Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel

Abstract

1. Introduction

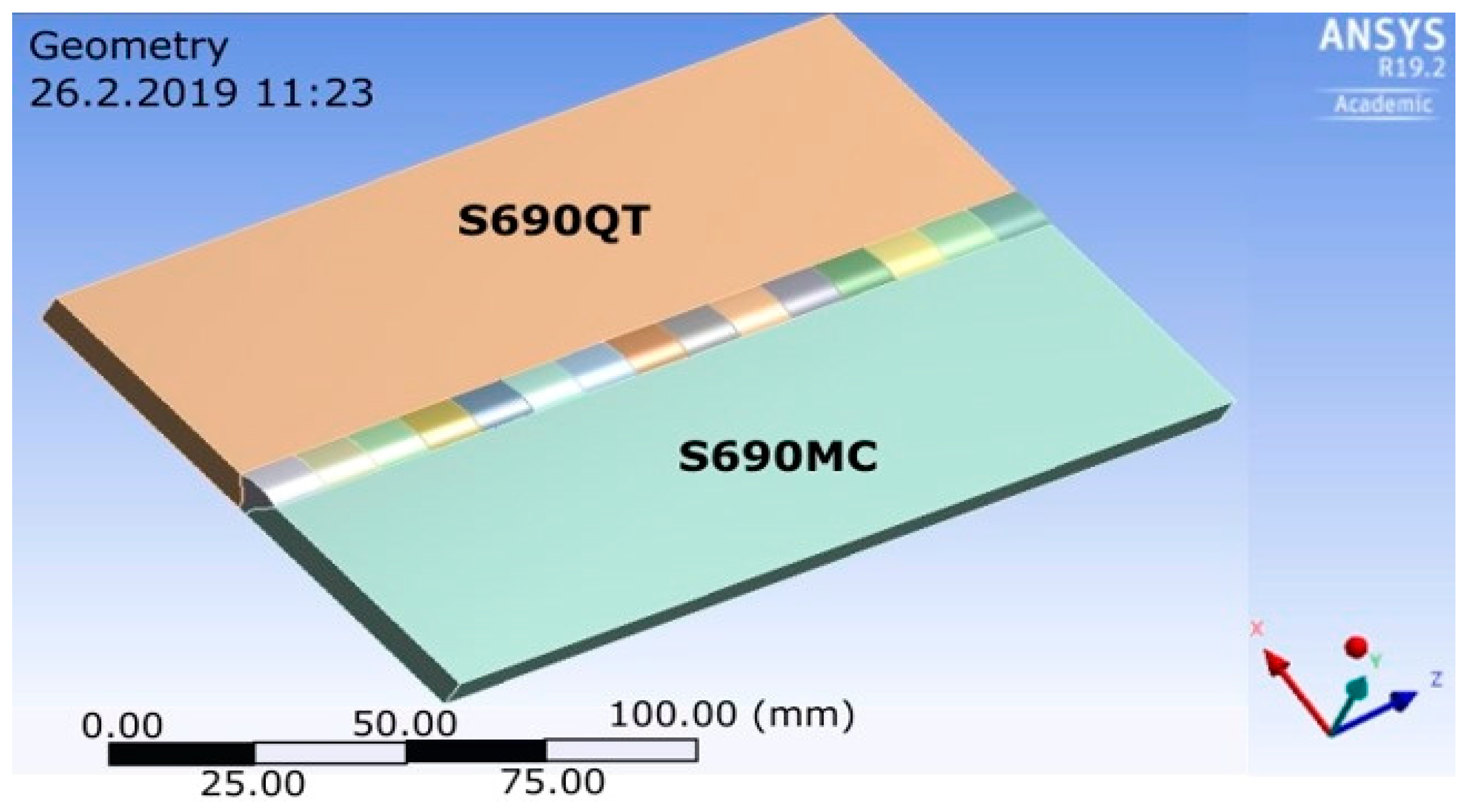

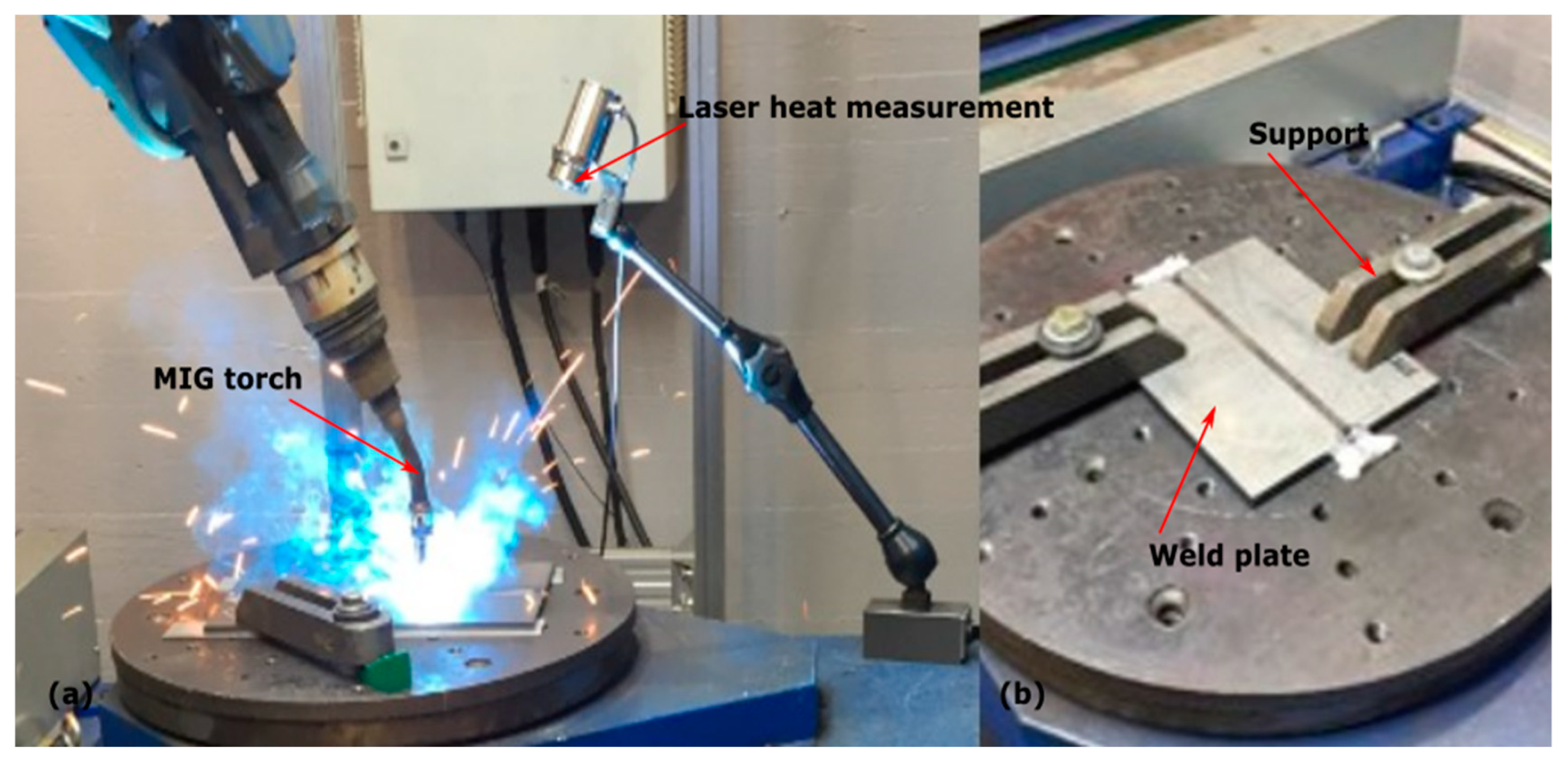

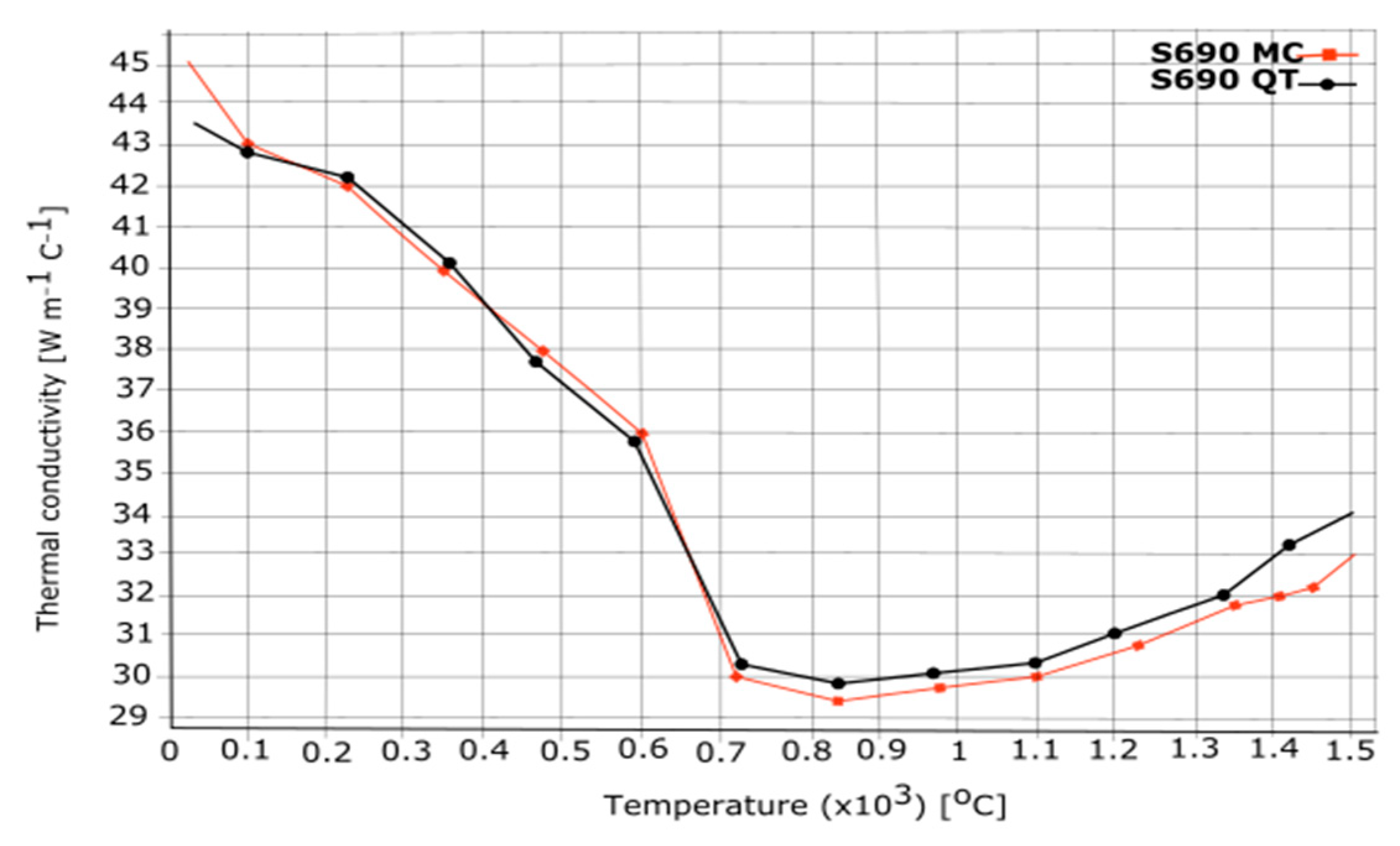

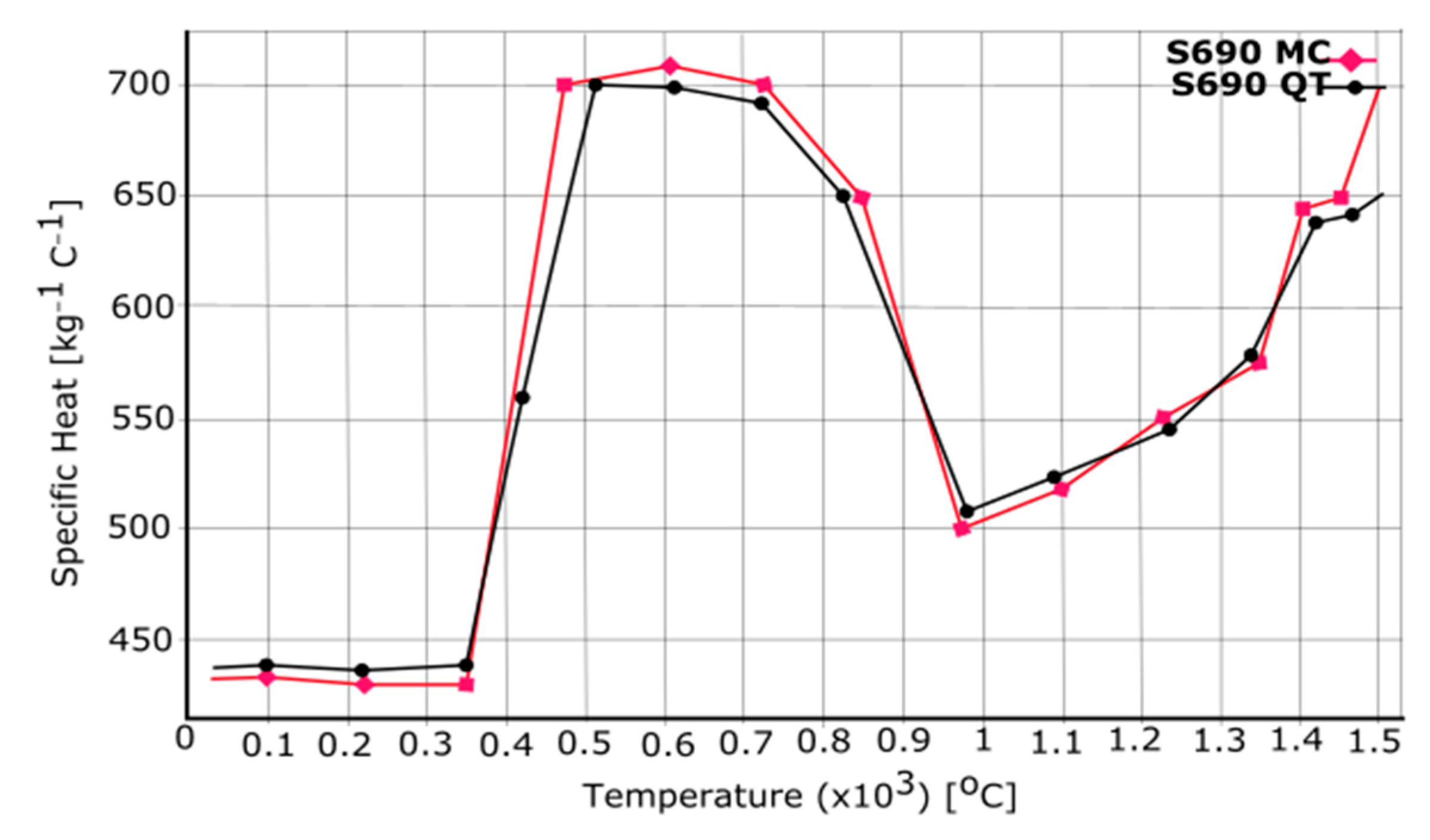

2. Materials and Methods

3. Numerical Formulations

4. Results and Discussion

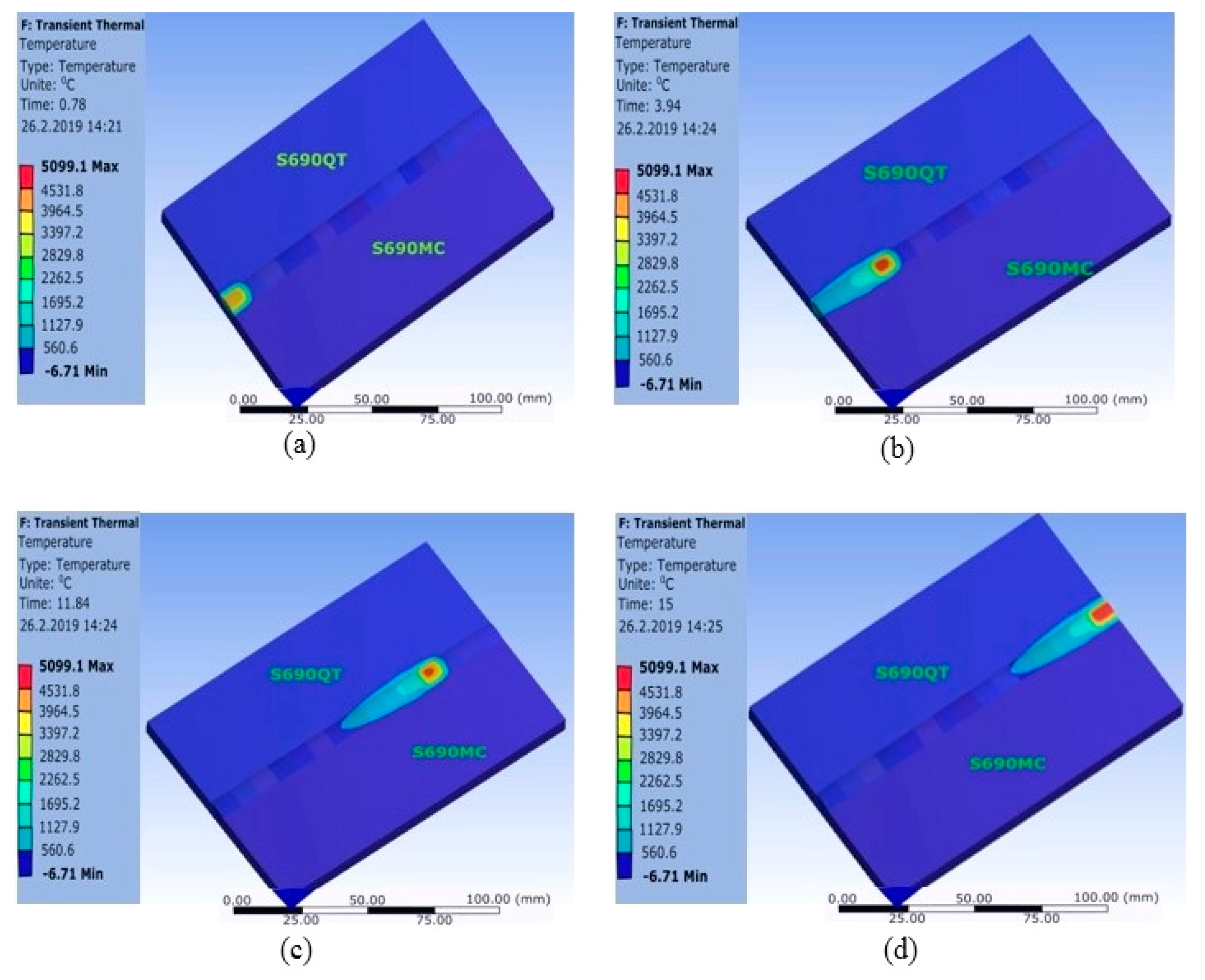

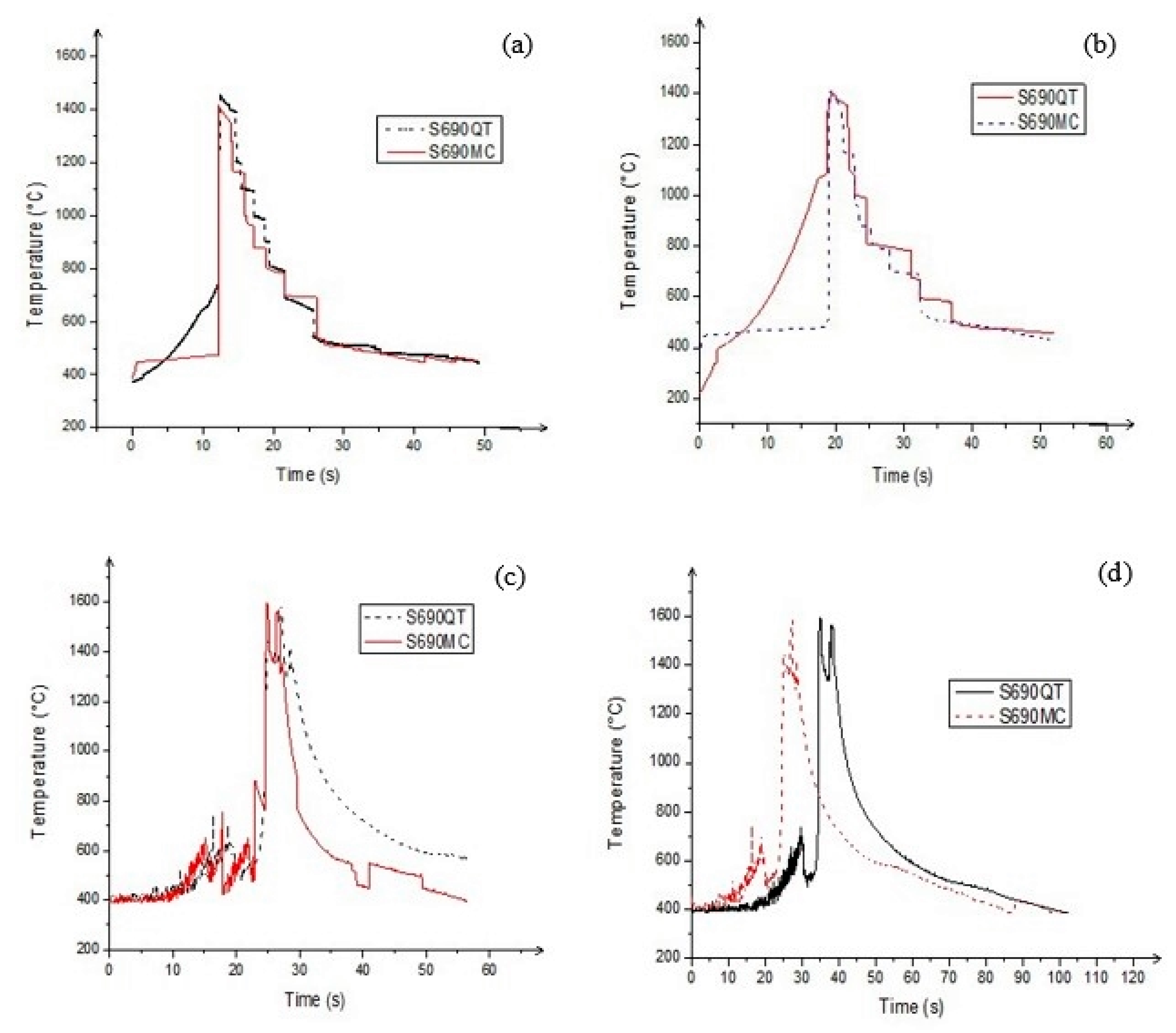

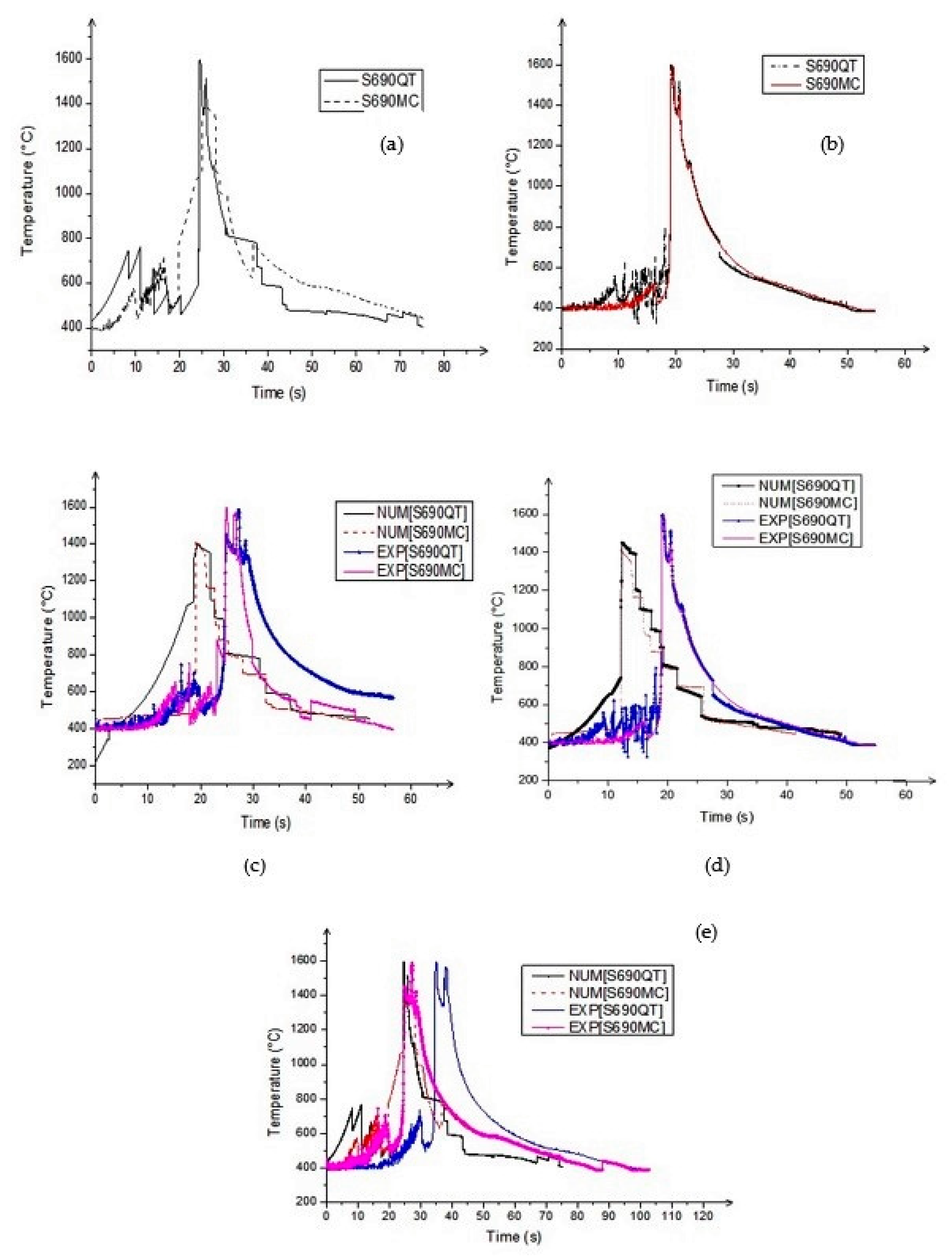

4.1. Thermal Variations

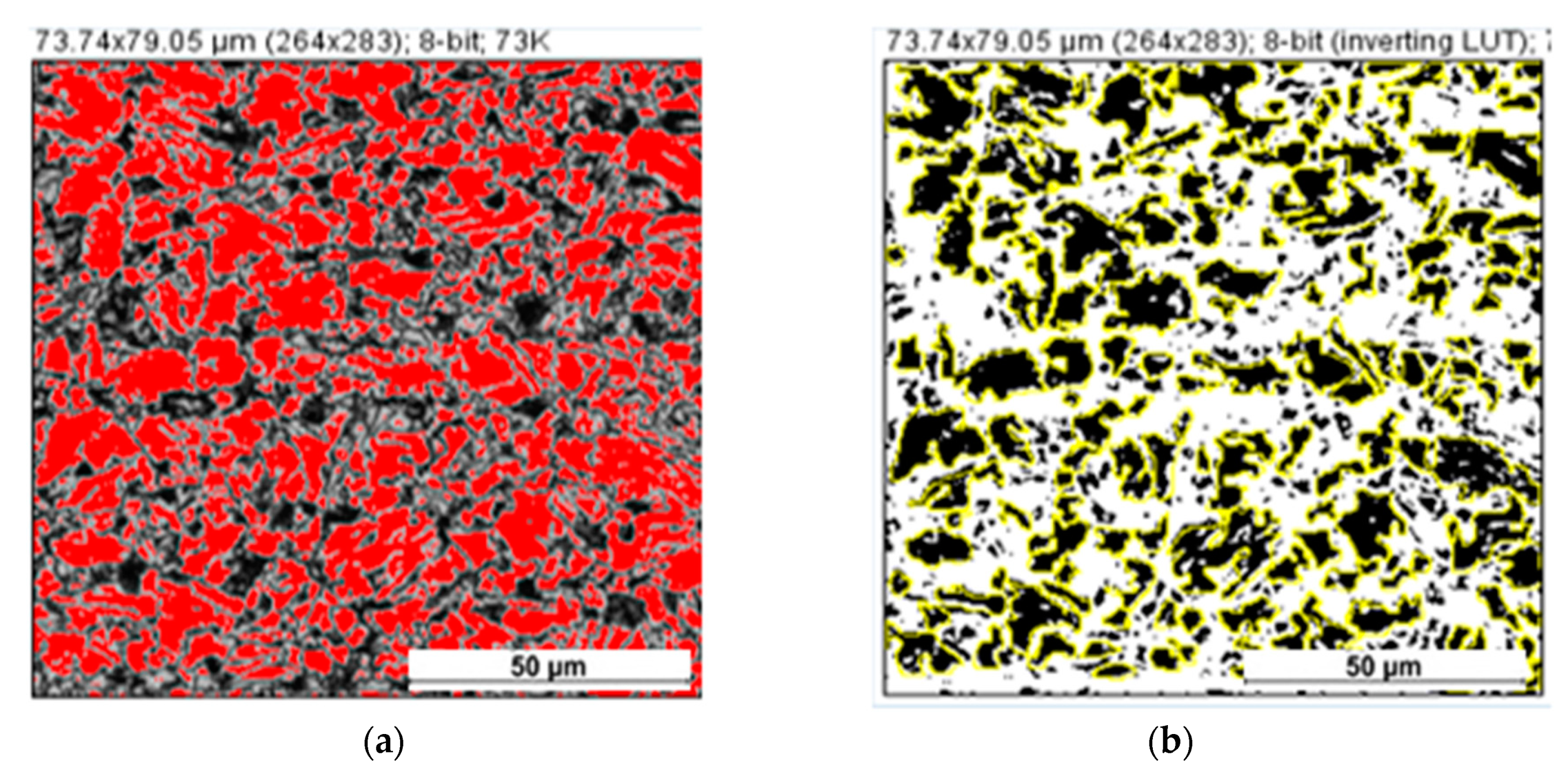

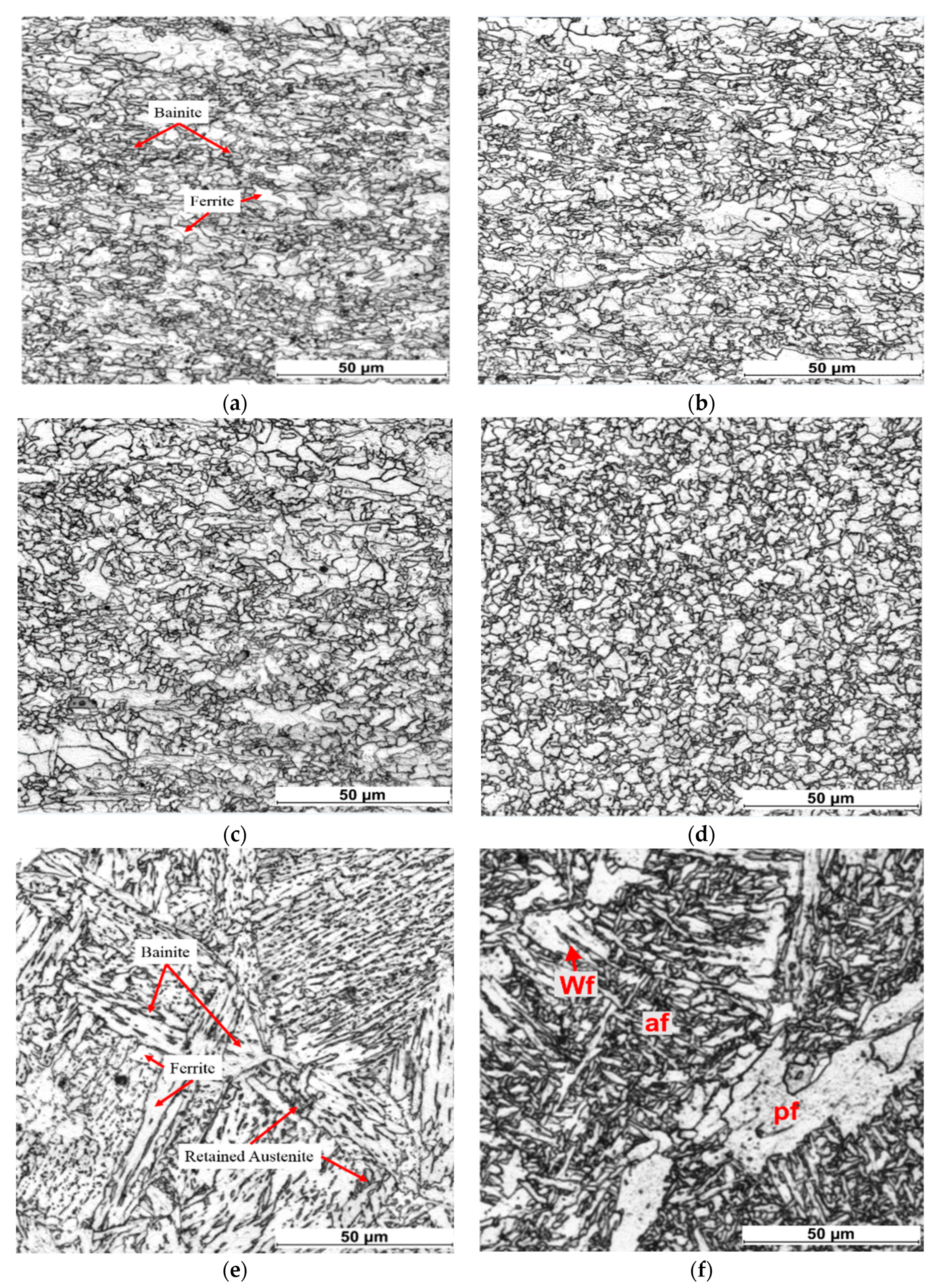

