Intermetallic Phases in High-Entropy Alloys: Statistical Analysis of their Prevalence and Structural Inheritance

Abstract

1. Introduction

2. Construction of the Alloy Database

3. Results and Discussion

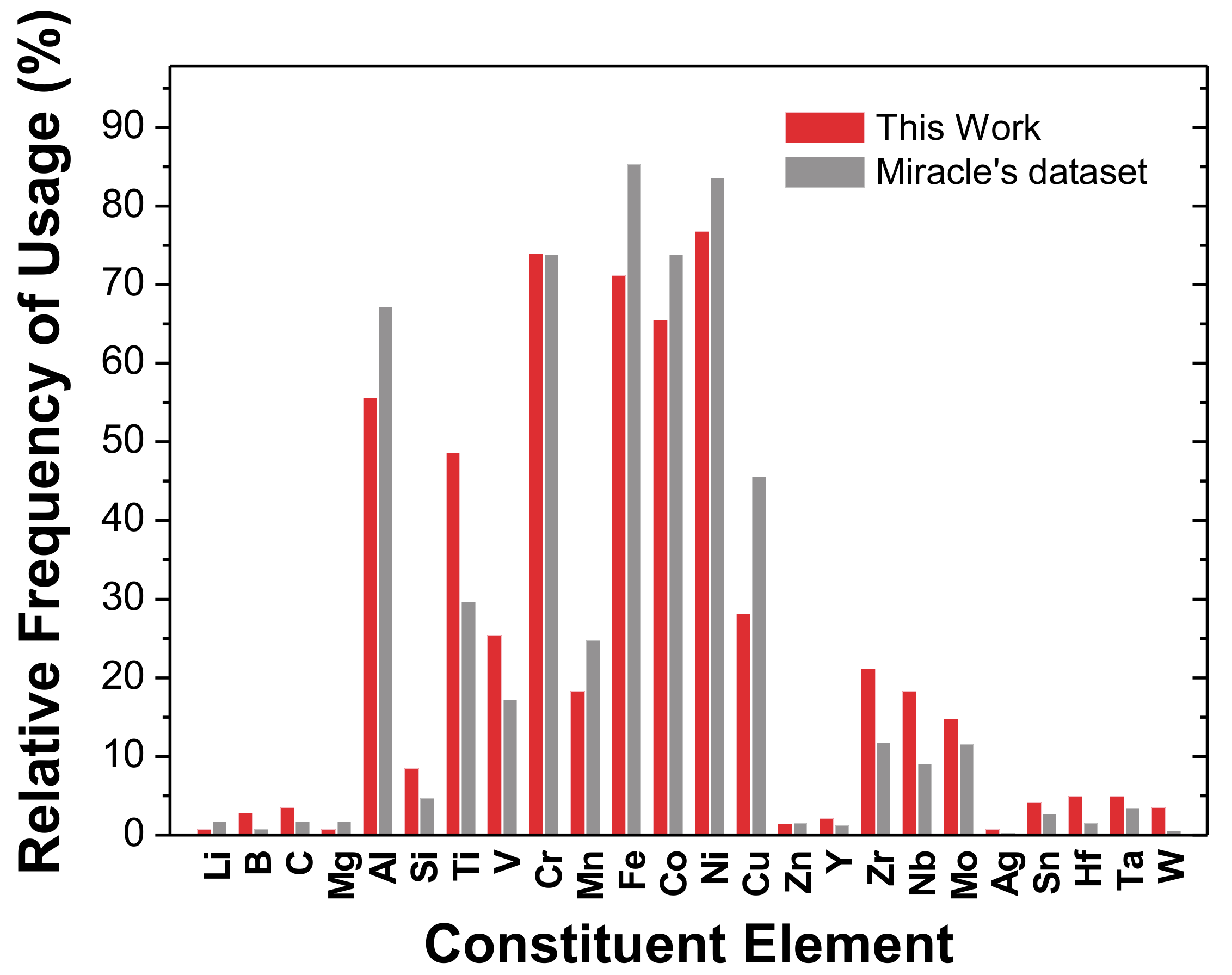

3.1. Characterization of the Database

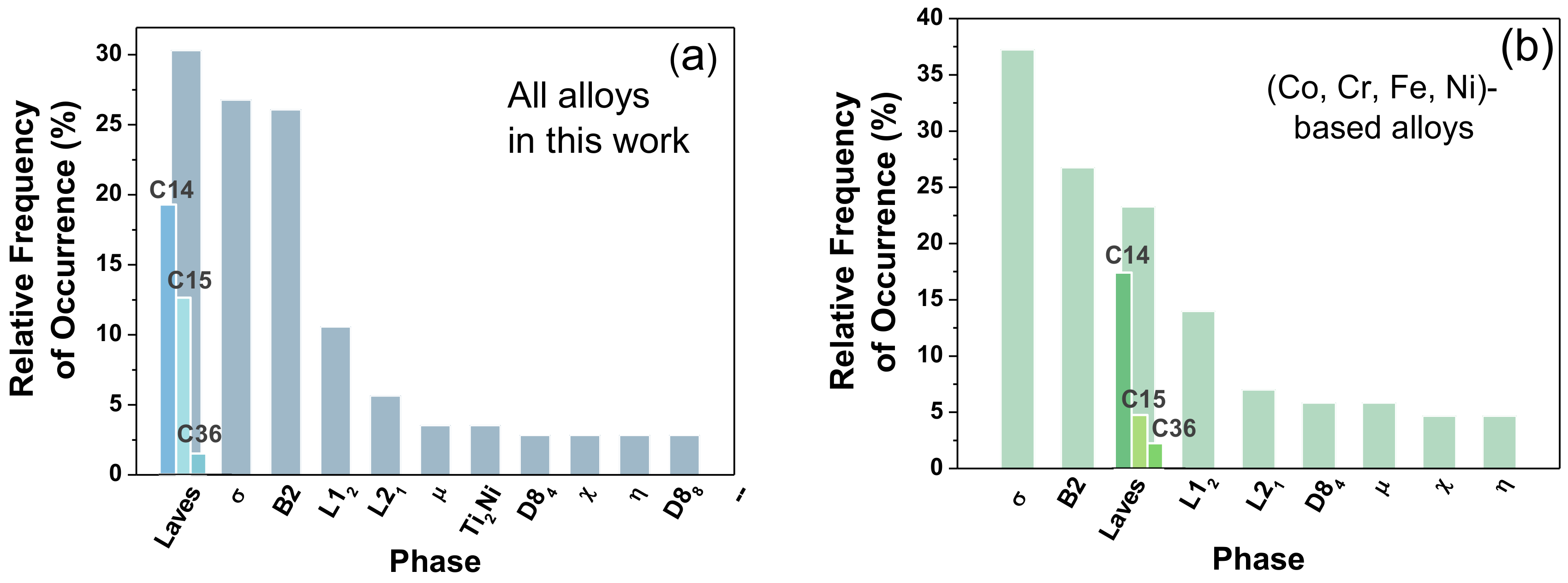

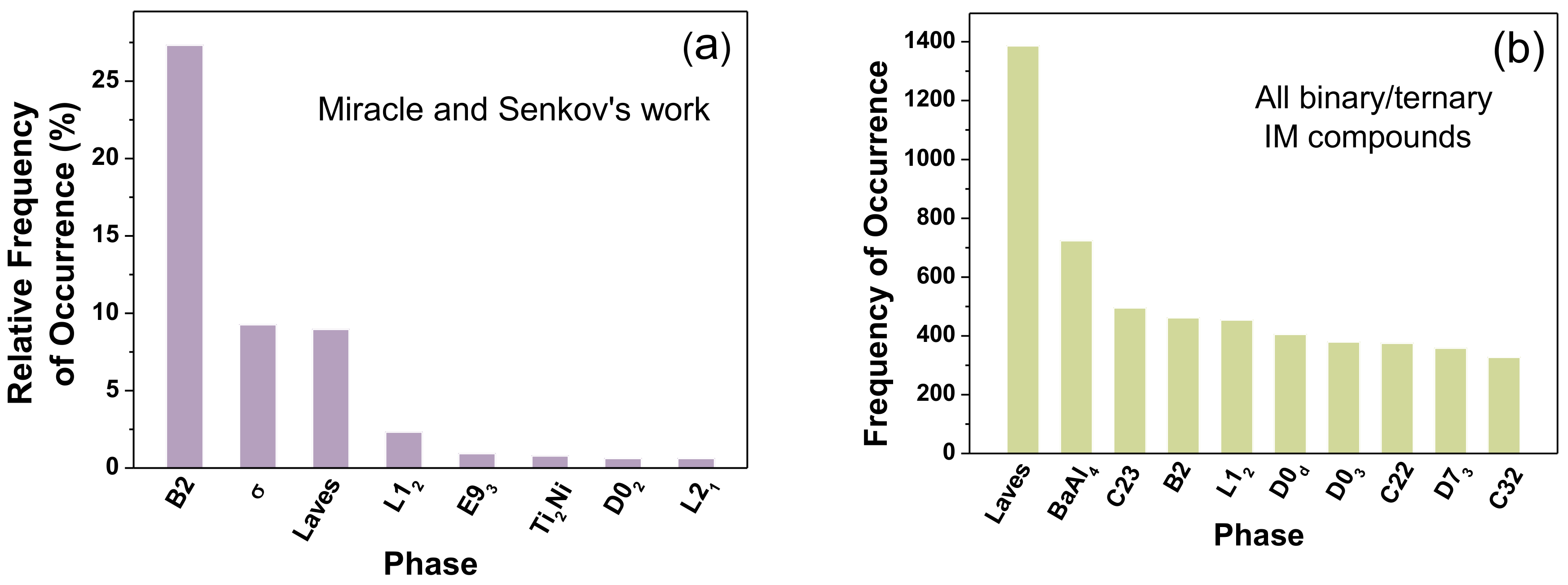

3.2. The Most Prevalent IM Structures

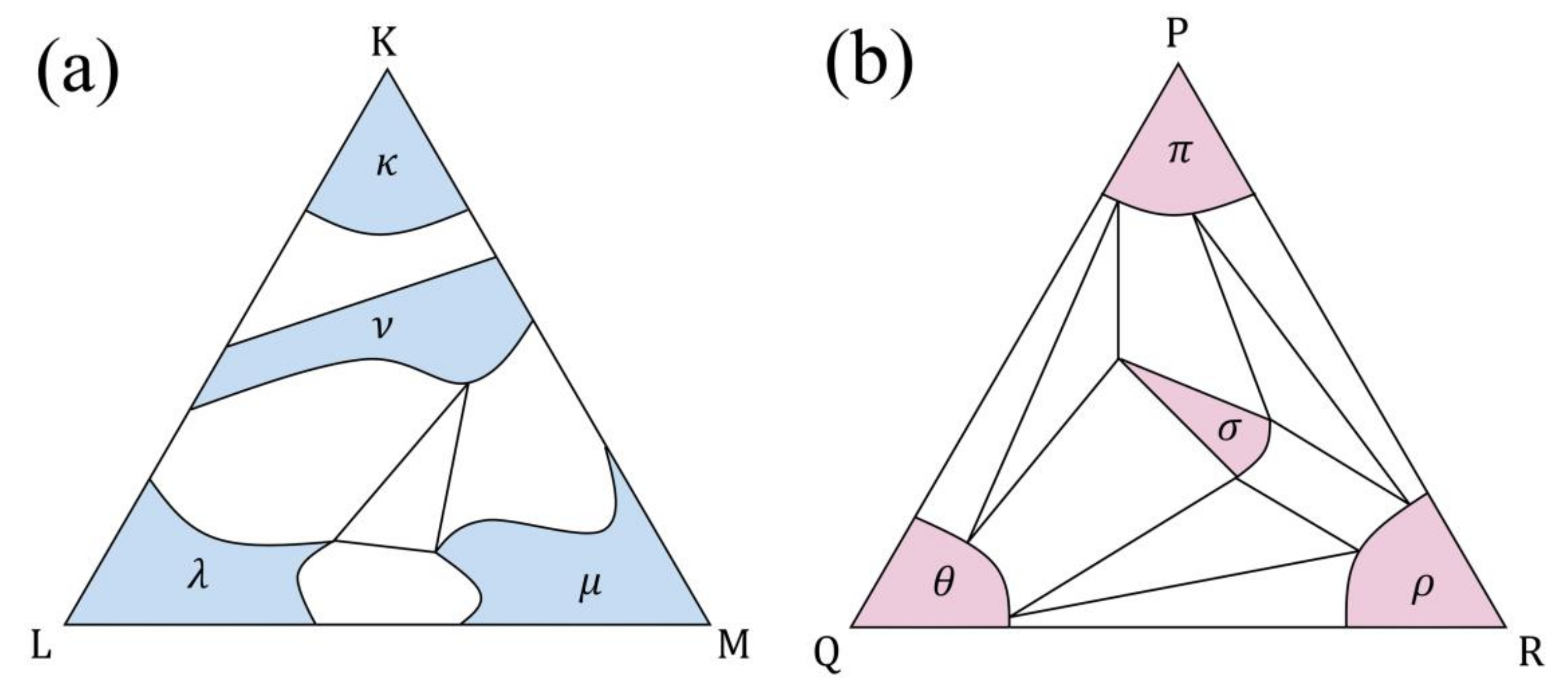

3.3. Structure Inheritance in HEAs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Guo, S.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef]

- Guo, S. Phase selection rules for cast high entropy alloys: An overview. Mater. Sci. Technol. 2015, 31, 1223–1230. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Zaddach, A.J.; Niu, C.; Koch, C.C.; Irving, D.L. Mechanical Properties and Stacking Fault Energies of NiFeCrCoMn High-Entropy Alloy. JOM 2013, 65, 1780–1789. [Google Scholar] [CrossRef]

- Liu, W.H.; Wu, Y.; He, J.Y.; Nieh, T.G.; Lu, Z.P. Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Laplanche, G.; Gadaud, P.; Horst, O.; Otto, F.; Eggeler, G.; George, E.P. Temperature dependencies of the elastic moduli and thermal expansion coefficient of an equiatomic, single-phase CoCrFeMnNi high-entropy alloy. J. Alloys Compd. 2015, 623, 348–353. [Google Scholar] [CrossRef]

