On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions

Abstract

:1. Introduction

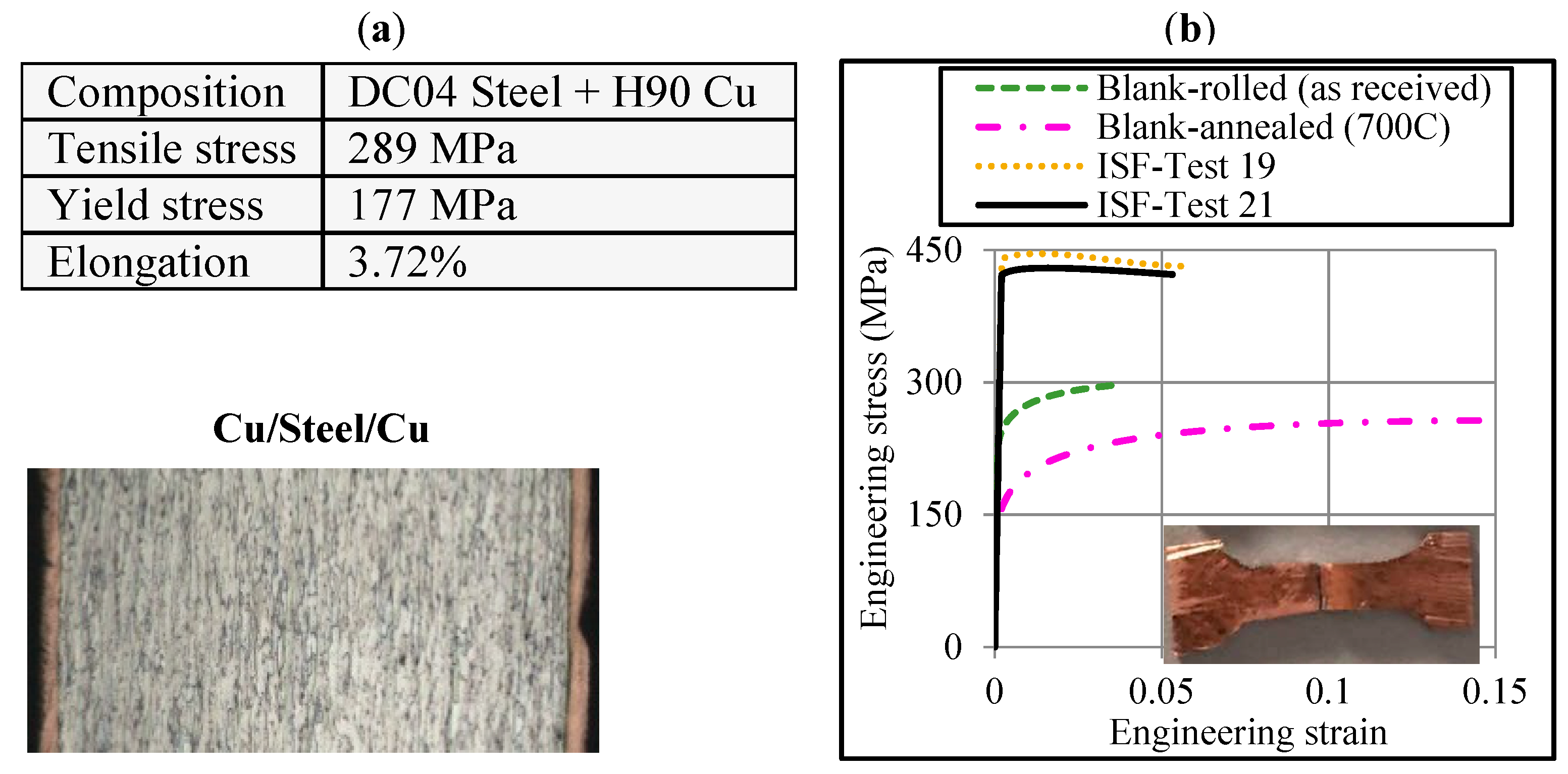

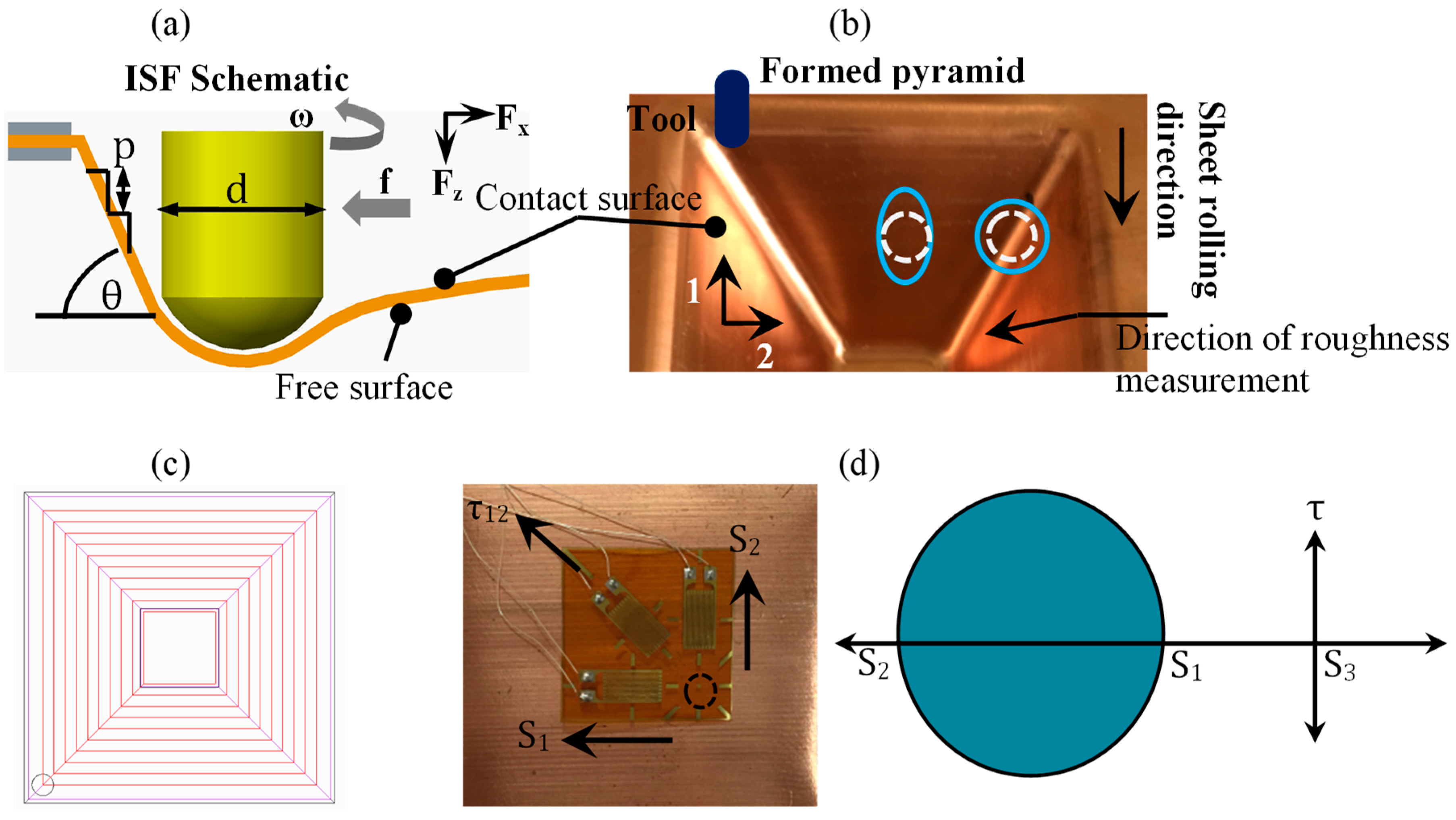

2. Experimental Methodology

2.1. Experiments

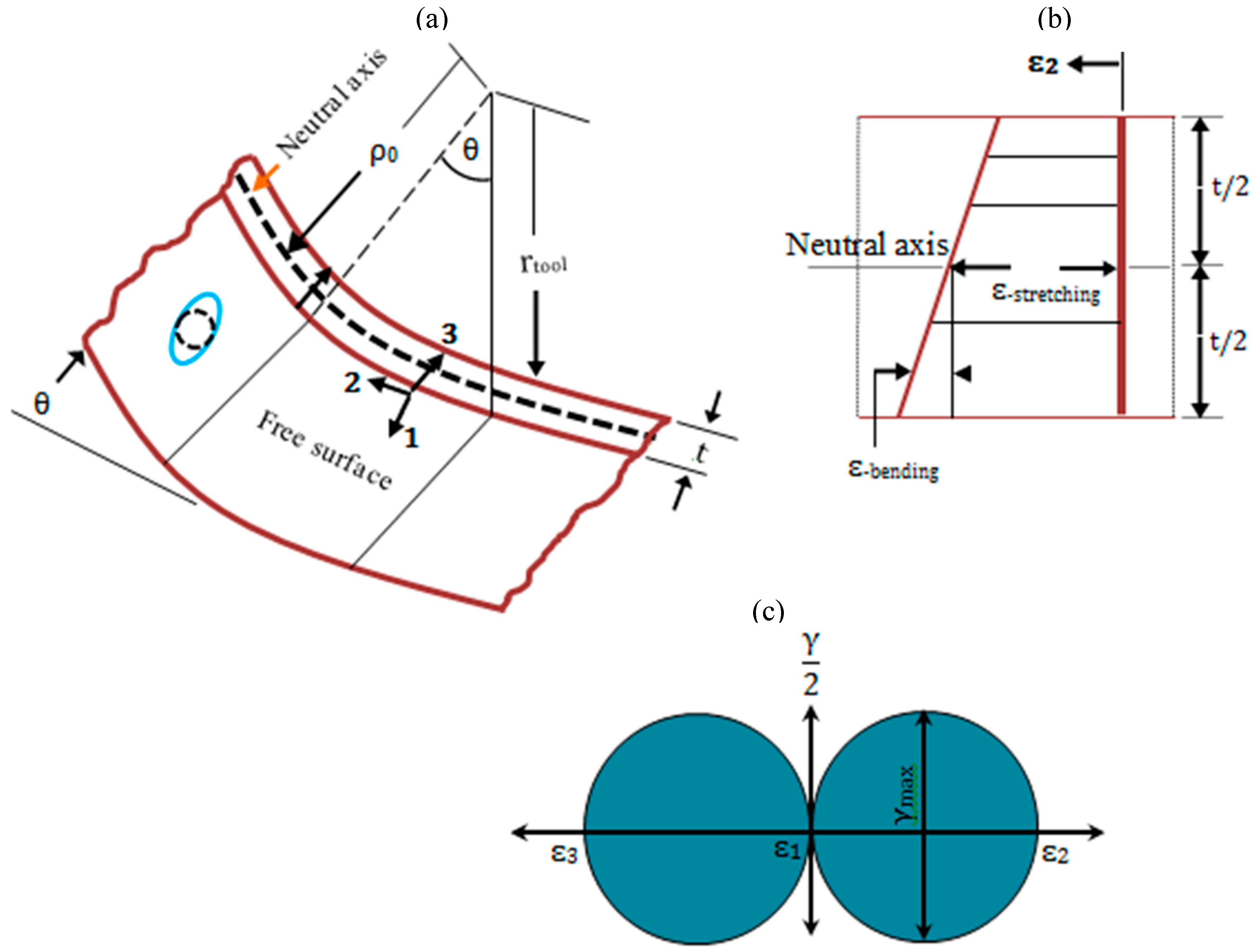

2.2. Strain Measurement

- ɛ2 is the principal surface strain in longitudinal direction;

- ɛ3 is the principal thickness strain;

- is the curvature radius of neutral surface;

- is the arbitrary curvature radius of section ranging from rtool to (rtool + t);

- to is the thickness of unformed sheet;

- t is the thickness of formed sheet.

