3. Results and Discussions

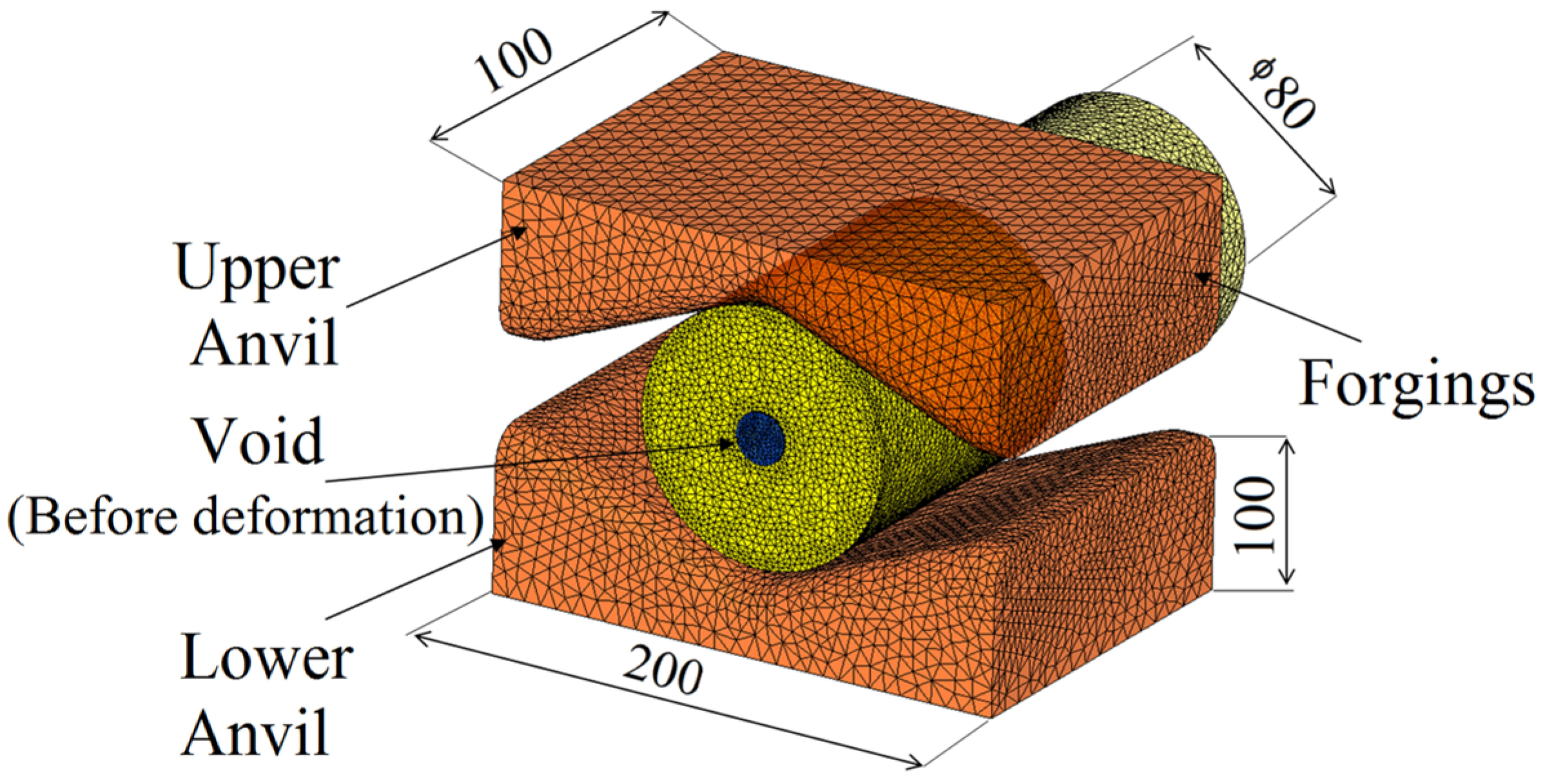

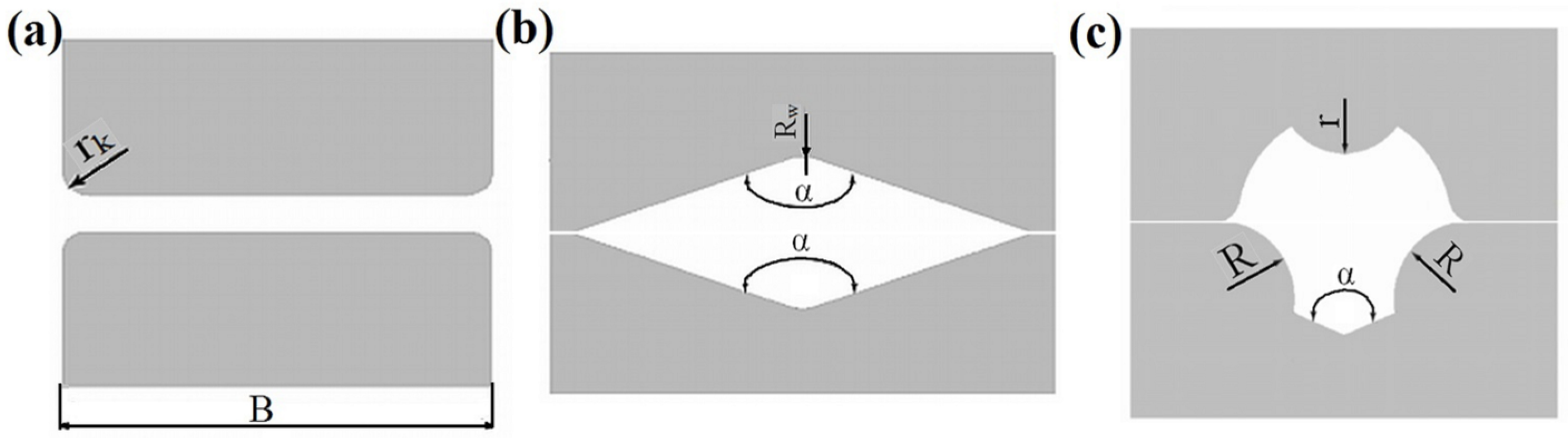

The local values characterizing the state of deformation, state of stress, and temperature distribution and the values of the Normalized C&L criterion in regions around the closing void and in the volume of a forging in the course of the cogging process of the X40CrMoV511 steel on flat anvils, V-shaped anvils, and an assembly of the three-radial anvils, were determined. The choice of flat anvils was dictated by their wide use in industrial practice.

