Effects of Yttrium on Microstructure Stability and Tensile Properties of China Low Activation Martensitic Steel

Abstract

1. Introduction

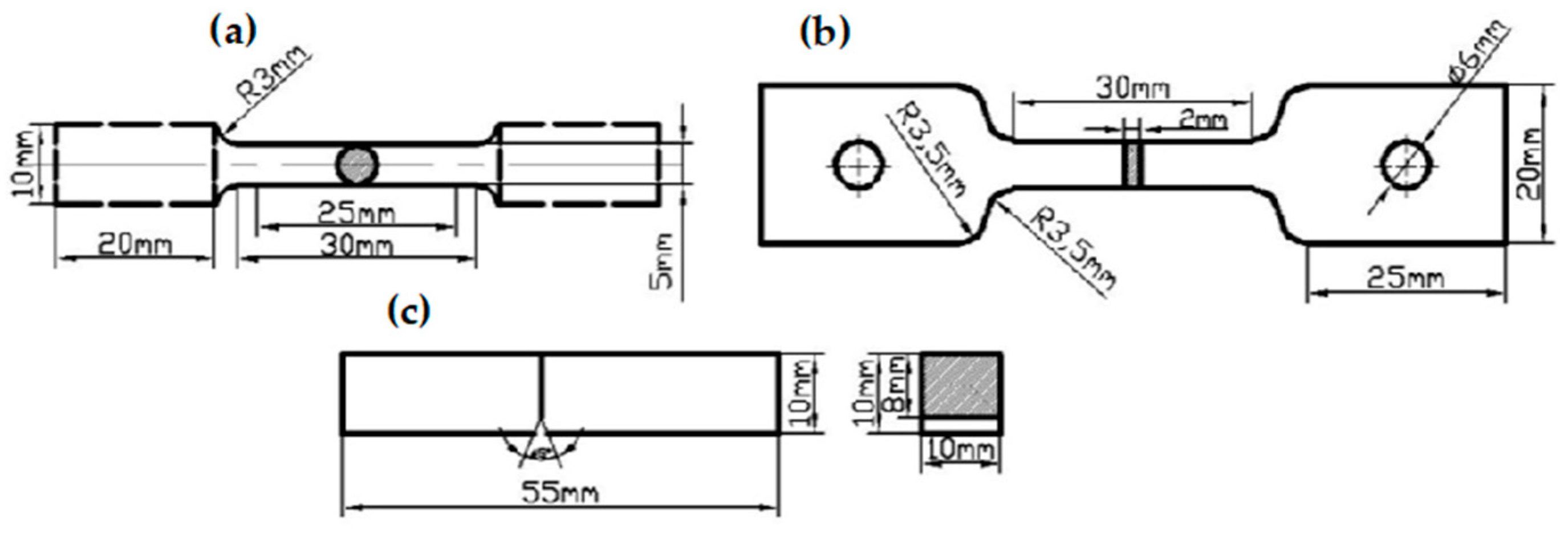

2. Materials and Methods

3. Results and Discussion

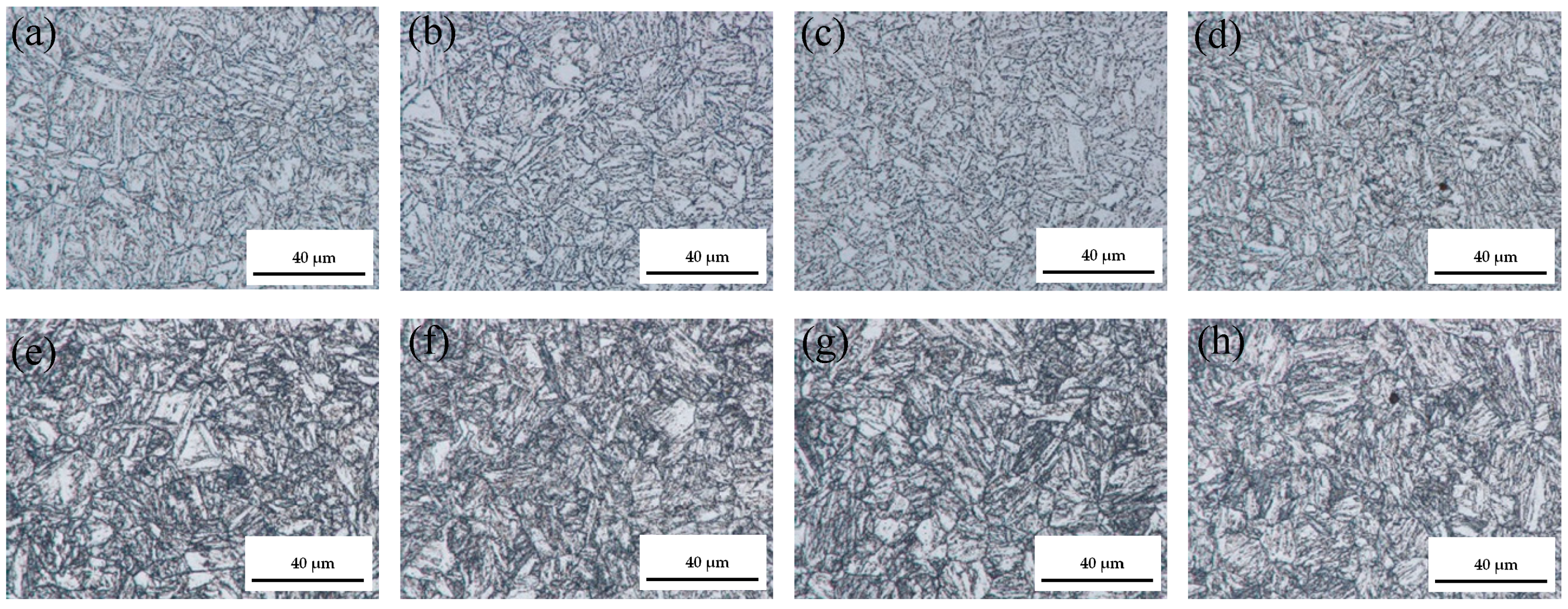

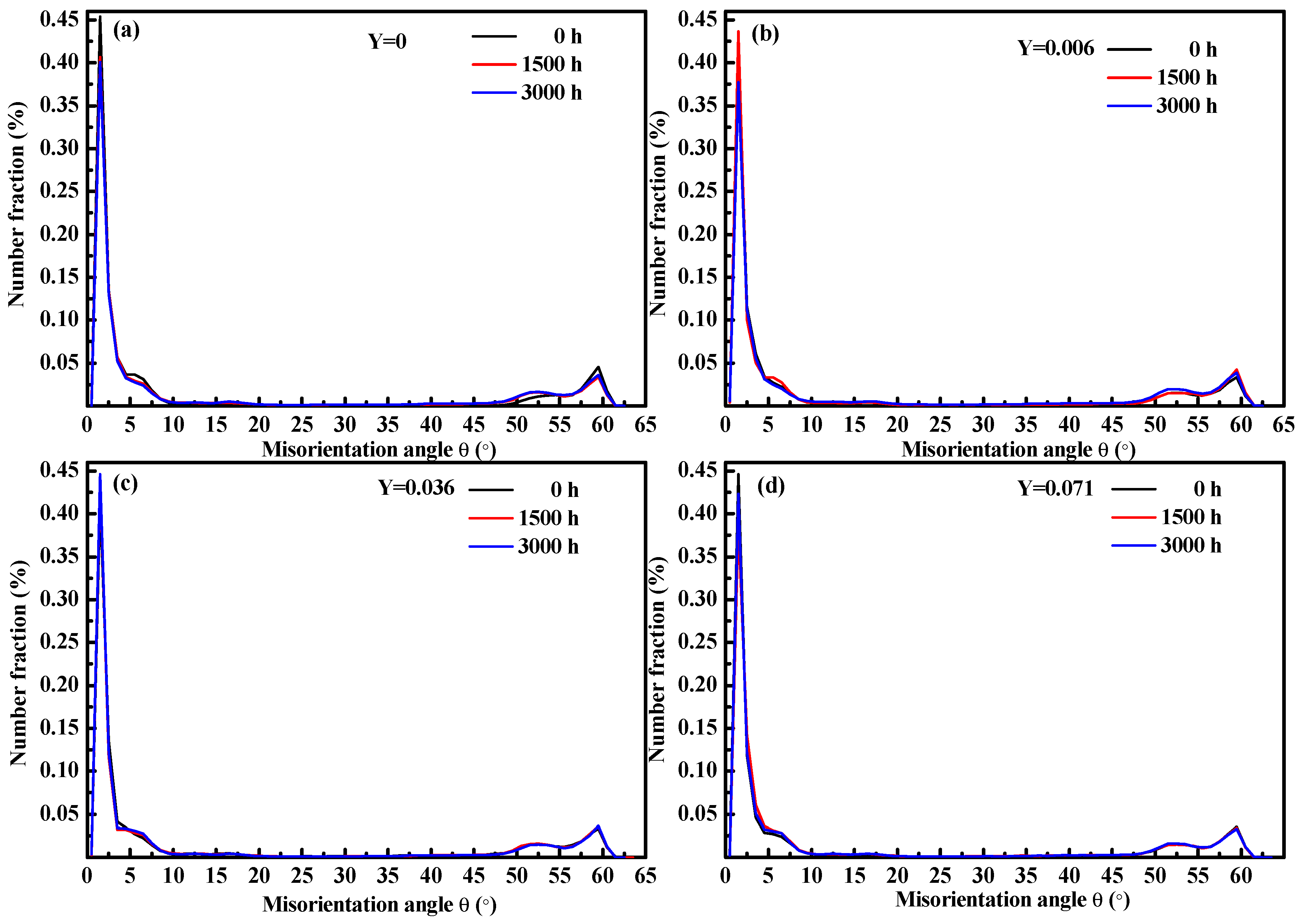