3. Results

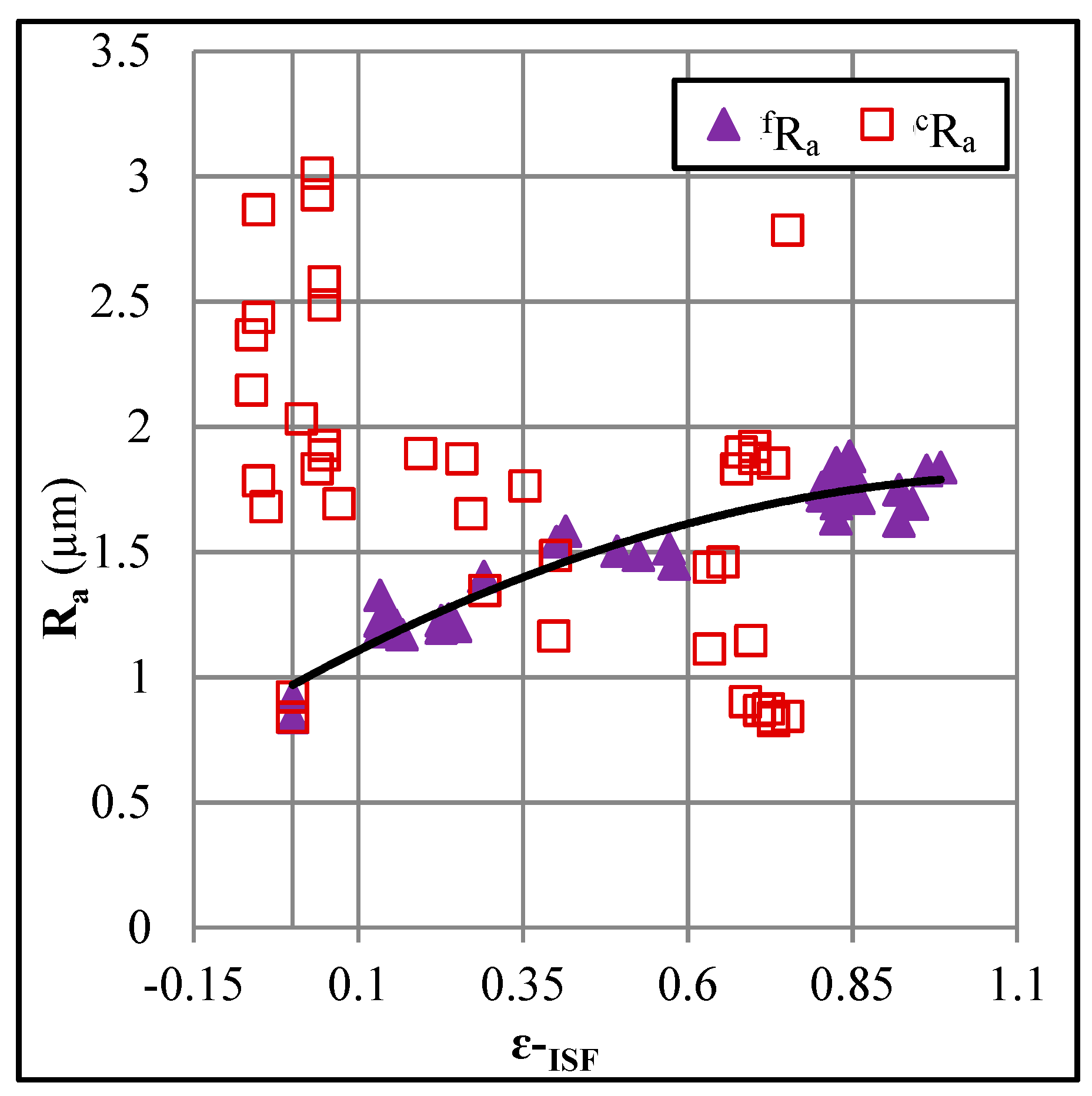

3.1. Influence of ISF Strain on Free-Surface Roughness

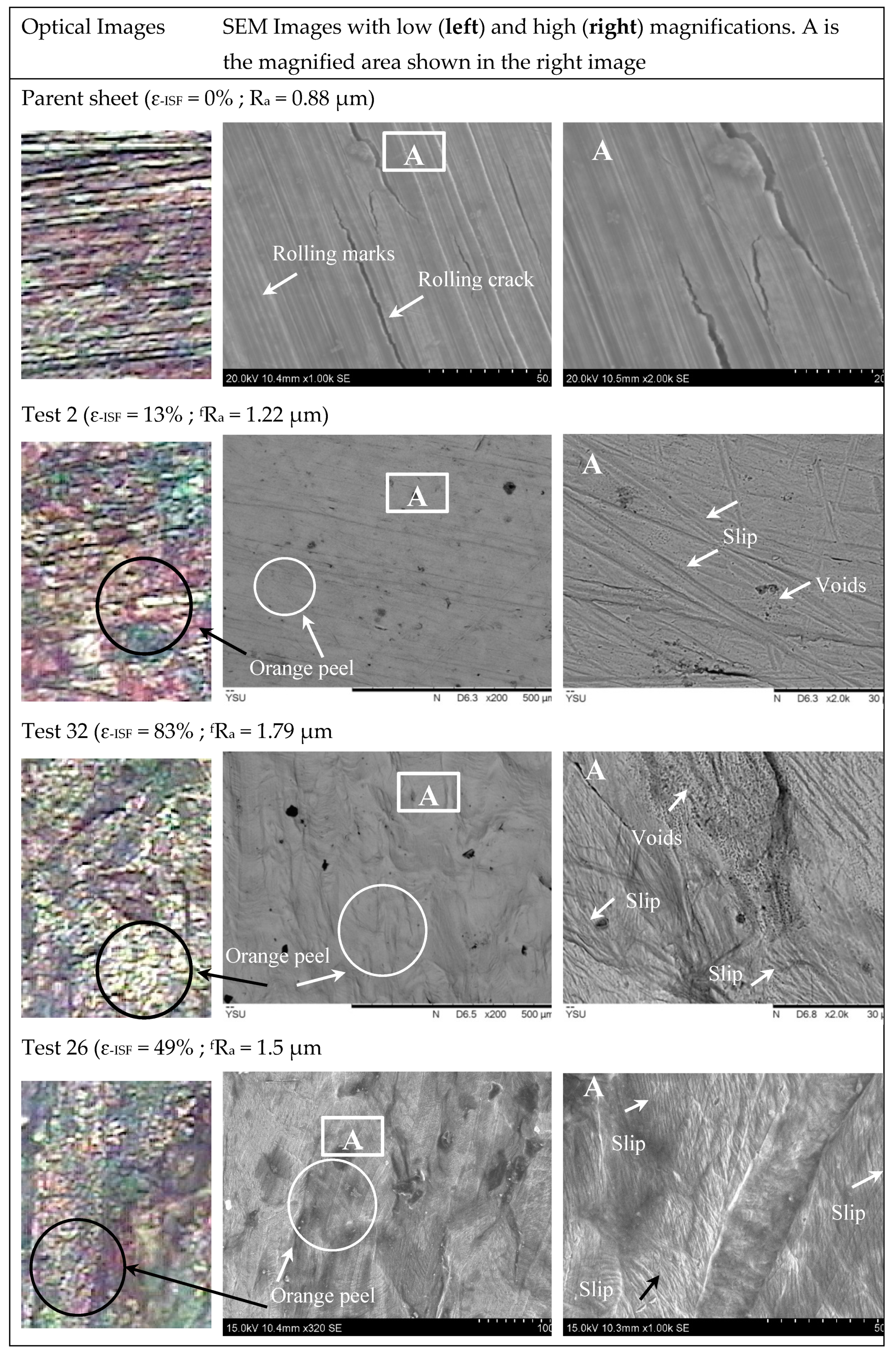

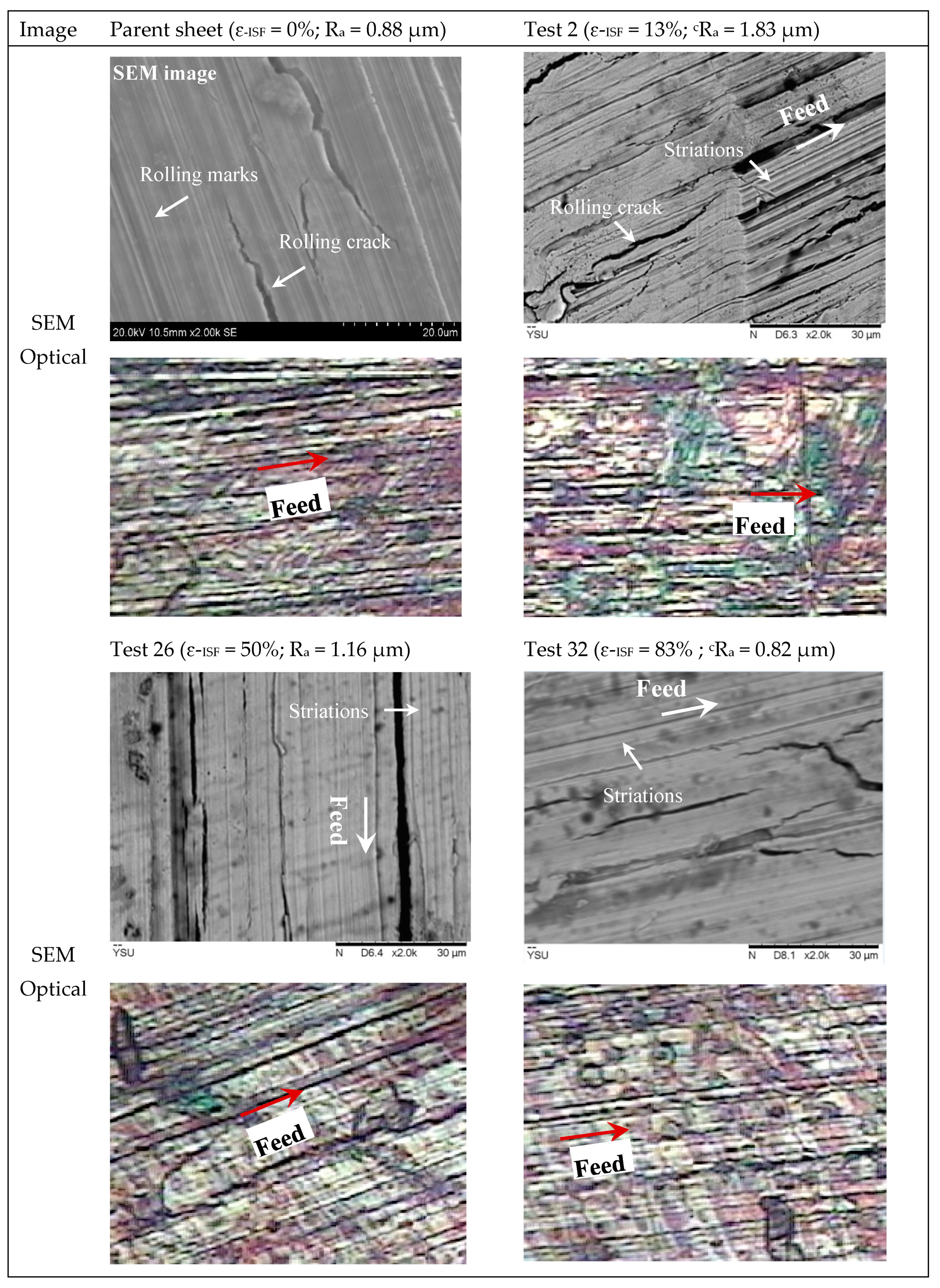

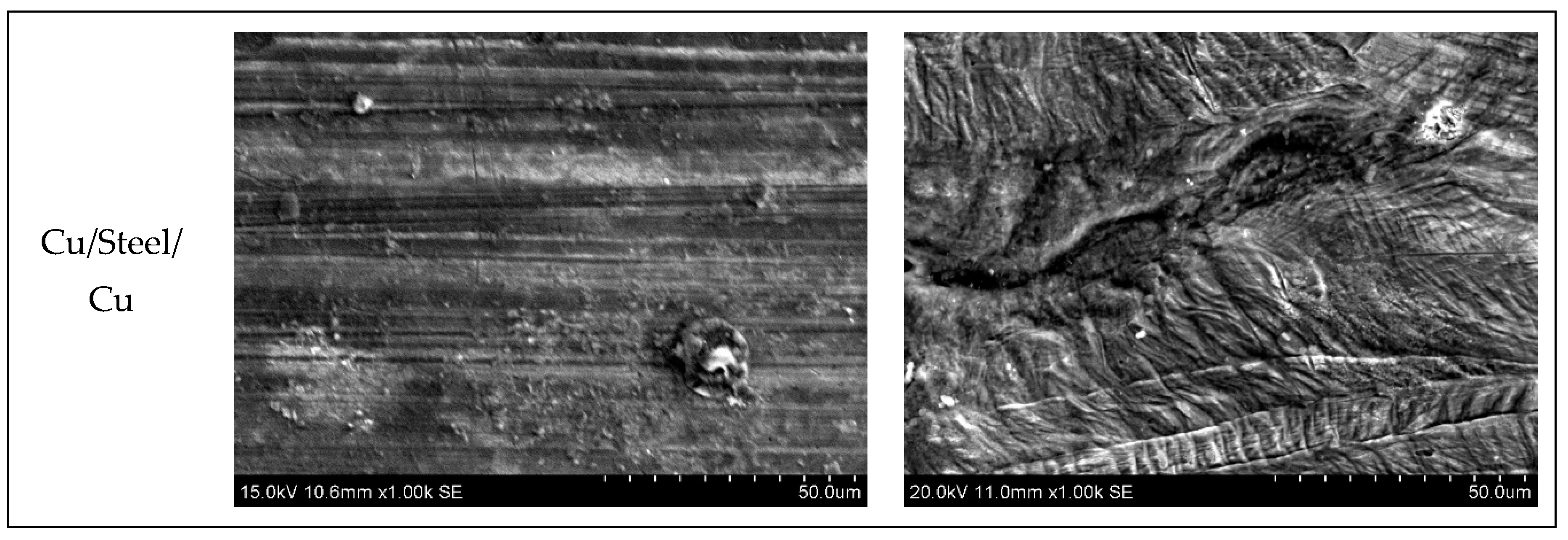

3.2. Surface Morphology

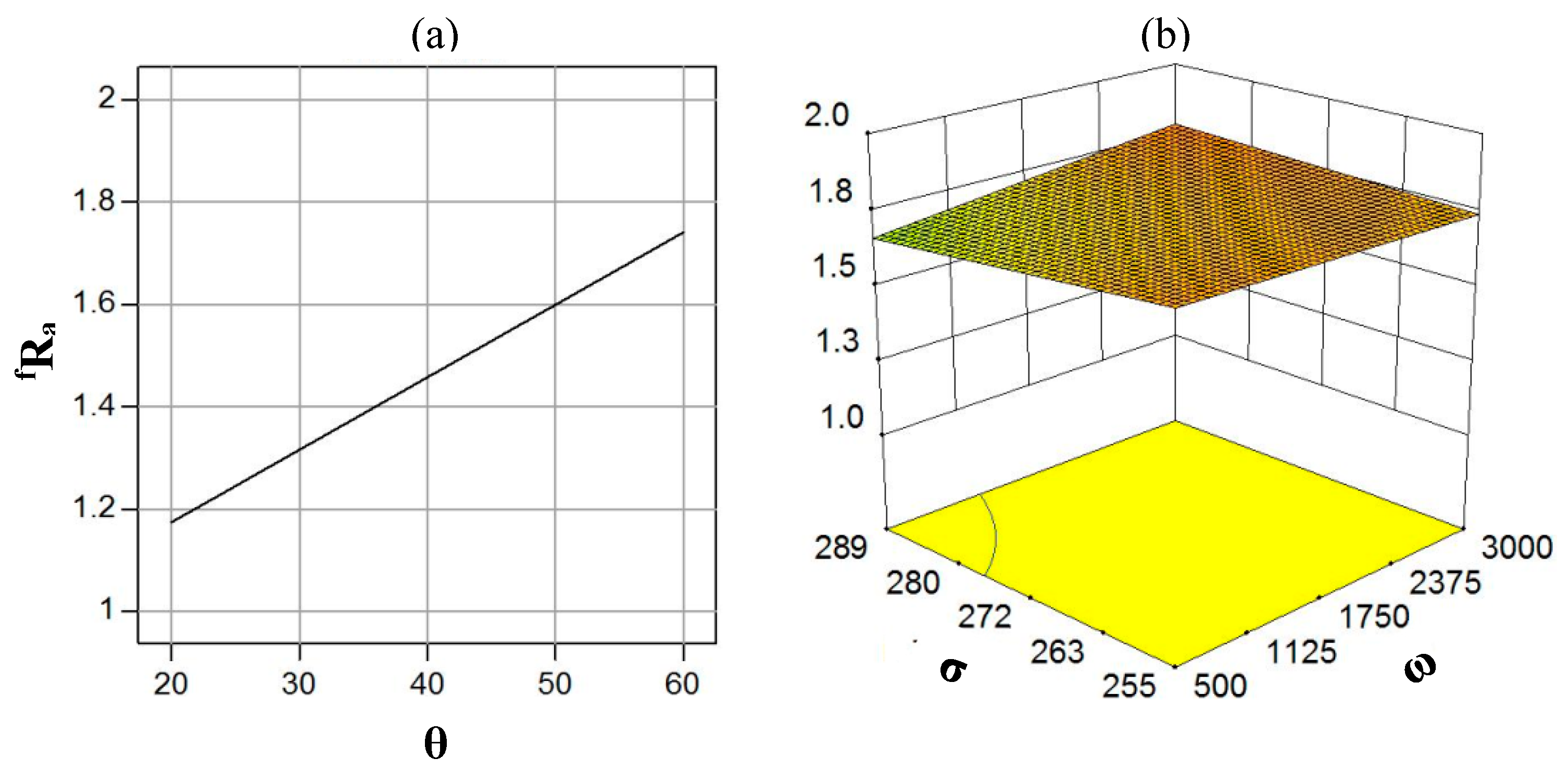

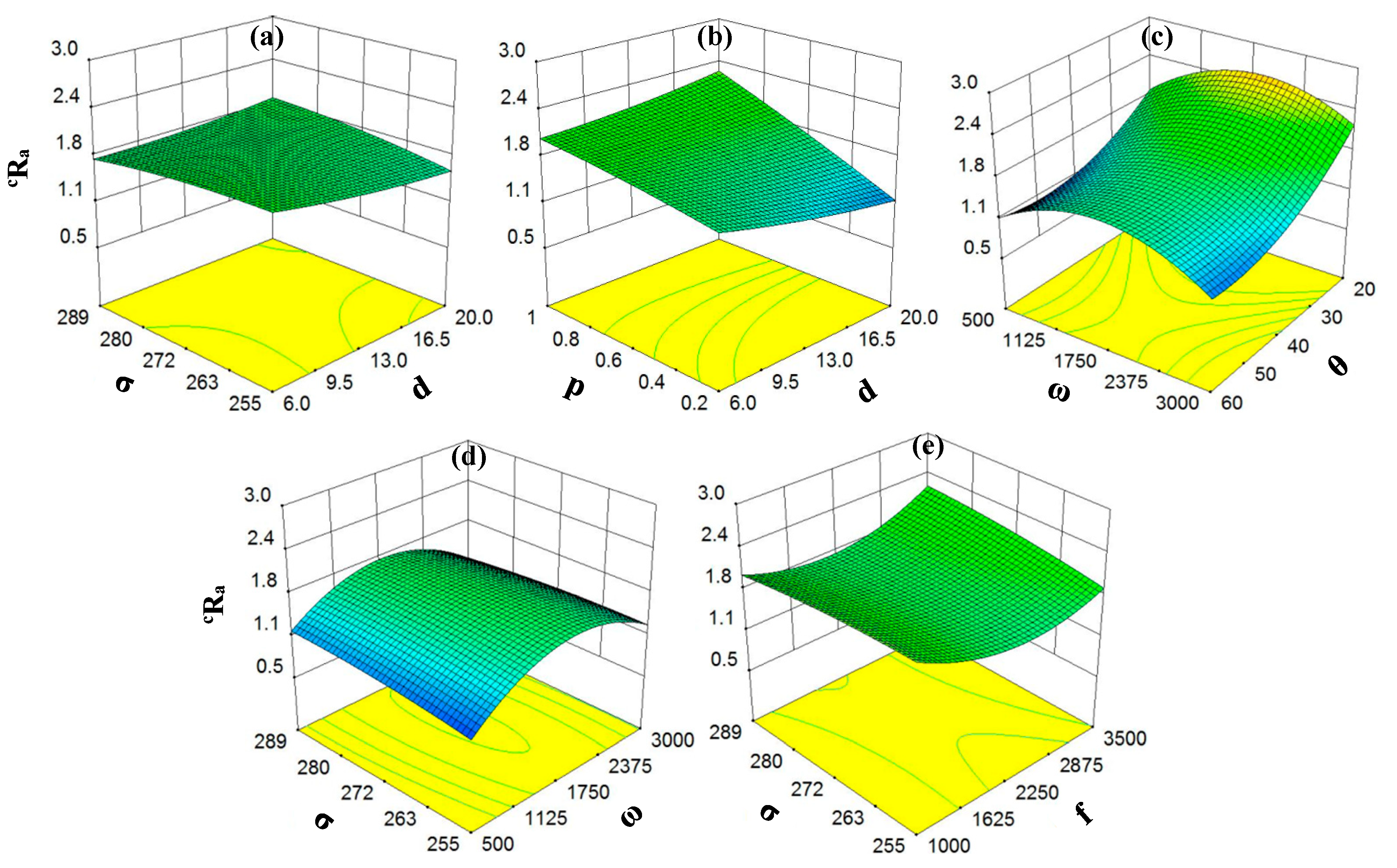

3.3. Significant Effects and Comparison Between the Free and Contact Surfaces from the Perspective of Roughness

3.4. Roughness Comparison Among the Layered and Monolithic Sheets and Research Opportunities

- The strength difference in the two contiguous metallic layers (Cu and Steel) affects the free-surface roughness of the Cu layer of a bonded sheet, as found in the current study. This, according to Equations (12) and (13), happens because the low-strength Cu being attached with the high-strength steel possibly receives a redundant load, resulting in additional hydrostatic tension and surface defects (e.g., orange peel). However, this point requires validation for which efforts should be spent to analyze the forming forces and tensile stresses on the free surface considering layered and monolithic sheets. Moreover, this exercise should be repeated at varying strength differences.

- The type of material and initial roughness of the sheet affects the surface deformation, thereby affecting the free-surface roughness in metal forming [7]. Detailed studies must be carried out in this direction, with the purpose of developing a generalized process window to control roughness in ISF.

