Characterization of Microstructural Evolution by Ultrasonic Nonlinear Parameters Adjusted by Attenuation Factor

Abstract

1. Introduction

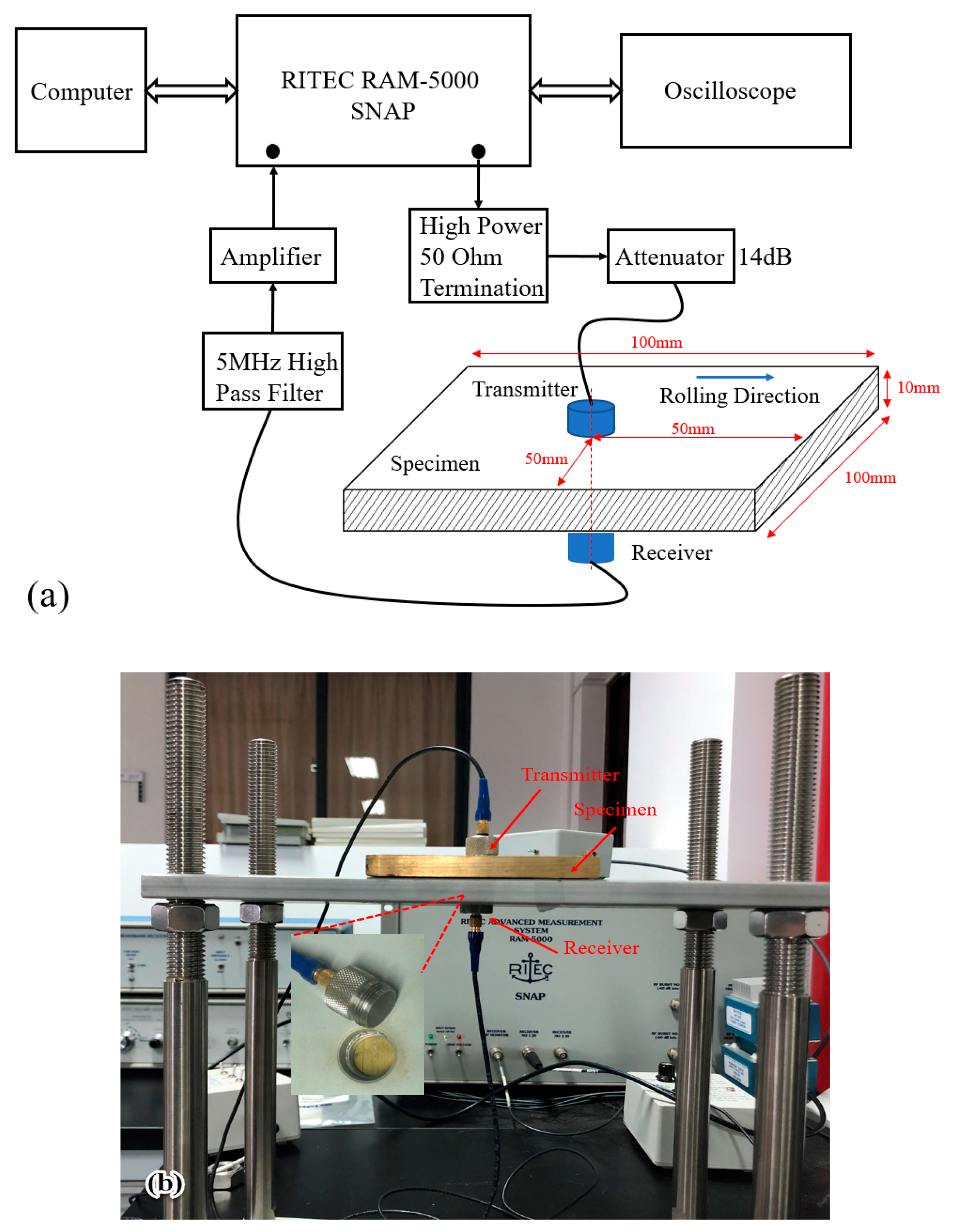

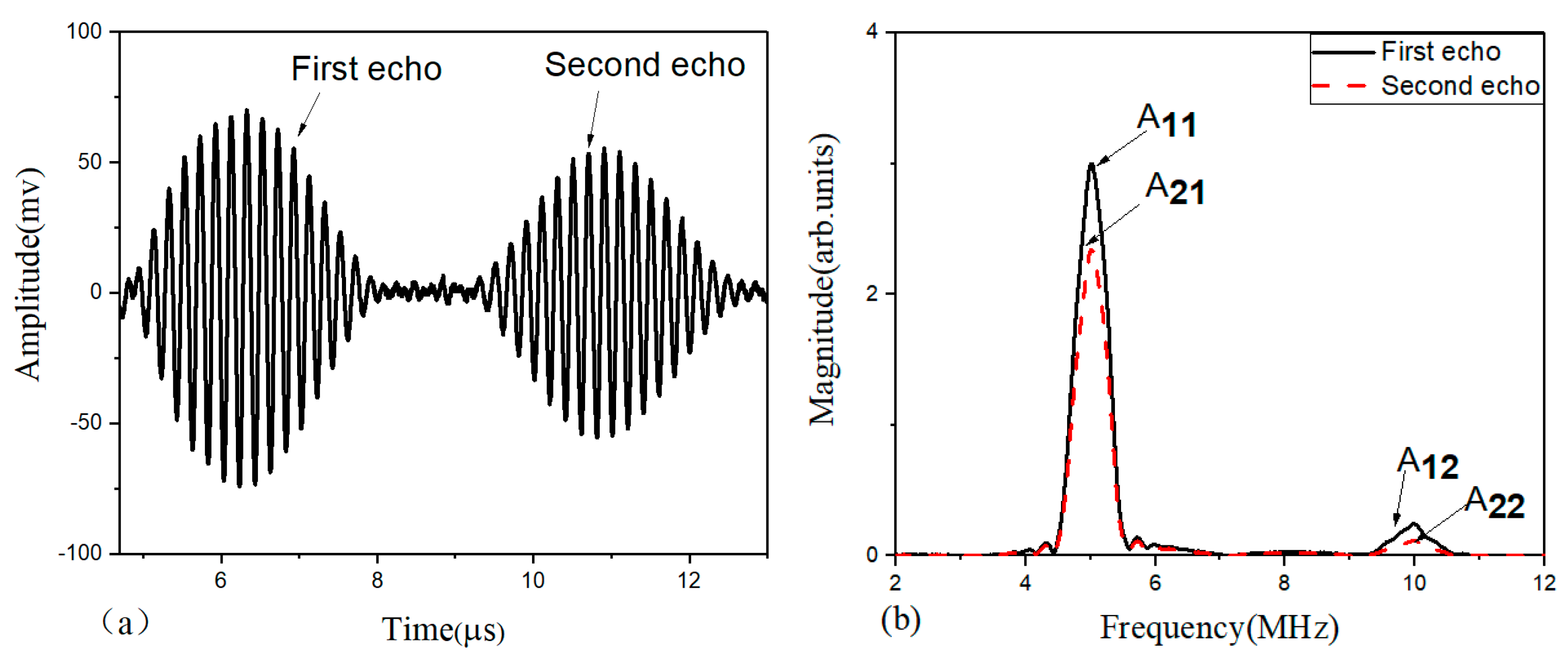

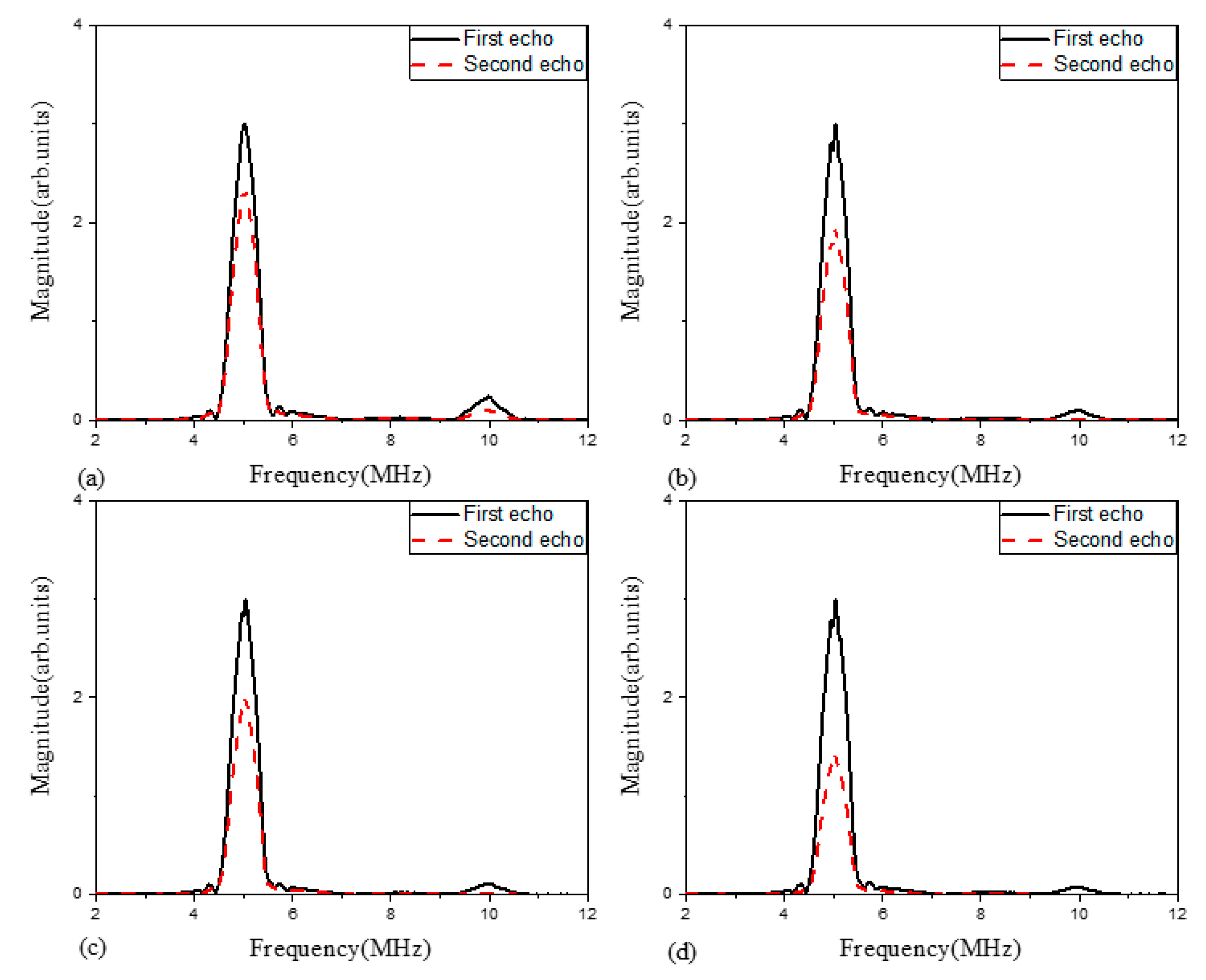

2. Nonlinear Ultrasonic Test

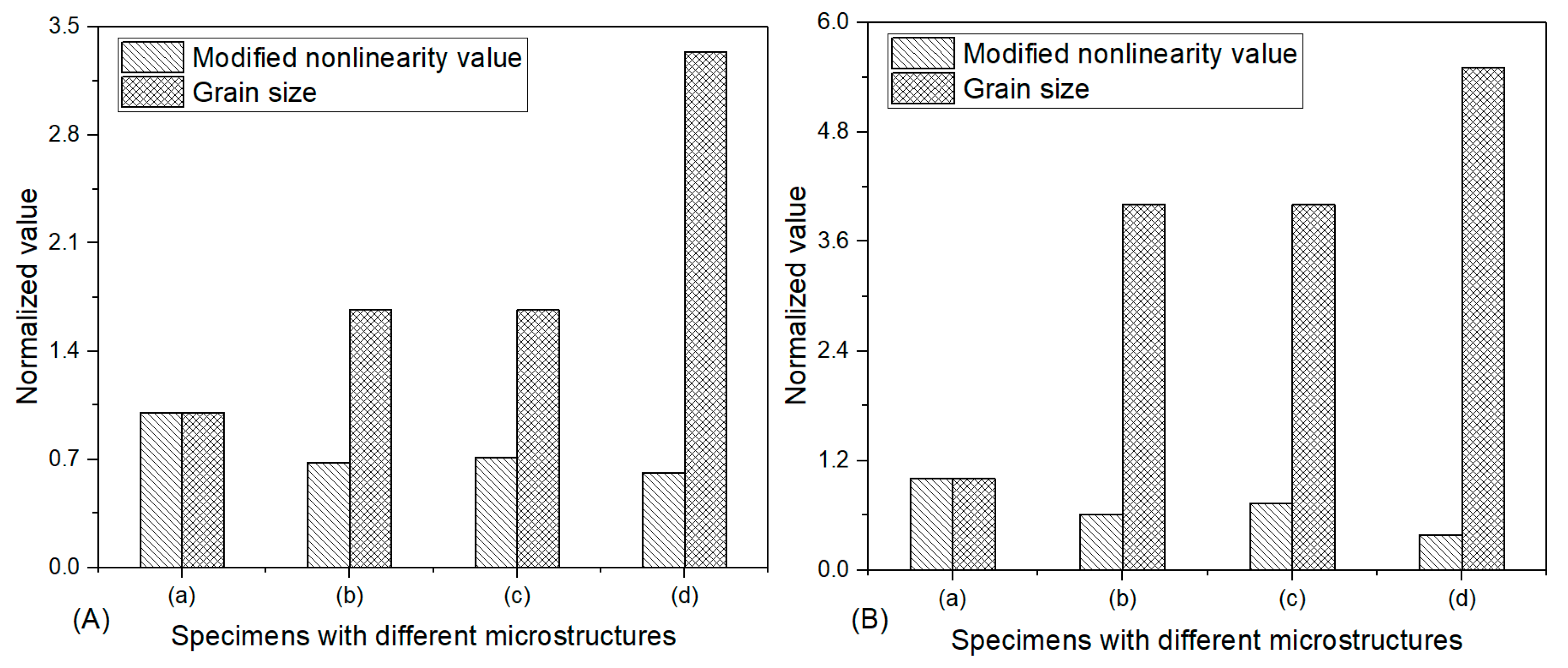

3. Nonlinearity Adjusted by Attenuation Factor

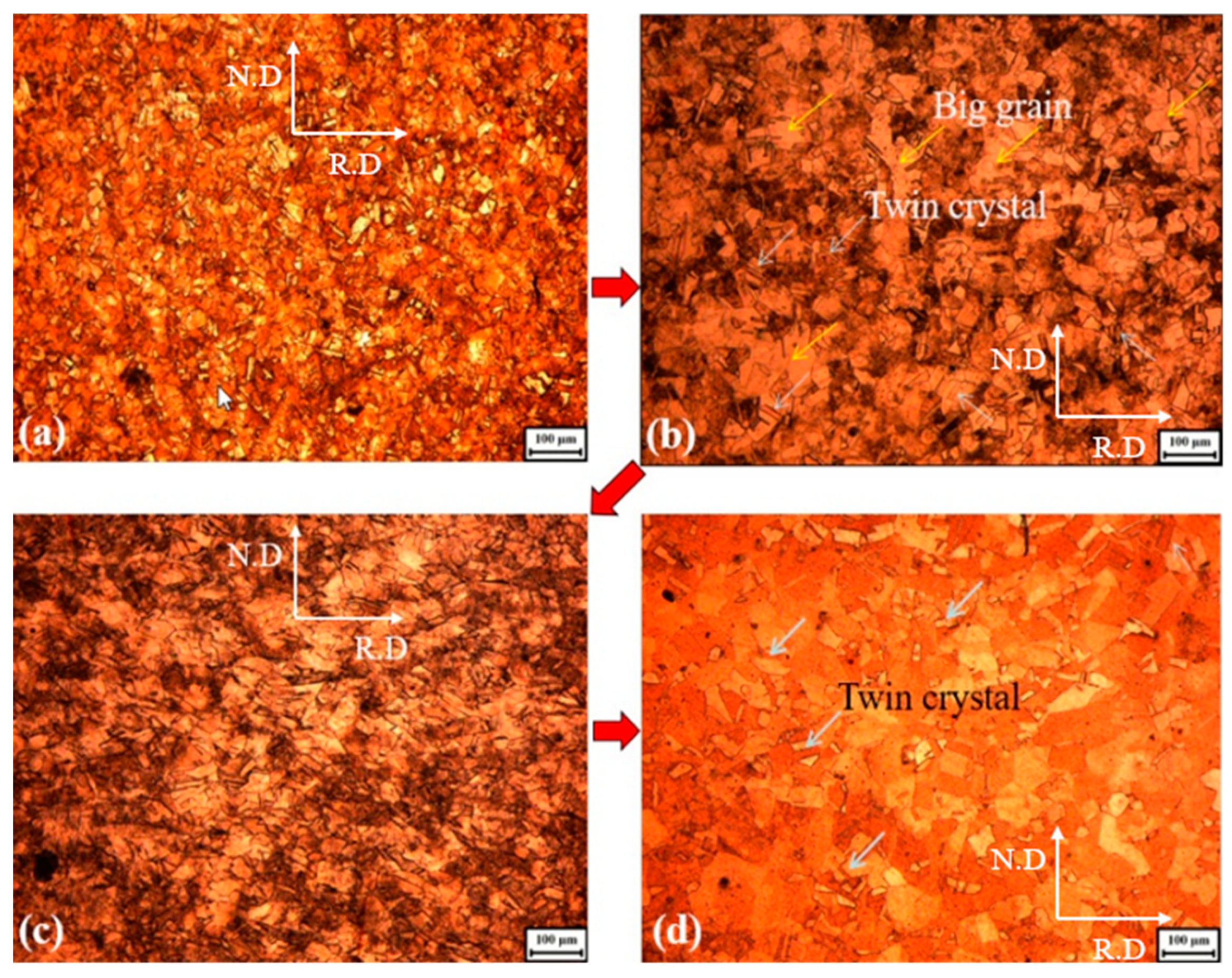

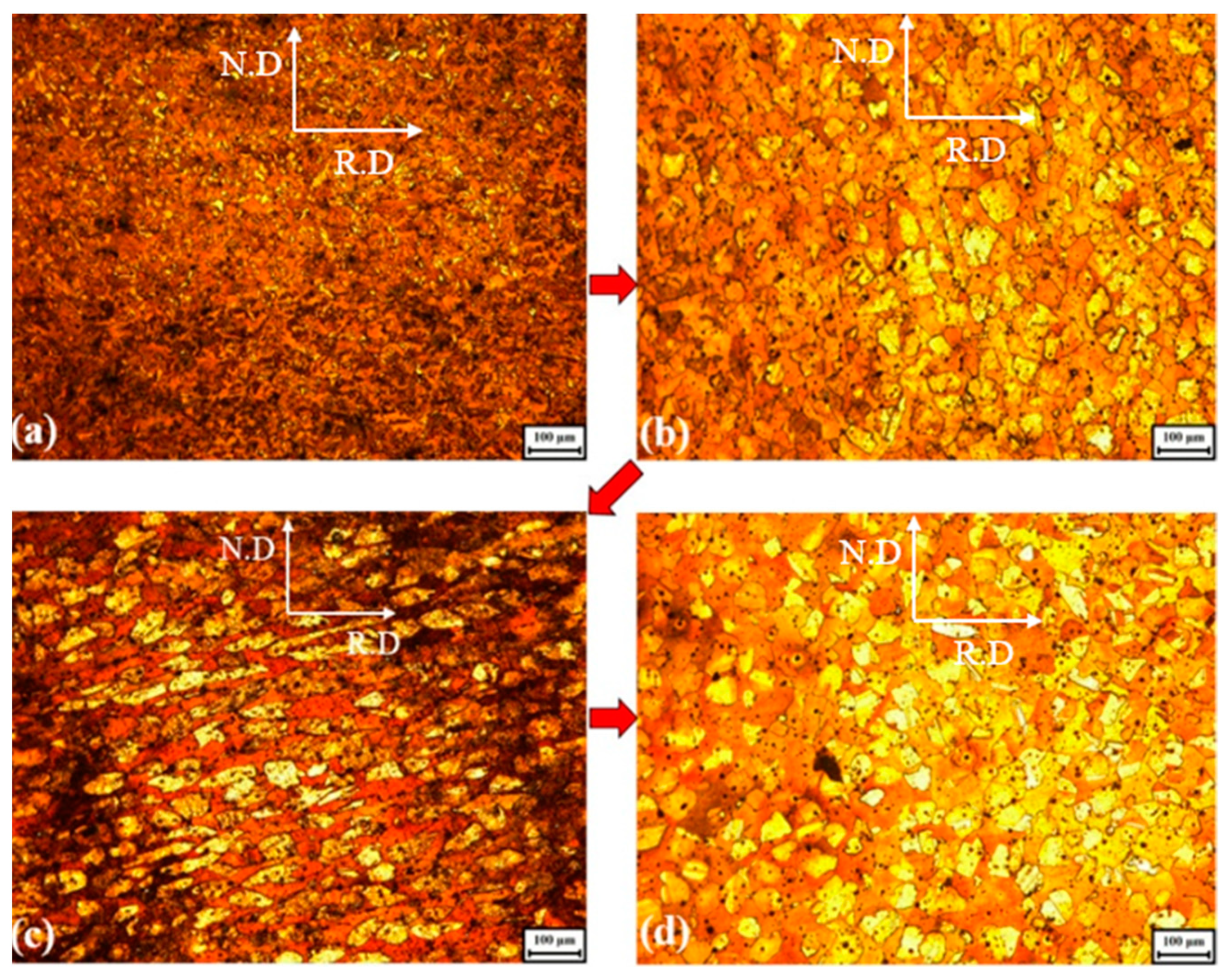

