Compositional Design of Soft Magnetic High Entropy Alloys by Minimizing Magnetostriction Coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x System

Abstract

1. Introduction

- (1).

- high thermal stability and resistance to heat softening;

- (2).

- easier to break the tradeoff between strength and ductility;

- (3).

- very low stacking-fault energy;

- (4).

- high irradiation resistance;

- (5).

- high corrosion resistance.

2. Materials and Methods

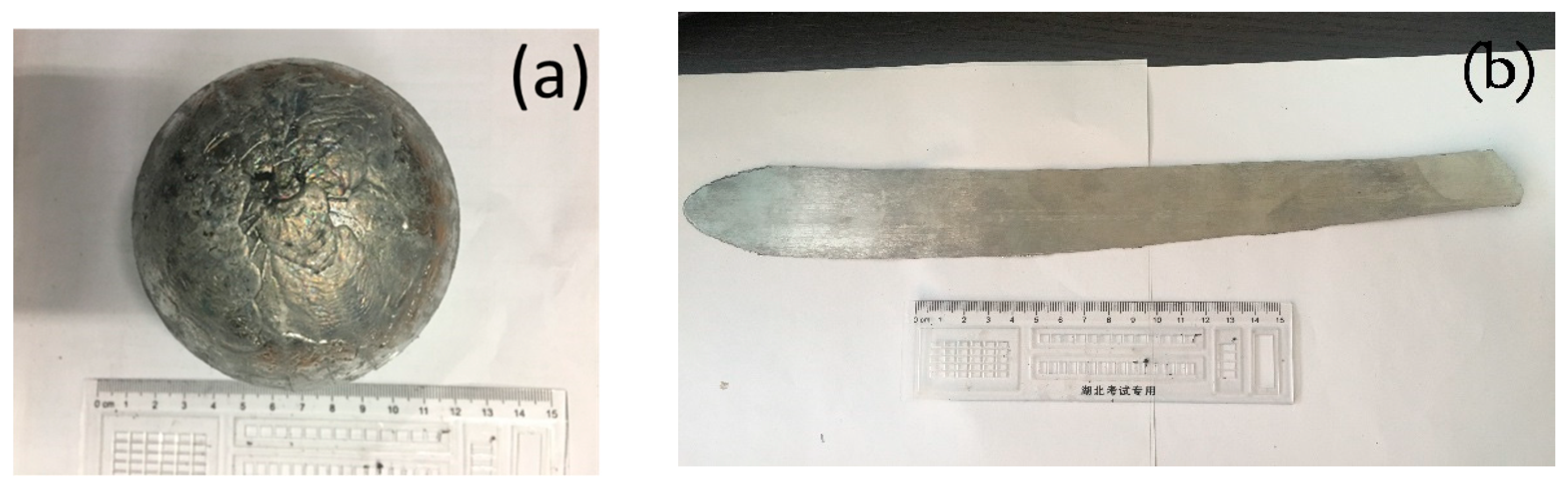

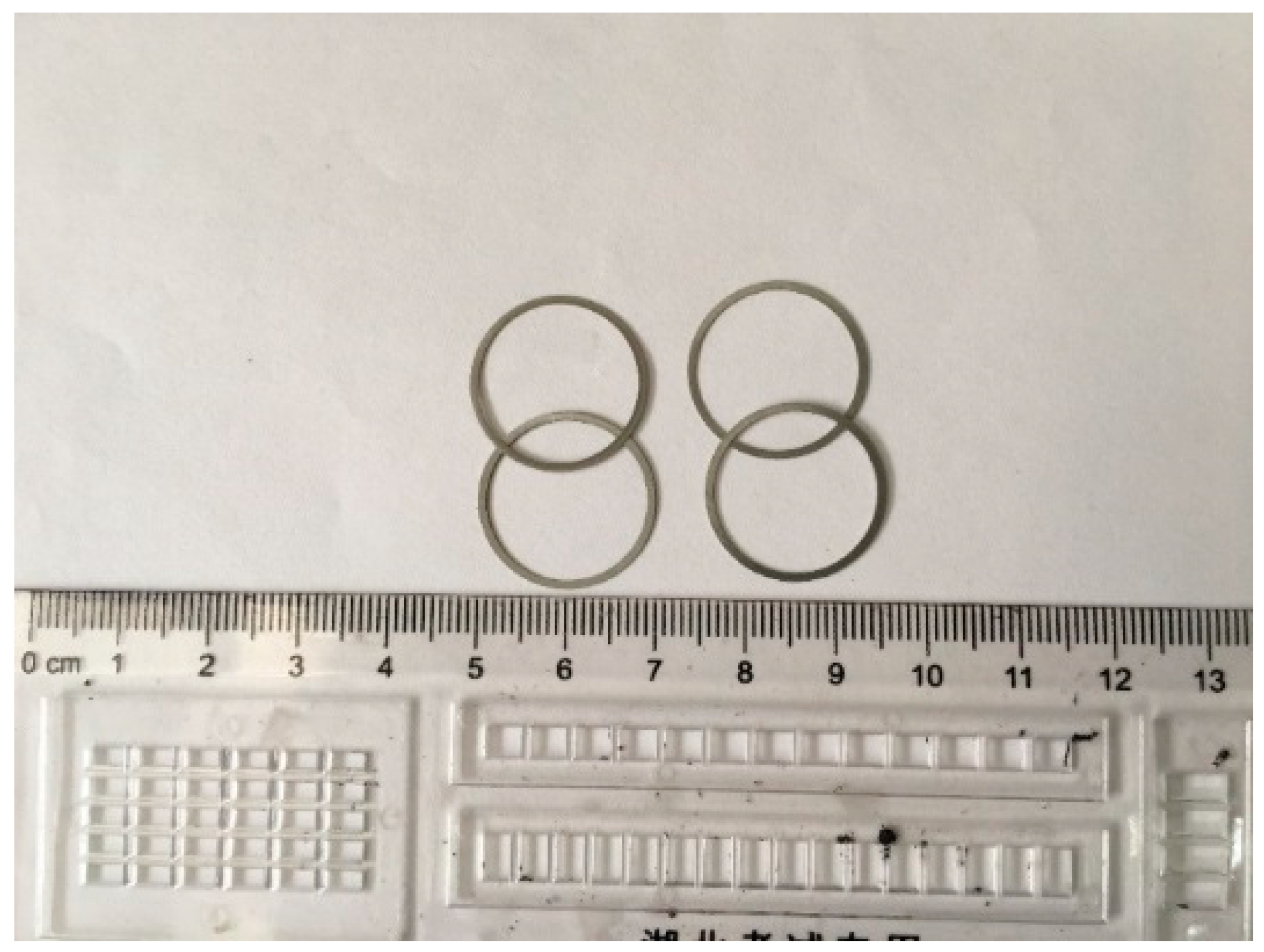

2.1. Alloys Preparation

2.2. Structural Characterization and Performance Experiments

3. Results

4. Conclusions

- (1)