- During forming, a low strength sheet (Cu) was stacked below a high strength sheet (steel) in the present study. By inversing the stacking sequence, the strength difference in the two adjoining layers might not influence the load on the free surface and, thus, the free-surface roughness may remain insensitive to layering.

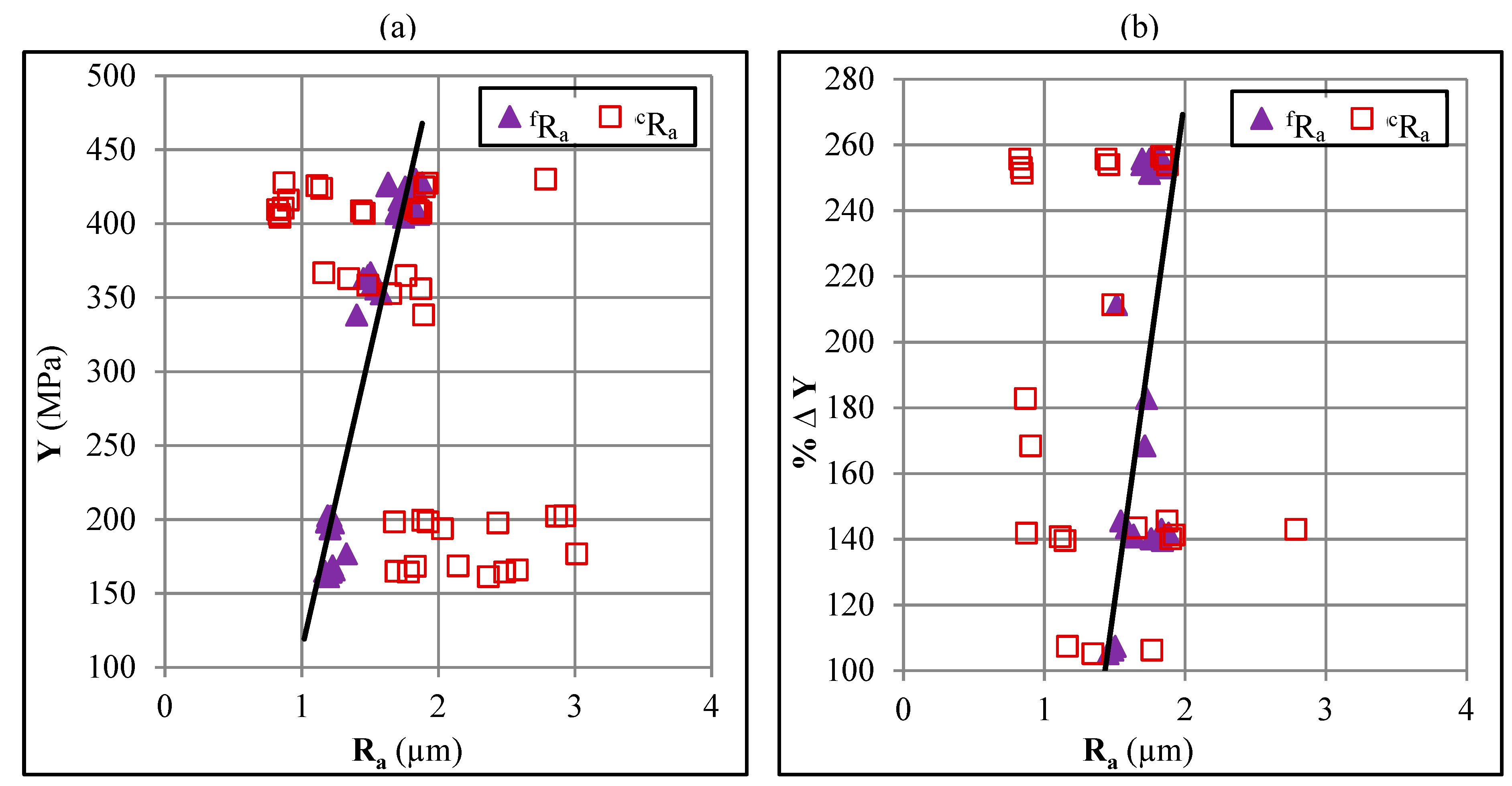

- Figure 4 depicts that the free-surface roughness increases with strain hardening (or post-forming strength) of the sheet in ISF, thereby pointing out that the mentioned roughening probably occurred due to a corresponding increase in the tensile stresses on the free surface during forming. This point needs to be ascertained. Moreover, the said hardening occurred due to the combined effect of bending and stretching strains. Thus, the two effects should be isolated in order to identify the most influential one.

- The tool path can affect the strain distribution and, thus, the roughness. This aspect should be explored in detail by considering various tool paths.

- A close association among various deformation quantities identified in this study points to the peculiar deformation mechanics of the ISF process. Further work in this direction can deepen the process understanding.

