Multi-Objective Optimization of Friction Stir Spot-Welded Parameters on Aluminum Alloy Sheets Based on Automotive Joint Loads

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Characterization

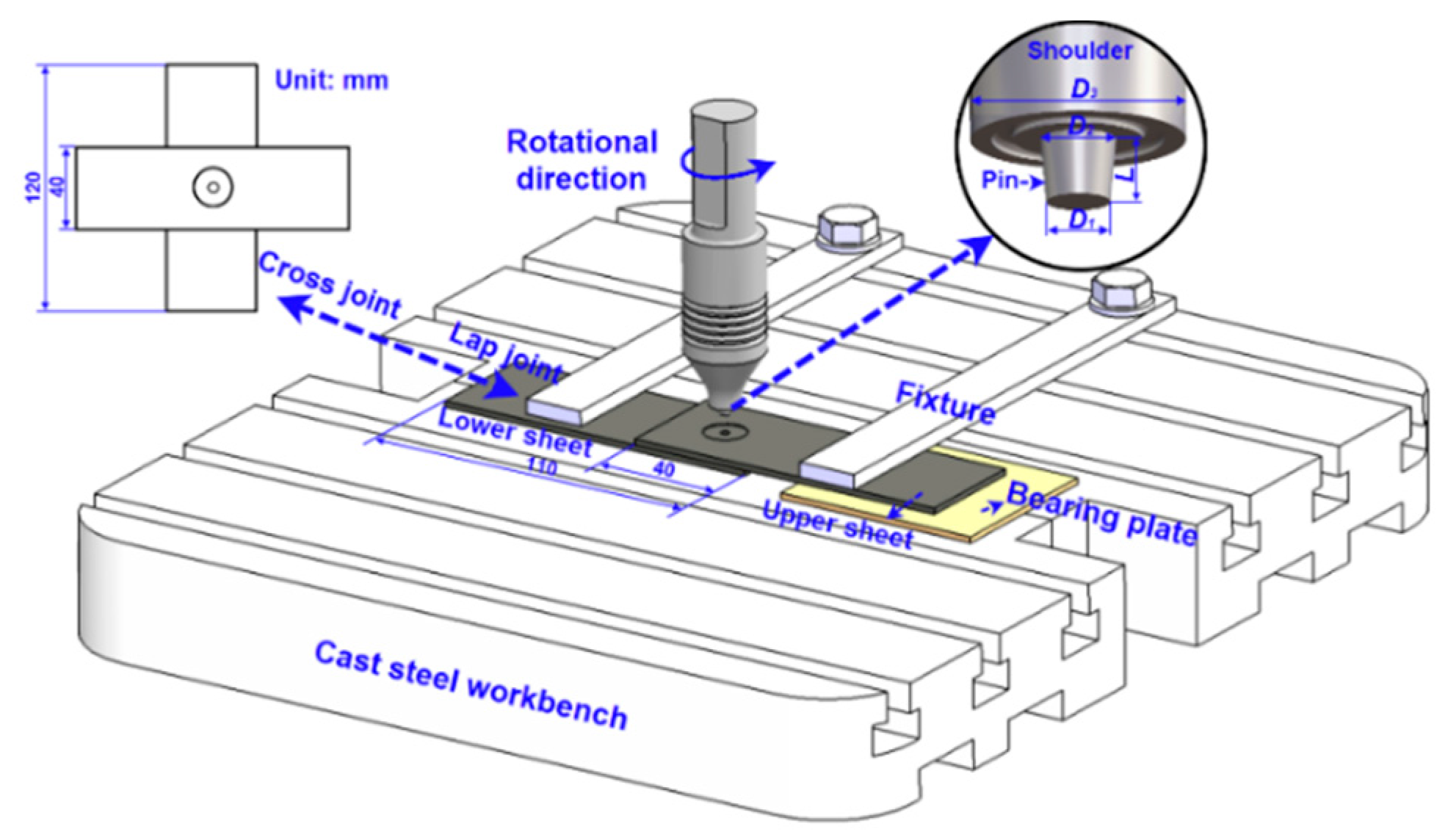

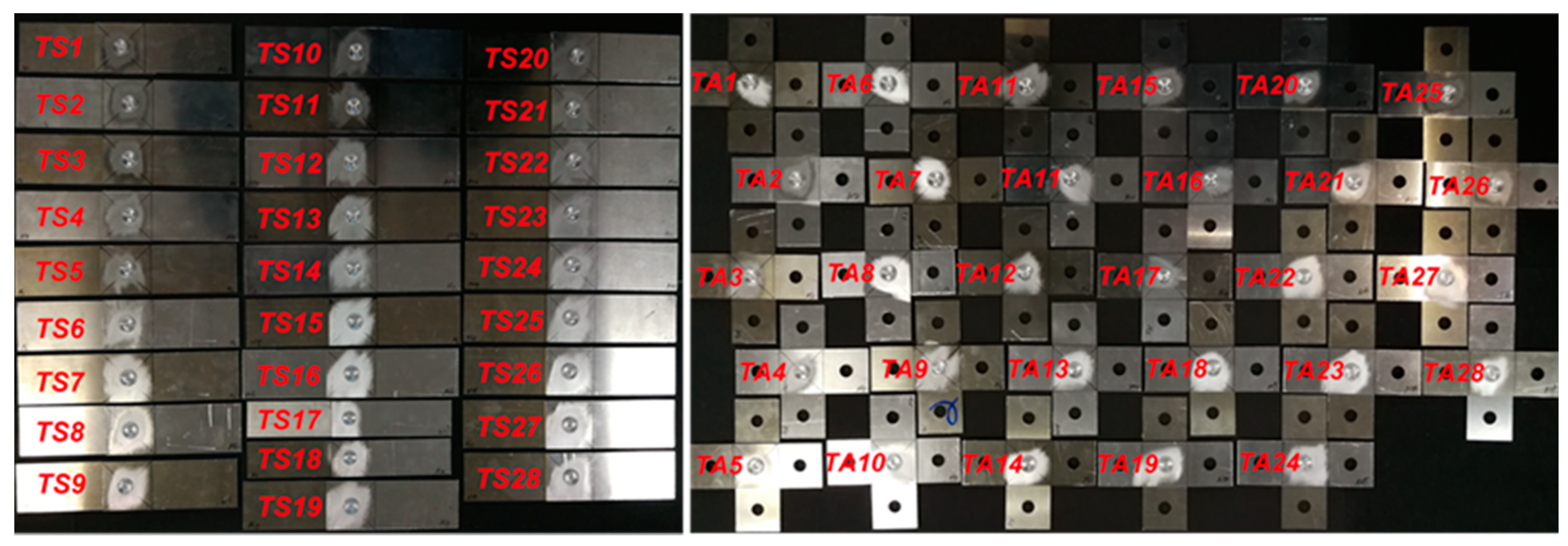

2.2. Experimental Setup

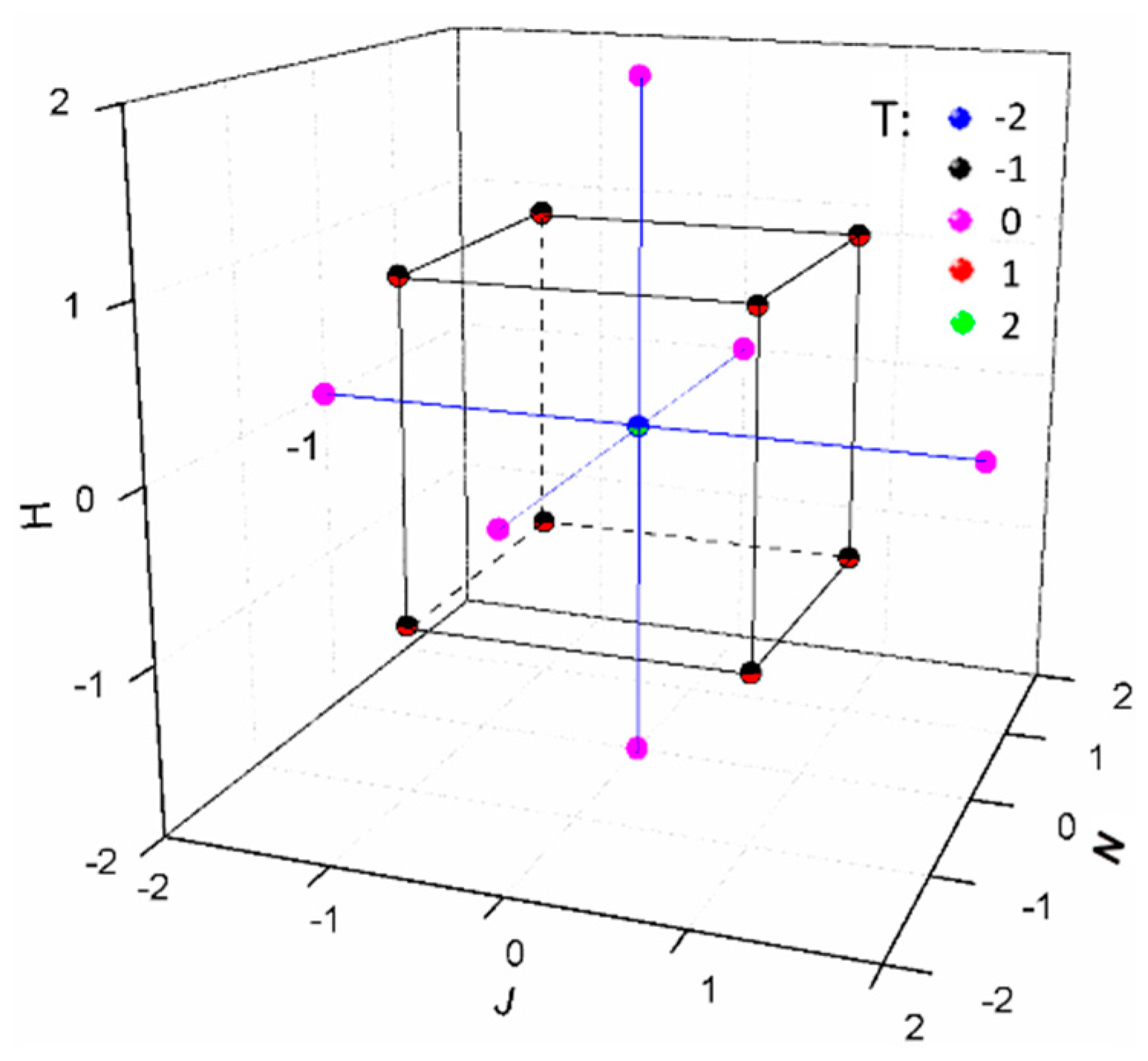

2.3. Experimental Design

3. Resultsand Discussion

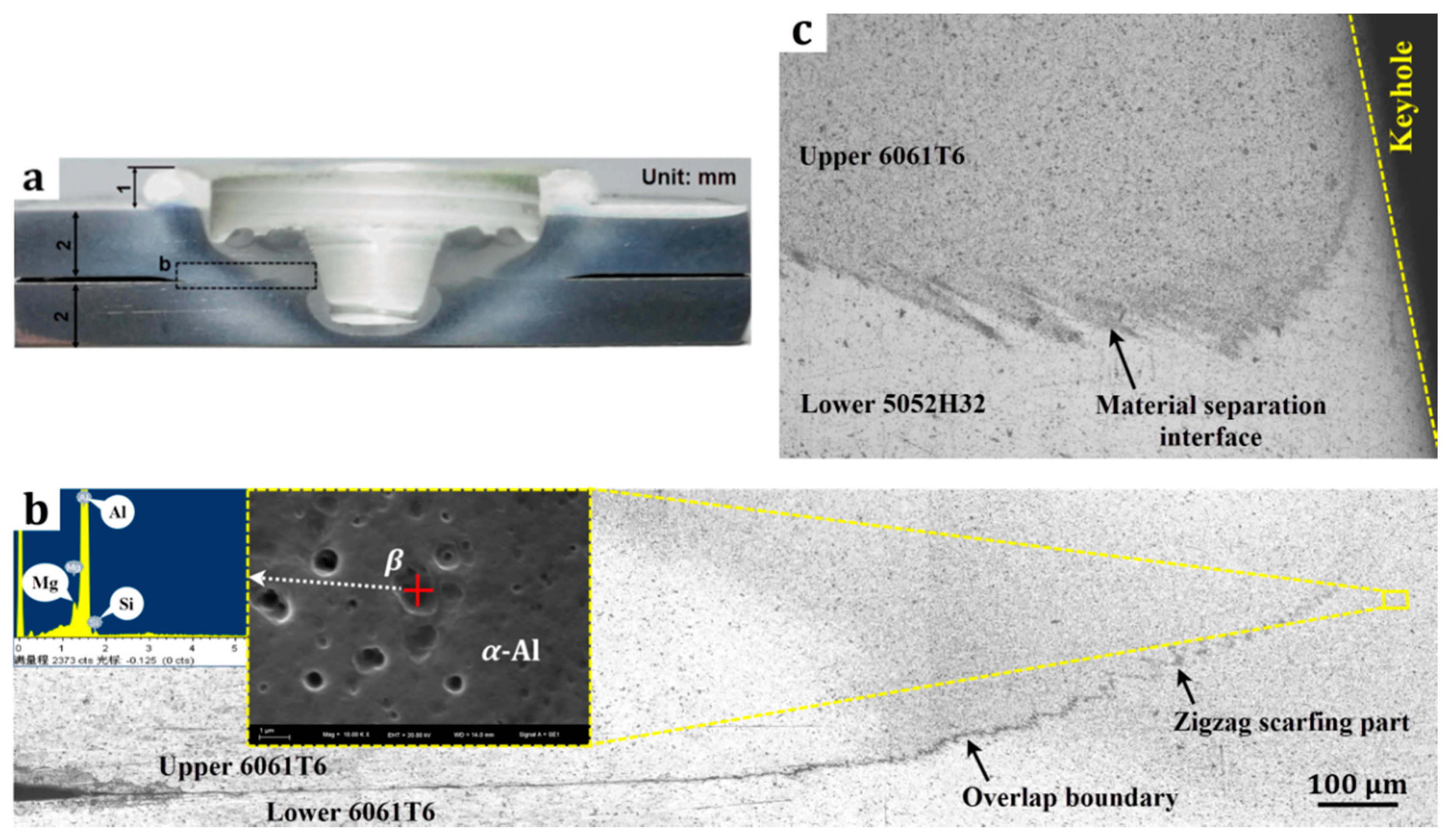

3.1. Microstructural Investigation of Bonding Interface

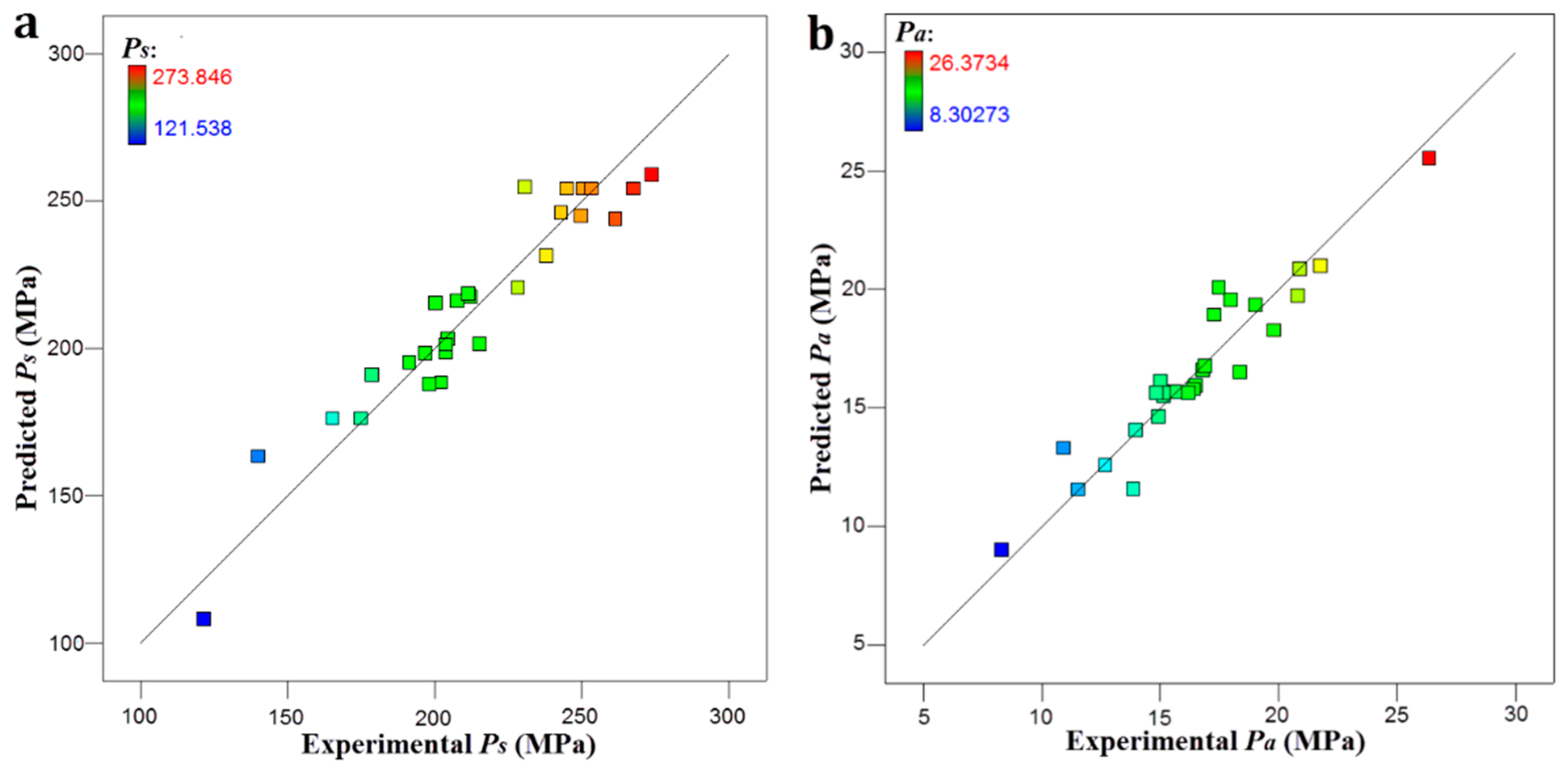

3.2. Modeling Using RSM

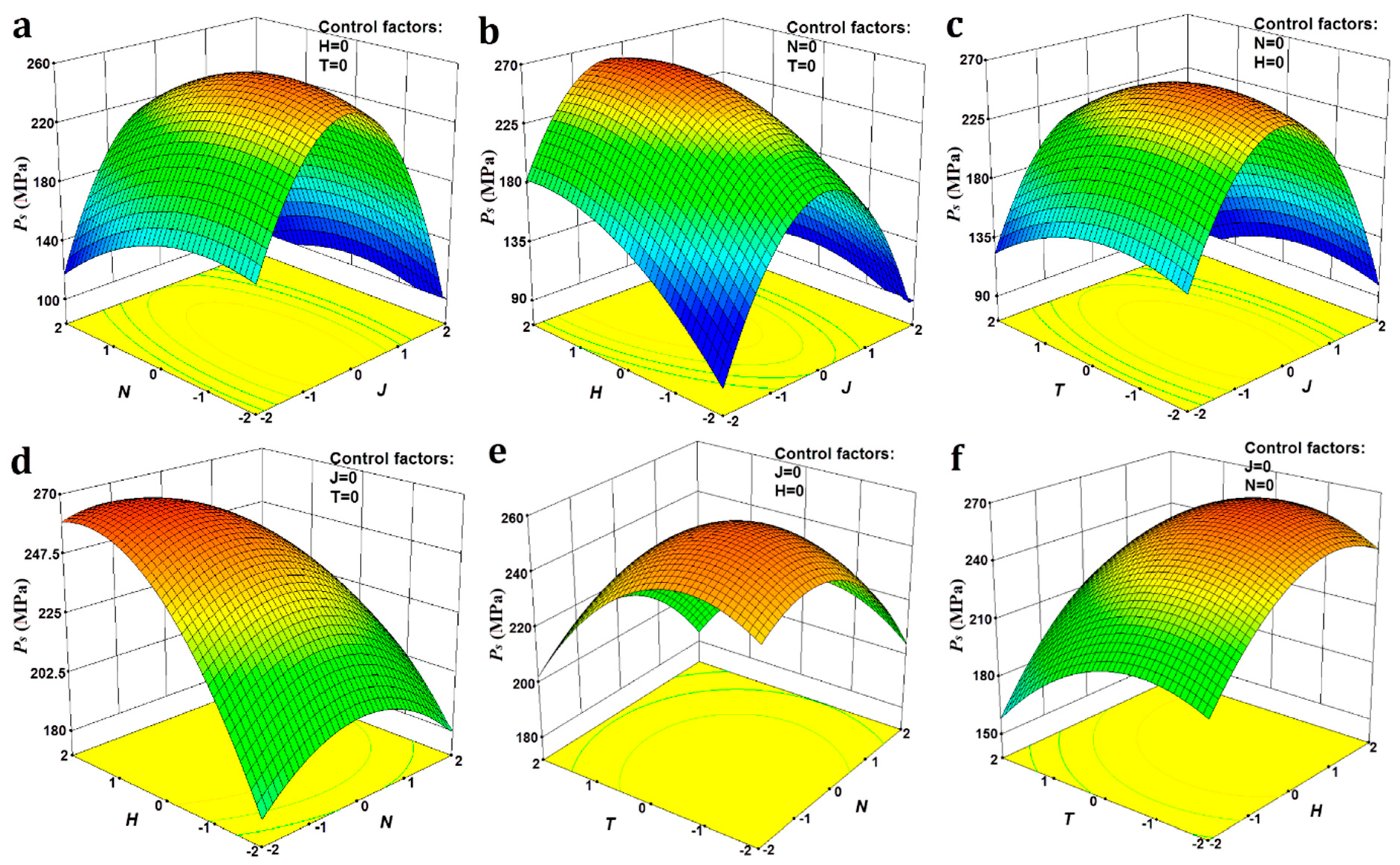

3.3. Effects of Process Parameters on Responses

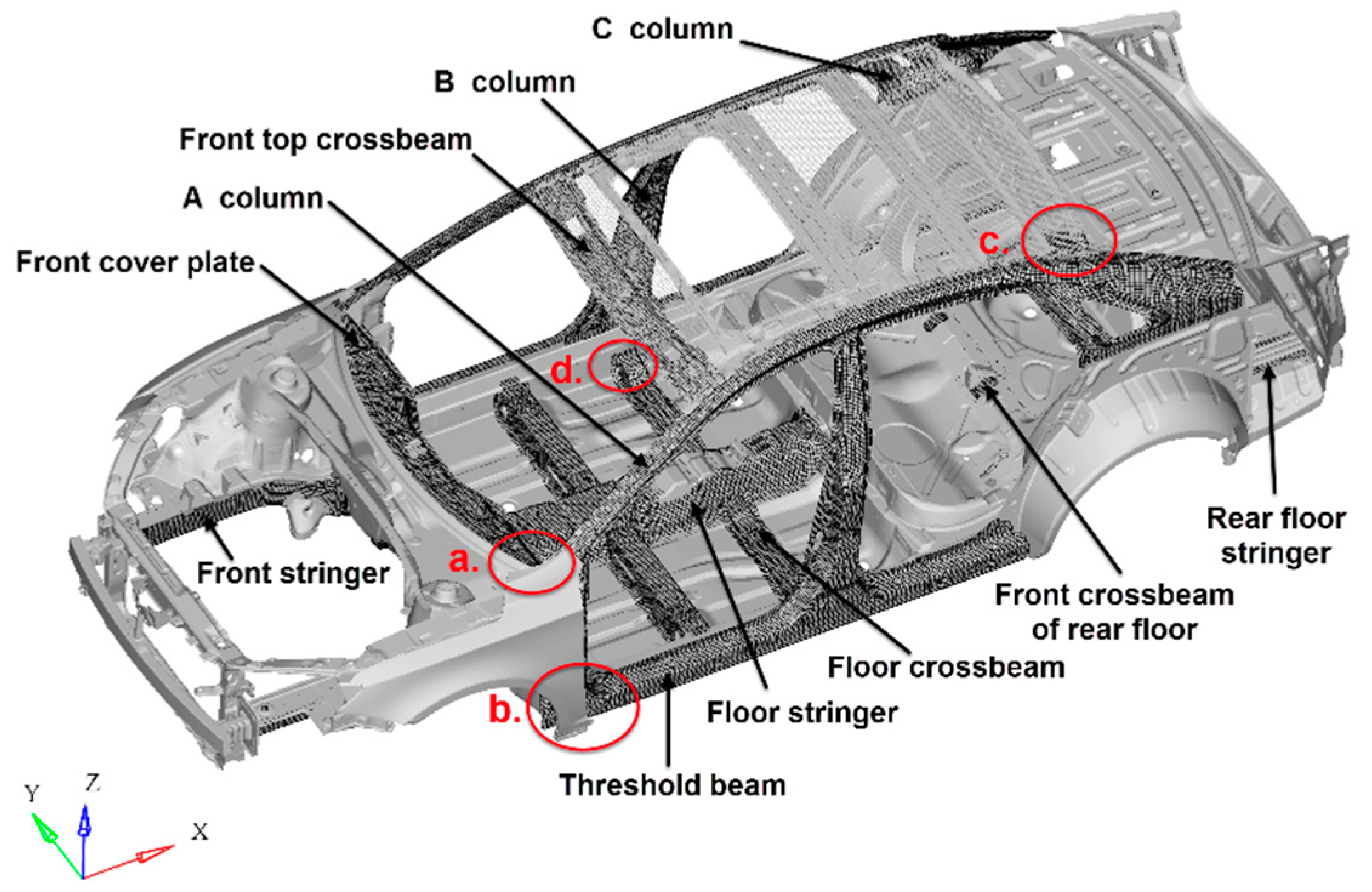

4. Loads Analysis of Automotive Joints

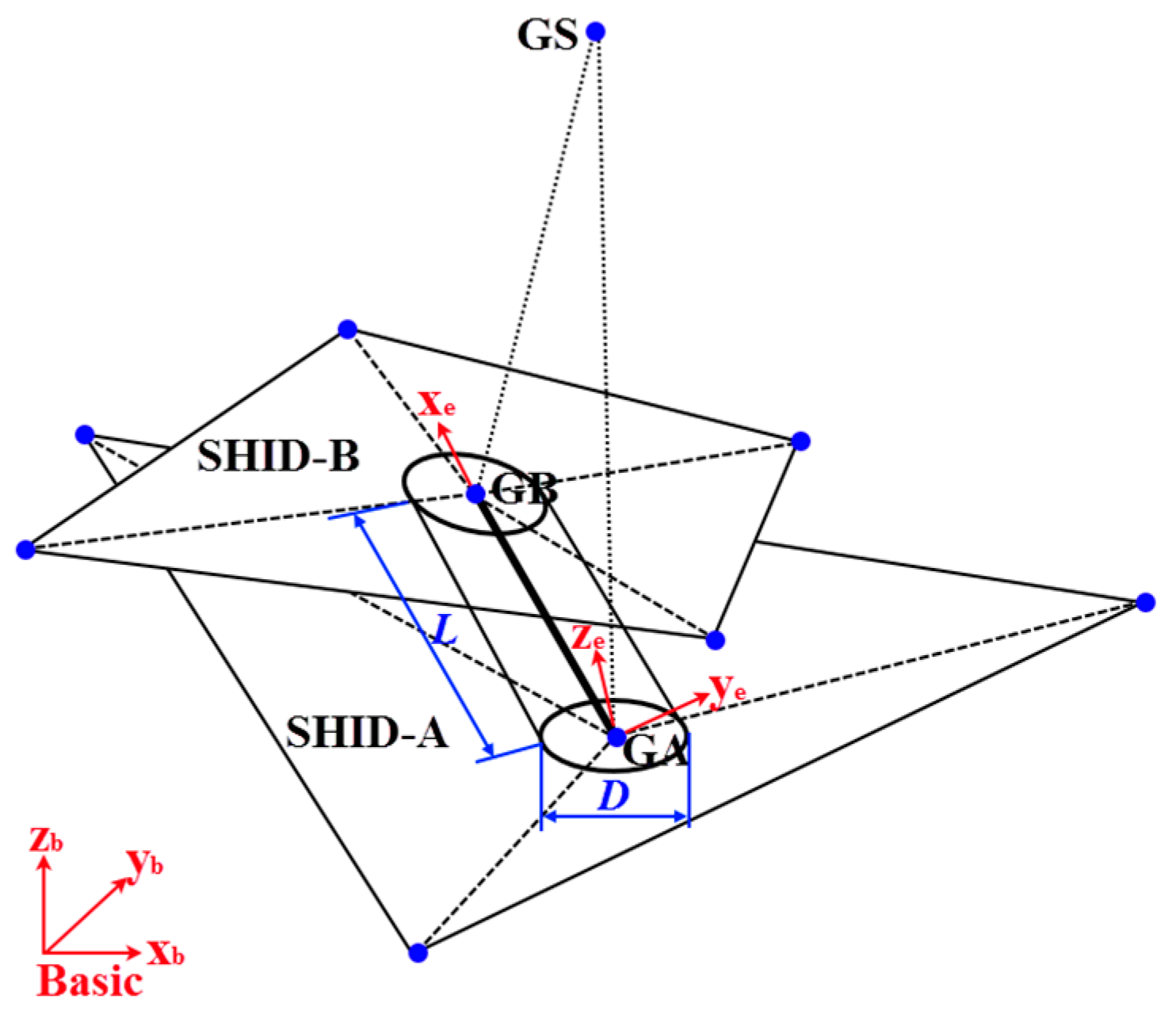

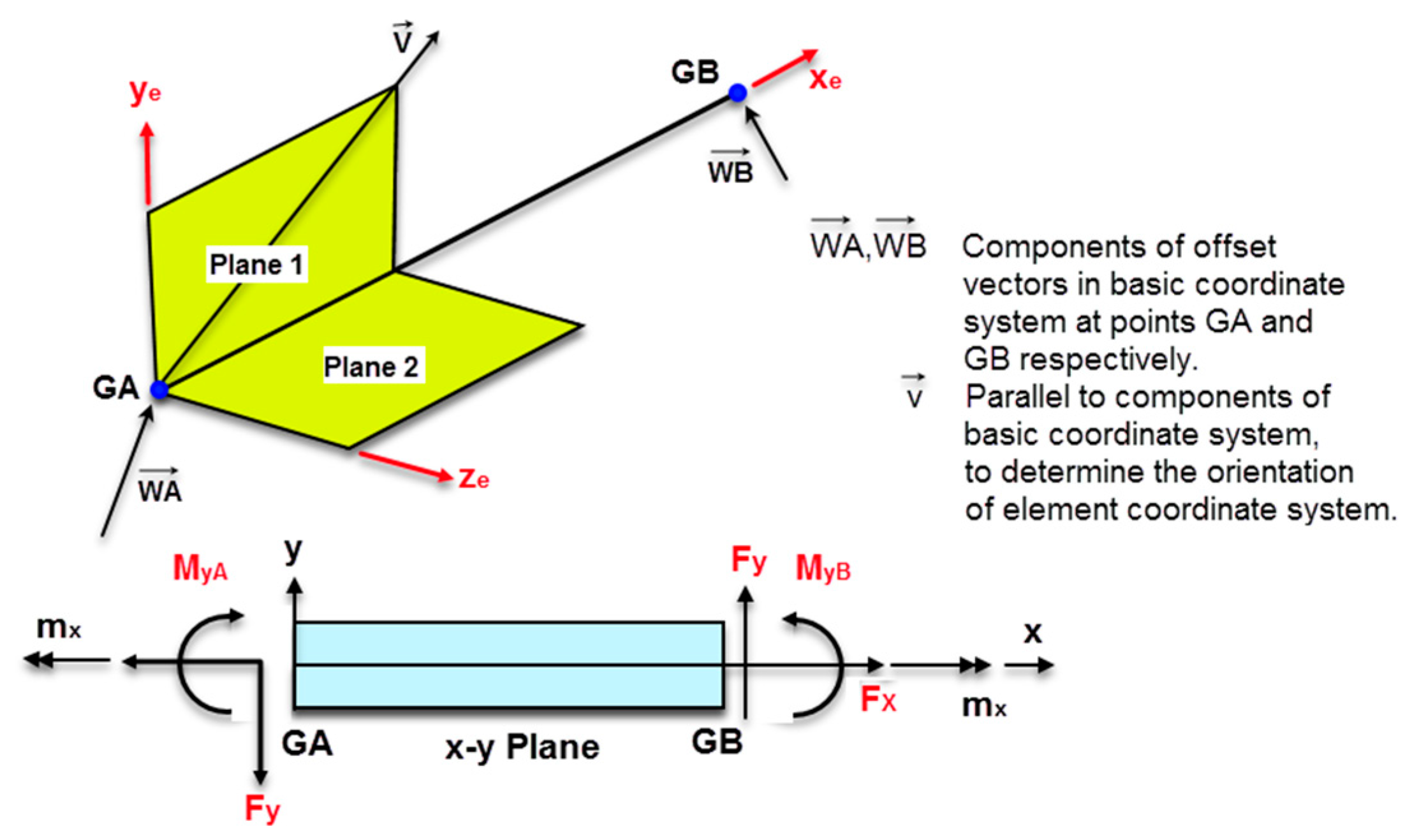

4.1. Connecting Element for Decoupling Joint Loads

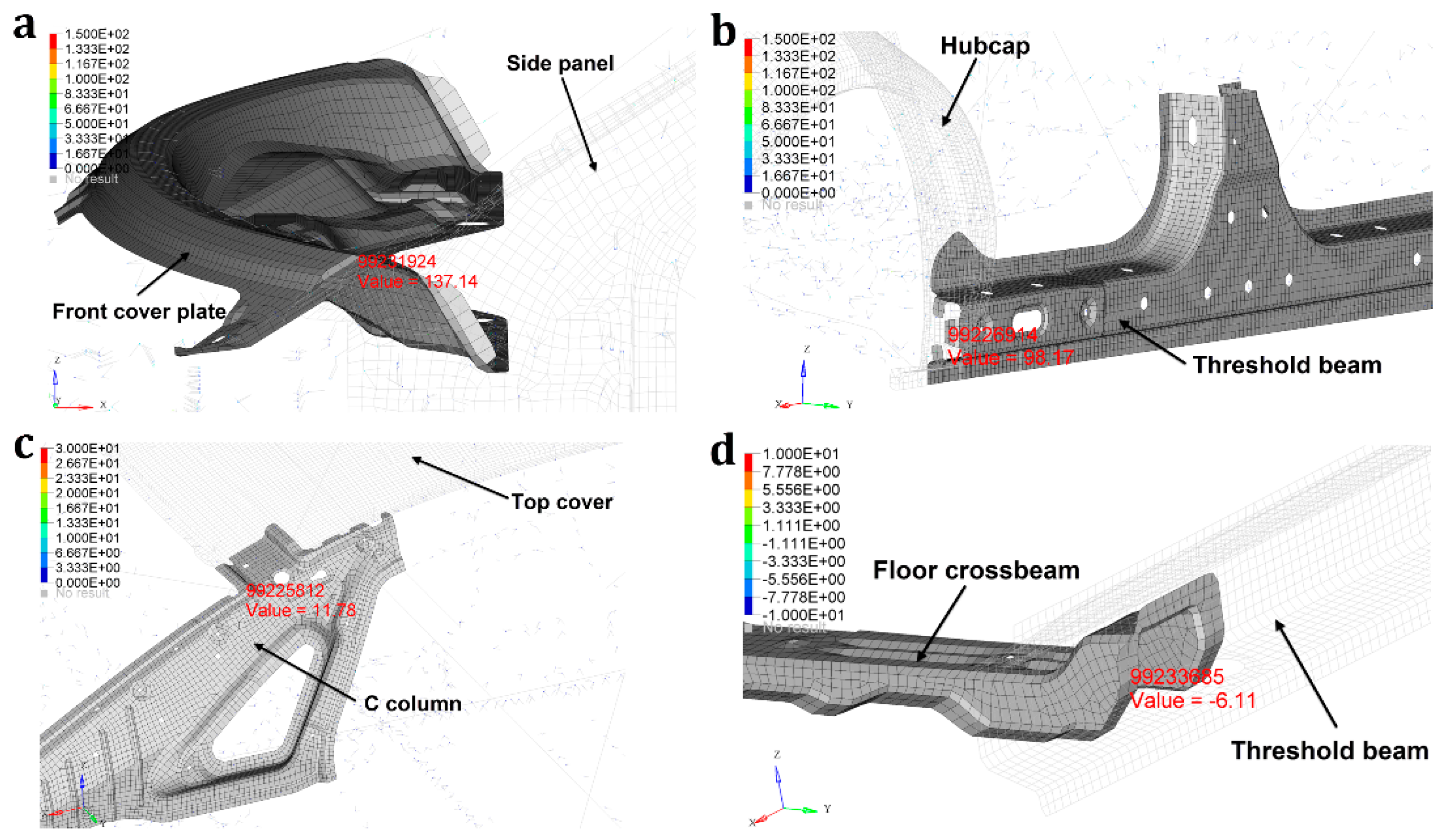