- Laplanche, G.; Bonneville, J.; Varvenne, C.; Curtin, W.A.; George, E.P. Thermal activation parameters of plastic flow reveal deformation mechanisms in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 143, 257–264. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Stocks, G.M.; Jin, K.; Lu, C.; Bei, H.; Sales, B.C.; Wang, L.; Beland, L.K.; Stoller, R.E.; Samolyuk, G.D.; et al. Influence of chemical disorder on energy dissipation and defect evolution in concentrated solid solution alloys. Nat. Commun. 2015, 6, 8376. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Mao, M.M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 10143. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Ma, H.; Spolenak, R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat. Commun. 2015, 6, 7748. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Gludovatz, B.; George, E.P.; Ritchie, R.O. Processing, Microstructure and Mechanical Properties of the CrMnFeCoNi High-Entropy Alloy. JOM 2015, 67, 2262–2270. [Google Scholar] [CrossRef]

- Miracle, D.; Miller, J.; Senkov, O.; Woodward, C.; Uchic, M.; Tiley, J. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Lu, Z.P.; Wang, H.; Chen, M.W.; Baker, I.; Yeh, J.W.; Liu, C.T.; Nieh, T.G. An assessment on the future development of high-entropy alloys: Summary from a recent workshop. Intermetallics 2015, 66, 67–76. [Google Scholar] [CrossRef]