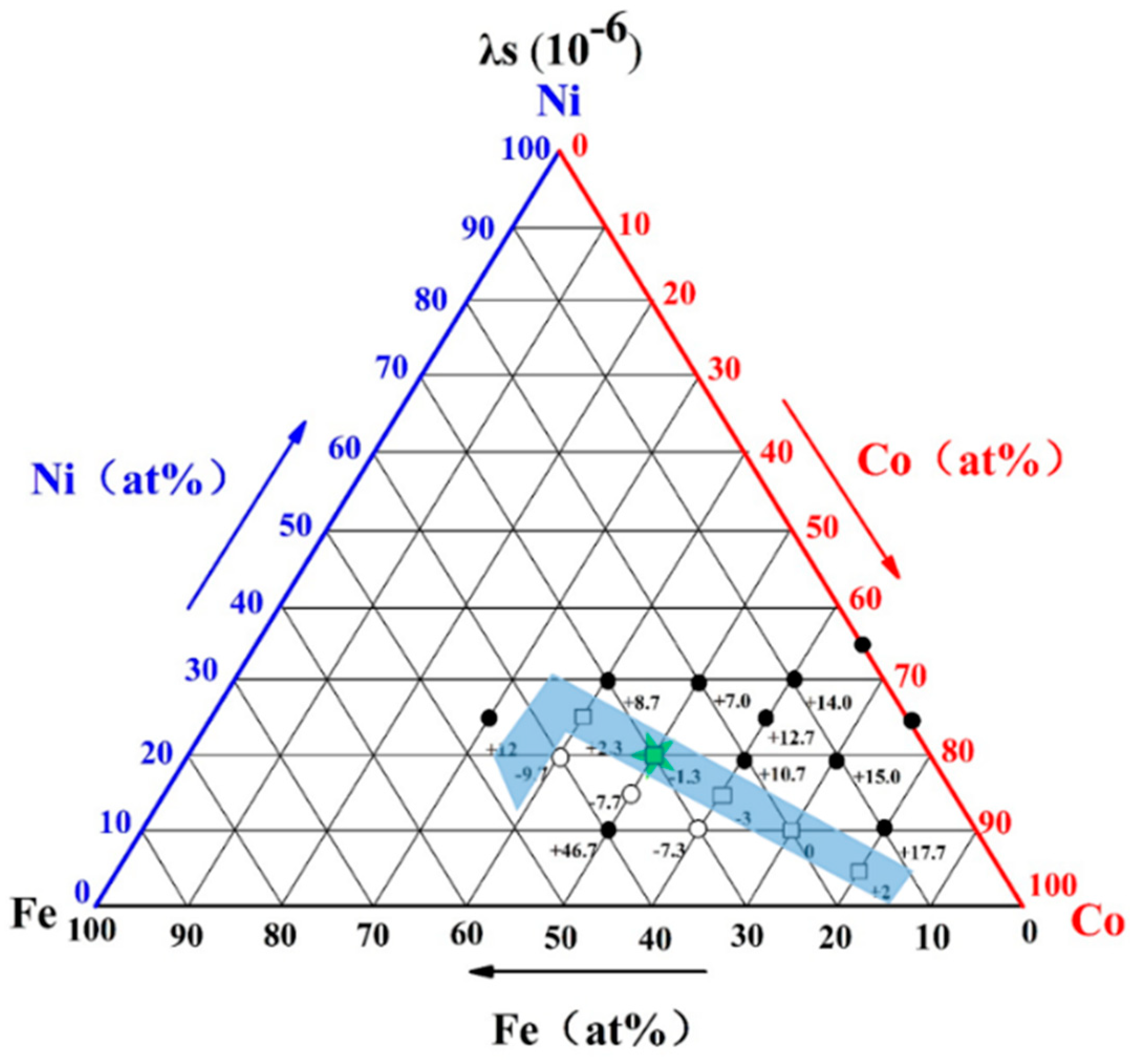

- The Fe0.3Co0.5Ni0.2 base alloy was chosen since it has very small saturation magnetostriction coefficient.

- (2)

