The Comparison of Cracking Susceptibility of IN52M and IN52MSS Overlay Welds

Abstract

1. Introduction

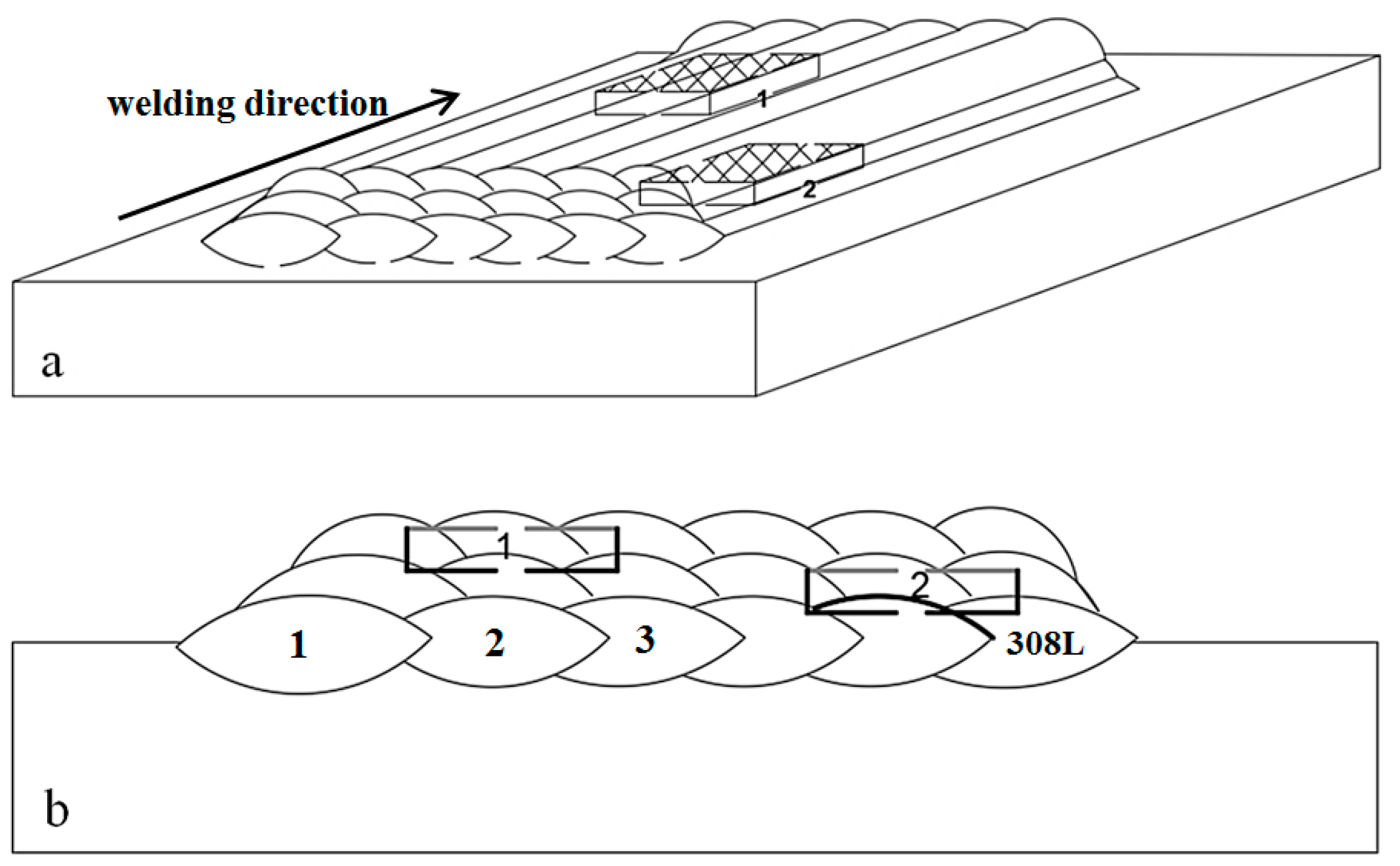

2. Materials and Experimental Procedures

3. Results and Discussion

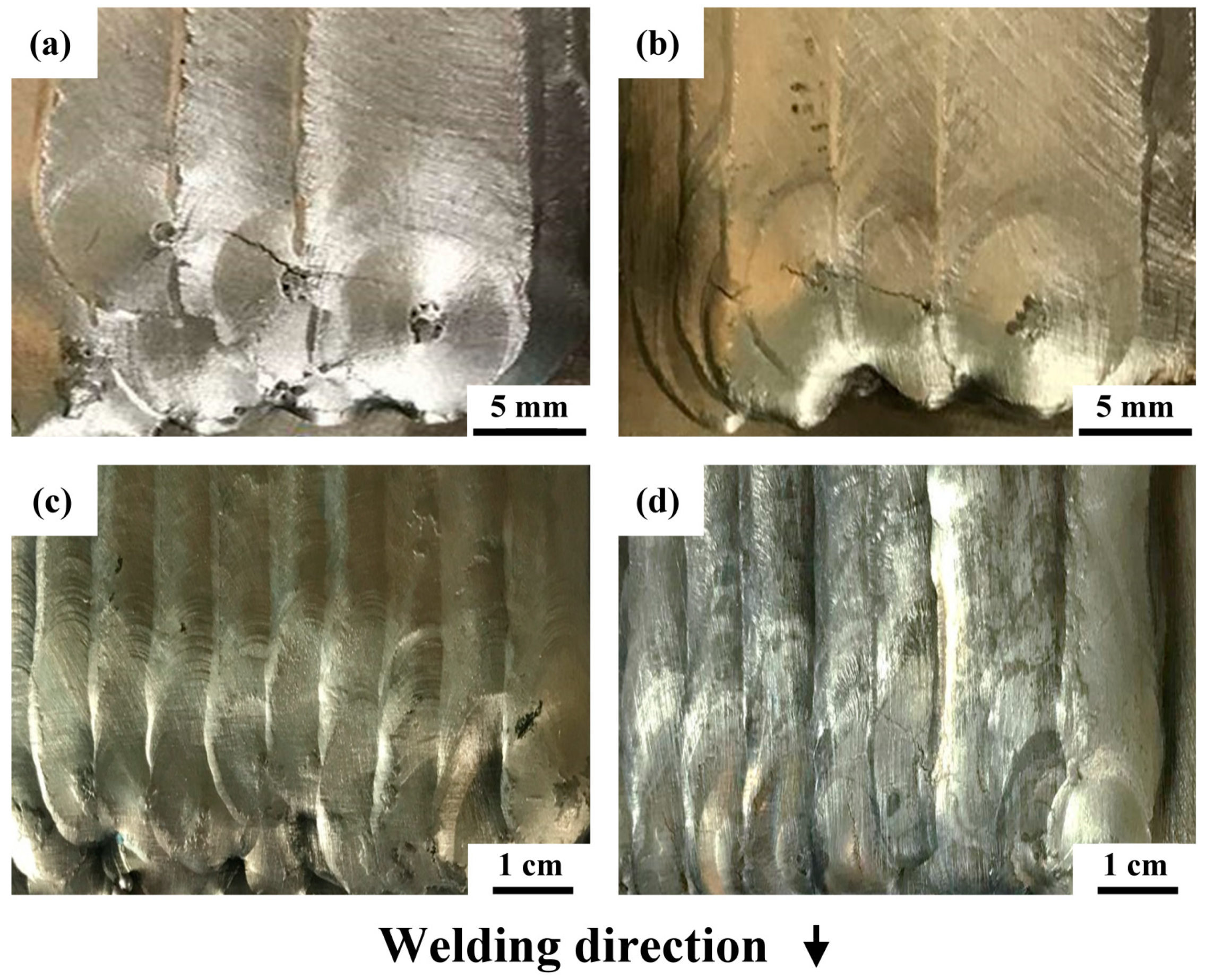

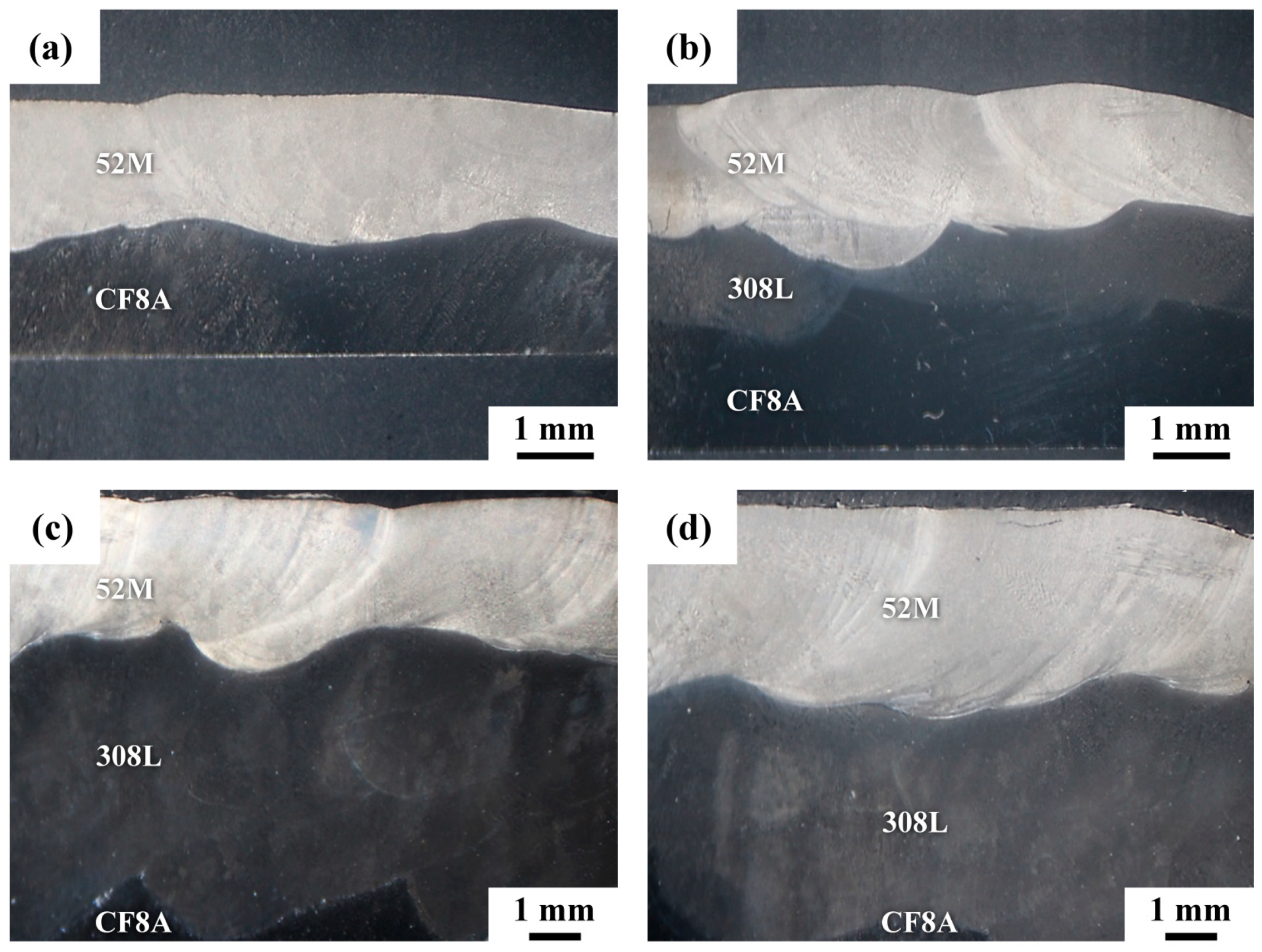