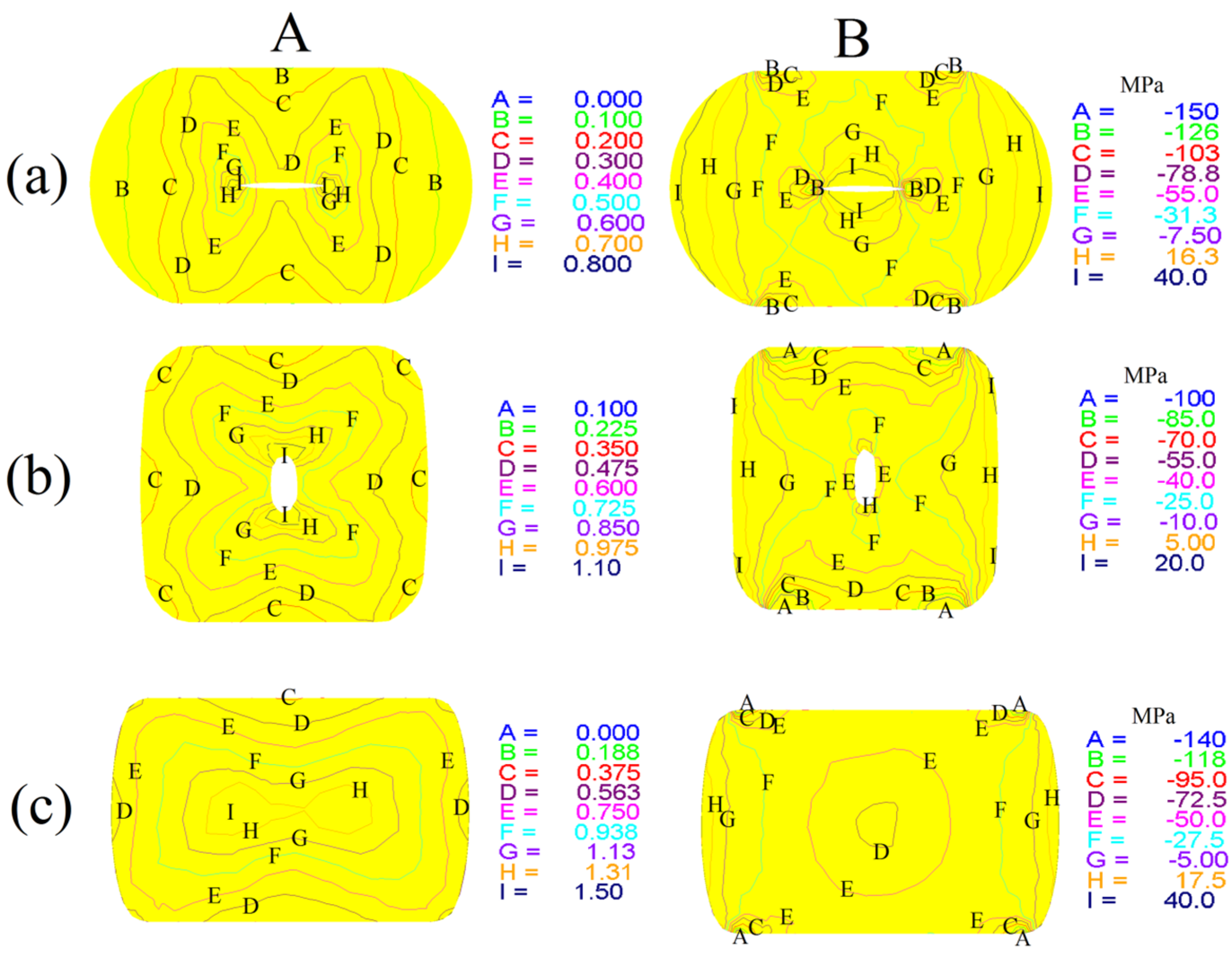

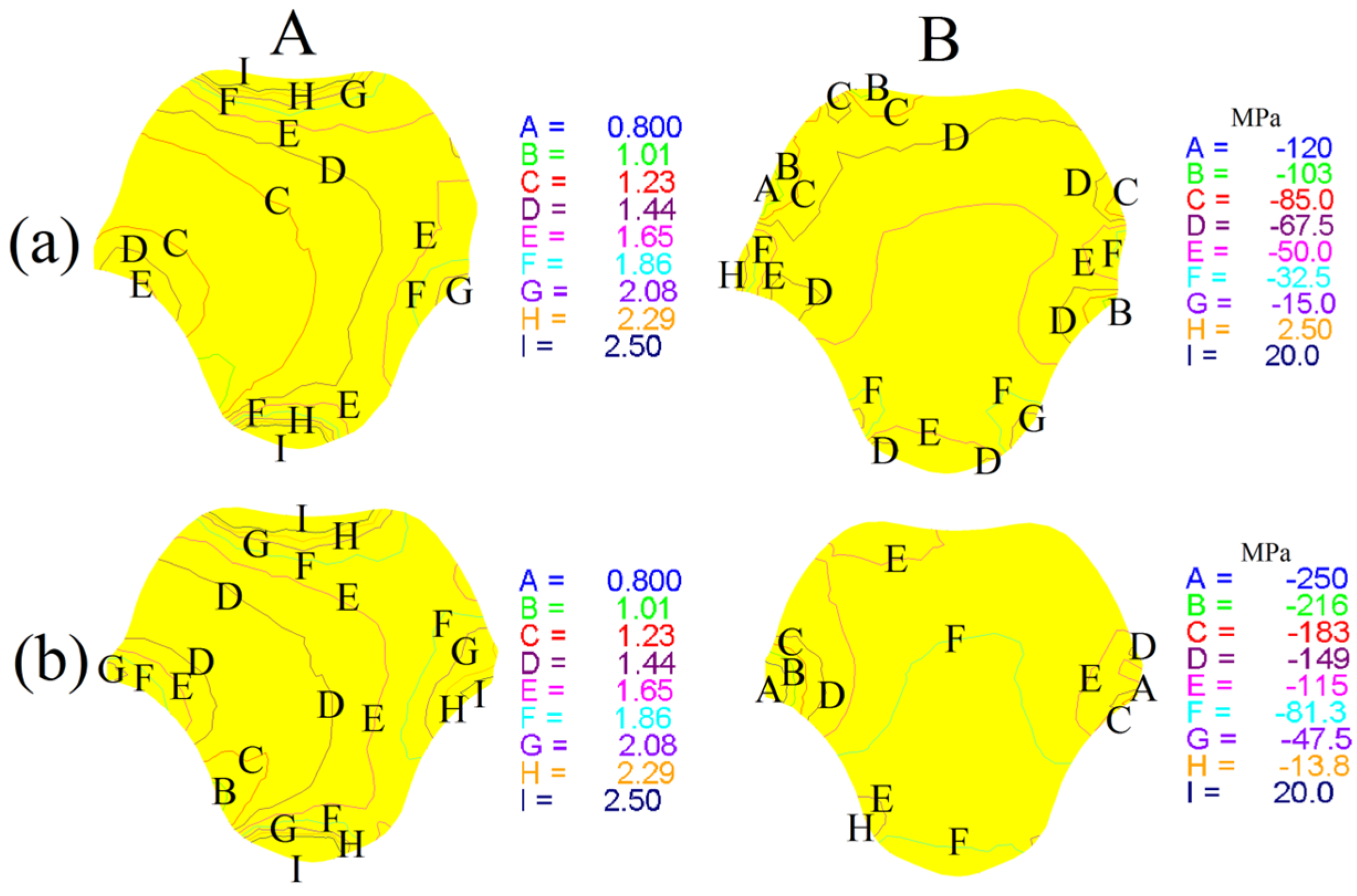

Figure 8 shows the distribution of effective strain and mean stress on the cross-sectional surface, located in the mid-length of the billet after the cogging process on flat anvils. The change in the selected axial void having the initial diameter of 16mm (

d0/

D0 = 0.20) in three consecutive technological passes is presented, with turning after each pass by a rotation angle of 90°. The state of stress and of strain around an existing void significantly influenced the process of its evolution in the aspect of shape and size. The greatest deformations occurred in the central part of a forging, in which the greatest metallurgical discontinuities in the form of voids and a central pore occurred (shown in

Figure 8A). In this region, the values of effective strain

exceeded the value of the preset reduction ratio

(

= 1.25). The region adjacent to the surfaces of the anvils experienced a small effective strain (

= 0.35–0.55), whereas the side zones of the forging were the regions of indirect effective strain (

= 0.55–0.85). In the first technological pass, the region around the axial void was subjected to tensile stress (shown in

Figure 8B), and, in the subsequent pass, underwent improvement. At the moment of concluding the axial void closure process (shown in

Figure 8B(c)), the compressive stress in the central part of the forging was observed.

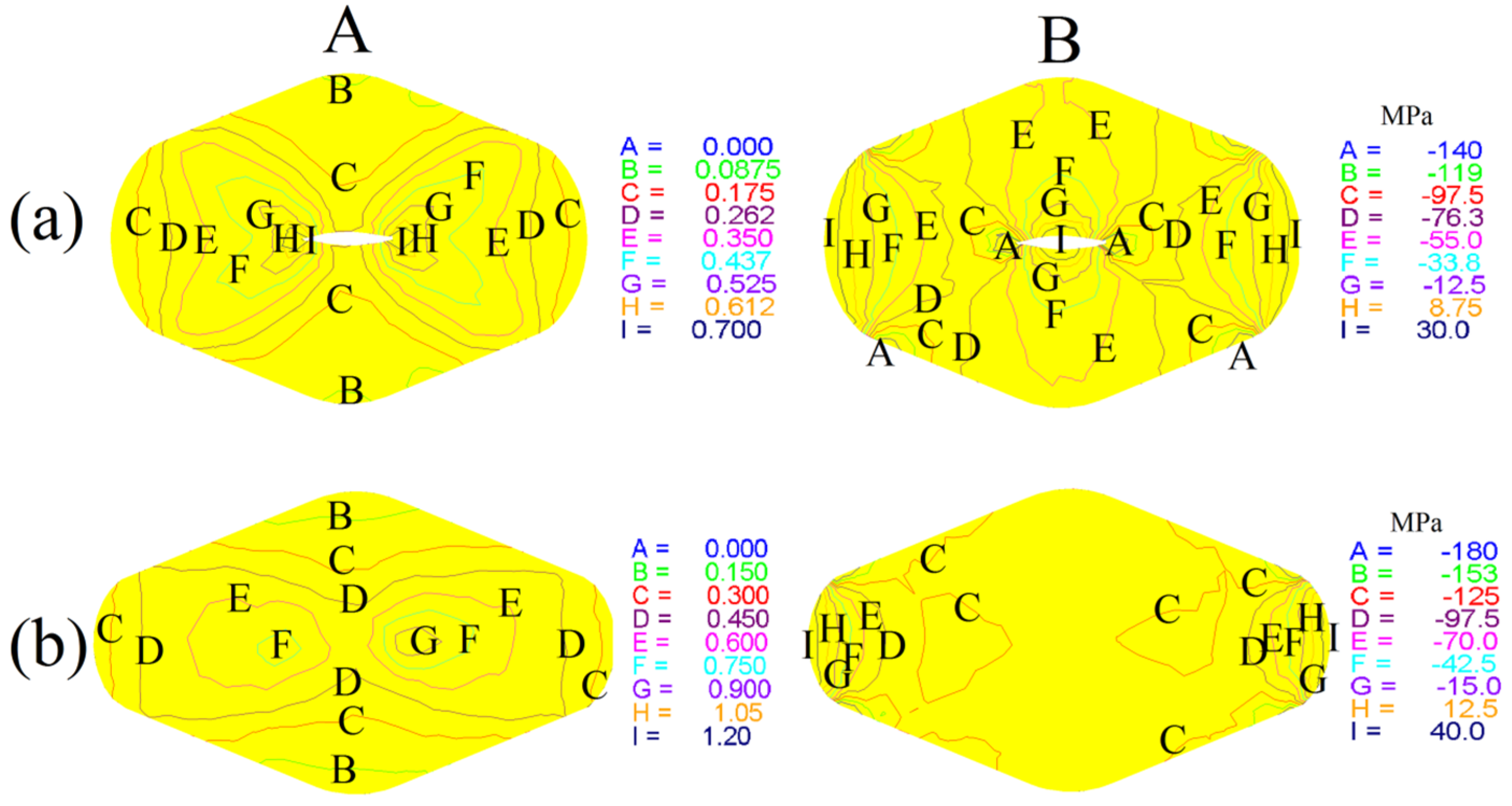

Figure 9 shows the distribution of effective strain and mean stress on the cross-sectional surface during the cogging process on

V-shaped anvils with an impression angle of 130° × 130° (

d0/

D0 = 0.20). The

V-shaped anvils turned out to be more efficient than the flat anvils. On the majority of a cross section, a very favorable and nearly uniform effective strain distribution was obtained, whereas the region having the maximum values of effective strain was situated in the direct vicinity of the center in the deformation zone and was subjected to an effective strain of

= 2.35–2.55 (shown in

Figure 9A). Such large values of effective strain in the axial zone of a billet being deformed brought about the conditions favorable to axial void closing already at the stage of the first technological pass (

Figure 9A(b)). Deviations in the effective strain distribution existed in the corners and in the side zones of the forging. At the initial stages of the first technological pass, the region around the axial void was subjected to tensile stress (shown in

Figure 9B) and, at the final stage of concluding axial void closure process, underwent a favorable change.

Figure 10 shows the distribution of effective strain and mean stress on the cross-sectional surface of a forging deformed in the assembly of three radial anvils during and after the third pass (

d0/

D0 = 0.20). The largest values of effective strain were seen in the regions of a forging situated under the convex surfaces of the anvils, whereas the central parts of the forging were the region characterized by the smaller values of effective strain (

Figure 10A). Closing of the smallest axial void (

d0/

D0 = 0.05) occurred in the second technological pass, whereas the remaining voids (

d0/

D0 = 0.10 and 0.20) still required an additional pass (

Figure 10A(b)). The efficiency of the assembly of three radial anvils in the void closure process was, admittedly, lower than that of the

V-shaped anvils. A major advantage of forging on these anvils is comparatively high uniformity of the effective strain distribution in the deformation zone and the absence of tensile stress in the axial workpiece zone (shown in

Figure 10B).

