Numerical Analysis of a New Nonlinear Twist Extrusion Process

Abstract

1. Introduction

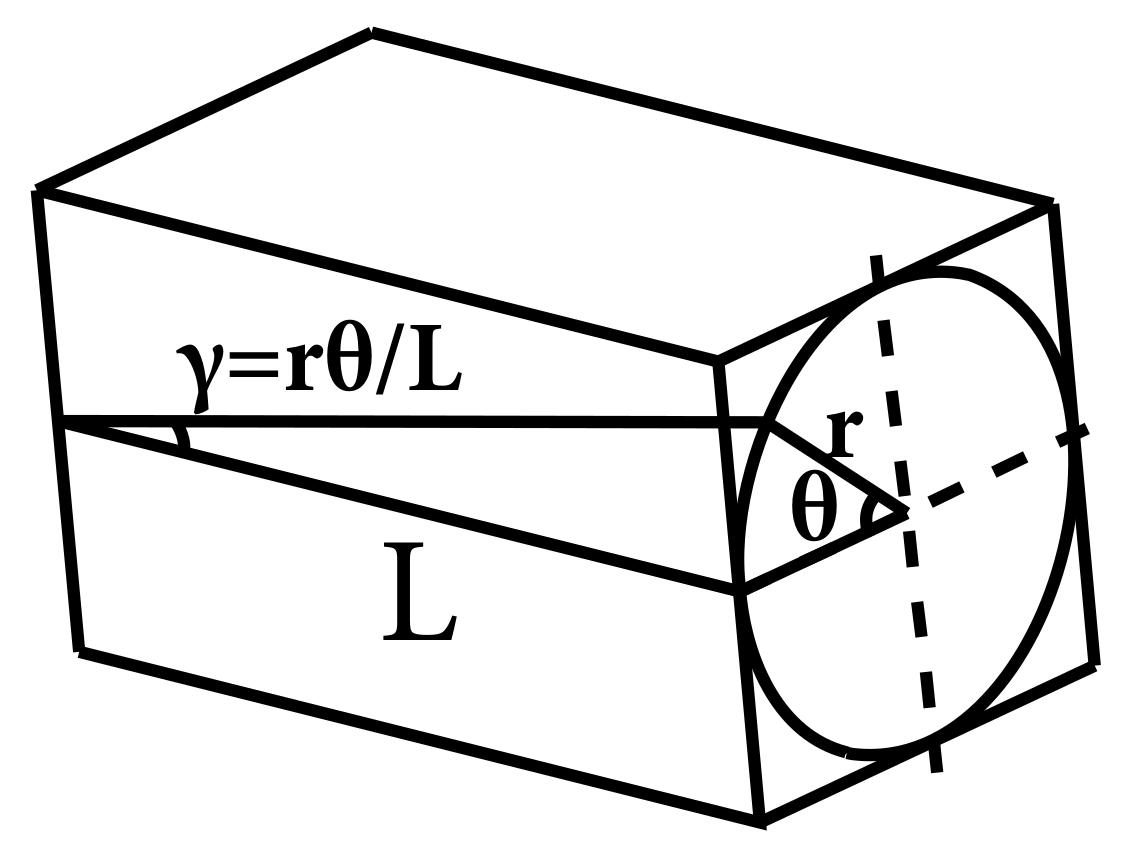

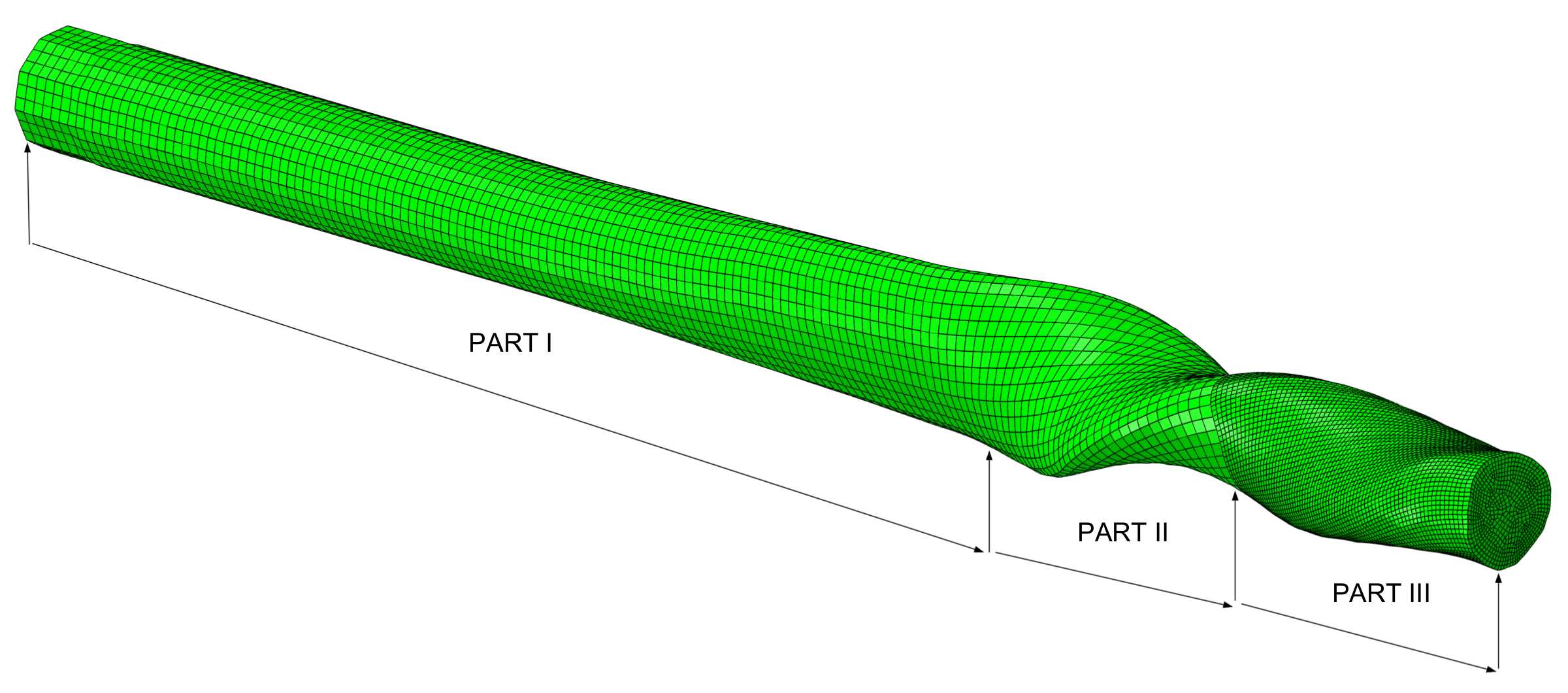

