Abstract

During the two-pass stretch forming process for manufacturing of thin-walled aluminum alloy sheet components, abnormal grain growth may happen if an improper pre-deformation degree was conducted before solution heat treatment, which is negative to the performance and surface quality of the final components. In order to overcome this problem, the effect of pre-stretching deformation was investigated on the change of grain structures of 2219 aluminum alloy sheets. The 2219 aluminum alloy sheets were pre-stretched with various deformation degrees, and then were heated to 540 °C for about 50 min for solution treatment. The grain structures before and after solution treatment were characterized using an optical microscope (OM) and electron back scattering diffraction (EBSD). Results show that the grains grew up gradually during the solution treatment with an increase of pre-stretching. The critical pre-stretching degree is about 3%. Once the pre-deformation exceeds 3%, the grain growth is significant, especially when it reaches 5%. Moreover, the pre-stretching has little influence on the orientation distribution. Some near a copper texture {112}<111> were generated as the pre-stretching degree was increased to 5%. All the results suggest that the pre-stretching before solution treatment cannot be larger than 3% in the two-pass stretch forming of a 2219 aluminum sheet.

1. Introduction

In recent years, the technology of deep space exploration has become important for a country as a symbol of comprehensive strength and innovation ability [1]. Therefore, higher requirements, such as lightweight, high strength and accuracy, are put forward for the manufacturing of complex thin-walled components with the rapid development of aerospace industry [2,3,4]. As a typical light and high strength aluminum alloy, 2xxx aluminum alloys are widely used in the launch vehicle and aircraft, especially the rocket propellant tank, due to its higher mechanical properties at low and high temperature, lower density, high stress corrosion cracking resistance, and better weldability [5]. At present, the aluminum-copper alloy 2219 is a widely used material for the new generation rocket tank components [6]. For the thin-walled components with a large size, they are usually manufactured using the stretch forming process, which is widely used in the field of aerospace. During the stretch forming process, the sheet material is first clamped between the two jaws of the machine and is stretched by the jaws until it completely contacted with the die surface [7].

However, the strength of the work-hardened components after stretch forming is insufficient for use. Because the 2219 aluminum alloy is heat-treatable, a heat treatment can be conducted before and/or after the stretch forming process. In this case, the microstructure and mechanical properties of the thin-walled 2219 aluminum alloy components can be improved efficiently by the combined action of stretching deformation and heat treatment strengthening [8]. The common route is solution heat treatment → stretch forming → aging treatment (or stretch forming → solution heat treatment → aging treatment) for the manufacture of thin-walled 2219 aluminum alloy components. However, in such a one-pass stretch forming process, the asymmetric structure of the thin-walled component and non-simultaneous contact with the dye surface lead to inhomogeneous deformation in the whole range. In addition, if the stretch forming is conducted before solution heat treatment, abnormal grain growth in the subsequent heating stage is negative to the performance and surface quality of the final component. In this case, another manufacturing route was proposed, i.e., pre-stretching → solution heat treatment → final-stretching → aging treatment, which can be described as a two-pass stretch forming process [9]. Reasonable matching of two-pass stretching and heat treatment can improve the deformation uniformity and strength simultaneously. But it should be noted that the 2219 aluminum alloy sheet must undergo the appropriate deformation amount in the pre-stretching stage, otherwise its microstructure may be deteriorated in the subsequent solution heat treatment stage [10].

Therefore, the effect of pre-deformation on the microstructure and properties of the 2219 aluminum alloy during the heat treatment stage has been investigated extensively over the past decade [11,12,13]. Lu et al. [11] and Wang et al. [12] investigated the effect of the pre-compression amount on the microstructure and mechanical properties of solution treated 2219 aluminum alloy during subsequent aging treatment. They found that the pre-compression deformation between solution treatment and artificial aging not only shortened the aging time, but also led to an increase of the dislocation density in the matrix, which gives rise to the formation of dense, smaller, and dispersive θ’ precipitates. This is beneficial to the microstructure improvement and strength enhancement, especially at pre-deformation of 3%. Similar results were also found in an aged 2524 aluminum alloy with pre-stretching deformation before aging treatment [14]. To simultaneously enhance the strength and ductility of age-hardened Al-Cu-Mg alloys, cold rolling deformation at room temperature was introduced between the solution and aging. It was found that the high density of nanosized S’’-phase precipitates and dislocations caused an increase in strength [15]. For an Al-Cu-Li alloy, if 3% pre-stretching deformation or 8% pre-rolling deformation was conducted between solution and aging treatment, the pole density level of Goss texture was decreased remarkably and the intensity of brass, cube texture was increased lightly. The damage tolerance of the alloy is increased by the pre-deformation treatment [8]. All of these investigations show that pre-deformation between solution and aging treatment is beneficial.

