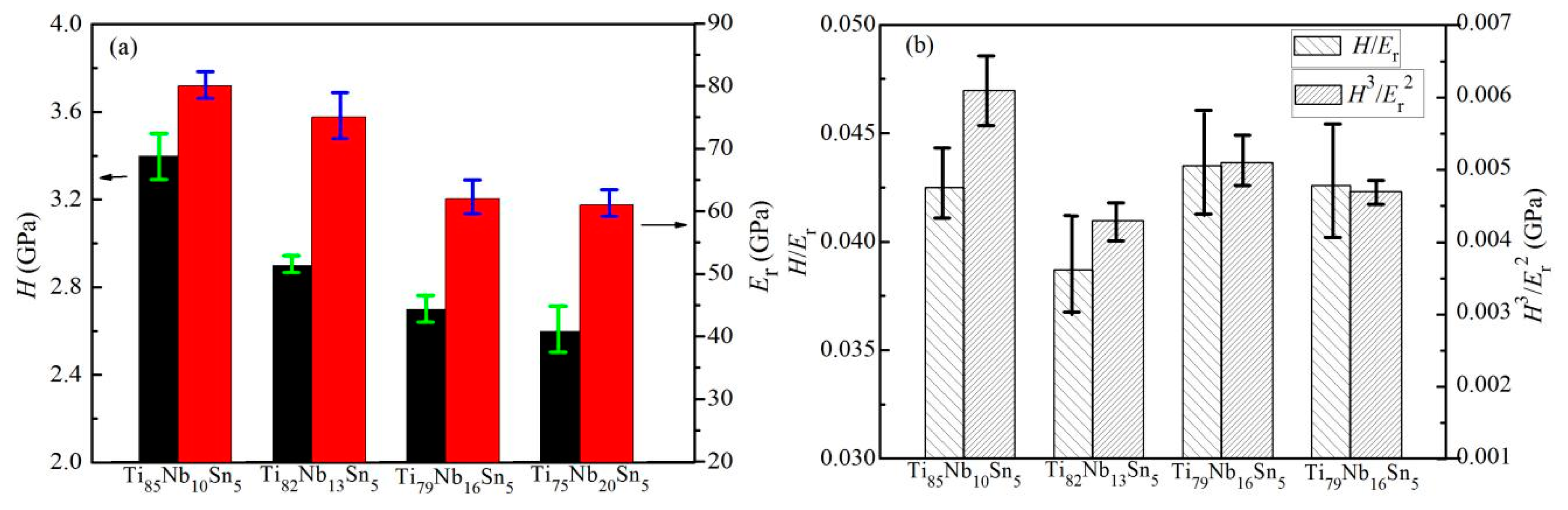

3.6. Nanoindentation of Ti–Nb–Sn Alloys

4. Conclusions

- (1)

- The Ti85Nb10Sn5 and Ti75Nb20Sn5 alloys are composed of simpleαand β phase, respectively; the Ti82Nb13Sn5 and Ti79Nb16Sn5 alloys are composed of β and α″ phases. The content of martensite phase decreases with the increase of Nb content.

- (2)

- The Ti82Nb13Sn5 and Ti79Nb16Sn5 alloys show inverse martensitic phase transition during heating. No martensite phase transition is found during cooling from 150 °C to –100 °C. The Ti–Nb–Sn alloys with no martensitic transformation in the temperature range that human body can bear can be considered as the good biomedical alloy for implantation.

- (3)

- The final residual strain values that tend to be stable for the Ti85Nb10Sn5 and Ti82Nb13Sn5 alloys are 0.39% and 0.29%, respectively, indicating the good superelastic properties of the alloys in 10-times cyclic loading.