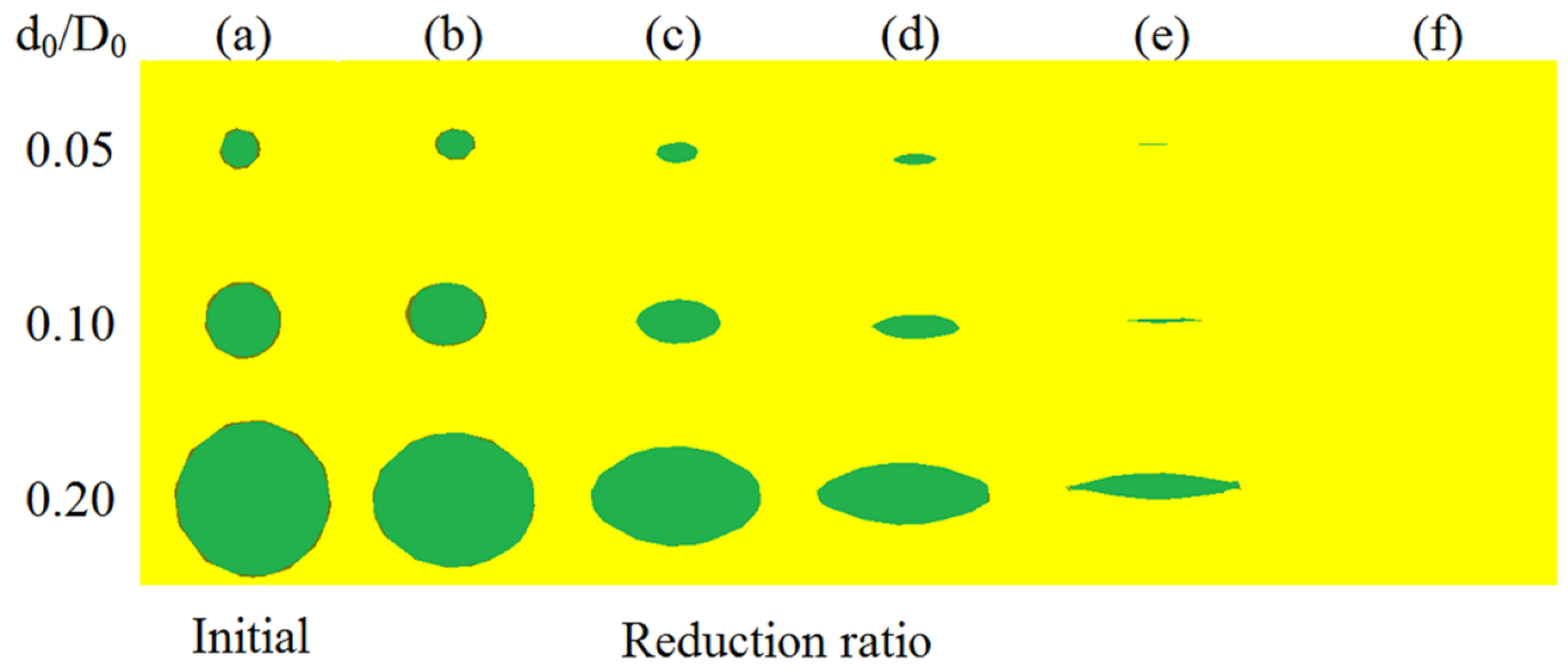

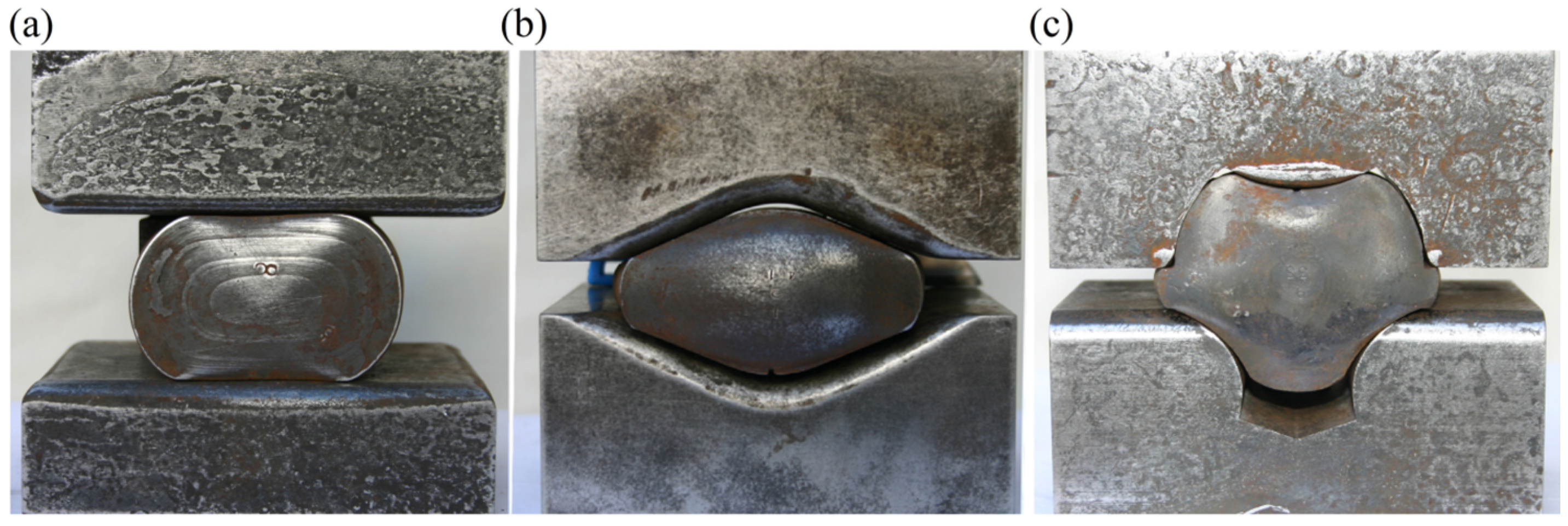

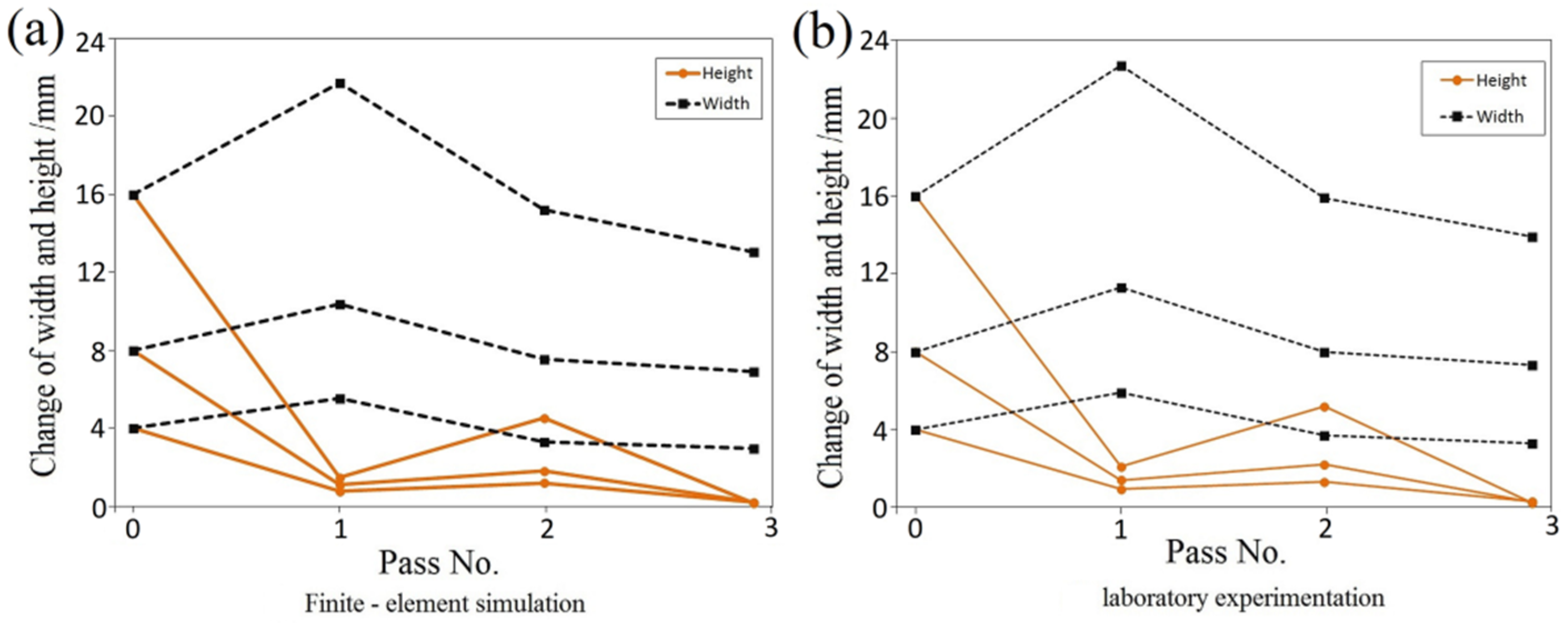

Changes in the width and height of the axial voids being researched, are presented in

Figure 11a. The results of numerical research were confirmed experimentally, as shown in

Figure 11b.

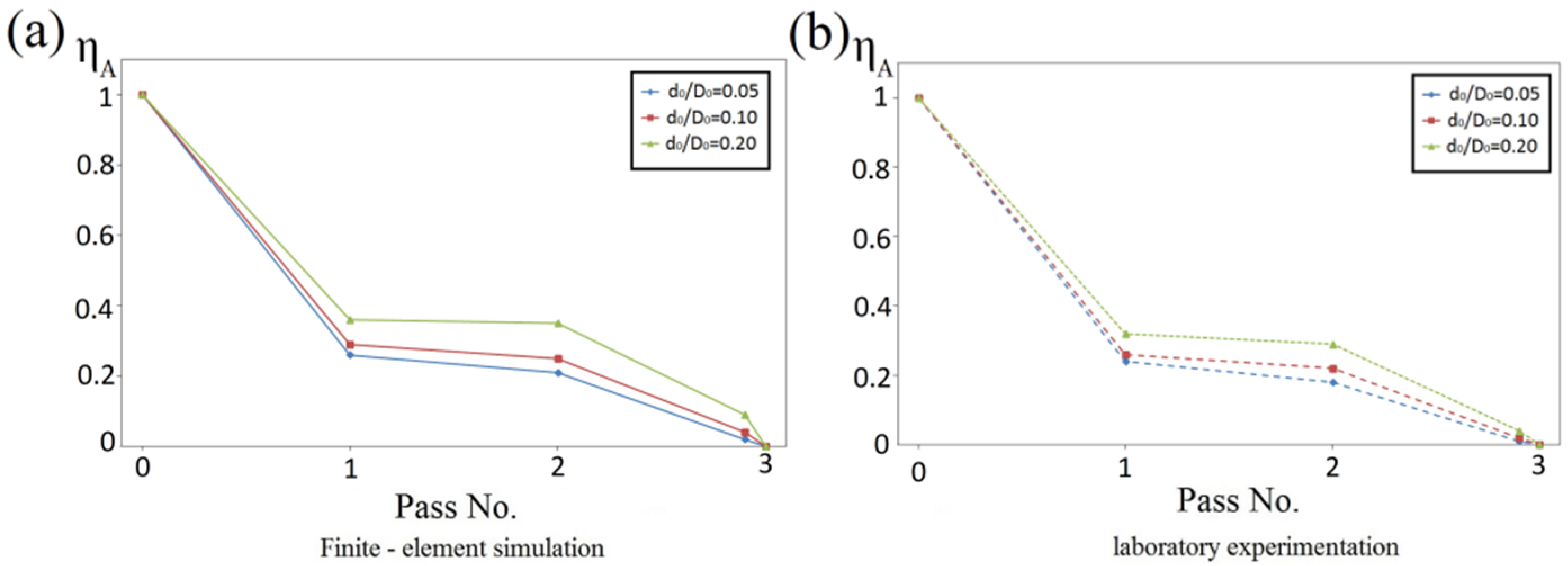

Figure 12a shows changes of the area ratio of the axial void

ηA at different cogging passes during deformation on flat anvils. The results of numerical research were confirmed experimentally, which is shown in

Figure 12b. It was observed that voids with different diameters were closing during the cogging process at the third pass.

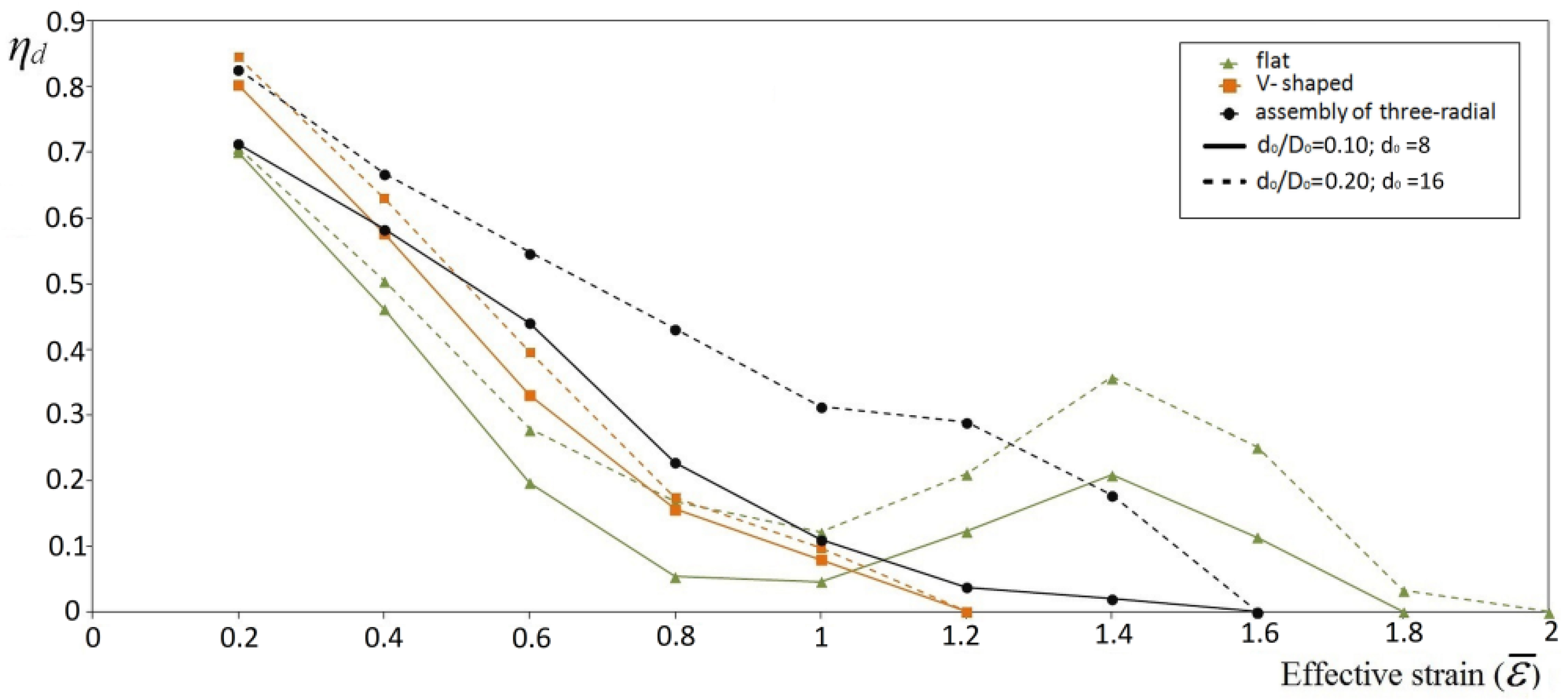

Figure 13 displays the relationship between effective strain and the relative void diameter ratio

ηd at different sizes of voids (

d0/

D0) with different anvils shapes.