4. Conclusions

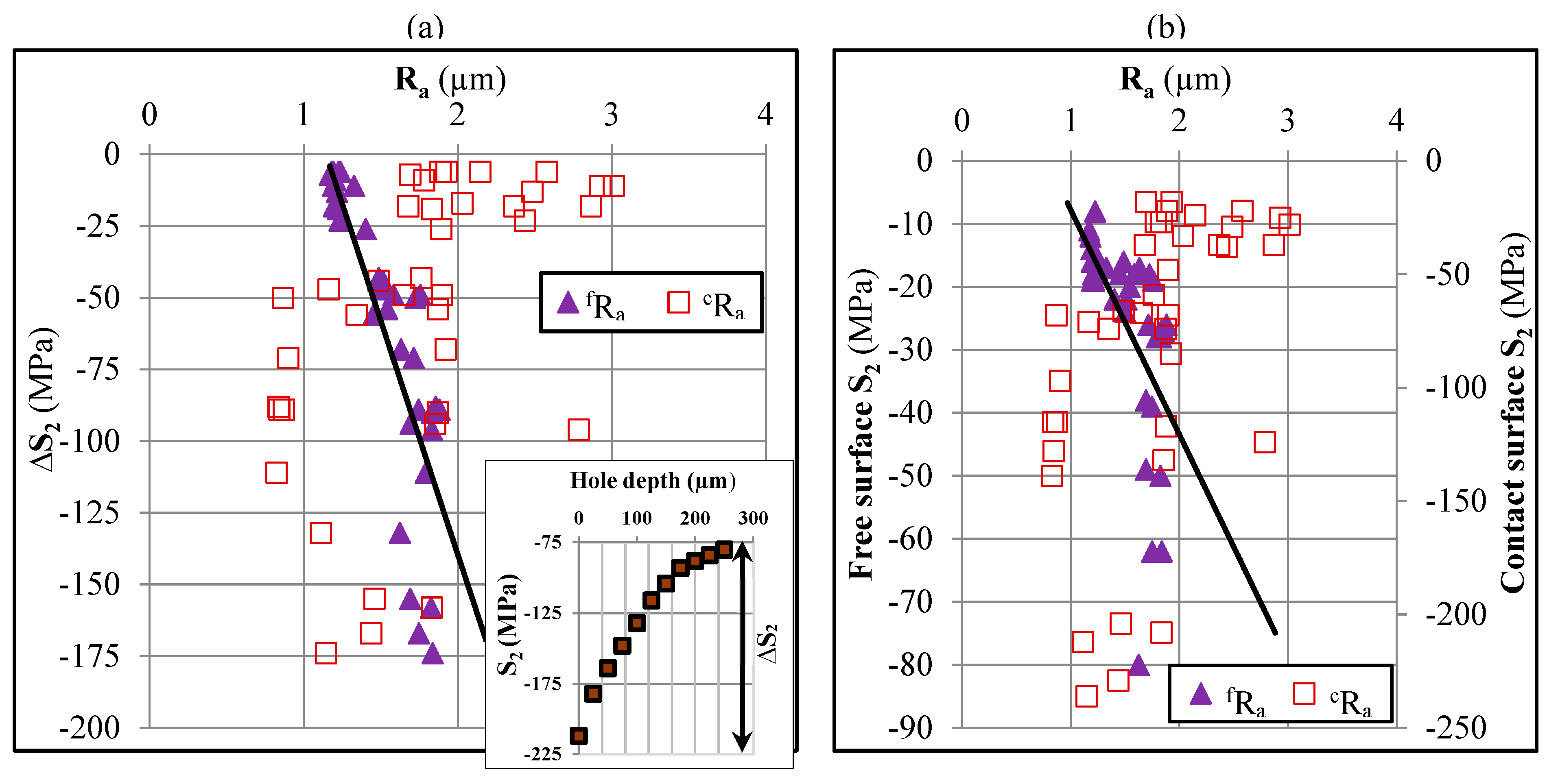

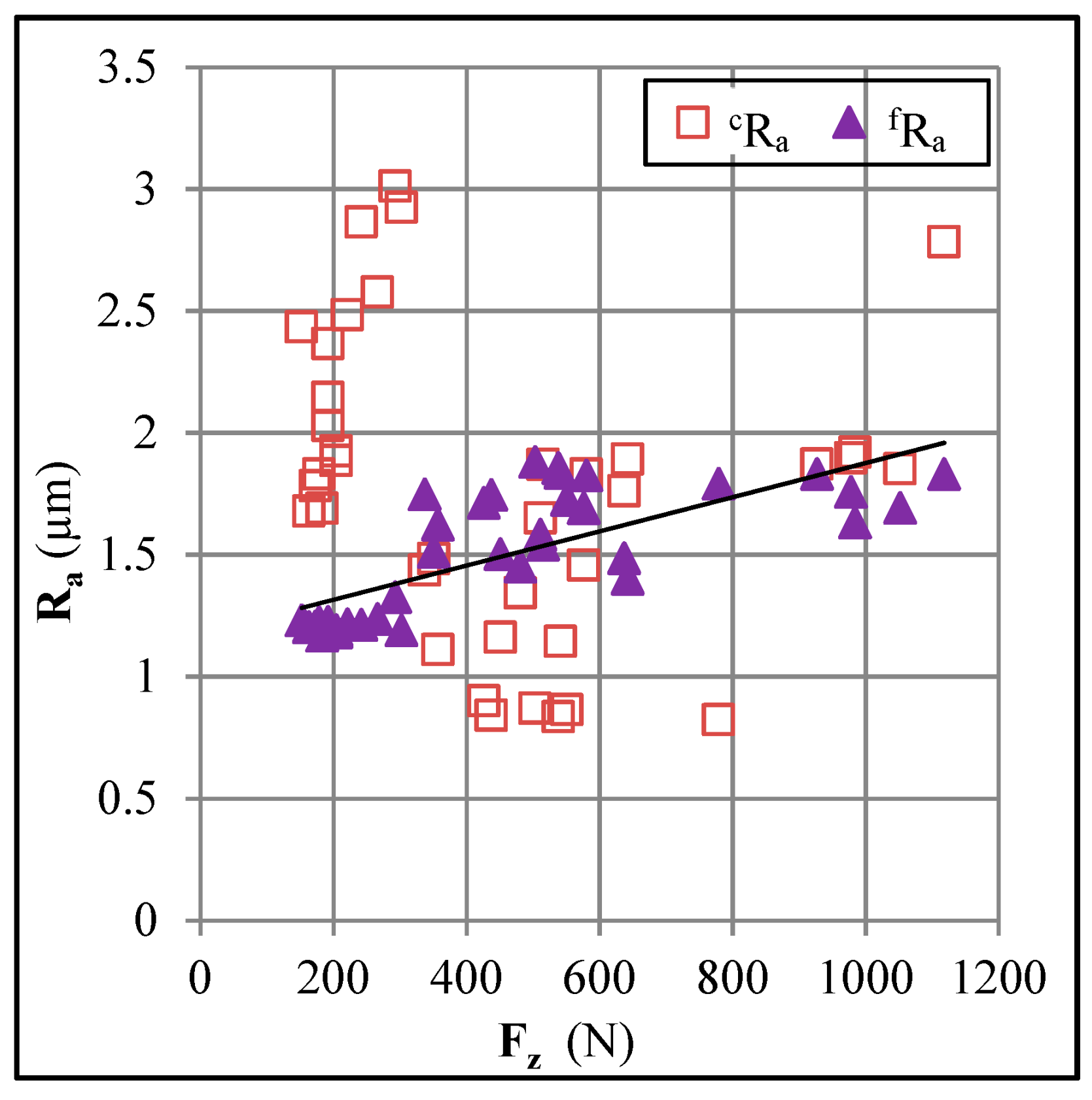

- The free-surface roughness increased non-linearly as the normal surface strain (stretching + bending with the following strain state on the surface: ɛ1 = 0, ɛ2 > 0, γmax = ɛ2) increased from 13% to 98%, thereby showing that the free-surface roughening in ISF occurred due to surface deformation. The roughness also increased with the post-forming sheet strength, residual stress, and forming force, thus indicating that strain hardening has a direct effect on roughening in ISF. This finding also reveals that material strengthening in ISF was achieved at the cost of surface quality, although the rise in sheet strength was high in comparison to that in roughness. These quantities were found to correlate closely, information from which can be extracted to incorporate into deformation models to improve the process modeling.

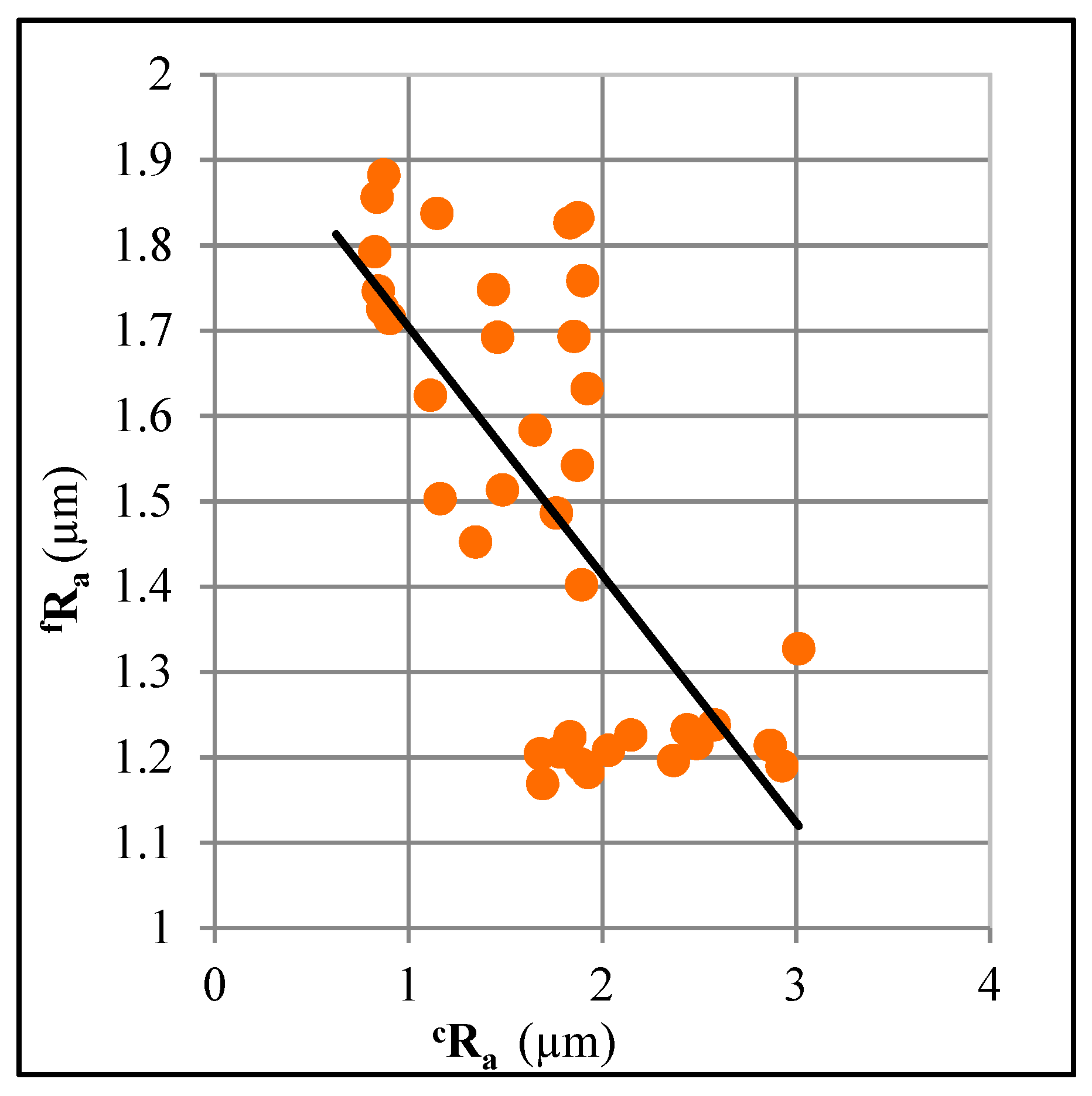

- The free-surface roughness and the contact-surface roughness were related inversely, as responses of the two roughnesses to ISF processing were mutually exclusive, in most respects, thereby pointing out a need to choose a judicious set of process conditions to produce components with low roughness on both surfaces. Therefore, the significance and nature of various process conditions for both types of roughnesses were analyzed/classified and presented in this study. The analysis disclosed that the forming angle amongst various parameters had the highest contribution.