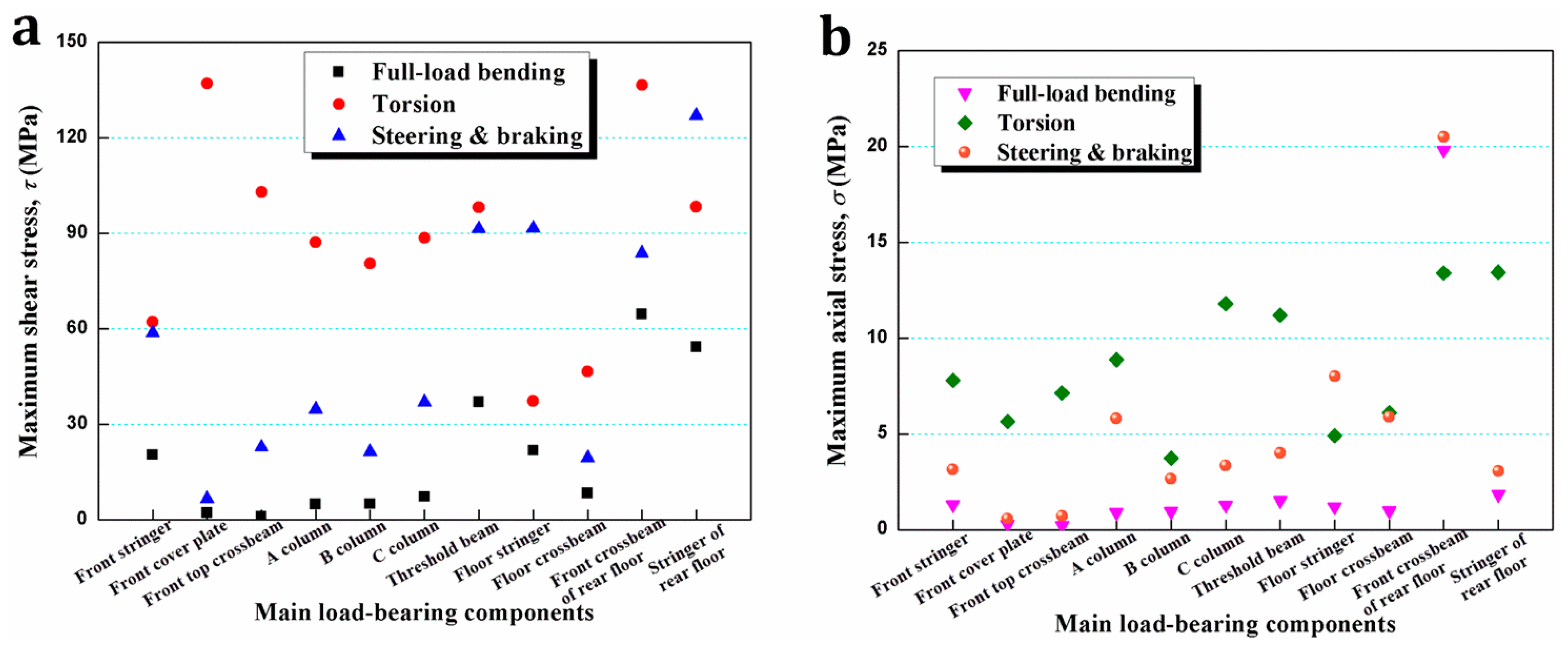

4.2. Multi-Axial Stress Analysis

5. Multi-Objective Optimization

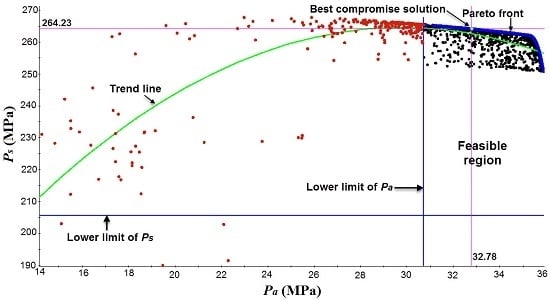

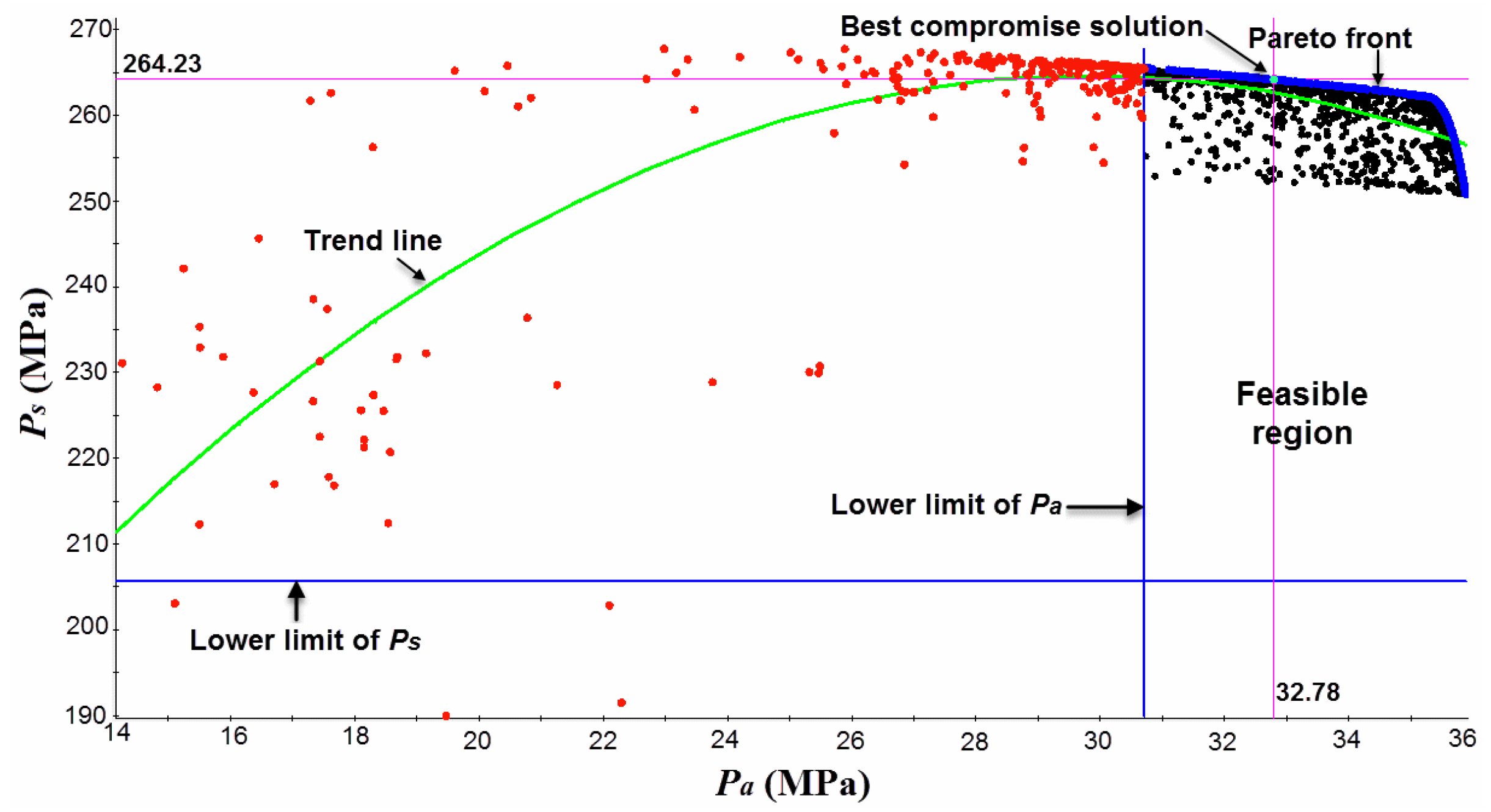

5.1. Applicability Constraints and Optimization Using NSGA-II

5.2. Optimization Results and Verification

6. Conclusions

- (1)

- The empirical relationships were developed to estimate the effects of different welded sheet combinations and corresponding weld parameters on multi-axial tensile strength of formed solder joints. The results reveal that the original base material properties play a significant role in determining the shear strength with a positive contribution percentage of 77.1%, followed by plunged depth, dwell time and rotation speed. The dwell time has no significant effect on the peel strength.

- (2)