V-shaped anvils appeared to be the most effective tool, allowing axial voids to close in the presence of effective strain in the central part of the forging amounting to

= 1.20. On flat anvils, the axial void closure process occurred in the case of

= 1.80–2.0, whereas higher values were necessary for larger voids (

d0/

D0 = 0.20). The assembly of three radial anvils required intermediate values of effective strain for the closure of axial voids (

= 1.60).

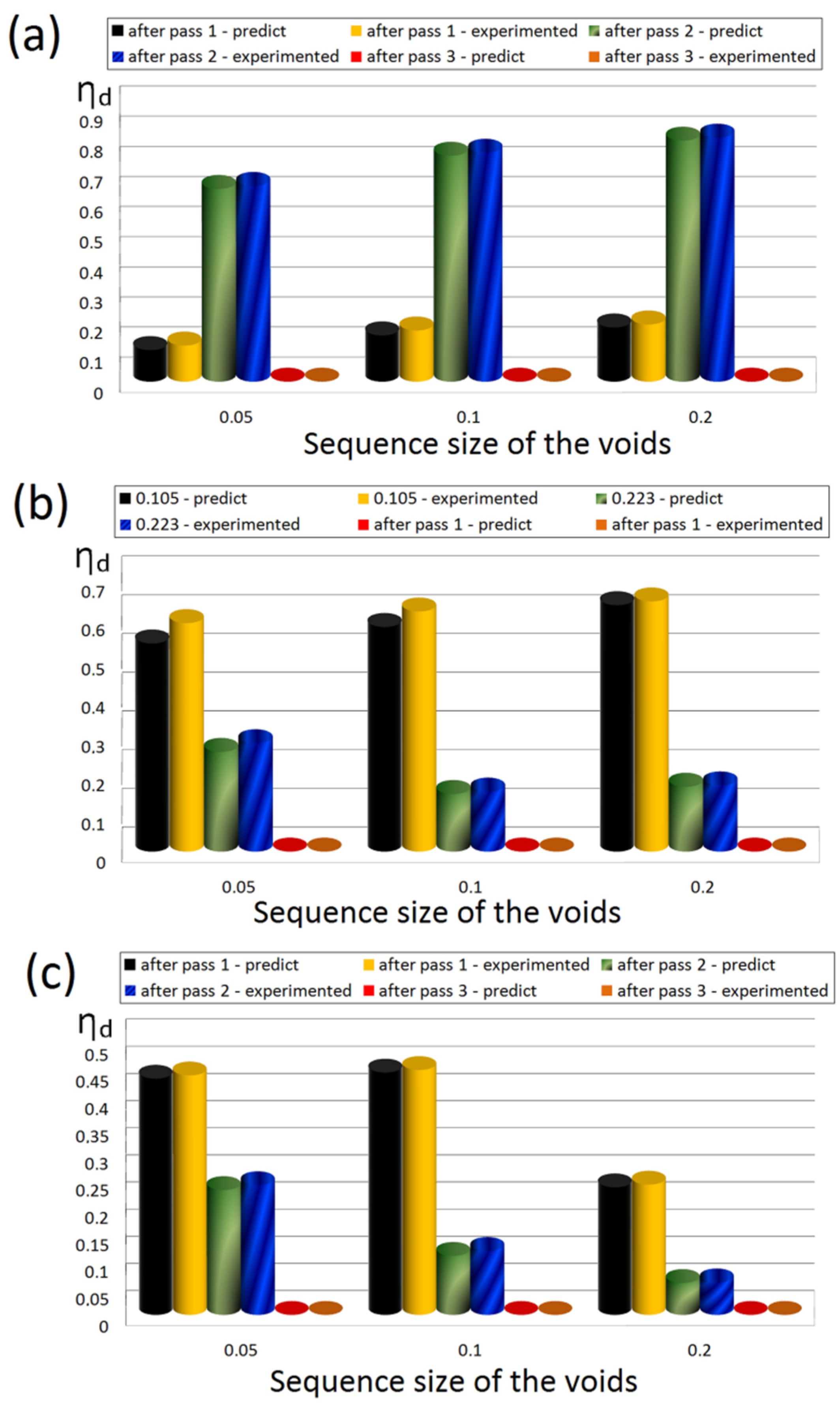

The comparison of the efficiency of void closure with the three different tools is shown in

Figure 14, which, in the form of the relative void diameter ratio (

ηd), characterizes the axial void closure process concerning voids of three sizes (

d0/

D0 = 0.05, 0.10, 0.20) in consecutive passes. Within the experimental part of the research, tests were conducted for identical cogging process parameters, using the same tools as those described in the numerical study methodology section. For laboratory tests,

φ 80 mm-diameter and 200 mm-long cylindrical specimens were used, and in the mid-length of each specimen (after cutting), a hole of a diameter and depth identical to those of the numerical model was drilled. The samples were heated in a resistance furnace up to the temperature of 1373 K and afterwards deformed on a hydraulic press exerting a pressure of 2.5 MN. After the deformation, the specimens were cut at 0.5 of their length, the cut surfaces were ground, the geometrical measurements of voids were performed, and then the shapes and dimensions of the voids were compared, after particular passes, with the theoretical results.

Figure 14a–c shows that the predicted results of the numerical investigation concerning the relative void diameter ratio (

ηd) for axial voids with three different sizes were in complete agreement with the measurements in the experimental investigation.

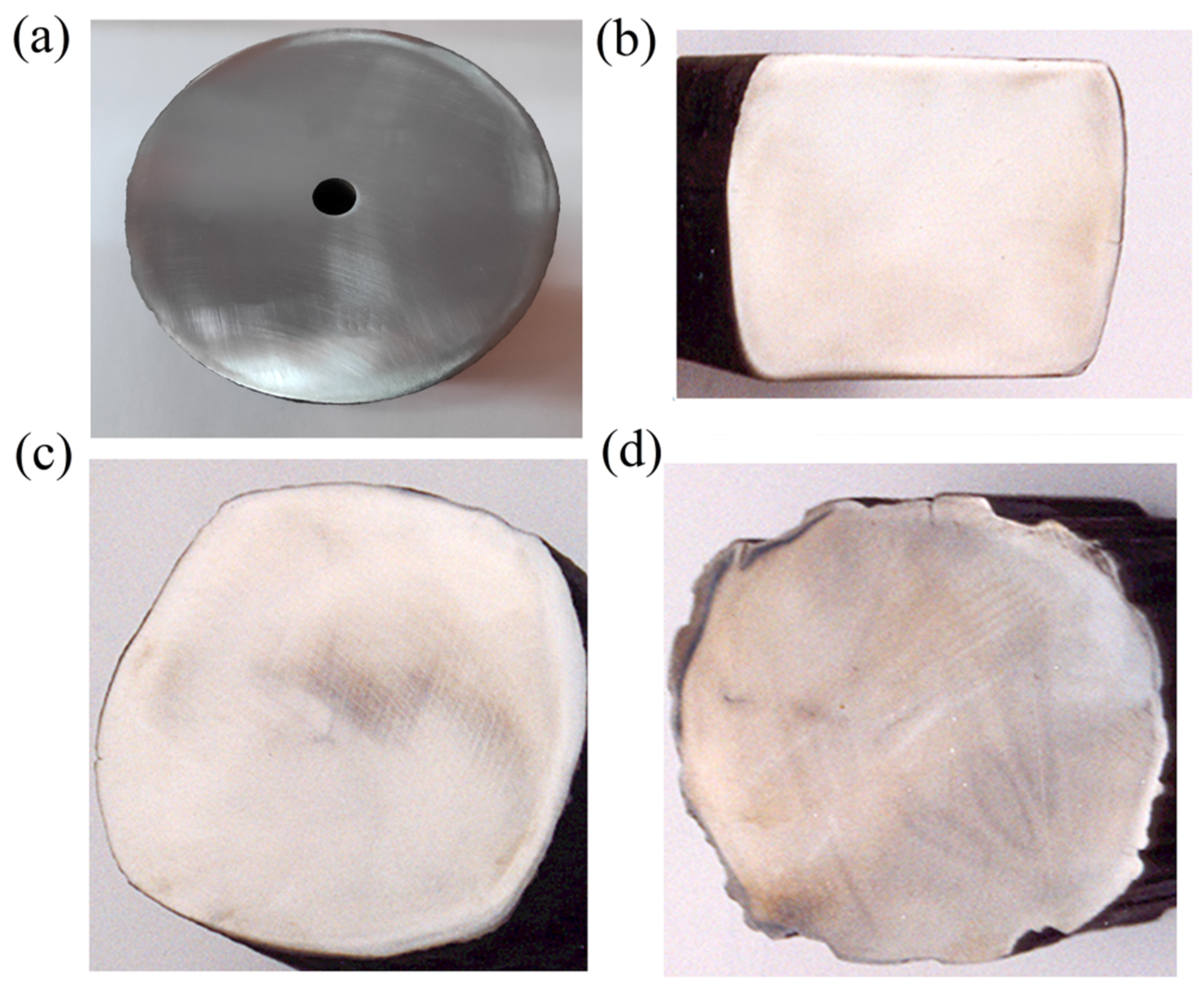

Figure 15 presents a view of the selected macro-sections of specimens after closing an axial void (

d0/

D0 = 0.20) forged in anvils of different shapes. The investigation showed that the best result in closing an axial cylindrical void was obtained from cogging in

V-shaped anvils. Using those anvils was very efficient in terms of void closure, as the cogging resulted in almost a complete closure of the void in the first forging pass (

Figure 15c). The use of flat anvils required a much larger total deformation; after the third pass the upper and lower void surfaces were closed together simultaneously, which was confirmed by experimental tests (

Figure 15b).

Figure 15d shows a view of a macro-section after the third pass with the assembly of three radial anvils demonstrating levelling of the formed unevenness in flat anvils.