3.1. Macro-Appearance of Overlay Welds

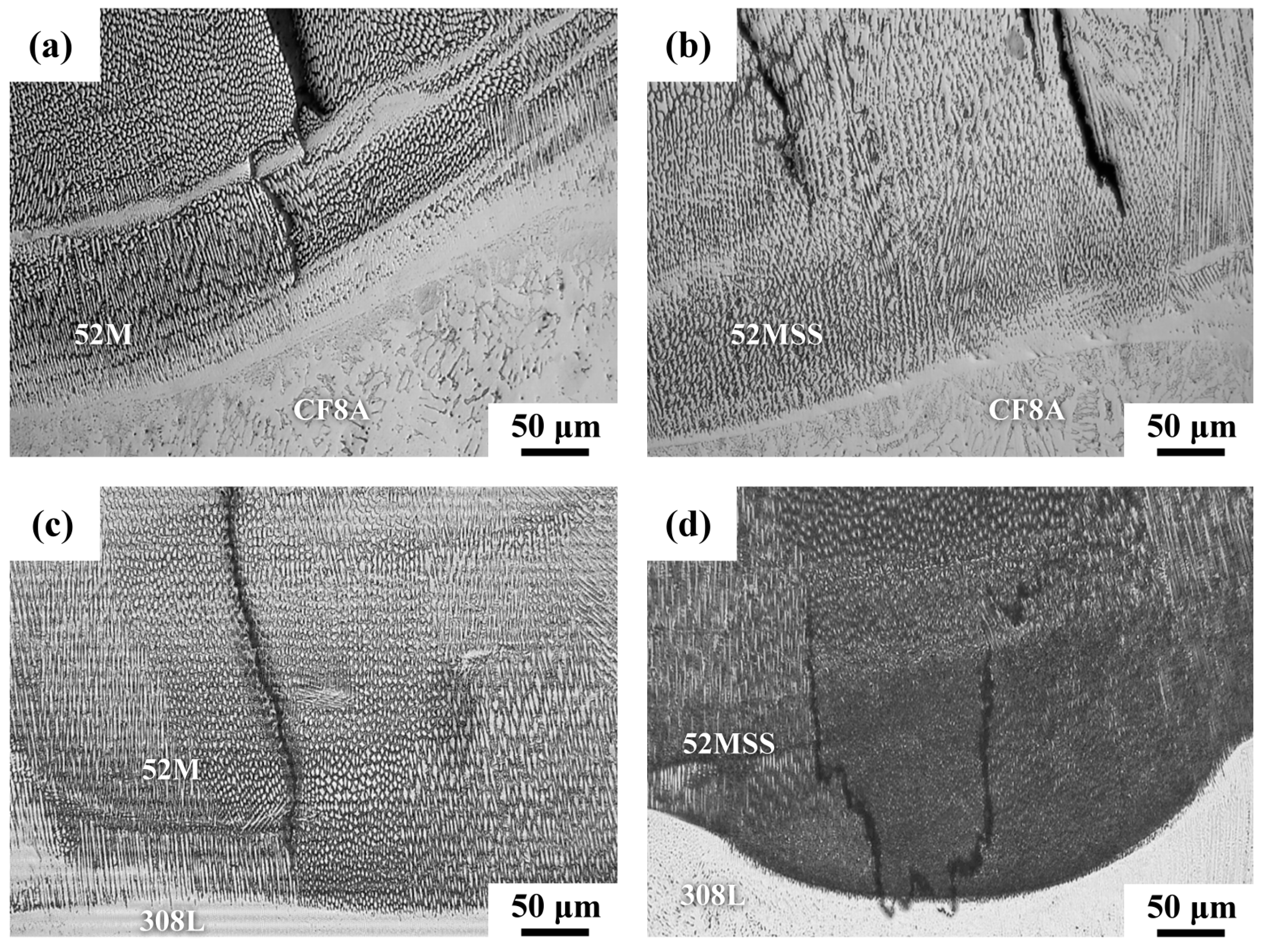

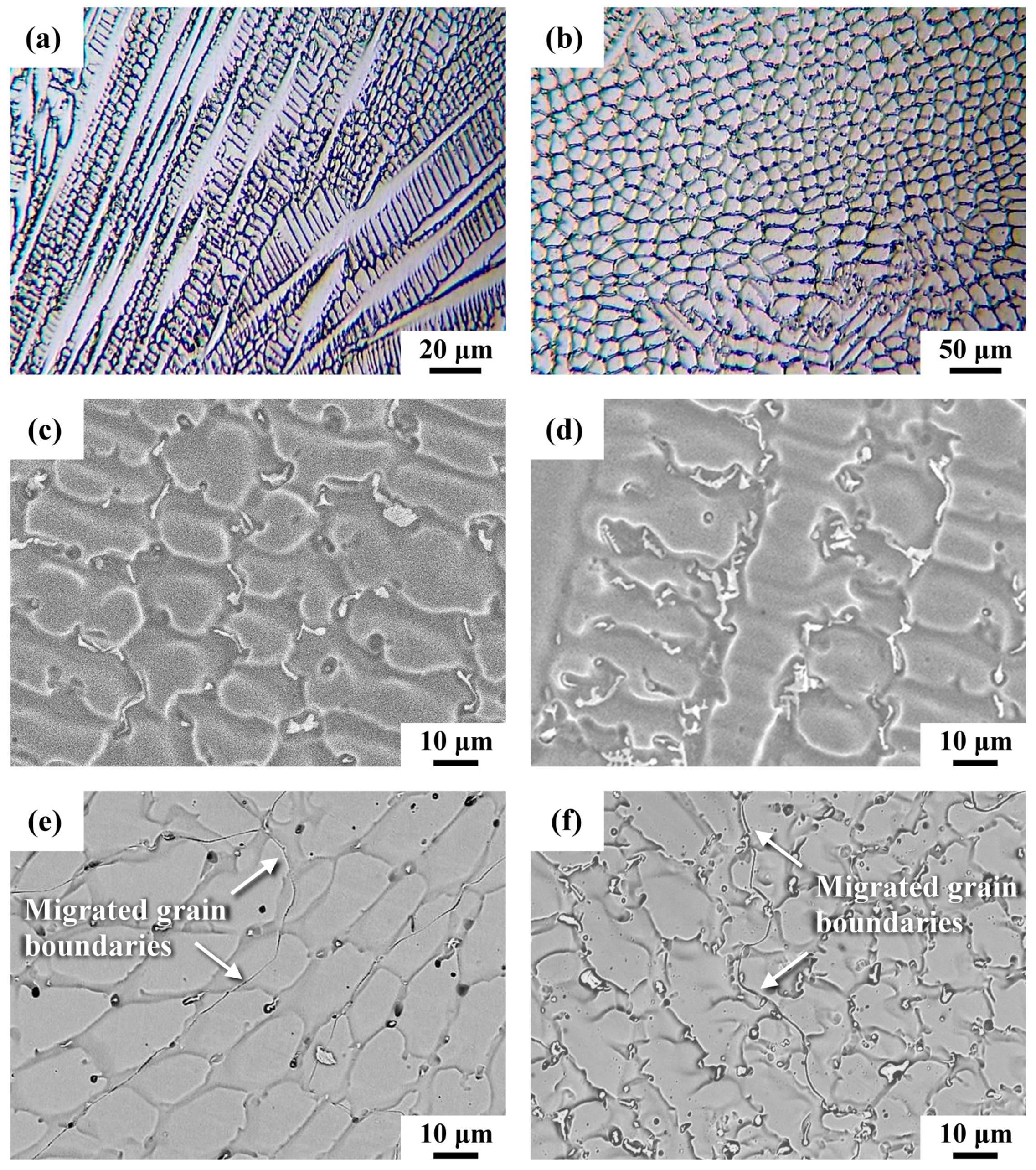

3.2. Microstructural Observations

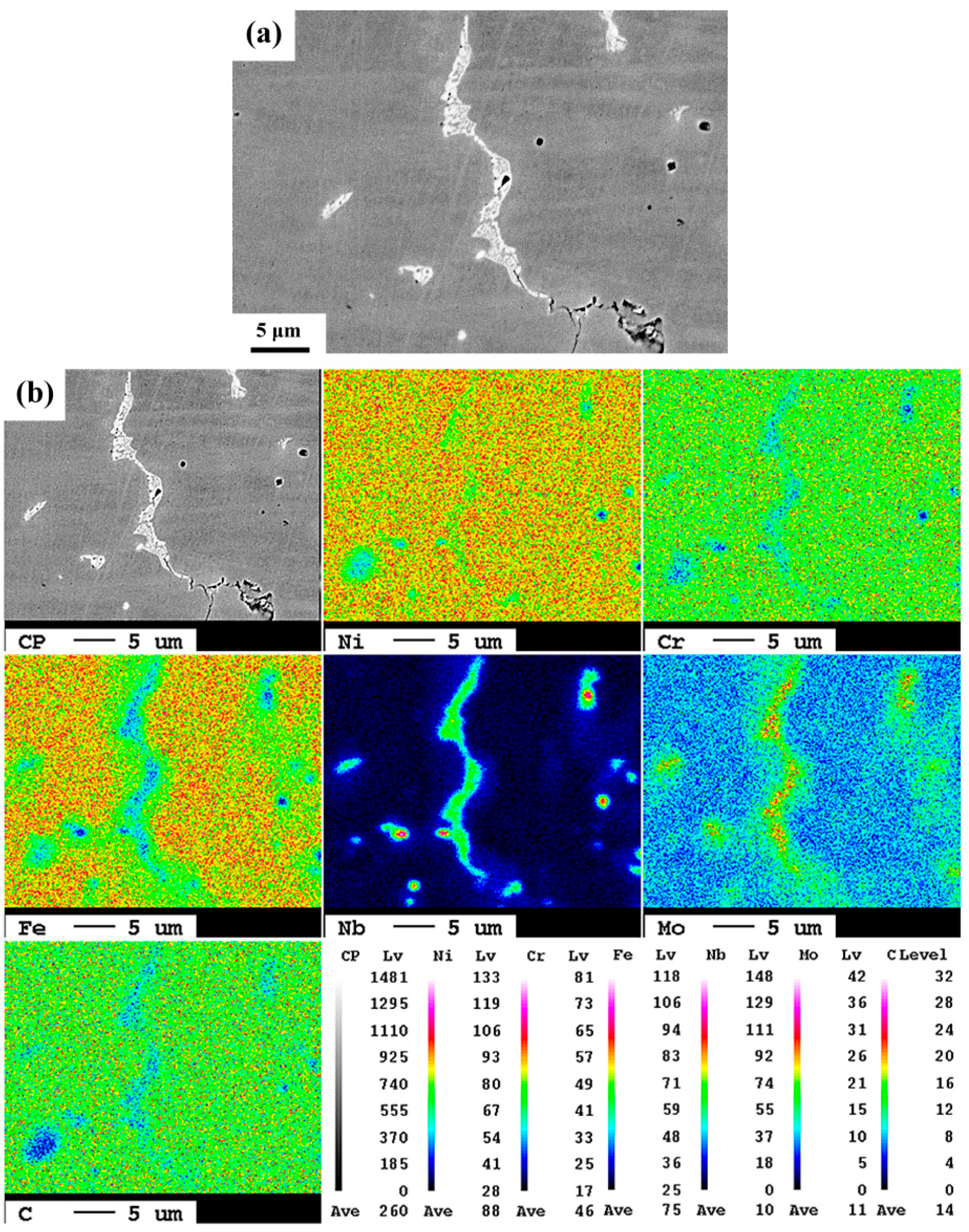

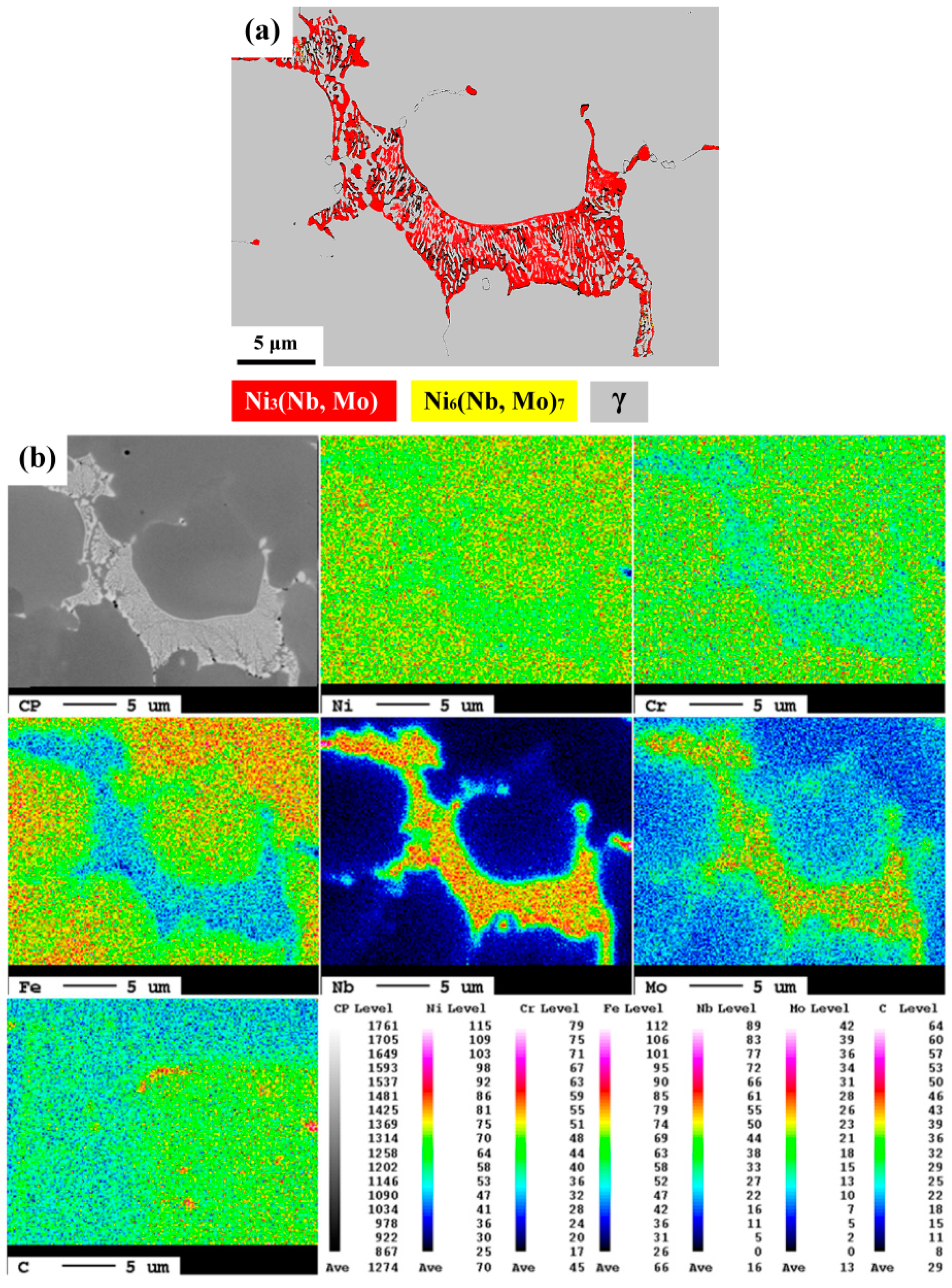

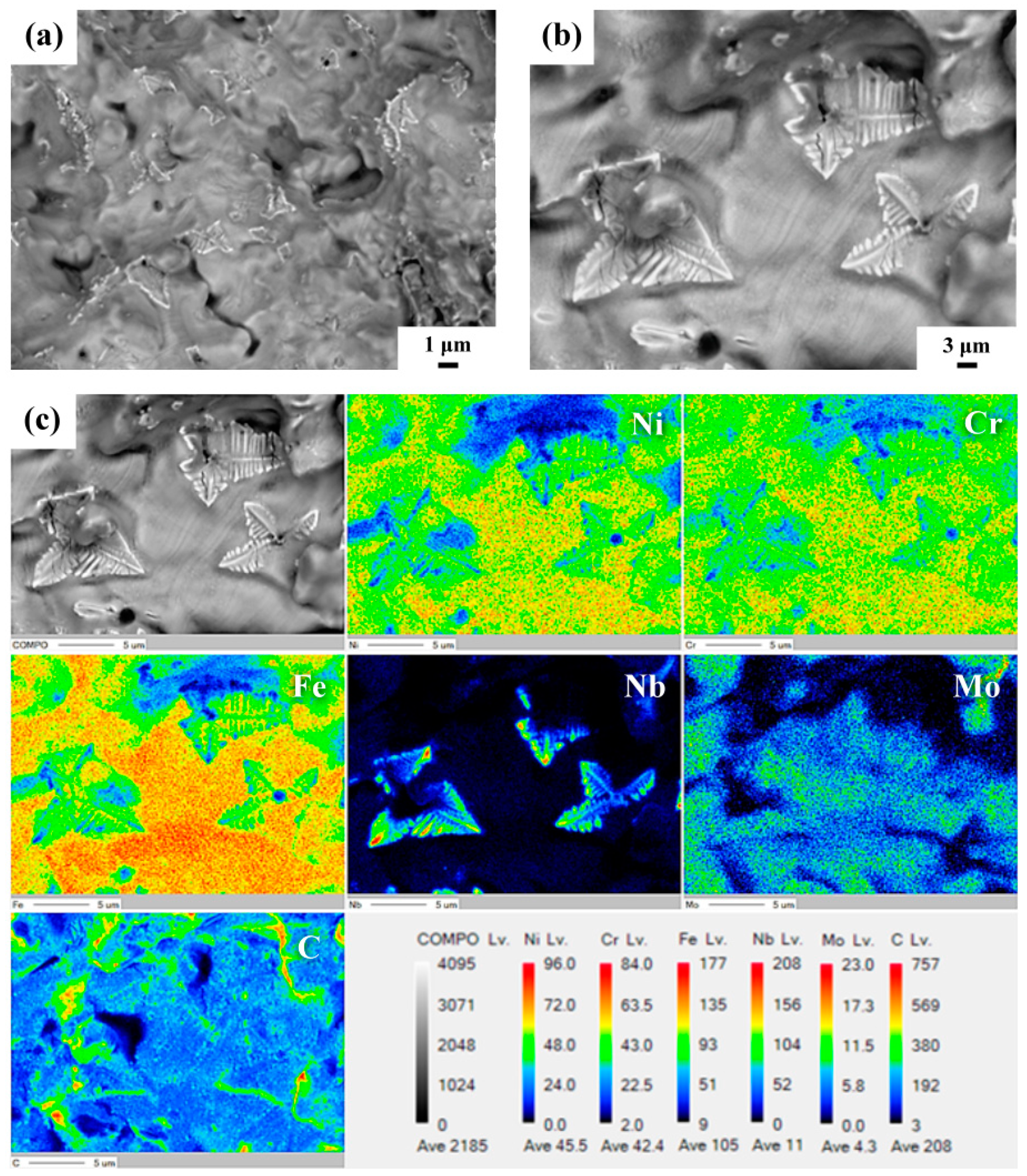

