Digital Design, Analysis and 3D Printing of Prosthesis Scaffolds for Mandibular Reconstruction

Abstract

1. Introduction

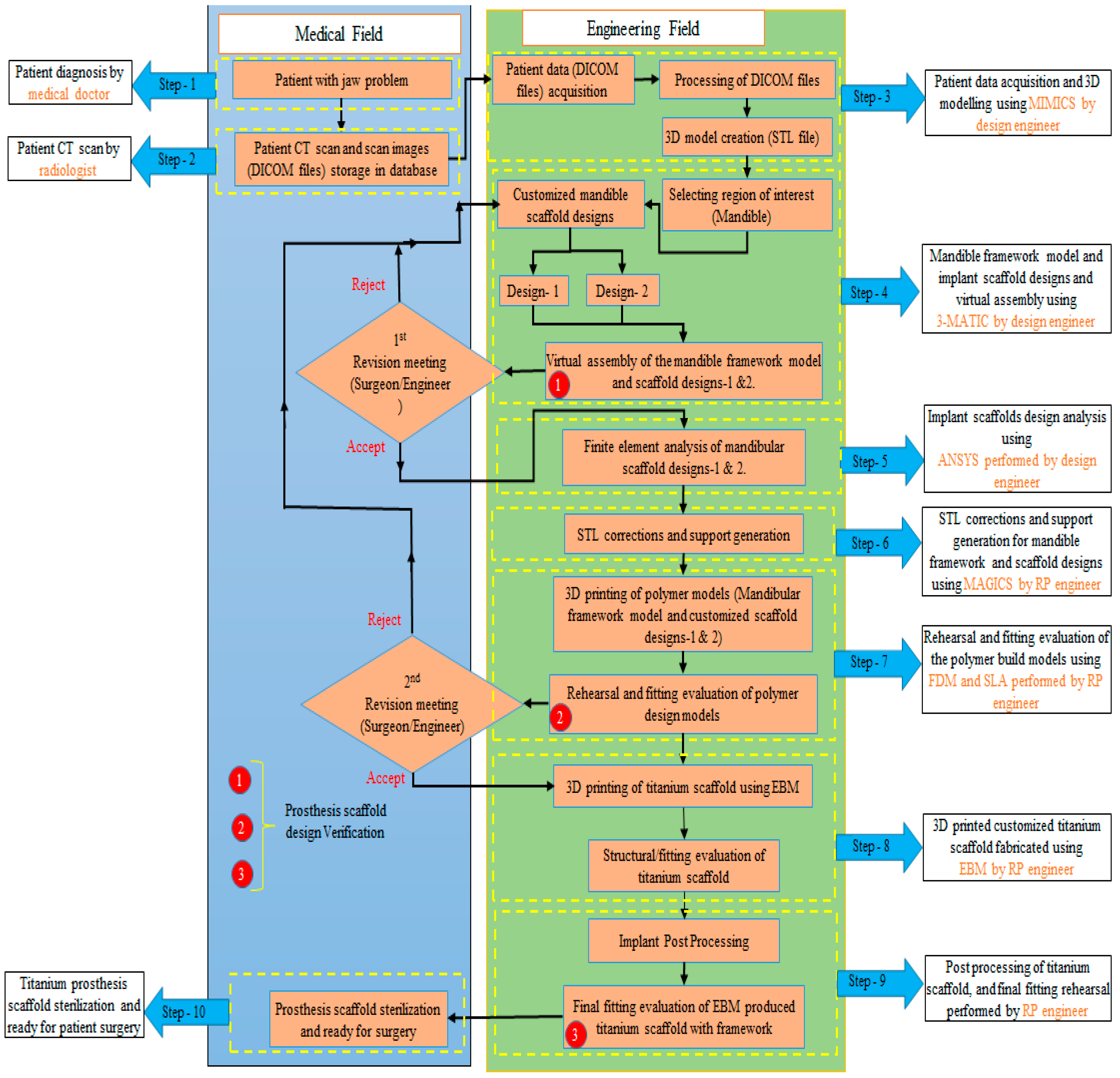

