Influence of Residual Stress on Fatigue Weak Areas and Simulation Analysis on Fatigue Properties Based on Continuous Performance of FSW Joints

Abstract

1. Introduction

2. Experimental

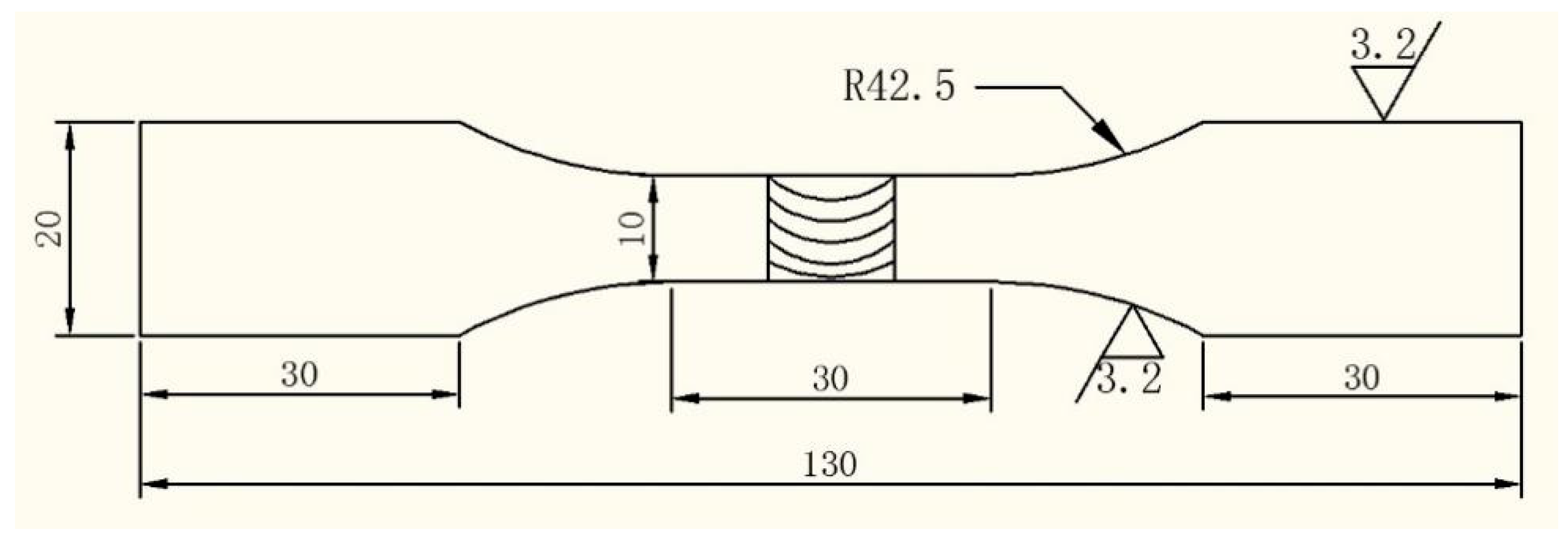

2.1. Materials and Specimens

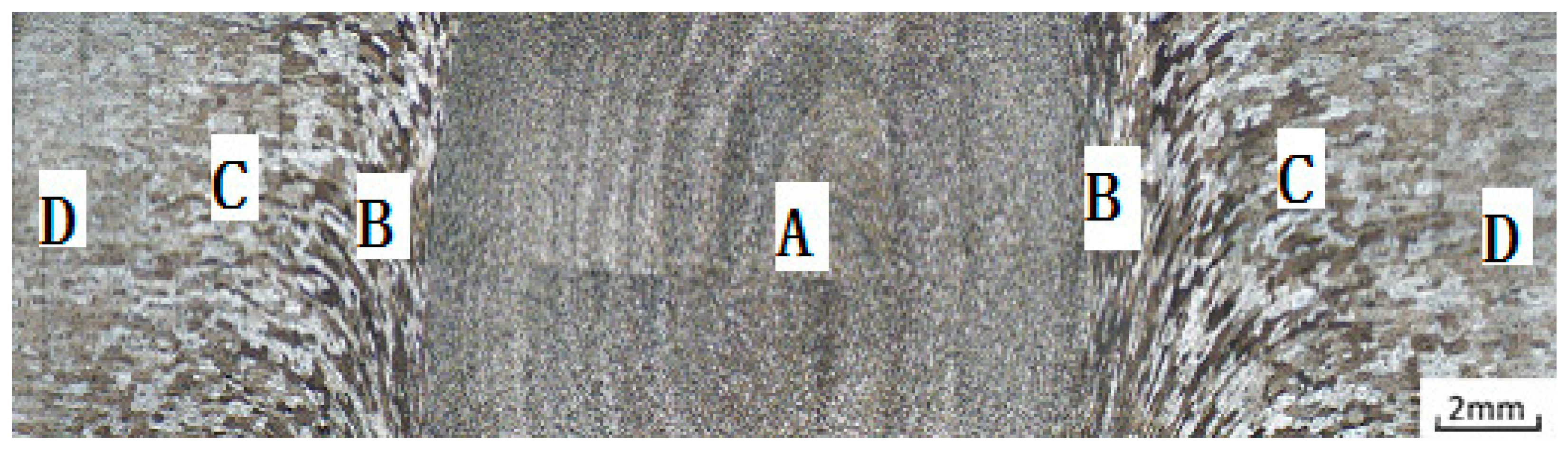

2.2. Metallographic Morphology

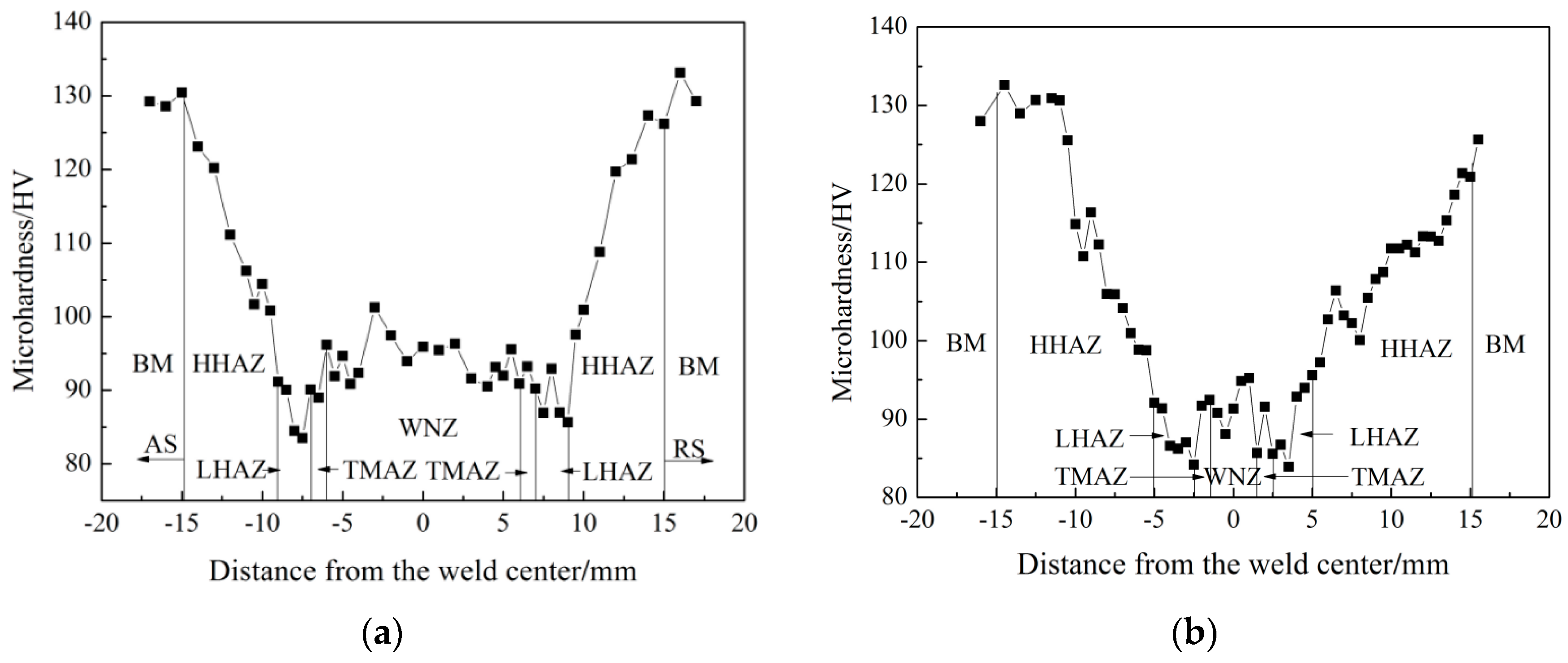

2.3. Hardness Measurements

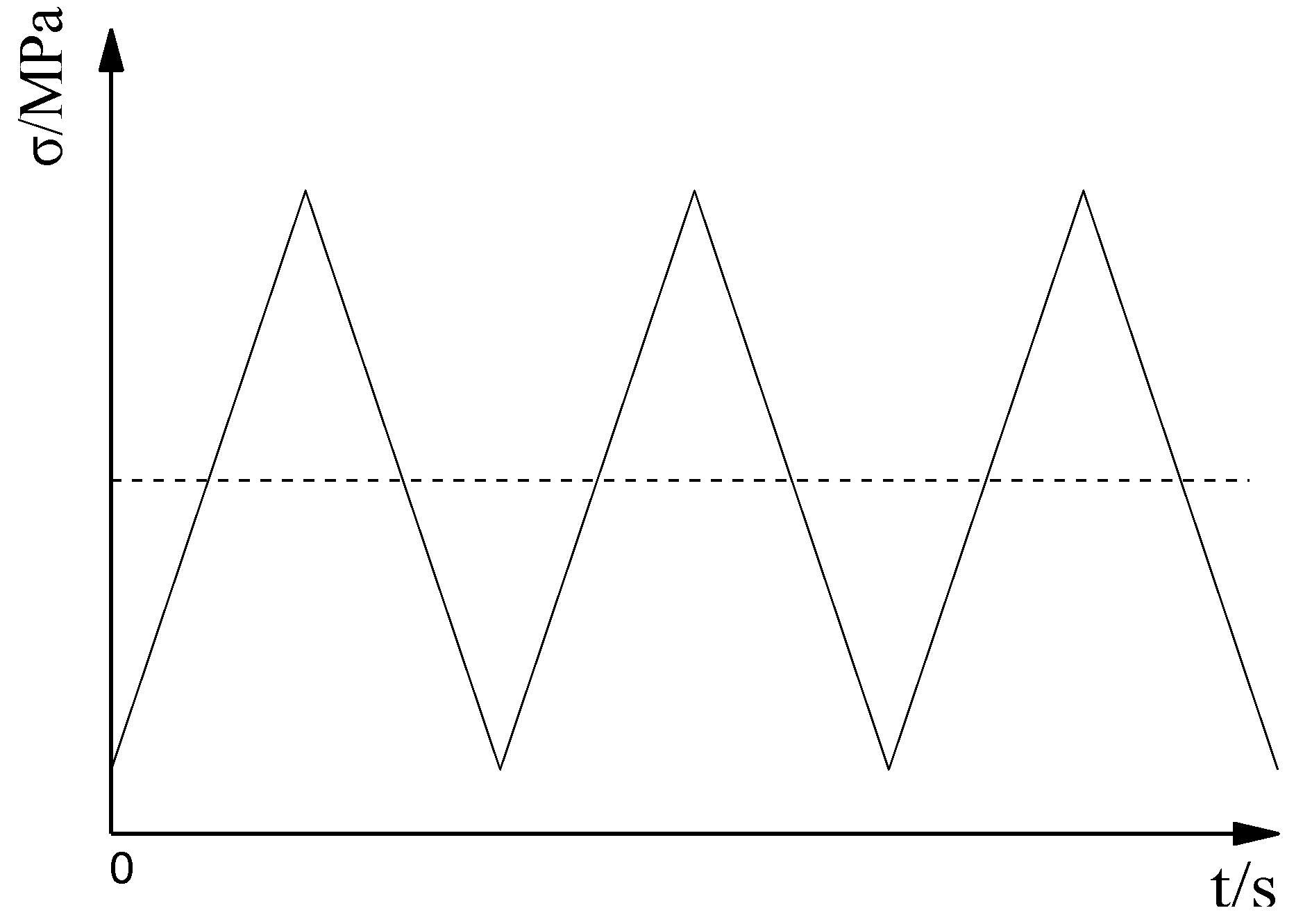

2.4. Fatigue Experiments

2.5. Residual Stress Measurements

3. Experimental Results

3.1. Hardness Distribution

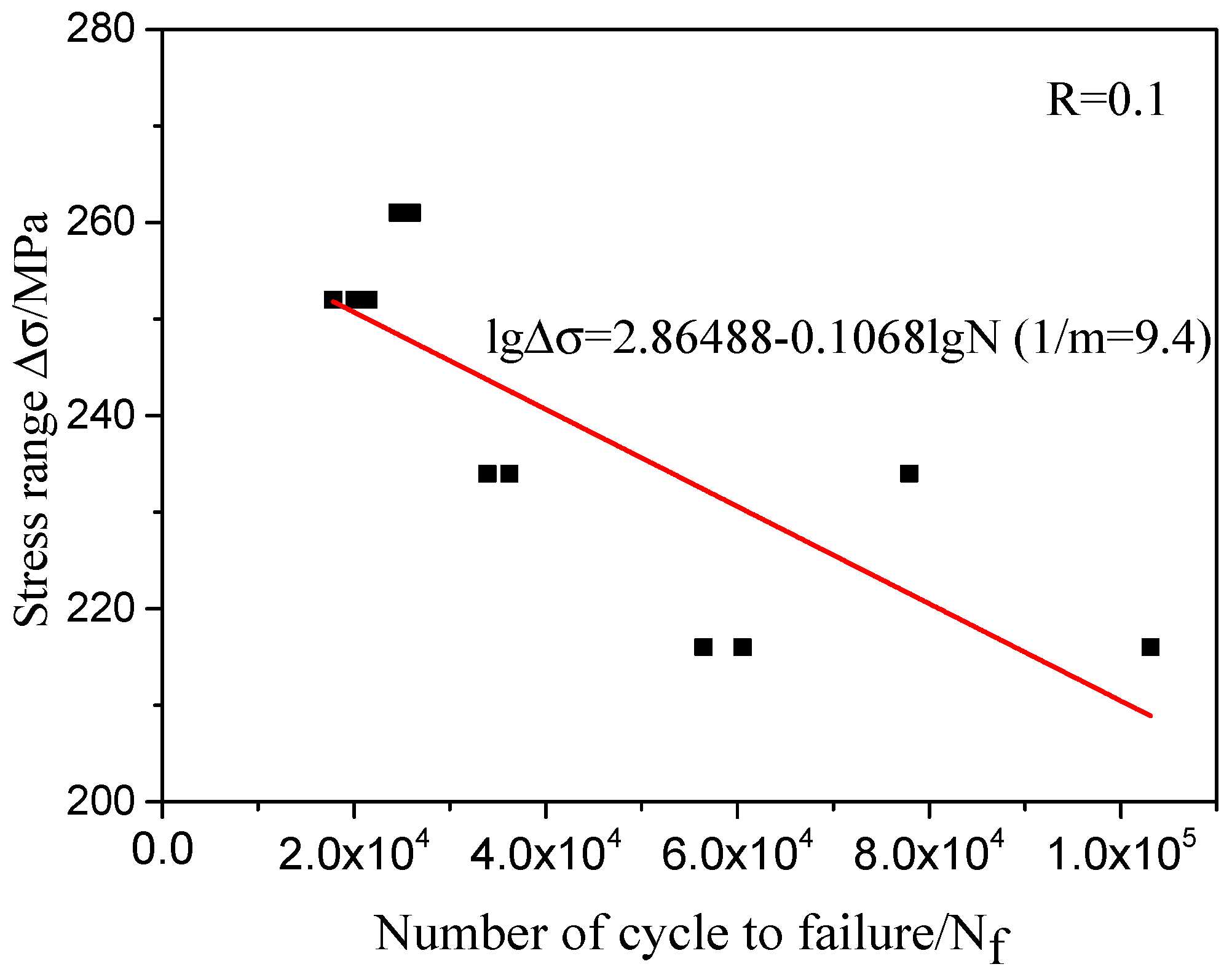

3.2. Fatigue Experimental Results