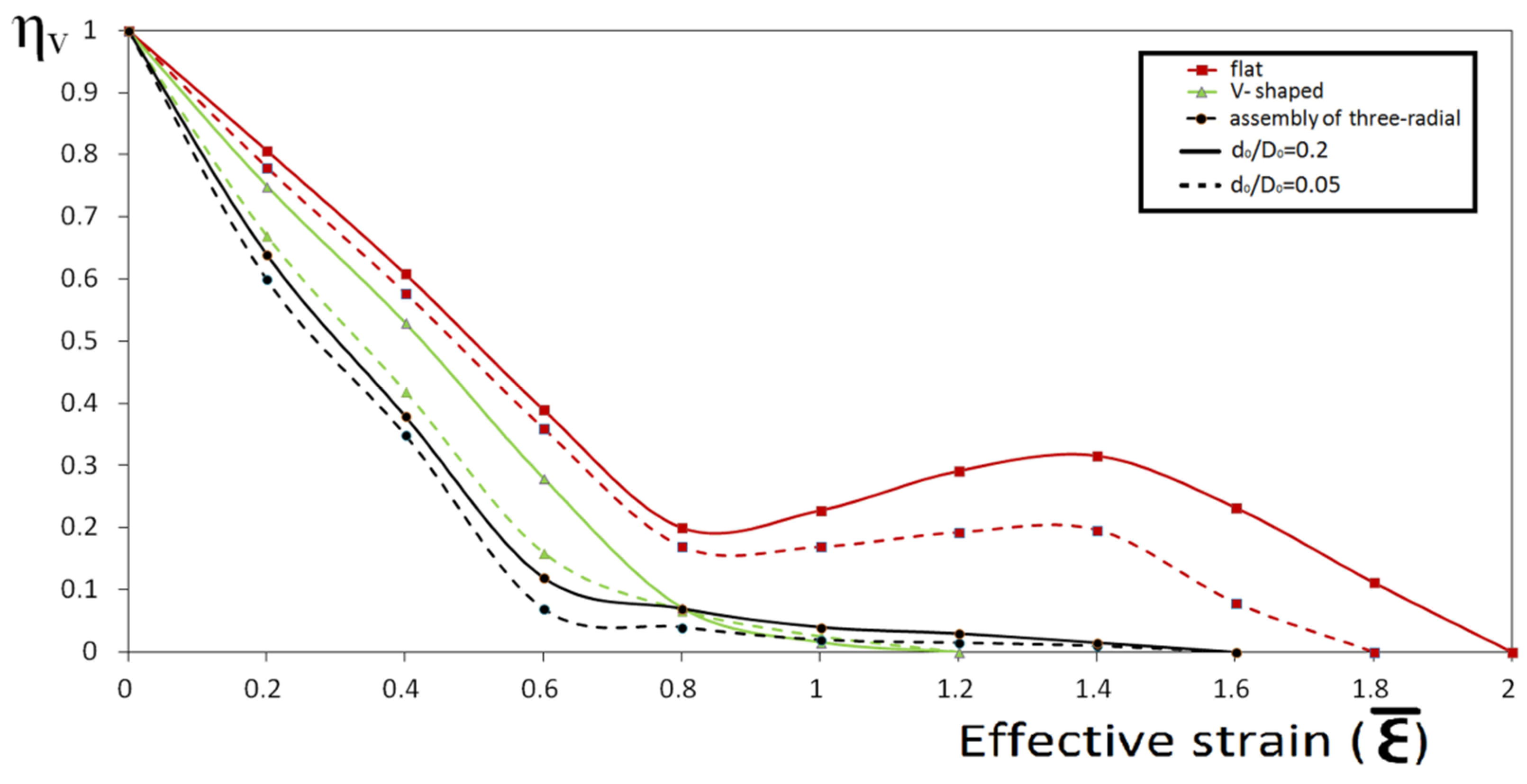

The distribution of the relative void volume evolution ratio (

ηV) as the function of effective strain and anvils shape is shown in

Figure 16. The complete closure of an axial void occurred when the effective strain around it reached the values of 1.20, 1.60, and 1.80–2.0 for the

V-shaped anvils, the assembly of three radial anvils, and the flat anvils, respectively; the value

= 2.0 concerned the void having larger size (

d0/

D0 = 0.20). The value of the effective strain indispensable for the closure of the void was a very effective parameter.

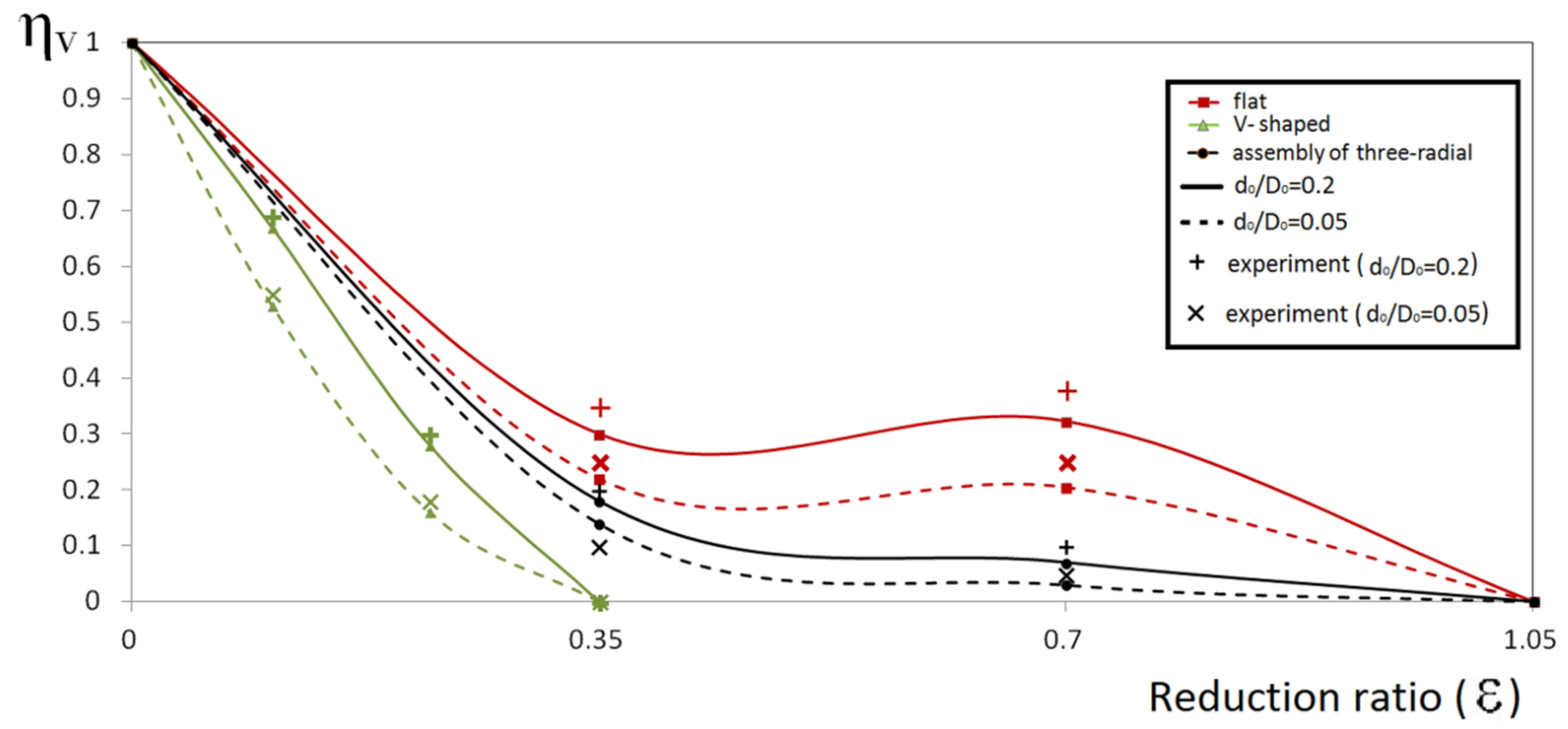

The relative void volume evolution ratio as a function of the reduction ratio and the shape of anvils is shown in

Figure 17. For the purpose of the assessment, the total reduction ratio and three shapes of anvils were considered. For the verification of the theoretical studies, selected experimental test results are presented for the same tools and the same cogging process parameters as those adopted in the computer simulations of void closing. The experimental test results after particular passes are plotted in

Figure 17. It was observed that the changes in morphology of voids having different initial diameters were similar.

V-shaped anvils turned out to be the most effective in the void closure process. After the first pass, all three differentially sized axial voids underwent a complete closure (

ε = 0.35). In the assembly of three radial anvils and in flat anvils, a complete closure of all three differentially sized axial voids occurred after the third pass (

ε = 1.05). The processed results showed that the predicted results of the numerical investigation concerning the relative void volume evolution ratio were in a full agreement with those of the experimental investigation.

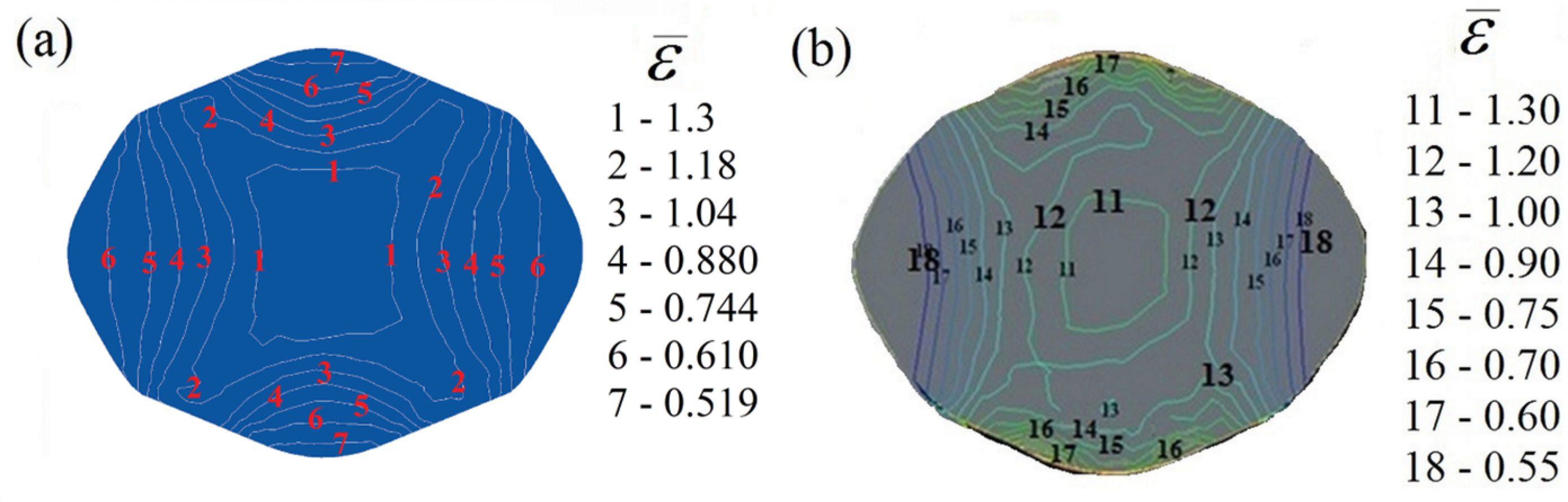

The results of the experimental and numerical investigations of the distribution of the effective strain in the course of cogging in

V-shaped anvils (

α = 130° × 130°) are shown in

Figure 18. The state of strain was determined with the application of the coordinate grid method. The performed comparative analysis of the effective strains obtained by means of numerical calculations and of experiments manifested a comparatively good agreement between them.