2. Methodology

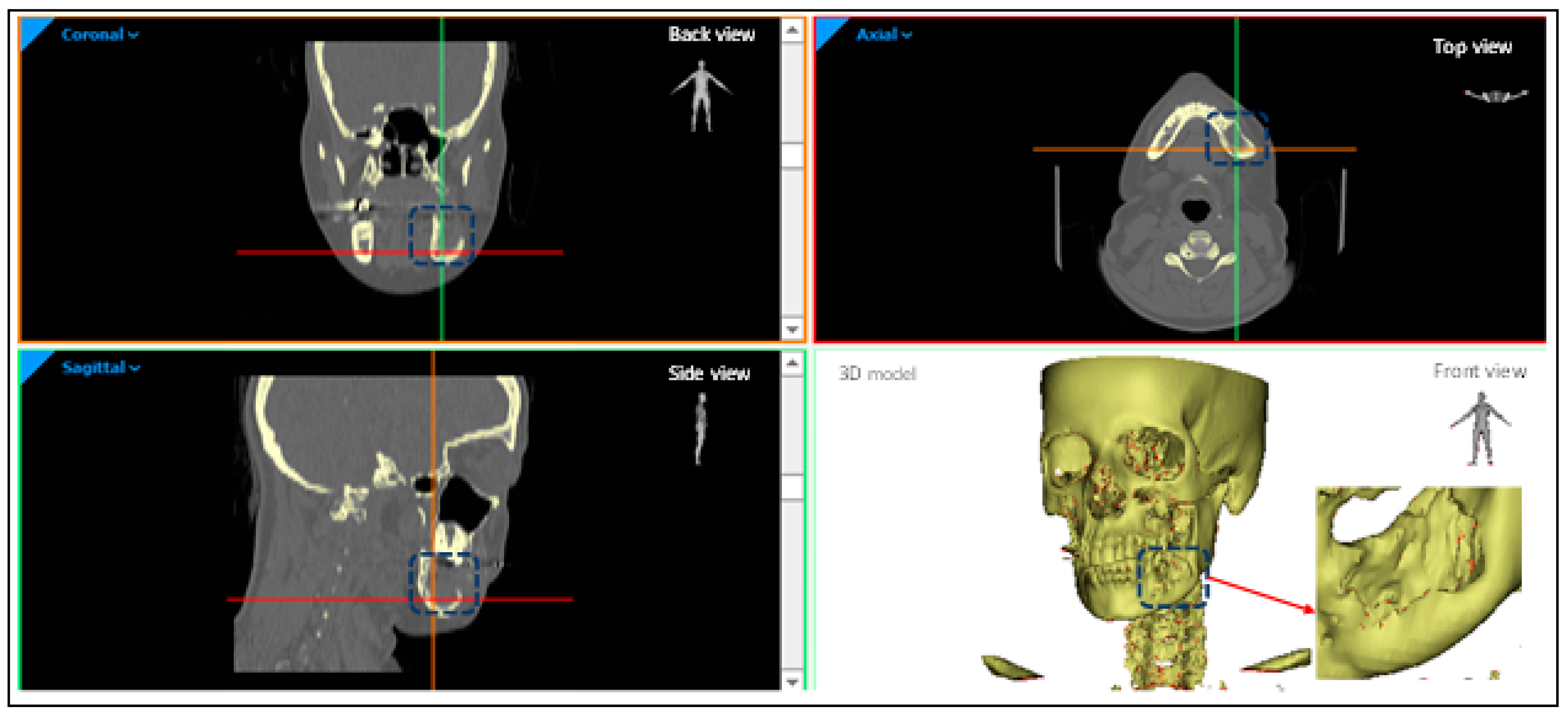

2.1. Data Acquisition

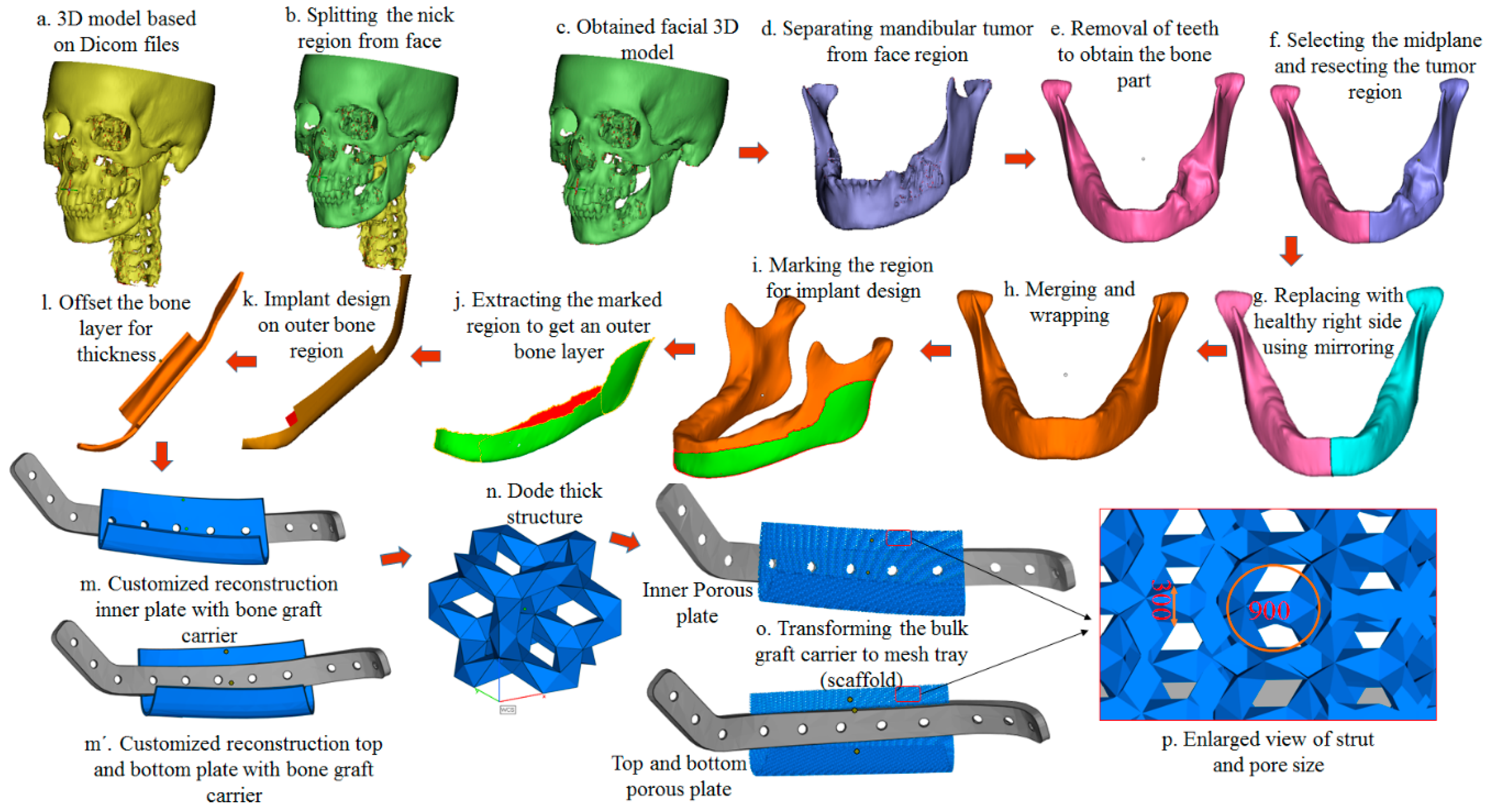

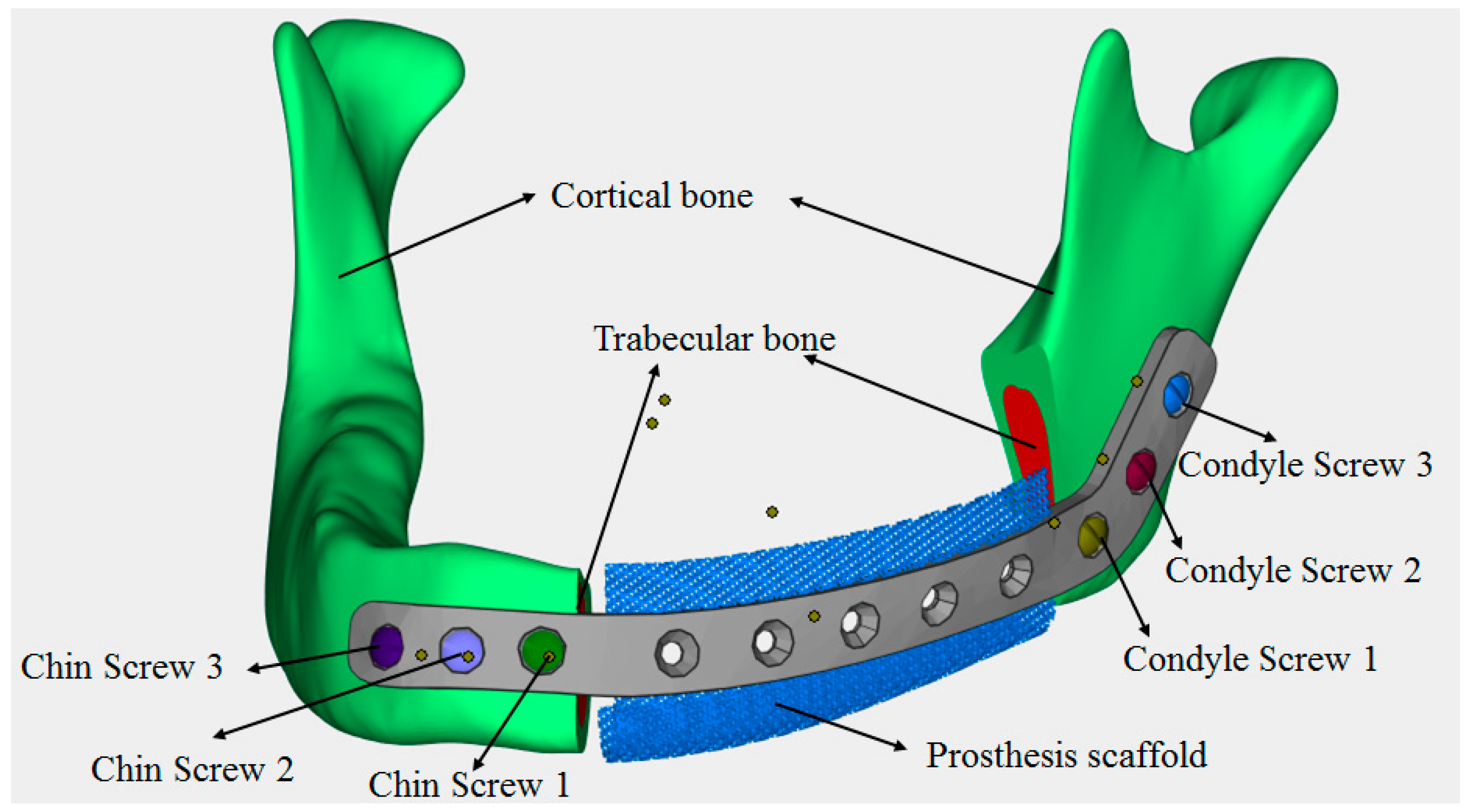