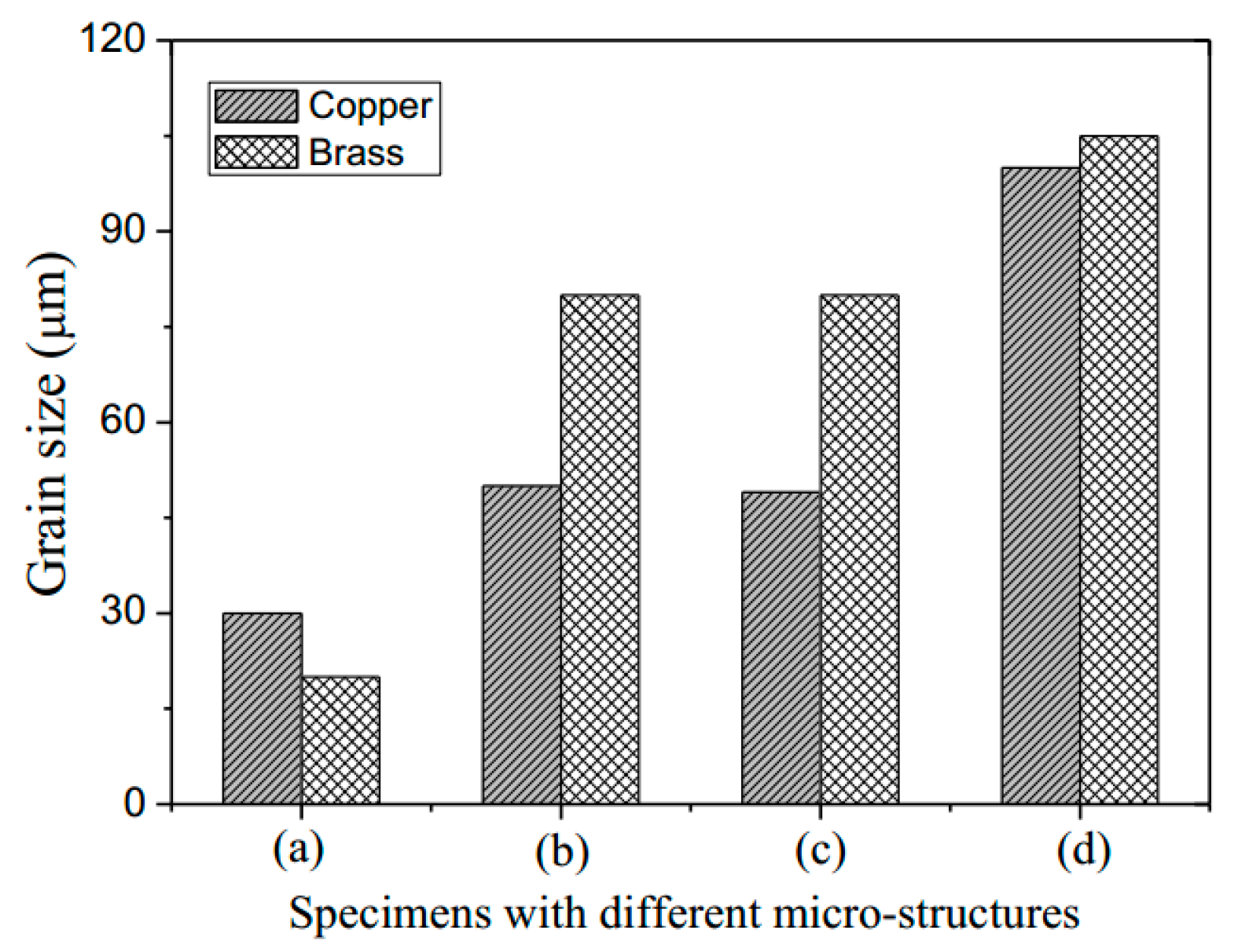

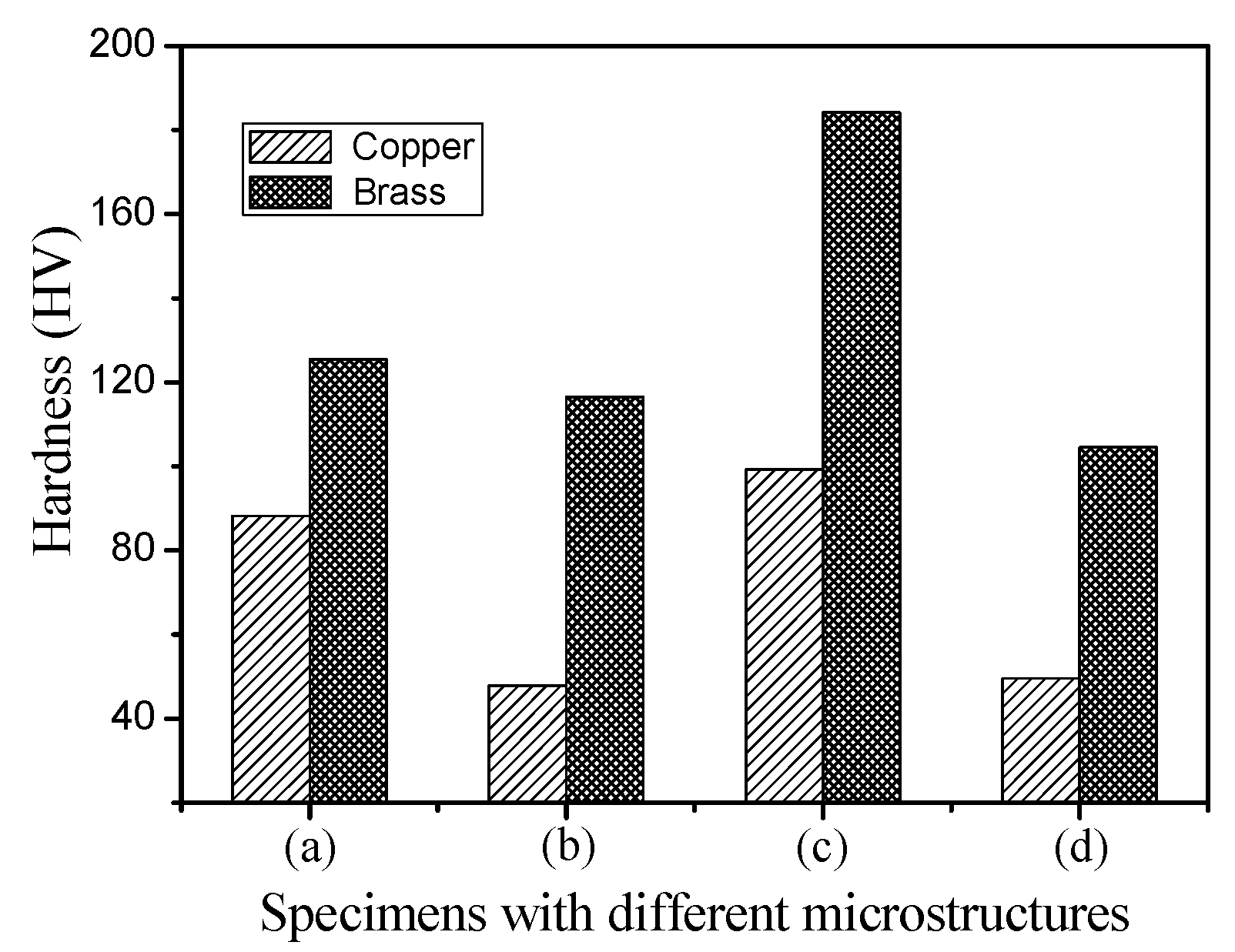

4. Experiment

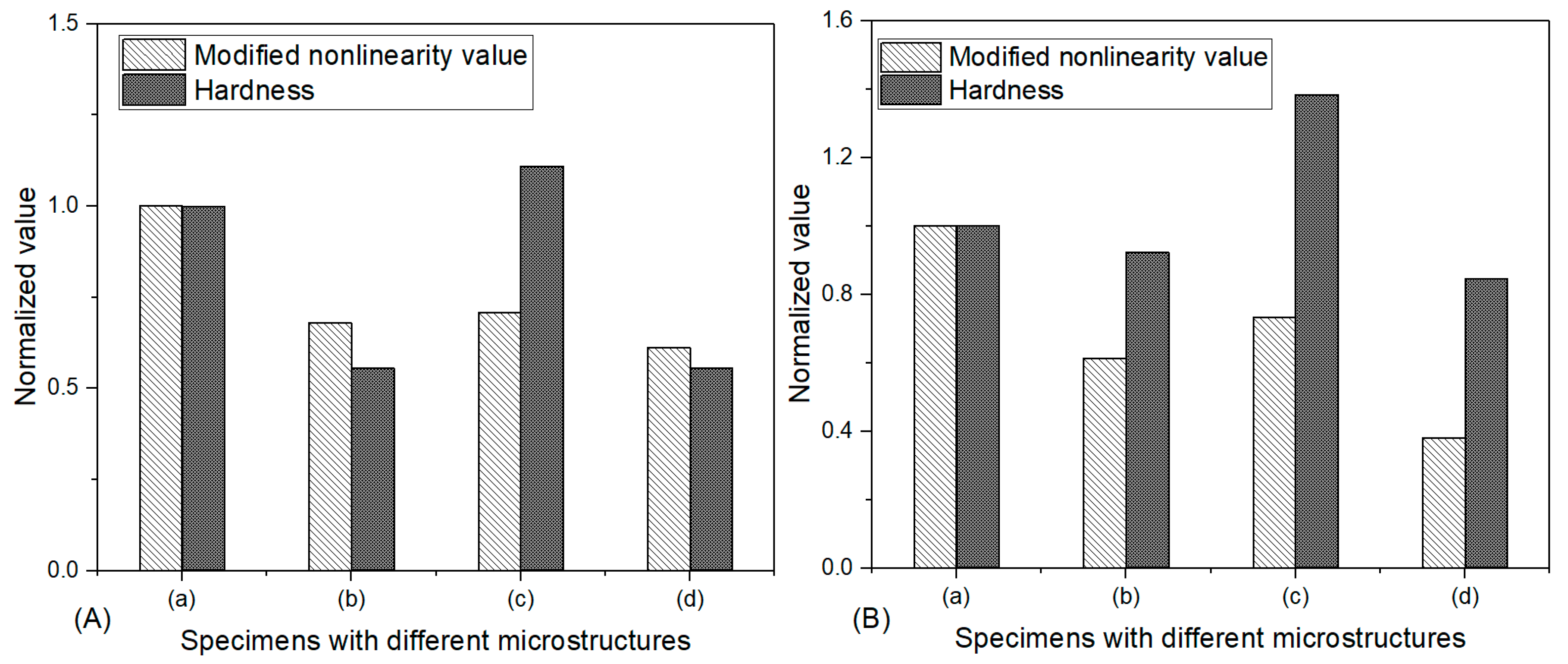

5. Results and Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cantrell, J.H.; Yost, W.T. Nonlinear ultrasonic characterization of fatigue microstructures. Int. J. Fatigue 2001, 23, 487–490. [Google Scholar] [CrossRef]

- Nagy, P.B. Fatigue damage assessment by nonlinear ultrasonic materials characterization. Ultrasonics 1998, 36, 375–381. [Google Scholar] [CrossRef]