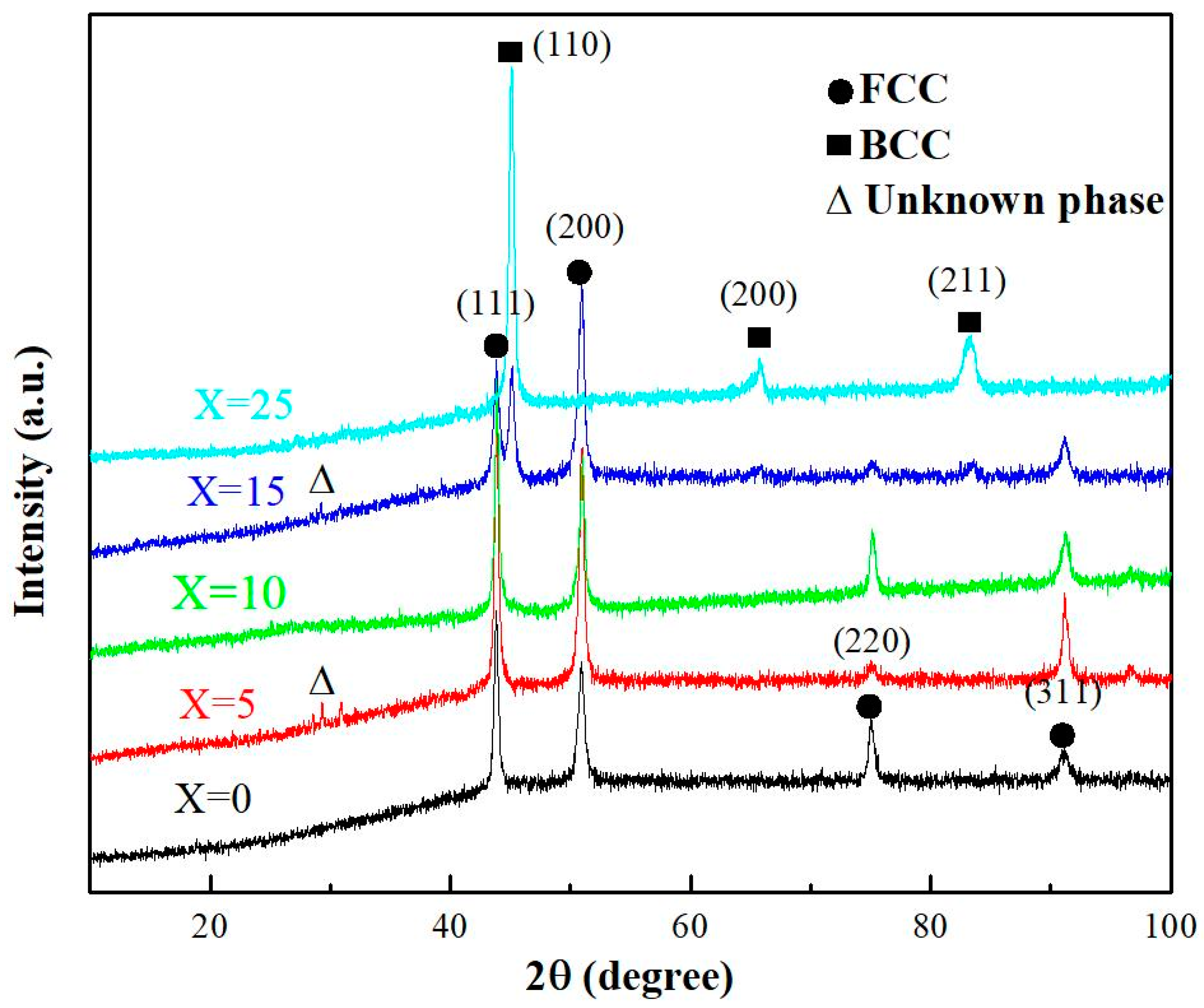

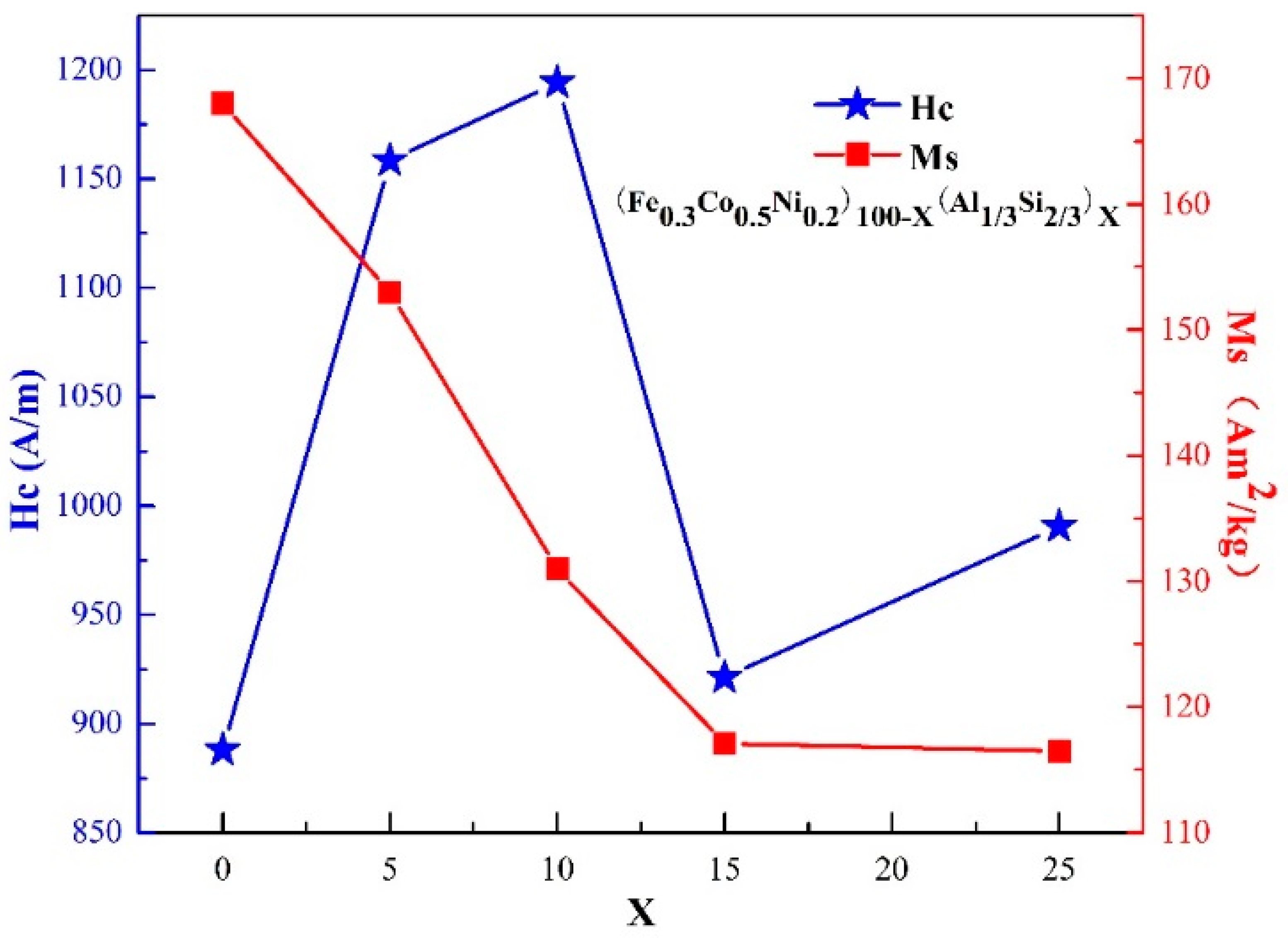

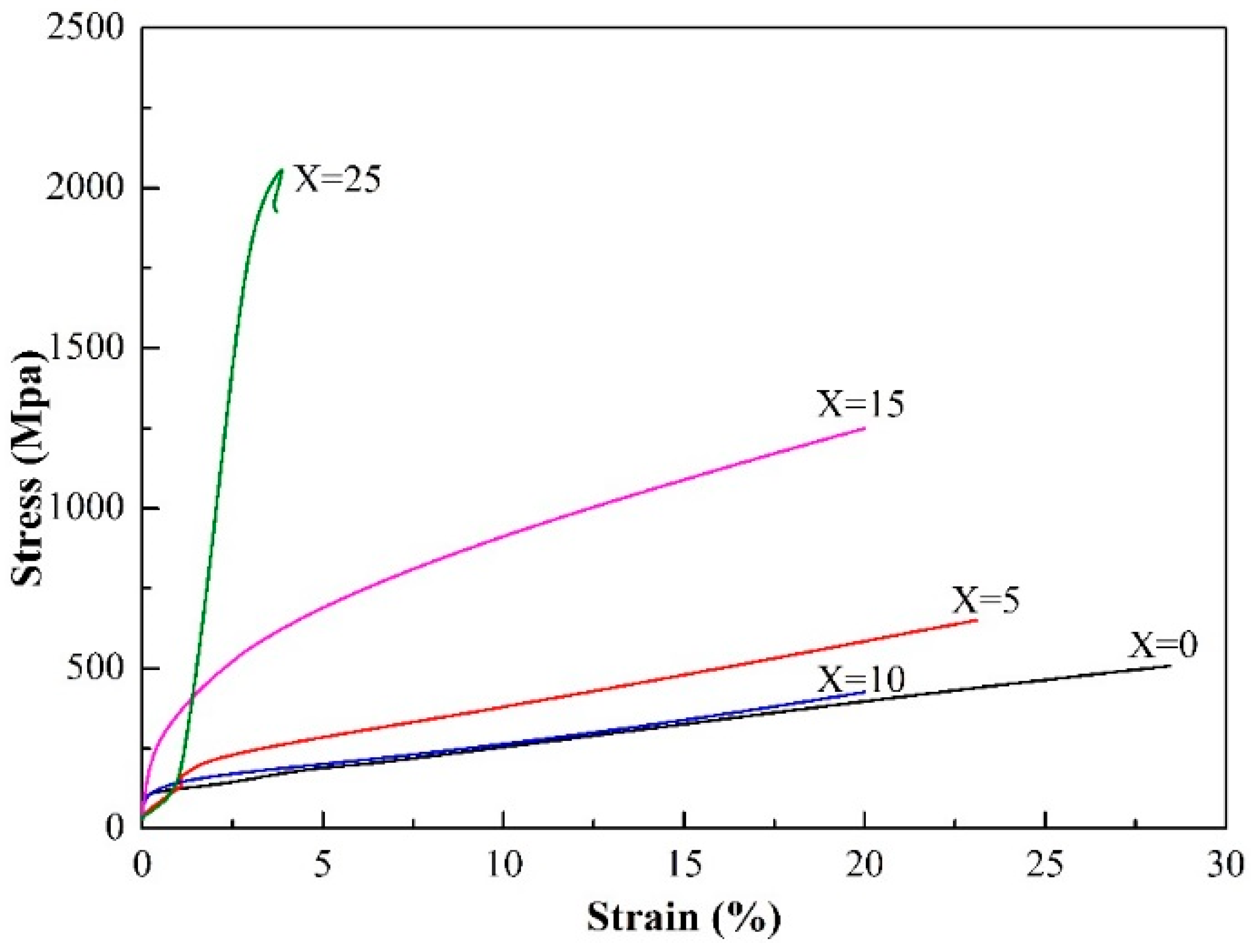

- The alloys in the as-cast state maintain an FCC solid solution structure when X ≤ 10. More addition of Al1/3Si2/3 causes formation of BCC phase. The overall trend is that increasing Al1/3Si2/3 contents increases the strength of the alloy at the cost of reduced ductility.

- (3)