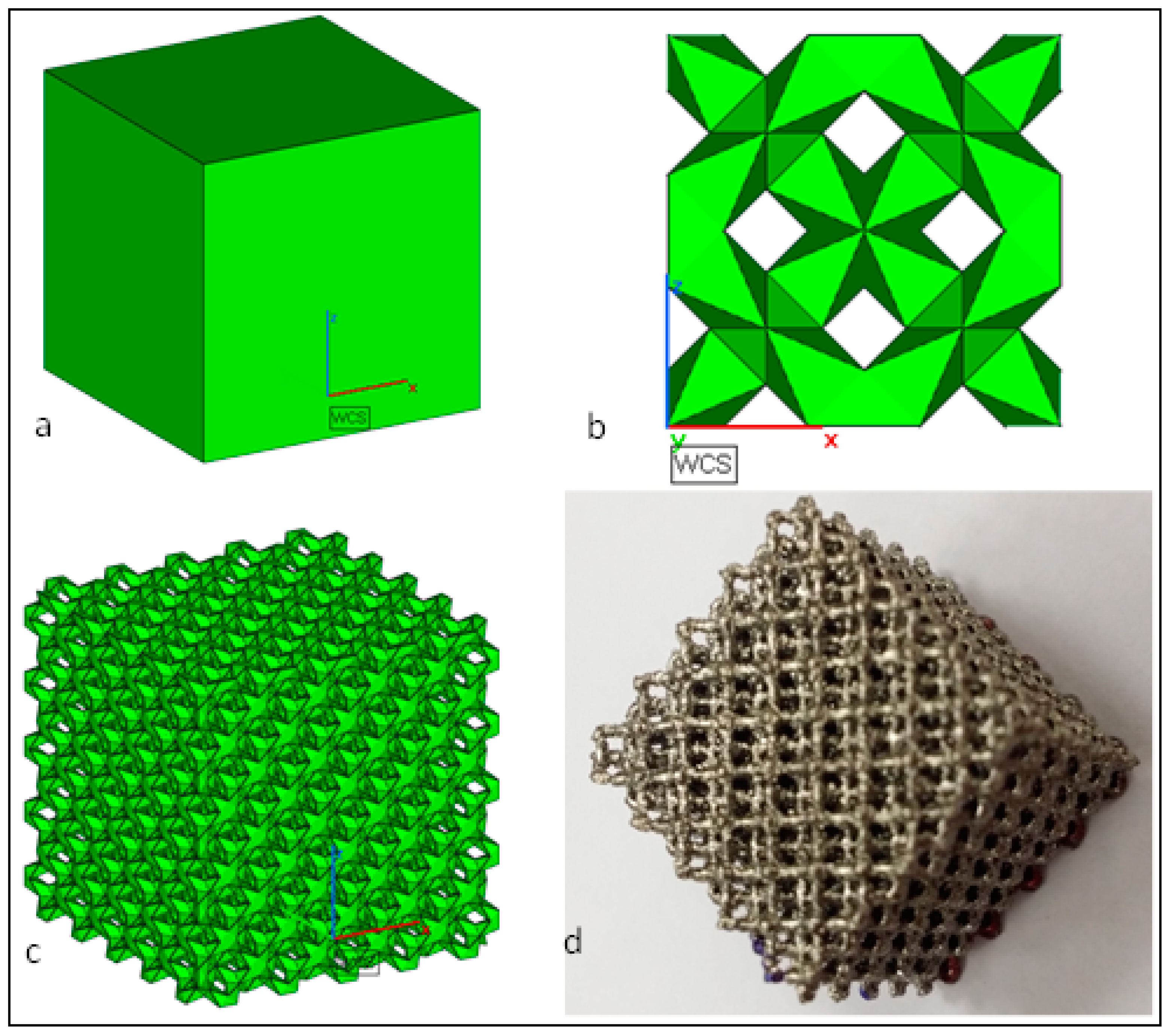

2.2. Customized Implant Design and Modeling

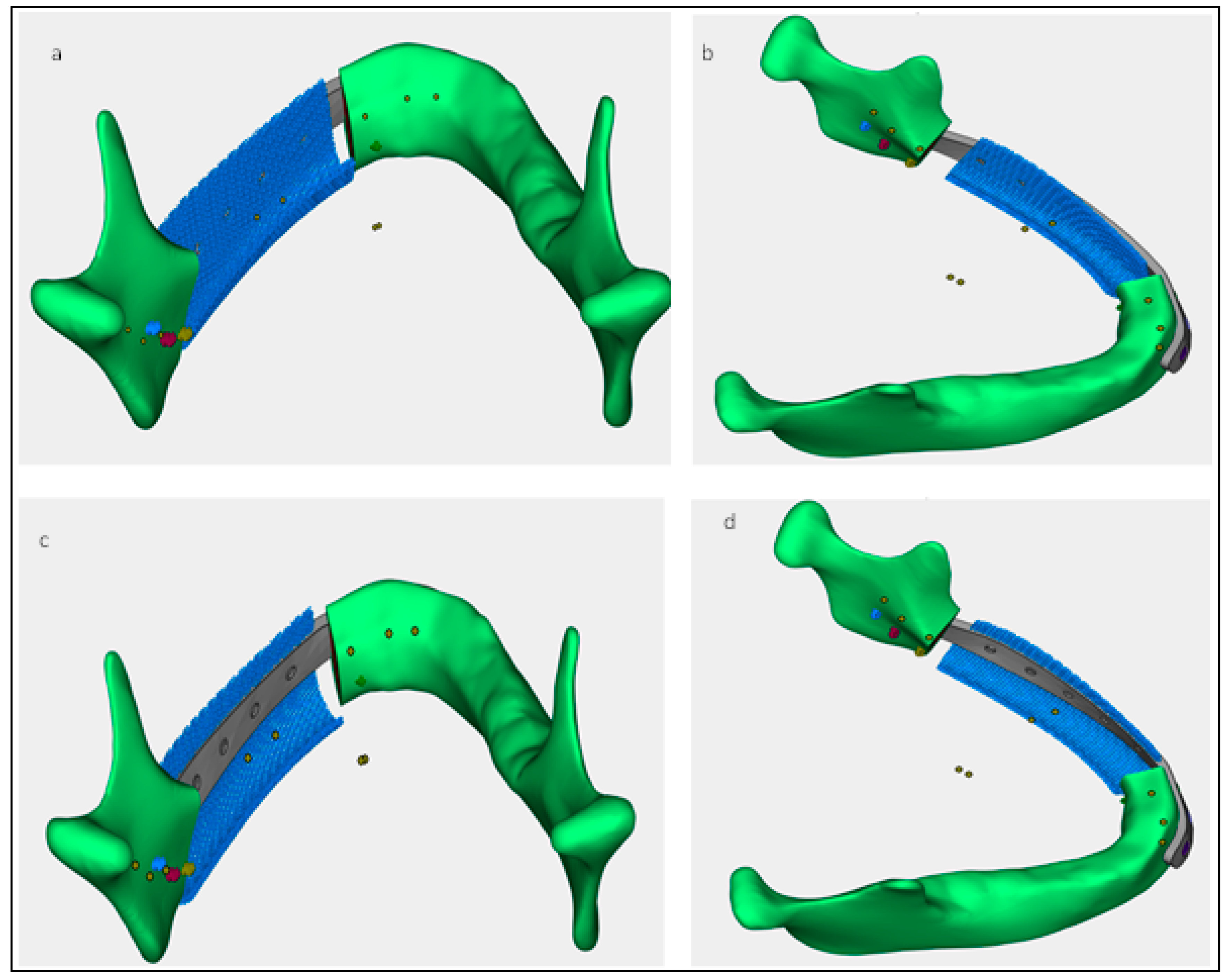

2.3. Virtual Assembly

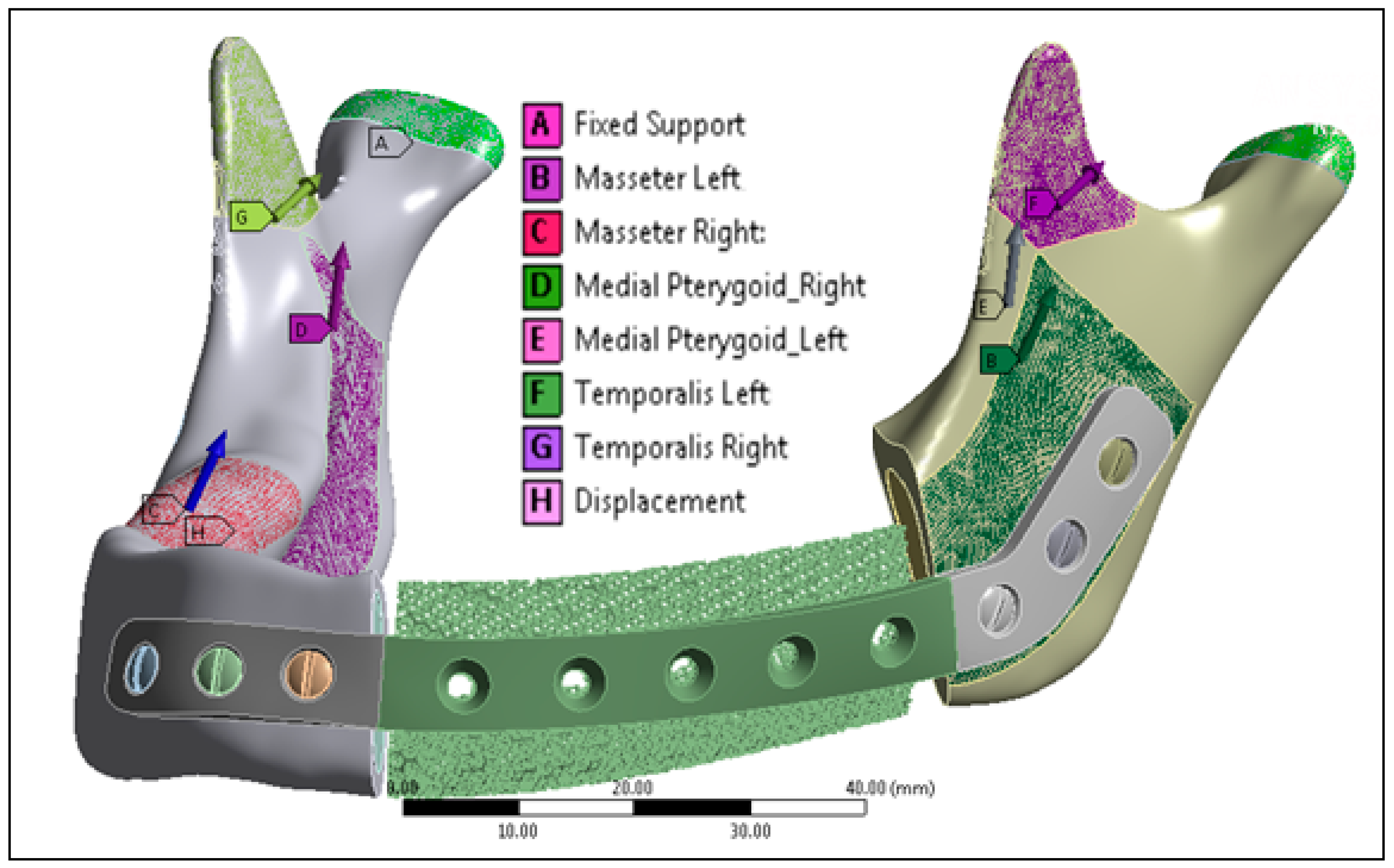

