Structural Stress Method to Evaluate Fatigue Properties of Similar and Dissimilar Self-Piercing Riveted Joints

Abstract

:1. Introduction

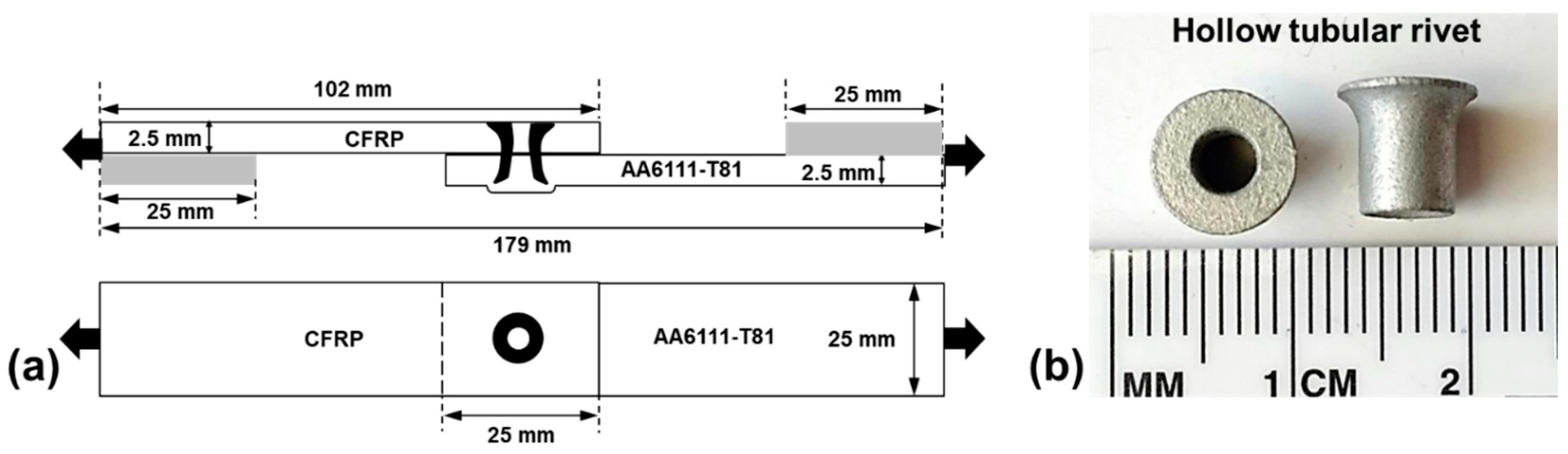

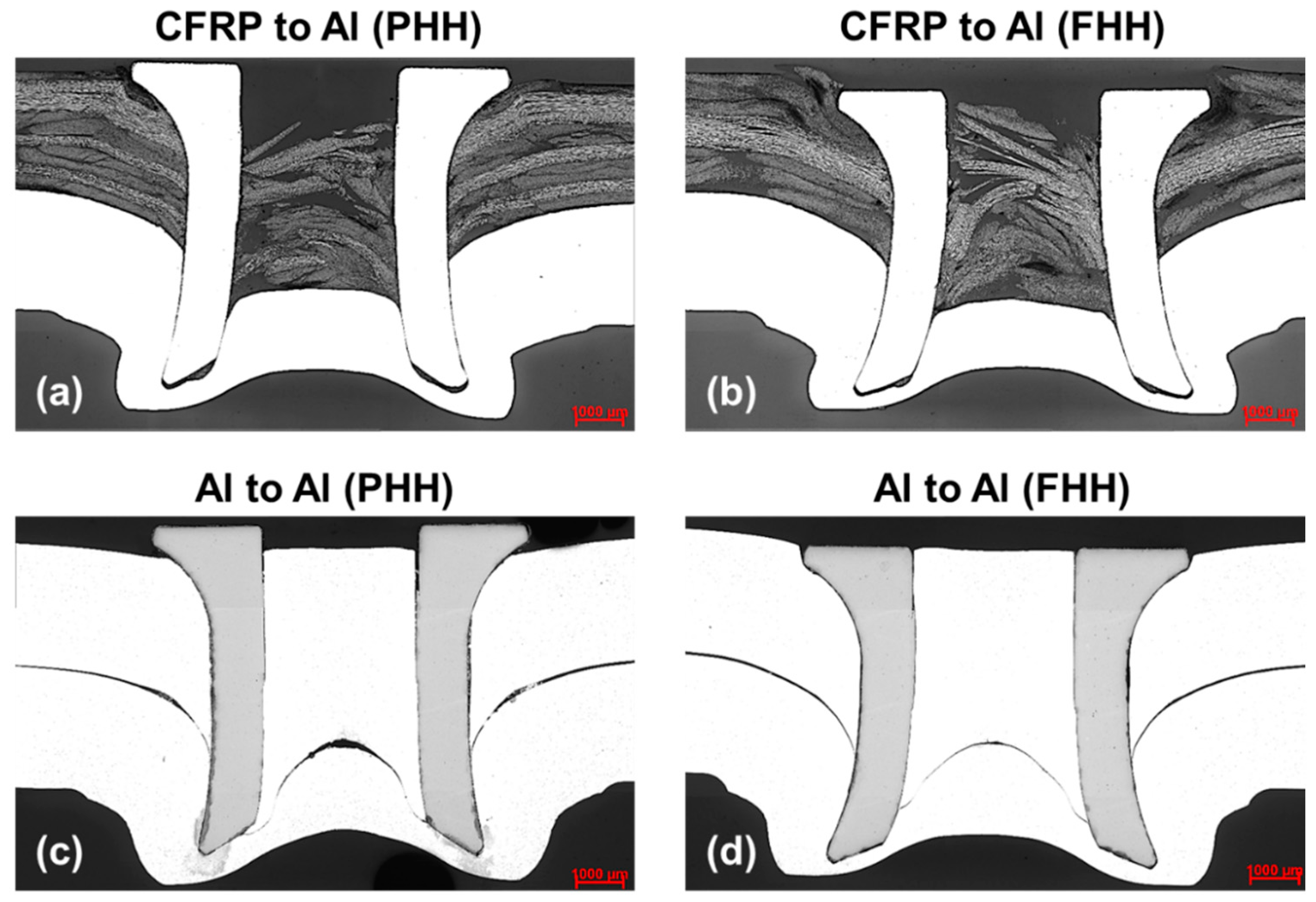

2. Materials and Methods

3. Results and Discussion

3.1. Quasi-Static and Fatigue Test

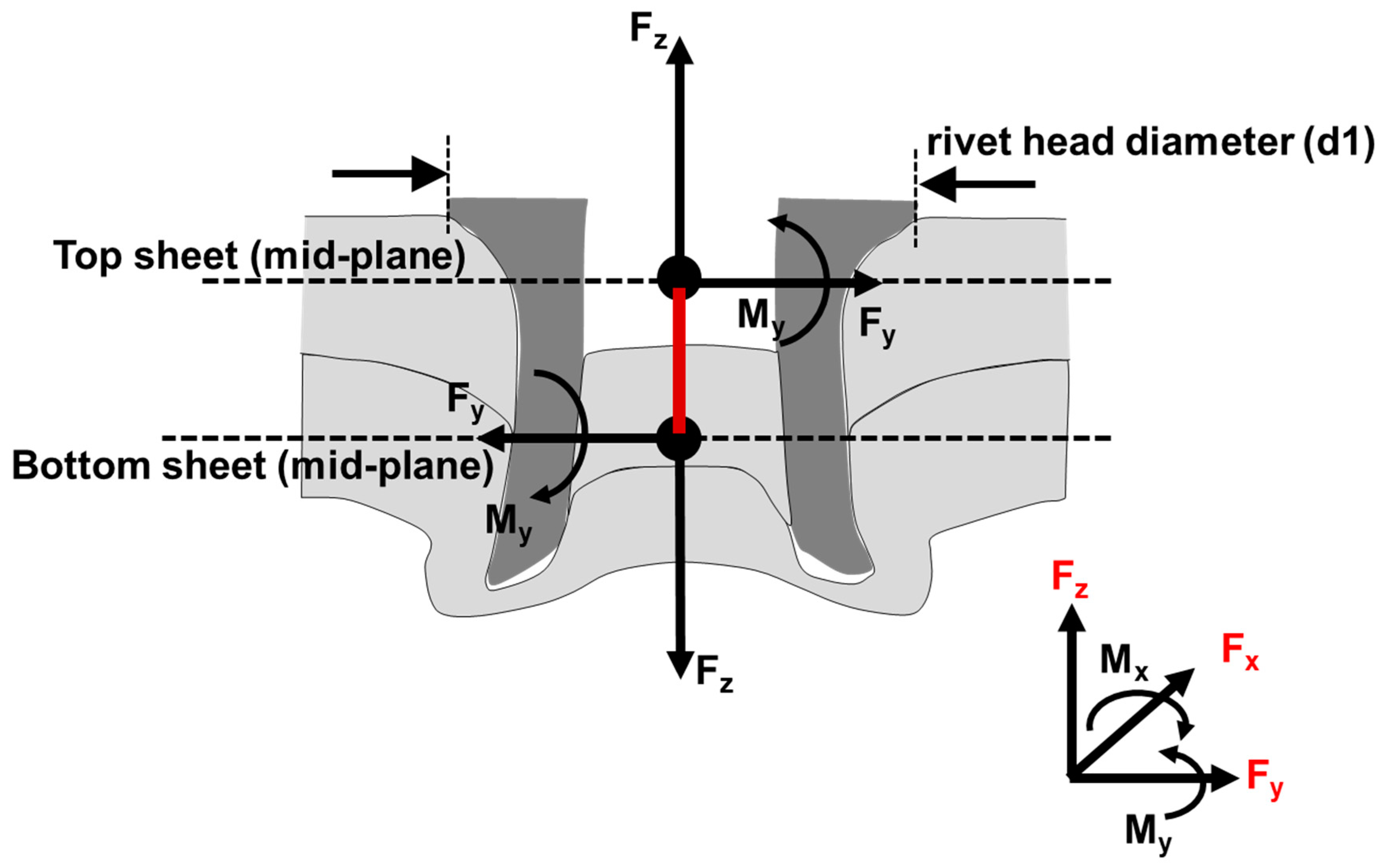

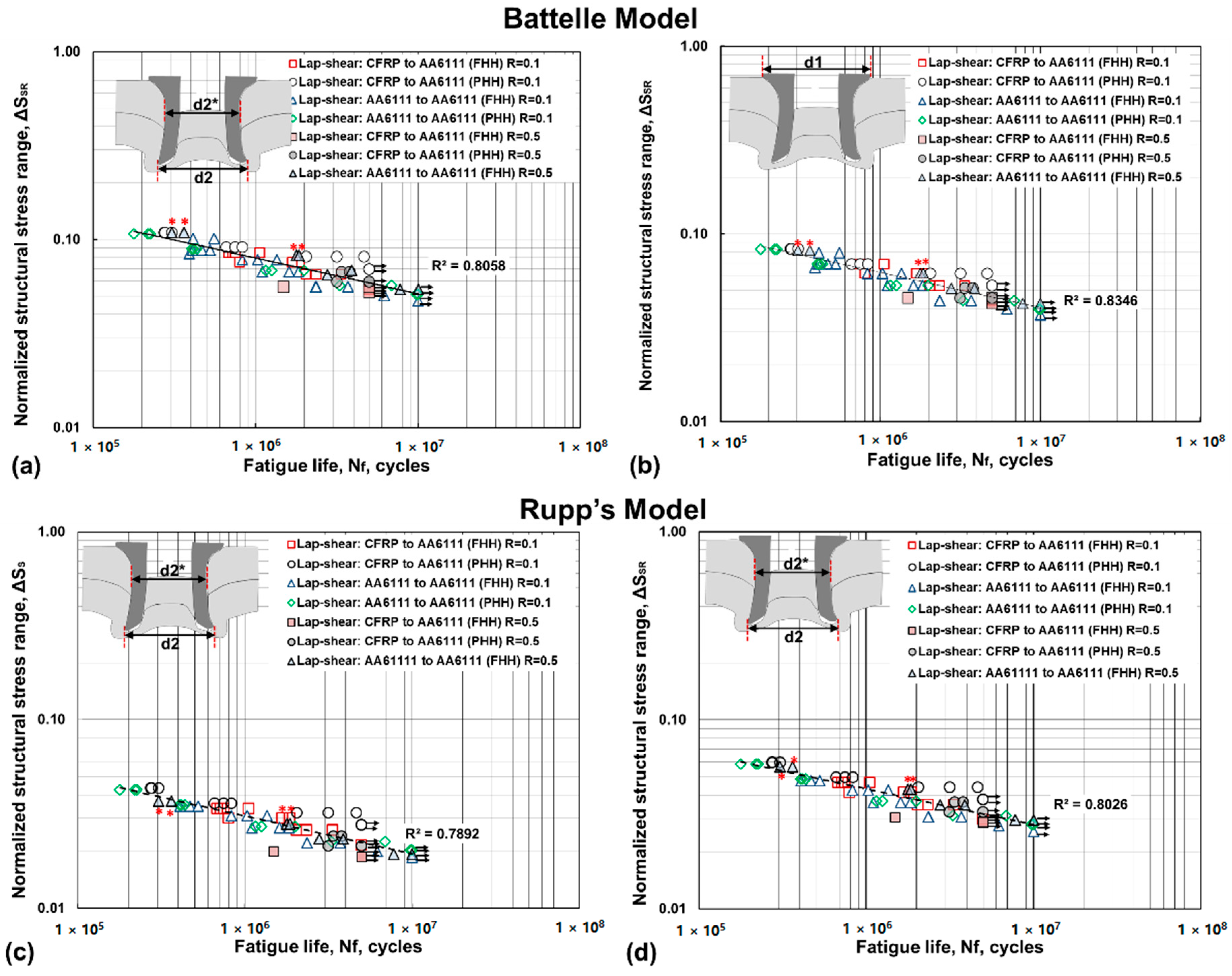

3.2. Battelle Structural Stress Method

4. Conclusions

- The simplified Battelle structural stress method and Rupp’s structural stress methods are both useful tools for predicting the fatigue life in lap-shear SPR joints.