- Using the developed connecting element, the multi-axis load-bearing characteristics of automotive joints under multiple driving conditions were analyzed. Automotive spot-joints have proven to be primarily shear resistance. In order to balance dual properties in multi-objective optimization, the weights of shear stress and axial stress were statistically found to be 0.905 and 0.095, respectively.

- (3)

- Under the automotive applicability constraints, NSGA-II was effectively utilized to deal with such multi-objective optimization problem. Corresponding optimal weld parameters for various joint types were obtained and subsequently validated to be in good agreement with the experimental ones.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Du, J.; Ouyang, M.; Chen, J. Prospects for Chinese electric vehicle technologies in 2016–2020: Ambition and rationality. Energy 2016, 120, 584–596. [Google Scholar] [CrossRef]

- Park, D.H.; Choi, S.W.; Kim, J.H.; Lee, J.M. Cryogenic mechanical behavior of 5000- and 6000-series aluminum alloys: Issues on application to offshore plants. Cryogenics 2015, 68, 44–58. [Google Scholar] [CrossRef]

- Mirza, F.A.; Macwan, A.; Bhole, S.D.; Chen, D.L.; Chen, X.G. Effect of welding energy on microstructure and strength of ultrasonic spot welded dissimilar joints of aluminum to steel sheets. Mater. Sci. Eng. A 2016, 668, 73–85. [Google Scholar] [CrossRef]

- Lei, H.Y.; Li, Y.B.; Carlson, B.E. Cold metal transfer spot welding of 1 mm thick AA6061-T6. J. Manuf. Process. 2017, 28, 209–219. [Google Scholar] [CrossRef]

- Florea, R.S.; Solanki, K.N.; Bammann, D.J.; Baird, J.C.; Jordon, J.B.; Castanier, M.P. Resistance spot welding of 6061-T6 aluminum: Failure loads and deformation. Mater. Design. 2012, 34, 624–630. [Google Scholar] [CrossRef]

- Li, Z.; Ji, S.; Ma, Y.; Chai, P.; Yue, Y.; Gao, S. Fracture mechanism of refill friction stir spot-welded 2024-T4 aluminum alloy. Int. J. Adv. Manuf. Technol. 2016, 86, 1925–1932. [Google Scholar] [CrossRef]