3.1. Grain Structural Characteristics

3.1.1. Microstructure

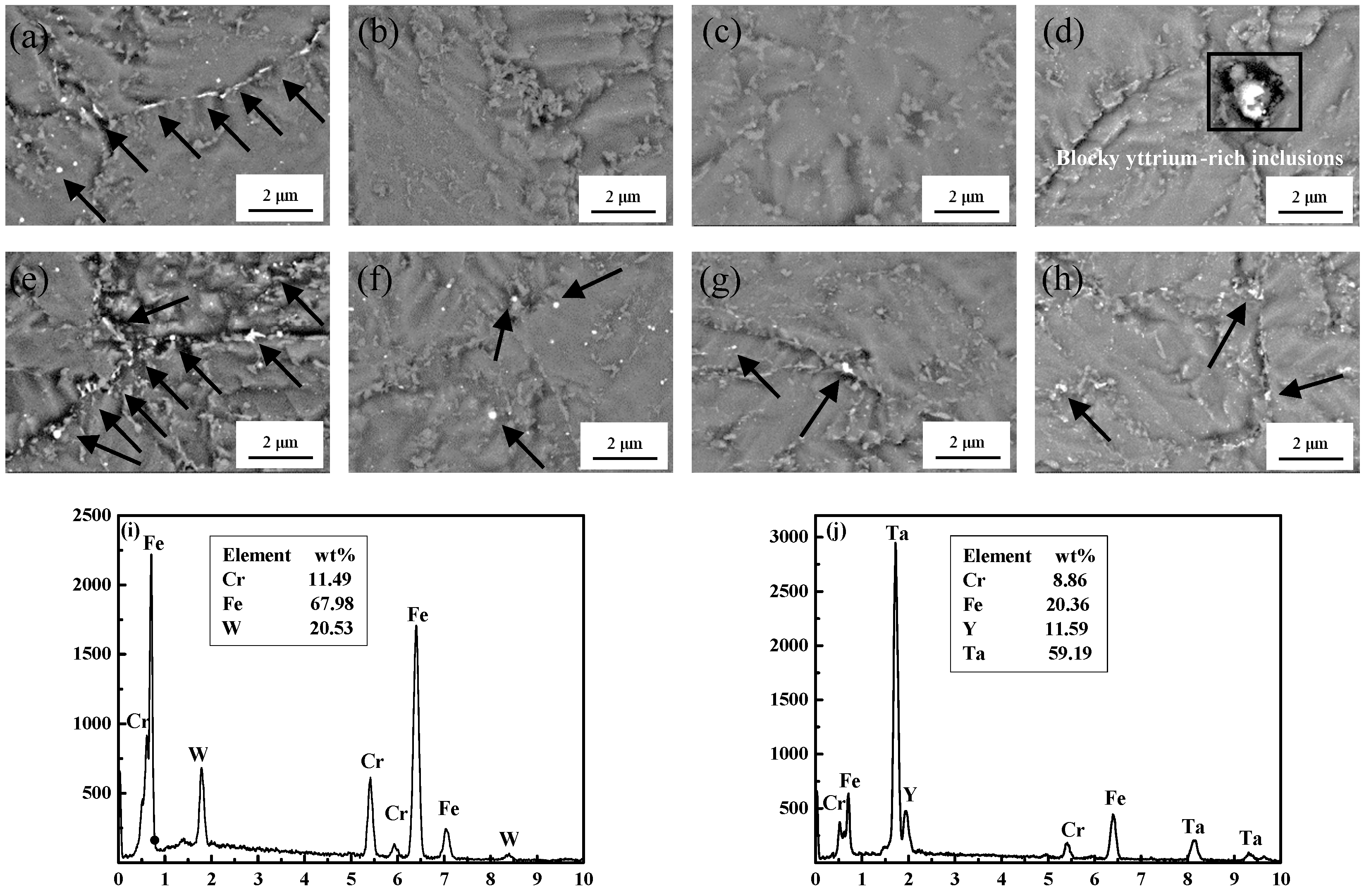

3.1.2. Precipitations

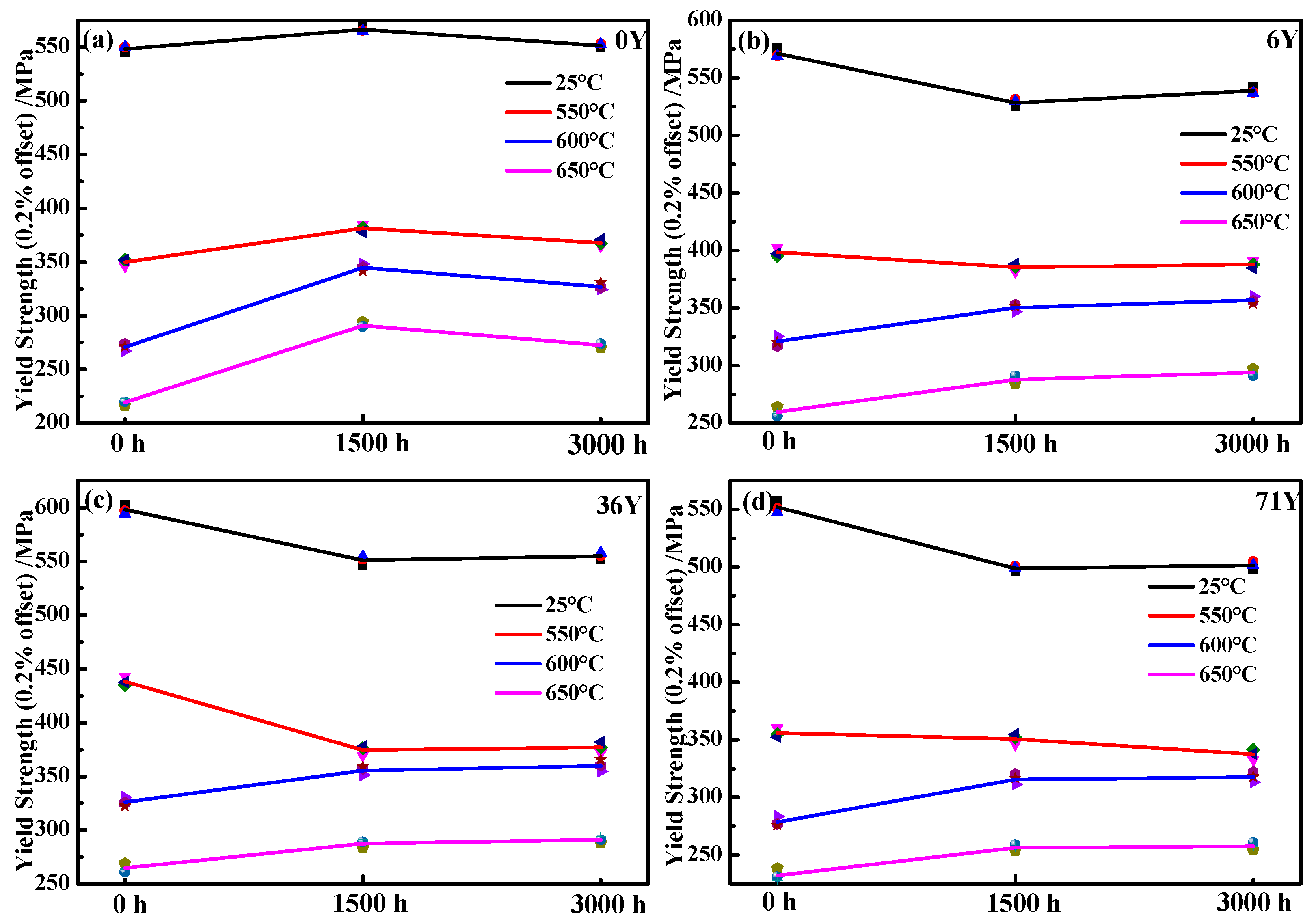