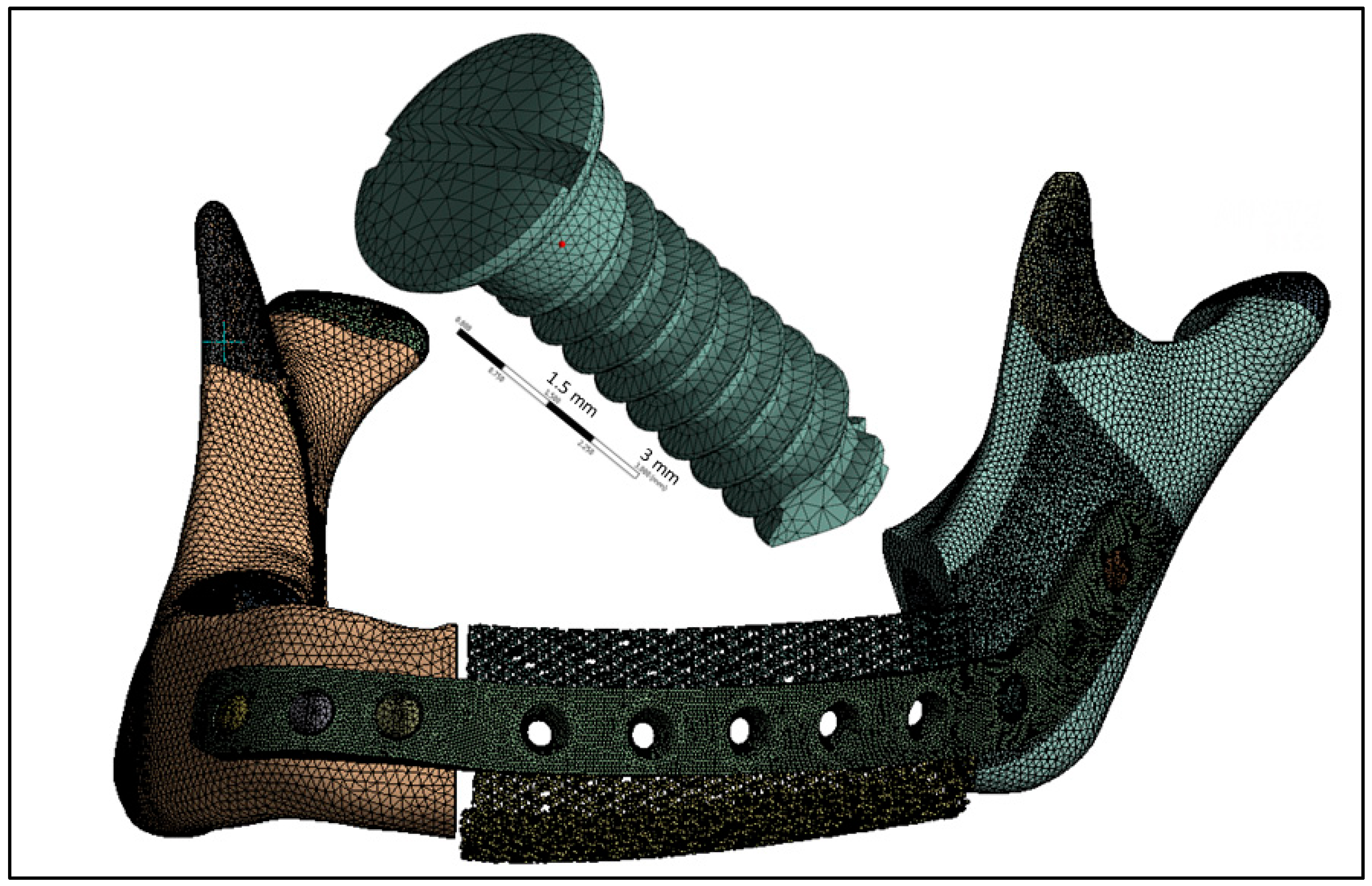

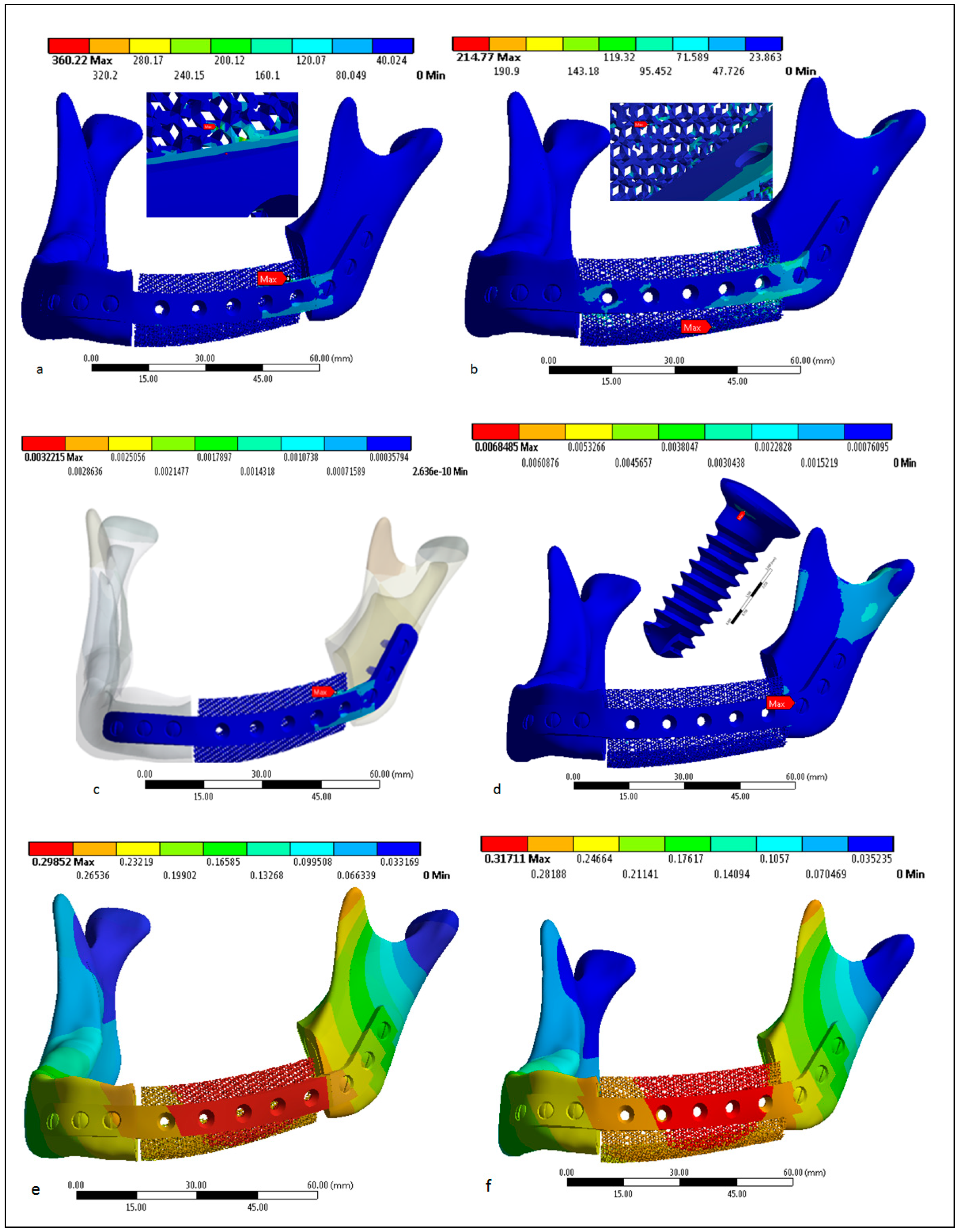

2.4. Finite Element Analysis

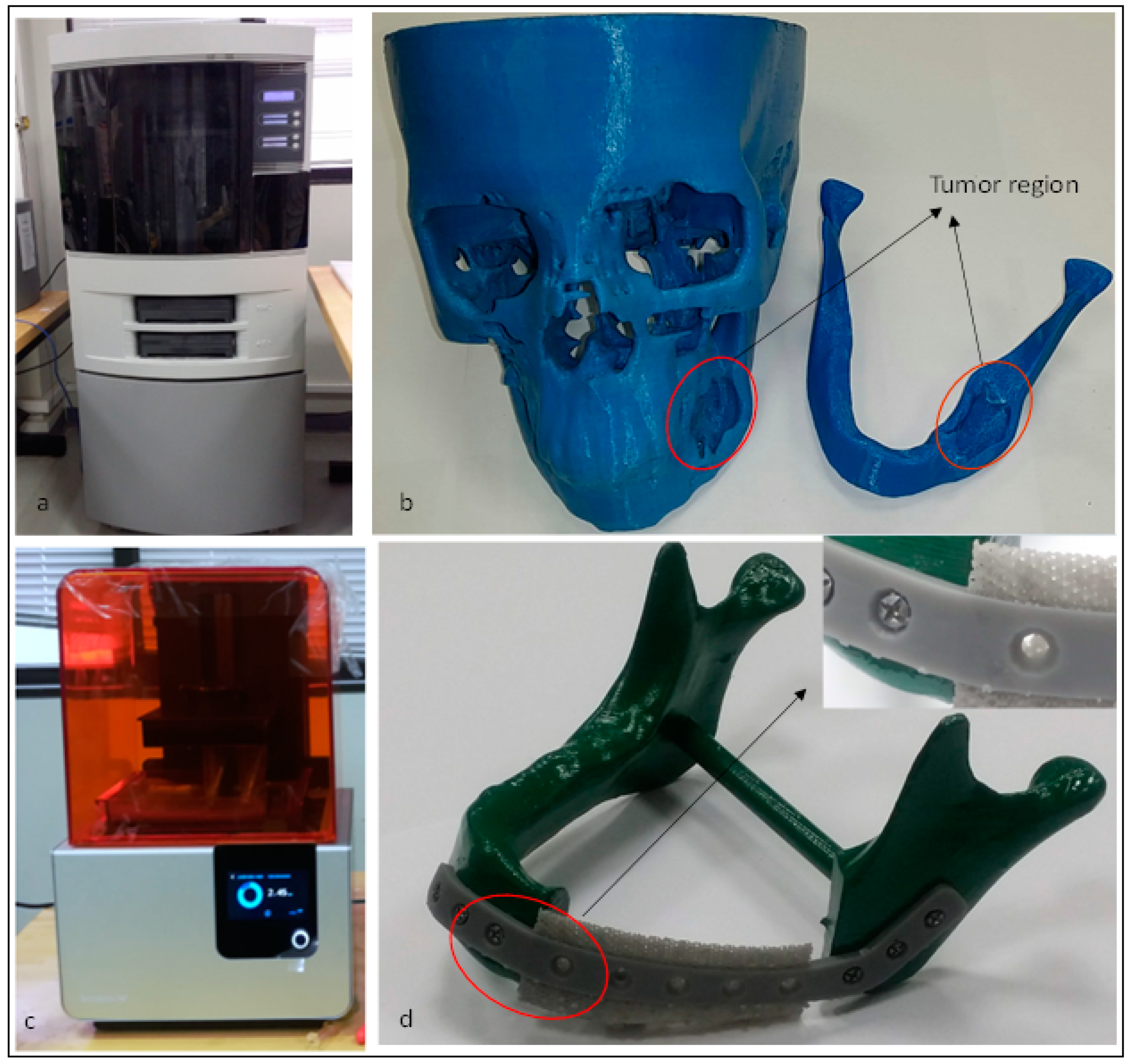

