An Investigation of the Adhesive Effect on the Flank Wear Properties of a WC/Co-based TiAlN-Coated Tool for Milling a Be/Cu Alloy

Abstract

:1. Introduction

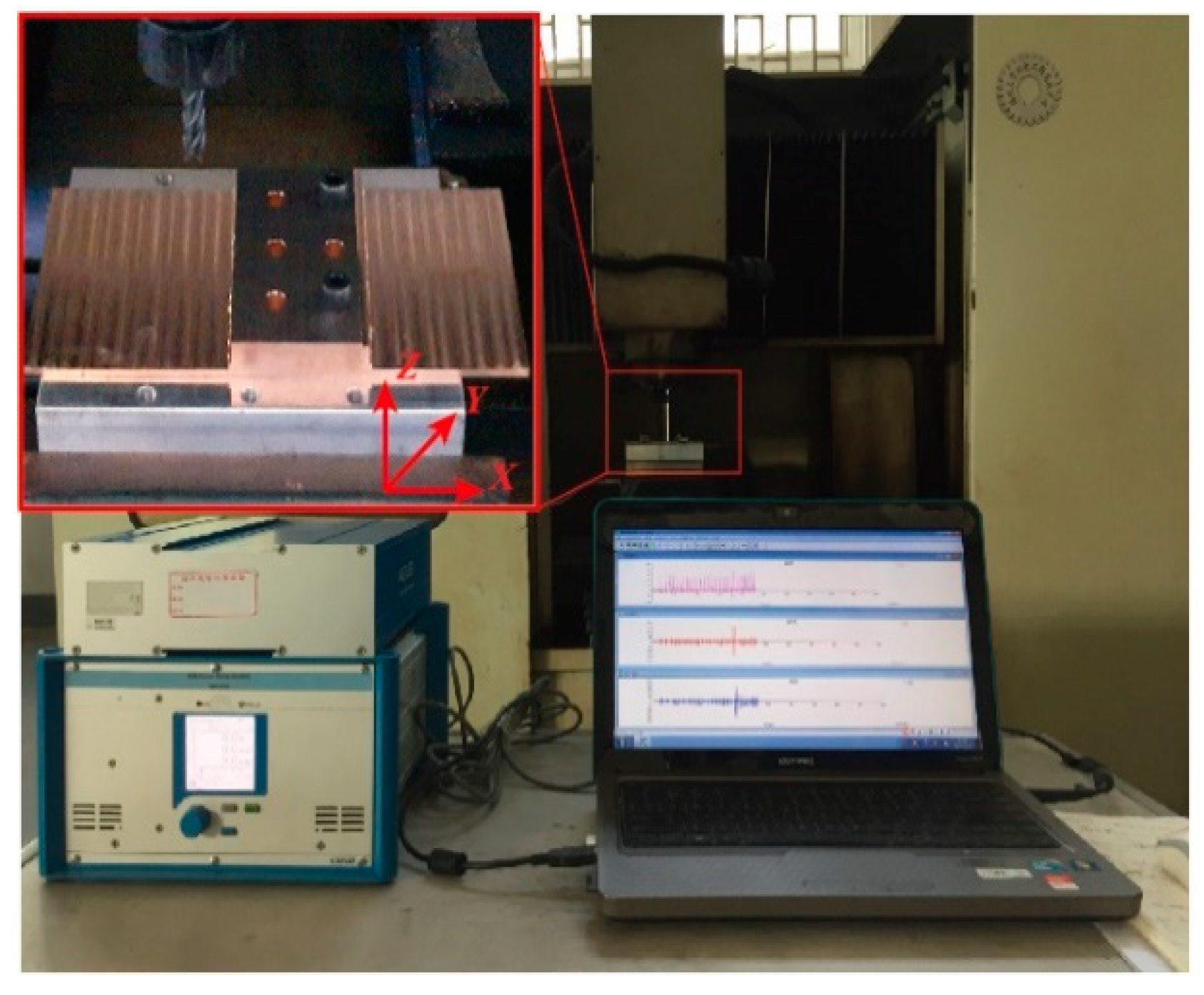

2. Materials and Method

2.1. Materials And Experimental Setup

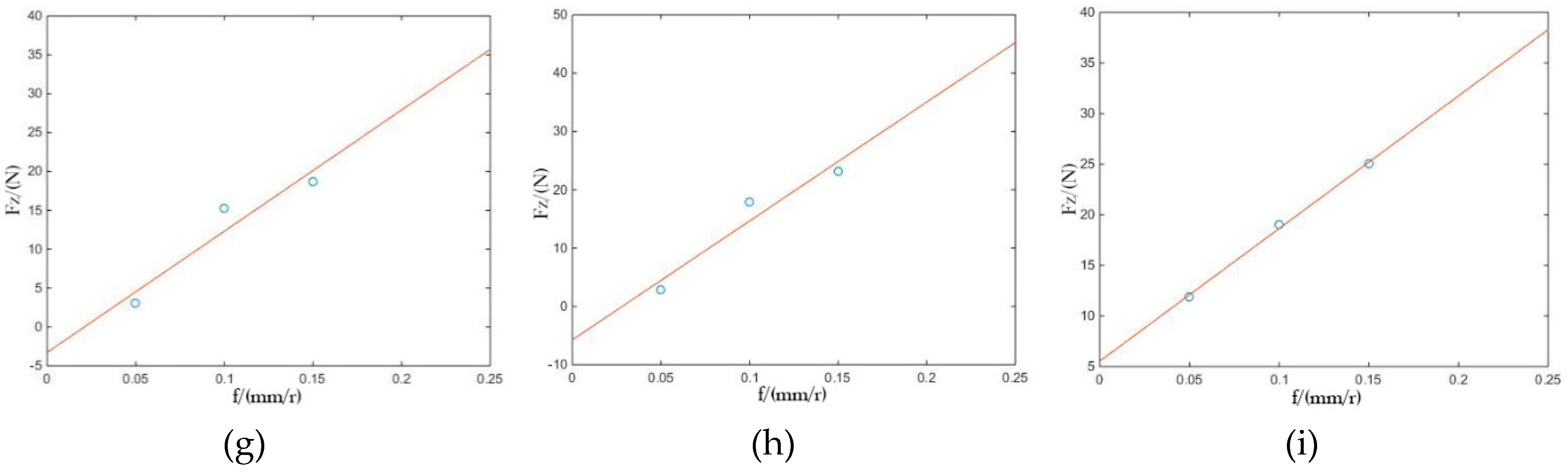

2.2. Calculation of Cutting Force

2.3. Wear Process and Force Condition

3. Results

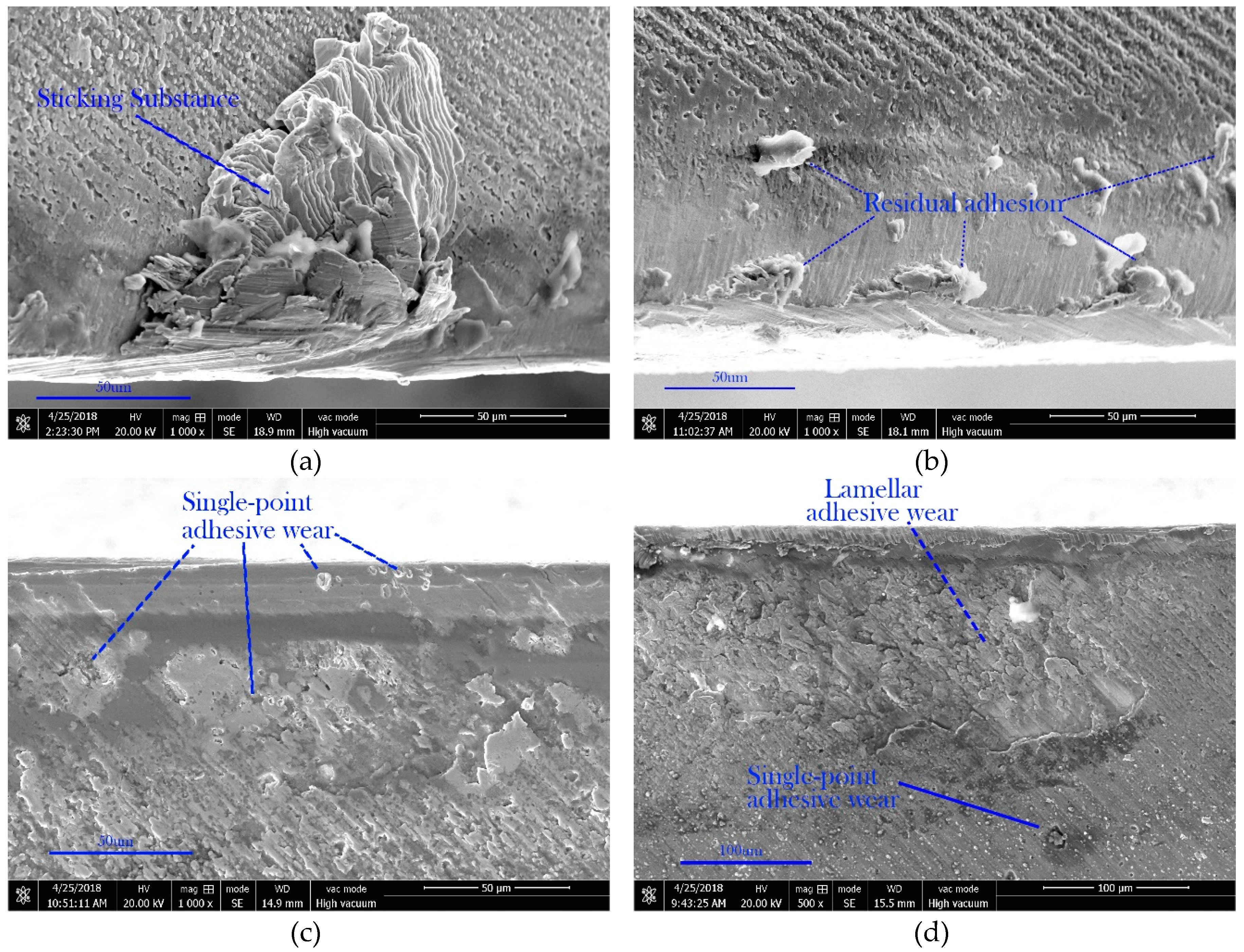

3.1. Spectrum Analysis and Sticking Substance

3.2. Cutting Force and its Parameters

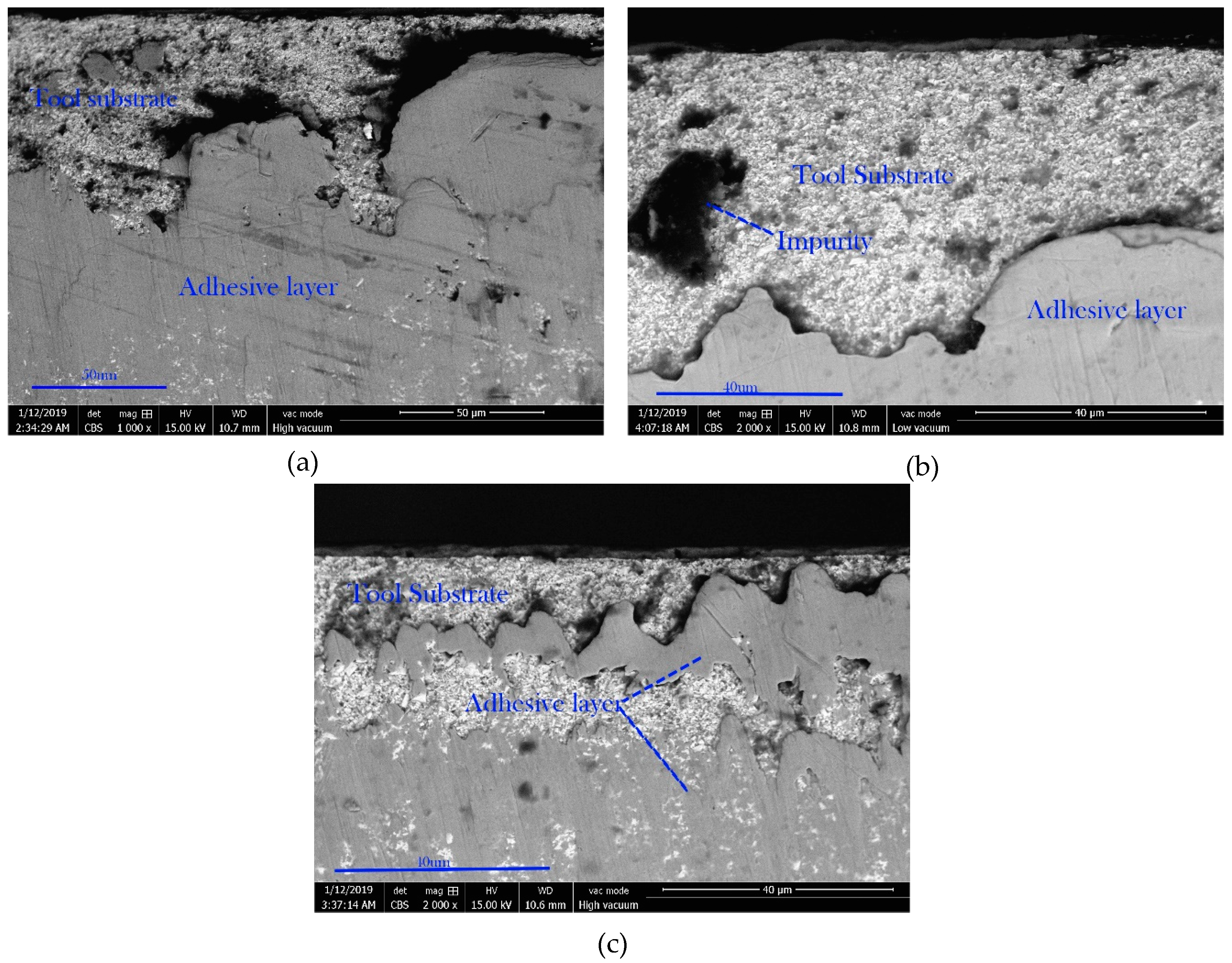

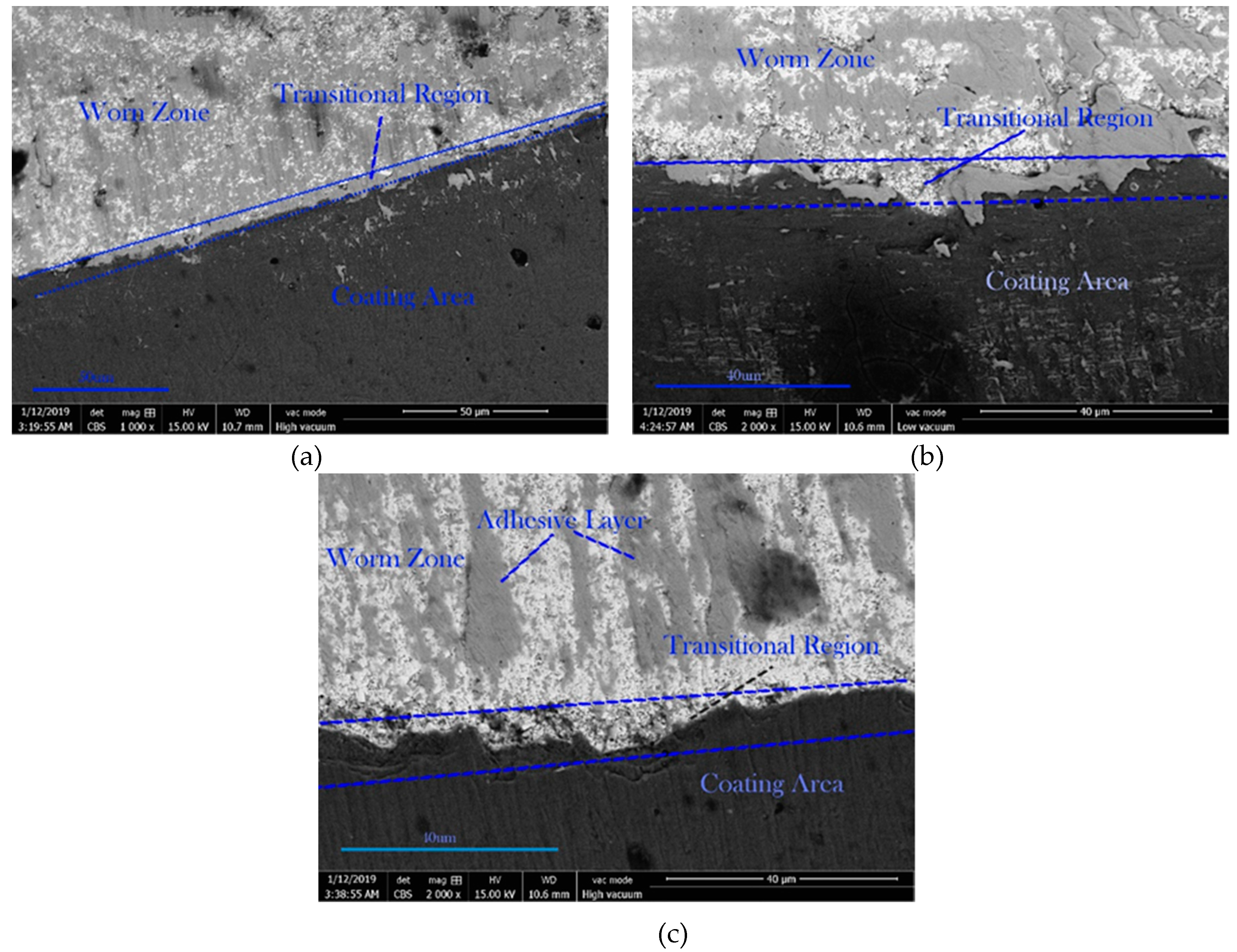

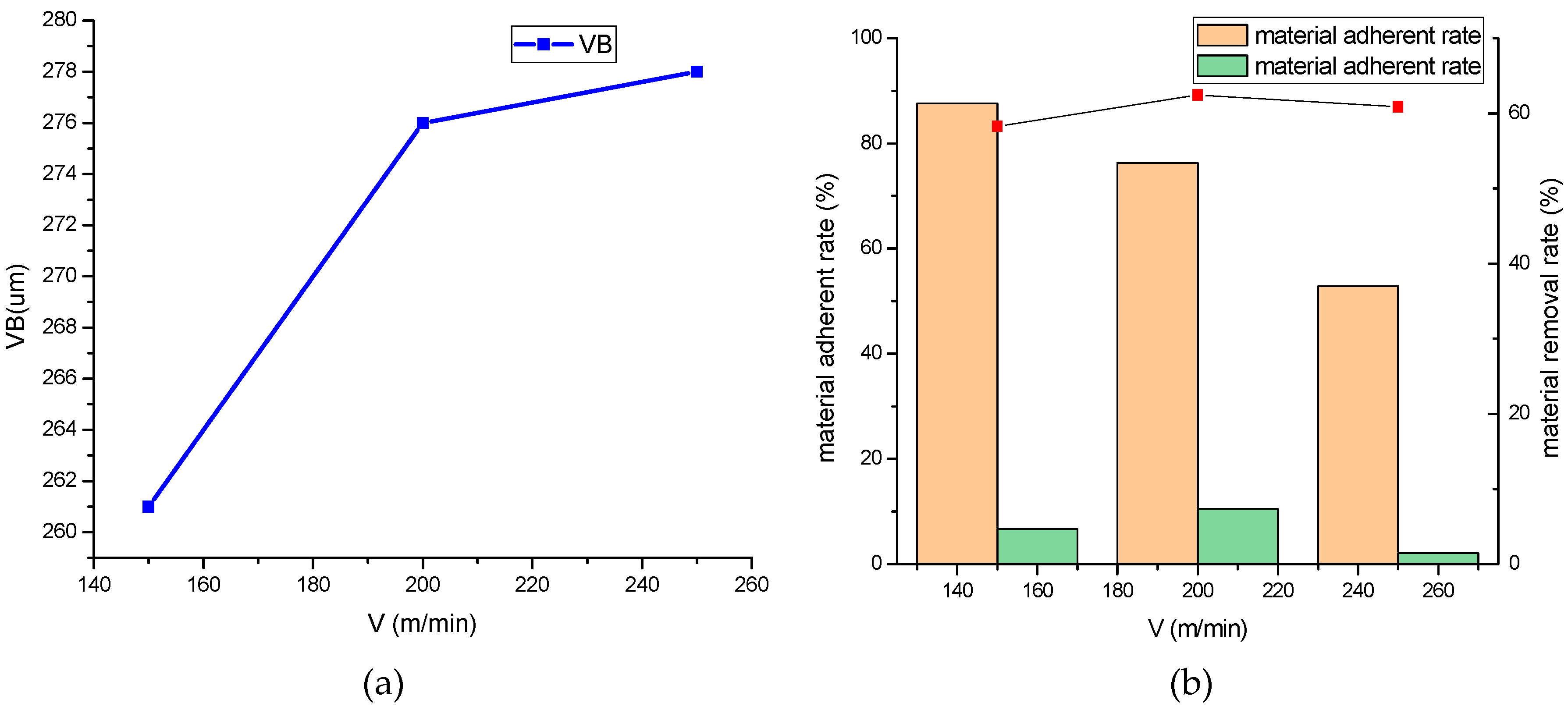

3.3. Wearing Capacity and Back-Scattered Electron Imaging

4. Discussion