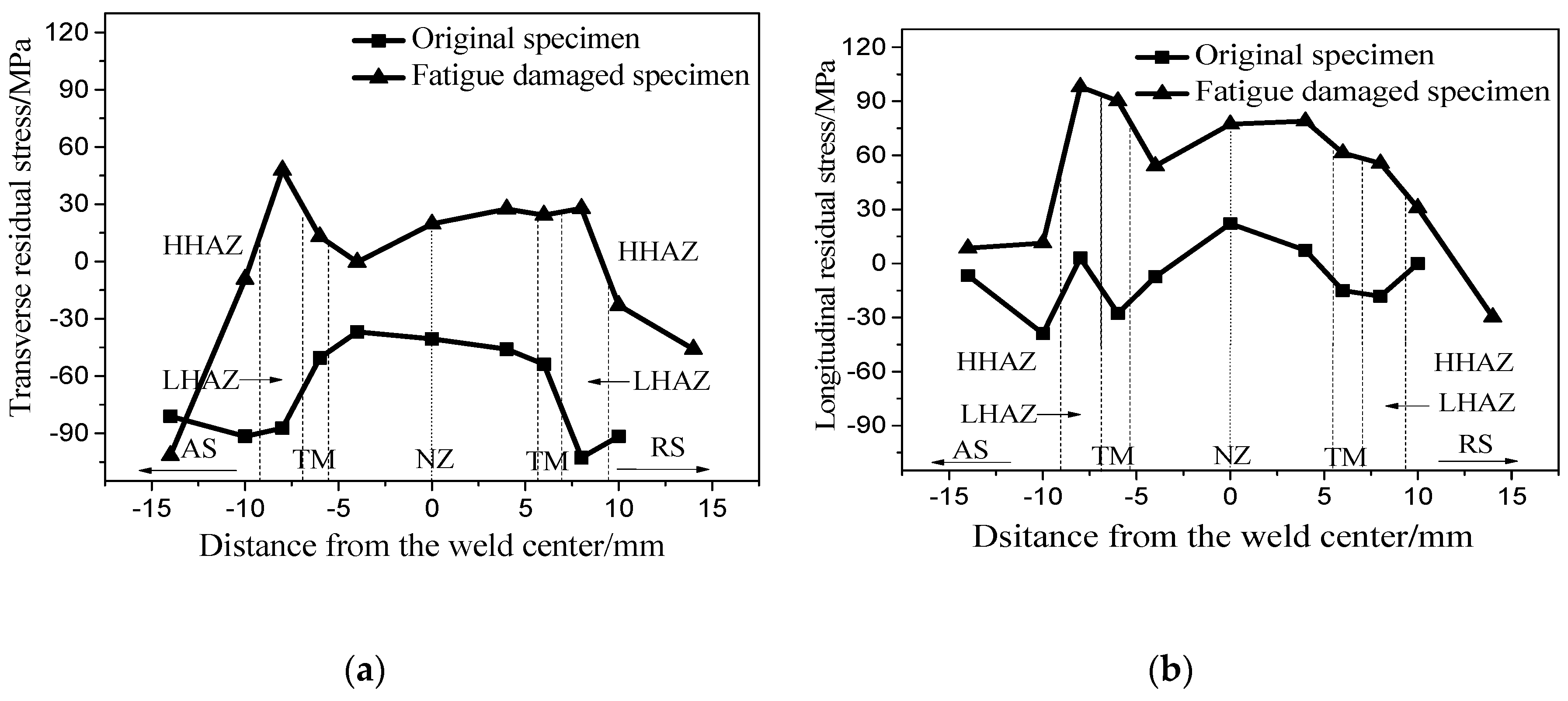

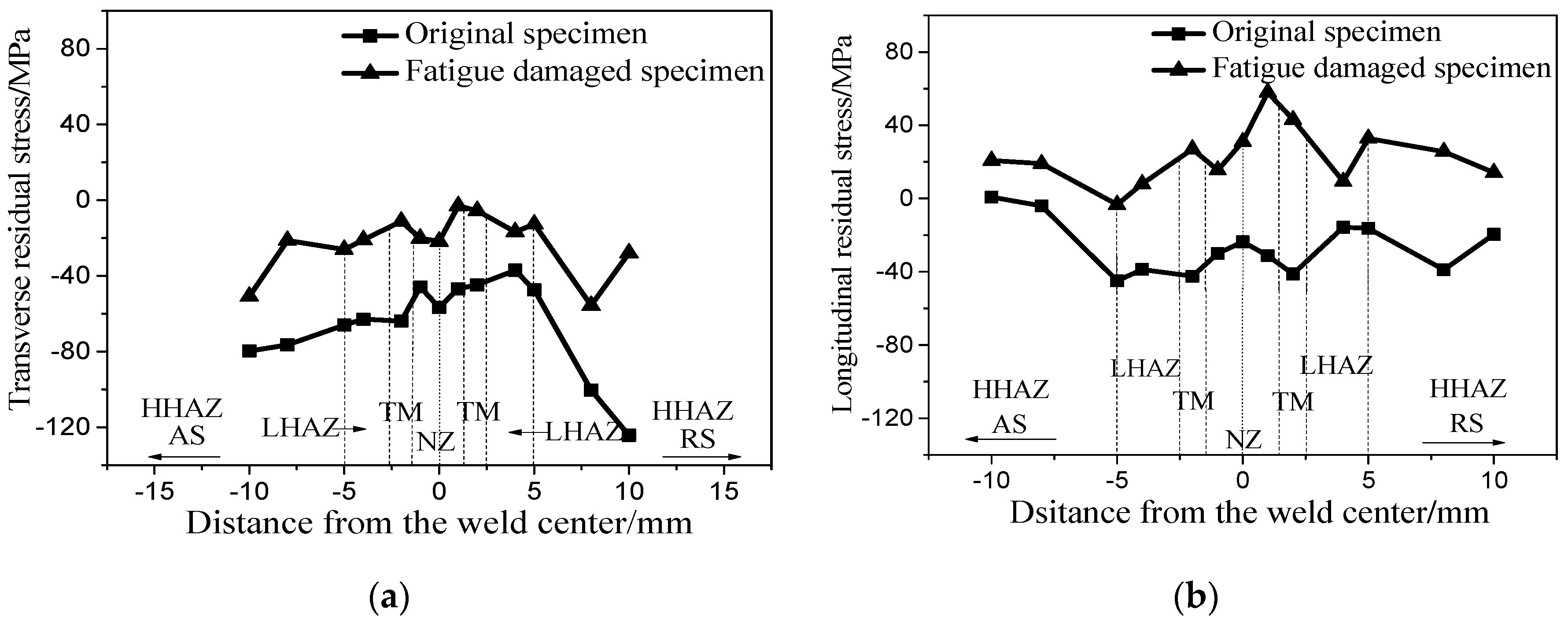

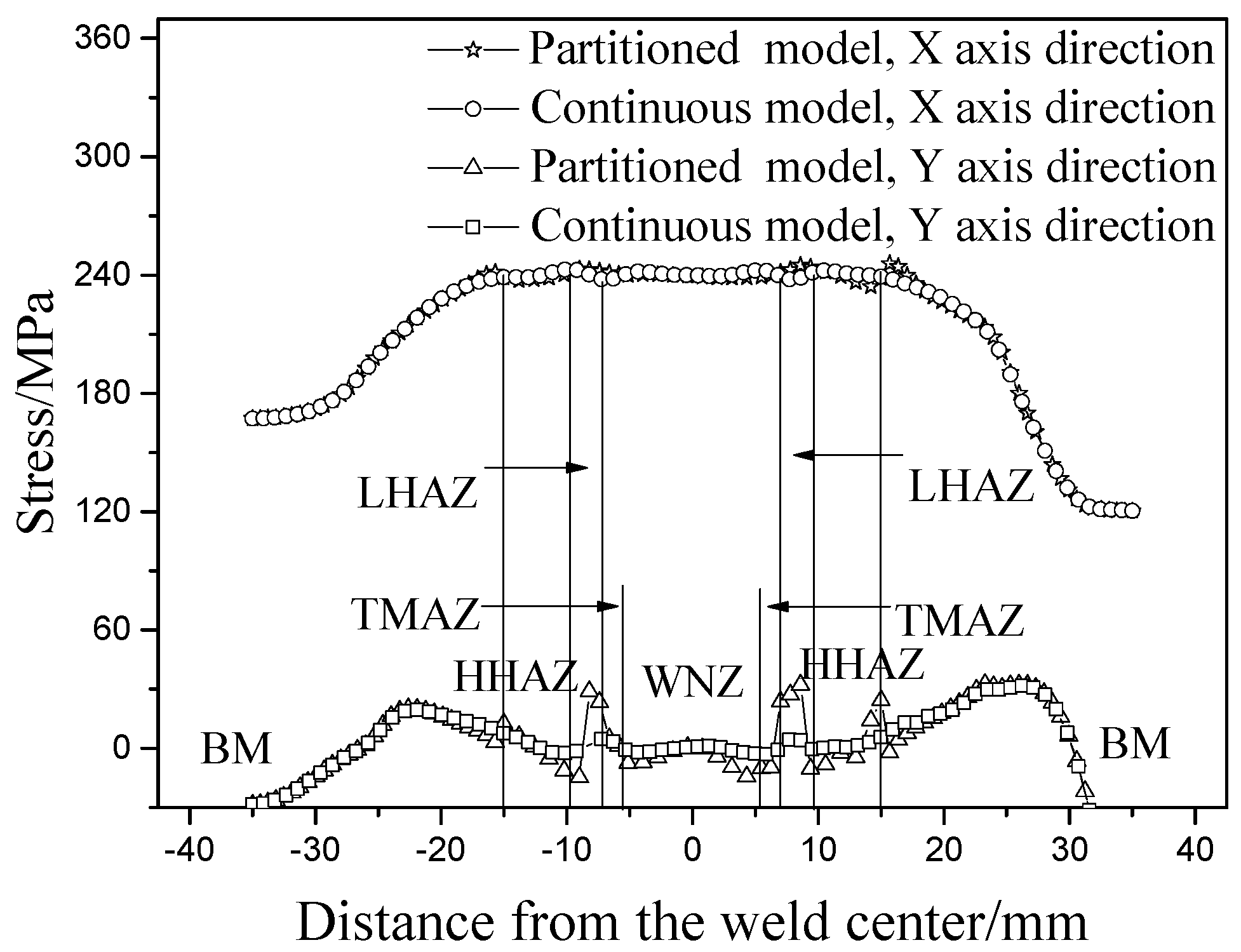

3.3. Residual Stress Distribution

4. Fatigue Numerical Simulation

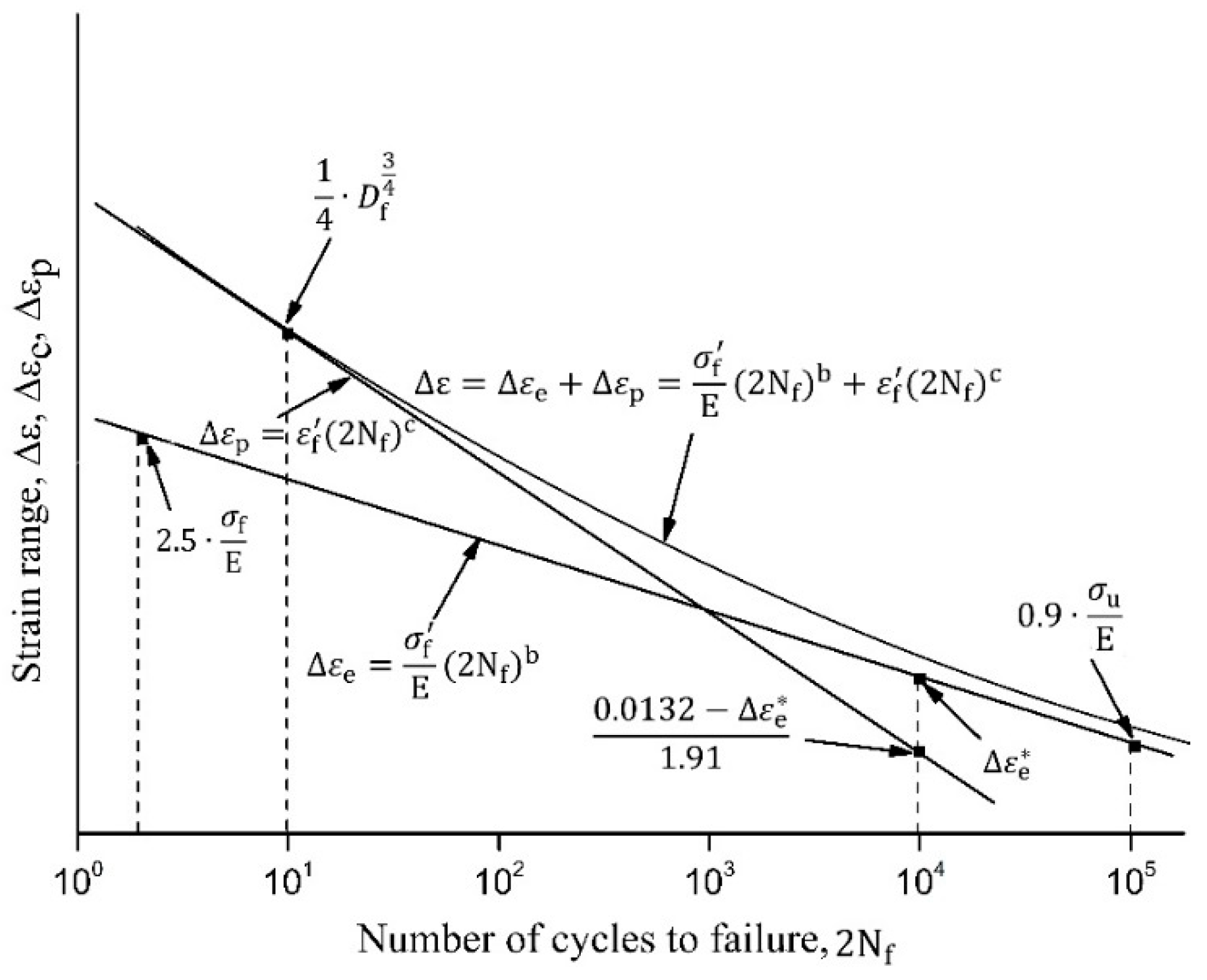

4.1. Fatigue Parameters of the Welded Joint

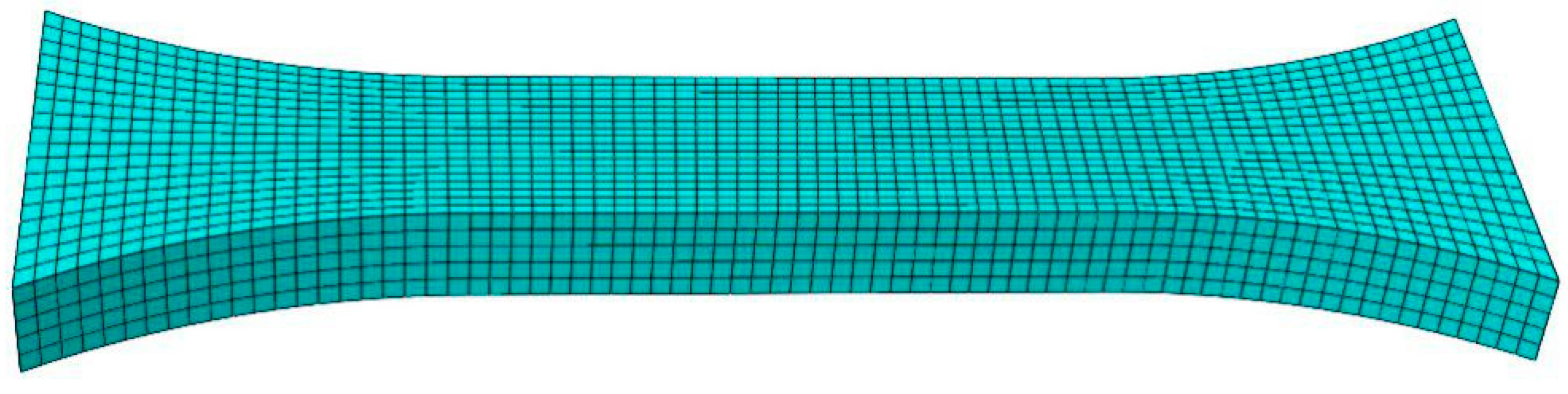

4.2. Continuous Performance Joint Model

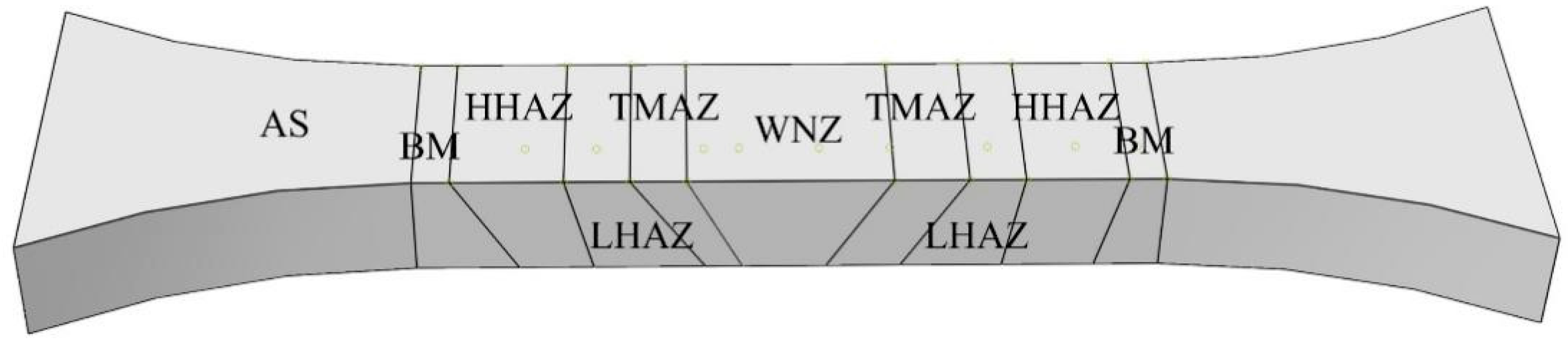

4.3. Partitioned Performance Joint Model

5. Simulation Results

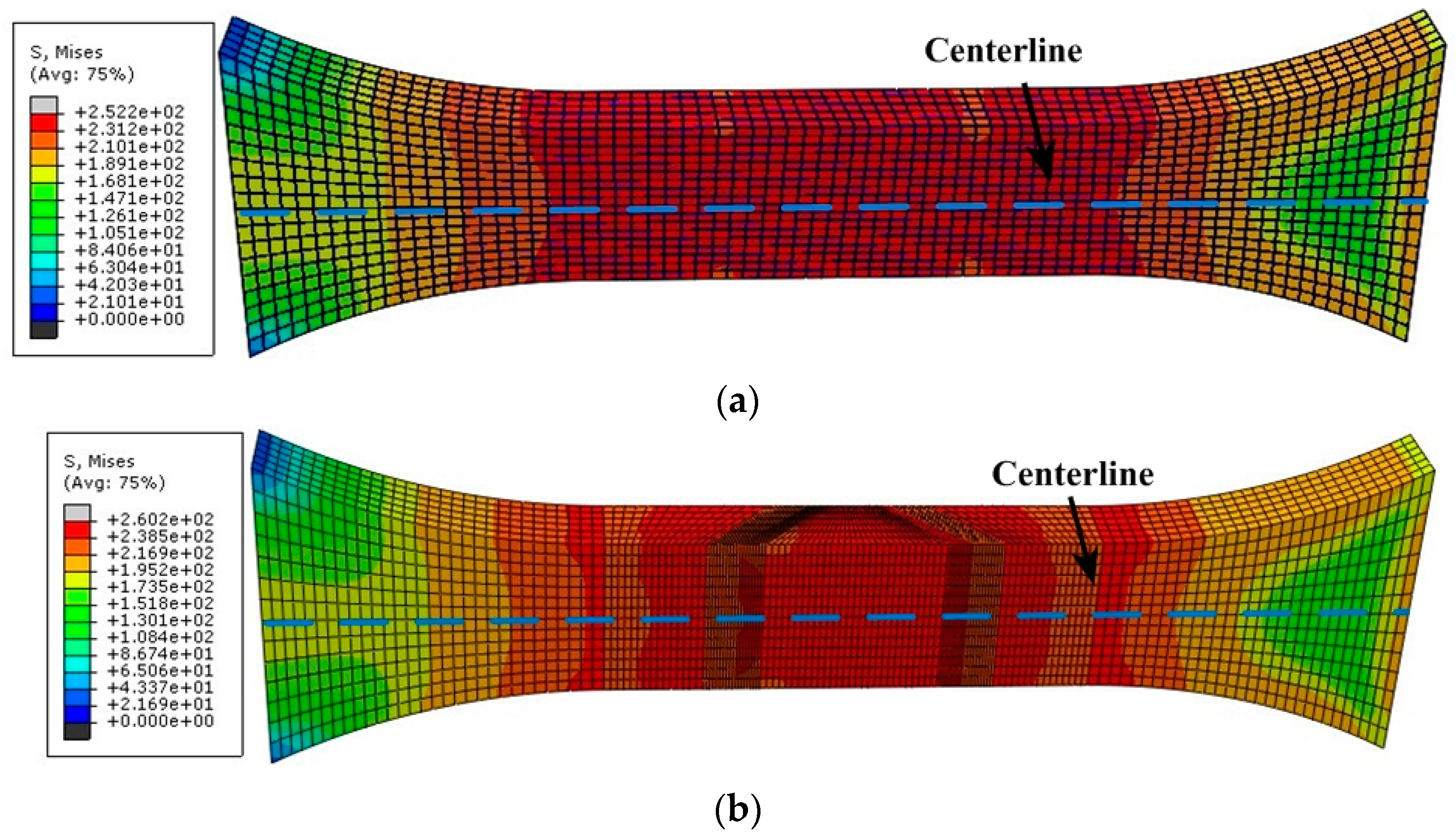

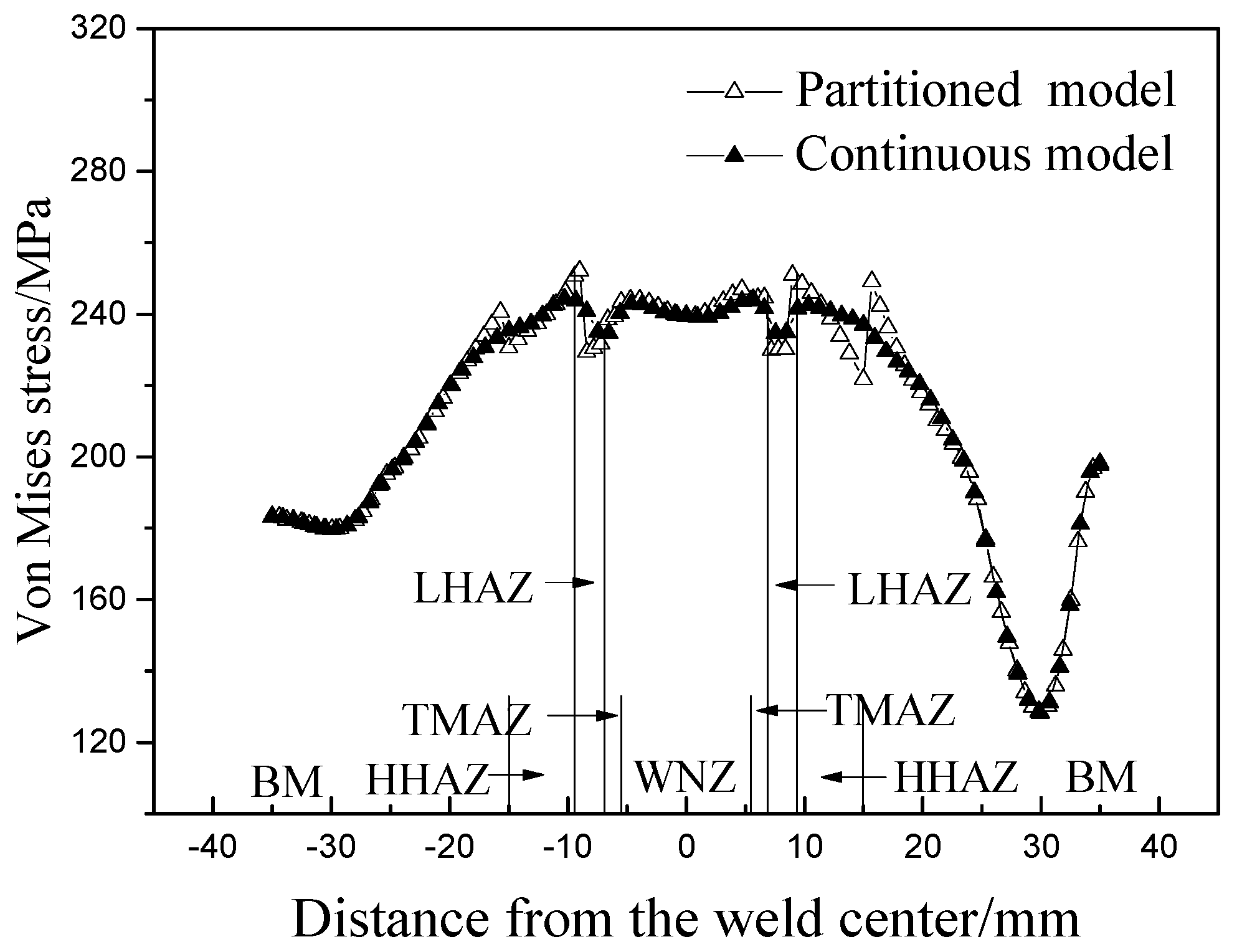

5.1. Stress Distribution

5.2. Strain Distribution

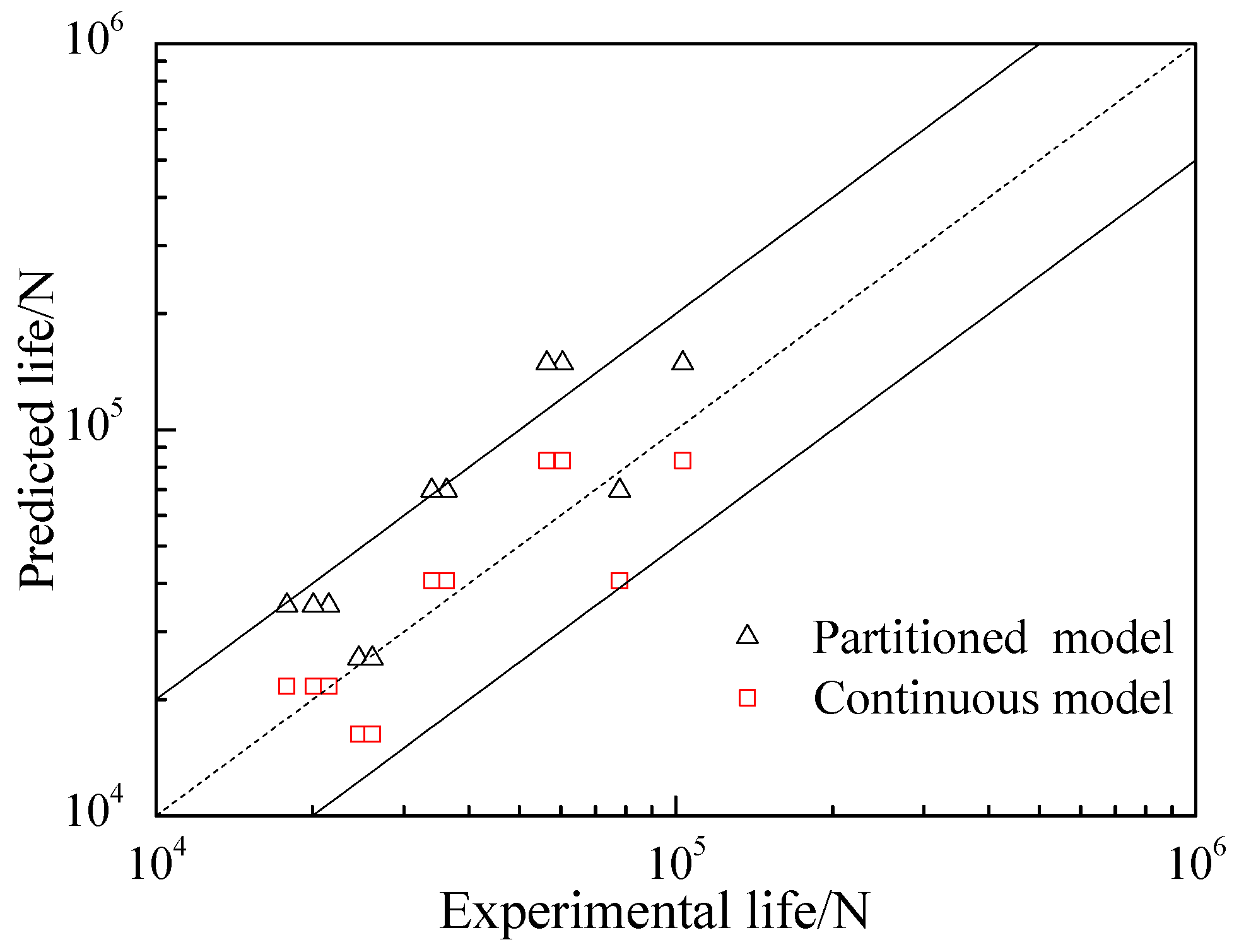

