Effects of Al and Heat Treatment on the Microstructure and Hardness of Ti–Al Synthesized via In Situ Melting using LENS

Abstract

1. Introduction

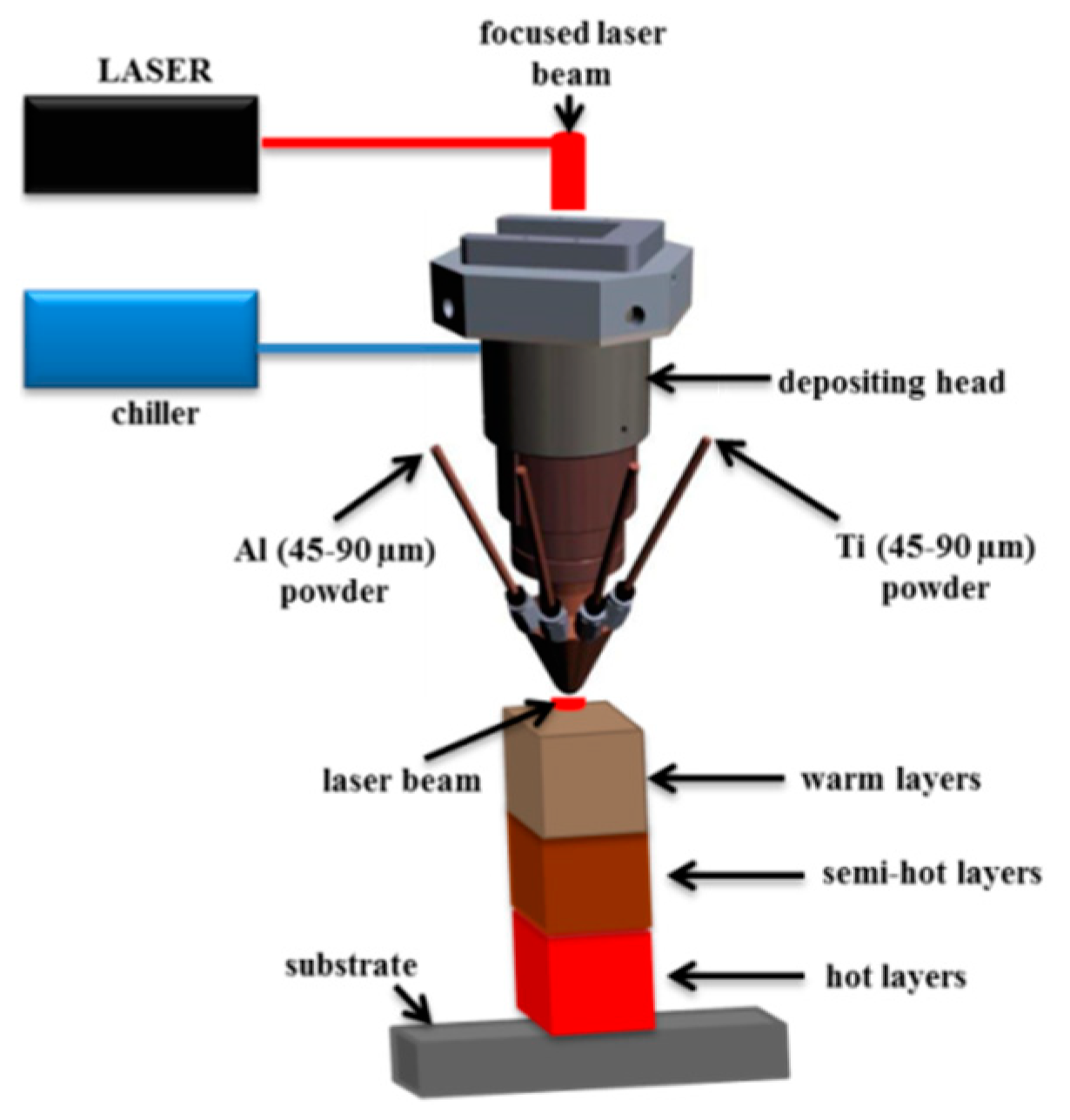

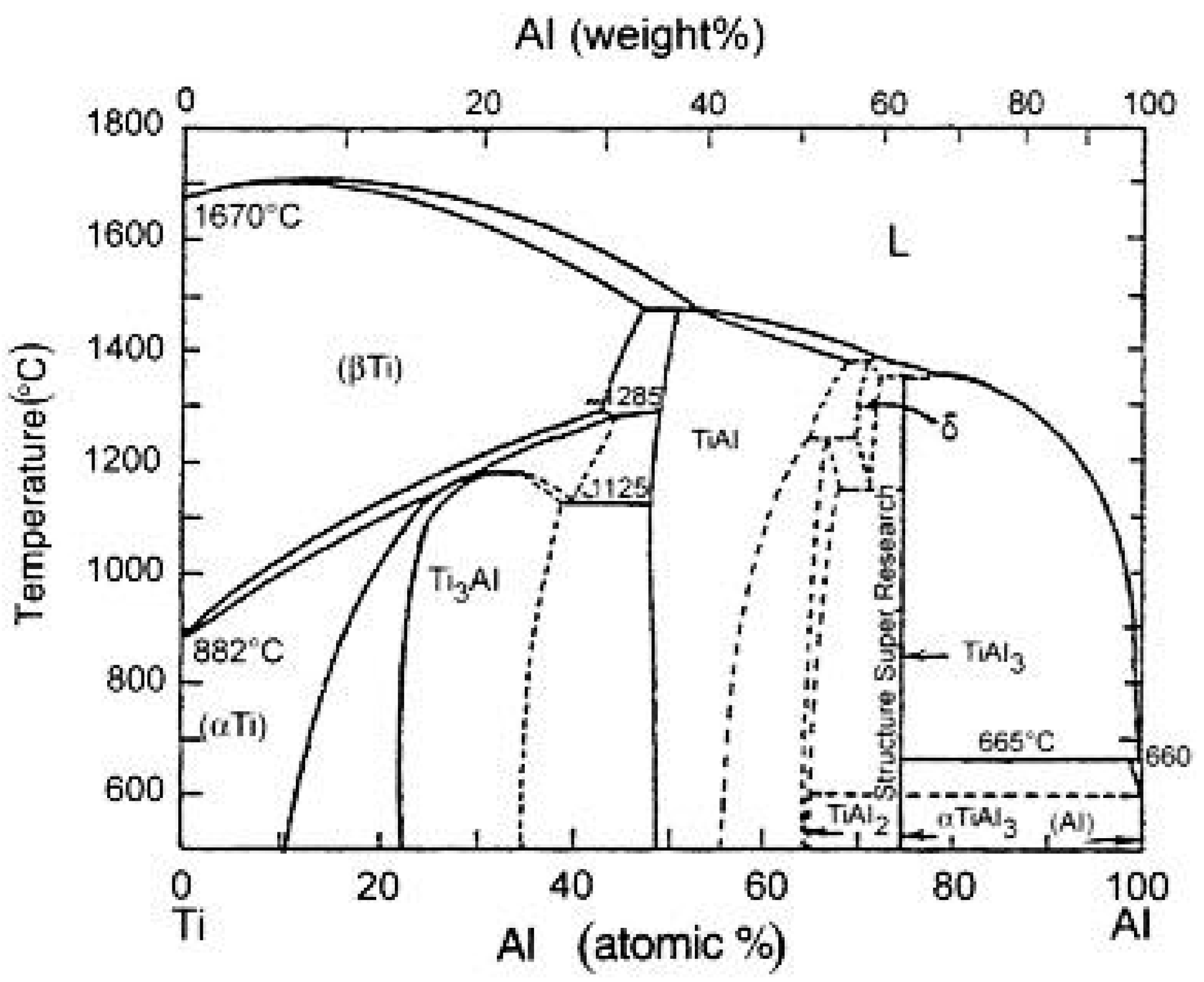

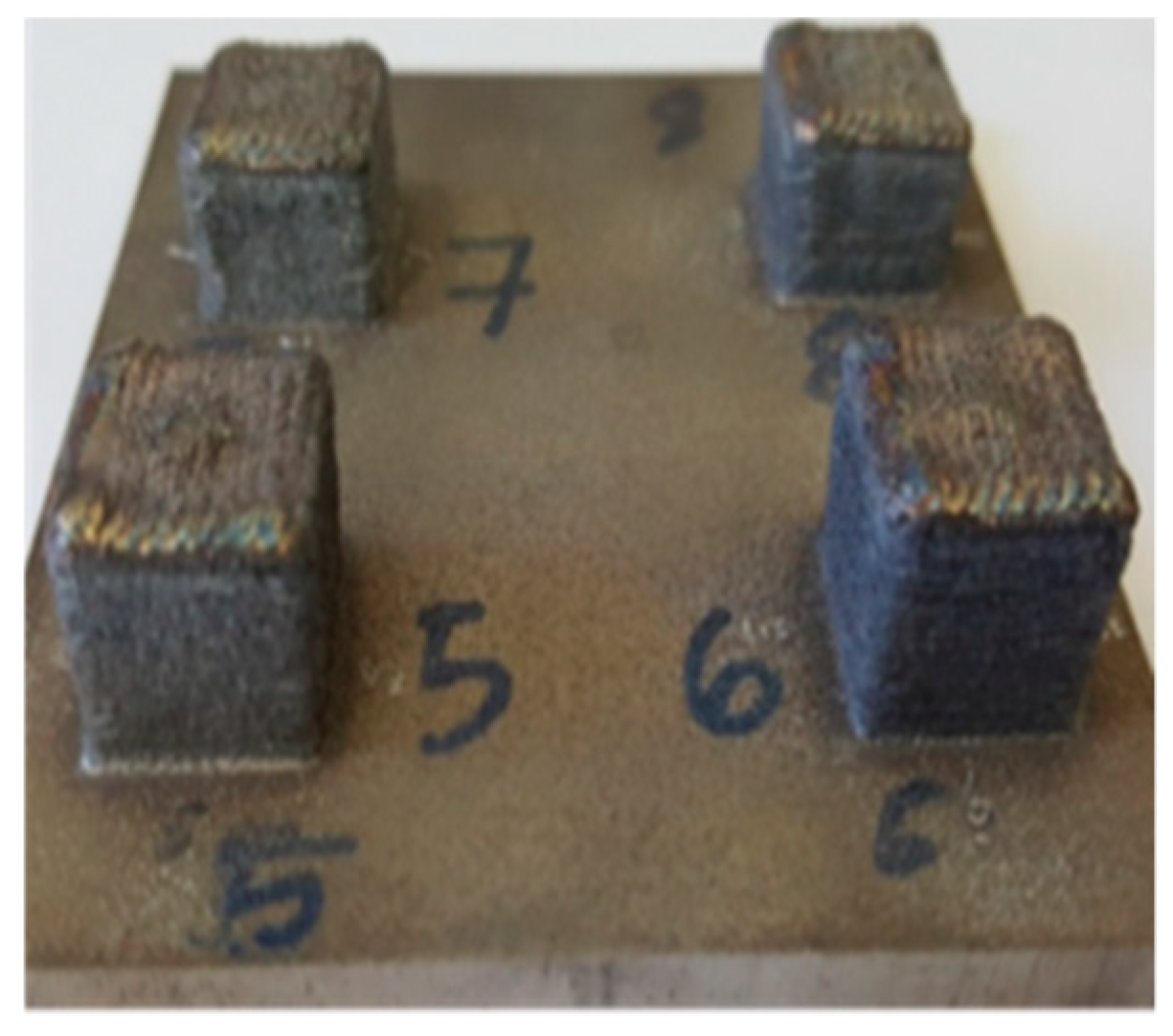

2. Materials and Methods

3. Results and Discussion

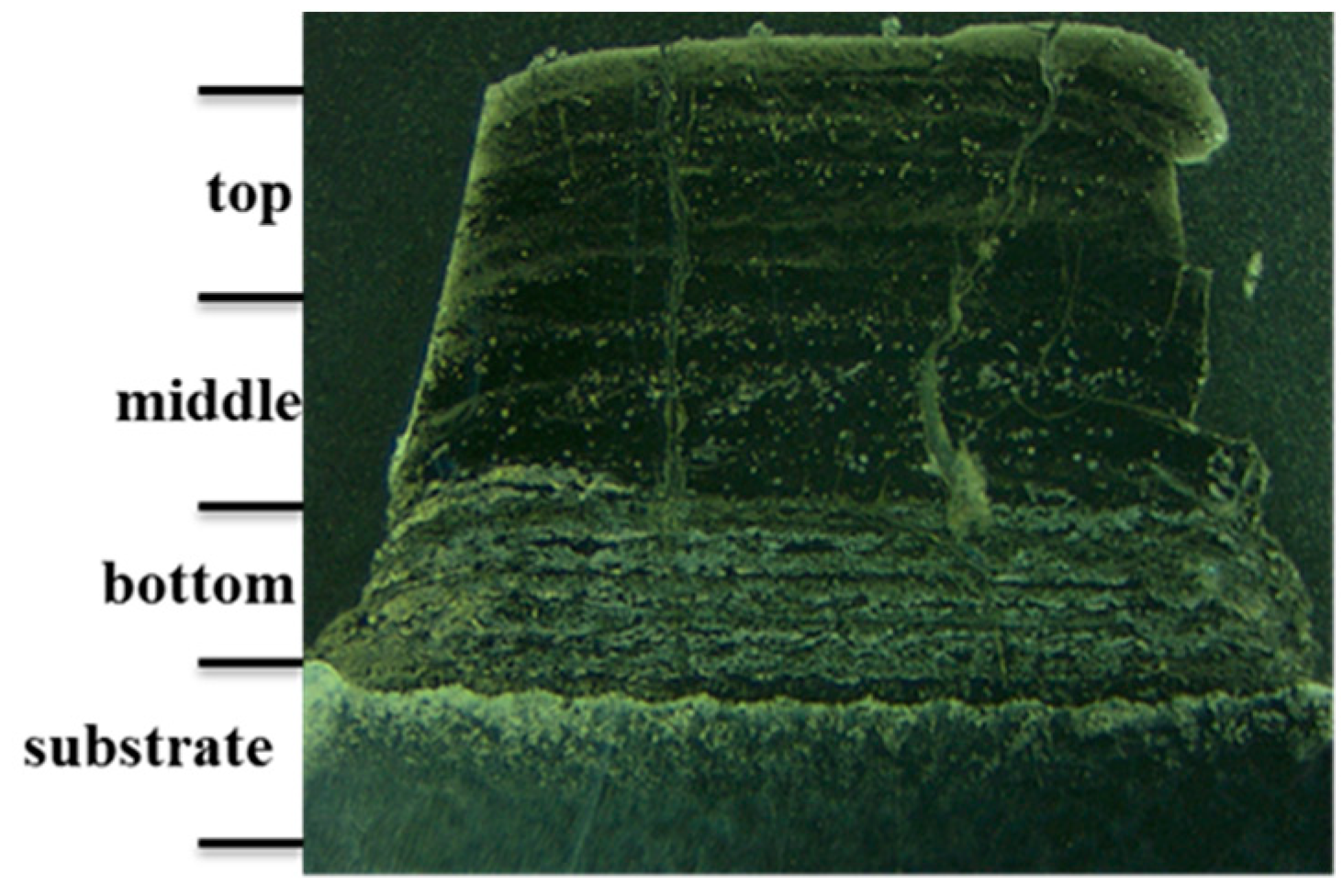

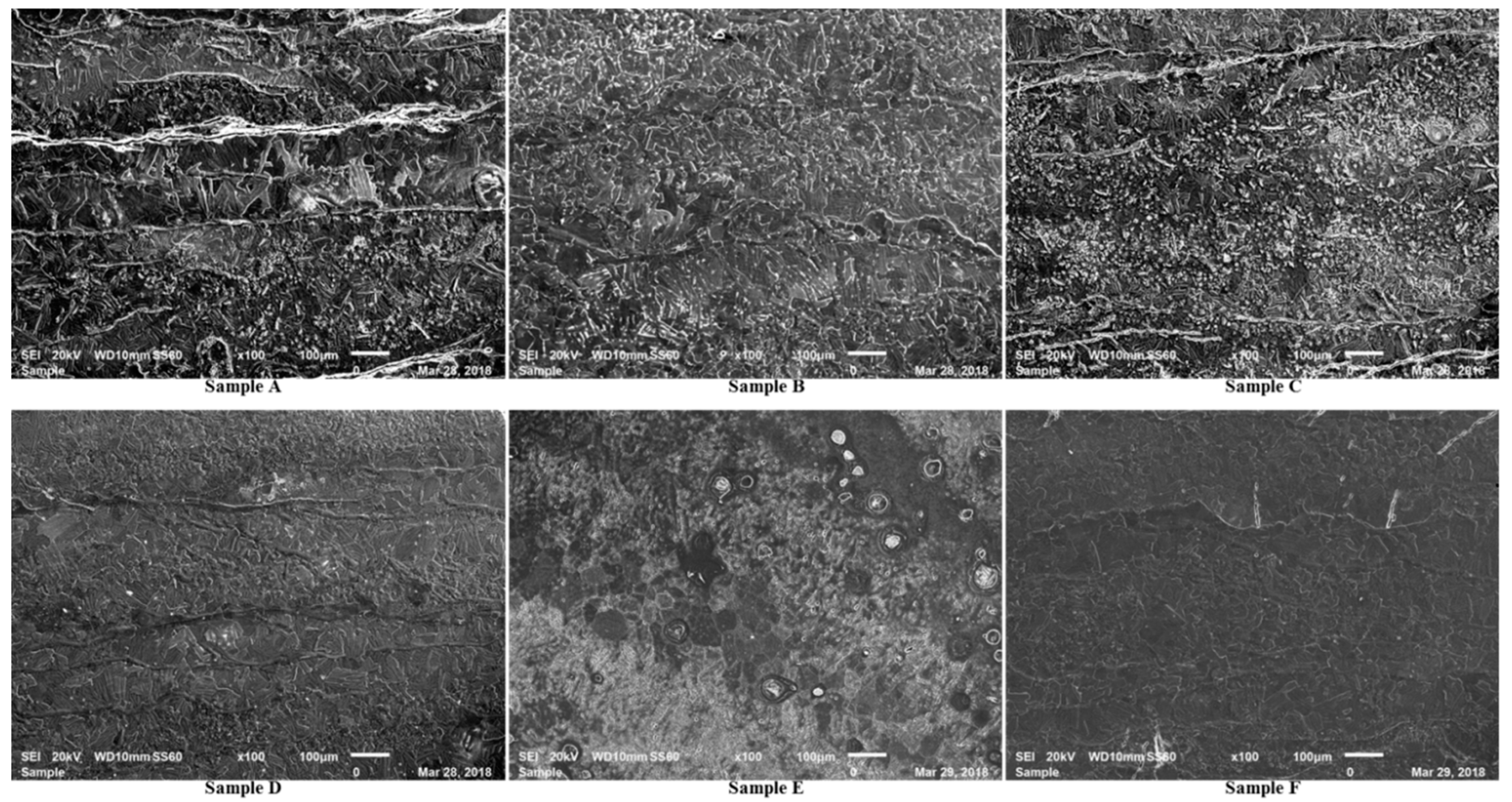

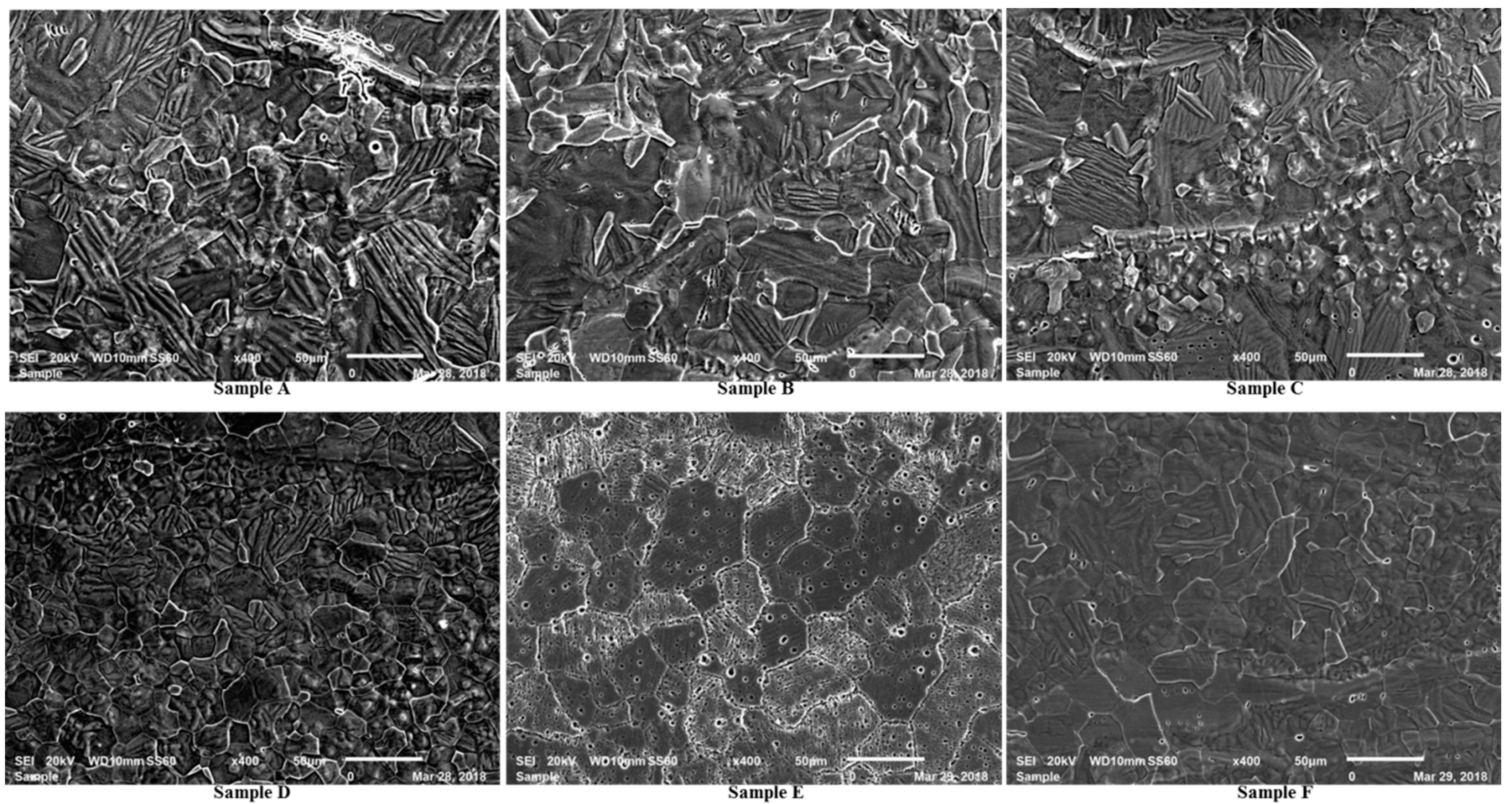

3.1. As-Built Samples

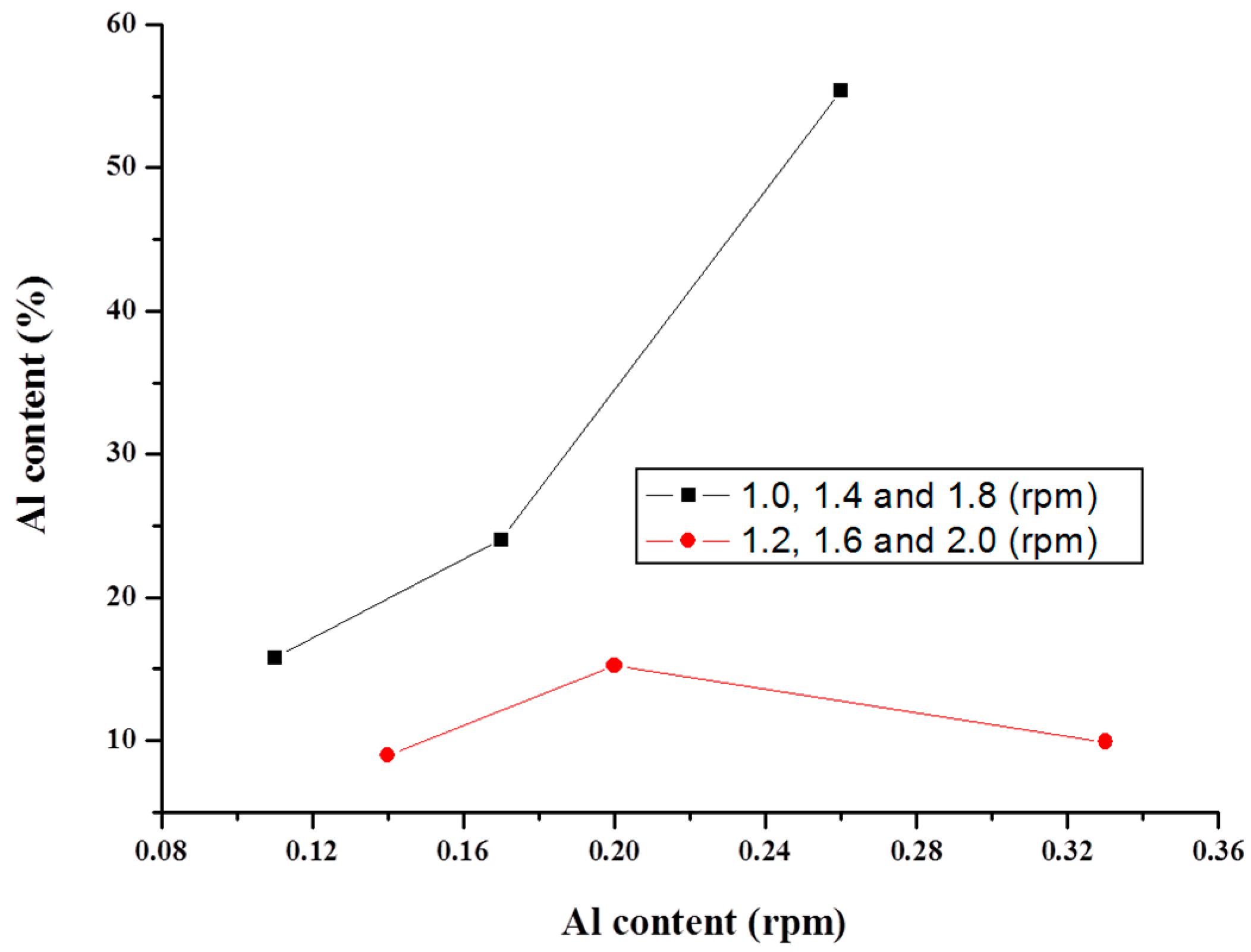

3.2. Chemical Composition and Microstructure

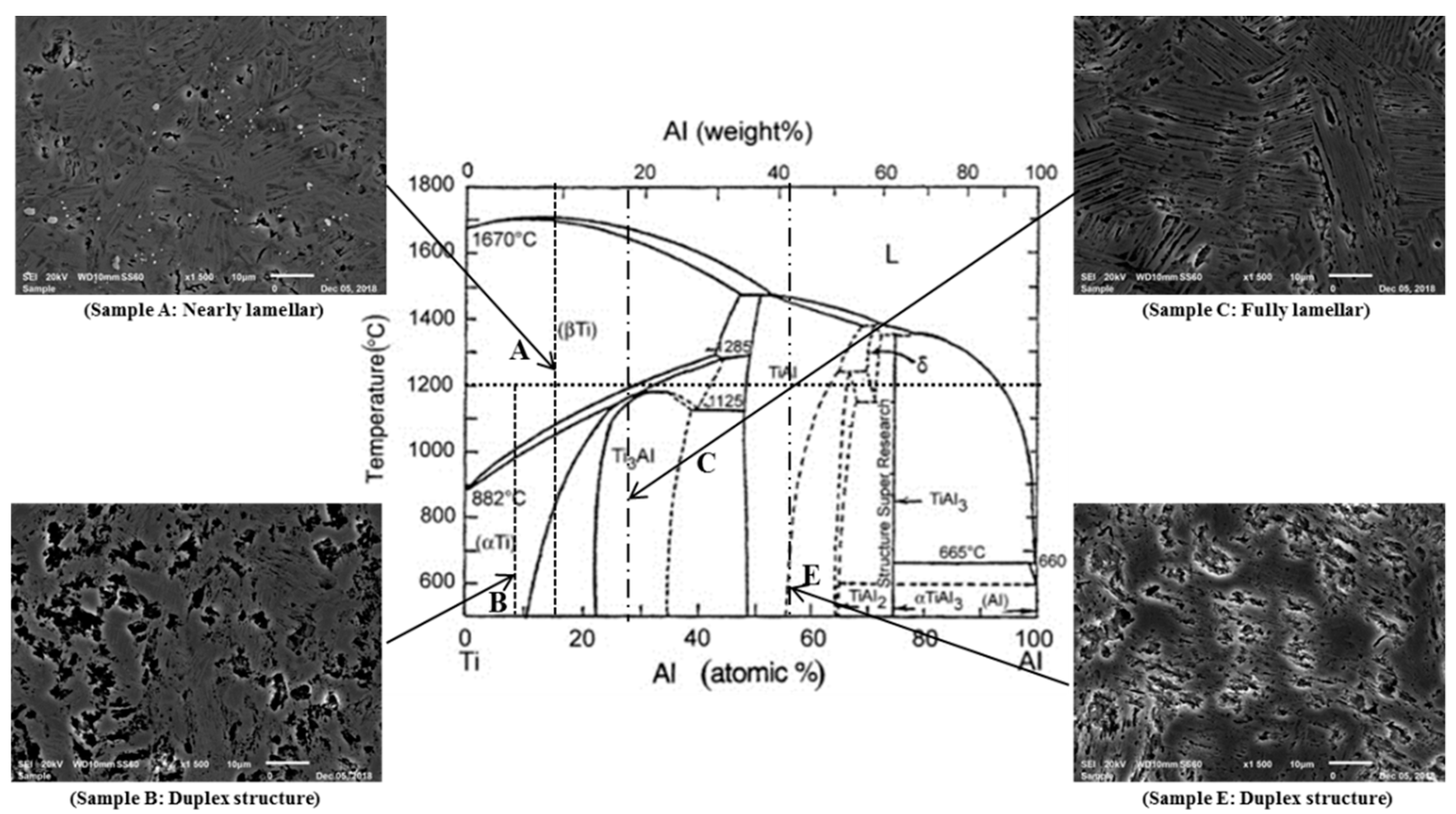

3.3. Heat Treated Samples

3.4. Chemical Composition and Microstructures

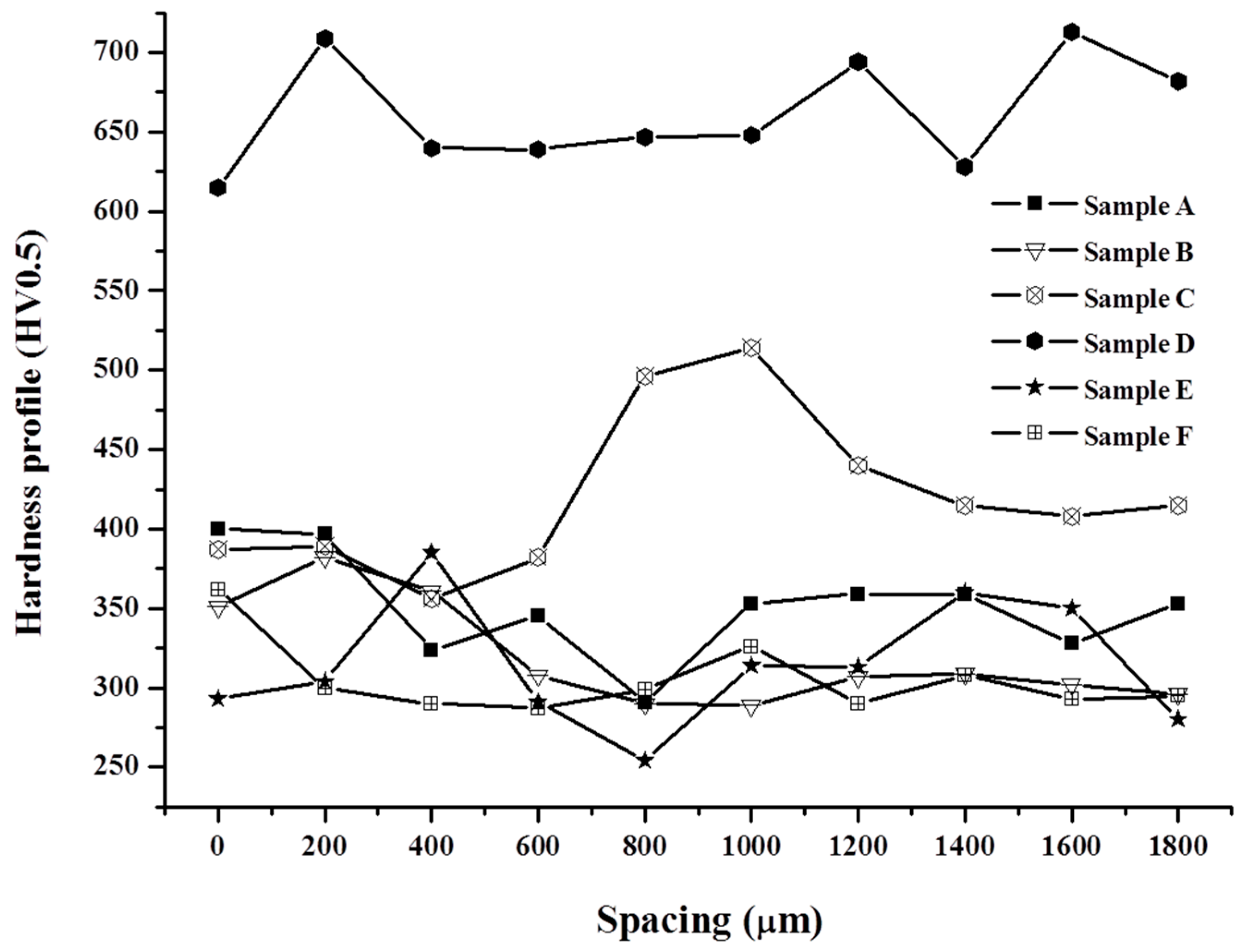

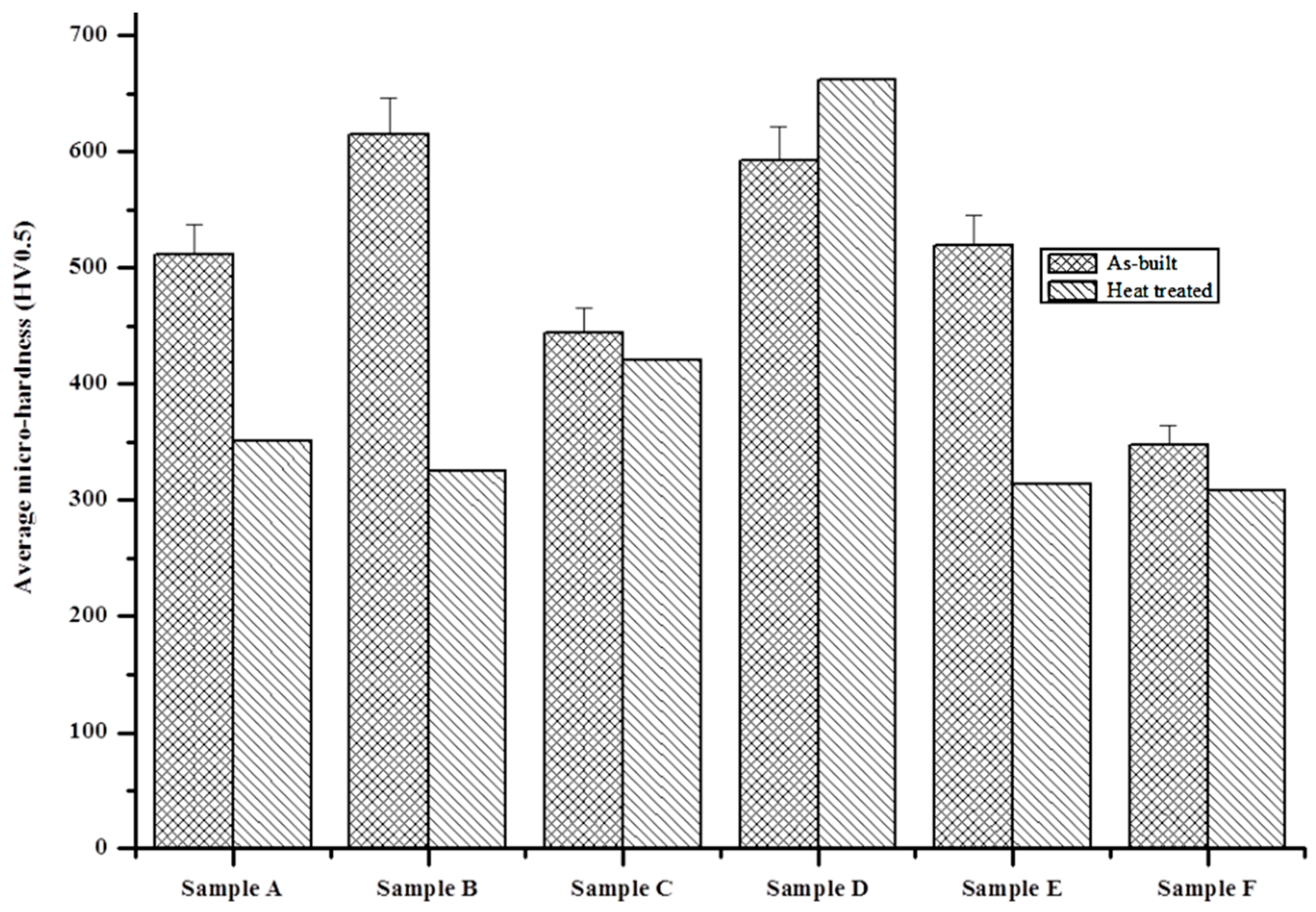

3.5. Micro-Hardness

4. Conclusions

5. Future Work