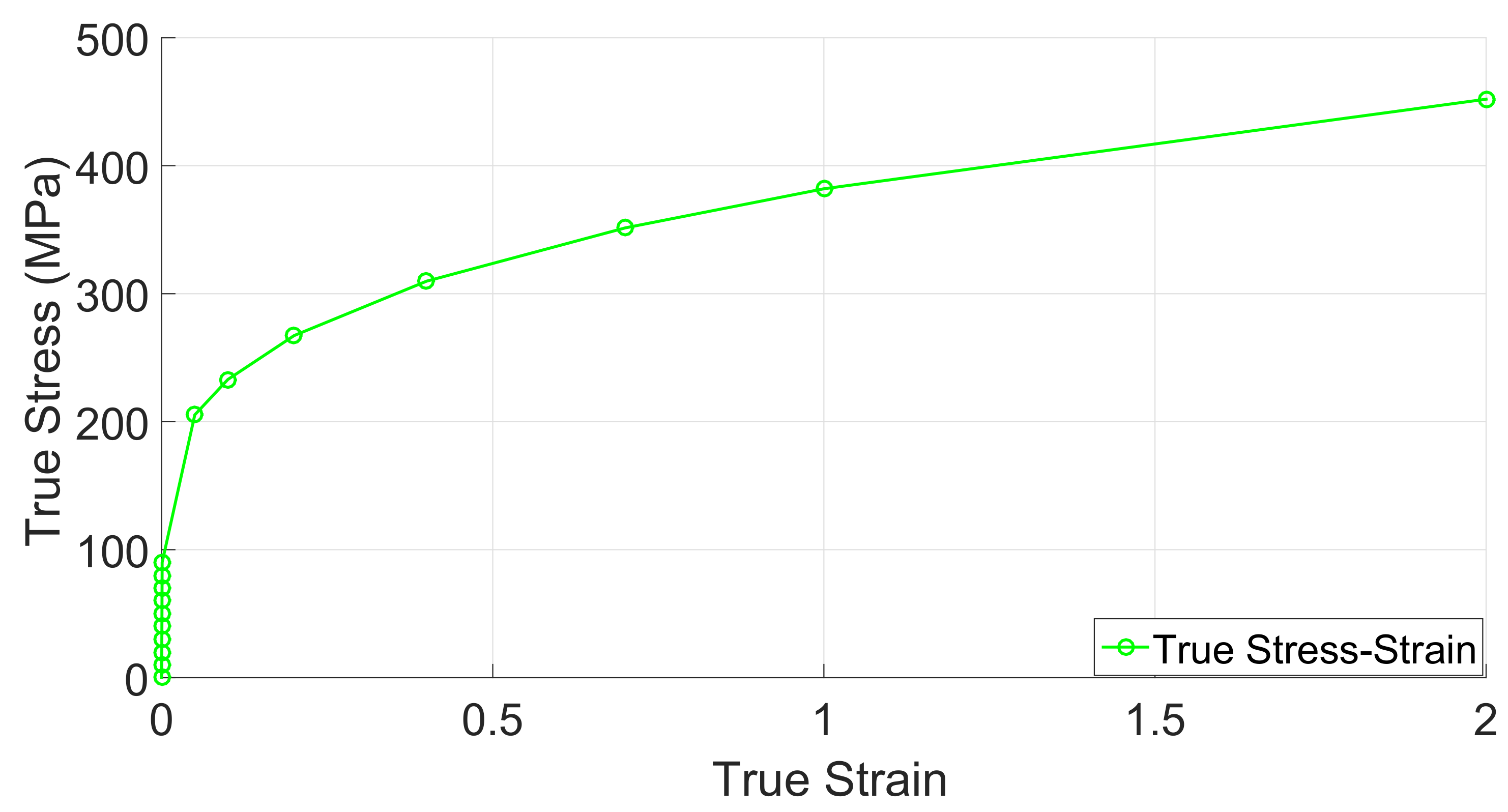

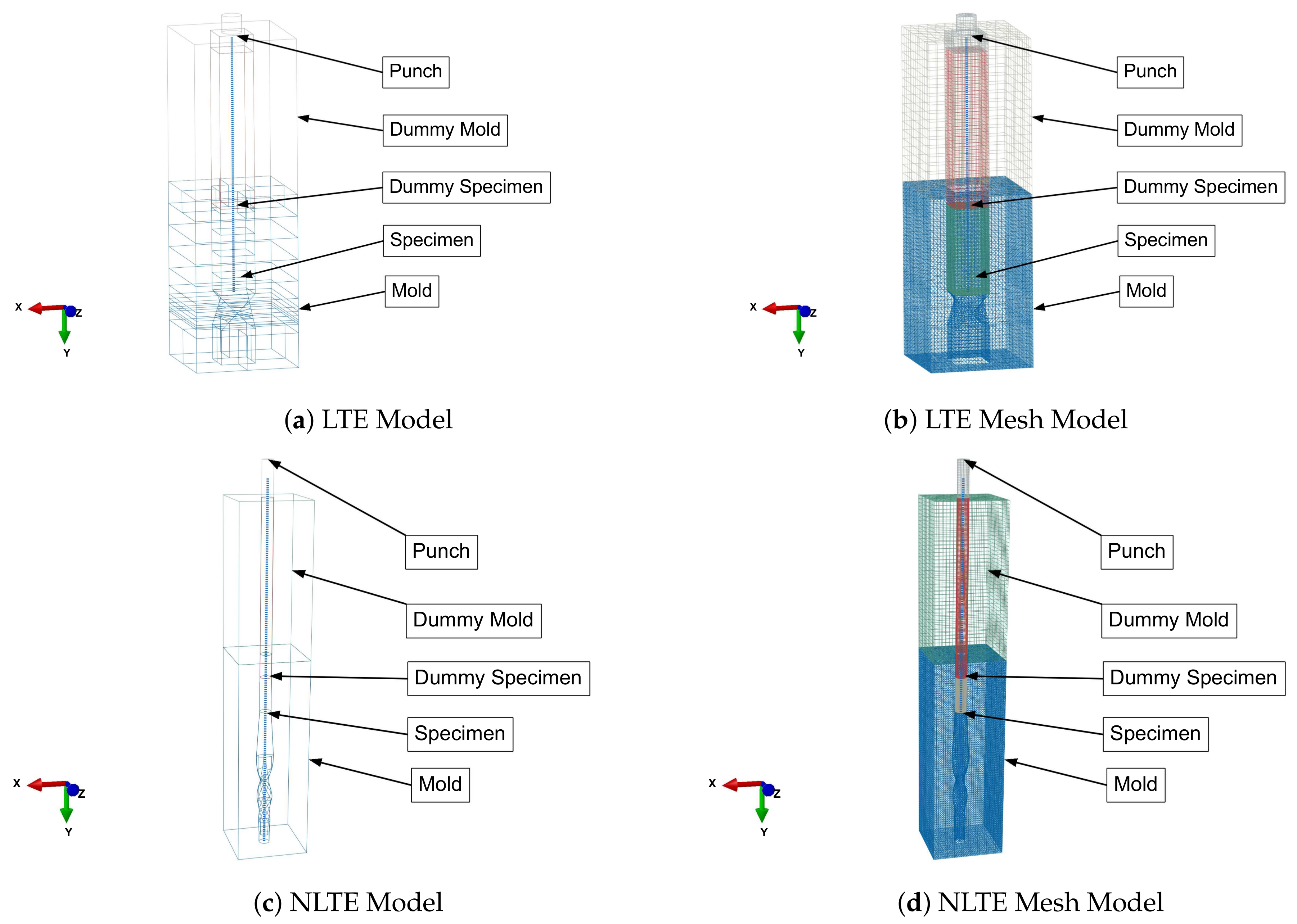

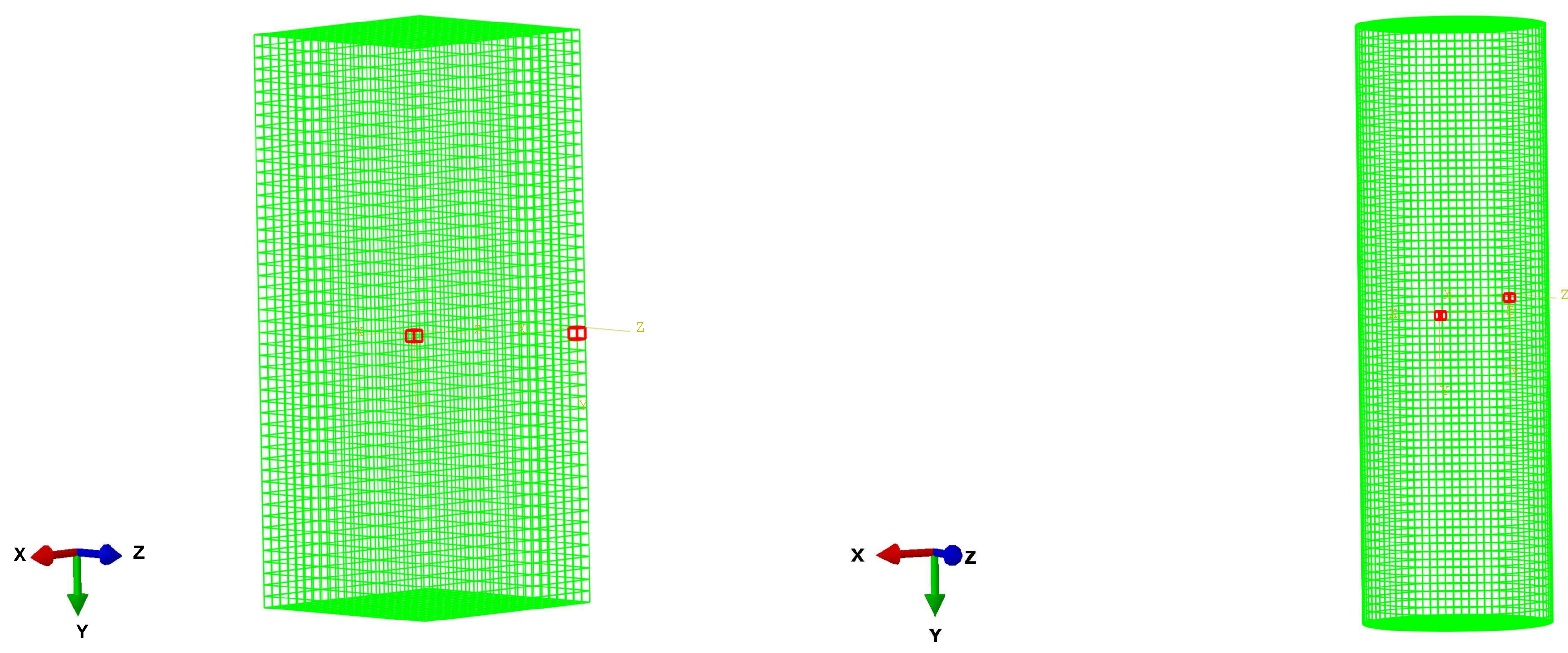

2. Kinetics and Kinematics of NLTE Process

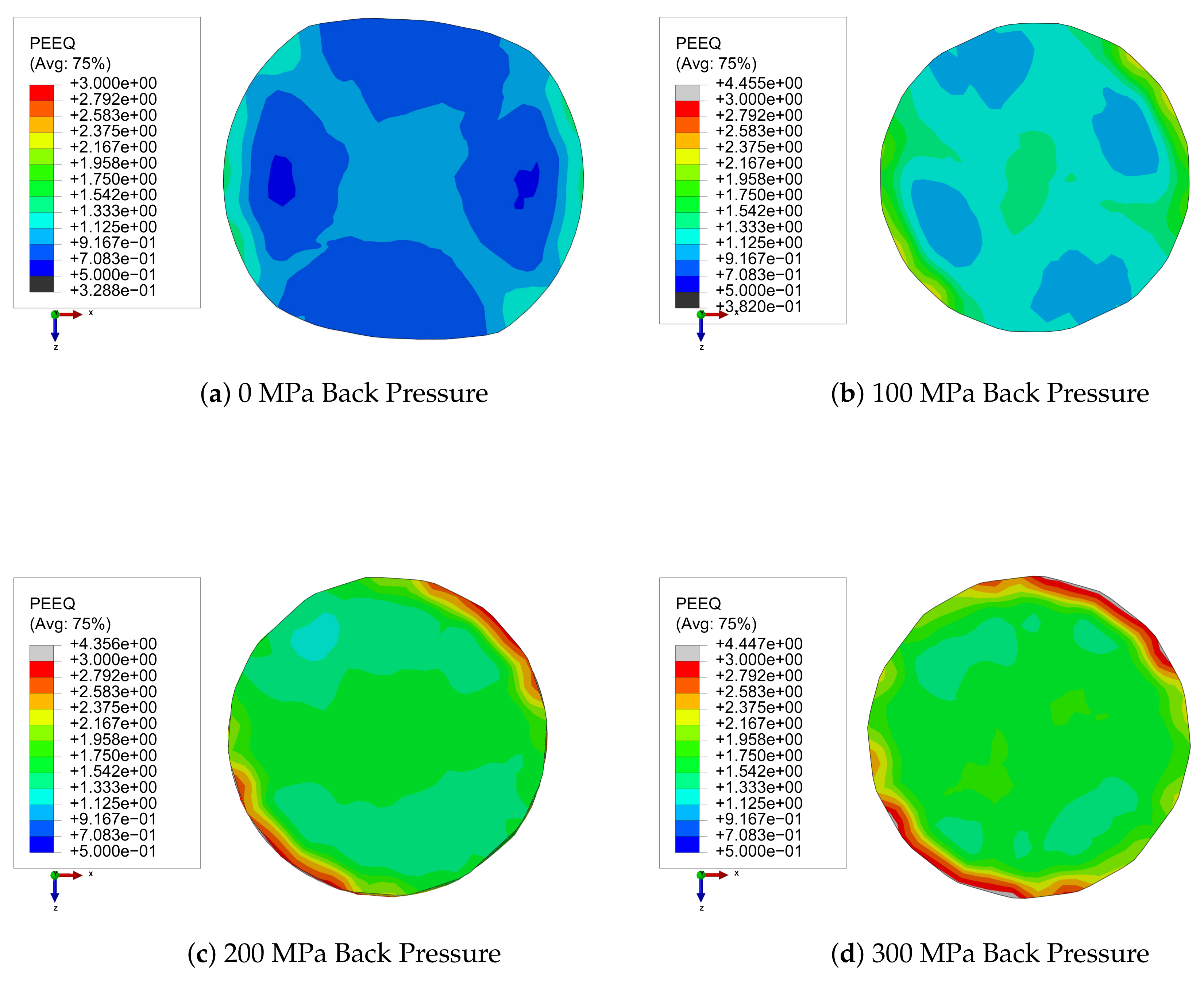