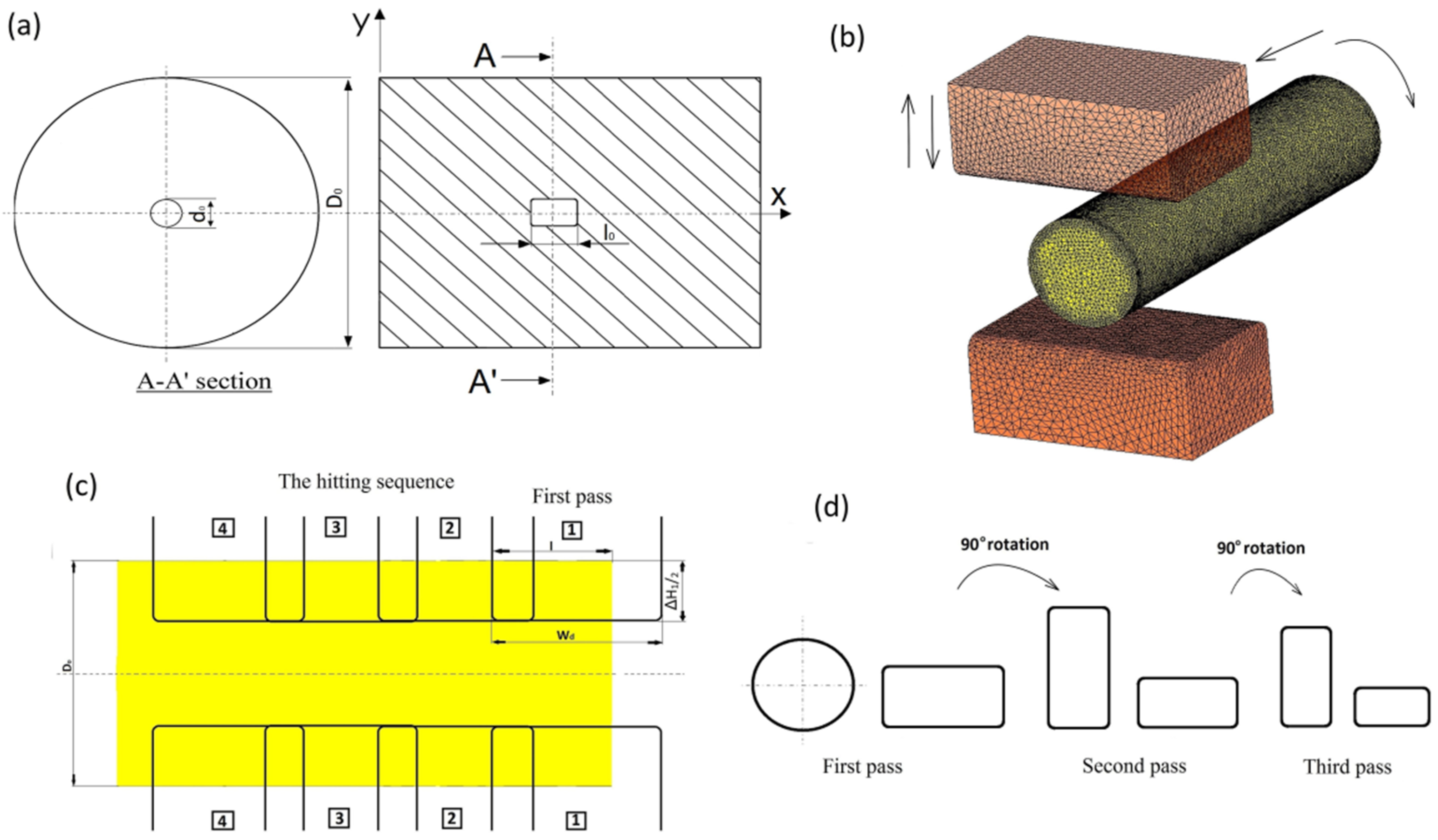

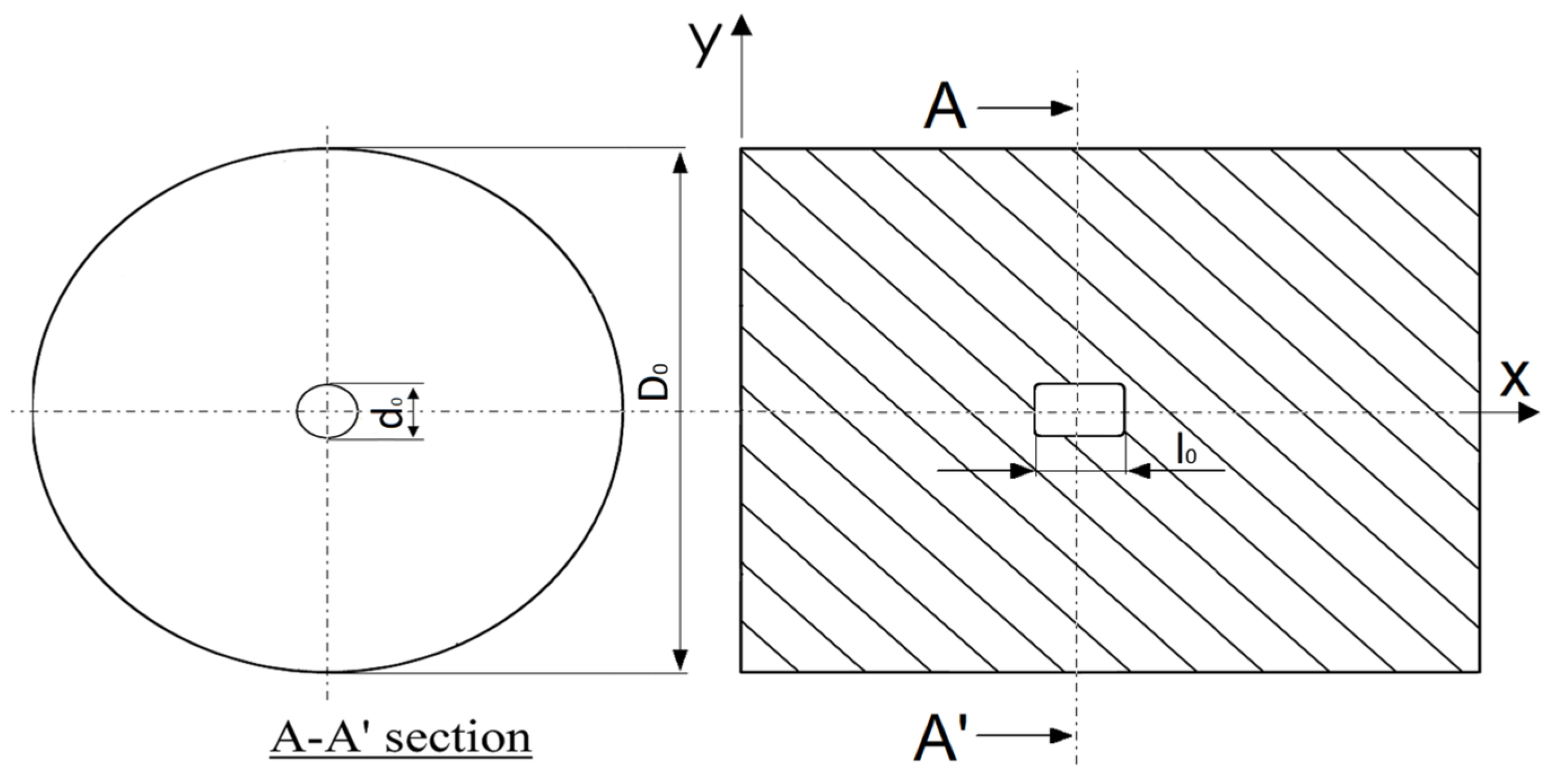

The initial billet with a void of different sizes for the multi-pass cogging process in flat anvils, in the form of an initially forged ingot having the dimensions φ 800 mm × 2000 mm, is shown in

Figure 19. The relative sizes of the void were the same as in the model investigations (

d0/

D0 = 0.05, 0.10, and 0.20). The same diagram of passes as in the model investigations was applied. The forging was performed in eight consecutive passes in order to reach the forging ratio of

K = 3.0 (with interoperation rotation of 90°), while maintaining a reduction ratio of

ε = 0.35 and a constant feed rate of

lw = 0.75 in every pass. The initial temperature of the billet was 1373 K, and that of the anvils was 573 K. The choice of flat anvils in further analysis of the void closure process was determined by their frequent application in industrial practice.

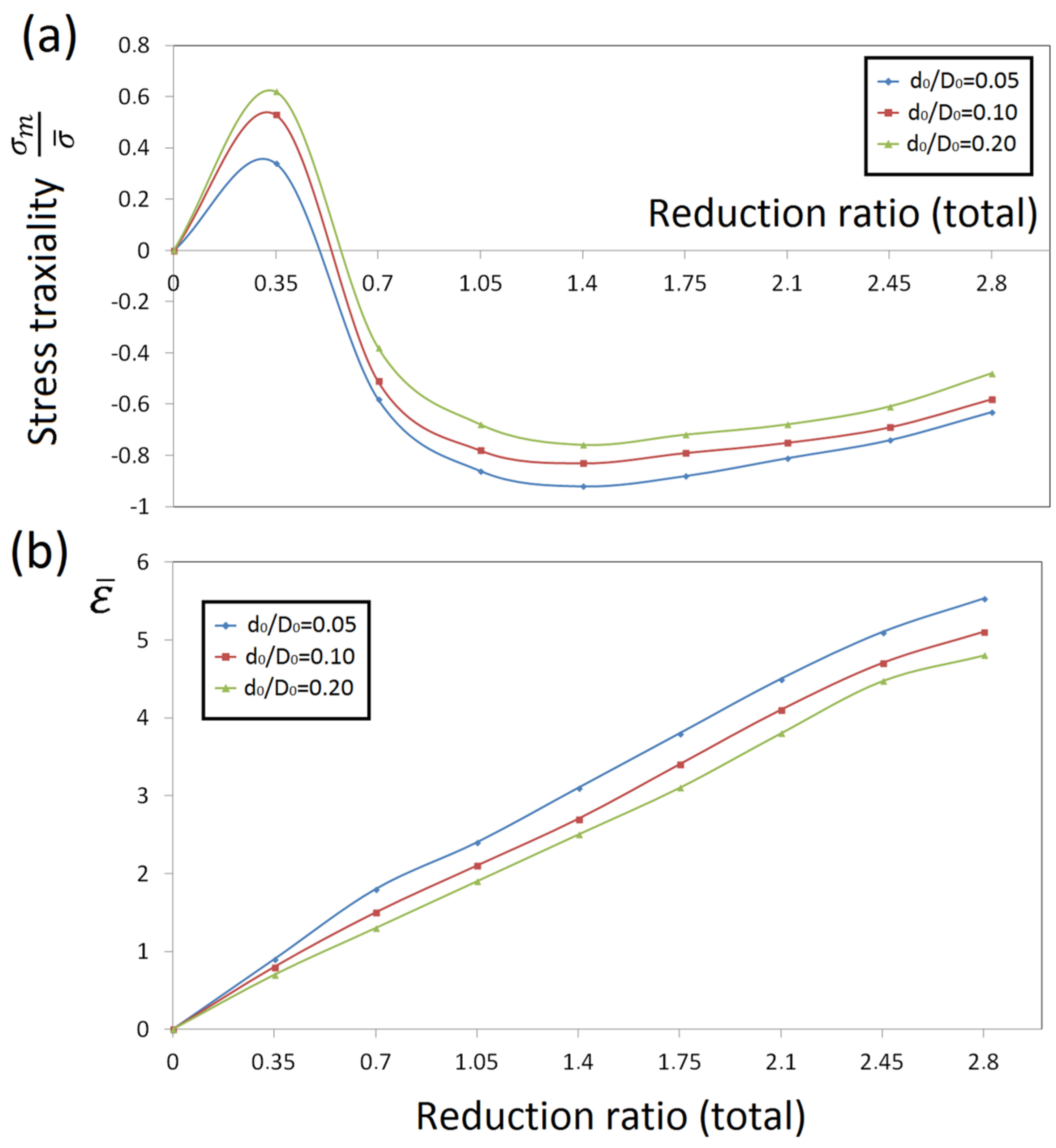

Figure 20a illustrates the results of the calculations of stress triaxiality for axial voids with different sizes, i.e.,

d0/

D0 = 0.05, 0.10, and 0.20 in the course of cogging in eight passes (forging ratio

K = 3.0) in flat anvils. The figure shows that the first two passes were completed in the presence of tensile stresses around the void. Commencing with the third passes, a higher hydrostatic pressure, which increased the effectiveness of void closure, was generated. All the sizes of the axial void, commencing with the third pass, underwent deformation in the presence of compressive stresses. The correlation between the effective strain and the total reduction ratio is shown in

Figure 20b. While the reduction ratio was increasing, the values of the effective strain around the axial void were rising intensively, regardless of the size of it, which exerted a positive influence on the process of void closure.