- Both methods are able to collapse a large set of laboratory-generated fatigue data into one single S-N curve without much difference between them.

- The original Battelle structural stress method incorporates the load ratio effect in the model while the original Rupp’s method needs a modification in order to include the load ratio effect. The modified Rupp’s method provides a slightly better correlation compared to the original Rupp’s method and is comparable to the master S-N curve obtained using the Battelle method.

- Between the original and modified Battelle method, not much of a difference in correlation was observed. This is predominantly due to very small variations between the rivet head diameter (d1) and flared rivet diameter (d2, d2*).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cai, W.; Wang, P.C.; Yang, W. Assembly dimensional prediction for self-piercing riveted aluminum panels. Int. J. Mach. Tools Manuf. 2005, 45, 695–704. [Google Scholar] [CrossRef]

- Mortimer, J. Jaguar uses X350 car to pioneer use of self-piercing rivets. Ind. Robot Int. J. 2001, 28, 192–198. [Google Scholar] [CrossRef]

- Barnes, T.A.; Pashby, I.R. Joining techniques for aluminum spaceframes used in automobiles. Part II—Adhesive bonding and mechanical fasteners. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar] [CrossRef]

- Eusebi, E. Composite intensive vehicles: Past present and future. In Proceedings of the PNGV Symposium on Structural Materials Challenges, Washington, DC, USA, 22–23 February 1995; U.S. Department of Commerce: Washington, DC, USA, 1995. [Google Scholar]

- Gjostein, N.A. Technology needs beyond PNGV. In Proceedings of the Basic Needs for Vehicles of the Future, New Orleans, LA, USA, 5 January 1995. [Google Scholar]