5. Conclusions

- Four kinds of cutter surface morphology were analyzed in this paper to show the possibility of adhesive layer formation on a flank surface at cutter speeds of 150, 200, and 250 m/min, which represent three different states in the adhesive process: adhesion, shedding, and residual.

- The cutting force parameters (based on Altintas [30]) were calculated in this paper, and the results show that the force parameters produced a relatively obvious turning point at 200 m/min. The tool geometry and its variation could be the main reason for a significant variation of milling force and tool wear.

- Compared with tool surface composition under different cutting speeds, the adhesive layer content reached a peak value at 200 m/min. Additionally, the thermal–mechanical effect of the work-piece on a processed surface leads to serious adhesive–abrasion wear on the flank surface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Quantity Unit |

| f | Feed per tooth mm/z |

| Fc | Cutting force in orthogonal cutting N |

| τ | Shear Stress MPa |

| Ft | Thrust force in orthogonal cutting N |

| v | Cutting speed m/min |

| Average cutting force in orthogonal cutting N | |

| n | Spindle rotate speed r/min |

| Average thrust force in orthogonal cutting N | |

| ap | Axial depth of cut mm |

| Fx | Milling force in the X direction N |

| ϕ | Shear angle deg |

| Fy | Milling force in the Y direction N |

| T | Torsion N |

| Fz | Milling force in the Z direction N |

| Ktx | Cutting parameter in the X direction |

| F | Total cutting force N |

| Krx | Cutting parameter in the Y direction |

| h | Cut thickness mm |

| Kax | Cutting parameter in the Z direction |

| b | Side milling width mm |

| β | Helical angle deg |

| z | Tooth number |

| D | Cutter diameter mm |

References

- Yan, M.F.; Zhu, Y.D.; Zhang, C.S.; Zhang, Y.X.; Wang, Y.X.; Yang, L. Microstructure and mechanical properties of copper-titanium-nitrogen multiphase layers produced by a duplex treatment on C17200 copper-beryllium alloy. Mater. Des. 2015, 84, 10–17. [Google Scholar] [CrossRef]