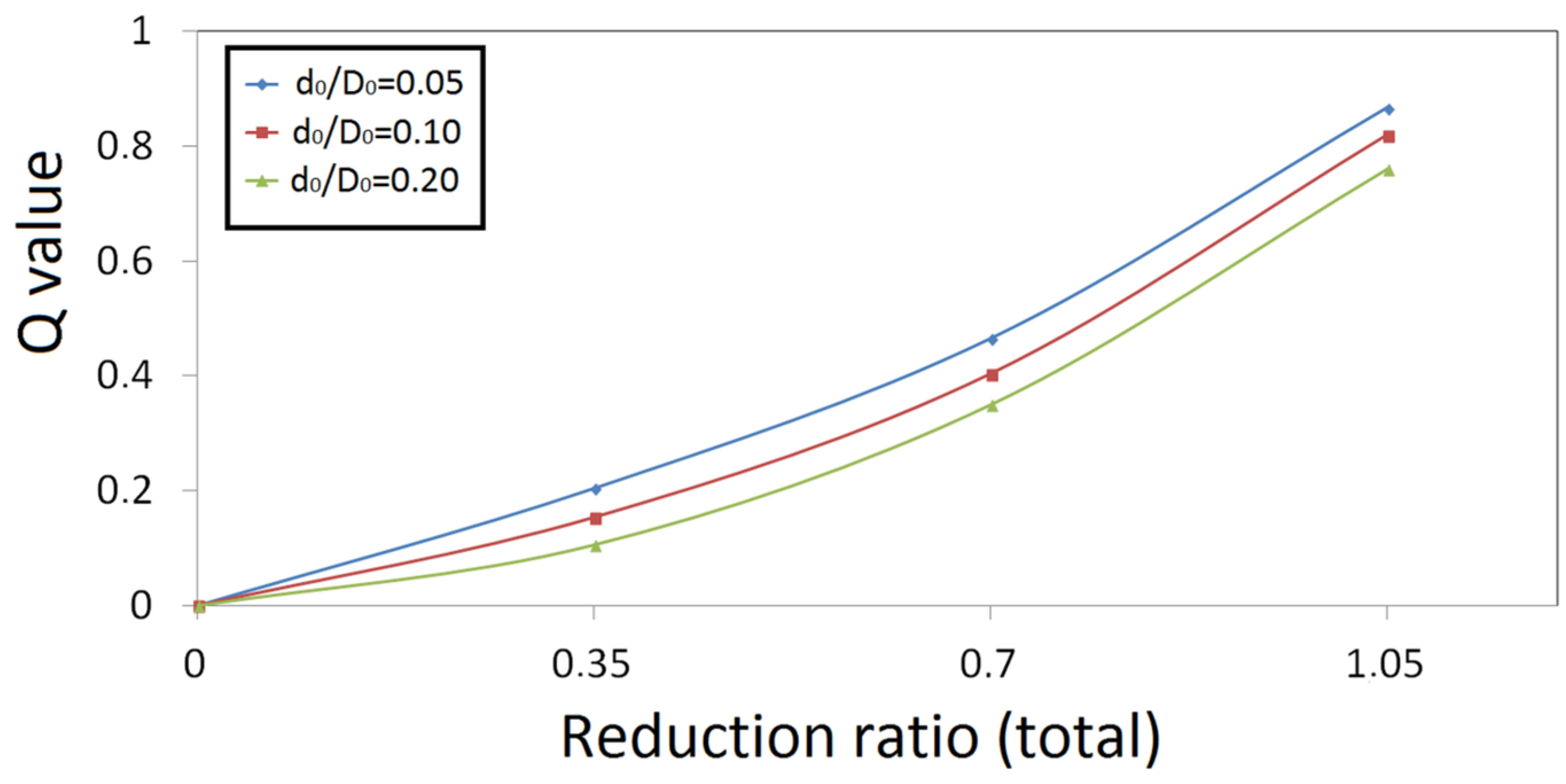

The variation of the void closure evaluation index (

Q value) as a function of the reduction ratio and for three sizes of axial void (

d0/

D0 = 0.05, 0.10, and 0.20) is plotted in

Figure 21. The presented correlations give rise to the claim that the values of

Q value for particular sizes of axial void were between 0.75 and 0.85, according to the closure time.

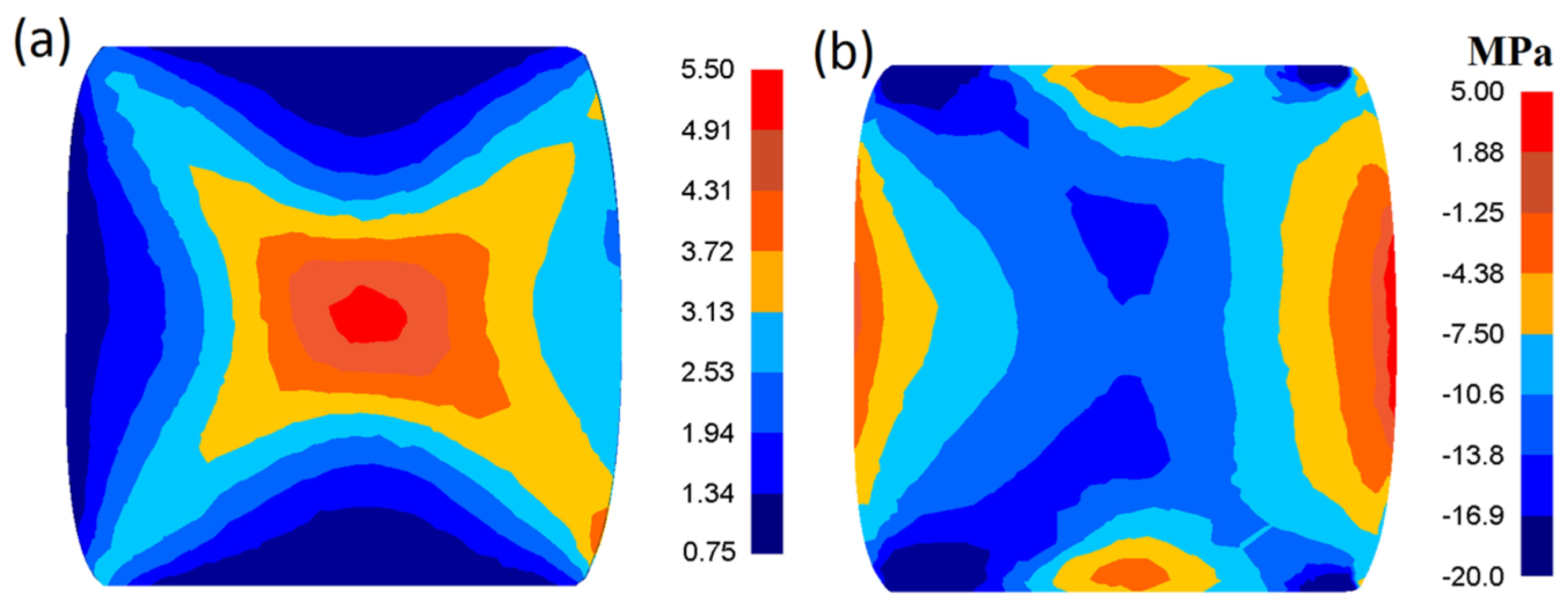

In the practice of cogging, a very important parameter in the assessment of the internal quality of forgings is the minimum critical forging ratio. In the contemporary production process, in order to ensure that all voids can be eliminated, it is recommended that the critical forging ratio amount to 3.0, as confirmed by Zhang et al. [

13]. The distribution of effective strain and mean stress on cross-section surfaces after the multi-pass cogging process on flat anvils with a forging ratio of

K = 3.0 is shown in

Figure 22. In the case of such a forging ratio in the central part of the cross section of a forging, large values of the effective strain, amounting to

= 3.72–4.91 (

Figure 22a), with compressive stresses dominating in this zone, were observed (

Figure 22b). In the remaining zones, much smaller effective strain values were observed.