- Tsai, M.H. Three Strategies for the Design of Advanced High-Entropy Alloys. Entropy 2016, 18, 252. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Tsai, C.W.; Yang, N.H.; Chang, S.Y.; Yeh, J.W.; Chen, S.K.; Lin, S.J. Intrinsic surface hardening and precipitation kinetics of Al0.3CrFe1.5MnNi0.5 multi-component alloy. J. Alloys Compd. 2013, 551, 12–18. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Liu, W.H.; Lu, Z.P.; He, J.Y.; Luan, J.H.; Wang, Z.J.; Liu, B.; Liu, Y.; Chen, M.W.; Liu, C.T. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016, 116, 332–342. [Google Scholar] [CrossRef]

- Wani, I.S.; Bhattacharjee, T.; Sheikh, S.; Lu, Y.P.; Chatterjee, S.; Bhattacharjee, P.P.; Guo, S.; Tsuji, N. Ultrafine-grained AlCoCrFeNi2.1 eutectic high-entropy alloy. Mater. Res. Lett. 2016, 4, 174–179. [Google Scholar] [CrossRef]

- Ming, K.S.; Bi, X.F.; Wang, J. Precipitation strengthening of ductile Cr15Fe20Co35Ni20Mo10 alloys. Scr. Mater. 2017, 137, 88–93. [Google Scholar] [CrossRef]

- Troparevsky, M.C.; Morris, J.R.; Kent, P.R.C.; Lupini, A.R.; Stocks, G.M. Criteria for Predicting the Formation of Single-Phase High-Entropy Alloys. Phys. Rev. X 2015, 5, 011041. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B. A new thermodynamic parameter to predict formation of solid solution or intermetallic phases in high entropy alloys. J. Alloys Compd. 2016, 658, 603–607. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. Design of high entropy alloys: A single-parameter thermodynamic rule. Scr. Mater. 2015, 104, 53–55. [Google Scholar] [CrossRef]