- The surface morphology revealed that the free surfaces contained orange peel, slip lines, and micro-voids. Furthermore, the density of these features, along with the roughness, increased with the ISF strain, thus showing that the roughening of free surfaces in ISF occurred mainly due to surface deformation, possibly with a tensile state of stress, while the contact surfaces were observed to contain striations, thereby showing the influence of tool/sheet interaction.

- The present study offers a basic and first knowledge of its nature in the ISF process. Moreover, based on the obtained results, several new research directions were identified and discussed to further comprehend free-surface roughening in ISF.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Symbols

| d | Tool diameter |

| θ | Forming angle |

| ω | Spindle rotation |

| f | Feed rate |

| σ | Pre-forming tensile stress of sheet |

| p | Step size |

| fRa | Mean free-surface-roughness |

| cRa | Mean contact-surface-roughness |

| YS | Post-forming yield strength |

| UTS | Post-forming tensile strength |

| ɛ-ISF | Applied ISF strain |

| Fz | Forming force in Z axis. |

References

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J. Asymmetric single point incremental forming of sheet metal. CIRP Ann. 2005, 54, 623–650. [Google Scholar] [CrossRef]

- Racz, S.G.; Breaz, R.E.; Tera, M.; Gîrjob, G.; Biris, G.; Chicea, A.L.; Bologa, O. Incremental forming of titanium Ti6Al4V alloy for canioplasty plates—Decision-making process and technological approaches. Metals 2018, 8, 626. [Google Scholar] [CrossRef]

- Jeswiet, J.; Adams, D.; Doolan, M.; McAnulty, T.; Gupta, P. Single point and asymmetric incremental forming. Adv. Manuf. 2015, 3, 253–262. [Google Scholar] [CrossRef]

- Stoudt, M.R.; Hubbard, J.B.; Iadicola, M.A.; Banovic, S.W. A study of the fundamental relationships between deformation-induced surface roughness and strain localization in AA5754. Metall. Mater. Trans. A 2009, 40, 1611–1622. [Google Scholar] [CrossRef]

- Stoudt, M.R.; Hubbard, J.B.; Leigh, S.D. On the relationship between deformation-induced surface roughness and plastic strain in AA5052—Is it really linear? Metall. Mater. Trans. A 2011, 42, 2668–2679. [Google Scholar] [CrossRef]

- Wu, P.D.; Lloyd, D.J.; Jain, M.; Neale, K.W.; Huang, Y. Effects of spatial grain orientation distribution and initial surface topography on sheet metal necking. Int. J. Plast. 2007, 23, 1084–1104. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, P.Z.; Jin, H.; Wu, P.D.; Lloyd, D.J. Analysis of surface roughening in AA6111 automotive sheet under pure bending. Metall. Mater. Trans. A 2016, 47, 949–960. [Google Scholar] [CrossRef]

- Al-Quershi, H.A.; Klein, A.N.; Fredel, M.C. Grain size and surface roughness effect on the instability strains in sheet metal stretching. J. Mater. Proc. Technol. 2005, 170, 204–210. [Google Scholar] [CrossRef]

- Azushima, A.; Sakuramoto, M. Effects of plastic strain on surface roughness and coefficient of friction in tension-bending test. CIRP Ann. 2006, 55, 303–306. [Google Scholar] [CrossRef]

- Gatea, S.; Ou, H.; McCartney, G. Review on the influence of process parameters in incremental sheet forming. Int. J. Adv. Manuf. Technol. 2016, 87, 479–499. [Google Scholar] [CrossRef]

- Echrif, S.B.M.; Hrairi, M. Significant parameters for the surface roughness in incremental forming process. Mater. Manuf. Process. 2014, 29, 697–703. [Google Scholar] [CrossRef]

- Hagan, E.; Jeswiet, J. Analysis of surface roughness for parts formed by computer numerical controlled incremental forming. Proc. Inst. Mech. Eng. J. Eng. Manuf. 2004, 218, 1307–1312. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Langella, A.; Memola, F.; Minutolo, C. The influence of tool rotation on an incremental forming process. J. Mater. Process. Technol. 2009, 209, 4621–4626. [Google Scholar] [CrossRef]

- Baruah, A.; Pandivelan, C.; Jeevanantham, A.K. Optimization of AA5052 in incremental sheet forming using grey relational analysis. Measurement 2017, 106, 95–100. [Google Scholar] [CrossRef]

- Suresh, K.; Nasih, H.R.; Srinivasa, P.R.; Amit, K.G. Modeling and optimization of surface roughness in single point incremental forming process. J. Mater. Res. Technol. 2015, 3, 304–313. [Google Scholar]

- Azevedo, N.G.; Farias, J.S.; Bastos, R.P.; Teixeira, P.; Davim, J.P.; De-Sousa, R.S.J. Lubrication aspects during single point incremental forming for steel and aluminum materials. Int. J. Precis. Eng. Manuf. 2015, 16, 589–595. [Google Scholar] [CrossRef]

- Hamilton, K.; Jeswiet, J. Single point incremental forming at high feed rates and rotational speeds: Surface and structural consequences. CIRP Ann. 2010, 59, 311–314. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, B.; Chen, J.; Xu, D.K.; Ou, H. Analytical and experimental investigations on deformation mechanism and fracture behavior in single point incremental forming. J. Mater. Process. Technol. 2014, 214, 1503–1515. [Google Scholar] [CrossRef]

- Marteau, J.; Bigerelle, M. Relation between surface hardening and roughness induced by ultrasonic shot peening. Tribol. Int. 2015, 83, 105–113. [Google Scholar] [CrossRef]

- Llaneza, V.; Belzunce, F.J. Study of the effects produced by shot peening on the surface of quenched and tempered steels: Roughness, residual stresses and work hardening. Appl. Surf. Sci. 2015, 356, 475–485. [Google Scholar] [CrossRef]

- Ulrik, B.; Norman, A.F. Strain gradient effects in surface roughening. Model. Simul. Mater. Sci. Eng. 2007, 15, S1–S12. [Google Scholar]

- Sasaki, K.; Burstein, G. The generation of surface roughness during slurry erosion-corrosion and its effect on the pitting potential. Corros. Sci. 1996, 38, 2111–2120. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, S.; Li, Y.; Meehan, P.A. Modeling and optimization of surface roughness in incremental sheet forming using a multi-objective function. Mater. Manuf. Process. 2014, 29, 808–818. [Google Scholar] [CrossRef]

- Prates, P.A.; Adaixo, A.S.; Oliveira, M.C.; Fernandes, J.V. Numerical study on the effect of mechanical properties variability in sheet metal forming processes. Int. J. Adv. Manuf. Technol. 2018, 96, 561–580. [Google Scholar] [CrossRef]

- Anderson, M.J.; Whitcomb, P.J. RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Al-Ghamdi, K.A.; Hussain, G. Forming forces in incremental forming of a geometry with corner feature: Investigation into the effect of forming parameters using response surface approach. Int. J. Adv. Manuf. Technol. 2015, 76, 2185–2197. [Google Scholar] [CrossRef]

- Baharudin, B.T.H.T.; Azpen, Q.M.; Sulaima, S.; Mustapha, F. Experimental investigation of forming forces in frictional stir incremental forming of aluminum alloy AA6061-T6. Metals 2017, 7, 484. [Google Scholar] [CrossRef]

- Shi, X.; Hussain, G.; Butt, S.I.; Song, F.; Huang, D.; Liu, Y. The state of residual stresses in the Cu/Steel bonded laminates after ISF deformation: An experimental analysis. J. Manuf. Process. 2017, 30, 14–26. [Google Scholar] [CrossRef]

- Shao, C.W.; Zhang, P.; Zhu, Y.K.; Zhang, Z.J.; Tian, Y.Z.; Zhang, Z.F. Simultaneous improvement of strength and plasticity: Additional work-hardening from gradient microstructure. Acta Mater. 2018, 145, 413–428. [Google Scholar] [CrossRef]

- Jiménez, I.; Siller, H.R.; López, C.; Diabb, J.; Martinez-Romero, O.; Sandoval-Robles, J.A.; Mares, P.; Elías-Zúñiga, A. Investigation of residual stress distribution in single point incremental forming of aluminum parts by X-ray diffraction technique. Int. J. Adv. Manuf. Technol. 2017, 91, 2571–2580. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Langella, A. Observations on the Influence of Tool-Sheet Contact Conditions on an Incremental Forming Process. J. Mater. Eng. Perform. 2011, 20, 941–946. [Google Scholar] [CrossRef]

- Al-Ghamdi, K.A.; Hussain, G. Threshold tool-radius condition maximizing the formability in SPIF considering a variety of materials: Experimental and FE investigations. Int. J. Mach. Tool Manuf. 2015, 88, 82–94. [Google Scholar] [CrossRef]