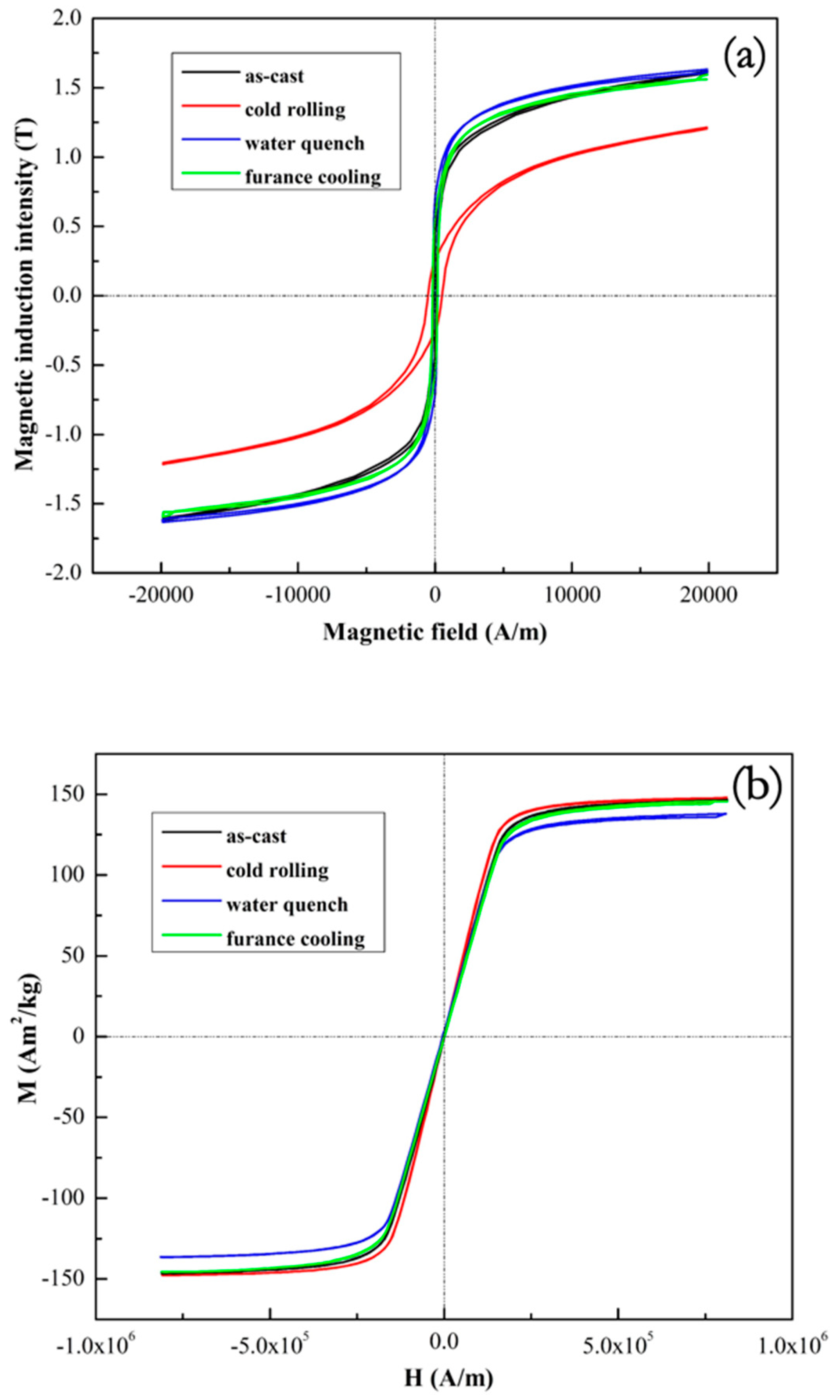

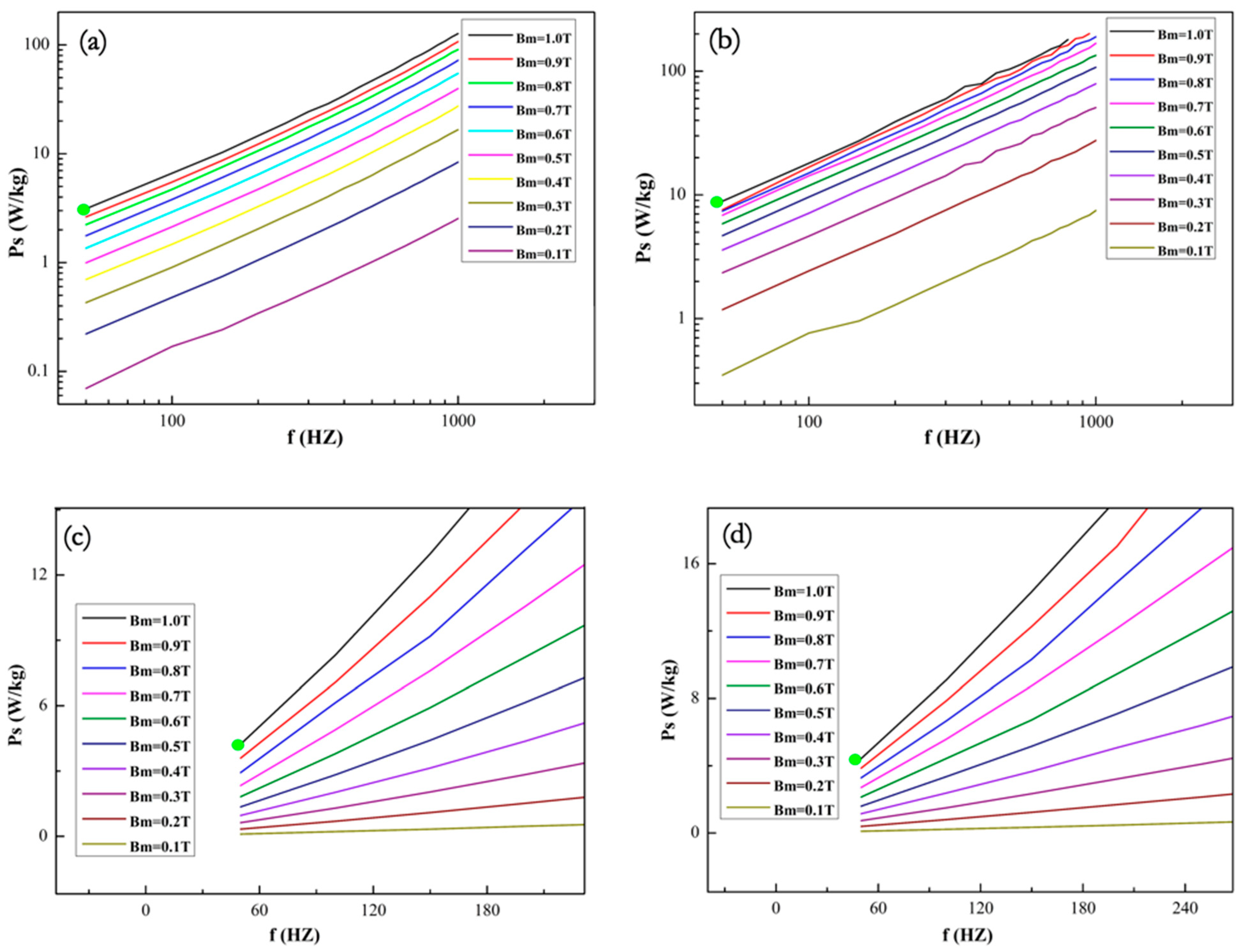

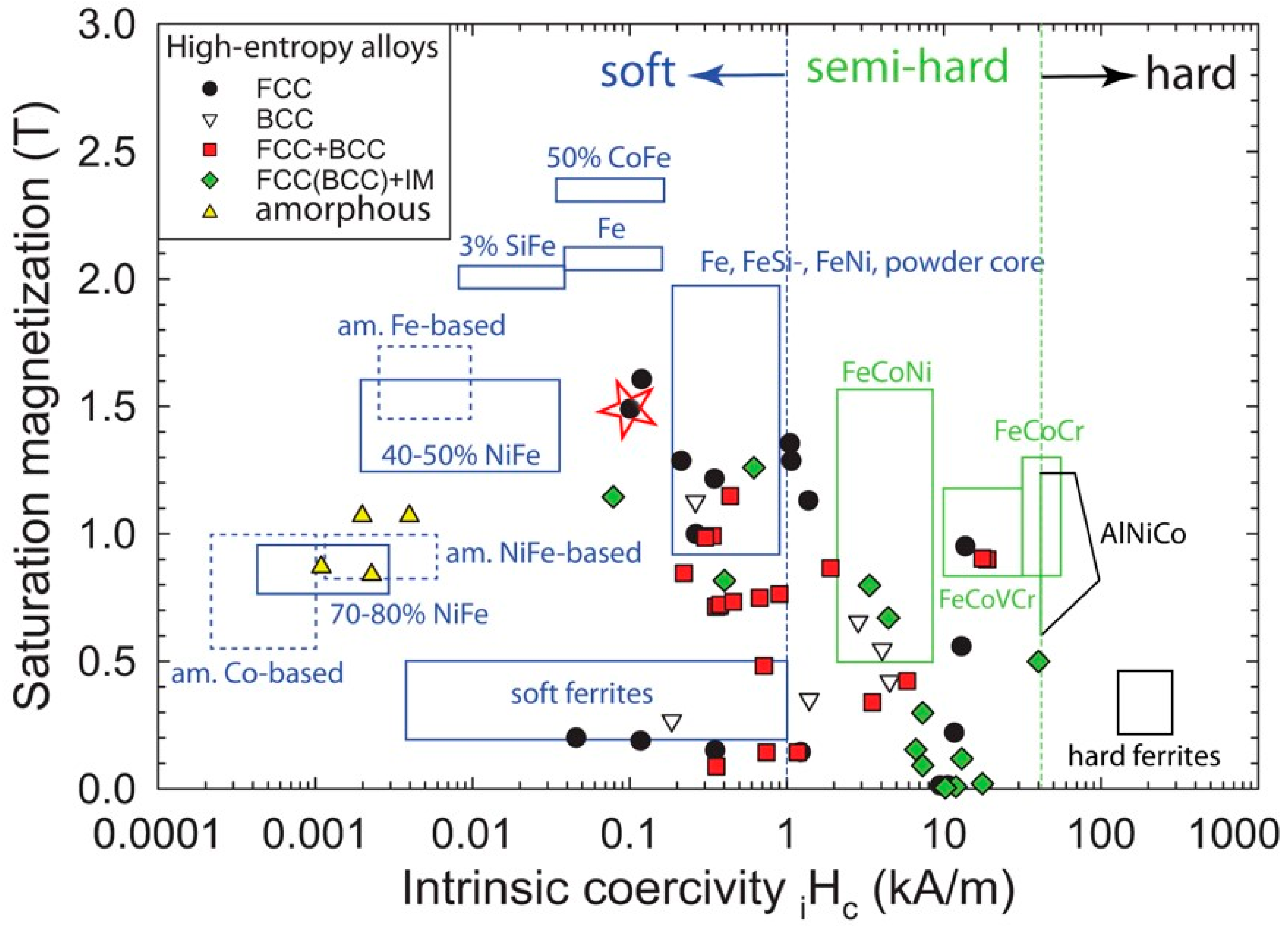

- The (Fe0.3Co0.5Ni0.2)95(Al1/3Si2/3)5 alloy was prepared via maglev melting and then underwent cold-rolling and subsequent heat treatment. The alloy shows high saturation magnetic induction and saturation magnetization. The lower coercive force (about 100 A/m) is found in as-cast and annealed states. The hysteresis loss at low power frequency is about 3-4.5 W/kg.

- (4)

- The (Fe0.3Co0.5Ni0.2)95(Al1/3Si2/3)5 alloy in the as-cast and after annealing exhibits considerable deformation ability (ductility up to 25% and 38% elongation, respectively) at room temperature.

- (5)

- The (Fe0.3Co0.5Ni0.2)95(Al1/3Si2/3)5 alloy shows high saturation magnetic induction intensity, low coercivity, and excellent ductility. Hence, it holds good potential as next-generation high-performance soft magnetic materials for wide ranges of energy-saving applications.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Lu, Z.P.; Wang, H.; Chen, M.W.; Baker, I.; Yeh, J.W.; Liu, C.T.; Nieh, T.G. An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics 2015, 66, 67–76. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.; Wang, T.; Wen, B.; Wang, Z.; Jie, J.; Cao, Z.; et al. A promising new class of high-temperature alloys: eutectic high-entropy alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef]

- Lilensten, L.; Couzinié, J.P.; Perrière, L.; Bourgon, J.; Emery, N.; Guillot, I. New structure in refractory high-entropy alloys. Mater. Lett. 2014, 132, 123–125. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yeh, J.-W. High-entropy alloys: a critical review. Mate. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; Tsuzaki, K.; Raabe, D. An overview of dual-phase steels: advances in microstructure-oriented processing and micromechanically guided design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Lyu, Z.; Lee, C.; Wang, S.-Y.; Fan, X.; Yeh, J.-W.; Liaw, P.K. Effects of constituent elements and fabrication methods on mechanical behavior of high-entropy alloys: A review. Metall. Mater. Trans. A 2019, 50, 1–28. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.-W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys; Springer: Berlin, Germany, 2016. [Google Scholar]