- Tsai, M.H.; Li, J.H.; Fan, A.C.; Tsai, P.H. Incorrect predictions of simple solid solution high entropy alloys: Cause and possible solution. Scr. Mater. 2017, 127, 6–9. [Google Scholar] [CrossRef]

- Tsai, M.H.; Fan, A.C.; Wang, H.A. Effect of atomic size difference on the type of major intermetallic phase in arc-melted CoCrFeNiX high-entropy alloys. J. Alloys Compd. 2017, 695, 1479–1487. [Google Scholar] [CrossRef]

- Tsai, M.H.; Tsai, K.Y.; Tsai, C.W.; Lee, C.; Juan, C.C.; Yeh, J.W. Criterion for sigma phase formation in Cr- and V-containing high-entropy alloys. Mater. Res. Lett. 2013, 1, 207–212. [Google Scholar] [CrossRef]

- Tsai, M.H.; Chang, K.C.; Li, J.H.; Tsai, R.C.; Cheng, A.H. A second criterion for sigma phase formation in high-entropy alloys. Mater. Res. Lett. 2016, 4, 90–95. [Google Scholar] [CrossRef]

- Yurchenko, N.; Stepanov, N.; Salishchev, G. Laves-phase formation criterion for high-entropy alloys. J. Energy Mater. 2016, 11, 17–22. [Google Scholar] [CrossRef]

- Villars, P.; Calvert, L.D. (Eds.) Pearson’s Handbook of Crystallographic Data for Intermetallic Phases, 2nd ed.; ASM International: Materials Park, OH, USA, 1991. [Google Scholar]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Ferro, P.; Saccone, A. Structure of Intermetallic Compounds and Phases. In Physical Metallurgy, 4th ed.; Cahn, R.W., Haasen, P., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1996; Volume 1, pp. 206–369. [Google Scholar]

- Villars, P.; Prince, A.; Okamoto, H. Handbook of Ternary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1995; Volume 3. [Google Scholar]

- Baker, H. (Ed.) ASM Handbook: Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1992. [Google Scholar]

- Villars, P.; Cenzual, K.; Gladyshevskii, R. Handbook of Inorganic Substances 2015; De Gruyter: Berlin, Germany, 2015. [Google Scholar]

- Zhou, Y.; Zhang, Y.; Wang, Y.; Chen, G. Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 181904. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, S.; Zhang, C.; Zhang, H.; Dong, S. Phase evolution and cavitation erosion-corrosion behavior of FeCoCrAlNiTix high entropy alloy coatings on 304 stainless steel by laser surface alloying. J. Alloys Compd. 2017, 698, 761–770. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Choudhuri, D.; Lee, M.; Hwang, J.; Nam, S.; Ryu, H.; Hong, S.; Banerjee, R. Stability of ordered L12 and B2 precipitates in face centered cubic based high entropy alloys-Al0.3CoFeCrNi and Al0.3CuFeCrNi2. Scr. Mater. 2016, 123, 130–134. [Google Scholar] [CrossRef]

- Hsu, U.S.; Hung, U.D.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Yang, C.C. Alloying behavior of iron, gold and silver in AlCoCrCuNi-based equimolar high-entropy alloys. Mater. Sci. Eng. A 2007, 460, 403–408. [Google Scholar] [CrossRef]

- Lee, C.; Chen, Y.; Hsu, C.; Yeh, J.; Shih, H. Effect of Boron on the Corrosion Properties of Al0.5CoCrCuFeNiBx High Entropy Alloys in 1N Sulfuric Acid. In Proceedings of the 209th Electrochemical Society (ECS) Meeting, Denver, CO, USA, 7–12 May 2006. [Google Scholar]

- Zhang, H.; He, Y.; Pan, Y. Enhanced hardness and fracture toughness of the laser-solidified FeCoNiCrCuTiMoAlSiB0.5 high-entropy alloy by martensite strengthening. Scr. Mater. 2013, 69, 342–345. [Google Scholar] [CrossRef]

- Shun, T.-T.; Du, Y.-C. Age hardening of the Al0.3CoCrFeNiC0.1 high entropy alloy. J. Alloys Compd. 2009, 478, 269–272. [Google Scholar] [CrossRef]

- Fang, S.; Chen, W.; Fu, Z. Microstructure and mechanical properties of twinned Al0.5CrFeNiCo0.3C0.2 high entropy alloy processed by mechanical alloying and spark plasma sintering. Mater. Des. (1980-2015) 2014, 54, 973–979. [Google Scholar] [CrossRef]

- Praveen, S.; Murty, B.S.; Kottada, R.S. Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A 2012, 534, 83–89. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Zhang, Y.; Wang, Y.L.; Chen, G.L. Microstructure and compressive properties of multicomponent Alx(TiVCrMnFeCoNiCu)100−x high-entropy alloys. Mater. Sci. Eng. A 2007, 454–455, 260–265. [Google Scholar] [CrossRef]

- Yuhu, F.; Yunpeng, Z.; Hongyan, G.; Huimin, S.; Li, H. AlNiCrFexMo0.2CoCu High Entropy Alloys Prepared by Powder Metallurgy. Rare Met. Mater. Eng. 2013, 42, 1127–1129. [Google Scholar] [CrossRef]

- Manzoni, A.M.; Daoud, H.M.; Voelkl, R.; Glatzel, U.; Wanderka, N. Influence of W, Mo and Ti trace elements on the phase separation in Al8Co17Cr17Cu8Fe17Ni33 based high entropy alloy. Ultramicroscopy 2015, 159 Pt 2, 265–271. [Google Scholar] [CrossRef]

- Ng, C.; Guo, S.; Luan, J.; Shi, S.; Liu, C.T. Entropy-driven phase stability and slow diffusion kinetics in an Al0.5CoCrCuFeNi high entropy alloy. Intermetallics 2012, 31, 165–172. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Jensen, J.; Welk, B.; Williams, R.; Sosa, J.; Huber, D.; Senkov, O.; Viswanathan, G.; Fraser, H. Characterization of the microstructure of the compositionally complex alloy Al1Mo0.5Nb1Ta0.5Ti1Zr1. Scr. Mater. 2016, 121, 1–4. [Google Scholar] [CrossRef]