- Moshwan, R.; Yusof, F.; Hassan, M.A.; Rahmat, S.M. Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded AA 5052-O alloy. Mater. Design. 2015, 66, 118–128. [Google Scholar]

- Debroy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; Zhang, W. Additive manufacturing of metallic components – process, structure and properties. Prog. Mater. Sci. 2017, 92, 112–224. [Google Scholar] [CrossRef]

- Chu, Q.; Li, W.Y.; Yang, X.W.; Shen, J.J.; Vairis, A.; Feng, W.Y.; Wang, W.B. Microstructure and mechanical optimization of probeless friction stir spot welded joint of an Al-Li alloy. J. Mater. Sci. Technol. 2018, 34, 1739–1746. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Z.; Ji, S.; Zhang, L. Refill friction stir spot welding of 5083-O aluminum alloy. J. Mater. Sci. Technol. 2018, 34, 878–885. [Google Scholar] [CrossRef]

- Xie, X.; Shen, J.; Gong, F.; Wu, D.; Zhang, T.; Luo, X.; Li, Y. Effects of dwell time on the microstructures and mechanical properties of water bath friction stir spot-welded AZ31 magnesium alloy joints. Int. J. Adv. Manuf. Technol. 2016, 82, 75–83. [Google Scholar] [CrossRef]

- Tutar, M.; Aydin, H.; Yuce, C.; Yavuz, N.; Bayram, A. The optimisation of process parameters for friction stir spot-welded AA3003-H12 aluminium alloy using a Taguchi orthogonal array. Mater. Des. 2014, 63, 789–797. [Google Scholar] [CrossRef]

- Lakshminarayanan, A.K.; Balasubramanian, V. Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique. Trans. Nonferrous Met. Soc. China 2008, 18, 548–554. [Google Scholar] [CrossRef]

- Vijayan, S.; Raju, R.; Krao, S.R. Multiobjective optimization of friction stir welding process parameters on aluminum alloy AA 5083 using Taguchi-based grey relation analysis. Mater. Manuf. Process. 2010, 25, 1206–1212. [Google Scholar] [CrossRef]