- Xiang, Y.; Deng, M.; Xuan, F.Z. Creep damage characterization using nonlinear ultrasonic guided wave method: A mesoscale model. J. Appl. Phys. 2014, 115, 004914. [Google Scholar] [CrossRef]

- Balasubramaniam, K.; Valluri, J.S.; Prakash, R.V. Creep damage characterization using a low amplitude nonlinear ultrasonic technique. Mater. Charact. 2011, 62, 275–286. [Google Scholar] [CrossRef]

- Li, W.; Cho, Y. Thermal fatigue damage assessment in an isotropic pipe using nonlinear ultrasonic guided waves. Exp. Mech. 2014, 54, 1309–1318. [Google Scholar] [CrossRef]

- Cantrell, J.H. Dependence of microelastic-plastic nonlinearity of martensitic stainless steel on fatigue damage accumulation. J. Appl. Phys. 2006, 100, 063508. [Google Scholar] [CrossRef]

- Li, W.; Lee, J.; Cho, Y.; Achenbach, J.D. Assessment of heat treated inconel x-750 alloy by nonlinear ultrasonics. Exp. Mech. 2013, 53, 775–781. [Google Scholar] [CrossRef]

- Jhang, K.Y. Applications of nonlinear ultrasonics to the NDE of material degradation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 540–548. [Google Scholar] [CrossRef] [PubMed]

- Cantrell, J.H. Substructural organization, dislocation plasticity and harmonic generation in cyclically stressed wavy slip metals. Proc. R. Soc. London Ser. A 2004, 460, 757–780. [Google Scholar] [CrossRef]

- Cantrell, J.H. Crystalline structure and symmetry dependence of acoustic nonlinearity parameters. J. Appl. Phys. 1994, 76, 3372–3380. [Google Scholar] [CrossRef]

- Pruell, C.; Kim, J.Y.; Qu, J.; Jacobs, L.J. Evaluation of plasticity driven material damage using lamb waves. Appl. Phys. Lett. 2007, 91, 231911. [Google Scholar] [CrossRef]

- Kim, J.Y.; Jacobs, L.J.; Qu, J.; Littles, J.W. Experimental characterization of fatigue damage in a nickel-base superalloy using nonlinear ultrasonic waves. J. Acoust. Soc. Am. 2006, 120, 1266–1273. [Google Scholar] [CrossRef]

- Mini, R.S.; Balasubramaniam, K.; Ravindran, P. An experimental investigation on the influence of annealed microstructure on wave propagation. Exp. Mech. 2015, 55, 1023–1030. [Google Scholar] [CrossRef]

- Zinck, A.A.; Krishnaswamy, S. Ultrasonic nonlinearity measurements on rolled polycrystalline copper. AIP Conf. Proc. 2010, 1211, 1404–1409. [Google Scholar]