- Chen, M.-R.; Lin, S.-J.; Yeh, J.-W.; Chen, S.-K.; Huang, Y.-S.; Tu, C.-P. Microstructure and Properties of Al0.5CoCrCuFeNiTix (x = 0-2.0) High-Entropy Alloys. Jpn. Inst. Met. 2006, 47, 1395–1401. [Google Scholar]

- Chen, M.-R.; Lin, S.-J.; Yeh, J.-W.; Chuang, M.-H.; Chen, S.-K.; Huang, Y.-S. Effect of vanadium addition on the microstructure, hardness, and wear resistance of Al0.5CoCrCuFeNi high-entropy alloy. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2006, 37, 1363–1369. [Google Scholar] [CrossRef]

- Young, K.; Ouchi, T.; Huang, B.; Reichman, B.; Fetcenko, M.A. Studies of copper as a modifier in C14-predominant AB2 metal hydride alloys. J. Power Sources 2012, 204, 205–212. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Yue, H.; Shi, G.; Wang, S. Microstructure, thermodynamics and compressive properties of AlCoCrCuMn-x (x=Fe, Ti) high-entropy alloys. Mater. Sci. Eng. A 2015, 627, 391–398. [Google Scholar] [CrossRef]

- Yeh, J.W.; Lin, S.J.; Chin, T.S.; Gan, J.Y.; Chen, S.K.; Shun, T.T.; Tsau, C.H.; Chou, S.Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Hu, Z.; Zhan, Y.; Zhang, G.; She, J.; Li, C. Effect of rare earth Y addition on the microstructure and mechanical properties of high entropy AlCoCrCuNiTi alloys. Mater. Des. 2010, 31, 1599–1602. [Google Scholar] [CrossRef]

- Juan, C.C.; Hsu, C.Y.; Tsai, C.W.; Wang, W.R.; Sheu, T.S.; Yeh, J.W.; Chen, S.K. On microstructure and mechanical performance of AlCoCrFeMo0.5Nix high-entropy alloys. Intermetallics 2013, 32, 401–407. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 2012, 532, 480–486. [Google Scholar] [CrossRef]

- Zhang, H.; He, Y.-Z.; Pan, Y.; Pei, L.-Z. Phase selection, microstructure and properties of laser rapidly solidified FeCoNiCrAl2Si coating. Intermetallics 2011, 19, 1130–1135. [Google Scholar] [CrossRef]

- Wang, L.; Chen, C.; Yeh, J.; Ke, S. The microstructure and strengthening mechanism of thermal spray coating NixCo0.6Fe0.2CrySizAlTi0.2 high-entropy alloys. Mater. Chem. Phys. 2011, 126, 880–885. [Google Scholar] [CrossRef]

- Lee, C.-F.; Shun, T.-T. Effect of Fe content on microstructure and mechanical properties of Al0.5CoCrFexNiTi0.5 high-entropy alloys. Mater. Charact. 2016, 114, 179–184. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, Z.; Zhang, J.; Wang, W.; Wang, H.; Wang, Y.; Zhang, Q.; Shi, J. Microstructure and mechanical properties of CoCrFeNiTiAlx high-entropy alloys. Mater. Sci. Eng. A 2009, 508, 214–219. [Google Scholar] [CrossRef]

- Chen, J.; Niu, P.; Liu, Y.; Lu, Y.; Wang, X.; Peng, Y.; Liu, J. Effect of Zr content on microstructure and mechanical properties of AlCoCrFeNi high entropy alloy. Mater. Des. 2016, 94, 39–44. [Google Scholar] [CrossRef]

- Lee, C.-F.; Shun, T.-T. Age hardening of the Al0.5CoCrNiTi0.5 high-entropy alloy. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2014, 45, 191–195. [Google Scholar] [CrossRef]

- Liu, L.; He, L.; Qi, J.; Wang, B.; Zhao, Z.; Shang, J.; Zhang, Y. Effects of Sn element on microstructure and properties of SnxAl2.5FeCoNiCu multi-component alloys. J. Alloys Compd. 2016, 654, 327–332. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.; Hou, C.; Li, J.; Jiang, Q. Dense and smooth amorphous films of multicomponent FeCoNiCuVZrAl high-entropy alloy deposited by direct current magnetron sputtering. Mater. Des. 2013, 46, 675–679. [Google Scholar] [CrossRef]

- Zhuang, Y.; Liu, W.; Chen, Z.; Xue, H.; He, J. Effect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys. Mater. Sci. Eng. A 2012, 556, 395–399. [Google Scholar] [CrossRef]

- Mohanty, S.; Gurao, N.; Biswas, K. Sinter ageing of equiatomic Al20Co20Cu20Zn20Ni20 high entropy alloy via mechanical alloying. Mater. Sci. Eng. A 2014, 617, 211–218. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Juan, C.-C.; Wang, W.-R.; Sheu, T.-S.; Yeh, J.-W.; Chen, S.-K. On the superior hot hardness and softening resistance of AlCoCrxFeMo0.5 Ni high-entropy alloys. Mater. Sci. Eng. A 2011, 528, 3581–3588. [Google Scholar] [CrossRef]

- Butler, T.; Alfano, J.; Martens, R.; Weaver, M. High-temperature oxidation behavior of Al-Co-Cr-Ni-(Fe or Si) multicomponent high-entropy alloys. JOM 2015, 67, 246–259. [Google Scholar] [CrossRef]

- Maulik, O.; Kumar, D.; Kumar, S.; Fabijanic, D.M.; Kumar, V. Structural evolution of spark plasma sintered AlFeCuCrMgx (x= 0, 0.5, 1, 1.7) high entropy alloys. Intermetallics 2016, 77, 46–56. [Google Scholar] [CrossRef]