- Plaine, A.H.; Gonzalez, A.R.; Suhuddin, U.F.H.; dos Santos, J.F.; Alcântara, N.G. The optimization of friction spot welding process parameters in AA6181-T4 and Ti6Al4V dissimilar joints. Mater. Des. 2015, 83, 36–41. [Google Scholar] [CrossRef]

- Dwivedi, S.P. Effect of process parameters on tensile strength of friction stir welding A356/C355 aluminium alloys joint. J. Mech. Sci. Technol. 2014, 28, 285–291. [Google Scholar] [CrossRef]

- Shanavas, S.; Dhas, J.E.R. Parametric optimization of friction stir welding parameters of marine grade aluminium alloy using response surface methodology. Trans. Nonferrous Met. Soc. China 2017, 27, 2334–2344. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Akbari, M.; Asadi, P. Multi objective optimization of friction stir welding parameters using FEM and neural network. Int. J. Precis. Eng. Manuf. 2014, 15, 2351–2356. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Behnagh, R.A.; Akbari, M.; Givi, M.K.B.; Farhani, F. Modelling and Pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm. Mater. Des. 2013, 44, 190–198. [Google Scholar] [CrossRef]

- Kubit, A.; Kluz, R.; Trzepieciński, T.; Wydrzyński, D.; Bochnowski, W. Analysis of the mechanical properties and of micrographs of refill friction stir spot welded 7075-T6 aluminium sheets. Arch. Civ. Mech. Eng. 2018, 18, 235–244. [Google Scholar] [CrossRef]

- ASTM E8/E8M-09. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Karthikeyan, R.; Balasubramanian, V. Predictions of the optimized friction stir spot welding process parameters for joining AA2024 aluminum alloy using RSM. Int. J. Adv. Manuf. Technol. 2010, 51, 173–183. [Google Scholar] [CrossRef]

- Periyasamy, P.; Mohan, B.; Balasubramanian, V.; Rajakumar, S.; Venugopal, S. Multi-objective optimization of friction stir welding parameters using desirability approach to join Al/SiCp metal matrix composites. Trans. Nonferrous Met. Soc. China 2013, 23, 942–955. [Google Scholar] [CrossRef]

- Selvamani, S.T.; Divagar, S.; Vigneshwar, M. Application of response surface methodology (RSM) in friction welding AISI 1020 grade steel joints. Int. J. Eng. Res. Africa 2015, 16, 38–44. [Google Scholar] [CrossRef]

- Cao, J.Y.; Wang, M.; Kong, L.; Zhao, H.X.; Chai, P. Microstructure, texture and mechanical properties during refill friction stir spot welding of 6061-T6 alloy. Mater. Charact. 2017, 128, 54–62. [Google Scholar] [CrossRef]

- Ibrahim, I.J.; Yapici, G.G. Application of a novel friction stir spot welding process on dissimilar aluminum joints. J. Manuf. Process. 2018, 35, 282–288. [Google Scholar] [CrossRef]

- Tao, X.; Chang, Y.; Guo, Y.; Li, W.; Li, M. Microstructure and mechanical properties of friction stir welded oxide dispersion strengthened AA6063 aluminum matrix composites enhanced by post-weld heat treatment. Mater. Sci. Eng. A 2018, 725, 19–27. [Google Scholar] [CrossRef]

- Sun, Y.; Morisada, Y.; Fujii, H.; Tsuji, N. Ultrafine grained structure and improved mechanical properties of low temperature friction stir spot welded 6061-T6 Al alloys. Mater. Charact. 2017, 135, 124–133. [Google Scholar] [CrossRef]

- Li, W.Y.; Chu, Q.; Yang, X.W.; Shen, J.J.; Vairis, A.; Wang, W.B. Microstructure and morphology evolution of probeless friction stir spot welded joints of aluminum alloy. J. Mater. Process. Technol. 2018, 252, 69–80. [Google Scholar] [CrossRef]

- Alvarez, R.O.D.A.; Ferguson, N.S.; Mace, B.R. A robust spot weld model for structural vibration analysis. Finite Elem. Anal. Des. 2014, 89, 1–7. [Google Scholar] [CrossRef]

- Hucho, W.H. Chapter 1—Introduction to automobile aerodynamics. Aerodynamics of Road Vehicles; SAE International: Warrendale, PA, USA, 1987; pp. 1–46. [Google Scholar]

- Coello, C.A.C. A Comprehensive Survey of Evolutionary-Based Multiobjective Optimization Techniques. Knowl. Inf. Syst. 1999, 1, 269–308. [Google Scholar] [CrossRef]

| Samples | Si | Cu | Mg | Zn | Mn | Cr | Fe | Al |

|---|---|---|---|---|---|---|---|---|

| AA 5052-H32 | 0.2 | 0.0 | 2.5 | 0.0 | 0.1 | 0.2 | 0.2 | Bal. |

| AA 6061-T6 | 0.7 | 0.1 | 1.1 | 0.1 | 0.1 | 0.2 | 0.1 | Bal. |

| Samples | Young’s Modulus (GPa) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation at 50-mm Gauge (%) | Section Shrinkage (%) | Hardness at 0.5 N Load (Hv) |

|---|---|---|---|---|---|---|

| 5052-H32 | 69.5 | 141.8 | 217.5 | 20.9 | 49.9 | 59.0 |

| 6061-T6 | 69.8 | 241.2 | 320.2 | 14.9 | 34.7 | 74.2 |

| No. | Corresponding Total Plate Thickness (mm) | D1 (mm) | D2 (mm) | D3 (mm) | L (mm) |

|---|---|---|---|---|---|

| Tool-1 | 3.0 (1.0+2.0) | 2.6 | 3.0 | 10.0 | 2.0 |

| Tool-2 | 4.0 (2.0+2.0) | 3.0 | 3.5 | 14.0 | 3.0 |

| Factor | Level | |||||

|---|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | ||

| Material and thickness (mm) combination of welded metals, J | Upper | 5052; 1.0 | 6061; 2.0 | 5052; 2.0 | 5052; 2.0 | 5052; 1.0 |

| Lower | 5052; 2.0 | 6061; 2.0 | 6061; 2.0 | 5052; 2.0 | 6061; 2.0 | |

| Rotational speed, N (rpm) | 600 | 900 | 1200 | 1500 | 1800 | |

| Plunged depth by shoulder, H (mm) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | |

| Dwell time, T (s) | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | |

| Trial Run | Factor | Tensile Fracture Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| J | N | H | T | Shear, Ps | Peel, Pa | |

| 1 | −1 | −1 | −1 | −1 | 212.31 | 16.51 |

| 2 | 1 | −1 | −1 | −1 | 191.54 | 10.94 |

| 3 | −1 | 1 | −1 | −1 | 204.62 | 13.97 |

| 4 | 1 | 1 | −1 | −1 | 178.85 | 15.14 |

| 5 | −1 | −1 | 1 | −1 | 273.85 | 19.05 |

| 6 | 1 | −1 | 1 | −1 | 207.69 | 21.78 |

| 7 | −1 | 1 | 1 | −1 | 238.08 | 12.70 |

| 8 | 1 | 1 | 1 | −1 | 203.85 | 19.83 |

| 9 | −1 | −1 | −1 | 1 | 196.92 | 17.29 |

| 10 | 1 | −1 | −1 | 1 | 175.00 | 16.41 |

| 11 | −1 | 1 | −1 | 1 | 202.31 | 15.63 |

| 12 | 1 | 1 | −1 | 1 | 165.38 | 16.80 |

| 13 | −1 | −1 | 1 | 1 | 261.54 | 20.81 |

| 14 | 1 | −1 | 1 | 1 | 203.85 | 20.90 |

| 15 | −1 | 1 | 1 | 1 | 228.46 | 13.87 |

| 16 | 1 | 1 | 1 | 1 | 198.46 | 16.90 |

| 17 | −2 | 0 | 0 | 0 | 140.00 | 8.30 |

| 18 | 2 | 0 | 0 | 0 | 121.54 | 11.53 |

| 19 | 0 | −2 | 0 | 0 | 243.08 | 26.37 |

| 20 | 0 | 2 | 0 | 0 | 211.54 | 17.97 |

| 21 | 0 | 0 | −2 | 0 | 215.38 | 18.36 |

| 22 | 0 | 0 | 2 | 0 | 230.77 | 17.48 |

| 23 | 0 | 0 | 0 | −2 | 250.00 | 14.94 |

| 24 | 0 | 0 | 0 | 2 | 200.38 | 15.04 |

| 25 | 0 | 0 | 0 | 0 | 250.38 | 15.14 |

| 26 | 0 | 0 | 0 | 0 | 267.69 | 16.21 |

| 27 | 0 | 0 | 0 | 0 | 245.00 | 14.86 |

| 28 | 0 | 0 | 0 | 0 | 253.46 | 16.22 |

| Source | Df | Adj SS | MS | F-Value | p-Value | Contribution (%) | |

|---|---|---|---|---|---|---|---|

| Std. Dev. = 16.23, Mean = 213.28, C.V. = 7.6%, R2 = 0.918, Adj R2 = 0.865, Adeq precision = 12.70 | Model | 14 | 33190.18 | 2370.73 | 9.00 | <0.001 | 100.0 |