3.3. Microstructural Identifications

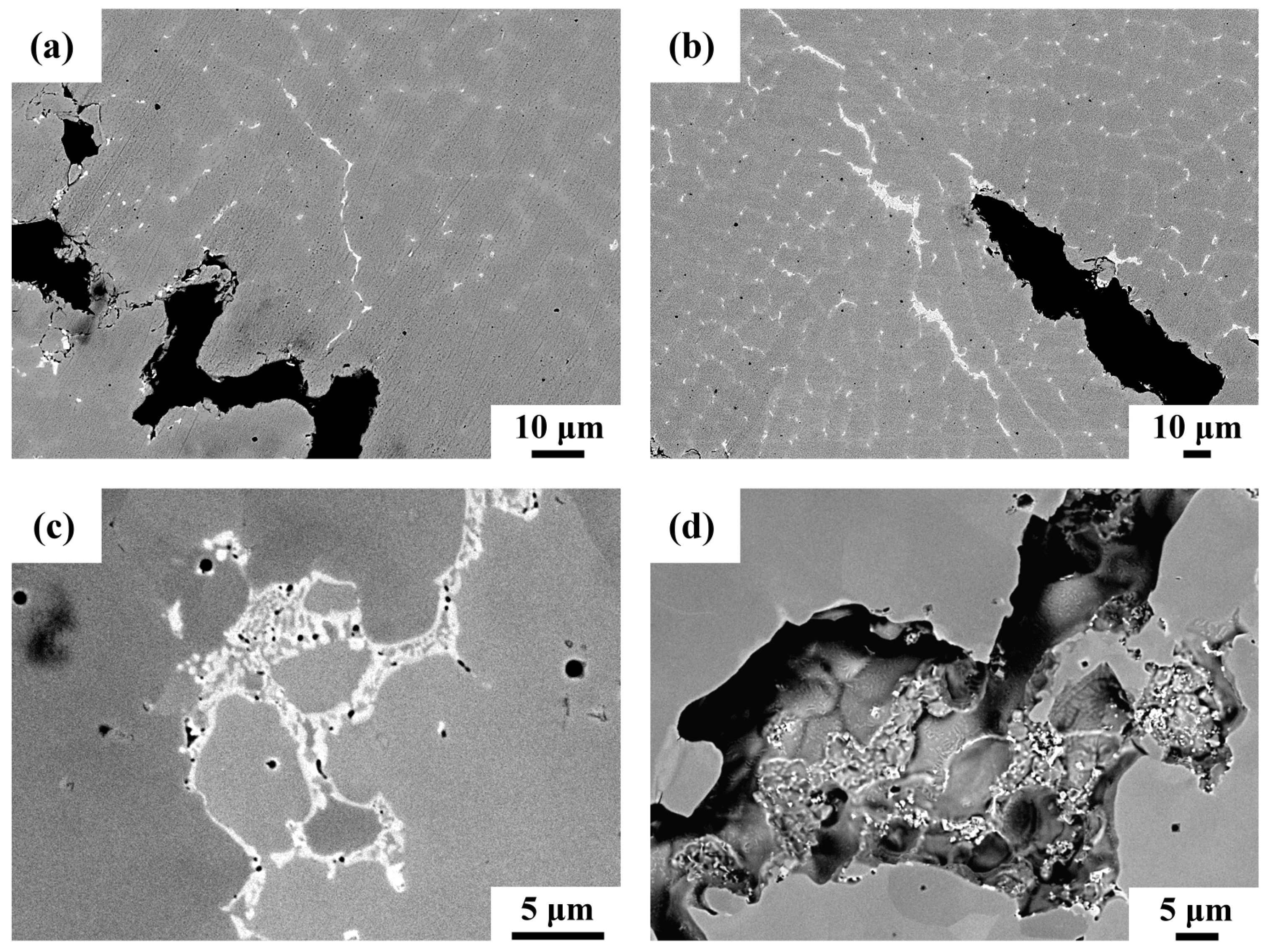

3.4. Hot Crack Features

4. Discussion

5. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Park, J.-H.; Chopra, O.K.; Natesan, K.; Shack, W.J.; Cullen, W.H., Jr. Boric acid corrosion of light water reactor pressure vessel head materials. In Proceedings of the 12th International Conference on Environmentally Degradation of Materials in Nuclear systems—Water Reactors, Pittsburgh, PA, USA, 14–18 August 2005; pp. 459–468. [Google Scholar]

- Bamford, W.; Hall, J. A review of alloy 600 cracking in operating nuclear plants including alloy 82 and 182 weld behavior. In Proceedings of the 12th International Conference on Nuclear Engineering, New York, NY, USA, 25–29 April 2004; pp. 131–139. [Google Scholar]

- Scott, P.M.; Combrade, P. On the mechanism of stress corrosion crack initiation and growth in alloy 600 exposed to PWR primary water. In Proceedings of the 11th International Conference on Environmental Degradation of Materials in Nuclear Power System-Water Reactors, La Grange Park, IL, USA, 10–14 August 2003; pp. 29–38. [Google Scholar]