- Khanchandani, H.; Sharma, P.; Kumar, R.; Maulik, O.; Kumar, V. Effect of sintering on phase evolution in AlMgFeCuCrNi4.75 high entropy alloy. Adv. Powder Technol. 2016, 27, 289–294. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Liu, C.T. Anomalous solidification microstructures in Co-free AlxCrCuFeNi2 high-entropy alloys. J. Alloys Compd. 2013, 557, 77–81. [Google Scholar] [CrossRef]

- Choudhuri, D.; Gwalani, B.; Gorsse, S.; Mikler, C.; Ramanujan, R.; Gibson, M.; Banerjee, R. Change in the primary solidification phase from fcc to bcc-based B2 in high entropy or complex concentrated alloys. Scr. Mater. 2017, 127, 186–190. [Google Scholar] [CrossRef]

- Pi, J.-H.; Pan, Y.; Zhang, L.; Zhang, H. Microstructure and property of AlTiCrFeNiCu high-entropy alloy. J. Alloys Compd. 2011, 509, 5641–5645. [Google Scholar] [CrossRef]

- Baker, I.; Meng, F.; Wu, M.; Brandenberg, A. Recrystallization of a novel two-phase FeNiMnAlCr high entropy alloy. J. Alloys Compd. 2016, 656, 458–464. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yuan, H.; Cheng, G.; Xu, W.; Jian, W.W.; Chuang, M.-H.; Juan, C.-C.; Yeh, A.-C.; Lin, S.-J.; Zhu, Y. Significant hardening due to the formation of a sigma phase matrix in a high entropy alloy. Intermetallics 2013, 33, 81–86. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, X.; Lu, Y.; Wang, T.; Li, T. A multi-component AlCrFe2Ni2 alloy with excellent mechanical properties. Mater. Lett. 2016, 169, 62–64. [Google Scholar] [CrossRef]

- Dong, Y.; Lu, Y.; Kong, J.; Zhang, J.; Li, T. Microstructure and mechanical properties of multi-component AlCrFeNiMox high-entropy alloys. J. Alloys Compd. 2013, 573, 96–101. [Google Scholar] [CrossRef]

- Lin, C.W.; Tsai, M.H.; Tsai, C.W.; Yeh, J.W.; Chen, S.K. Microstructure and aging behaviour of Al5Cr32Fe35Ni22Ti6 high entropy alloy. Mater. Sci. Technol. 2015, 31, 1165–1170. [Google Scholar] [CrossRef]

- Young, K.; Regmi, R.; Lawes, G.; Ouchi, T.; Reichman, B.; Fetcenko, M.; Wu, A. Effects of aluminum substitution in C14-rich multi-component alloys for NiMH battery application. J. Alloys Compd. 2010, 490, 282–292. [Google Scholar] [CrossRef]

- Chen, H.; Kauffmann, A.; Gorr, B.; Schliephake, D.; Seemüller, C.; Wagner, J.; Christ, H.-J.; Heilmaier, M. Microstructure and mechanical properties at elevated temperatures of a new Al-containing refractory high-entropy alloy Nb-Mo-Cr-Ti-Al. J. Alloys Compd. 2016, 661, 206–215. [Google Scholar] [CrossRef]

- Chang, H.-W.; Huang, P.-K.; Davison, A.; Yeh, J.-W.; Tsau, C.-H.; Yang, C.-C. Nitride films deposited from an equimolar Al–Cr–Mo–Si–Ti alloy target by reactive direct current magnetron sputtering. Thin Solid Films 2008, 516, 6402–6408. [Google Scholar] [CrossRef]

- Stepanov, N.; Yurchenko, N.Y.; Panina, E.; Tikhonovsky, M.; Zherebtsov, S. Precipitation-strengthened refractory Al0.5CrNbTi2V0.5 high entropy alloy. Mater. Lett. 2017, 188, 162–164. [Google Scholar] [CrossRef]

- Yurchenko, N.Y.; Stepanov, N.; Shaysultanov, D.; Tikhonovsky, M.; Salishchev, G. Effect of Al content on structure and mechanical properties of the AlxCrNbTiVZr (x= 0; 0.25; 0.5; 1) high-entropy alloys. Mater. Charact. 2016, 121, 125–134. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.; Shen, J.; Vilar, R. Thermal stability and oxidation resistance of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V alloy. Surf. Coat. Technol. 2011, 206, 1389–1395. [Google Scholar] [CrossRef]

- Yang, X.; Chen, S.; Cotton, J.; Zhang, Y. Phase stability of low-density, multiprincipal component alloys containing aluminum, magnesium, and lithium. JOM 2014, 66, 2009–2020. [Google Scholar] [CrossRef]

- Zhang, Z.; Axinte, E.; Ge, W.; Shang, C.; Wang, Y. Microstructure, mechanical properties and corrosion resistance of CuZrY/Al, Ti, Hf series high-entropy alloys. Mater. Des. 2016, 108, 106–113. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, M.; Cai, Z.; Chen, S.; Baker, I. Effect of Ti content on the microstructure and mechanical behavior of (Fe36Ni18Mn33Al13)100−xTix high entropy alloys. Intermetallics 2016, 75, 79–87. [Google Scholar] [CrossRef]

- Poletti, M.; Branz, S.; Fiore, G.; Szost, B.; Crichton, W.; Battezzati, L. Equilibrium high entropy phases in X-NbTaTiZr (X= Al, V, Cr and Sn) multiprincipal component alloys. J. Alloys Compd. 2016, 655, 138–146. [Google Scholar] [CrossRef]

- Tan, X.-R.; Zhang, G.-P.; Zhi, Q.; Liu, Z.-X. Effects of milling on the microstructure and hardness of Al2NbTi3V2Zr high-entropy alloy. Mater. Des. 2016, 109, 27–36. [Google Scholar] [CrossRef]