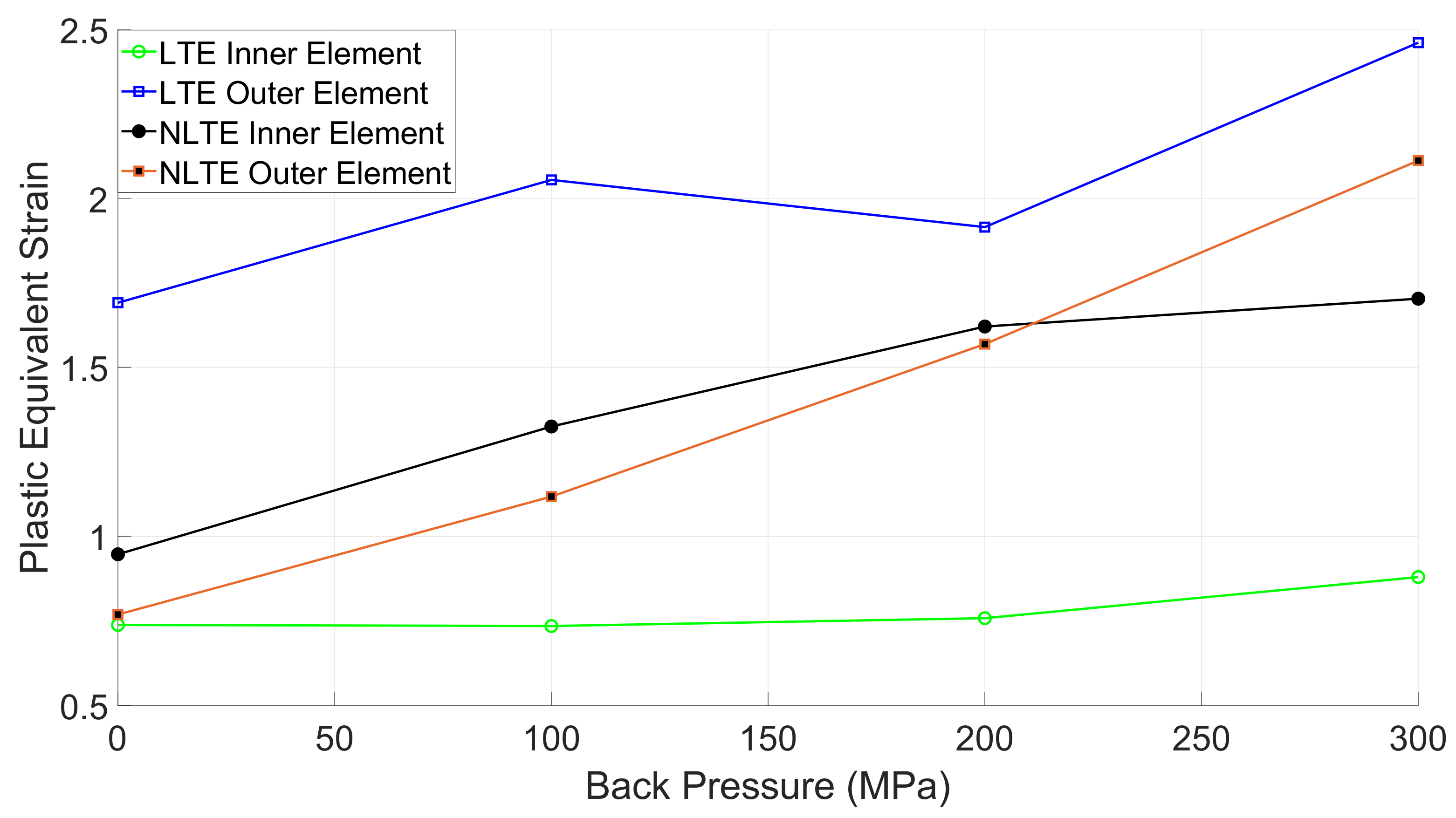

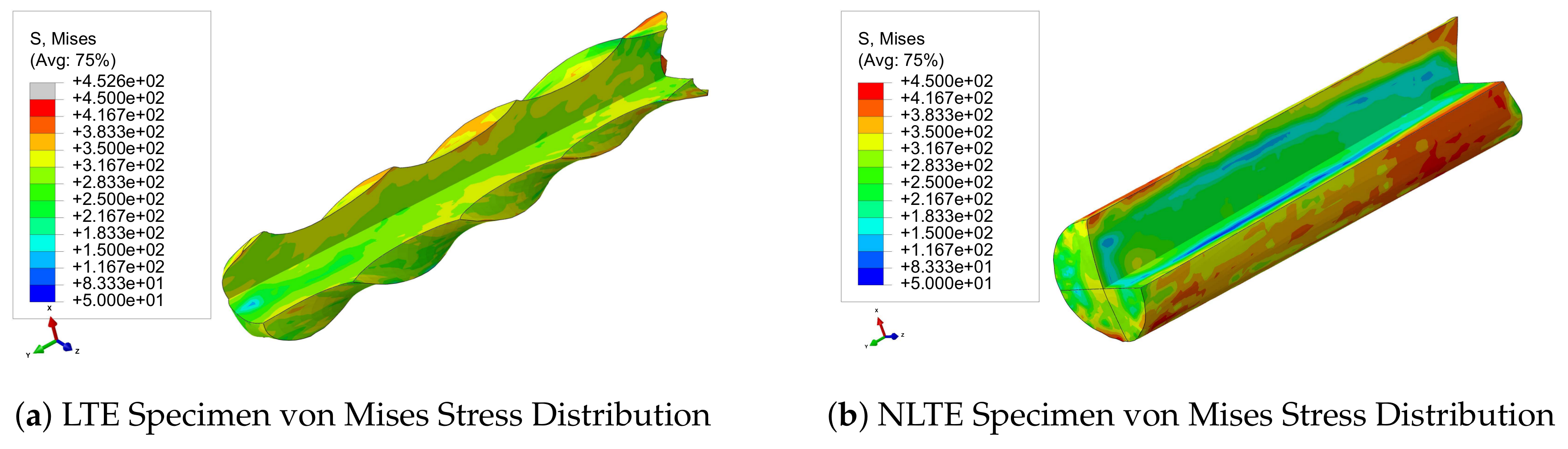

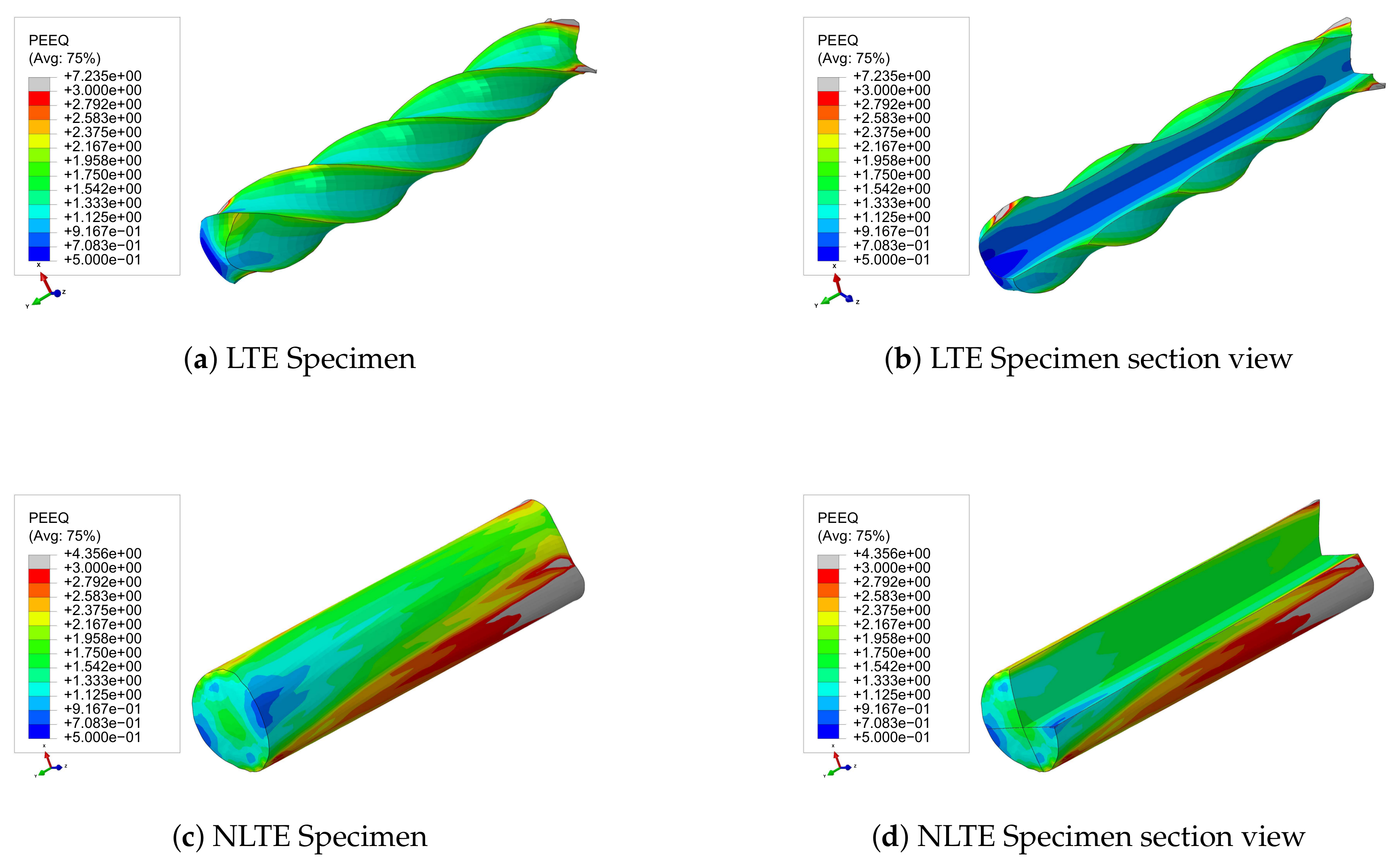

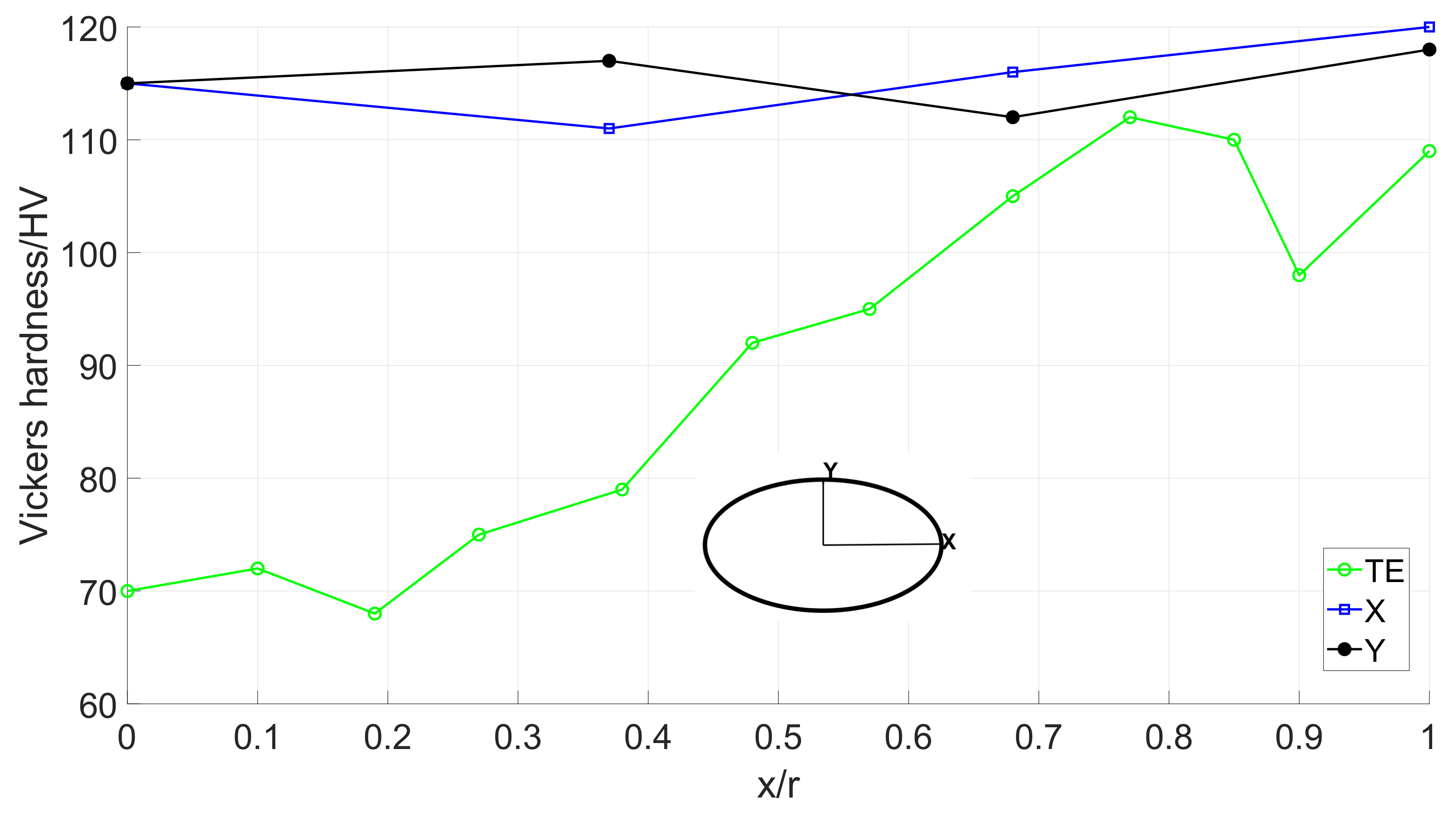