2.5. Fabrication

2.5.1. Polymer Fabrication

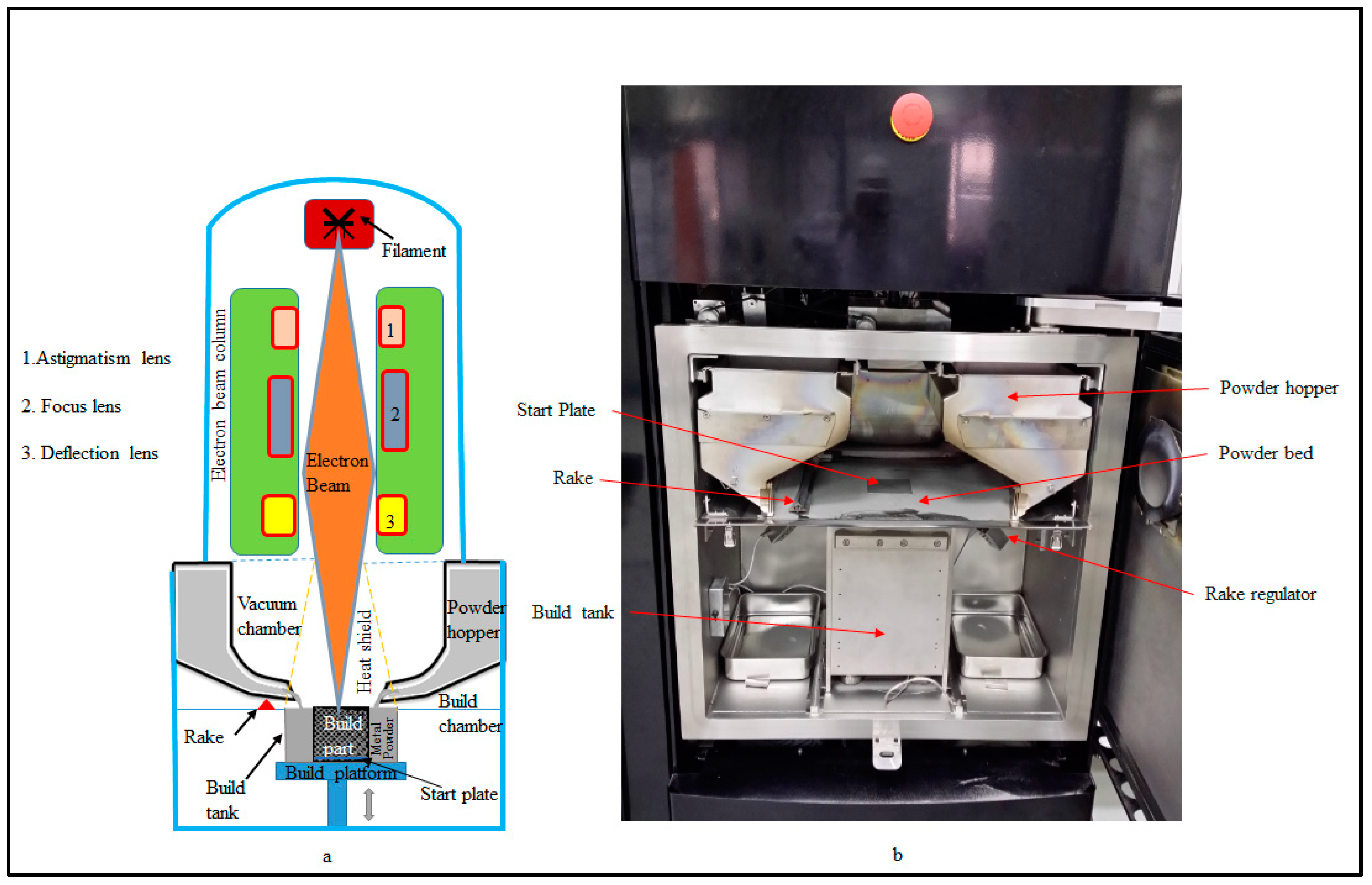

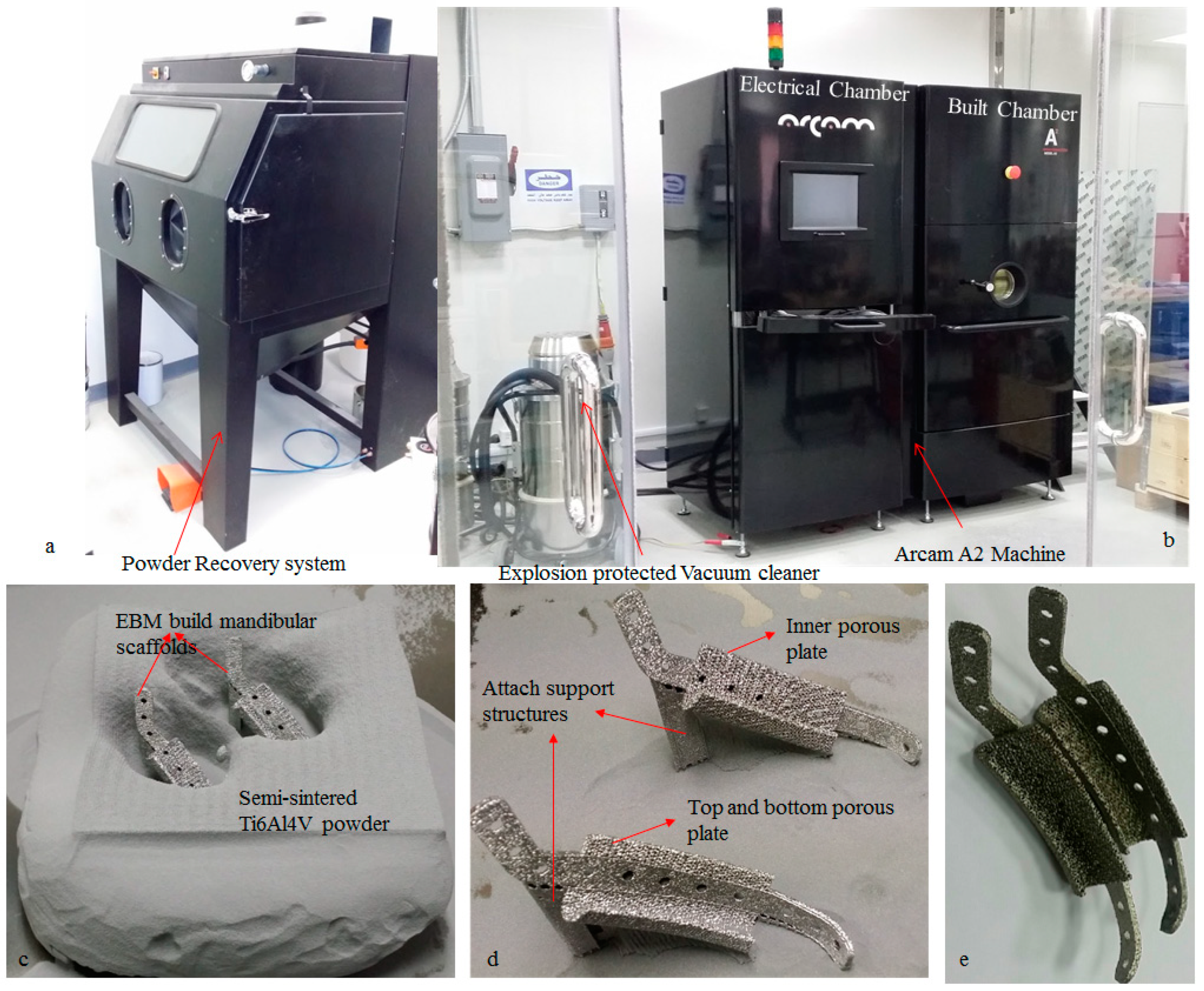

2.5.2. Titanium Fabrication

- (1).