- Yurchenko, N.Y.; Stepanov, N.D.; Tikhonovsky, M.A.; Salishchev, G.A. Phase Evolution of the AlxNbTiVZr (x= 0; 0.5; 1; 1.5) High Entropy Alloys. Metals 2016, 6, 298. [Google Scholar] [CrossRef]

- Ding, J.; Inoue, A.; Han, Y.; Kong, F.; Zhu, S.; Wang, Z.; Shalaan, E.; Al-Marzouki, F. High entropy effect on structure and properties of (Fe, Co, Ni, Cr)-B amorphous alloys. J. Alloys Compd. 2017, 696, 345–352. [Google Scholar] [CrossRef]

- Stepanov, N.; Yurchenko, N.Y.; Tikhonovsky, M.; Salishchev, G. Effect of carbon content and annealing on structure and hardness of the CoCrFeNiMn-based high entropy alloys. J. Alloys Compd. 2016, 687, 59–71. [Google Scholar] [CrossRef]

- Guo, N.; Wang, L.; Luo, L.; Li, X.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Microstructure and mechanical properties of in-situ MC-carbide particulates-reinforced refractory high-entropy Mo0.5NbHf0.5ZrTi matrix alloy composite. Intermetallics 2016, 69, 74–77. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Qiao, Y.; Chen, G. Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys. Intermetallics 2007, 15, 357–362. [Google Scholar] [CrossRef]

- Guo, S.; Hu, Q.; Ng, C.; Liu, C. More than entropy in high-entropy alloys: Forming solid solutions or amorphous phase. Intermetallics 2013, 41, 96–103. [Google Scholar] [CrossRef]

- Huo, W.-Y.; Shi, H.-F.; Ren, X.; Zhang, J.-Y. Microstructure and wear behavior of CoCrFeMnNbNi high-entropy alloy coating by TIG cladding. Adv. Mater. Sci. Eng. 2015, 2015, 647351. [Google Scholar] [CrossRef]

- Stepanov, N.; Shaysultanov, D.; Salishchev, G.; Tikhonovsky, M.; Oleynik, E.; Tortika, A.; Senkov, O. Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J. Alloys Compd. 2015, 628, 170–185. [Google Scholar] [CrossRef]

- Shun, T.-T.; Chang, L.-Y.; Shiu, M.-H. Microstructure and mechanical properties of multiprincipal component CoCrFeNiMox alloys. Mater. Charact. 2012, 70, 63–67. [Google Scholar] [CrossRef]

- Shun, T.T.; Chang, L.Y.; Shiu, M.H. Age-hardening of the CoCrFeNiMo0.85 high-entropy alloy. Mater. Charact. 2013, 81, 92–96. [Google Scholar] [CrossRef]

- Chou, Y.; Yeh, J.; Shih, H. The effect of molybdenum on the corrosion behaviour of the high-entropy alloys Co1.5CrFeNi1.5Ti0.5Mox in aqueous environments. Corros. Sci. 2010, 52, 2571–2581. [Google Scholar] [CrossRef]

- Liu, W.; He, J.; Huang, H.; Wang, H.; Lu, Z.; Liu, C. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys. Intermetallics 2015, 60, 1–8. [Google Scholar] [CrossRef]

- Shun, T.-T.; Hung, C.-H.; Lee, C.-F. Formation of ordered/disordered nanoparticles in FCC high entropy alloys. J. Alloys Compd. 2010, 493, 105–109. [Google Scholar] [CrossRef]

- Shun, T.T.; Chang, L.Y.; Shiu, M.-H. Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys. Mater. Sci. Eng. A 2012, 556, 170–174. [Google Scholar] [CrossRef]

- Jiang, L.; Lu, Y.; Dong, Y.; Wang, T.; Cao, Z.; Li, T. Annealing effects on the microstructure and properties of bulk high-entropy CoCrFeNiTi 0.5 alloy casting ingot. Intermetallics 2014, 44, 37–43. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, Z. Effects of annealing treatment on phase composition and microstructure of CoCrFeNiTiAlx high-entropy alloys. Intermetallics 2012, 22, 24–32. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Cai, Z.; Jin, G.; Cui, X.; Li, Y.; Fan, Y.; Song, J. Experimental and simulated data about microstructure and phase composition of a NiCrCoTiV high-entropy alloy prepared by vacuum hot-pressing sintering. Vacuum 2016, 124, 5–10. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.; Zhang, C.; Li, J.; Jiang, Q. Microstructure and the properties of FeCoCuNiSnx high entropy alloys. Mater. Sci. Eng. A 2012, 548, 64–68. [Google Scholar] [CrossRef]

- Samal, S.; Rahul, M.; Kottada, R.S.; Phanikumar, G. Hot deformation behaviour and processing map of Co-Cu-Fe-Ni-Ti eutectic high entropy alloy. Mater. Sci. Eng. A 2016, 664, 227–235. [Google Scholar] [CrossRef]

- Kao, Y.-F.; Chen, S.-K.; Sheu, J.-H.; Lin, J.-T.; Lin, W.-E.; Yeh, J.-W.; Lin, S.-J.; Liou, T.-H.; Wang, C.-W. Hydrogen storage properties of multi-principal-component CoFeMnTixVyZrz alloys. Int. J. Hydrogen Energy 2010, 35, 9046–9059. [Google Scholar] [CrossRef]

- Jiang, L.; Cao, Z.; Jie, J.; Zhang, J.; Lu, Y.; Wang, T.; Li, T. Effect of Mo and Ni elements on microstructure evolution and mechanical properties of the CoFeNixVMoy high entropy alloys. J. Alloys Compd. 2015, 649, 585–590. [Google Scholar] [CrossRef]

- Jiang, L.; Lu, Y.; Wu, W.; Cao, Z.; Li, T. Microstructure and Mechanical Properties of a CoFeNi2V0.5Nb0.75 Eutectic High Entropy Alloy in As-cast and Heat-treated Conditions. J. Mater. Sci. Technol. 2016, 32, 245–250. [Google Scholar] [CrossRef]