3.2. Tensile Test

Tensile Properties

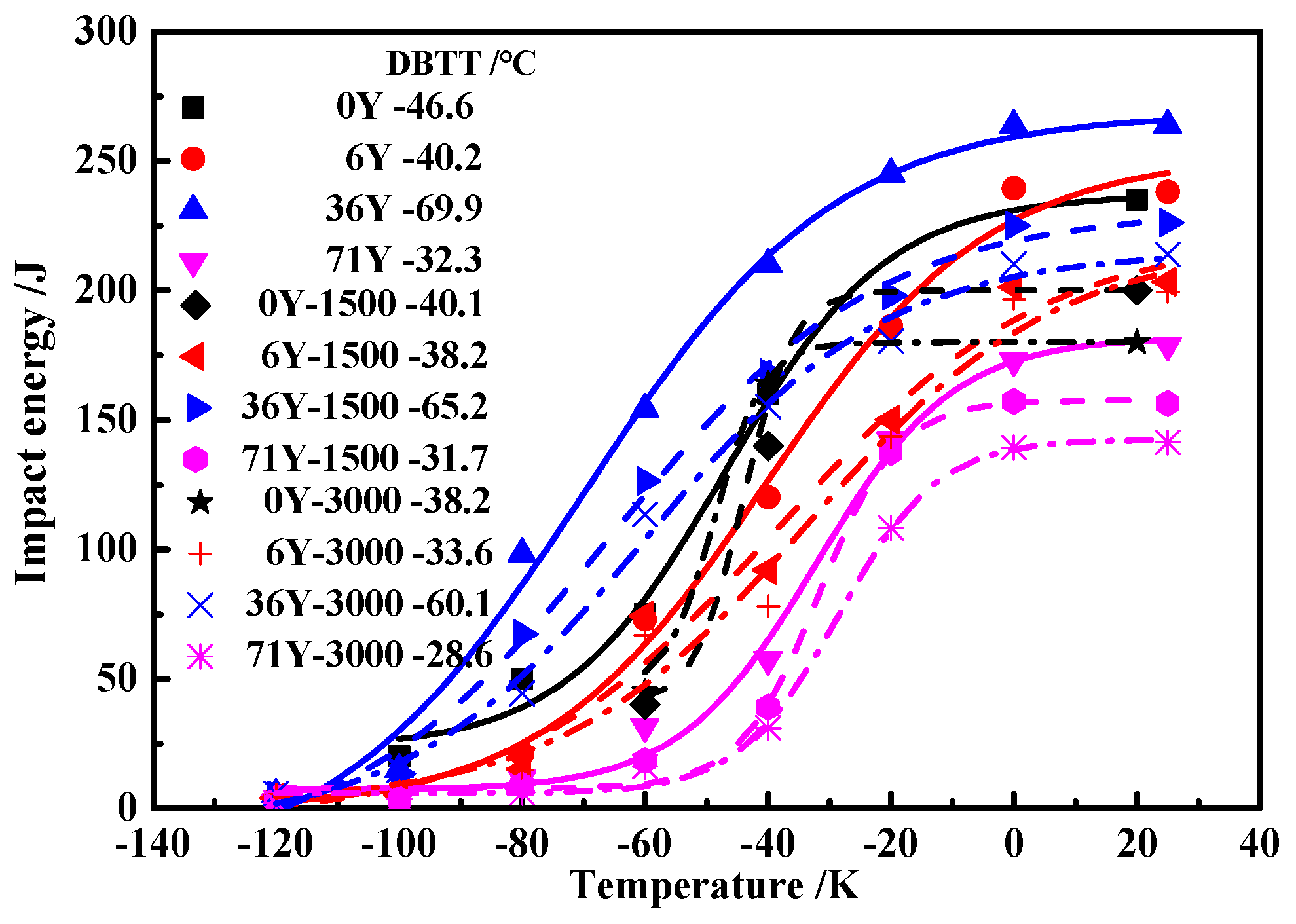

3.3. Charpy Impact Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gorley, M.J. Critical Assessment 12: Prospects for reduced activation steel for fusion plant. Mater. Sci. Technol. 2015, 31, 975–980. [Google Scholar] [CrossRef]