- Kang, J.; Rao, H.; Zhang, R.; Avery, K.; Su, X. Tensile and fatigue behaviour of self-piercing rivets of CFRP to aluminium for automotive application. IOP Conf. Ser. Mater. Sci. Eng. 2016, 137, 12–25. [Google Scholar] [CrossRef]

- Di Franco, G.; Fratini, L.; Pasta, A. Analysis of the mechanical performance of hybrid (SPR/bonded) single-lap joints between CFRP panels and aluminum blanks. Int. J. Adhes. Adhes. 2013, 41, 24–32. [Google Scholar] [CrossRef]

- Kroll, L.; Mueller, S.; Mauermann, R.; Gruetzner, R.; Technology, F.; Structures, L.; Gmbh, E. Strength of self-piercing riveted joints for cfrp/aluminium sheets. In Proceedings of the 18th International Conference on Composite Materials, ICCM 2011, Jeju, Korea, 21–26 August 2011. [Google Scholar]

- Zhang, J.; Yang, S. Self-piercing riveting of aluminum alloy and thermoplastic composites. J. Compos. Mater. 2014, 49. [Google Scholar] [CrossRef]

- Pickin, C.G.; Young, K.; Tuersley, I. Joining of lightweight sandwich sheets to aluminium using self-pierce riveting. Mater. Des. 2007, 28, 2361–2365. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Galtieri, G.; Alagna, F.; Borsellino, C.; Valenza, A. Mechanical behaviour of spr/co-cured composite to aluminium joints. In Proceedings of the ECCM15-15th European Conference of Composite Materials, Venice, Italy, 24–28 June 2012; pp. 24–28. [Google Scholar]

- Fratini, L.; Ruisi, V.F. Self-piercing riveting for aluminium alloys-composites hybrid joints. Int. J. Adv. Manuf. Technol. 2009, 43, 61–66. [Google Scholar] [CrossRef]

- Di Franco, G.; Fratini, L.; Pasta, A. Influence of the distance between rivets in self-piercing riveting bonded joints made of carbon fiber panels and AA2024 blanks. Mater. Des. 2012, 35, 342–349. [Google Scholar] [CrossRef]

- Di Franco, G.; Fratini, L.; Pasta, A.; Ruisi, V.F. On the self-piercing riveting of aluminium blanks and carbon fibre composite panels. Int. J. Mater. Form. 2013, 6, 137–144. [Google Scholar] [CrossRef]

- Rao, H.M.H.M.; Kang, J.; Huff, G.; Avery, K.; Su, X. Impact of rivet head height on the tensile and fatigue properties of lap shear self-pierced riveted CFRP to aluminum. SAE Int. J. Mater. Manuf. 2017, 10. [Google Scholar] [CrossRef]

- Rao, H.M.; Kang, J.; Huff, G.; Avery, K. Impact of specimen configuration on fatigue properties of self-piercing riveted aluminum to carbon fiber reinforced polymer composite. Int. J. Fatigue 2018, 113, 11–22. [Google Scholar] [CrossRef]

- Bonnen, J.J.; Agrawal, H.; Amaya, M.A.; Iyengar, R.M.; Kang, H.T.; Khosrovaneh, A.K.; Shih, H.-C.; Walp, M.; Yan, B. Fatigue of advanced high strength steel spot-welds. SAE 2006 Trans. J. Mater. Manuf. 2006, 115. [Google Scholar] [CrossRef]

- Lin, P.; Pan, J. Closed-form structural stress and stress intensity factor solutions for spot welds in commonly used specimens. Eng. Fract. Mech. 2008, 75, 5187–5206. [Google Scholar] [CrossRef]

- Swellam, M.H.; Lawrence, F.V. A fatigue design parameter for spot welds. Ph.D. Thesis, University of Illinois at Urbaba-Champaign, Champaign, IL, USA, 1991. [Google Scholar]

- Rupp, A.; Storzel, K.; Grubisic, V. Computer aided dimensioning of spot-welded automitive structures. In Proceedings of the SAE International Congress and Exposition, Detroit, MI, USA, 27 February–2 March 1995. [Google Scholar]