- Sharma, A.; Datta, D.; Balasubramaniam, R. An investigation of tool and hard particle interaction in nanoscale cutting of copper beryllium. Comput. Mater. Sci. 2018, 145, 208–223. [Google Scholar]

- Bushlya, V.; Johansson, D.; Lenrick, F.; Ståhl, J.-E.; Schultheiss, F. Wear mechanisms of uncoated and coated cemented carbide tools in machining lead-free silicon brass. Wear 2017, 376–377, 143–151. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z. Tool wear behaviors and corresponding machined surface topography during high-speed machining of Ti6Al4V with fine grain tools. Tribol. Int. 2018, 121, 321–332. [Google Scholar] [CrossRef]

- Naskar, A.; Chattopadhyay, A.K. Investigation on flank wear mechanism of CVD and PVD hard coatings in high speed dry turning of low and high carbon steel. Wear 2018, 396–397, 98–106. [Google Scholar] [CrossRef]

- Sui, S.C.; Feng, P.F. The influence of tool wear on Ti6Al4V cutting temperature and burn defect. Int. J. Manuf. Technol. 2016, 85, 2831–2838. [Google Scholar] [CrossRef]

- Wang, C.; Ming, W.; Chen, M. Milling tool’s flank wear prediction by temperature dependent wear mechanism determination when machining Inconel 182 overlays. Tribol. Int. 2016, 104, 140–156. [Google Scholar] [CrossRef]

- Zheng, G.; Cheng, X.; Yang, X.; Xu, R.; Zhao, J.; Zhao, G. Self-organization wear characteristics of MTCVD-TiCN-Al2O3 coated tool against 300M steel. Ceram. Int. 2017, 43, 13214–13223. [Google Scholar] [CrossRef]