Moreover, different cold rolling pre-deformations (5%, 10%, 20%, and 30%) were imposed on 2219 aluminum alloys by Lu et al. [16] before solution heat treatment. It was found that 20% pre-deformation was the best condition for the formation of fine and dispersive θ′ phases. He et al. [17] found that a higher number of coarse Al2Cu particles could dissolve in the Al matrix during solution treatment if a bigger cold pre-deformation was performed before solution treatment. Finally, the mechanical properties of the forgings after aging were further improved. However, in their work, a 2.5% deformation was also conducted between the solution and aging treatment, whose effect on mechanical properties of the forgings could not be ruled out. He et al. [18] also conducted a multidirectional forging (MDF) at 360–510 °C before solution treatment, and investigated the effect of forging temperature on second-phase particles and mechanical properties of a 2219 Al-Cu alloy. Moreover, the approach of “thermal compression tests + solid solution treatment experiments” was used by Liu et al. [19] to explore the effects of deformation parameters (i.e., temperature, strain, and strain rate) on grain refinement of a coarse grain 2219 aluminum alloy. In our previous preliminary work about the two-pass stretch forming process of 2219 aluminum alloy sheets [10], it was found that the tensile strength of a 2219 aluminum alloy sheet reaches the maximum value when the pre-stretching deformation is about 2%, after which the strength decreased. The decrease of strength may be related to the change of grain structure during the solution treatment at 535 °C. However, the effect of pre-deformation on the grain structure of the 2219 aluminum alloy during solid solution treatment has not been studied. In the two-pass stretch forming process, fine grain 2219 aluminum alloy sheets are often used as the original blank. If an improper pre-stretching degree is conducted before solution heat treatment, the grains may grow abnormally in the subsequent solution heating stage, which is negative to the performance and surface quality of final components. Therefore, it is necessary to conduct thorough research about the grain structure change with different pre-stretching deformations, so as to reveal the grain coarsening process and its formation mechanism, and a suitable pre-stretching amount can be determined based on this investigation. This is very important from a technological point of view.

In this paper, the 2219 aluminum alloy sheets were pre-stretched with various deformation degrees before the solution heat treatment. Then, the pre-stretched samples were heated in an air circulation quenching furnace for the solution heat treatment. The grain structures of the 2219 aluminum alloy sheets before and after solution heat treatment were characterized using an optical microscope (OM) and electron back scattering diffraction (EBSD). Based on these results, the change of grain structure is discussed and the grain coarsening mechanism is revealed. Finally, the critical pre-stretching amount is determined for preventing abnormal grain growth.

2. Materials and Experimental Methods

2.1. Materials

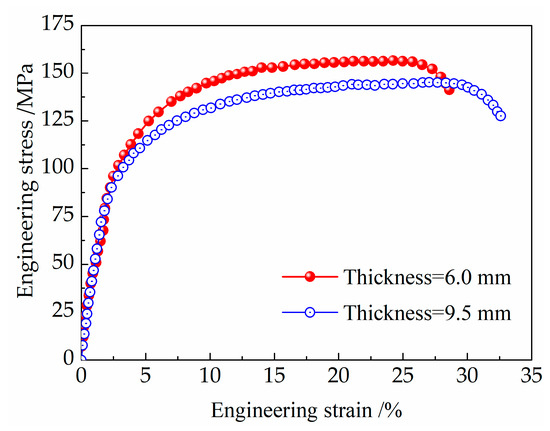

The as-received sheet materials used in this investigation were 2219 aluminum alloy sheets in an annealed state. It was an aluminum-copper alloy with the composition of 5.8–6.8 wt.% Cu, 0.2–0.4 wt.% Mn, ≤0.2 wt.% Si, 0.10–0.25 wt.% Zr, ≤0.3 wt.% Fe, ≤0.02 wt.% Mg, 0.1 wt.% Zn, 0.05–0.15 wt.% V, 0.02–0.10 wt.% Ti, and balance Al. Their nominal thicknesses were 6.0 mm and 9.5 mm, respectively. The uniaxial tensile tests were conducted on a universal material testing machine along the rolling direction of the two types of sheet materials. Their engineering stress-strain curves are presented in Figure 1, and the corresponding mechanical parameters are listed in Table 1.