- Jenssen, A.; Norrgaard, K.; Lagerstroem, J.; Embring, G.; Tice, D.R. Assessment of cracking in dissimilar metal welds. In Proceedings of the 10th International Conference on Environmentally Degradation of Materials in Nuclear systems - Water Reactors; NACE International, Houston, TX, USA, 5–9 August 2001. [Google Scholar]

- King, C.; Frederick, G. Technical basis for Preemptive Weld Overlays for Alloy 82/182 Butt Welds in PWRs (MRP-169) Revision 1; EPRI: Palo Alto, CA, USA, 2008. [Google Scholar]

- Xie, Y.; Wu, Y.; Burns, J.; Zhang, J. Characterization of stress corrosion cracks in Ni-based weld alloys 52, 52M and 152 grown in high-temperature water. Mater. Charact. 2016, 112, 87–97. [Google Scholar] [CrossRef]

- Li, G.; Zhang, M.; Huang, J.; Sun, Z.; Wu, Y. A comparative study on microstructure and properties of Inconel 52M overlays deposited by laser beam and GTA cladding. Int. J. Adv. Manuf. Technol. 2015, 81, 103–112. [Google Scholar] [CrossRef]

- Song, T.K.; Bae, H.R.; Kim, Y.J.; Lee, K.S. Numerical investigation on welding residual stresses in a PWR pressurizer safety/relief nozzle. Fatigue Fract. Eng. Mater. Struct. 2010, 33, 689–702. [Google Scholar] [CrossRef]

- Huang, C.C.; Liu, R.F. Structural integrity analyses for preemptive weld overlay on the dissimilar metal weld of a pressurizer nozzle. Int. J. Press. Vessel. Pip. 2012, 90–91, 77–83. [Google Scholar] [CrossRef]

- Fink, C.; Zinke, M.; Keil, D. Evaluation of hot cracking susceptibility of nickel-based alloys by the PVR test. Weld. World 2012, 56, 37–43. [Google Scholar] [CrossRef]

- Chen, T.C.; Cheng, Y.H.; Tsay, L.W.; Shiue, R.K. Effects of grain boundary microconstituents on heat-affected zone cracks in a Mar-M004 weldment. Metals 2018, 8, 201. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Chen, J.T.; Shiue, R.K.; Tsay, L.W. The evolution of cast microstructures on the HAZ liquation cracking of Mar-M004 weld. Metals 2018, 8, 35. [Google Scholar] [CrossRef]

- Chen, K.C.; Chen, T.C.; Shiue, R.K.; Tsay, L.W. Liquation cracking in the heat-affected zone of IN738 superalloy weld. Metals 2018, 8, 387. [Google Scholar] [CrossRef]

- Angella, G.; Barbieri, G.; Donnini, R.; Montanari, R.; Richetta, M.; Varone, A. Electron beam welding of IN792 DS: effects of pass speed and PWHT on microstructure and hardness. Materials 2017, 10, 1033. [Google Scholar] [CrossRef]

- Li, Q.; Lin, X.; Wang, X.; Yang, H.; Song, M.; Huang, W. Research on the grain boundary liquation mechanism in heat affected zones of laser forming repaired K465 nickel-based superalloy. Metals 2016, 6, 64. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kiser, S.D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Hänninen, H.; Brederholm, A.; Saukkonen, T. Hot Cracking Susceptibility of Ni-base Alloy Dissimilar Metal Welds, Hot Cracking Phenomena in Welds II; Springer: Berlin, Heidelberg, 2008; pp. 171–191. [Google Scholar]

- Chu, H.A.; Young, M.C.; Chu, H.C.; Tsay, L.W.; Chen, C. Hot cracking susceptibility of Alloy 52M weld overlays onto CF8 stainless steel. J. Nucl. Mater. 2013, 433, 419–423. [Google Scholar] [CrossRef]

- Shih, Y.-J. Mitigation of hot cracking of alloy 52M overlay on cast stainless steel CF8A. Sci. Technol. Weld. Join. 2013, 18, 566–572. [Google Scholar] [CrossRef]

- Lin, C.-M. Relationships between microstructures and properties of buffer layer with Inconel 52M clad on AISI 316L stainless steel by GTAW processing. Surf. Coatings Technol. 2013, 228, 234–241. [Google Scholar] [CrossRef]

- Chu, H.A.; Young, M.C.; Chu, H.C.; Tsay, L.W.; Chen, C. The effect of Nb and S segregation on the solidification cracking of alloy 52M weld overlay on CF8 stainless steel. J. Mater. Eng. Perform. 2014, 23, 967–974. [Google Scholar] [CrossRef]

- Ko, G.; Seo, K.M.; Kim, H.J.; Hong, H. Characteristics of hot cracking in dissimilar joint of A690 overlay and stainless steel clad. Weld. World 2017, 61, 945–953. [Google Scholar] [CrossRef]

- Tsai, K.-C.; Jeng, S.-L. A feasibility study of applying SS 307Si buffer layer for mitigating the hot cracking of Ni-based weld overlay. J. Mater. Eng. Perform. 2017, 26, 3698–3709. [Google Scholar] [CrossRef]

- Li, G.; Lu, X.; Zhu, X.; Huang, J.; Liu, L.; Wu, Y. The segregation and liquation crackings in the HAZ of multipass laser-welded joints for nuclear power plants. J. Mater. Eng. Perform. 2017, 26, 4083–4091. [Google Scholar] [CrossRef]

- Jeng, S.-L.; Chang, Y.-H. The influence of Nb and Mo on the microstructure and mechanical properties of Ni–Cr–Fe GTAW welds. Mater. Sci. Eng. A 2012, 555, 1–12. [Google Scholar] [CrossRef]

- Zhang, X.; Li, D.-Z.; Li, Y.-Y.; Lu, S.-P. Effect of Nb and Mo on the microstructure, mechanical properties and ductility-dip cracking of Ni–Cr–Fe weld metals. Acta Metall. Sin. English Lett. 2016, 29, 928–939. [Google Scholar] [CrossRef]