- Sheppard, S.D.; Strange, M. Fatigue life estimation in resistance spot welds: Initiation and early growth phase. Fatigue Fract. Eng. Mater. Struct. 1992, 15, 531–549. [Google Scholar] [CrossRef]

- Dong, P. A structural stress definition and numerical implementation for fatigue analysis of welded joints. Int. J. Fatigue 2001, 23, 865–876. [Google Scholar] [CrossRef]

- Kang, H.T. Fatigue damage parameter of spot welded joints under proportional loading. Int. J. Automot. Technol. 2005, 6, 285–291. [Google Scholar]

- Cox, A.; Hong, J. Fatigue Evaluation Procedure Development for Self-Piercing Riveted Joints Using the Battelle Structural Stress Method. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Hong, J.K. The development of a simplified spot weld model for battelle structural stress calculation. SAE Int. J. Mater. Manuf. 2011, 4, 602–612. [Google Scholar] [CrossRef]

- Moraes, J.F.C.; Rao, H.M.; Jordon, J.B.; Barkey, M.E. High cycle fatigue mechanisms of aluminum self-piercing riveted joints. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 57–70. [Google Scholar] [CrossRef]

- Han, L.; Chrysanthou, A.; Young, K.W.; O’Sullivan, J.M. Characterization of fretting fatigue in self-piercing riveted aluminium alloy sheets. Fatigue Fract. Eng. Mater. Struct. 2006, 29, 646–654. [Google Scholar] [CrossRef]

- Iyer, K.; Hu, S.J.; Brittman, F.L.; Wang, P.C.; Hayden, D.B.; Marin, S.P. Fatigue of single- And double-rivet self-piercing riveted lap joints. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 997–1007. [Google Scholar] [CrossRef]

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Fatigue behaviors of self-piercing rivets joining similar and dissimilar sheet metals. Int. J. Fatigue 2007, 29, 370–386. [Google Scholar] [CrossRef]

- Huang, L.; Shi, Y.; Guo, H.; Su, X. Fatigue behavior and life prediction of self-piercing riveted joint. Int. J. Fatigue 2016, 88, 96–110. [Google Scholar] [CrossRef]

- Hong, J.K.; Forte, T.P. Fatig procedures for bi-axial loaded plate joints using the battelle structural stress method. Procedia Eng. 2015, 133, 410–419. [Google Scholar] [CrossRef]

| Stack Configuration | Average Rivet Head Height (mm) | Average Rivet Toe Diameter at Flaring, d2, (mm) |

|---|---|---|

| CFRP-to-Al (PHH) | 0.29 (+0.06/−0.07) | 6.1 |

| CFRP-to-Al (FHH) | 0.00 (+0.10/−0.06) | 6.5 |

| Al-to-Al (FHH) | −0.01 (+0.07/−0.04) | 6.4 |

| Al-to-Al (PHH) | 0.28 (+0.05/−0.06) | 6.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, H.M.; Kang, J.; Huff, G.; Avery, K. Structural Stress Method to Evaluate Fatigue Properties of Similar and Dissimilar Self-Piercing Riveted Joints. Metals 2019, 9, 359. https://doi.org/10.3390/met9030359

Rao HM, Kang J, Huff G, Avery K. Structural Stress Method to Evaluate Fatigue Properties of Similar and Dissimilar Self-Piercing Riveted Joints. Metals. 2019; 9(3):359. https://doi.org/10.3390/met9030359

Chicago/Turabian StyleRao, Harish M., Jidong Kang, Garret Huff, and Katherine Avery. 2019. "Structural Stress Method to Evaluate Fatigue Properties of Similar and Dissimilar Self-Piercing Riveted Joints" Metals 9, no. 3: 359. https://doi.org/10.3390/met9030359

APA StyleRao, H. M., Kang, J., Huff, G., & Avery, K. (2019). Structural Stress Method to Evaluate Fatigue Properties of Similar and Dissimilar Self-Piercing Riveted Joints. Metals, 9(3), 359. https://doi.org/10.3390/met9030359