Figure 1.

Engineering stress-strain curves of annealed 2219 aluminum alloy sheets.

Table 1.

Mechanical properties of as-received 2219 sheet materials along the rolling direction.

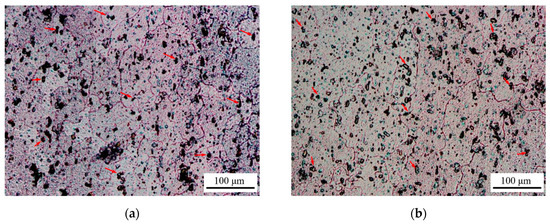

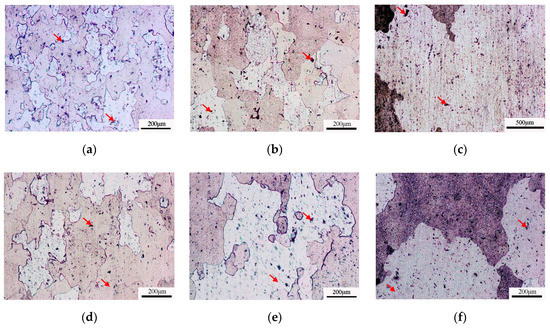

Figure 2 shows the initial metallographic structure of the 2219 aluminum alloy sheets with different thicknesses. There are many black spots, as identified by the red arrows, which may be produced during the chemical etching process at the position of porosity or second phase. In spite of this, the grain boundary is clearly visible for the measurement of the average grain sizes, which were not affected by the black spots. Therefore, their average grain sizes were measured from Figure 2 using the intercept line method. It was calculated that the 6.0 mm thick 2219 aluminum alloy sheet had an average grain size of 57 μm while the 9.5 mm thick sheet had an average grain size of 100 μm. It was found that the average grain size of the two kinds of 2219 aluminum alloy sheets was less than 100 μm, which means they are fine grain materials. Moreover, it was seen that the average grain size of the 9.5 mm thick sheet was bigger than that of the 6.0 mm thick sheet, which may be related to the rolling process.

Figure 2.

Initial metallographic structure of 2219 aluminum alloy sheets: (a) sheet with nominal thickness of 6.0 mm; (b) sheet with nominal thickness of 9.5 mm.

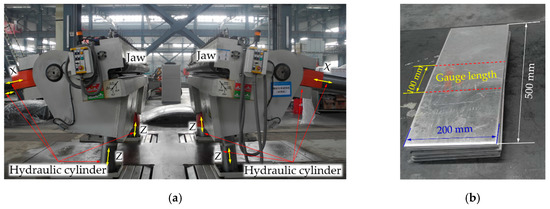

2.2. Experimental Equipment for Stretching

Figure 3 shows the CNC (Computerized Numerical Control) sheet stretch forming equipment used for the stretching deformation and the 2219 aluminum alloy sheet specimens. This is the FET-1500 stretch forming machine manufactured by the Alstom-ACB (Nantes, France), and continuous stretch forming action is available on it. The clamping motion device of the stretch forming machine consists of two jaws and respective four telescopic hydraulic cylinders. In the stretching process, the sheet was gripped between the two jaws and was stretched with the combined movement of the hydraulic cylinders according to the predetermined trajectory. The maximum vertical tensile force of the machine is 15,000 kN, and the maximum horizontal tensile force is 7500 kN. Moreover, a sheet with maximum size of 6000 mm × 4000 mm can be stretched using this equipment.

Figure 3.

CNC sheet stretch forming equipment and specimens: (a) stretch forming equipment; (b) the 2219 aluminum alloy sheet specimens.