- Momeni, S.; Tillmann, W. Investigation of the self-healing sliding wear characteristics of NiTi-based PVD coatings on tool steel. Wear 2016, 368–369, 53–59. [Google Scholar] [CrossRef]

- Budak, E.; Altintas, Y. Peripheral milling conditions for improved dimensional accuracy. Int. J. Mach. Tools Manuf. 1994, 34, 907–918. [Google Scholar] [CrossRef]

- Shirase, K.; Altintas, Y. Cutting force and dimensional surface error generation in peripheral milling with variable pitch helical end mills. Int. J. Mach. Tools Manuf. 1996, 36, 567–584. [Google Scholar] [CrossRef]

- Budak, E.; Altintas, Y. Modeling and avoiding of static form errors in peripheral milling of plates. Int. J. Mach. Tools Manuf. 1995, 35, 459–476. [Google Scholar] [CrossRef]

- Mane, I.; Gagnol, V.; Bouzgarrou, B.C.; Ray, P. Stability-based spindle speed control during flexible workpiece high-speed milling. Int. J. Mach. Tools Manuf. 2008, 48, 184–194. [Google Scholar] [CrossRef]

- Vettivel, S.C.; Jegan, R.; Vignesh, J.; Suresh, S. Surface characteristics and wear depth profile of the TiN, TiAlN and AlCrN coated stainless steel in dry sliding wear condition. Surf. Interfaces 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Pang, L.; Hosseini, A.; Hussein, H.M.; Deiab, I.; Kishawy, H.A. Application of a new thick zone model to the cutting mechanics during end-milling. Int. J. Mech. Sci. 2015, 96–97, 91–100. [Google Scholar] [CrossRef]

- Mia, M.; Rifat, A.; Tanvir, M.F.; Gupta, M.K.; Hossain, M.J.; Goswami, A. Multi-objective optimization of chip-tool interaction parameters using Grey-Taguchi method in MQL-assisted turning. Measurment 2018, 129, 156–166. [Google Scholar] [CrossRef]

- Seguy, S.; Dessein, G.; Arnaud, L. Surface roughness variation of thin wall milling, related to modal interaction. Int. J. Mach. Tools Manuf. 2008, 48, 261–274. [Google Scholar] [CrossRef]

- Wan, M.; Feng, J.; Ma, Y.-C.; Zhang, W.-H. Identification of milling process damping using operational modal analysis. Int. J. Mach. Tools Manuf. 2017, 122, 120–131. [Google Scholar] [CrossRef]

- Wan, M.; Yin, W.; Zhang, W.-H.; Liu, H. Improved inverse filter for the correction of distorted measured cutting force. Int. J. Mech. Sci. 2017, 120, 276–285. [Google Scholar] [CrossRef]

- Li, A.; Zhao, J.; Hou, G. Effect of cutting speed on chip formation and wear mechanisms of coated carbide tools when ultra-high-speed face milling titanium alloy Ti6-Al-4V. Adv. Mech. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Du, S.; Chen, M.; Xie, L.; Zhu, Z.; Wang, X. Optimization of process parameters in the high-speed milling of titanium alloy TB17 for surface integrity by the Taguchi-Grey relational analysis method. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Zeng, H.; Yan, R.; Du, P.; Zhang, M.; Peng, F. Notch wear prediction model in high speed milling of AerMet100 steel with bull-nose tool considering the influence of stress concentration. Wear 2018, 408–409, 228–237. [Google Scholar] [CrossRef]

- Heigel, J.C.; Whitenton, E.; Lane, B.; Donmez, M.A.; Madhavan, V.; Moscoso-Kingsley, W. Infrared measurement of the temperature at the tool-chip interface while machining Ti-6Al-4V. J. Mater. Process. Technol. 2017, 243, 123–130. [Google Scholar] [CrossRef]

- Werschmoeller, D.; Li, X. Measurement of tool internal temperatures in the tool-chip contact region by embedded micro thin film thermocouple. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2010; pp. 371–377. [Google Scholar]

- An, Q.; Wang, C.; Xu, J.; Liu, P.; Chen, M. Experimental investigation on hard milling of high strength steel using PVD-AlTiN coated cemented carbide tool. Int. J. Refract. Met. Hard Mater. 2014, 43, 94–101. [Google Scholar] [CrossRef]