| J * | 1 | 4548.08 | 4548.08 | 17.27 | 0.001 | 13.7 | |

| N * | 1 | 1144.98 | 1144.98 | 4.35 | 0.057 | 3.5 | |

| H * | 1 | 4256.42 | 4256.42 | 16.16 | 0.002 | 12.8 | |

| T * | 1 | 1321.31 | 1321.31 | 5.02 | 0.043 | 4.0 | |

| JN | 1 | 98.09 | 98.09 | 0.37 | 0.552 | 0.3 | |

| JH | 1 | 427.38 | 427.38 | 1.62 | 0.225 | 1.3 | |

| JT | 1 | 9.246 × 10−3 | 9.246 × 10−3 | 3.51 × 10−5 | 0.995 | 0.0 | |

| NH | 1 | 178.63 | 178.63 | 0.68 | 0.425 | 0.5 | |

| NT | 1 | 18.72 | 18.72 | 0.07 | 0.794 | 0.1 | |

| HT | 1 | 17.10 | 17.10 | 0.06 | 0.803 | 0.1 | |

| J2 * | 1 | 21,055.40 | 21,055.40 | 79.96 | <0.001 | 63.4 | |

| N2 | 1 | 721.99 | 721.99 | 2.74 | 0.122 | 2.2 | |

| H2 * | 1 | 1027.29 | 1027.29 | 3.90 | 0.070 | 3.1 | |

| T2 * | 1 | 867.93 | 867.93 | 3.30 | 0.093 | 2.6 | |

| Residual | 13 | 3423.27 | 263.33 | - | - | - | |

| Total | 27 | 36,613.46 | - | - | - | - | |

| Std. Dev. = 1.65, Mean = 16.46, C.V. = 10.0%, R2 = 0.905, Adj R2 = 0.849, Adeq precision = 13.65 | Model | 14 | 315.36 | 22.53 | 8.26 | <0.001 | 100.0 |

| J * | 1 | 9.80 | 9.80 | 3.59 | 0.0805 | 3.1 | |

| N * | 1 | 52.96 | 52.96 | 19.42 | 0.001 | 16.8 | |

| H * | 1 | 19.07 | 19.07 | 6.99 | 0.020 | 6.2 | |

| T | 1 | 3.29 | 3.29 | 1.21 | 0.292 | 1.0 | |

| JN * | 1 | 16.23 | 16.23 | 5.95 | 0.030 | 5.1 | |

| JH * | 1 | 18.26 | 18.26 | 6.70 | 0.023 | 5.8 | |

| JT | 1 | 0.26 | 0.26 | 0.096 | 0.761 | 0.1 | |

| NH * | 1 | 24.09 | 24.09 | 8.83 | 0.011 | 7.6 | |

| NT | 1 | 1.94 | 1.94 | 0.71 | 0.415 | 0.6 | |

| HT | 1 | 6.83 | 6.83 | 2.50 | 0.138 | 2.2 | |

| J2 * | 1 | 42.75 | 42.75 | 15.67 | 0.002 | 13.6 | |

| N2 * | 1 | 71.83 | 71.83 | 26.34 | <0.001 | 22.8 | |

| H2 * | 1 | 10.70 | 10.70 | 3.92 | 0.069 | 3.4 | |

| T2 | 1 | 0.10 | 0.10 | 0.037 | 0.851 | 0.0 | |

| Residual | 13 | 35.46 | 2.73 | - | - | - | |

| Total | 27 | 350.82 | - | - | - | - |

| Test Points | Factor Code | Ps (MPa) | Relative Error (%) | Pa (MPa) | Relative Error (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| J | N | H | T | Predicted | Test | Predicted | Test | |||

| No. 1 | −1 | 0.5 | 2 | 1 | 221.88 | 213.95 | 3.57 | 13.87 | 14.84 | 6.99 |

| No. 2 | 1 | −2 | 0 | −1.5 | 218.40 | 203.70 | 6.73 | 22.75 | 20.80 | 8.57 |

| No. 3 | 0 | 1.5 | −1 | −0.5 | 219.61 | 225.19 | 2.54 | 18.85 | 19.36 | 2.71 |

| No. 4 | −2 | 0 | 0.5 | 2 | 132.41 | 145.27 | 9.71 | 8.50 | 7.75 | 8.82 |

| Conditions | Full-Load Bending | Torsion | Integrated Full-Load Steering and Braking |

|---|---|---|---|

| Loading conditions | Double H points loaded with moment of 7000 Nm | Torque of 3000 Nm | Bidirectional acceleration: ax = 1.1 g; ay = 0.5 g |

| Rigidity, K | 11,571 N/mm | 10,929 Nm/(°) | - |

| Dynamic safety factor | 1.4–1.6 | 1.3–1.8 | 1.4–1.75 |

| Joint type, J | −2 | −1 | 0 | 1 | 2 |

|---|---|---|---|---|---|

| Weight of Ps | 0.905 | ||||

| Weight of Pa | 0.095 | ||||

| Lower limit of Ps (MPa) | 190.5 | 205.7 | 205.7 | 205.7 | 90.3 |

| Lower limit of Pa (MPa) | 20.2 | 30.7 | 30.7 | 30.7 | 11.7 |

| Joint type, J | −2 | −1 | 0 | 1 | 2 | |

|---|---|---|---|---|---|---|

| Optimal code, (N, H, T) | (−2.0, 2.0, −0.65) | (−2.0, 2.0, −0.64) | (−1.9, 1.77, −0.65) | (−1.86, 1.62, −0.67) | (−0.93, 0.99, −0.64) | |

| Actual parameters, (N, H, T) | (1800, 0.5, 2.4) | (1800, 0.5, 2.4) | (630, 0.48, 2.4) | (642, 0.46, 2.3) | (921, 0.4, 2.4) | |

| Ps | Optimized (MPa) | 201.9 | 261.7 | 264.2 | 208.6 | 107.0 |

| Experimental (MPa) | 188.3 | 275.9 | 245.6 | 215.2 | 100.6 | |

| Relative error (%) | 6.74 | 5.42 | 7.04 | 3.16 | 5.98 | |

| Pa | Optimized (MPa) | 28.3 | 33.1 | 32.8 | 30.8 | 17.7 |

| Experimental (MPa) | 26.2 | 35.9 | 30.1 | 32.2 | 16.0 | |

| Relative error (%) | 7.42 | 8.46 | 8.23 | 4.55 | 9.60 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Chen, X.; Pan, K.; Wang, J. Multi-Objective Optimization of Friction Stir Spot-Welded Parameters on Aluminum Alloy Sheets Based on Automotive Joint Loads. Metals 2019, 9, 520. https://doi.org/10.3390/met9050520

Zhang B, Chen X, Pan K, Wang J. Multi-Objective Optimization of Friction Stir Spot-Welded Parameters on Aluminum Alloy Sheets Based on Automotive Joint Loads. Metals. 2019; 9(5):520. https://doi.org/10.3390/met9050520

Chicago/Turabian StyleZhang, Biao, Xin Chen, Kaixuan Pan, and Jianing Wang. 2019. "Multi-Objective Optimization of Friction Stir Spot-Welded Parameters on Aluminum Alloy Sheets Based on Automotive Joint Loads" Metals 9, no. 5: 520. https://doi.org/10.3390/met9050520

APA StyleZhang, B., Chen, X., Pan, K., & Wang, J. (2019). Multi-Objective Optimization of Friction Stir Spot-Welded Parameters on Aluminum Alloy Sheets Based on Automotive Joint Loads. Metals, 9(5), 520. https://doi.org/10.3390/met9050520