2.3. Experimental Methods and Schemes

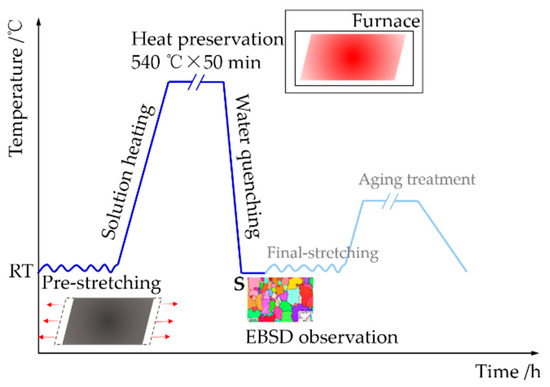

In stretch forming, a two-pass stretching process was often applied on the 2219 aluminum alloy sheets at room temperature, as shown in Figure 4. The specific experimental process is as follows: (1) pre-stretching in the annealed state; (2) solution heat treatment; (3) final-stretching; (4) aging treatment. In this investigation, the annealed 2219 aluminum alloy sheet was first pre-stretched with different deformation amounts at room temperature using the CNC sheet stretch forming equipment. The initial size of 2219 aluminum alloy sheet samples was 500 mm × 200 mm, as shown in Figure 3b. The pre-stretching deformation of the 100 mm gauge length was 3%, 4% and 5%, respectively. After pre-stretching, the deformed samples were heated in an air circulation quenching furnace for the solution heat treatment. The solution temperature and time were selected as 540 °C and 50 min, respectively. Finally, the 2219 sheet samples were taken out from the furnace quickly and were quenched in water in order to preserve the supersaturated solid solution.

Figure 4.

Schematic diagram of two-pass stretching process.

After water quenching (point S, Figure 4), the grain structure of the 2219 aluminum alloy sheet specimens were analyzed by an optical microscope (OM, Leica, Wetzlar, Germany) and electron backscattering diffraction (EBSD) technique on a Quanta 200 FEG-SEM machine (FEI, Portland, OR, USA). Both of the OM and EBSD specimens were cut from the center of the 2219 aluminum alloy sheet. The specimens were milled progressively using the 100 #, 400 #, 800 # and 1000 # metallographic abrasive papers, and then were electropolished in electrolytic solution containing 90% absolute ethyl alcohol and 10% perchloric acid for about 45 s. During the electropolishing, the temperature of the electrolytic solution was kept at about −25 °C with the aid of liquid nitrogen, and the electric current was about 0.8 A. After electropolishing, the specimens were directly used for the EBSD observation. The working distance and step size were defined as 13 mm and 6 μm, respectively. The dimension of selected area was 1500 × 1195 μm2. The beam intensity and operating voltage were set as 20 A and 30 kV, respectively. Finally, a good result with an average image quality of 259.9 can be obtained, and the EBSD data were analyzed using the TSL OIM 6.1 software (EDAX, Mahwah, NJ, USA). For the OM observation, the electropolished specimens should be then chemically etched in a solution of 10 mL hydrofluoric acid, 5 mL hydrochloric acid, 5 mL nitric acid, and 380 mL H2O. The grain size was measured using the software of Nano Measurer 1.2 (Fudan University, Shanghai, China) through the intercept line method.

3. Results and Discussion

3.1. Grain Structure

Figure 5 shows the influence of pre-stretching deformation on grain structure change in solution heat treatment. There were also some black spots on the metallography, as identified using the red arrows. It was obvious that the grains of the two kinds of 2219 aluminum alloy sheets grew up with increased pre-deformation. When the pre-deformation degree was 3%, the grain distribution was similar to the as-received sheets, presenting the typical near-equiaxed grain distribution. As the pre-deformation degree was increased, the grain grew up gradually. When the pre-deformation degree was 5%, the grain was very coarse, accompanied by obvious grain growth.

Figure 5.

Dependence of grain structure on pre-stretching for two kinds of sheets: (a) 3%, (b) 4%; (c) 5% with 6.0 mm in thickness; (d) 3%, (e) 4%; (f) 5% with 9.5 mm in thickness.