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

References

- Wang, G.; Dahms, M. Synthesizing gamma-TiAl alloys by reactive powder processing. JOM 1993, 45, 52–56. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Hoye, N.; Li, H.; Pan, Z. Characterization of in-situ alloyed and additively manufactured titanium aluminides. Metall. Mater. Trans. B 2014, 45B, 2299–2303. [Google Scholar] [CrossRef]

- Balla, V.K.; Das, M.; Mohammad, A.; Al-Ahmari, A.M. Additive manufacturing of γ-TiAl: Processing, Microstructure, and Properties. Adv. Energy Mater. 2016, 18, 1208–1215. [Google Scholar] [CrossRef]

- Rittingshaus, S.-K.; Hecht, U.; Werner, V.; Weisheit, A. Heat treatment of laser metal deposited TiAl TNM alloy. Intermetallics 2018, 95, 94–101. [Google Scholar] [CrossRef]

- Wang, G.-X.; Bartels, A.; Dahms, M. Influence of heat treatment on microstructure and deformation behaviour of the Alloy Ti50Al48Cr2 prepared by reactive powder processing. Mater. Trans. JIM 1993, 34, 228–235. [Google Scholar]

- Appel, F.; Clemens, H.; Fischer, F.D. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Appel, F.; Oehring, M.; Paul, J.D.H. A novel in situ composite structure in TiAl alloys. Mater. Sci. Eng. A 2008, 493, 232–236. [Google Scholar] [CrossRef]

- Rostamian, A.; Jacot, A. A numerical model for the description of the lamellar and massive phase transformations in TiAl alloys. Intermetallics 2008, 16, 1227–1236. [Google Scholar] [CrossRef]

- Brueckner, F.; Seidel, A.; Straubel, A.; Willner, R.; Leyens, C.; Beyer, E. Laser-based manufacturing of components of components using materials with high cracking susceptibility. J. Laser Appl. 2016, 28, 1–7. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Tlotleng, M. Microstructural properties of heat-treated LENS in situ additively manufactured titanium aluminide. J. Mater. Eng. Perform. 2019, 28, 701–708. [Google Scholar] [CrossRef]

- Nochovnaya, N.A.; Panin, P.V.; Kochetkov, A.S.; Bokov, K.A. Modern refractory alloys based on titanium gamma-aluminide: Prospects of development and application. Met. Sci. Heat Treat. 2014, 56, 23–27. [Google Scholar] [CrossRef]

- Clemens, A.; Bartels, A.; Bystrzanowski, S.; Chladil, H.; Leitner, H.; Dehm, G.; Gerling, R.; Schimansky, F.P. Grain refinement in γ-TiAl based alloys by solid state phase transformations. Intermetallics 2006, 14, 1380–1385. [Google Scholar] [CrossRef]

- Wang, Y.H.; Lin, J.P.; He, Y.H.; Lu, X.; Wang, Y.L.; Chen, G.L. Microstructure and mechanical properties of high Nb containing TiAl alloys by reactive hot pressing. J. Alloys Compd. 2008, 461, 367–372. [Google Scholar] [CrossRef]

- Couturier, R.; Escaravage, C. High temperature alloys for the HTGR gas turbine: Required properties and development needs; International Atomic Energy Agency: Vienna, Austria, 2001; pp. 163–176. ISSN 1011-4289. [Google Scholar]

- Shishkovsky, I.; Missemer, F.; Smurov, I. Direct metal deposition of functional graded structures in Ti-Al system. Physics Procedia 2012, 39, 382–391. [Google Scholar] [CrossRef]

- Gasper, A.N.D.; Smith, C.-S.; Clare, A.T. In-situ synthesis of titanium aluminides by direct metal deposition. J. Mater. Sci. Technol. 2017, 239, 230–239. [Google Scholar] [CrossRef]