- (4)

- The reduced elastic modulus of Ti75Nb20Sn5 alloy is 61 GPa, which is 2–6 times of that of human bone (10–30 GPa), and is smaller than that of commercial Ti-6Al-4V biomedical alloy (120 GPa). The Ti75Nb20Sn5 alloy can be considered as a novel biomedical alloy. The H/Er and H3/Er2 values of the four alloys are higher than those of the CP-Ti alloy (0.0238), which indicates that the presented alloys have good wear resistance and anti-wear capability.

Author Contributions

Conflicts of Interest

References

- Liu, Y.J.; Li, X.P.; Zhang, L.C.; Sercombe, T.B. Processing and properties of topologically optimised biomedical Ti-24Nb-4Zr-8Sn scaffolds manufactured by selective laser melting. Mater. Sci. Eng. A 2015, 642, 268–278. [Google Scholar] [CrossRef]

- Ninomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33A, 477–486. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.J.; Zhang, B.C.; Liao, H.L.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Chaves, J.M.; Florêncio, O.; Silva, P.S.; Marques, P.W.B.; Afonso, C.R.M. Influence of phase transformations on dynamical elastic modulus and anelasticity of beta Ti–Nb–Fe alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2015, 46, 184–196. [Google Scholar] [CrossRef]

- Niinomi, M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci. Technol. Adv. Mater. 2003, 4, 445–454. [Google Scholar] [CrossRef]

- Hon, Y.H.; Wang, J.Y.; Pan, Y.N. Composition/phase structure and properties of Titanium-Niobium alloys. Mater. Trans. 2003, 44, 2384–2390. [Google Scholar] [CrossRef]

- Li, P.Y. Microstructural and mechanical properties of novel β-type Ti–Nb–Ni alloys containing a second phase. Int. J. Mater. Res. 2018, 109, 708–715. [Google Scholar] [CrossRef]

- Ozaki, T.; Matsumoto, H.; Watanabe, S.; Hanada, S. Beta Ti alloys with low Young’s modulus. Mater. Trans. 2004, 45, 2776–2779. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanable, S.; Hanada, S. Beta TiNbSn alloys with low Young’s modulus and high strength. Mater. Trans. 2005, 46, 1070–1078. [Google Scholar] [CrossRef]

- Moraes, P.E.L.; Contieri, R.J.; Lopes, E.S.N.; Robin, A.; Caram, R. Effects of Sn addition on the microstructure, mechanical properties and corrosion behavior of Ti–Nb–Sn alloys. Mater. Charact. 2014, 96, 273–281. [Google Scholar] [CrossRef]

- Attar, H.; Haghighi, S.E.; Kent, D.; Wu, X.H.; Dargusch, M.S. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng. A 2017, 705, 385–393. [Google Scholar] [CrossRef]

- Ho, W.F.; Wu, S.C.; Hsu, S.K.; Li, Y.C.; Hsu, H.C. Effects of molybdenum content on the structure and mechanical properties of as-cast Ti–10Zr-based alloys for biomedical applications. Mater. Sci. Eng. C 2012, 32, 517–522. [Google Scholar] [CrossRef]

- Ho, W.F.; Pan, C.H.; Wu, S.C.; Hsu, H.C. Mechanical properties and deformation behavior of Ti–5Cr–xFe alloys. J. Alloys Compd. 2009, 472, 546–550. [Google Scholar] [CrossRef]

- Silva, H.; Schneider, S.; Neto, C.M. Study of nontoxic aluminum and vanadium-free titanium alloys for biomedical applications. Mater. Sci. Eng. C 2004, 24, 679–682. [Google Scholar] [CrossRef]

- Hsu, H.C.; Hsu, S.K.; Wu, S.C.; Lee, C.J.; Ho, W.F. Structure and mechanical properties of as-cast Ti–5Nb–xFe alloys. Mater. Charact. 2010, 61, 851–858. [Google Scholar] [CrossRef]

- Chang, L.L.; Wang, Y.D.; Ren, Y. In-situ investigation of stress-induced martensitic transformation in Ti–Nb binary alloys with low Young’s modulus. Mater. Sci. Eng. A 2016, 651, 442–448. [Google Scholar] [CrossRef]