- Ogi, H.; Hirao, M.; Aoki, S. Noncontact monitoring of surface-wave nonlinearity for predicting the remaining life of fatigued steels. J. Appl. Phys. 2001, 90, 438–442. [Google Scholar] [CrossRef]

- Hurley, D.C.; Balzar, D.; Purtscher, P.T.; Hollman, K.W. Nonlinear ultrasonic parameter in quenched martensitic steels. J. Appl. Phys. 1998, 83, 4584–4588. [Google Scholar] [CrossRef]

- Barnard, D.J. Variation of nonlinearity parameter at low fundamental amplitudes. Appl. Phys. Lett. 1999, 74, 2447–2449. [Google Scholar] [CrossRef]

- Abarkane, C.; Gale-Lamuela, D.; Benavent-Climent, A.; Suarez, E.; Gallego, A. Ultrasonic pulse-echo signal analysis for damage evaluation of metallic slit-plate hysteretic dampers. Metals 2017, 7, 526. [Google Scholar] [CrossRef]

- Norris, A.N. Finite-amplitude waves in solids. In Nonlinear Acoustics; Hamilton, M.F., Blackstocks, D.T., Eds.; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Rose, J.L. Ultrasonic Waves in Solid Media; Combridge University Press: Combridge, UK, 1999. [Google Scholar]

- Liu, D.; Turner, J.A. Numerical analysis of longitudinal ultrasonic attenuation in sintered materials using a simplified two-phase model. J. Acoust. Soc. Am. 2017, 141, 1226. [Google Scholar] [CrossRef] [PubMed]

- Cantrell, J.H. Ultrasonic harmonic generation from fatigue-induced dislocation substructures in planar slip metals and assessment of remaining fatigue life. J. Appl. Phys. 2009, 106, 093516. [Google Scholar] [CrossRef]

- Hurley, D.C.; Balzar, D.; Purtscher, P.T. Nonlinear ultrasonic assessment of precipitation hardening in ASTM A710 steel. J. Mater. Res. 2000, 15, 2036–2042. [Google Scholar] [CrossRef]

- ASTM E112-13, Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2013; Available online: http://www.astm.org/cgi-bin/resolver.cgi?E112-13 (accessed on 21 February 2019).

- GB/T6394-2017, Determination of estimating the average grain size of metal (In Chinese); Standardization Administration of China: Beijing, China, 2017; Available online: http://www.gb688.cn/bzgk/gb/newGbInfo?hcno=B83409D8E921097A674E11ED5A66BB06 (accessed on 21 February 2019).

| Cu | O | Pb | S | Bi |

|---|---|---|---|---|

| 99.7 | 0.1 | 0.01 | 0.01 | 0.002 |

| Cu | Zn | Fe | Pb | P | Sb | Bi |

|---|---|---|---|---|---|---|

| 63.5 | 36 | 0.15 | 0.08 | 0.01 | 0.005 | 0.002 |

| Specimens (Copper) | (db/cm) | (db/cm) | (10−2) | (10−2) | (10−2) | |

|---|---|---|---|---|---|---|

| (a) | 0.0124 | 0.1476 | 1.12 | 3.6 | 4.032 | 0.132 |

| (b) | 0.0215 | 0.3792 | 1.37 | 2.0 | 2.74 | 0.23 |

| (c) | 0.0205 | 0.3697 | 1.36 | 2.1 | 2.856 | 0.236 |

| (d) | 0.0374 | 0.7643 | 1.54 | 1.6 | 2.464 | 0.214 |

| Specimens (Brass) | (db/cm) | (db/cm) | (10−2) | (10−2) | (10−2) | |

|---|---|---|---|---|---|---|

| (a) | 0.0232 | 0.3513 | 1.33 | 4.8 | 6.384 | 0.704 |

| (b) | 0.0337 | 0.6018 | 1.63 | 2.4 | 3.912 | 0.712 |

| (c) | 0.0316 | 0.5874 | 1.61 | 2.9 | 4.669 | 0.559 |

| (d) | 0.0446 | 0.8019 | 1.87 | 1.3 | 2.431 | 0.201 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Chen, B.; Qing, X.; Cho, Y. Characterization of Microstructural Evolution by Ultrasonic Nonlinear Parameters Adjusted by Attenuation Factor. Metals 2019, 9, 271. https://doi.org/10.3390/met9030271

Li W, Chen B, Qing X, Cho Y. Characterization of Microstructural Evolution by Ultrasonic Nonlinear Parameters Adjusted by Attenuation Factor. Metals. 2019; 9(3):271. https://doi.org/10.3390/met9030271

Chicago/Turabian StyleLi, Weibin, Bingyao Chen, Xinlin Qing, and Younho Cho. 2019. "Characterization of Microstructural Evolution by Ultrasonic Nonlinear Parameters Adjusted by Attenuation Factor" Metals 9, no. 3: 271. https://doi.org/10.3390/met9030271

APA StyleLi, W., Chen, B., Qing, X., & Cho, Y. (2019). Characterization of Microstructural Evolution by Ultrasonic Nonlinear Parameters Adjusted by Attenuation Factor. Metals, 9(3), 271. https://doi.org/10.3390/met9030271