- Preheating the metal powder: The Ti6Al4V ELI metal powder spread on the powder bed is preheated by multiple beams of electron at high scan speed and low beam current to reduce the internal residual stresses.

- (2).

- Scanning and melting: The high velocity beam of electrons scans the metal powder and melts the power in line as per the defined CAD geometry. The melting process consist of two steps, melting the contours (outer and inner boundary) and infill hatching. The majority of the melting takes place in hatching where the beam current and scan speed are increased.

- (3).

- Lowering build table and raking of powder: The build table is lowered after each melt layer cycle (50 μm) and a new layer of powder is fed from hoppers and spread evenly on the previously solidified powder layer using rakes. This process continues till the final 3D part is built.

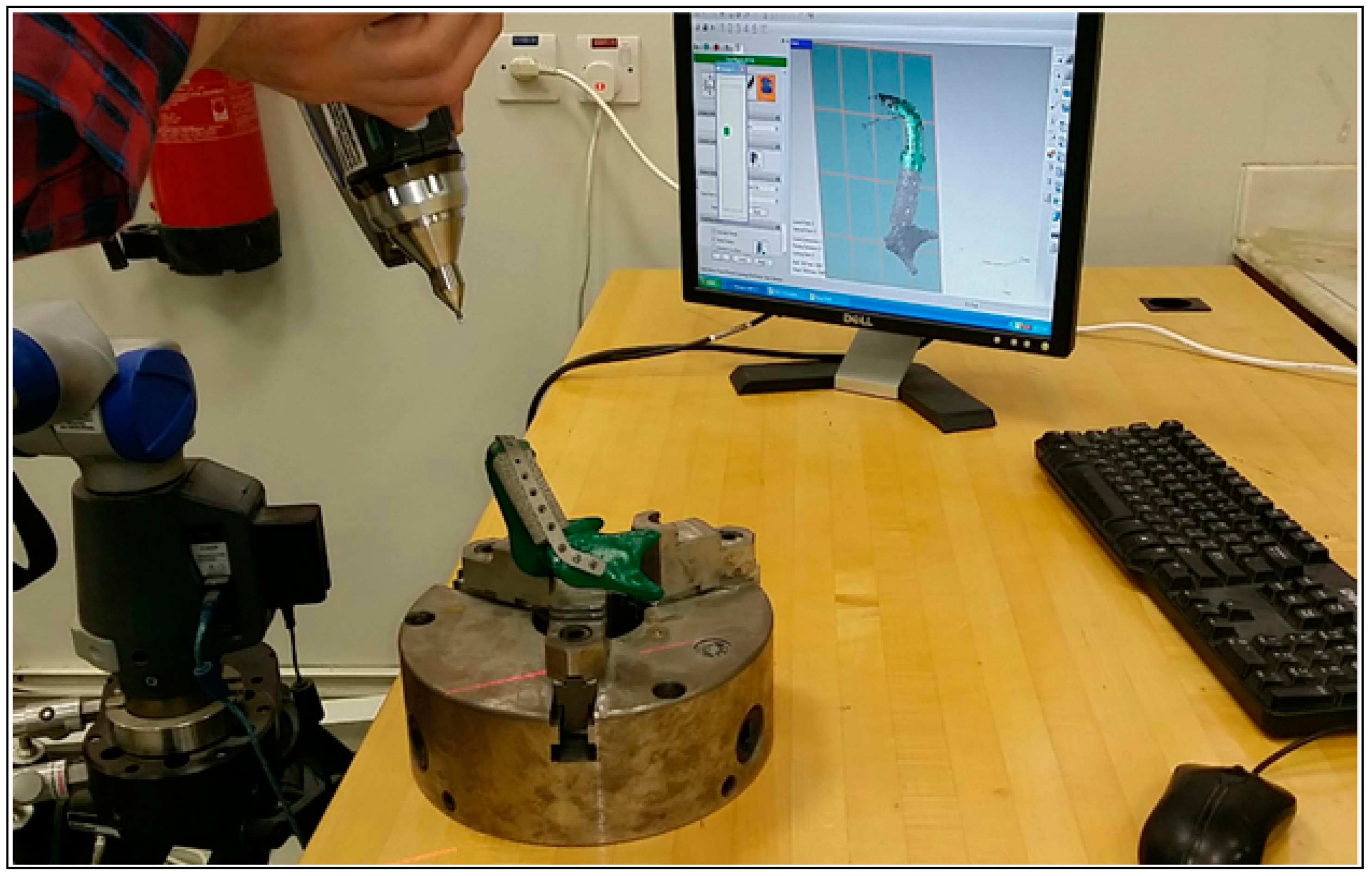

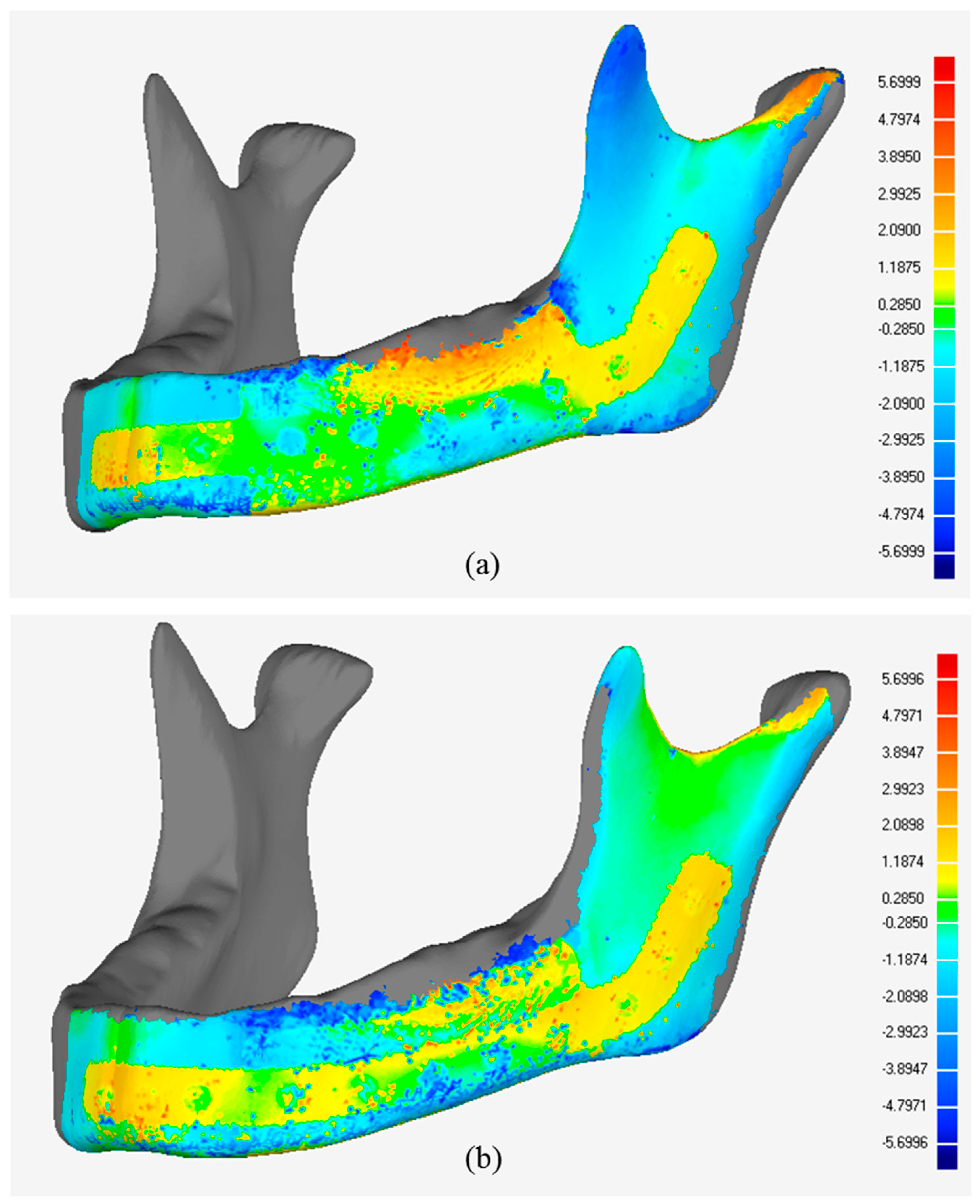

2.6. Evaluation and Validation

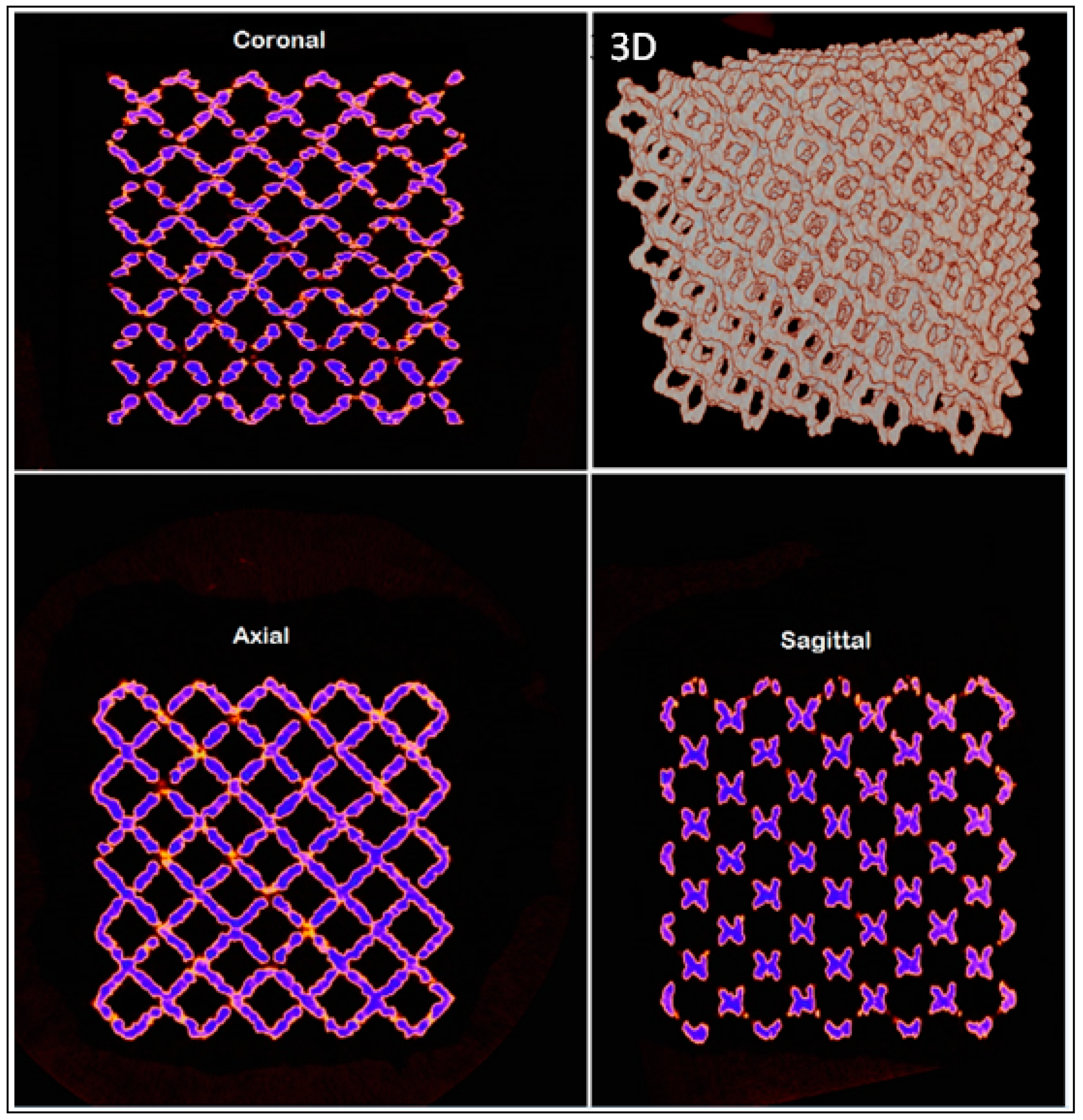

2.6.1. Micro-CT Scan on Titanium Lattice Structure

2.6.2. 3D Comparison

2.6.3. Weights of the Scaffold Designs

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wong, R.C.W.; Tideman, H.; Kin, L.; Merkx, M.A.W. Biomechanics of mandibular reconstruction: a review. Int. J. Oral Maxillofac. Surg. 2010, 39, 313–319. [Google Scholar] [CrossRef]

- Yan, R.; Luo, D.; Huang, H.; Li, R.; Yu, N.; Liu, C.; Hu, M.; Rong, Q. Electron beam melting in the fabrication of three-dimensional mesh titanium mandibular prosthesis scaffold. Sci. Rep. 2018, 8, 750. [Google Scholar] [CrossRef]

- Miles, B.A.; Goldstein, D.P.; Gilbert, R.W.; Gullane, P.J. Mandible reconstruction. Curr. Opin. Otolaryngol. Head Neck Surg. 2010, 18, 317–322. [Google Scholar]

- Hayden, R.E.; Mullin, D.P.; Patel, A.K. Reconstruction of the segmental mandibular defect: current state of the art. Curr. Opin. Otolaryngol. Head Neck Surg. 2012, 20, 231–236. [Google Scholar] [CrossRef]

- Von Cramon-Taubadel, N. Global human mandibular variation reflects differences in agricultural and hunter-gatherer subsistence strategies. Proc. Natl. Acad. Sci. USA 2011, 108, 19546–19551. [Google Scholar] [CrossRef]

- Yuan, J.; Cui, L.; Zhang, W.J.; Liu, W.; Cao, Y. Repair of canine mandibular bone defects with bone marrow stromal cells and porous β-tricalcium phosphate. Biomaterials 2007, 28, 1005–1013. [Google Scholar] [CrossRef] [PubMed]

- Moiduddin, K. Implementation of Computer-Assisted Design, Analysis, and Additive Manufactured Customized Mandibular Implants. J. Med. Biol. Eng. 2018, 38, 744–756. [Google Scholar] [CrossRef]

- Chanchareonsook, N.; Junker, R.; Jongpaiboonkit, L.; Jansen, J.A. Tissue-engineered mandibular bone reconstruction for continuity defects: A systematic approach to the literature. Tissue Eng. Part B Rev. 2014, 20, 147–162. [Google Scholar] [CrossRef] [PubMed]