- Luo, H.; Li, Z.; Lu, W.; Ponge, D.; Raabe, D. Hydrogen embrittlement of an interstitial equimolar high-entropy alloy. Corros. Sci. 2018, 136, 403–408. [Google Scholar] [CrossRef]

- Shun, T.-T.; Du, Y.-C. Microstructure and tensile behaviors of fcc Al0.3cocrfeni high entropy alloy. J. Alloys Compd. 2009, 479, 157–160. [Google Scholar] [CrossRef]

- Basu, S.; Li, Z.; Pradeep, K.G.; Raabe, D. Strain rate sensitivity of a trip-assisted dual-phase high-entropy alloy. Front. Mater. Struct. Mater. 2018, 5, 1–10. [Google Scholar] [CrossRef]

- Gu, J.; Song, M. Annealing-induced abnormal hardening in a cold rolled crmnfeconi high entropy alloy. Scr. Mater. 2019, 162, 345–349. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Feng, T.; Zhang, Y.; Sha, G.; Lewandowski, J.J.; Liaw, P.K.; Zhang, Y. High-entropy Al 0.3 cocrfeni alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017, 123, 285–294. [Google Scholar] [CrossRef]

- Feuerbacher, M.; Lienig, T.; Thomas, C. A single-phase bcc high-entropy alloy in the refractory Zr-Nb-Ti-V-Hf system. Scr. Mater. 2018, 152, 40–43. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Qiao, J.W.; Ma, S.G.; Gao, M.C.; Yang, H.J.; Chen, M.W.; Zhang, Y. A hexagonal close-packed high-entropy alloy: the effect of entropy. Mater. Des. 2016, 96, 10–15. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the maximum strength in nanotwinned copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef]

- Gao, M.C.; Zhang, B.; Guo, S.M.; Qiao, J.W.; Hawk, J.A. High-entropy alloys in hexagonal close-packed structure. Metall. Mater. Trans. A 2016, 47, 3322–3332. [Google Scholar] [CrossRef]

- Nagase, T.; Takeuchi, A.; Amiya, K.; Egami, T. Solid state amorphization of metastable Al0.5TiZrPdCuNi high entropy alloy investigated by high voltage electron microscopy. Mater. Chem. Phys. 2018, 210, 291–300. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; An, K.; Wu, W.; Lu, Z. Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef]

- Li, Z.; Tasan, C.C.; Pradeep, K.G.; Raabe, D. A trip-assisted dual-phase high-entropy alloy: grain size and phase fraction effects on deformation behavior. Acta Mater. 2017, 131, 323–335. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Miracle, D.; Miller, J.; Senkov, O.; Woodward, C.; Uchic, M.; Tiley, J. Exploration and development of high entropy alloys for structural applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Tong, Y.; Chen, D.; Han, B.; Wang, J.; Feng, R.; Yang, T.; Zhao, C.; Zhao, Y.L.; Guo, W.; Shimizu, Y. Outstanding tensile properties of a precipitation-strengthened FeCoNiCrTi0.2 high-entropy alloy at room and cryogenic temperatures. Acta Mater. 2019, 165, 228–240. [Google Scholar] [CrossRef]

- Sun, S.J.; Tian, Y.Z.; Lin, H.R.; Yang, H.J.; Dong, X.G.; Wang, Y.H.; Zhang, Z.F. Achieving high ductility in the 1.7 GPa grade cocrfemnni high-entropy alloy at 77 K. Mater. Sci. Eng. A 2019, 740–741, 336–341. [Google Scholar] [CrossRef]

- Liu, K.; Komarasamy, M.; Gwalani, B.; Shukla, S.; Mishra, R.S. Fatigue behavior of ultrafine grained triplex Al0.3CoCrFeNi high entropy alloy. Scr. Mater. 2019, 158, 116–120. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Zheng, Y.; Mishra, R.S.; Banerjee, R. Tensile yield strength of a single bulk Al0.3CoCrFeNi high entropy alloy can be tuned from 160 MPa to 1800 MPa. Scr. Mater. 2019, 162, 18–23. [Google Scholar] [CrossRef]

- Couzinié, J.P.; Dirras, G. Body-centered cubic high-entropy alloys: from processing to underlying deformation mechanisms. Mater. Charact. 2019, 147, 533–544. [Google Scholar] [CrossRef]

- Li, D.; Gao, M.C.; Hawk, J.A.; Zhang, Y. Annealing effect for the Al0.3CoCrFeNi high-entropy alloy fibers. J. Alloys Compd. 2019, 778, 23–29. [Google Scholar] [CrossRef]

- Zuo, T.; Gao, M.C.; Ouyang, L.; Yang, X.; Cheng, Y.; Feng, R.; Chen, S.; Liaw, P.K.; Hawk, J.A.; Zhang, Y. Tailoring magnetic behavior of CoFeMnNix (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping. Acta Mater. 2017, 130, 10–18. [Google Scholar] [CrossRef]

- Zuo, T.; Yang, X.; Liaw, P.K.; Zhang, Y. Influence of bridgman solidification on microstructures and magnetic behaviors of a non-equiatomic FeCoNiAlSi high-entropy alloy. Intermetallics 2015, 67, 171–176. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.; Cheng, Y.; Liaw, P.K. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 2013, 3, 1455. [Google Scholar] [CrossRef] [PubMed]

- Lucas, M.S.; Mauger, L.; Munoz, J.A.; Xiao, Y.; Sheets, A.O.; Semiatin, S.L.; Horwath, J.; Turgut, Z. Magnetic and vibrational properties of high-entropy alloys. J. Appl. Phys. 2011, 109, 07E307. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Kiefer, K.; Siemensmeyer, K.; Banhart, J. Effect of decomposition of the Cr–Fe–Co rich phase of alcocrcufeni high entropy alloy on magnetic properties. Ultramicroscopy 2011, 111, 619–622. [Google Scholar] [CrossRef] [PubMed]

- Hu, F.-X.; Shen, B.-G.; Sun, J.-R. Magnetic entropy change in Ni51.5Mn22.7Ga25.8 alloy. Appl. Phys. Lett. 2000, 76, 3460–3462. [Google Scholar] [CrossRef]