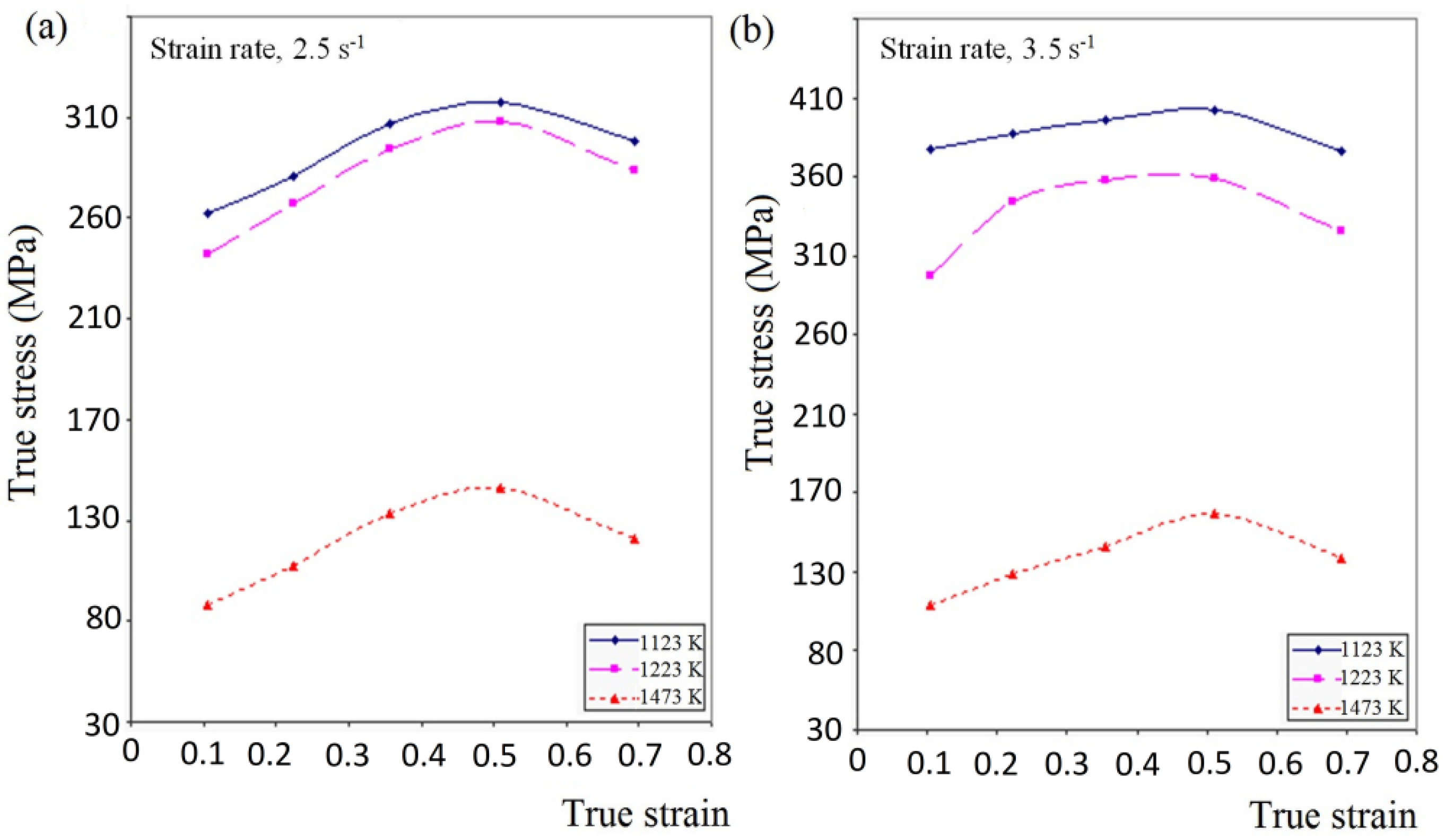

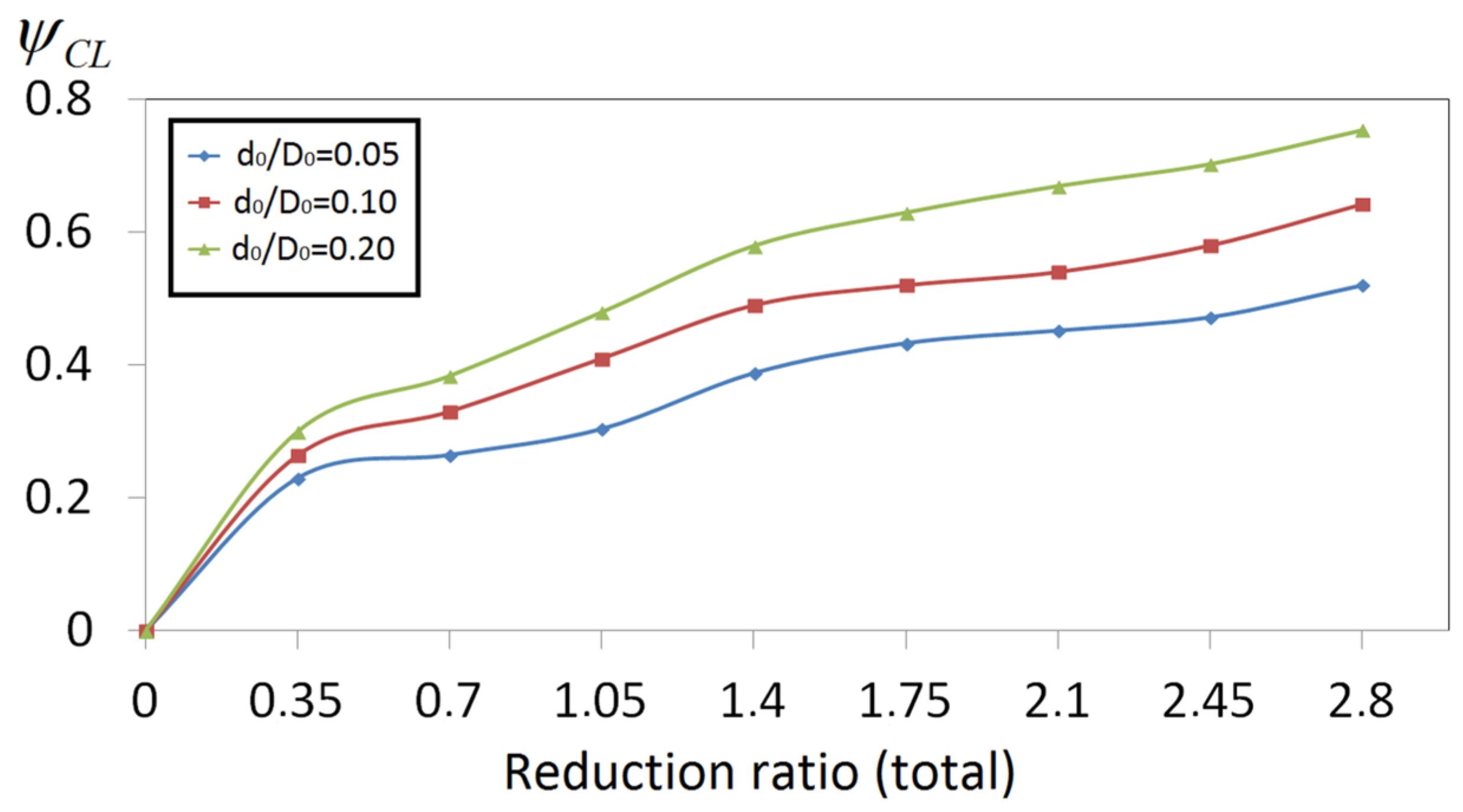

Figure 23 presents the correlation between the total reduction ratio and the damage factor for axial voids with different sizes (

d0/

D0 = 0.05, 0.10, and 0.20) in the course of a multi-pass cogging process in flat anvils. The applied Normalized Cockcroft and Latham Criterion (

ψCL) presented different values depending on the size of the axial void. The highest values of

ψCL were found for

d0/

D0 = 0.20, and they manifested a tendency to grow with the increase in the reduction ratio. The lowest values of

ψCL were obtained for the smallest void (

d0/

D0 = 0.05). After the third pass (

ε = 1.05), when the axial void underwent complete closure, the values of

ψCL for the investigated sizes of void did not exceed the critical damage value and amounted to: 0.30, 0.42, and 0.48 for

d0/

D0 = 0.05, 0.10, and 0.20, respectively.

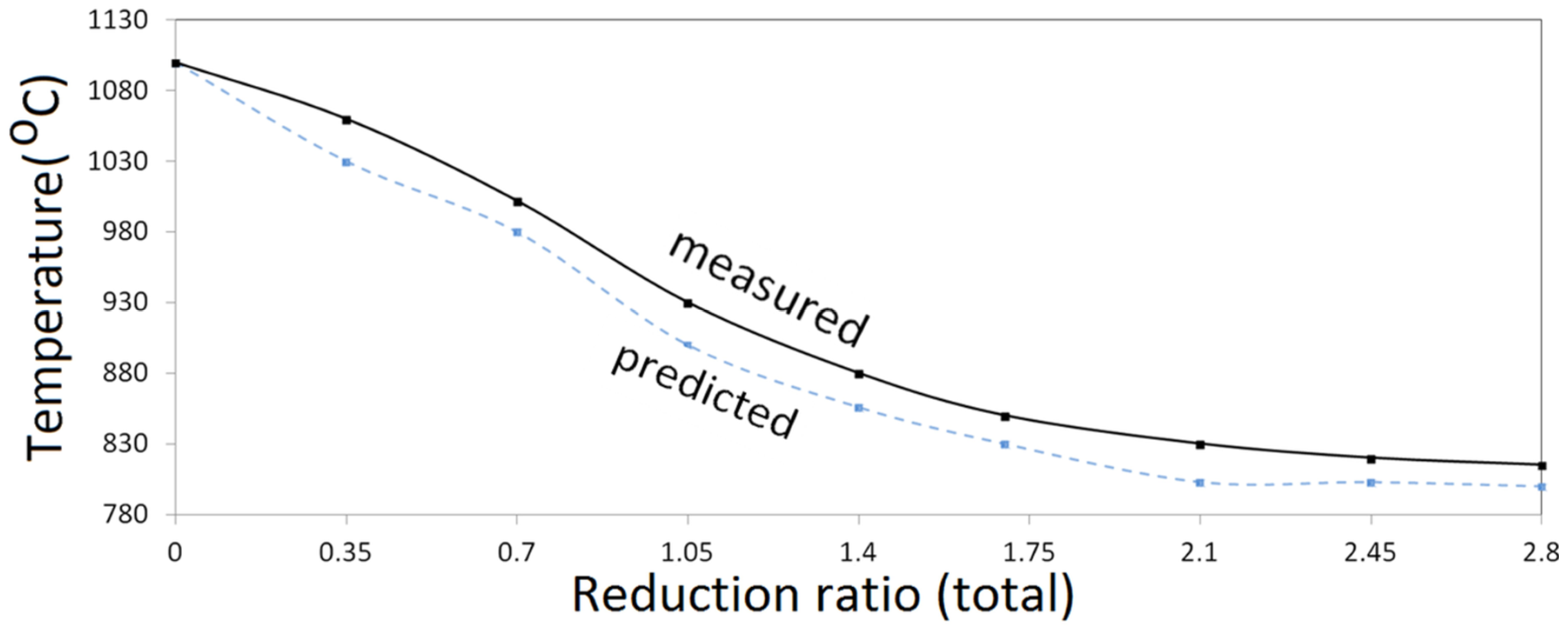

The calculated temperature after particular technological passes was compared with the experimental temperature measured at selected points on the surface of the deformed workpiece during the multi-pass cogging process in an integrated computer-controlled forging line with a 20 MPa hydraulic press (

Figure 24). The measurement of temperature was performed with the use of a thermo-visual camera. The comparison showed a good agreement between the predicted and the experimental measurements.

4. Conclusions

This article reports the most important findings related to the study of the effect of hot cogging process parameters and shape of anvils on void closure efficiency (a novelty for forging technology). Void closure is an important scientific and technical problem, which requires a new complex methodology to eliminate voids. In this study, new forgings systems were investigated in comparison with the cogging process in flat anvils. The influence of the different initial sizes of the axial void and of the shape of the tools, the analysis of the indices characterizing the void closure process in the consecutive passes, the state of stress and of strains around the void were determined quantitatively. The major results are summarized as follows:

(a) For the quantitative analysis of the closure of an axial void, the following indices were introduced: the relative void diameter ratio (), the void area ratio (), the relative void volume evolution ratio (), and the internal closure evaluation index (Q value). When , , and become 0, the axial void will be closed. The relative void volume evolution ratio () was the first-order index during the multi-stage void closure process, when the workpiece is rotated between each forming stage. In the course of the multi-pass cogging process of an ingot on flat anvils, the complete closure of an axial void was ascertained when the internal void closure evaluation index Q was equal to 0.85.

Furthermore, for the purpose of the assessment of the void closure process, the effective strain and the hydrostatic stress around the void, the stress triaxiality (), and the critical reduction ratio were determined. The effective strain and the hydrostatic stress in the region surrounding the void were very effective parameters which dominated the closure of voids during cogging. The complete closure of an axial void occurred ( = 0) when the effective strain around it reached the values of 1.20, 1.60, and 2.0 for the V-shaped anvils, the assembly of three radial anvils, and the flat anvils, respectively.

The state of stress around an existing void significantly influenced the process of its evolution. The absence of tensile stress in the axial workpiece zone was observed in V-shaped anvils and in the assembly of three radial anvils. In the cogging process on flat anvils, compressive stress in the central part of the forging was observed in the third pass. All differentially sized axial voids, commencing with the third pass, underwent deformation in the presence of compressive stresses (the stress triaxiality reached the values of −0.9).

The complete closure of all three differentially sized axial voids (d0/D0 = 0.05, 0.10, 0.20) occurred when the critical reduction ratio amounted to 0.35 (after the first pass), 1.05, and 1.05 (after the third pass) for the V-shaped anvils, the assembly of three radial anvils, and the flat anvils, respectively.

In the practice of forging, a very important parameter in the assessment of the internal quality of forgings is the minimum critical forging ratio. In order to ensure that all voids are eliminated, a critical forging ratio of K = 3.0 is recommended. In the case of such a forging ratio in the central part of a forging, large values of the effective strain amounting to = 3.72–4.91 (on flat anvils, K = 3.0), with compressive stresses dominating in this zone, were observed.

(b) V-shaped anvils (α = 130° × 130°) were found to be the most effective in the void closure process in the case of an axial void with different sizes, in comparison with the other anvils. Flat anvils were found to be the least effective in the void closure process. The efficiency of the assembly of three radial anvils in the void closure process was significantly lower than the efficiency of V-shaped anvils, but their greatest asset was a highly uniformity of the effective strain distribution in the deformation zone, accompanied by the absence of tensile stresses in the axial zone of the workpiece.

(c) On the basis of the Cockcroft–Latham criterion, the ductile damage model was developed for predicting the formation of cracks during the multi-pass cogging process in flat anvils. The effect of the size and the effect of the total reduction ratio and deformation temperature on the value of the ψCL criterion were examined. After the complete closure of an axial void, the values of ψCL did not exceed the critical damage value.