- Kurtz, R.J.; Alamo, A.; Lucon, E.; Huang, Q.; Jitsukawa, S.; Kimura, A.; Klueh, R.L.; Odette, G.R.; Petersen, C.; Sokolov, M.A.; et al. Recent progress toward development of reduced activation ferritic/martensitic steels for fusion structural applications. J. Nucl. Mater. 2009, 386–388, 411–417. [Google Scholar] [CrossRef]

- Tanigawa, H.; Shiba, K.; Möslang, A.; Stoller, R.E.; Lindau, R.; Sokolov, M.A.; Odette, G.R.; Kurtz, R.J.; Jitsukawa, S. Status and key issues of reduced activation ferritic/martensitic steels as the structural material for a DEMO blanket. J. Nucl. Mater. 2011, 417, 9–15. [Google Scholar] [CrossRef]

- Lindau, R.; Moslang, A.; Rieth, M.; Klimiankou, M.; Materna-Morris, E.; Alamo, A.; Tavassoli, A.-A.F.; Cayron, C.; Lancha, A.M.; Fernandez, P.; et al. Present development status of EUROFER and ODS-EUROFER for application in blanket concepts. Fusion Eng. Des. 2005, 75–79, 989–996. [Google Scholar] [CrossRef]

- Tan, L.; Yang, Y.; Busby, J.T. Effects of alloying elements and thermomechanical treatment on 9Cr Reduced Activation Ferritic–Martensitic (RAFM) steels. J. Nucl. Mater. 2013, 442, S13–S17. [Google Scholar] [CrossRef]

- Tan, L.; Katoh, Y.; Tavassoli, A.-A.F.; Henry, J.; Rieth, M.; Sakasegawa, H.; Tanigawa, H.; Huang, Q. Recent status and improvement of reduced-activation ferritic-martensitic steels for high-temperature service. J. Nucl. Mater. 2016, 479, 515–523. [Google Scholar] [CrossRef]

- Baluc, N.; Gelles, D.S.; Jitsukawa, S.; Kimura, A.; Klueh, R.L.; Odette, G.R.; van der Schaaf, B.; Yu, J. Status of reduced activation ferritic/martensitic steel development. J. Nucl. Mater. 2007, 367–370, 33–41. [Google Scholar] [CrossRef]

- Huang, Q.; Wu, Q.; Liu, S.; Li, C.; Huang, B.; Peng, L.; Zheng, S.; Han, Q.; Wu, Y. Latest progress on R&D of ITER DFLL-TBM in China. Fusion Eng. Des. 2011, 86, 2611–2615. [Google Scholar]

- Gao, S.; Huang, Q.; Zhu, Z.; Guo, Z.; Ling, X.; Chen, Y. Corrosion behavior of CLAM steel in static and flowing LiPb at 480 °C and 550 °C. Fusion Eng. Des. 2011, 86, 2627–2631. [Google Scholar] [CrossRef]

- Li, C.; Huang, Q.; Wu, Q.; Liu, S.; Lei, Y.; Muroga, T.; Nagasaka, T.; Zhang, J.; Li, J. Welding techniques development of CLAM steel for test blanket module. Fusion Eng. Des. 2009, 84, 1184–1187. [Google Scholar] [CrossRef]

- Huang, Q.; Li, J.; Chen, Y. Study of irradiation effects in China low activation martensitic steel CLAM. J. Nucl. Mater. 2004, 329–333, 268–272. [Google Scholar] [CrossRef]

- Wu, Y. Design analysis of the China dual-functional lithium lead (DFLL) test blanket module in ITER. Fusion Eng. Des. 2007, 82, 1893–1903. [Google Scholar] [CrossRef]

- Pan, F.; Zhang, J.; Chen, H.-L.; Su, Y.-H.; Kuo, C.-L.; Su, Y.-H.; Chen, S.-H.; Lin, K.-J.; Hsieh, P.-H.; Hwang, W.-S. Effects of Rare Earth Metals on Steel Microstructures. Materials 2017, 9, 419. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, Y.; Wang, S.; Li, H. Effects of cerium addition on solidification structure and mechanical properties of 434 ferritic stainless steel. J. Rare Earths 2017, 35, 518–524. [Google Scholar] [CrossRef]

- Nunes, F.C.; de Almeida, L.D.; Dille, J.; Delplancke, J.-L.; Le May, I. Microstructural changes caused by yttrium addition to NbTi-modified centrifugally cast HP-type stainless steels. Mater. Charact. 2007, 58, 132–142. [Google Scholar] [CrossRef]