6. Fatigue Life Prediction

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| FSW | Friction stir welding |

| WNZ | Weld nugget zone |

| TMAZ | Thermo-mechanically affected zone |

| HAZ | Heat affect zone |

| BM | Base material |

| HHAZ | High-hardness heat affect zone |

| LHAZ | Low-hardness heat affect zone |

| AS | Advancing side |

| RS | Retreating side |

| SWT | Smith-Watson-Topper |

References

- Charitidis, C.A.; Dragatogiannis, D.A.; Koumoulos, E.P.; Kartsonakis, I.A. Residual stress and deformation mechanism of friction stir welded aluminum alloys by nanoindentation. Mater. Sci. Eng. A 2012, 540, 226–234. [Google Scholar] [CrossRef]

- Abdulstaar, M.A.; Al-Fadhalah, K.J.; Wagner, L. Microstructural variation through weld thickness and mechanical properties of peened friction stir welded 6061 aluminum alloy joints. Mater. Charact. 2017, 126, 64–73. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, X.; Ma, M.; Zhang, J.; Liu, W.C.; Fu, R.D.; Xiang, S. A study on microstructure and mechanical properties of AA 3003 aluminum alloy joints by underwater friction stir welding. Mater. Charact. 2017, 127, 41–52. [Google Scholar] [CrossRef]

- Fratini, L.; Pasta, S.; Reynolds, A.P. Fatigue crack growth in 2024-T351 friction stir welded joints: Longitudinal