- Haghighi, S.E.; Liu, Y.J.; Cao, G.H.; Zhang, L.C. Phase transition, microstructural evolution and mechanical properties of Ti–Nb–Fe alloys induced by Fe addition. Mater. Des. 2016, 97, 279–286. [Google Scholar] [CrossRef]

- Haghighi, S.E.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evalution of mechanical and wear properties of Ti–xNb–7Fe alloys disinged for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Wen, M.; Wen, C.; Hodgson, P.; Li, Y. Fabrication of Ti–Nb–Ag alloy via powder metallurgy for biomedical applications. Mater. Des. 2014, 56, 629–634. [Google Scholar] [CrossRef]

- Xu, W.; Kim, K.B.; Das, J.; Calin, M.; Eckert, J. Phase stability and its effffect on the deformation behavior of Ti–Nb–Ta–In/Cr b alloys. Scr. Mater. 2006, 54, 1943–1948. [Google Scholar] [CrossRef]

- Haghighi, S.E.; Liu, Y.J.; Cao, G.H.; Zhang, L.C. Influence of Nb on the β→α″ martensitic phase transformation and properties of the newly designed Ti–Fe–Nb alloys. Mater. Sci. Eng. C 2017, 60, 503–510. [Google Scholar] [CrossRef]

- Li, P.Y.; Zhang, H.; Tong, T.; He, Z.R. The rapidly solidified β-type Ti–Fe–Sn alloys with high specific strength and low elastic modulus. J. Alloys Compd. 2019, 786, 986–994. [Google Scholar] [CrossRef]

- Nnamchi, P.S.; Obayi, C.S.; Todd, I.; Rainforth, M.W. Mechanical and electrochemical characterisation of new Ti–Mo–Nb–Zr alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2016, 60, 68–77. [Google Scholar] [CrossRef]

- Ruzic, J.; Emura, X.; Ji, X.; Watanabe, I. Mo segregation and distribution in Ti–Mo alloy investigated using nanoindentation. Mater. Sci. Eng. A 2018, 718, 48–55. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Lin, J.X.; Li, Y.C.; Ping, D.H.; Yamabe-Mitarai, Y.; Wen, C. Investigations into Ti–(Nb, Ta)–Fe alloys for biomedical application. Acta Biomater. 2016, 32, 336–347. [Google Scholar] [CrossRef]

- Pavón, L.L.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Effect of Nb content and heat treatment temperature on superelastic properties of Ti–24Zr–(8–12)Nb–2Sn alloys. Scripta Mater. 2015, 95, 46–49. [Google Scholar] [CrossRef]

- Qu, W.T.; Sun, X.G.; Yuan, B.F.; Xiong, C.Y.; Zhang, F.; Li, Y.; Sun, B.H. Microstructures and phase transformations of Ti–30Zr–xNb (x = 5, 7, 9, 13 at.%) shape memory alloys. Mater. Charact. 2016, 122, 1–5. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ikehara, Y.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater. 2006, 54, 2419–2429. [Google Scholar] [CrossRef]

- Zhang, D.C.; Lin, J.G.; Jiang, W.J.; Ma, M.; Peng, Z.G. Shape memory and superelastic behavior of Ti-7.5Nb-4Mo-1Sn alloy. Mater. Des. 2011, 32, 4614–4617. [Google Scholar] [CrossRef]

- Horiuchi, Y.; Nakayama, K.; Inamura, T.; Kim, H.Y.; Wakashima, K.; Miyazaki, S.; Hosoda, H. Effect of Cu addition on shape memory behavior of Ti-18 mol%Nb alloys. Mater. Trans. 2007, 48, 414–421. [Google Scholar] [CrossRef]