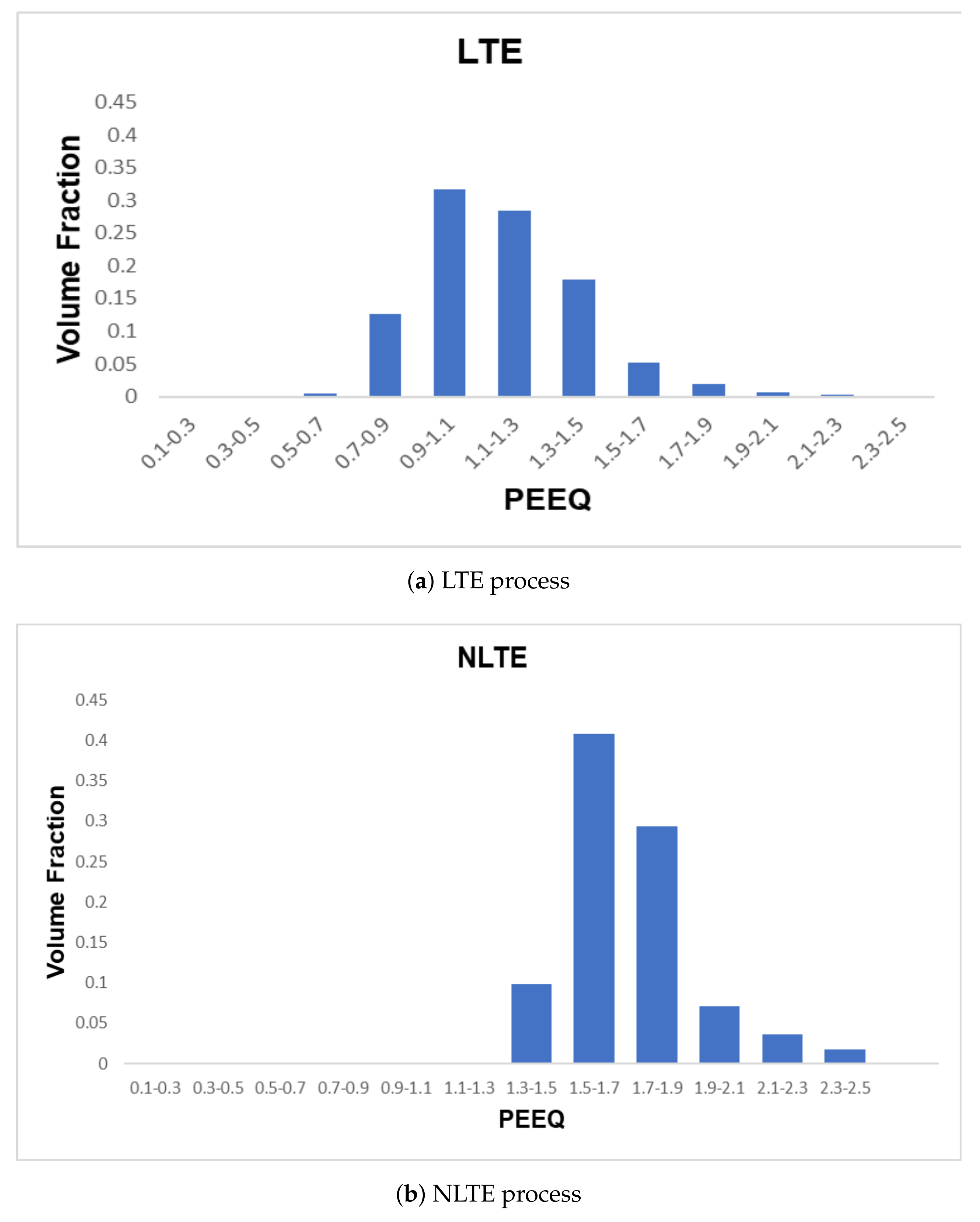

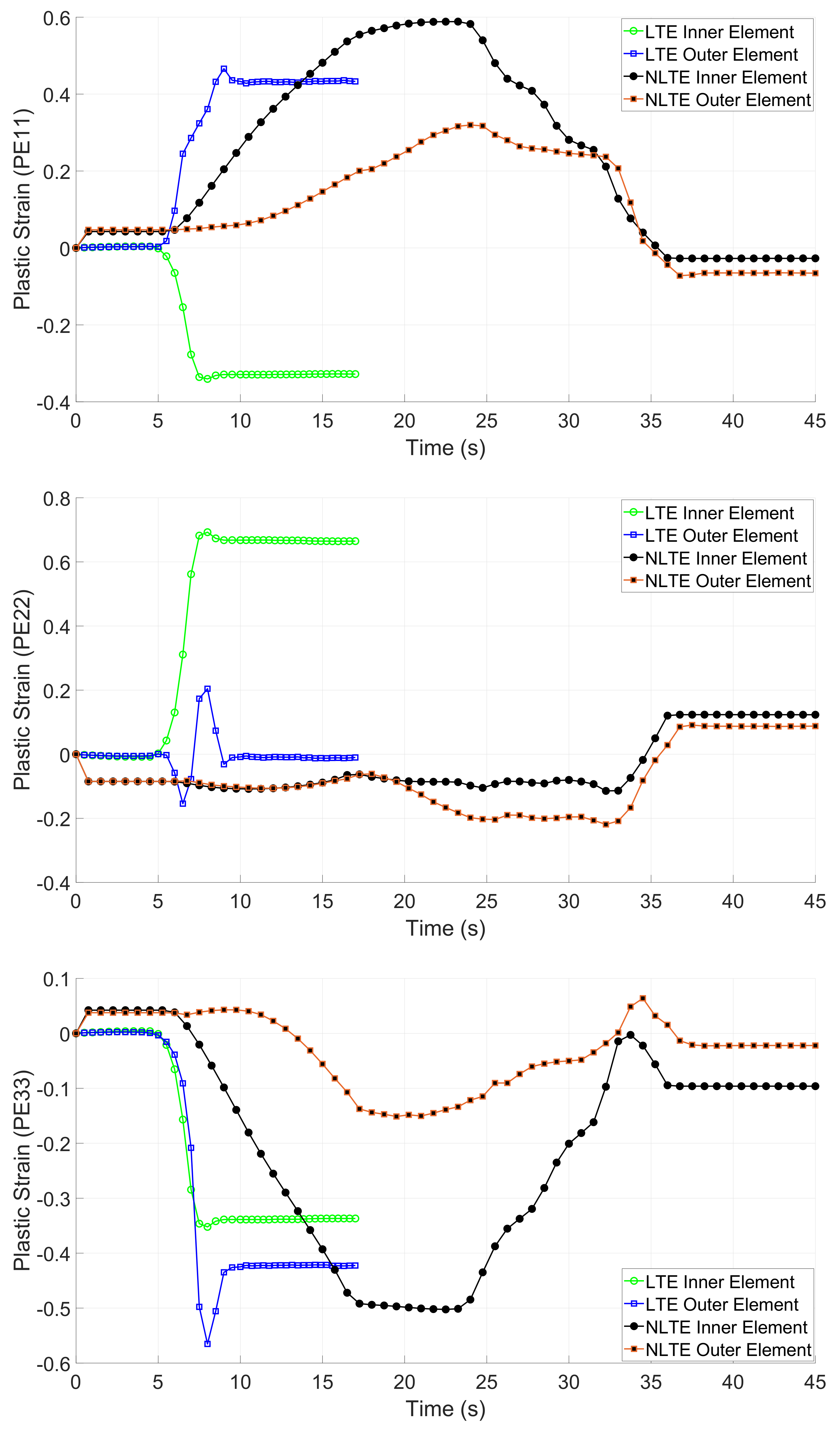

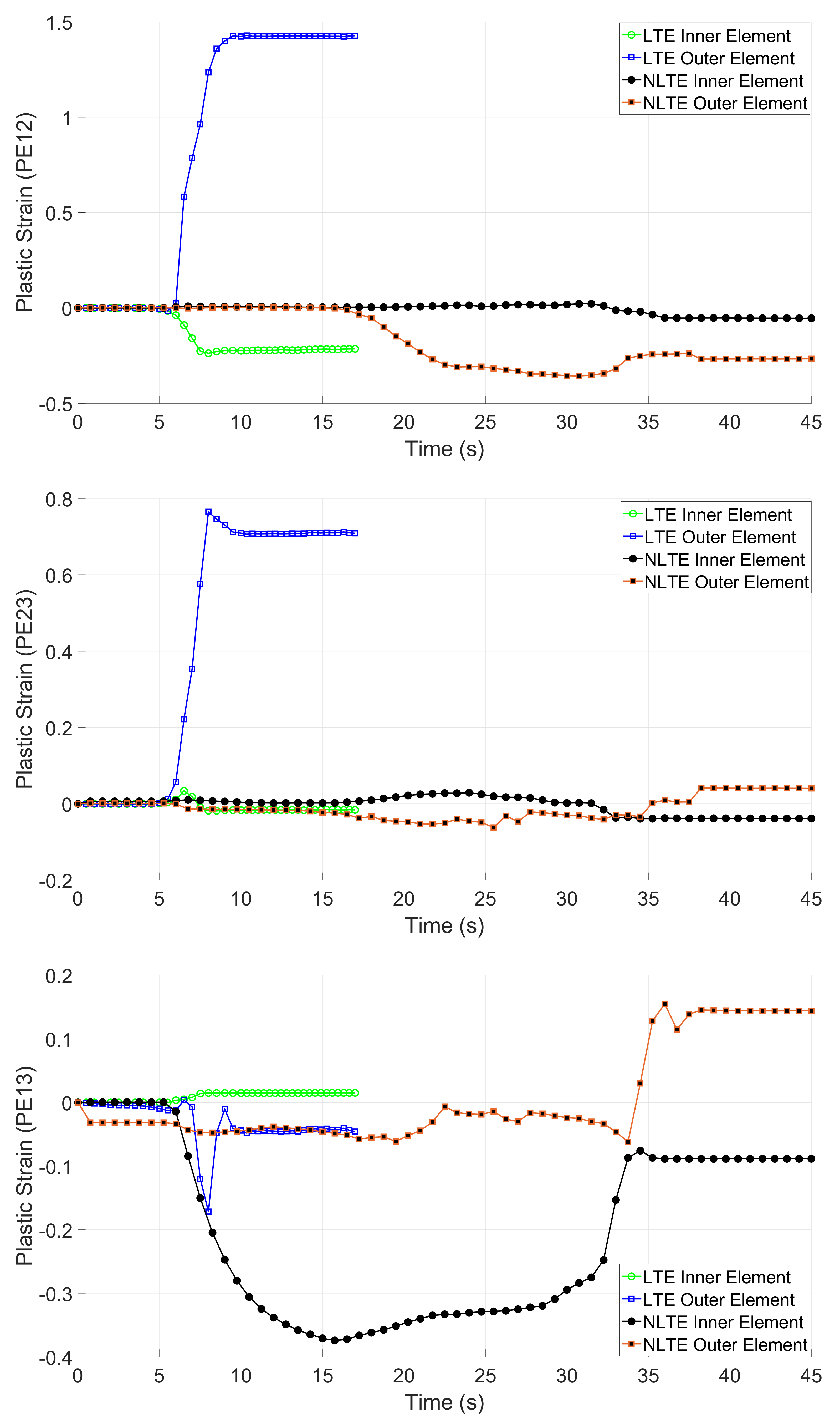

3. Simulations of the Linear and the Nonlinear Twist Extrusion