residual stress and microstructural effects. Int. J. Fatigue 2009, 31, 495–500. [Google Scholar] [CrossRef]

- Eslami, N.; Hischer, Y.; Harms, A.; Lauterbach, D.; Böhm, S. Optimization of process parameters for friction stir welding of aluminum and copper using the taguchi method. Metals 2019, 9, 63. [Google Scholar] [CrossRef]

- Metz, D.F.; Weishaupt, E.R.; Barkey, M.E.; Fairbee, B.S. A microstructure and microhardness characterization of a friction plug weld in friction stir welded 2195 Al-Li. J. Eng. Mater. Technol. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Besel, M.; Besel, Y.; Alfaro Mercado, U.; Kakiuchi, T.; Uematsu, Y. Fatigue behavior of friction stir welded Al–Mg–Sc alloy. Int. J. Fatigue 2015, 77, 1–11. [Google Scholar] [CrossRef]

- Sillapasa, K.; Surapunt, S.; Miyashita, Y.; Mutoh, Y.; Seo, N. Tensile and fatigue behavior of SZ, HAZ and BM in friction stir welded joint of rolled 6N01 aluminum alloy plate. Int. J. Fatigue 2014, 63, 162–170. [Google Scholar] [CrossRef]

- Rajakumar, S.; Balasubramanian, V. Correlation between weld nugget grain size, weld nugget hardness and tensile strength of friction stir welded commercial grade aluminium alloy joints. Mater. Des. 2012, 34, 242–251. [Google Scholar] [CrossRef]

- Sun, T.; Reynolds, A.P.; Roy, M.J.; Withers, P.J.; Prangnell, P.B. The effect of shoulder coupling on the residual stress and hardness distribution in AA7050 friction stir butt welds. Mater. Sci. Eng. A 2018, 735, 218–227. [Google Scholar] [CrossRef]

- Lemos, G.V.B.; Cunha, P.H.C.P.; Nunes, R.M.; Bergmann, L.; Dos Santos, J.F.; Clarke, T. Residual stress and microstructural features of friction-stir-welded GL E36 shipbuilding steel. Mater. Sci. Technol. 2018, 34, 95–103. [Google Scholar] [CrossRef]

- Xu, W.; Liu, J.; Zhu, H. Analysis of residual stresses in thick aluminum friction stir welded butt joints. Mater. Des. 2011, 32, 2000–2005. [Google Scholar] [CrossRef]