- Lucas, M.S.; Belyea, D.; Bauer, C.; Bryant, N.; Michel, E.; Turgut, Z.; Leontsev, S.O.; Horwath, J.; Semiatin, S.L.; Mchenry, M.E. Thermomagnetic analysis of fecocr X Ni alloys: magnetic entropy of high-entropy alloys. J. Appl. Phys. 2013, 113, 17A923. [Google Scholar] [CrossRef]

- Madni, A.M.; Ross, A. Exploring concept trade-offs. In Using Tradeoff Analyses to Identify Value and Risk; Wiley: New York, NY, USA, 2016. [Google Scholar]

- Gao, M.C.; Miracle, D.B.; Maurice, D.; Yan, X.; Zhang, Y.; Hawk, J.A. High-Entropy functional materials. J. Mater. Res. 2018, 33, 3138–3155. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon steel parts produced using selective laser melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Kruzic, J.J. Bulk metallic glasses as structural materials: A review. Adv. Eng. Mater. 2016, 18, 1308–1331. [Google Scholar] [CrossRef]

- Da Silveira, G.; Slack, N. Exploring the trade-off concept. Inter. J. Oper. Prod. Manage. 2001, 21, 949–964. [Google Scholar] [CrossRef]

- Zuo, T.T.; Li, R.B.; Ren, X.J.; Zhang, Y. Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy. J. Magn. Magn. Mater. 2014, 371, 60–68. [Google Scholar] [CrossRef]

- Zhang, M. Soft magnetic properties of (Fe0.3Co0.5Ni0.2) 100-X (Al1/3Si2/3) X high-entropy alloy. Master’s Thesis, University of Science and Technology Beijing, Beijing, China, 1 January 2019. [Google Scholar]

- Tang, Z.; Gao, M.C.; Diao, H.; Yang, T.; Liu, J.; Zuo, T.; Zhang, Y.; Lu, Z.; Cheng, Y.; Zhang, Y. Aluminum alloying effects on lattice types, microstructures, and mechanical behavior of high-entropy alloys systems. JOM 2013, 65, 1848–1858. [Google Scholar] [CrossRef]

- Vasquez, M.; Ascasibar, E.; Hernando, A.; Nielsen, O.V. Co-Si-B and Fe-Co-B amorphous alloys: induced anisotropy and various magnetic properties. J. Magn. Magn. Mater. 1987, 66, 37–44. [Google Scholar] [CrossRef]

- Hernando, B.; Sanchez, M.L.; Prida, V.M.; Tejedor, M.; Vázquez, M. Magnetoimpedance effect in amorphous and nanocrystalline ribbons. J. Appl. Phys. 2001, 90, 4783–4790. [Google Scholar] [CrossRef]

- Caltun, O.; Rao, G.S.N.; Rao, K.H.; Parvatheeswara Rao, B.; Dumitru, I.; Kim, C.-O.; Kim, C. The influence of Mn doping level on magnetostriction coefficient of cobalt ferrite. J. Magn. Magn. Mater. 2007, 316, e618–e620. [Google Scholar] [CrossRef]

- Zhukov, A.; Churyukanova, M.; Kaloshkin, S.; Semenkova, V.; Gudoshnikov, S.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Zhukova, V. Effect of annealing on magnetic properties and magnetostriction coefficient of Fe-Ni-based amorphous microwires. J. Alloys Compd. 2015, 651, 718–723. [Google Scholar] [CrossRef]

| Alloys | Hc (A/m) | Ms (Am2/kg) | σ0.2 (MPa) | σmax (MPa) | εp (%) |

|---|---|---|---|---|---|

| X = 0 | 887.93 | 168.06 | 96 | - | >20 |

| X = 5 | 1158.37 | 153.45 | 122 | - | >20 |

| X = 10 | 1194.29 | 130.97 | 116 | - | >20 |

| X = 15 | 921.25 | 117.10 | 243 | - | >20 |

| X = 25 | 990.48 | 116.48 | 1445 | 2050 | 2.71 |

| (Fe0.3Co0.5Ni0.2)95(Al1/3Si2/3)5 | Hc (A/m) | Ms (T) | σ0.2 (MPa) | σmax (MPa) | εp (%) |

|---|---|---|---|---|---|

| Magnetic levitation melting | 96 | 1.49 | 176.1 | 402.4 | 26.8 |

| Cold rolling | 510 | 1.48 | 779.6 | 917.7 | 1.3 |

| Water quenching | 130 | 1.40 | 261.5 | 558.3 | 38.3 |

| Furnace cooling | 165 | 1.47 | 235.5 | 572.4 | 33.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, M.; Li, D.; Zuo, T.; Zhou, K.; Gao, M.C.; Sun, B.; Shen, T. Compositional Design of Soft Magnetic High Entropy Alloys by Minimizing Magnetostriction Coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x System. Metals 2019, 9, 382. https://doi.org/10.3390/met9030382

Zhang Y, Zhang M, Li D, Zuo T, Zhou K, Gao MC, Sun B, Shen T. Compositional Design of Soft Magnetic High Entropy Alloys by Minimizing Magnetostriction Coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x System. Metals. 2019; 9(3):382. https://doi.org/10.3390/met9030382

Chicago/Turabian StyleZhang, Yong, Min Zhang, Dongyue Li, Tingting Zuo, Kaixuan Zhou, Michael C. Gao, Baoru Sun, and Tongde Shen. 2019. "Compositional Design of Soft Magnetic High Entropy Alloys by Minimizing Magnetostriction Coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x System" Metals 9, no. 3: 382. https://doi.org/10.3390/met9030382

APA StyleZhang, Y., Zhang, M., Li, D., Zuo, T., Zhou, K., Gao, M. C., Sun, B., & Shen, T. (2019). Compositional Design of Soft Magnetic High Entropy Alloys by Minimizing Magnetostriction Coefficient in (Fe0.3Co0.5Ni0.2)100−x(Al1/3Si2/3)x System. Metals, 9(3), 382. https://doi.org/10.3390/met9030382