4.2. Microstructure Behavior of the QT Steel Welded Joint

4.3. Microstructure Behavior of the TMCP Steel Welded Joint

4.4. The Microstructure of the Weld Metal

4.5. Comparison of Dissimilar Weld Joint Hardness Profiles

5. Conclusions

- For developing the numerical analysis, a three-dimensional (3D) nonlinear thermal analysis finite element model was used to predict the thermal fields during the welding. The results showed an acceptable confirmation between the experimental and numerical thermal fields of the three samples within a range of 7–19% in predicting the temperature.

- The maximum respective values of the temperature measured in QT steel and TMCP steel were about 1300 and 1200 °C for a heat input of 10 kJ/cm, 1400 and 1300 °C for a heat input of 14 kJ/cm, and 1600 and 1450 °C for a heat input of 17 kJ/cm.

- A heat input of 10 kJ/cm resulted in the maximum rapid cooling time (numerical t8/5, 14.5 s, and experimental, 18.84 s), which increased hardness by 15% to 310 HV0.1 in the CGHAZ region of the QT steel and decreased the hardness value by 10% to 260 vs. 290 HV0.1 for the TMCP steel. In the QT steel, local brittle zone formations in the martensite–bainite microstructure in the CGHAZ were observed.

- In the TMCP steel, the hardness drop was caused by a reconstructive transformation in the primary recrystallization of the microstructure and the formation of more equilibrium products of austenite decomposition (CGHAZ), with lowest hardness seen in the fine-grain heat-affected zone (FGHAZ) region due to the creation of polygonal ferrite.

- Upon increasing heat input from 14 to 17 kJ/cm, the cooling time of the welding process was increased (numerical t8/5, 29 s, and experimental, 36 s), leading to a decrease in the hardness of the CGHAZ in the QT steel by 16% from 310 to 260 HV0.1 due to the full austenite (thermal weld cycle), while maintaining the hardness value of the TMCP steel. This helped avoid the brittle formation in the inter-critical coarse-grain HAZ (ICCGHAZ) of TMCP steel and also to avoid defects in the weld zone.

- In the FGHAZ, the hardness of the two steels underwent the greatest decrease—20% for the QT steel, and 30% for the TMCP steel.

- The SCHAZ area was greatly impacted with a very low hardness value of 180 HV0.1 when the heat source was high (17 kJ/cm). The main reason for that softening was a high heat input; thus, heat input should be controlled and limited, especially for a thick plate, because the softening effect of the welded joint is proportional to the plate thickness.

- The coarse-grain heat-affected zone (CGHAZ) showed relatively high hardness and large-size grains, and the tempering zone had comparable hardness and grain size to the base metal.