- Aval, H.J. Microstructure and residual stress distributions in friction stir welding of dissimilar aluminium alloys. Mater. Des. 2015, 87, 405–413. [Google Scholar] [CrossRef]

- Prime, M.B.; Thomas, G.H.; Baumann, J.A.; Lederich, R.J.; Bowden, D.M. Residual stress measurements in a thick, dissimilar aluminum alloy friction stir weld. Acta Mater. 2006, 54, 4013–4021. [Google Scholar] [CrossRef]

- Toribio, J.; Matos, J.C.; González, B.; Escuadra, J. Fatigue crack growth in round bars for rock anchorages: The role of residual stresses. Procedia Struct. Integr. 2016, 2, 2734–2741. [Google Scholar] [CrossRef]

- Benachoura, M.; Benachoura, N.; Benguediab, M. Effect of compressive residual stress generated by plastic preload on fatigue initiation of 6061 Al-alloy. Procedia Struct. Integr. 2016, 2, 3090–3097. [Google Scholar] [CrossRef]

- Citarella, R.; Carlone, P.; Lepore, M.; Palazzo, G.S. Numerical-experimental crack growth analysis in AA2024-T3 FSWed butt joints. Adv. Eng. Softw. 2015, 80, 47–57. [Google Scholar] [CrossRef]

- Shen, F.; Zhao, B.; Li, L.; Chua, C.K.; Zhou, K. Fatigue damage evolution and lifetime prediction of welded joints with the consideration of residual stresses and porosity. Int. J. Fatigue 2017, 103, 272–279. [Google Scholar] [CrossRef]

- Sowards, J.W.; Gnäupel-Herold, T.; McColskey, J.D.; Pereira, V.F.; Ramirez, A.J. Characterization of mechanical properties, fatigue-crack propagation, and residual stresses in a microalloyed pipeline-steel friction-stir weld. Mater. Des. 2015, 88, 632–642. [Google Scholar] [CrossRef]

- Servetti, G.; Zhang, X. Predicting fatigue crack growth rate in a welded butt joint: The role of effective R ratio in accounting for residual stress effect. Eng. Fract. Mech. 2009, 76, 1589–1602. [Google Scholar] [CrossRef]

- Rao, D.; Huber, K.; Heerens, J.; Dos Santos, J.F.; Huber, N. Asymmetric mechanical properties and tensile behaviour prediction of aluminum alloy 5083 friction stir welding joints. Mater. Sci. Eng. A 2013, 565, 44–50. [Google Scholar] [CrossRef]

- Simar, A.; Bréchet, Y.; Meester, B.D.; Denquin, A.; Pardoen, T. Microstructure, local and global mechanical properties of friction stir welds in aluminum alloy 6005A-T6. Mater. Sci. Eng. A 2008, 486, 85–95. [Google Scholar] [CrossRef]

- Nielsen, K.L. Ductile damage development in friction stir welded aluminum (AA2024) joints. Eng. Fract. Mech. 2008, 75, 2795–2811. [Google Scholar] [CrossRef]

- Nielsen, K.L.; Pardoen, T.; Tvergaard, V.; Meester, B.D.; Simar, A. Modelling of plastic flow localisation and damage development in friction stir welded 6005A aluminium alloy using physics based strain hardening law. Int. J. Solids Struct. 2010, 47, 2359–2370. [Google Scholar] [CrossRef]

- Sun, G.; Niu, J.; Wang, D.; Chen, S. Fatigue experimental analysis and numerical simulation of FSW joints for 2219 Al-Cu alloy. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 445–455. [Google Scholar] [CrossRef]

- Manson, S.S. A complex subject-some simple approximations. Exp. Mech. 1965, 5, 193–226. [Google Scholar] [CrossRef]

- Smith, K.N.; Watson, P.; Topper, T.H. A stress-strain function for the fatigue of metals. J. Mater. 1970, 5, 767–778. [Google Scholar]

- Liu, X.; Zhang, L.; Wang, L.; Wu, S.; Fang, H. Fatigue behavior and life prediction of A7N01 aluminum alloy welded join. Trans. Nonferr. Met. Soc. China 2012, 22, 2930–2936. [Google Scholar] [CrossRef]

- Zhang, Y.; Maddox, S. Fatigue life prediction for toe ground welded joints. Int. J. Fatigue 2009, 31, 1124–1136. [Google Scholar] [CrossRef]

| Chemical Composition (wt%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cu | Mn | Fe | Zn | Si | Zr | Ti | V | Al |

| 6.48 | 0.32 | 0.23 | 0.04 | 0.49 | 0.2 | 0.06 | 0.08 | balance |

| Material | Elasticity Modulus (GPa) | Ultimate Strength σu (MPa) | Yield Strength σp0.2 (MPa) |

|---|---|---|---|

| 2219-T6 | 72 | 416 | 315 |

| Cutting Cites of the Micro Specimens X (mm) | Elastic Modulus E (GPa) | Fatigue Strength Coefficient σ′f (MPa) | Fatigue Strength Exponent b | Fatigue Ductility Exponent c | Fatigue Ductility Coefficient ε′f | Cyclic Strength Coefficient K′(MPa) | Cyclic Strain Hardening Exponent n′ |

|---|---|---|---|---|---|---|---|

| −11 | 64 | 364 | −0.078 | −0.33 | 0.041 | 781 | 0.24 |

| −7 | 53 | 275 | −0.079 | −0.31 | 0.037 | 635 | 0.25 |

| −5 | 58 | 324 | −0.077 | −0.37 | 0.062 | 578 | 0.21 |

| 0 | 59 | 334 | −0.078 | −0.37 | 0.059 | 610 | 0.21 |

| 6 | 61 | 313 | −0.076 | −0.35 | 0.055 | 581 | 0.21 |

| 8 | 62 | 263 | −0.058 | −0.33 | 0.043 | 458 | 0.18 |

| 11 | 63 | 328 | −0.076 | −0.34 | 0.047 | 656 | 0.23 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, G.; Wei, X.; Niu, J.; Shang, D.; Chen, S. Influence of Residual Stress on Fatigue Weak Areas and Simulation Analysis on Fatigue Properties Based on Continuous Performance of FSW Joints. Metals 2019, 9, 284. https://doi.org/10.3390/met9030284

Sun G, Wei X, Niu J, Shang D, Chen S. Influence of Residual Stress on Fatigue Weak Areas and Simulation Analysis on Fatigue Properties Based on Continuous Performance of FSW Joints. Metals. 2019; 9(3):284. https://doi.org/10.3390/met9030284

Chicago/Turabian StyleSun, Guoqin, Xinhai Wei, Jiangpei Niu, Deguang Shang, and Shujun Chen. 2019. "Influence of Residual Stress on Fatigue Weak Areas and Simulation Analysis on Fatigue Properties Based on Continuous Performance of FSW Joints" Metals 9, no. 3: 284. https://doi.org/10.3390/met9030284

APA StyleSun, G., Wei, X., Niu, J., Shang, D., & Chen, S. (2019). Influence of Residual Stress on Fatigue Weak Areas and Simulation Analysis on Fatigue Properties Based on Continuous Performance of FSW Joints. Metals, 9(3), 284. https://doi.org/10.3390/met9030284