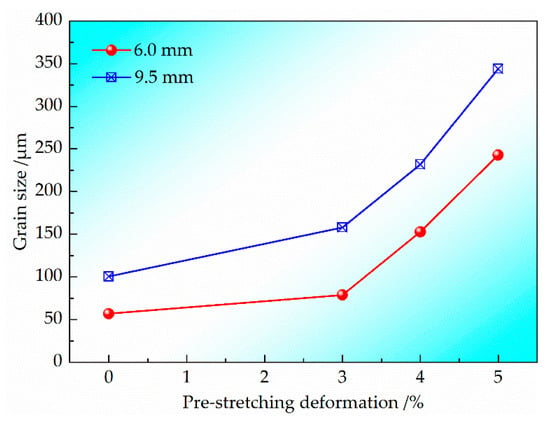

In order to quantitatively characterize the change of grain size with the increasing pre-deformation, the grain size was calculated with the average widths of more than 50 grains though a intercept line method. Figure 6 shows the grain size varying with the increasing pre-deformation. It is obvious that the grain size was increased after the pre-deformation exceeded 3%. When the pre-deformation was 5%, the grain size was increased to 350 μm, being 250% higher than the grain size without pre-deformation. The coarse grain might cause a series of problems like decreasing plasticity and surface roughing [20]. That is to say, the pre-deformation before solution heat treatment could not be larger than 3%, otherwise, the grain would grow up during solution heat treatment.

Figure 6.

Dependence of grain size on pre-deformation for the two kinds of sheets with thicknesses of 6.0 mm and 9.5 mm.

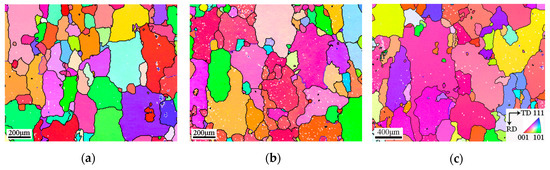

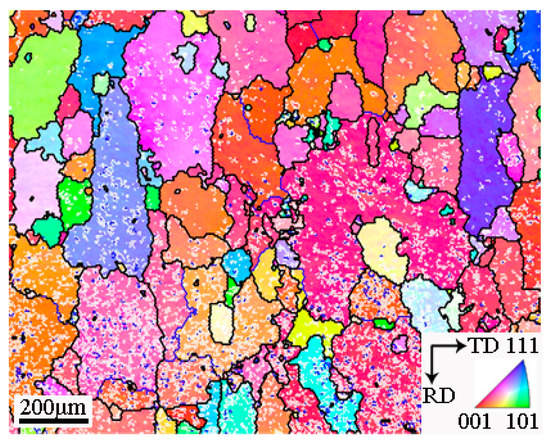

In order to further characterize the effect of pre-deformation on the grain structure and orientation changing in solution heat treatment, EBSD observations were carried out on the 2219 aluminum alloy samples with initial thickness of 9.5 mm, as shown in Figure 7. From the EBSD data, the [001] inverse pole figures (IPFs) were calculated to describe the grain structure. The IPF map was a color-coded map where the color gave an indication of the crystal direction aligned with the normal direction (ND) of the sample. Different colors represented different orientations of the grains. The high angle grain boundaries (HAGBs, >15°) were shown in black. The low angle grain boundaries (LAGBs) including 2–5° and 5–15°, were shown in white and blue, respectively. The grains indexed by EBSD are the regions enclosed by HAGBs. The results obtained were similar to the metallographic observation. It was shown from Figure 7 that there was no obvious change of grain structure when the pre-deformation was increased to 3%. After the pre-deformation was raised to 5%, the grain grew up obviously. The corresponding average grain area was 104.4% higher than the sample without pre-deformation. Meanwhile, the LAGBs almost disappeared, which illustrated that the static recovery and recrystallization occurred in the solution heat treatment.

Figure 7.

Inverse pole figure maps in the normal direction (ND) for grain structure of 9.5 mm thick 2219 aluminum alloy sheet under different pre-stretching deformation: (a) 0%; (b) 3%; (c) 5%.