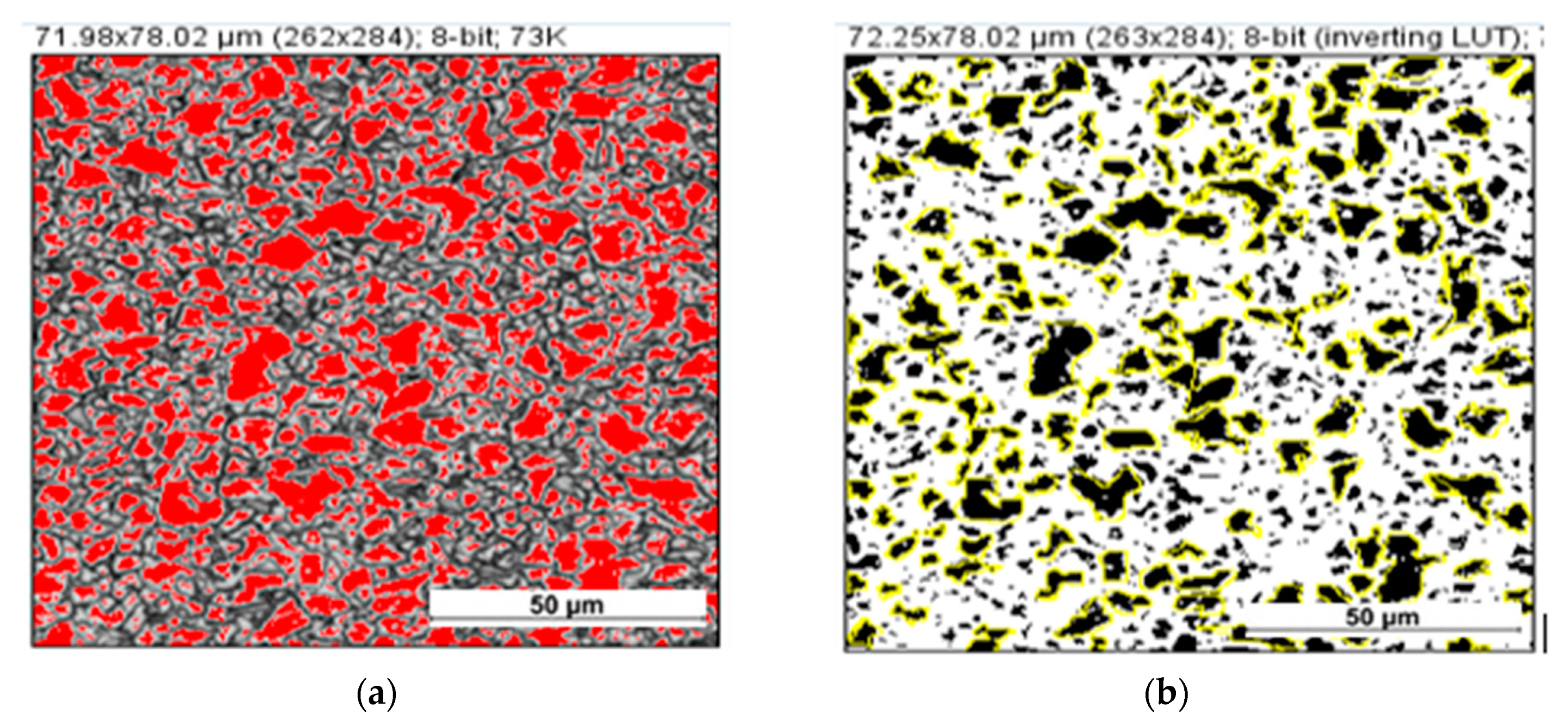

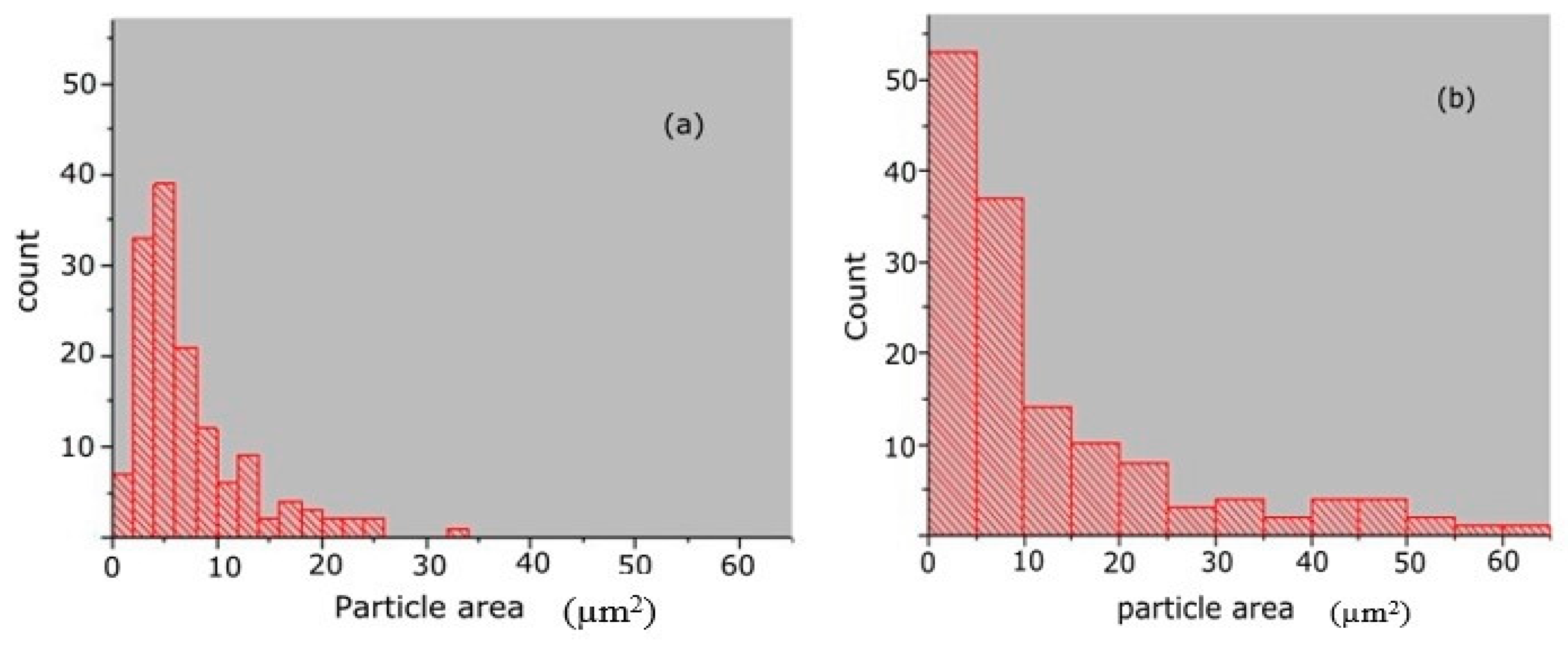

- The analyzed grain samples showed an increased surface on the 690 QT steel (12.6 µm2) compared to the 690 TMCP steel (4.43 µm2). A probable reason is that the carbon content in QT steel, higher compared to 690 TMCP steel, caused carbon diffusion during para-equilibrium nucleation and growth in the austenite grain size.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Haslberger, P.; Holly, S.; Ernst, W.; Schnitzer, R. Microstructure and mechanical properties of high-strength steel welding consumables with a minimum yield strength of 1100 MPa. J. Mater. Sci. 2018, 53, 6968–6979. [Google Scholar] [CrossRef]

- Di, H.; Sun, Q.; Wang, X.; Li, J. Microstructure and properties in dissimilar/similar weld joints between DP780 and DP980 steels processed by fiber laser welding. J. Mater. Sci. Technol. 2017, 33, 1561–1571. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.; Kumar, P.; Thakre, G.; Saini, N. Role of evolving microstructure on the mechanical behavior of P92 steel welded joint in as-welded and post weld heat treated state. J. Mater. Proc. Technol. 2019, 263, 241–255. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.; Yoneyama, S.; Kokawa, H.; Fujii, T.; Hirano, S. Microstructure and tensile behavior of friction-stir welded TRIP steel. Mater. Sci. Eng. A 2018, 717, 26–33. [Google Scholar] [CrossRef]

- Hulka, K.; Gray, J.M. High-temperature processing of line-pipe steels/niobium science and technology. In Proceedings of the International Symposium Niobium, Orlando, FL, USA, 2–5 December 2001. [Google Scholar]

- Nishioka, K.; Ichikawa, K. Progress in thermomechanical control of steel plates and their commercialization. Sci. Techol. Adv. Mater. 2012, 13, 203001. [Google Scholar]

- Hochhauser, F.; Ernest, W.; Rauch, R.; Vallant, R.; Enzinger, N. Influence of the soft zone on the strength of welded modern HSLA steels. Weld. World 2006, 56, 77–85. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S.; Kim, J.; Lee, D. Microstructure and local brittle zone phenomena in high-strength low-alloy steel welds. Metall. Trans. A 1999, 22, 139–149. [Google Scholar] [CrossRef]