- Yin, S.; Yan, X.; Chen, C.; Jenkins, R.; Liu, M.; Lupoi, R. Hybrid additive manufacturing of Al-Ti6Al-4V functional graded materials with selective laser melting and cold spraying. J. Mater. Process. Technol. 2018, 255, 650–655. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Hopkins, N. Laser melting functionally graded composition of Waspaloy® and Zirconia powders. J. Mater. Sci. 2007, 42, 7647–7656. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Hughes, J.I.; Ridgway, K. Characterisation of titanium aluminide components manufactured by laser metal deposition. Intermetalllics 2018, 93, 89–92. [Google Scholar] [CrossRef]

- Cormier, D.; Harrysson, O.; Mahale, T.; West, H. Freeform fabrication of titanium aluminide via electron beam melting using pre-alloyed and blended powders. Mater. Res. Lett. 2007, 1–4. [Google Scholar]

- Murr, L.E.; Gaytan, S.M.; Ceylan, A.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; et al. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Körner, C. Selective electron beam melting of Ti-48Al-2Nb-2Cr: Microstructure and aluminium loss. Intermetallics 2014, 49, 29–35. [Google Scholar] [CrossRef]

- Tang, H.P.; Yang, G.Y.; Jia, W.P.; He, W.W.; Lu, S.L.; Qian, M. Additive manufacturing of a high niobium-containing titanium aluminide alloy by selective electron beam melting. Mater. Sci. Eng. A 2015, 636, 103–107. [Google Scholar] [CrossRef]

- Todai, M.; Nakano, T.; Liu, T.; Yasuda, Y.H.; Hagihara, K.; Cho, K.; Ueda, M.; Takeyama, M. Effect of building direction on the microstructure and tensile properties of Ti-48Al-2Cr-2Nb alloy additively manufactured by electron beam melting. Addit. Manuf. 2017, 13, 61–70. [Google Scholar] [CrossRef]