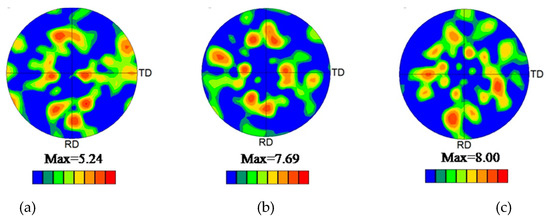

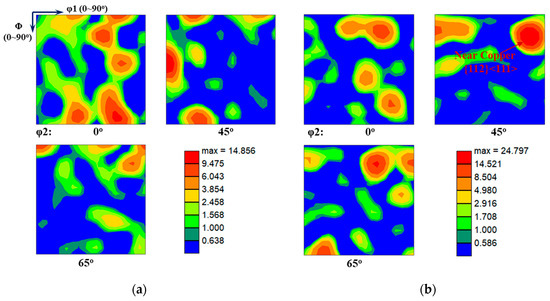

The pole figure (PF) was calculated to describe the grain orientation evolution, which could show the distinct texture components. The volume fraction of typical texture components was calculated with a widely used tolerance of 15°. It should be noted that the texture typically develops around brass {110}<112>, S {123}<634> and copper {112}<111> orientations during the rolling process, and around cube {100}<001> and Goss {110}<001> orientations during the annealing process [21,22]. Figure 8 shows the {111} PFs illustrating the texture evolution with increasing pre-deformation degree. It is shown that the orientation distribution was relatively random, accompanying weak near-Goss and copper textures. The pre-deformation had little influence on the orientation distribution due to the static recovery and recrystallization caused during solution heat treatment. In order to clearly show the effect of pre-deformation on the change of texture, orientation distribution functions (ODF) are also given in Figure 9. The orientation distribution in the un-deformed sample after solution treatment was similar to the texture distribution of as-received material in the annealing state. As the pre-deformation degree was increased to 5%, some near-copper texture {112}<111> was generated during the stretching and subsequent solution heat treatment processes (Figure 9b).

Figure 8.

Grain orientation of the 9.5 mm thick 2219 aluminum alloy sheet under different pre-stretching deformation: (a) 0%; (b) 3%; (c) 5%.

Figure 9.

Orientation distribution functions of the 9.5 mm thick 2219 aluminum alloy sheet for un-deformed and 5% pre-stretched samples: (a) 0%; (b) 5%.

3.2. Grain Coarsening Mechanism

Figure 10 shows the grain structure of the pre-stretching sample with a deformation degree of 5%, as well as the corresponding grain boundary distribution. It is apparent that the grain size did not change during the pre-stretching process, a large number of LAGBs were produced. The volume fraction of 2–5° and 5–15° grain boundaries were 60.0% and 6.5%, respectively. Compared with the solution heat treated sample (Figure 7c), the proportion of LAGBs was very high, and the grain growth did not occur. It illustrates that the grain growth was produced in solution heat treatment.

Figure 10.

Grain structure of the pre-stretching sample with deformation degree of 5%.

It should be noted that the energy stored in completely annealed metallic materials is usually a small fraction of the enthalpy of fusion. Significantly higher enthalpies can be stored via subsequent plastic deformation. A high density of dislocations and low angle boundaries can be produced within the grains. These microstructural features indicate high values of stored energy that will undergo recovery and recrystallization at elevated temperatures [23]. Grain growth in coarse grained materials can take place by boundary migration controlled by bulk diffusion or GB diffusion [24].

The kinetics of grain growth for recrystallized grains driven by GB surface energy is commonly expressed by the following equation:

where D0 is the initial grain size, t is the annealing time, n is the grain growth exponent and k1 is a temperature dependent parameter. The n value is mainly decided by the stored energy. In this process, the stored energy was increased with increased pre-stretching deformation, as shown in Figure 10, which resulted in grain coarsening under the other same conditions. By contrast, it was also found that the growth of some grains was not obvious after solution heat treatment, and the growth of several grains was remarkable. The reason was that a higher volume fraction of LAGBs were caused within these grains, resulting in the coarse grains.

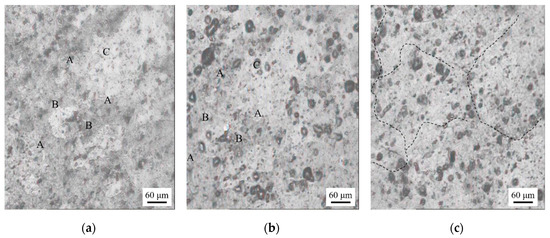

In order to further reveal the grain growth mechanism of the 2219 aluminum alloy sheets, in situ metallographic microscopy observation at elevated temperature was carried out. A sample with a pre-stretching deformation degree of 5% was sliced into 0.3 mm, polished and placed on the heating table of a high temperature metallographic microscope. The sample was heated to 535 °C at a heating rate of 10 °C/min. Figure 11 shows the metallographic structure evolution of three typical regions including A, B and C. Among them, region A contained many fine grains, region B had relatively coarse grains and region C had very coarse grains. It can be found that the phenomenon of grain growth was not obvious during the heating process, which exhibited the similar metallographic structure. After the temperature reached 535 °C, especially when soaking time was adopted at 6 min, obvious grain growth was caused. It illustrates that enough stored energy was produced, resulting in the grain coarsening.