- Ryan, G.; Pandit, A.; Apatsidis, D. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 2006, 27, 2651–2670. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Moiduddin, K.; Al-Ahmari, A.; Kindi, M.A.; Nasr, E.S.A.; Mohammad, A.; Ramalingam, S. Customized porous implants by additive manufacturing for zygomatic reconstruction. Biocybern. Biomed. Eng. 2016, 36, 719–730. [Google Scholar] [CrossRef]

- Pei, X.; Zhang, B.; Fan, Y.; Zhu, X.; Sun, Y.; Wang, Q.; Zhang, X.; Zhou, C. Bionic mechanical design of titanium bone tissue implants and 3D printing manufacture. Mater. Lett. 2017, 208, 133–137. [Google Scholar] [CrossRef]

- Raghavendra, S.; Wood, M.C.; Taylor, T.D. Early wound healing around endosseous implants: a review of the literature. Int. J. Oral Maxillofac. Implant. 2005, 20, 425–431. [Google Scholar]

- Singare, S.; Lian, Q.; Wang, W.P.; Wang, J.; Liu, Y.; Li, D.; Lu, B. Rapid prototyping assisted surgery planning and custom implant design. Rapid Prototyp. J. 2009, 15, 19–23. [Google Scholar] [CrossRef]

- Emadabouel, N.; Abdulrahman, A.-A.; Khaja, M.; Al Kindi, M.; Kamrani, A. A digital design methodology for surgical planning and fabrication of customized mandible implants. Rapid Prototyp. J. 2016, 23, 101–109. [Google Scholar]

- Chua, C.K.; Wong, C.H.; Yeong, W.Y. Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing; Academic Press: London, UK, 2017. [Google Scholar]

- Electron Beam Melting—EBM Process, Additive Manufacturing. Available online: http://www.arcam.com/technology/electron-beam-melting/ (accessed on 7 July 2017).

- Moiduddin, K.; Darwish, S.; Al-Ahmari, A.; El Watidy, S.; Mohammad, A.; Ameen, W. Structural and mechanical characterization of custom design cranial implant created using additive manufacturing. Electron. J. Biotechnol. 2017, 29, 22–31. [Google Scholar] [CrossRef]

- Moiduddin, K.; Anwar, S.; Ahmed, N.; Ashfaq, M.; Al-Ahmari, A. Computer assisted design and analysis of customized porous plate for mandibular reconstruction. IRBM 2017, 38, 78–89. [Google Scholar] [CrossRef]

- Narra, N.; Valášek, J.; Hannula, M.; Marcián, P.; Sándor, G.K.; Hyttinen, J.; Wolff, J. Finite element analysis of customized reconstruction plates for mandibular continuity defect therapy. J. Biomech. 2014, 47, 264–268. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, Y.; Jiang, X.; Baur, D.A. A customized fixation plate with novel structure designed by topological optimization for mandibular angle fracture based on finite element analysis. Biomed. Eng. Online 2017, 16, 131. [Google Scholar] [CrossRef]

- Planmeca ProMax 3D Max—Dental Imaging to the Max. Available online: https://www.planmeca.com/imaging/3d-imaging/planmeca-promax-3d-max/ (accessed on 09 April 2019).