- Wang, B.L.; Zheng, Y.F.; Zhao, L.C. Effects of Sn content on the microstructure, phase constitution and shape memory effect of Ti–Nb–Sn alloys. Mater. Sci. Eng. A 2008, 486, 146–151. [Google Scholar] [CrossRef]

- Kim, J.I.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Shape memory characteristics of Ti–22Nb–(2–8)Zr (at.%) biomedical alloys. Mater. Sci. Eng. A 2005, 403, 334–339. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gülsoy, H.O. Characterization of biomedical Ti-16Nb-(0-4) Sn alloys produced by powder injection molding. Vacuum 2017, 142, 164–174. [Google Scholar]

- Guo, S.; Shang, Y.; Zhang, J.S.; Meng, Q.K.; Cheng, X.N.; Zhao, X.Q. In situ synchrotron X-ray diffraction study of deformation behaviour of a metastable β-type Ti-33Nb-4Sn alloy. Mater. Sci. Eng. A 2017, 692, 81–89. [Google Scholar] [CrossRef]

- Hanada, S.; Masahashi, N.; Jung, T.K.; Yamada, N.; Yamako, G.; Itoi, E. Fabrication of a high-performance hip prosthetic stem using β Ti-33.6Nb-4Sn. J. Mech. Behav. Biomed. Mater. 2014, 30, 140–149. [Google Scholar] [CrossRef]

- Miura, K.K.; Yamada, N.; Hanada, S.J.; Jung, T.K.; Itoi, E. The bone tissue compatibolity of a new Ti-Nb-Sn alloy with low Young’s modulus. Acta. Biomater. 2011, 7, 2320–2326. [Google Scholar] [CrossRef]

- Li, P.Y. Microstructure and mechanical properties of novel β-type Ti–Co–Zr alloys with high specific strength. Mater. Res. Express 2019, 6, 076559. [Google Scholar] [CrossRef]

- Yang, H.; Wen, J.; Quan, M.; Wang, J. Evaluation of the volume fraction of nanocrystals devitrified in Al-based amorphous alloys. J. Non-Cryst. Solids 2009, 355, 235–238. [Google Scholar] [CrossRef]

- Kolli, R.P.; Joost, W.J.; Ankem, S. Phase stability and stress-induced transformation in beta Titanium alloys. JOM 2015, 67, 1273–1280. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, C.; Liaw, P.K. Structural stabilities of β-Ti alloys studied using a new Mo equivalent derived from [β/(α+β)] phase-boundary slopes. Metall. Mater. Trans. A 2015, 46, 3440–3447. [Google Scholar] [CrossRef]

- Cui, B.; Yao, J.; Wu, Y.; Zhang, X.; Wang, F.L.; Sui, J.H.; Cai, W. Precipitation behavior and mechanical properties of Ti–Ni–Nb–Co alloys. Intermetallics 2018, 95, 40–47. [Google Scholar] [CrossRef]

- Hussein, A.H.; Gepreel, M.A.H.; Gouda, M.K.; Hefnawy, A.M.; Kandil, S.H. Biocompatibility of new Ti–Nb–Ta base alloys. Mater. Sci. Eng. C 2016, 61, 574–578. [Google Scholar] [CrossRef]

- Fischer, F.D.; Reisner, G.; Werner, E.; Tanaka, K.; Cailletaud, G.; Antretter, T. A new view on transformation induced plasticity (TRIP). Int. J. Plast. 2000, 16, 723–748. [Google Scholar] [CrossRef]

- He, Z.R.; Wang, Q.; Wang, F.; Wang, Y.S.; Yang, J. Effect of annealing temperatures on microstructure and tensile properties of Ti–Ni–Cr low-temperature superelasticity alloy. Rare Met. Mater. Eng. 2011, 40, 1998–2001. [Google Scholar]