- Kumar, D.; Prakash, U.; Dabhade, V.V.; Laha, K.; Sakthivel, T. Influence of Yttria on Oxide Dispersion Strengthened (ODS) Ferritic Steel. Mater. Today 2018, 5, 3909–3913. [Google Scholar] [CrossRef]

- Li, Y.; Huang, Q.; Wu, Y.; Zheng, Y.; Zuo, Y.; Zhu, S. Effects of addition of yttrium on properties and microstructure for China Low Activation Martensitic (CLAM) steel. Fusion Eng. Des. 2007, 82, 2683–2688. [Google Scholar] [CrossRef]

- Shi, Z.; Han, F. The microstructure and mechanical properties of micro-scale Y2O3, strengthened 9Cr steel fabricated by vacuum casting. Mater. Des. 2015, 66, 304–308. [Google Scholar] [CrossRef]

- Qiu, G.; Zhan, D.; Li, C.; Qi, M.; Jiang, Z.; Zhang, H. Effects of yttrium on microstructure and properties of reduced activation ferritic-martensitic steel. Mater. Sci. Technol. 2018, 34. [Google Scholar] [CrossRef]

- Cosgrove, G.J.; King, A.H. Adsorption, surface energy and the driving force for the migration of grain boundaries in substitutional alloys. Mater. Sci. Eng. A 1990, 123, 39–43. [Google Scholar] [CrossRef]

- Chen, S.; Rong, L. Effect of silicon on the microstructure and mechanical properties of reduced activation ferritic/martensitic steel. J. Nucl. Mater. 2015, 459, 13–19. [Google Scholar] [CrossRef]

- Yuan, Z.-X.; Yu, Z.-S.; Tan, P.; Song, S.-H. Effect of rare earths on the carburization of steel. Mater. Sci. Eng. A 1999, 267, 162–166. [Google Scholar] [CrossRef]

- Dhakar, B.M.; Dwivedi, D.K.; Sharma, S.P. Studies on remelting of tungsten carbide and rare earth modified nickel base alloy composite coating. Surf. Eng. 2012, 28, 73–80. [Google Scholar] [CrossRef]

- Yan, W.; Hu, P.; Wang, W.; Zhao, L.; Shan, Y.; Yang, K. Effect of yttrium on mechanical properties of 9Cr-2WVTa low active martensite steel. Chin. J. Nucl. Sci. Eng. 2009, 29, 50–55. [Google Scholar]

- Panait, C.G.; Bendick, W.; Fuchsmann, A.; Gourgues-Lorenzon, A.-F.; Besson, J. Study of the microstructure of the grade 91 steel after more than 100,000h of creep exposure at 600 °C. Int. J. Press. Vessels Pip. 2010, 87, 326–335. [Google Scholar] [CrossRef]

- Hu, X.; Huang, L.; Yan, W.; Wang, W.; Sha, W.; Shan, Y.; Yang, K. Evolution of microstructure and changes of mechanical properties of CLAM steel after long-term aging. Mater. Sci. Eng. A 2013, 586, 253–258. [Google Scholar] [CrossRef]

- Wang, W.; Liu, S.; Xu, G.; Zhang, B.; Huang, Q. Effect of Thermal Aging on Microstructure and Mechanical Properties of China Low-Activation Martensitic Steel at 550 °C. Nucl. Eng. Technol. 2016, 48, 518–524. [Google Scholar] [CrossRef]

- Li, Y.; Abe, H.; Li, F.; Satoh, Y.; Matsukawa, Y.; Matsunaga, T.; Muroga, T. Grain structural characterization of 9Cr–ODS steel aged at 973K up to 10,000 h by electron backscatter diffraction. J. Nucl. Mater. 2014, 455, 568–572. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Shi, J.; Hui, W.; Dong, H. Effect of microstructural refinement on the toughness of low carbon martensitic steel. Scr. Mater. 2008, 58, 492–495. [Google Scholar] [CrossRef]

- Karthikeyan, T.; Paul, V.T.; Saroja, S.; Moitra, A.; Sasikala, G.; Vijayalakshmi, M. Grain refinement to improve impact toughness in 9Cr–1Mo steel through a double austenitization treatment. J. Nucl. Mater. 2011, 419, 256–262. [Google Scholar] [CrossRef]

| Alloy | C | Cr | Mn | Si | W | V | S | Ta | P | N | O | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Y | 0.11 | 9.3 | 0.45 | 0.05 | 1.36 | 0.22 | 0.010 | 0.072 | 0.0085 | 0.0023 | 0.0060 | - |