- Arango-Ospina, M.; Cortés-Rodriguez, C.J. Engineering design and manufacturing of custom craniofacial implants. In The 15th International Conference on Biomedical Engineering; Goh, J., Ed.; Springer International Publishing: Basel, Switzerland, 2014; pp. 908–911. [Google Scholar]

- Zhou, L.; Shang, H.; He, L.; Bo, B.; Liu, G.; Liu, Y.; Zhao, J. Accurate Reconstruction of Discontinuous Mandible Using a Reverse Engineering/Computer-Aided Design/Rapid Prototyping Technique: A Preliminary Clinical Study. J. Oral Maxillofac. Surg. 2010, 68, 2115–2121. [Google Scholar] [CrossRef]

- Van Bael, S.; Chai, Y.C.; Truscello, S.; Moesen, M.; Kerckhofs, G.; Van Oosterwyck, H.; Kruth, J.-P.; Schrooten, J. The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds. Acta Biomater. 2012, 8, 2824–2834. [Google Scholar] [CrossRef] [PubMed]

- Ran, Q.; Yang, W.; Hu, Y.; Shen, X.; Yu, Y.; Xiang, Y.; Cai, K. Osteogenesis of 3D printed porous Ti6Al4V implants with different pore sizes. J. Mech. Behav. Biomed. Mater. 2018, 84, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Schaller, A.; Voigt, C.; Huempfner-Hierl, H.; Hemprich, A.; Hierl, T. Transient finite element analysis of a traumatic fracture of the zygomatic bone caused by a head collision. Int. J. Oral Maxillofac. Surg. 2012, 41, 66–73. [Google Scholar] [CrossRef]

- El-Anwar, M.I.; Mohammed, M.S. Comparison between two low profile attachments for implant mandibular overdentures. J. Genet. Eng. Biotechnol. 2014, 12, 45–53. [Google Scholar] [CrossRef]

- Ti6Al4V ELI Titanium Alloy. 2014. Available online: http://www.arcam.com/wp-content/uploads/Arcam-Ti6Al4V-ELI-Titanium-Alloy.pdf (accessed on 27 January 2019).

- Szucs, A.; Bujtár, P.; Sándor, G.K.B.; Barabás, J. Finite element analysis of the human mandible to assess the effect of removing an impacted third molar. J. Can. Dent. Assoc. 2010, 76, a72. [Google Scholar]

- Simonovics, J.; Bujtár, P.; Váradi, K. Effect of preloading on lower jaw implant. Biomech. Hungarica 2013, 6, 21–28. [Google Scholar] [CrossRef]

- What is FDM?: Fused Deposition Modeling Technology for 3D Printing | Stratasys n.d. Available online: https://www.stratasys.com/fdm-technology (accessed on 6 January 2019).

- High Resolution SLA and SLS 3D Printers for Professionals. Formlabs n.d. Available online: https://formlabs.com/ (accessed on 7 February 2019).

- FDM vs SLA: How does 3D Printing Technology Work? |. Pinshape 3D Printing Blog | Tutorials, Contests & Downloads 2017. Available online: https://pinshape.com/blog/fdm-vs-sla-how-does-3d-printer-tech-work/ (accessed on 7 February 2019).

- Kumar, A.; Nune, K.C.; Murr, L.E.; Misra, R.D.K. Biocompatibility and mechanical behaviour of three-dimensional scaffolds for biomedical devices: Process–structure–property paradigm. Int. Mater. Rev. 2016, 61, 20–45. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.A.; Marcellin-Little, D.J.; West, H.A.; Lascelles, B.D.X.; Aman, R. Flexural properties of Ti6Al4V rhombic dodecahedron open cellular structures fabricated with electron beam melting. Addit. Manuf. 2014, 1–4, 2–11. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; Bracke, J. Next-generation biomedical implants using additive manufacturing of complex cellular and functional mesh arrays. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2010, 368, 1999–2032. [Google Scholar] [CrossRef]

- Tang, H.P.; Wang, J.; Song, C.N.; Liu, N.; Jia, L.; Elambasseril, J.; Qian, M. Microstructure, mechanical properties, and flatness of sebm Ti-6Al-4V sheet in as-built and hot isostatically pressed conditions. JOM 2017, 69, 466–471. [Google Scholar] [CrossRef]

- Wang, M.; Li, H.Q.; Lou, D.J.; Qin, C.X.; Jiang, J.; Fang, X.Y.; Guo, Y.B. Microstructure anisotropy and its implication in mechanical properties of biomedical titanium alloy processed by electron beam melting. Mater. Sci. Eng. A 2019, 743, 123–137. [Google Scholar] [CrossRef]

- Balza, J.C.; Zujur, D.; Gil, L.; Subero, R.; Dominguez, E.; Delvasto, P.; Alvarez, J. Sandblasting as a surface modification technique on titanium alloys for biomedical applications: abrasive particle behavior. IOP Conf. Ser. Mater. Sci. Eng. 2013, 45, 012004. [Google Scholar] [CrossRef]

- Geomagic Control X. 3D Systems n.d. Available online: https://www.3dsystems.com/software/geomagic-control-x (accessed on 10 February 2019).

- Hammad Mian, S.; Abdul Mannan, M.; M. Al-Ahmari, A. The influence of surface topology on the quality of the point cloud data acquired with laser line scanning probe. Sens. Rev. 2014, 34, 255–265. [Google Scholar] [CrossRef]

- Ridtzwan, M.I.; Solehuddin, S.; Hassan, A.Y.; Shokri, A.A.; Mohamad Ibrahim, M.N. Problem of Stress Shielding and Improvement to the Hip Implant Designs: A Review. J. Med. Sci. 2007, 7, 460–467. [Google Scholar]

- Soh, C.-K.; Yang, Y.; Bhalla, S. (Eds.) Smart Materials in Structural Health Monitoring, Control and Biomechanics; Springer-Verlag: Berlin, Germany, 2012. [Google Scholar]

- Basciftci, F.A.; Korkmaz, H.H.; Üşümez, S.; Eraslan, O. Biomechanical evaluation of chincup treatment with various force vectors. Am. J. Orthod. Dentofac. Orthop. 2008, 134, 773–781. [Google Scholar] [CrossRef] [PubMed]

| Materials | Young’s Modulus (MPa) | Poisson’s Ratio | Yield Strength (MPa) |

|---|---|---|---|

| Compact Bone | 13,700 | 0.3 | 122 |

| Trabecular Bone | 1370 | 0.3 | 2 |

| Prosthesis scaffold, (Ti6Al4V ELI) | 120,000 | 0.3 | 930 |

| Masticatory Muscles | X (N) | Y (N) | Z (N) |

|---|---|---|---|

| Masseter | 50 | −50 | 200 |

| Medial pterygoid | 0 | −50 | 100 |

| Temporalis | 0 | 100 | 200 |

| FEA Outcomes | Stress on Chin Screw (MPa) | Stress on Condyl Screw (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Screw Numbers | |||||||||

| Designed Implant | Max Von Mises Stress (MPa) | Max Strain | Deformation | 1 | 2 | 3 | 1 | 2 | 3 |

| Inner porous plate | 360.22 | 0.0032 | 0.29852 | 55.85 | 38.26 | 50.52 | 122.9 | 121.74 | 81.5 |

| Top & bottom porous plate | 214.77 | 0.0068 | 0.31711 | 61.85 | 39.76 | 53.61 | 127.71 | 125.07 | 84.44 |

| Parts | Replaced Bone | Inner Porous | Top and Bottom Porous |

|---|---|---|---|

| Volume (mm3) | 11879.00 | 2016.00 | 1847.00 |

| Weight (g) | 19.00 | 10.67 | 8.14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moiduddin, K.; Mian, S.H.; Alkhalefah, H.; Umer, U. Digital Design, Analysis and 3D Printing of Prosthesis Scaffolds for Mandibular Reconstruction. Metals 2019, 9, 569. https://doi.org/10.3390/met9050569

Moiduddin K, Mian SH, Alkhalefah H, Umer U. Digital Design, Analysis and 3D Printing of Prosthesis Scaffolds for Mandibular Reconstruction. Metals. 2019; 9(5):569. https://doi.org/10.3390/met9050569

Chicago/Turabian StyleMoiduddin, Khaja, Syed Hammad Mian, Hisham Alkhalefah, and Usama Umer. 2019. "Digital Design, Analysis and 3D Printing of Prosthesis Scaffolds for Mandibular Reconstruction" Metals 9, no. 5: 569. https://doi.org/10.3390/met9050569

APA StyleMoiduddin, K., Mian, S. H., Alkhalefah, H., & Umer, U. (2019). Digital Design, Analysis and 3D Printing of Prosthesis Scaffolds for Mandibular Reconstruction. Metals, 9(5), 569. https://doi.org/10.3390/met9050569