- Löber, L.; Schimansky, F.P.; Kühn, U.; Pyczak, F.; Eckert, J. Selective laser melting of a beta-solidifying TNM-B1 titanium aluminide alloy. J. Mater. Process. Technol. 2014, 214, 1852–1860. [Google Scholar] [CrossRef]

- Gussone, J.; Hagedorn, Y.-C.; Gherekhloo, H.; Kasperovich, G.; Merzouk, T.; Hausmann, J. Microstructure of γ-titanium aluminide processed by selective laser melting at elevated temperatures. Intermetallics 2015, 66, 133–140. [Google Scholar] [CrossRef]

- Kenel, C.; Dasargyri, G.; Bauer, T.; Collela, A.; Spierings, A.B.; Leinenbach, C.; Wegener, K. Selective laser melting of an oxide dispersion strengthened (ODS) γ-TiAl alloy towards production of complex structures. Mater. Des. 2017, 134, 81–90. [Google Scholar] [CrossRef]

- Qu, H.P.; Wang, H.M. Microstructure and mechanical properties of laser melting deposition γ-TiAl intermetallic alloys. Mater. Sci. Eng. A 2007, 466, 187–194. [Google Scholar] [CrossRef]

- Guo, B.; Zhou, J.; Zhang, S.; Zhou, H.; Pu, Y.; Chen, J. Phase composition and tribological properties of Ti-Al coatings produced on pure Ti by laser cladding. Appl. Surf. Sci. 2007, 253, 9301–9310. [Google Scholar] [CrossRef]

- Qu, H.P.; Li, P.; Zhang, S.Q.; Li, A.; Wang, H.M. The effects of heat treatment on the microstructure and mechanical property of laser melting deposition γ-TiAl intermetallic alloys. Mater. Des. 2010, 31, 2201–2210. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Li, H.; Pan, Z.; Shen, C. The effect of postproduction heat treatment on γ-TiAl alloys produced by the GTAW-based additive manufacturing process. Mater. Sci. Eng. A 2016, 657, 86–95. [Google Scholar] [CrossRef]

- Thomas, M.; Malot, T.; Aubry, P. Laser metal deposition of the intermetallic TiAl alloy. Metall. Mater. Trans. A 2017, 48A, 3143–3157. [Google Scholar] [CrossRef]

- Maliutina, I.N.; Si-Mohand, H.; Sijobert, J.; Bertrand, P.; Lazurenko, D.V.; Bataev, I.A. Structure and oxidation behavior of γ-TiAl coating produced by laser cladding on titanium alloy. Surf. Coat. Technol. 2017, 319, 136–144. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, M.; Clare, A.T.; Lin, X.; Tan, H.; Chen, Y. Microstructure and mechanical properties of Ti-2Al alloyed with Mo formed in laser additive manufacturing. J. Alloys Compd. 2017, 727, 821–831. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Shen, C.; Li, H.; Pan, Z. Effect of interpass temperature on in-ng alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding. Addit. Manuf. 2015, 8, 71–77. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Perrut, M.; Couret, A. Obtained of a fine near-lamellar microstructure in TiAl alloys by spark plasma sintering. Intermetallics 2016, 71, 88–97. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Miyanaji, H.; Lassell, A.; Starr, T.L.; Stucker, B. A novel method to fabricate TiAl intermetallic alloy 3D parts using additive manufacturing. Defence Technol. 2017, 13, 72–76. [Google Scholar] [CrossRef]

- Tlotleng, M.; Masina, B.; Pityana, S. Characteristics of laser in-situ alloyed titanium aluminides coatings. Procedia Manuf. 2017, 7, 39–45. [Google Scholar] [CrossRef]

- Hoosain, S.E.; Pityana, S.; Freemantle, C.S.; Tlotleng, M. Heat treatment of In situ laser-fabricated titanium aluminide. Metals 2018, 8, 655. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Li, S.J.; Chen, G.L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

| Sample ID | Set Value (rpm) | Al Mass Flowrate (g/min) |

|---|---|---|

| Sample A | 1.0 | 0.11 |

| Sample B | 1.2 | 0.14 |

| Sample C | 1.4 | 0.17 |

| Sample D | 1.6 | 0.20 |

| Sample E | 1.8 | 0.26 |

| Sample F | 2.0 | 0.33 |

| Parameter | Symbol | Set-Value | Unit |

|---|---|---|---|

| Laser power | P | 400 | W |

| Laser spot size | D | 1.4 | mm |

| Focal length | L | 144 | mm |

| Stand-off distance | SOD | 8 | mm |

| Deposition speed | S | 80% | in/mm |

| Powder flow-rate (Ti) | M1 | 2 | rpm |

| Powder flow-rate (Al) | M2 | 1-2 | rpm |

| Layer thickness | D | 0.2 | mm |

| Hatch spacing | W | 0.66 | mm |

| Shielding gas flow-rate | f1 | 25 | L/min |

| Process gas flow-rate (Ti) | f2 | 4 | L/min |

| Process gas flow-rate (Al) | f3 | 6 | L/min |

| Sample ID | Ti | Al | Standard Deviation |

|---|---|---|---|

| Sample A | 84.20 | 15.80 | ±2.30 |

| Sample B | 91.01 | 8.99 | ±1.75 |

| Sample C | 75.94 | 24.06 | ±0.16 |

| Sample D | 84.74 | 15.26 | ±2.36 |

| Sample E | 44.62 | 55.38 | ±1.52 |

| Sample F | 90.06 | 9.94 | ±1.87 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tlotleng, M.; Pityana, S. Effects of Al and Heat Treatment on the Microstructure and Hardness of Ti–Al Synthesized via In Situ Melting using LENS. Metals 2019, 9, 623. https://doi.org/10.3390/met9060623

Tlotleng M, Pityana S. Effects of Al and Heat Treatment on the Microstructure and Hardness of Ti–Al Synthesized via In Situ Melting using LENS. Metals. 2019; 9(6):623. https://doi.org/10.3390/met9060623

Chicago/Turabian StyleTlotleng, Monnamme, and Sisa Pityana. 2019. "Effects of Al and Heat Treatment on the Microstructure and Hardness of Ti–Al Synthesized via In Situ Melting using LENS" Metals 9, no. 6: 623. https://doi.org/10.3390/met9060623

APA StyleTlotleng, M., & Pityana, S. (2019). Effects of Al and Heat Treatment on the Microstructure and Hardness of Ti–Al Synthesized via In Situ Melting using LENS. Metals, 9(6), 623. https://doi.org/10.3390/met9060623