- Loureiro, R. Effect of heat input on plastic deformation of undermatched weld. J. Mater. Proc. Technol. 2002, 128, 240–249. [Google Scholar] [CrossRef]

- Hwang, R.; Lee, T.; Lee, G. Correlation of microstructure and mechanical properties of thermo-mechanically processed low-carbon steels containing boron and copper. Metall. Mater. Trans. A 2010, 41, 85–96. [Google Scholar] [CrossRef]

- Chang, W.S. Microstructure and mechanical properties of 780 MPa high strength steel produced by direct quenching and tempering process. J. Mater. Sci. 2002, 37, 1973–1979. [Google Scholar] [CrossRef]

- Schroter, F. Structural steel for the application in offshore, wind and hydro energy production. Comparison of application and welding properties of frequently used materials. Int. J. Microstruct. Mater. Prop. 2011, 6, 4–19. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Gourgues, A.F.; Pineau, A. Austenite to bainite transformation in the heat-affected zone of a heat strength low carbon steel. Acta Mater. 2004, 52, 2337–2348. [Google Scholar] [CrossRef]

- Lanberte-Perlade, A.; Gourgues, A.F.; Besson, J.; Sturel, T.; Pineau, A. Mechanism and modeling of cleavage fracture in simulated heat-affected zone microstructures of high-strength low alloy steel. Metall. Mater. Trans. A 2004, 35, 1039–1053. [Google Scholar] [CrossRef]

- Bhatti, A.; Barsoum, Z.; Hidekazu, M.; Barsoum, I. Influence of thermo-mechanical material properties of different steel grades on welding residual stresses and angular distortion. Mater. Des. 2015, 65, 878–889. [Google Scholar] [CrossRef]

- Liu, D.; Li, T.; Emi, T. Microstructure and mechanical properties in hot-rolled extra high-yield-strength steel plates for offshore structure and shipbuilding. Metall. Mater. Trans. A 2011, 42, 1349–1361. [Google Scholar] [CrossRef]

- Layus, P.; Kah, P.; Ryabov, V.; Martikainen, J. Evaluation of applicability of thick E500 TMCP and F500W QT-steel plates for Artic service. Int. J. Mech. Mater. Eng. 2016, 11, 1–15. [Google Scholar] [CrossRef]

- Dusan, A.; Vukic, L.; Ruzica, R.; Srbislav, A.; Branislav, H.; Milan, D. Optimal welding technology of high strength steel S690QL. Mater. Eng. 2015, 22, 33–47. [Google Scholar]

- Porter, D.; Laukkanen, A.; Nevasmaa, P.; Rahka, K.; Wallin, K. Performance of TMCP-steel with respect to mechanical properties after cold forming and post-forming heat treatment. Int. J. Press. Vessel. Pip. 2004, 81, 867–877. [Google Scholar] [CrossRef]

- Sadeghian, M.; Shamanian, M.; Shafyei, A. Effect of heat on microstructure and mechanical properties of dissimilar joints between super duplex stainless steel and high strength low alloy steel. Mater. Des. 2014, 60, 678–684. [Google Scholar] [CrossRef]

- Ito, R.; Hiraoka, K.; Shiga, C. Characteristics of the heat-affected zone in ultra-fine-grained steel during ultra-narrow gap GMA welding. Weld. Int. 2005, 19, 458–466. [Google Scholar] [CrossRef]

- Hamada, M. Control of strength and toughness at the heat affected zone. Weld. Int. 2003, 17, 265–270. [Google Scholar] [CrossRef]

- Pirinen, M.; Martikainen, J.; Layus, P.; Karhin, V.; Ivanov, Y.S. Effect of heat input on the mechanical properties of welded joints in high-strength steel. Weld. Int. 2015, 2, 14–17. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Microstructural characteristics and toughness of the simulated coarse-grained heat affected zone of high strength low carbon bainite steel. Mater. Sci. Eng. A 2011, 529, 192–200. [Google Scholar] [CrossRef]

- Shi, Y.; Han, Z. Effect of thermal weld cycle on microstructure and fracture toughness of simulated heat-affected zone for an 800 MPa grade high strength low alloy steel. J. Mater. Proc. Technol. 2008, 207, 30–39. [Google Scholar] [CrossRef]

- Goldack, J.; Chkravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Al | B | Nb | Ti | V | Cu | Cr | Ni | Mo | N | P | S | CE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| QT | 0.137 | 0.28 | 1.39 | 0.061 | 0.0021 | 0.022 | 0.002 | 0.001 | 0.02 | 0.062 | 0.066 | 0.029 | 0.005 | 0.013 | 0.0013 | 0.41 |

| TMCP | 0.049 | 0.17 | 1.86 | 0.025 | - | 0.081 | 0.092 | 0.009 | - | - | - | 0.008 | 0.005 | 0.08 | 0.004 | 0.35 |

| 16834-A G 69 6 M21 Mn4ni1,5CrMo | 0.07 | 0.50 | 1.70 | - | - | - | 0.05 | - | ≤0.30 | 0.20 | 1,60 | 0,45 | 0.005 | 0.012 | 0.02 | 0,55 |

| Steel | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation A5 (%) |

|---|---|---|---|

| QT | 793 | 835 | 16.3 |

| TMCP | 761 | 821 | 20 |

| 16834-A G 69 6 M21 Mn4ni1,5CrMo | 720 | 780 | ≥17 |

| No. | Pass | Current (A) | Voltage (V) | Welding Speed (cm/min) | Net Power (W) | Heat Input (kJ/cm) |

|---|---|---|---|---|---|---|

| 1 | 1 | 230 | 25.6 | 27.18 | 4710 | 10 |

| 2 | 230 | 25.6 | 27.18 | 4710 | 10 | |

| 2 | 1 | 230 | 25.6 | 27.18 | 4710 | 10 |

| 2 | 268 | 29.0 | 27.12 | 6218 | 14 | |

| 3 | 1 | 230 | 25.6 | 27.18 | 4710 | 10 |

| 2 | 258 | 30.6 | 22.26 | 6316 | 17 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Njock Bayock, F.; Kah, P.; Layus, P.; Karkhin, V. Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel. Metals 2019, 9, 355. https://doi.org/10.3390/met9030355

Njock Bayock F, Kah P, Layus P, Karkhin V. Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel. Metals. 2019; 9(3):355. https://doi.org/10.3390/met9030355

Chicago/Turabian StyleNjock Bayock, Francois, Paul Kah, Pavel Layus, and Victor Karkhin. 2019. "Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel" Metals 9, no. 3: 355. https://doi.org/10.3390/met9030355

APA StyleNjock Bayock, F., Kah, P., Layus, P., & Karkhin, V. (2019). Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel. Metals, 9(3), 355. https://doi.org/10.3390/met9030355