Figure 11.

Metallographic structure evolution of the pre-stretched 2219 aluminum alloy sheet during solution heat treatment: (a) Initial state; (b) 535 °C; (c) 535 °C with a soaking time of 6 min.

4. Conclusions

In this investigation, the OM and EBSD were used to characterize the grain structure of pre-stretched 2219 aluminum alloy sheets during solid solution treatment. The change of grain structure was discussed and the corresponding mechanism of grain coarsening was revealed. The following conclusions can be drawn from above discussion:

(1) The grains of 2219 aluminum alloy sheets grew up obviously during the solution treatment with increased pre-stretching. When the pre-stretching deformation reached 5%, the grain size was increased to 350 μm, being 250% higher than the grain size without pre-deformation.

(2) The critical pre-stretching degree was about 3%. No obvious change of grain structure was observed after solution treatment when the pre-deformation was less than 3%, which is similar to the sample without pre-stretching. However, once the pre-deformation exceeded 3%, the grain growth was significant, which suggests that the pre-stretching before solution heat treatment could not be larger than 3%.

(3) The pre-stretching had little influence on the orientation distribution due to the caused static recovery and recrystallization during solution heat treatment. The orientation distribution in the un-deformed sample after solution treatment was similar to the texture distribution of as-received material. As the pre-stretching degree was increased to 5%, some near-copper texture {112}<111> was generated during the stretching and subsequent solution heat treatment processes.

(4) A high density of low angle boundaries (LAGBs) can be produced within the grains by the increasing the pre-stretching degree, which can increase the stored energy and result in the grain coarsening in subsequent solution heating. After the 5% pre-stretched sample was heated at 540 °C for about 6 min, obvious grain growth was caused.

Author Contributions

L.A. performed the pre-stretching and solution heat treatment and wrote the paper; J.L. prepared the samples and made the metallographic and EBSD observation, S.Y. proposed the conceptualization and experimental methodology, and provided all sorts of support during the work.

Funding

This research was funded by the National Natural Science Foundation of China, grant number U1637209, National Key Research and Development Program of China, grant number 2017YFB0306304, and the National Natural Science Foundation of Heilongjiang, grant number QC2018061. The authors wish to express their gratitude to the funding.

Acknowledgments

Special thanks to Xiaobo Fan and Xiaolei Cui for their helpful suggestions and discussions in the experiment and manuscript preparation.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Hady, G.G.; Abigail, C.D.; Sebastian, H.; Nicola, D.Q.; Andrea, A.; Damian, B. ALCIDES: A novel lunar mission concept study for the demonstration of enabling technologies in deep-space exploration and human-robots interaction. Acta Astronaut. 2018, 151, 270–283. [Google Scholar] [CrossRef]

- Gupta, P.; Jeswiet, J. Manufacture of an aerospace component by single point incremental forming. Procedia Manuf. 2019, 29, 112–119. [Google Scholar] [CrossRef]

- Jayakrishna, K.; Kar, V.R.; Sultan, M.T.H.; Rajesh, M. Materials selection for aerospace components. Sustain. Compos. Aerosp. Appl. 2018, 1–18. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, L.; Li, J.; Li, X.; Zhu, H.; Ma, F.; Ma, H.; Cui, J. Microstructure and Properties of Friction Stir Welded 2219 Aluminum Alloy under Heat Treatment and Electromagnetic Forming Process. Metals 2018, 8, 305. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Y.; Hao, Y. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing. J. Mater. Sci. Technol. 2018, 34, 73–91. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Gu, X.-J.; Zhang, W.-H.; Beckers, P. Structural design of aircraft skin stretch-forming die using topology optimization. J. Comput. Appl. Math. 2013, 246, 278–288. [Google Scholar] [CrossRef]