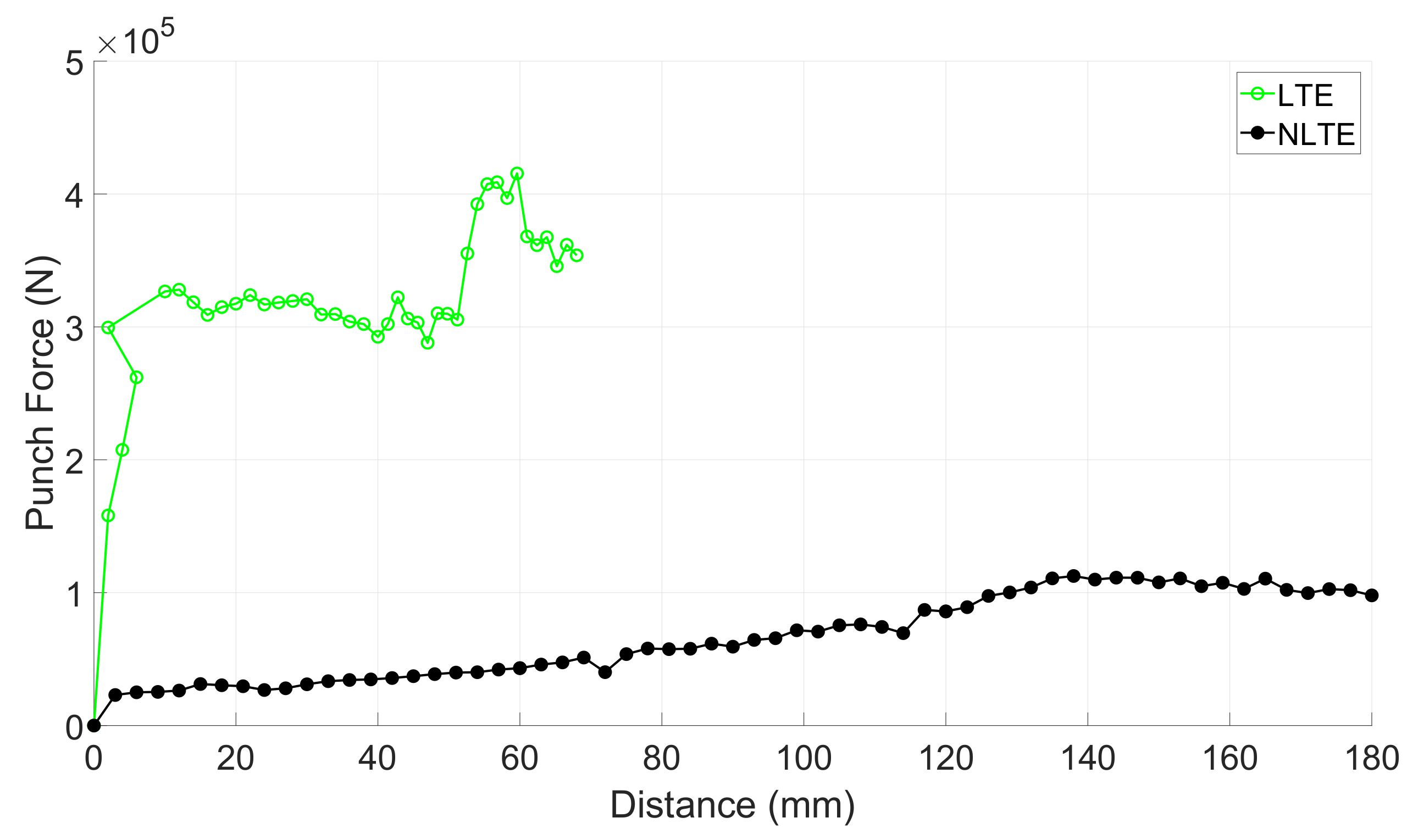

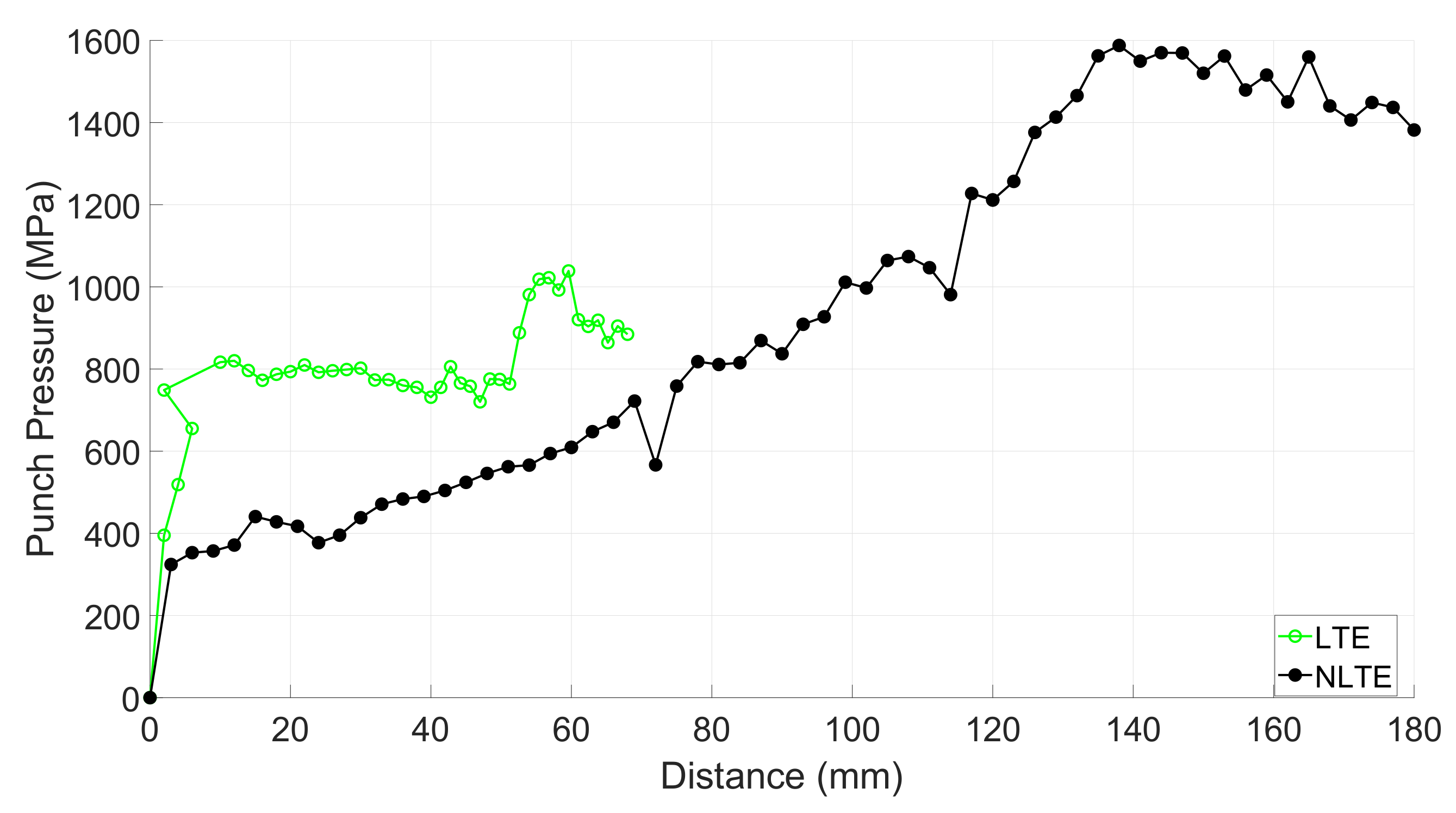

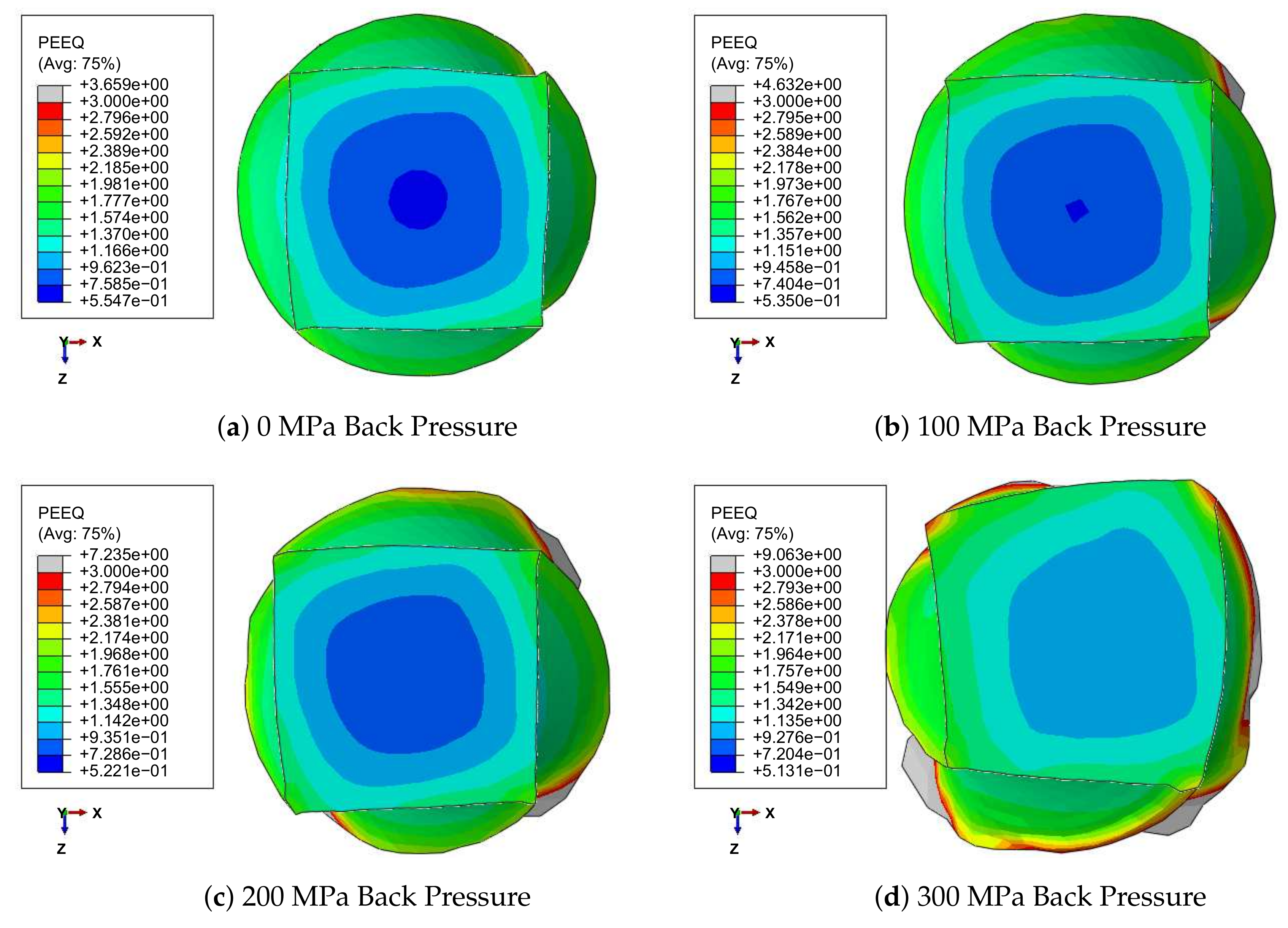

4. Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bridgman, P.W. Studies in Large Plastic Flow and Fracture; McGraw-Hill: New York, NY, USA, 1952. [Google Scholar]

- Valiev, R.Z.; Langdon, T.G. Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Segal, V.M.; Reznikov, V.I.; Drobyshevskiy, A.E.; Kopylov, V.I. Plastic working of metals by simple shear. Russ. Metall. 1981, 1, 99–105. [Google Scholar]