- Haghighi, S.E.; Cao, G.H.; Zhang, L.C. Nanoindentation study of mechanical properities of Ti based alloys with Fe and Ta additions. J. Alloys Compds. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Xu, J.; Wang, G.D.; Lu, X.; Liu, L.; Munroe, P.; Xie, Z.H. Mechanical and corrosion-resistant properties of Ti–Nb–Si–N nanocomposite films prepared by a double glow discharge plasma technique. Ceram. Int. 2014, 40, 8621–8630. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

| Alloys | σms (MPa) | σmf (MPa) | εmf (%) | σ0.2 (MPa) | ε0.2 (%) | HV | We × 106 (J⋅m−3) | Vα″ (%) | Vβ (%) | Moeq | TA (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti85Nb10Sn5 | 352 | 509 | 4.48 | 787 | 6.84 | 230 | -- | -- | -- | 7.83 | -- |

| Ti82Nb13Sn5 | 256 | 574 | 5.56 | 772 | 9.46 | 226 | -- | 26.5 | 73.5 | 9.02 | 169 |

| Ti79Nb16Sn5 | 370 | 508 | 3.21 | 611 | 5.30 | 220 | 1.65 | 7.1 | 92.9 | 10.14 | 177 |

| Ti75Nb20Sn5 | -- | -- | -- | 435 | 3.71 | 218 | 6.53 | 0.0 | 100 | 11.56 | -- |

| Alloys | Parameters | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti85Nb10Sn5 | Wd × 106 (J⋅m−3) | 7.44 | 8.54 | 7.08 | 6.5 | 6.43 | 6.44 | 5.77 | 5.73 | 5.72 | 5.70 |

| εr (%) | 2.17 | 1.32 | 0.92 | 0.86 | 0.70 | 0.67 | 0.58 | 0.56 | 0.46 | 0.39 | |

| εe (%) | 1.47 | 2.09 | 2.55 | 2.64 | 2.87 | 2.90 | 2.93 | 3.00 | 3.04 | 3.05 | |

| σm (MPa) | 405 | 538 | 684 | 750 | 802 | 829 | 842 | 863 | 872 | 881 | |

| Ti82Nb13Sn5 | Wd × 106 (J⋅m−3) | 3.82 | 4.97 | 4.84 | 3.95 | 3.25 | 3.28 | 3.13 | 3.13 | 3.13 | 3.13 |

| εr (%) | 1.77 | 1.52 | 0.99 | 0.65 | 0.5 | 0.41 | 0.36 | 0.32 | 0.29 | 0.29 | |

| εe (%) | 1.24 | 1.45 | 1.75 | 1.98 | 2.24 | 2.28 | 2.42 | 2.49 | 2.49 | 2.49 | |

| σm (MPa) | 227 | 284 | 365 | 492 | 591 | 658 | 710 | 736 | 756 | 766 |

| Alloys | Er (GPa) | H (GPa) | H/Er | H3/Er2 (GPa) |

|---|---|---|---|---|

| Ti85Nb10Sn5 | 80 | 3.4 | 0.0425 | 0.0061 |

| Ti82Nb13Sn5 | 75 | 2.9 | 0.0387 | 0.0043 |

| Ti79Nb16Sn5 | 62 | 2.7 | 0.0435 | 0.0051 |

| Ti75Nb20Sn5 | 61 | 2.6 | 0.0426 | 0.0047 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Ma, X.; Wang, D.; Zhang, H. Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus. Metals 2019, 9, 712. https://doi.org/10.3390/met9060712

Li P, Ma X, Wang D, Zhang H. Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus. Metals. 2019; 9(6):712. https://doi.org/10.3390/met9060712

Chicago/Turabian StyleLi, Peiyou, Xindi Ma, Duo Wang, and Hui Zhang. 2019. "Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus" Metals 9, no. 6: 712. https://doi.org/10.3390/met9060712

APA StyleLi, P., Ma, X., Wang, D., & Zhang, H. (2019). Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus. Metals, 9(6), 712. https://doi.org/10.3390/met9060712