- Liu, F.; Liu, Z.; Liu, M.; Hu, Y.; Chen, Y.; Bai, S. Analysis of empirical relation between microstructure, texture evolution and fatigue properties of an Al-Cu-Li alloy during different pre-deformation processes. Mater. Sci. Eng. A 2018, 726, 309–319. [Google Scholar] [CrossRef]

- Volz, M.P.; Chen, P.S.; Gorti, S.; Salvail, P. Development of aluminum-lithium 2195 gores by the stretch forming process. In Proceedings of the National Space and Missile Materials Symposium, Huntsville, AL, USA, 23–26 June 2014. Report number: M14-3222. [Google Scholar]

- An, L.; Cai, Y.; Liu, W.; Yuan, S.; Zhu, S.; Meng, F. Effect of pre-deformation on microstructure and mechanical properties of 2219 aluminum alloy sheet by thermomechanical treatment. Trans. Nonferrous Met. Soc. China 2012, 22, s370–s375. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J.; Li, X.; Chen, Y.; Zhou, D.; Zhou, G.; Xu, W. Effect of pre-deformation on the microstructures and properties of 2219 aluminum alloy during aging treatment. J. Alloys Compd. 2017, 699, 1140–1145. [Google Scholar] [CrossRef]

- Wang, H.; Yi, Y.; Huang, S. Influence of pre-deformation and subsequent ageing on the hardening behavior and microstructure of 2219 aluminum alloy forgings. J. Alloys Compd. 2016, 685, 941–948. [Google Scholar] [CrossRef]

- Li, H.; Liu, R.; Liang, X.; Deng, M.; Liao, H.; Huang, L. Effect of pre-deformation on microstructures and mechanical properties of high purity Al–Cu–Mg alloy. Trans. Nonferrous Met. Soc. China 2016, 26, 1482–1490. [Google Scholar] [CrossRef]

- Quan, L.; Zhao, G.; Gao, S.; Muddle, B.C. Effect of pre-stretching on microstructure of aged 2524 aluminium alloy. Trans. Nonferrous Met. Soc. China 2011, 21, 1957–1962. [Google Scholar] [CrossRef]

- Huang, Y.J.; Chen, Z.G.; Zheng, Z.Q. A conventional thermo-mechanical process of Al–Cu–Mg alloy for increasing ductility while maintaining high strength. Scr. Mater. 2011, 64, 382–385. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J.; Li, X.; Li, W.; Li, R.; Zhou, D. Effects of pre-deformation on the microstructures and corrosion behavior of 2219 aluminum alloys. Mater. Sci. Eng. A 2018, 723, 204–211. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of cold predeformation on dissolution of second-phase Al2Cu particles during solution treatment of 2219 Al-Cu alloy forgings. Mater. Charact. 2018, 135, 18–24. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of deformation temperature on second-phase particles and mechanical properties of 2219 Al-Cu alloy. Mater. Sci. Eng. A 2018, 712, 414–423. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Y.; Gong, H. Effects of Deformation Parameters on Microstructural Evolution of 2219 Aluminum Alloy during Intermediate Thermo-Mechanical Treatment Process. Materials 2018, 11, 1496. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, X.; Yuan, S. Analysis of surface roughening behavior of 6063 aluminum alloy by tensile testing of a trapezoidal uniaxial specimen. Mater. Sci. Eng. A 2016, 672, 184–193. [Google Scholar] [CrossRef]

- Yoshida, K.; Ishizaka, T.; Kuroda, M.; Ikawa, S. The effects of texture on formability of aluminum alloy sheets. Acta Mater. 2007, 55, 4499–4506. [Google Scholar] [CrossRef]

- Li, Z.-G.; Li, N.; Jiang, H.-W.; Xiong, Y.-Y.; Liu, L. Deformation texture evolution of pure aluminum sheet under electromagnetic bulging. J. Alloys Compd. 2014, 589, 164–173. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; McQueen, H.J. Grain growth and stabilisation of nanostructured aluminium at high temperatures: Review. Mater. Sci. Technol. 2015, 31, 1016–1034. [Google Scholar] [CrossRef]

- Gleiter, H. Nanostructured materials: basic concepts and microstructure. Acta Mater. 2000, 48, 1–29. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).