- Serban, N.; Cojocaru, V.D.; Butu, M. Mechanical Behavior and Microstructural Development of 6063-T1 Aluminum Alloy Processed by Equal-Channel Angular Pressing (ECAP): Pass Number Influence. JOM 2012, 64, 607–614. [Google Scholar] [CrossRef]

- Serban, N.; Ghiban, N.; Cojocaru, V.D. Mechanical Behavior and Microstructural Development of 6063-T1 Aluminum Alloy Processed by Equal-Channel Angular Pressing (ECAP): Die Channel Angle Influence. JOM 2013, 65, 1411–1418. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Romberg, J.; Freudenberger, J.; Bauder, H.; Plattner, G.; Krug, H.; Hollander, F.; Scharnweber, J.; Eschke, A.; Kuhn, U.; Klauss, H.; et al. Ti/Al Multi-Layered Sheets: Accumulative Roll Bonding (Part A). Metals 2016, 6, 30. [Google Scholar] [CrossRef]

- Romberg, J.; Freudenberger, J.; Watanabe, H.; Scharnweber, J.; Eschke, A.; Kuhn, U.; Klauss, H.; Oertel, C.G.; Skrotzki, W.; Eckert, J.; et al. Ti/Al Multi-Layered Sheets: Differential Speed Rolling (Part B). Metals 2016, 6, 31. [Google Scholar] [CrossRef]

- Utsunomiya, H.; Saito, Y.; Suzuki, H.; Sakai, T. Development of the continuous shear deformation process. Proc. Inst. Mech. Eng. Ser. B 2001, 215, 947–957. [Google Scholar] [CrossRef]

- Zisman, A.A.; Rybin, V.V.; Van Boxel, S.; Seefeldt, M.; Verlinden, M.B. Equal Channel Angular Drawing of Aluminium Sheet. Mater. Sci. Eng. A 2006, 427, 123–129. [Google Scholar] [CrossRef]

- Lee, J.C.; Seok, H.K.; Suh, J.Y. Microstructural evolutions of the Al strip prepared by cold rolling and continuous equal channel angular pressing. Acta Mater. 2002, 50, 4005–4019. [Google Scholar] [CrossRef]

- Orlov, D.; Beygelzimer, Y.; Synkov, S.; Varyukhin, V.; Horita, Z. Evolution of Microstructure and Hardness in Pure Al by Twist Extrusion. Mater. Trans. 2008, 49, 2–6. [Google Scholar] [CrossRef]

- Pardis, N.; Ebrahimi, R. Deformation behavior in Simple Shear Extrusion (SSE) as a new severe plastic deformation technique. Mater. Sci. Eng. A 2009, 527, 355–360. [Google Scholar] [CrossRef]

- Bagherpour, E.; Reihanian, M.; Ebrahimi, R. On the capability of severe plastic deformation of twining induced plasticity (TWIP) steel. Mater. Des. 2012, 36, 391–395. [Google Scholar] [CrossRef]

- Latypov, M.I.; Yoon, E.Y.; Lee, D.J.; Kulagin, R.; Beygelzimer, Y.; Seyed Salehi, M.; Kim, H.S. Microstructure and Mechanical Properties of Copper Processed by Twist Extrusion with a Reduced Twist-Line Slope. Metall. Mater. Trans. A 2014, 45, 2232–2241. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T. An investigation of microstructural evolution during equal-channel angular pressing. Acta Mater. 1997, 45, 4733–4741. [Google Scholar] [CrossRef]

- Wetscher, F.; Pippan, R. Cyclic high-pressure torsion of nickel and Armco iron. Philos. Mag. 2006, 86, 5867–5883. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Varyukhin, V.; Synkov, S.; Orlov, D. Useful properties of twist extrusion. Mater. Sci. Eng. A 2009, 503, 14–17. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Prilepo, D.; Kulagin, R.; Grishaev, V.; Abramova, O.; Varyukhin, V.; Kulakov, M. Planar Twist Extrusion versus Twist Extrusion. J. Mater. Process. Technol. 2011, 211, 522–529. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Reshetov, A.; Synkov, S.; Prokof’eva, O.; Kulagin, R. Kinematics of metal flow during twist extrusion investigated with a new experimental method. J. Mater. Process. Technol. 2009, 209, 3650–3656. [Google Scholar] [CrossRef]

- Latypov, M.; Alexandrov, I.; Beygelzimer, Y.; Lee, S.; Kim, H. Finite element analysis of plastic deformation in twist extrusion. Comput. Mater. Sci. 2012, 60, 194–200. [Google Scholar] [CrossRef]

- Maulidi, M.; Miyamoto, H.; Yuasa, M. Grain Refinement of Pure Magnesium Using Nonlinear Twist Extrusion. Mater. Sci. Forum 2018, 939, 54–62. [Google Scholar] [CrossRef]

- Fang, N. A New Quantitative Sensitivity Analysis of the Flow Stress of 18 Engineering Materials in Machining. J. Eng. Mater. Technol. 2005, 127, 192–196. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Shahab, A.R.; Mastoori, M. Computational study of Ti–6Al–4V flow behaviors during the twist extrusion process. Mater. Des. 2008, 29, 1316–1329. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Shahab, A.R.; Mastoori, M. Numerical and experimental studies of the plastic strains distribution using subsequent direct extrusion after three twist extrusion passes. Mater. Sci. Eng. A 2010, 527, 3967–3974. [Google Scholar] [CrossRef]

- Marat, I.; Latypov, Y.B.; Kim, H.S. Comparative Analysis of Two Twist-Based SPD Processes: Elliptical Cross-Section Spiral Equal-Channel Extrusion vs. Twist Extrusion. Mater. Trans. 2013, 54, 1587–1591. [Google Scholar]

- Marat, I.; Latypov, Y.B.; Kim, H.S. Finite element analysis of the plastic deformation in tandem process of simple shear extrusion and twist extrusion. Mater. Des. 2015, 83, 858–865. [Google Scholar]

- Lyszkowski, R.; Polkowski, W.; Czujko, T. Severe Plastic Deformation of Fe-22Al-5Cr Alloy by Cross-Channel Extrusion with Back Pressure. Materials 2018, 11, 2214. [Google Scholar] [CrossRef] [PubMed]

| Model | Element Type | Element Family | Number of Elements |

|---|---|---|---|

| LTE Die | Explicit-Tetrahedral-C3D4 | 3D Stress | 305,835 |

| LTE Dummy Die | Explicit-Hexahedral-C3D8R | 3D Stress | 2538 |

| LTE Punch | Explicit-Hexahedral-C3D8R | 3D Stress | 925 |

| LTE Specimen | Explicit-Hexahedral-C3D8R | 3D Stress | 20,000 |

| LTE Dummy Specimen | Explicit-Hexahedral-C3D8R | 3D Stress | 4500 |

| NLTE Die | Explicit-Tetrahedral-C3D4 | 3D Stress | 419,316 |

| NLTE Dummy Die | Explicit-Hexahedral-C3D8R | 3D Stress | 19,866 |

| NLTE Punch | Explicit-Hexahedral-C3D8R | 3D Stress | 1679 |

| NLTE Specimen | Explicit-Hexahedral-C3D8R | 3D Stress | 48,750 |

| NLTE Dummy Specimen | Explicit-Hexahedral-C3D8R | 3D Stress | 15,794 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yalçinkaya, T.; Şimşek, Ü.; Miyamoto, H.; Yuasa, M. Numerical Analysis of a New Nonlinear Twist Extrusion Process. Metals 2019, 9, 513. https://doi.org/10.3390/met9050513

Yalçinkaya T, Şimşek Ü, Miyamoto H, Yuasa M. Numerical Analysis of a New Nonlinear Twist Extrusion Process. Metals. 2019; 9(5):513. https://doi.org/10.3390/met9050513

Chicago/Turabian StyleYalçinkaya, Tuncay, Ülke Şimşek, Hiroyuki Miyamoto, and Motohiro Yuasa. 2019. "Numerical Analysis of a New Nonlinear Twist Extrusion Process" Metals 9, no. 5: 513. https://doi.org/10.3390/met9050513

APA StyleYalçinkaya, T., Şimşek, Ü., Miyamoto, H., & Yuasa, M. (2019). Numerical Analysis of a New Nonlinear Twist Extrusion Process. Metals, 9(5), 513. https://doi.org/10.3390/met9050513