- Hope, A.T.; Lippold, J.C. Development and testing of a high-chromium, Ni-based filler metal resistant to ductility dip cracking and solidification cracking. Weld. World 2017, 61, 325–332. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C. High temperature behavior of Ni-base weld metal: Part I. Ductility and microstructural characterization. Mater. Sci. Eng. A 2004, 380, 259–271. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C. High temperature behavior of Ni-base weld metal: Part II – Insight into the mechanism for ductility dip cracking. Mater. Sci. Eng. A 2004, 380, 245–258. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Sowards, J.W.; Lippold, J.C. Improving the ductility-dip cracking resistance of Ni-base alloys. J. Mater. Process. Technol. 2006, 179, 212–218. [Google Scholar] [CrossRef]

- Chen, J.Q.; Lu, H.; Cui, W.; Chen, J.M.; Huang, Y.F. Effect of grain boundary behaviour on ductility dip cracking mechanism. Mater. Sci. Technol. 2014, 30, 1189–1196. [Google Scholar] [CrossRef]

- Chen, J.Q.; Lu, H.; Yu, C.; Chen, J.M.; Zhang, M.L. Ductility dip cracking mechanism of Ni–Cr–Fe alloy based on grain boundary energy. Sci. Technol. Weld. Join. 2013, 18, 346–353. [Google Scholar] [CrossRef]

- Wu, W.T.; Tsai, C.H. Hot cracking susceptibility of fillers 52 And 82 in Alloy 690 welding. Metall. Mater. Trans. A 1999, 30A, 417426. [Google Scholar] [CrossRef]

- McCracken, S.L.; Alexandrov, B.T.; Lippold, J.C.; Sowards, J.W.; Hope, A.T. Hot cracking study of high chromium nickel-base weld filler metal 52MSS (ERNiCrFe-13) for nuclear applications. In Proceedings of the ASME 2010 Pressure Vessels & Piping Division Conference, Bellevue, DC, USA, 18–22 July 2010. [Google Scholar]

- Yushchenko, K.; Savchenko, V.; Chervyakov, N.; Zvyagintseva, A.; Guyot, E. Comparative hot cracking evaluation of welded joints of alloy 690 using filler metals Inconel 52 And 52 MSS. Weld. World 2011, 55, 28–35. [Google Scholar] [CrossRef]

- Brooks, J.A.; Lambert, F.J.J. The effects of phosphorus sulfur and ferrite content on weld cracking of type 309 stainless steel. Weld. J. 1978, 57, 139–143. [Google Scholar]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr. Mater. 2004, 50, 641–646. [Google Scholar] [CrossRef]

- Ojo, O.A.; Chaturvedi, M.C. Liquation microfissuring in the weld heat-affected zone of an overaged precipitation-hardened nickel-base superalloy. Metall. Mater. Trans. A 2007, 38, 356–369. [Google Scholar] [CrossRef]

- Montazeri, M.; Ghaini, F.M. The liquation cracking behavior of IN738LC superalloy during low power Nd:YAG pulsed laser welding. Mater. Charact. 2012, 67, 65–73. [Google Scholar] [CrossRef]

- Dupont, J.N.; Robino, C.V.; Michael, J.R.; Notis, M.R.; Marder, A.R. Solidification of Nb-bearing Superalloys: Part I. Reaction Sequences. Metall. Mater. Trans. A 1998, 29, 27852796. [Google Scholar] [CrossRef]

- Cieslak, M.J. The Welding and Solidification Metallurgy of Alloy 625. Weld. J. 1991, 70, 49–56. [Google Scholar]

| Materials | Elements | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Fe | Mn | Nb | Mo | Ti | Si | P | S | Nb + Ta | |

| CF8A | 0.05 | 18.3 | 8.2 | Bal. | 1.30 | - | - | - | 0.50 | 0.020 | 0.0060 | - |

| 308L | 0.01 | 20.0 | 10.0 | Bal. | 1.70 | - | 0.10 | - | 0.40 | 0.020 | 0.0100 | - |

| 52M | 0.02 | 29.7 | Bal. | 8.8 | 0.70 | 0.8 | 0.05 | 0.17 | 0.11 | 0.002 | 0.0005 | 0.14 |

| 52MSS | 0.023 | 29.5 | Bal. | 8.8 | 0.31 | 2.5 | 3.50 | 0.18 | 0.11 | 0.004 | 0.0005 | 0.01 |

| Materials | Temperature (°C) | ||

|---|---|---|---|

| TS | TL | ∆TL→S | |

| 52M filler | 1345 | 1381 | 36 |

| 52MSS filler | 1342 | 1399 | 57 |

| 52M overlay | 1310 | 1358 | 48 |

| 52MSS overlay | 1291 | 1378 | 81 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.-Y.; Wu, T.-J.; Chen, T.-C.; Jeng, S.-L.; Tsay, L.-W. The Comparison of Cracking Susceptibility of IN52M and IN52MSS Overlay Welds. Metals 2019, 9, 651. https://doi.org/10.3390/met9060651

Chen M-Y, Wu T-J, Chen T-C, Jeng S-L, Tsay L-W. The Comparison of Cracking Susceptibility of IN52M and IN52MSS Overlay Welds. Metals. 2019; 9(6):651. https://doi.org/10.3390/met9060651

Chicago/Turabian StyleChen, Min-Yi, Tai-Jung Wu, Tai-Cheng Chen, Sheng-Long Jeng, and Leu-Wen Tsay. 2019. "The Comparison of Cracking Susceptibility of IN52M and IN52MSS Overlay Welds" Metals 9, no. 6: 651. https://doi.org/10.3390/met9060651

APA StyleChen, M.-Y., Wu, T.-J., Chen, T.-C., Jeng, S.-L., & Tsay, L.-W. (2019). The Comparison of Cracking Susceptibility of IN52M and IN52MSS Overlay Welds. Metals, 9(6), 651. https://doi.org/10.3390/met9060651