- Martinho, R.P.; Silva, F.J.G.; Martins, C.; Lopes, H. Comparative study of PVD and CVD cutting tools performance in milling of duplex stainless steel. Int. J. Adv. Manuf. Technol. 2019, 2, 1–17. [Google Scholar] [CrossRef]

- Huang, P.; Li, J.; Sun, J.; Ge, M. Milling force vibration analysis in high-speed-milling titanium alloy using variable pitch angle mill. Int. J. Adv. Manuf. Technol. 2012, 58, 153–160. [Google Scholar] [CrossRef]

- Cheng, J.; Jin, Y.; Wu, J.; Wen, X.; Gong, Y.; Shi, J.; Cai, G. Experimental study on a novel minimization method of top burr formation in micro-end milling of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2016, 86, 2197–2217. [Google Scholar] [CrossRef]

- Wang, C.; Ding, F.; Tang, D.; Zheng, L.; Li, S.; Xie, Y. Modeling and simulation of the high-speed milling of hardened steel SKD11(61HRC) based on SHPB technology. Int. J. Mach. Tools Manuf. 2016, 108, 13–26. [Google Scholar] [CrossRef]

- Altintas, Y. Manufacturing automation: Metal cutting mechanics machine tool vibrations and CNC design; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Cui, D.; Zhang, D.; Wu, B.; Luo, M. An investigation of tool temperature in end milling considering the flank wear effect. Int. J. Mech. Sci. 2017, 131–132, 613–624. [Google Scholar] [CrossRef]

- Wan, M.; Ma, Y.-C.; Feng, J.; Zhang, W.-H. Study of static and dynamic ploughing mechanisms by establishing generalized model with static milling force. Int. J. Mech. Sci. 2016, 114, 120–131. [Google Scholar] [CrossRef]

- Fillot, N.; Iordanoff, I.; Berthier, Y. Modelling third body flows with a discrete element method—a tool for understanding wear with adhesive particles. Tribol. Int. 2007, 40, 973–981. [Google Scholar] [CrossRef]

- Aramesh, M.; Montazeri, S.; Vedhuis, S.C. A novel treatment for cutting tools for reducing the chipping and improving tool life durning machining of Inconel 718. Wear 2018, 414–415, 79–88. [Google Scholar] [CrossRef]

| Contents (wt.%) | Material Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Be | Co | Ni | Si | Fe | Al | Cu | Tensile Strength MPa | Hardness HRC | Yield Strength GPa |

| 1.9 | 0.35 | 0.20 | 0.15 | 0.15 | 0.15 | Bal | 1105 | 38–44 | 128 |

| V = 150 m/min | V = 200 m/min | V = 250 m/min | |||

|---|---|---|---|---|---|

| f/(mm·r−1) | ap/mm | f/(mm·r−1) | ap/mm | f/(mm·r−1) | ap/mm |

| 0.05 | 0.5 | 0.05 | 0.5 | 0.05 | 0.5 |

| 0.1 | 1 | 0.1 | 1 | 0.1 | 1 |

| 0.15 | 1.5 | 0.15 | 1.5 | 0.15 | 1.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, J.; Lin, Y.; He, M. An Investigation of the Adhesive Effect on the Flank Wear Properties of a WC/Co-based TiAlN-Coated Tool for Milling a Be/Cu Alloy. Metals 2019, 9, 444. https://doi.org/10.3390/met9040444

Zuo J, Lin Y, He M. An Investigation of the Adhesive Effect on the Flank Wear Properties of a WC/Co-based TiAlN-Coated Tool for Milling a Be/Cu Alloy. Metals. 2019; 9(4):444. https://doi.org/10.3390/met9040444

Chicago/Turabian StyleZuo, Junyan, Youxi Lin, and Ming He. 2019. "An Investigation of the Adhesive Effect on the Flank Wear Properties of a WC/Co-based TiAlN-Coated Tool for Milling a Be/Cu Alloy" Metals 9, no. 4: 444. https://doi.org/10.3390/met9040444

APA StyleZuo, J., Lin, Y., & He, M. (2019). An Investigation of the Adhesive Effect on the Flank Wear Properties of a WC/Co-based TiAlN-Coated Tool for Milling a Be/Cu Alloy. Metals, 9(4), 444. https://doi.org/10.3390/met9040444