- Centeno, G.; Martínez-Donaire, A.J.; Bagudanch, I.; Morales-Palma, D.; Garcia-Romeu, M.L.; Vallellano, C. Revisiting formability and failure of AISI304 sheets in SPIF: Experimental approach and numerical validation. Metals 2017, 7, 531. [Google Scholar] [CrossRef]

| Test | d | θ | ω | f | σ | p | fRa | cRa | YS | UTS |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (deg) | (rpm) | (mm/min) | (MPa) | (mm) | (µm) | (µm) | (MPa) | (MPa) | |

| 1 | 6 | 60 | 500 | 1000 | 289 | 0.2 | 1.624 | 1.112 | 425.6 | 445.7 |

| 2 | 20 | 20 | 1750 | 3500 | 255 | 0.2 | 1.224 | 1.832 | 168.2 | 295.4 |

| 3 | 6 | 20 | 3000 | 3500 | 289 | 0.2 | 1.232 | 2.436 | 197.5 | 294.6 |

| 4 | 20 | 60 | 3000 | 1000 | 277 | 0.2 | 1.725 | 0.866 | 410.3 | 436.5 |

| 5 | 6 | 46.7 | 500 | 2666 | 289 | 1 | 1.452 | 1.345 | 362.7 | 402.7 |

| 6 | 20 | 20 | 500 | 3500 | 289 | 1 | 1.19 | 2.926 | 202.3 | 290.4 |

| 7 | 20 | 20 | 3000 | 1000 | 255 | 0.47 | 1.216 | 2.486 | 164.3 | 296.3 |

| 8 | 20 | 20 | 3000 | 3500 | 271 | 1 | 1.327 | 3.013 | 176.7 | 298.6 |

| 9 | 13 | 20 | 3000 | 1000 | 289 | 0.2 | 1.208 | 2.031 | 193.6 | 292.4 |

| 10 | 15.3 | 60 | 500 | 1000 | 289 | 1 | 1.632 | 1.921 | 427.3 | 445.6 |

| 11 | 15.3 | 60 | 500 | 1000 | 289 | 1 | 1.758 | 1.898 | 424.8 | 444.7 |

| 12 | 10.7 | 60 | 500 | 3500 | 280 | 0.2 | 1.714 | 0.902 | 415.9 | 439.8 |

| 13 | 10.7 | 46.7 | 3000 | 3500 | 289 | 1 | 1.486 | 1.763 | 364.8 | 408.7 |

| 14 | 6 | 60 | 3000 | 3500 | 255 | 0.2 | 1.748 | 1.438 | 408.5 | 435.6 |

| 15 | 15.3 | 60 | 500 | 3500 | 255 | 1 | 1.832 | 1.873 | 407.2 | 441.3 |

| 16 | 13 | 40 | 1750 | 2250 | 277 | 0.6 | 1.583 | 1.652 | 352.6 | 398.2 |

| 17 | 20 | 60 | 500 | 1000 | 255 | 0.2 | 1.856 | 0.837 | 406.2 | 430.8 |

| 18 | 20 | 20 | 500 | 1000 | 289 | 0.2 | 1.192 | 1.887 | 199.3 | 300.4 |

| 19 | 20 | 60 | 1333 | 3500 | 289 | 1 | 1.832 | 2.785 | 430.1 | 449.2 |

| 20 | 20 | 20 | 500 | 1000 | 255 | 1 | 1.238 | 2.578 | 165.8 | 293.5 |

| 21 | 20 | 60 | 3000 | 1000 | 255 | 1 | 1.693 | 1.854 | 408.6 | 433.2 |

| 22 | 20 | 60 | 500 | 1000 | 255 | 0.2 | 1.746 | 0.843 | 404.2 | 429.6 |

| 23 | 6 | 60 | 3000 | 1833 | 255 | 1 | 1.692 | 1.459 | 406.8 | 428.3 |

| 24 | 13 | 40 | 1750 | 2250 | 277 | 0.6 | 1.542 | 1.872 | 355.8 | 402.7 |

| 25 | 6 | 20 | 500 | 2666 | 289 | 0.2 | 1.204 | 1.68 | 198.2 | 294.3 |

| 26 | 20 | 46.7 | 500 | 3500 | 289 | 0.2 | 1.503 | 1.163 | 366.7 | 406.2 |

| 27 | 20 | 33.3 | 3000 | 1000 | 289 | 1 | 1.402 | 1.893 | 338.2 | 388.4 |

| 28 | 20 | 20 | 1750 | 3500 | 255 | 0.2 | 1.169 | 1.692 | 164.8 | 288.5 |

| 29 | 6 | 60 | 500 | 1000 | 255 | 1 | 1.826 | 1.832 | 409.7 | 430.6 |

| 30 | 6 | 20 | 2166 | 1000 | 289 | 1 | 1.214 | 2.866 | 202.2 | 302.4 |

| 31 | 15.3 | 60 | 3000 | 2666 | 289 | 0.2 | 1.882 | 0.872 | 427.6 | 448.4 |

| 32 | 20 | 60 | 3000 | 3500 | 255 | 0.47 | 1.792 | 0.825 | 409.4 | 436.5 |

| 33 | 6 | 60 | 3000 | 1000 | 289 | 0.73 | 1.837 | 1.146 | 423.8 | 448.2 |

| 34 | 6 | 20 | 3000 | 2250 | 255 | 1 | 1.196 | 2.367 | 161.2 | 292.2 |

| 35 | 20 | 20 | 3000 | 3500 | 289 | 0.2 | 1.182 | 1.926 | 198.2 | 293.4 |

| 36 | 6 | 20 | 500 | 1833 | 255 | 0.2 | 1.206 | 1.783 | 164.3 | 296.3 |

| 37 | 6 | 20 | 500 | 3500 | 255 | 0.73 | 1.226 | 2.146 | 168.5 | 294.8 |

| 38 | 10.7 | 46.7 | 3000 | 1000 | 255 | 0.2 | 1.513 | 1.485 | 358.4 | 403.8 |

| Attribute | Deviation |

|---|---|

| fRa | ±0.07 µm |

| cRa | ±0.1 µm |

| Y | ±4.7 MPa |

| U | ±5 MPa |

| S1 | ±8 MPa |

| S2 | ±5 MPa |

| Fz | ±10 N |

| Source | cRa (Quadratic) | fRa (2FI) | ||||

|---|---|---|---|---|---|---|

| F-value - | p-value | Sig | F-value - | p-value | Significance | |

| Prob > F | Prob > F | |||||

| Model | 16.78 | < 0.0001 | √ | 19.19 | < 0.0001 | √ |

| θ | 138.13 | < 0.0001 | √ | 355.12 | < 0.0001 | √ |

| p | 112.56 | < 0.0001 | √ | 0.14 | 0.7101 | - |

| dσ | 9.05 | 0.0131 | √ | 3.82E-03 | 0.9515 | - |

| dp | 20.83 | 0.001 | √ | 0.57 | 0.4628 | - |

| θω | 5.31 | 0.0439 | √ | 0.024 | 0.8777 | - |

| ωσ | 5.14 | 0.0467 | √ | 5.78 | 0.0287 | √ |

| fσ | 10.93 | 0.0079 | √ | 0.18 | 0.6783 | - |

| θ2 | 8.63 | 0.0148 | √ | - | - | - |

| ω2 | 16.9 | 0.0021 | √ | - | - | - |

| f2 | 10.31 | 0.0093 | √ | - | - | - |

| Residual | - | - | - | - | - | - |

| Lack of Fit | 5.25 | 0.0651 | - | 1.57 | 0.353 | - |

| Test | ɛ-ISF | Cu/Steel/Cu Layered Sheet | Cu Monolithic Sheet | Steel Monolithic Sheet | |||

|---|---|---|---|---|---|---|---|

| (%) | fRa (µm) | ∆fRa (%) | fRa (µm) | ∆fRa (%) | fRa (µm) | ∆fRa (%) | |

| Parent blank | 0 | 0.97 ± 0.1 | 0.97 | 1.08 ± 0.08 | 1.08 | 1.62 ±0.1 | 1.62 |

| 31 | 85 | 1.79 ± 0.05 | 83.4 | 1.5 ± 0.07 | 38.14 | 2.1 ± 0.08 | 30 |

| 35 | 14 | 1.18 ± 0.06 | 21 | 1.12 ± 0.09 | 2.8 | 1.68 ± 0.07 | 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ghamdi, K.A.; Hussain, G. On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions. Metals 2019, 9, 553. https://doi.org/10.3390/met9050553

Al-Ghamdi KA, Hussain G. On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions. Metals. 2019; 9(5):553. https://doi.org/10.3390/met9050553

Chicago/Turabian StyleAl-Ghamdi, Khalid A, and G. Hussain. 2019. "On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions" Metals 9, no. 5: 553. https://doi.org/10.3390/met9050553

APA StyleAl-Ghamdi, K. A., & Hussain, G. (2019). On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions. Metals, 9(5), 553. https://doi.org/10.3390/met9050553