| 6Y | 0.11 | 9.4 | 0.46 | 0.05 | 1.35 | 0.22 | 0.007 | 0.071 | 0.0086 | 0.0023 | 0.0054 | 0.006 |

| 36Y | 0.11 | 9.4 | 0.45 | 0.05 | 1.35 | 0.21 | 0.004 | 0.073 | 0.0084 | 0.0022 | 0.0050 | 0.036 |

| 71Y | 0.11 | 9.4 | 0.45 | 0.05 | 1.35 | 0.22 | 0.003 | 0.071 | 0.0084 | 0.0022 | 0.0050 | 0.071 |

| Alloys | 0 h | 1500 h | 3000 h |

|---|---|---|---|

| 0Y | 14.7 (σ = 3.23) | 15.6 (σ = 3.42) | 16.9 (σ = 3.27) |

| 6Y | 14.3 (σ = 3.01) | 15.2 (σ = 3.07) | 16.3 (σ = 3.12) |

| 36Y | 11.7 (σ = 2.23) | 12.9 (σ = 2.34) | 13.2 (σ = 2.54) |

| 71Y | 11.6 (σ = 2.13) | 12.0 (σ = 2.04) | 13.1 (σ = 2.46) |

| Samples | 0Y | 6Y | 36Y | 71Y |

|---|---|---|---|---|

| 0 h | 0.37 | 0.28 | 0.29 | 0.33 |

| 1500 h | 0.47 | 0.34 | 0.35 | 0.44 |

| 3000 h | 0.63 | 0.36 | 0.36 | 0.47 |

| Aging Time | 0Y | 6Y | 36Y | 71Y | ||||

|---|---|---|---|---|---|---|---|---|

| HABs | LABs | HABs | LABs | HABs | LABs | HABs | LABs | |

| 0 h | 0.215 | 0.785 | 0.286 | 0.714 | 0.286 | 0.714 | 0.272 | 0.728 |

| 1500 h | 0.277 | 0.723 | 0.293 | 0.717 | 0.285 | 0.715 | 0.273 | 0.727 |

| 3000 h | 0.300 | 0.700 | 0.351 | 0.659 | 0.271 | 0.719 | 0.277 | 0.723 |

| Alloy | 0 h [19] | 1500 h | 3000 h | |||

|---|---|---|---|---|---|---|

| R0.2 | Rm | R0.2 | Rm | R0.2 | Rm | |

| 0Y | 548.2 ± 3.5 | 655.1 ± 2.4 | 566.5 ± 3.2 | 683.4 ± 3.2 | 551.4 ± 2.5 | 675.3 ± 2.2 |

| 6Y | 571.4 ± 4.6 | 699.3 ± 4.6 | 528.4 ± 3.6 | 666.4 ± 3.0 | 532.6 ± 3.5 | 681.5 ± 3.7 |

| 36Y | 598.6 ± 4.5 | 718.6 ± 4.7 | 551.0 ± 3.5 | 672.9 ± 3.3 | 555.2 ± 3.0 | 674.6 ± 4.3 |

| 71Y | 552.2 ± 5.7 | 663.3 ± 6.5 | 494.7 ± 2.7 | 645.8 ± 2.5 | 501.7 ± 3.4 | 652.9 ± 4.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, G.; Zhan, D.; Li, C.; Qi, M.; Yang, Y.; Jiang, Z.; Zhang, H. Effects of Yttrium on Microstructure Stability and Tensile Properties of China Low Activation Martensitic Steel. Metals 2019, 9, 446. https://doi.org/10.3390/met9040446

Qiu G, Zhan D, Li C, Qi M, Yang Y, Jiang Z, Zhang H. Effects of Yttrium on Microstructure Stability and Tensile Properties of China Low Activation Martensitic Steel. Metals. 2019; 9(4):446. https://doi.org/10.3390/met9040446

Chicago/Turabian StyleQiu, Guoxing, Dongping Zhan, Changsheng Li, Min Qi, Yongkun Yang, Zhouhua Jiang, and Huishu Zhang. 2019. "Effects of Yttrium on Microstructure Stability and Tensile Properties of China Low Activation Martensitic Steel" Metals 9, no. 4: 446. https://doi.org/10.3390/met9040446

APA StyleQiu, G., Zhan, D., Li, C., Qi, M., Yang, Y., Jiang, Z., & Zhang, H. (2019). Effects of Yttrium on Microstructure Stability and Tensile Properties of China Low Activation Martensitic Steel. Metals, 9(4), 446. https://doi.org/10.3390/met9040446