- Zuo, T.; Li, R.; Ren, X.; Zhang, Y. Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy. J. Magn. Magn. Mater. 2014, 371, 60–68. [Google Scholar] [CrossRef]

- Han, Z.; Liu, X.; Zhao, S.; Shao, Y.; Li, J.; Yao, K. Microstructure, phase stability and mechanical properties of Nb–Ni–Ti–Co–Zr and Nb–Ni–Ti–Co–Zr–Hf high entropy alloys. Prog. Nat. Sci. Mater. Int. 2015, 25, 365–369. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, H.; Huang, T.; Lu, Y.; Wang, T.; Li, T. Microstructures and mechanical properties of Co2MoxNi2VWx eutectic high entropy alloys. Mater. Des. 2016, 109, 539–546. [Google Scholar] [CrossRef]

- Lee, C.; Chang, C.; Chen, Y.; Yeh, J.; Shih, H. Effect of the aluminium content of AlxCrFe1.5MnNi0.5 high-entropy alloys on the corrosion behaviour in aqueous environments. Corros. Sci. 2008, 50, 2053–2060. [Google Scholar] [CrossRef]

- Kunce, I.; Polanski, M.; Bystrzycki, J. Structure and hydrogen storage properties of a high entropy ZrTiVCrFeNi alloy synthesized using Laser Engineered Net Shaping (LENS). Int. J. Hydrogen Energy 2013, 38, 12180–12189. [Google Scholar] [CrossRef]

- Jiang, H.; Jiang, L.; Han, K.; Lu, Y.; Wang, T.; Cao, Z.; Li, T. Effects of tungsten on microstructure and mechanical properties of CrFeNiV0.5Wx and CrFeNi2V0.5Wx high-entropy alloys. J. Mater. Eng. Perform. 2015, 24, 4594–4600. [Google Scholar] [CrossRef]

- Fazakas, E.; Zadorozhnyy, V.; Varga, L.; Inoue, A.; Louzguine-Luzgin, D.; Tian, F.; Vitos, L. Experimental and theoretical study of Ti20Zr20Hf20Nb20X20 (X= V or Cr) refractory high-entropy alloys. Int. J. Refract. Met. Hard Mater. 2014, 47, 131–138. [Google Scholar] [CrossRef]

- Senkov, O.; Woodward, C. Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy. Mater. Sci. Eng. A 2011, 529, 311–320. [Google Scholar] [CrossRef]

- Senkov, O.; Senkova, S.; Woodward, C.; Miracle, D. Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Takeuchi, A.; Wada, T.; Zhang, Y. MnFeNiCuPt and MnFeNiCuCo high-entropy alloys designed based on L1 0 structure in Pettifor map for binary compounds. Intermetallics 2017, 82, 107–115. [Google Scholar] [CrossRef]

- Guo, N.; Wang, L.; Luo, L.; Li, X.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Microstructure and mechanical properties of refractory high entropy (Mo0.5NbHf0.5ZrTi)BCC/M5Si3 in-situ compound. J. Alloys Compd. 2016, 660, 197–203. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Li, Y.; Chen, X.; Zhang, H. Microstructure and mechanical properties of a refractory HfNbTiVSi0.5 high-entropy alloy composite. Mater. Lett. 2016, 174, 82–85. [Google Scholar] [CrossRef]

- Wu, Y.; Cai, Y.; Chen, X.; Wang, T.; Si, J.; Wang, L.; Wang, Y.; Hui, X. Phase composition and solid solution strengthening effect in TiZrNbMoV high-entropy alloys. Mater. Des. 2015, 83, 651–660. [Google Scholar] [CrossRef]

- Anzorena, M.S.; Bertolo, A.; Gagetti, L.; Kreiner, A.; Mosca, H.; Bozzolo, G.; del Grosso, M. Characterization and modeling of a MoTaVWZr high entropy alloy. Mater. Des. 2016, 111, 382–388. [Google Scholar] [CrossRef]

| Alloy Composition | Processing Condition 1 | Solution Phases 2 | IM Phases 3 | IM Structure Found in | Ref | ||

|---|---|---|---|---|---|---|---|

| PhaseName | Compound Reported | Structure Prototype | |||||

| AgAlCoCrCuNi | AC | F, B | B2 | - | CsCl | Al-Ni | [45] |

| Al0.5BCoCrCuFeNi | AC | F | C32 | CrB2 | AlB2 | B-Cr | [46] |

| L12 | - | Cu3Au | Al-Ni | ||||

| AlB0.5CoCrCuFeMoNiSiTi | AC + 1173K | B | B2 | - | CsCl | Al-Ni | [47] |

| Al0.3C0.1CoCrFeNi | AC | F | - | (Cr, Fe)7C3 | Cr7C3/Mn7C3 | C-Cr | [48] |

| AC + 1273K/72h | F | D84 | (Cr, Fe)23C6 | Cr23C6 | C-Cr | [48] | |

| AC + 973K/72h | F | - | (Cr, Fe)7C3 | Cr7C3/Mn7C3 | C-Cr | [48] | |

| D84 | (Cr, Fe)23C6 | Cr23C6 | C-Cr | ||||

| Al0.5C0.2Co0.3CrFeNi | MA + SPS(1273K) | F, B | D84 | Cr23C6 | Cr23C6 | C-Cr | [49] |

| B2 | - | CsCl | Al-Ni | ||||

| AlCoCrCuFe | SPS(1173K) | F | B2 | - | CsCl | Al-Co | [50] |

| σ | - | CrFe | Cr-Fe | ||||

| Al4(CoCrCuFeMnNiTiV)96 | AC | B | D022 | Al3Ti | Al3Ti | Al-Ti | [51] |

| AlCoCrCuFeMo0.2Ni | Sinter(773K/0.5h) + 1573K/2h | F, B | σ | - | CrFe | Cr-Fe | [52] |

| Al8Co17Cr14Cu8Fe17Mo0.1Ni34.8TiW0.1 | AC | F | L12 | - | Cu3Au | Al-Ni | [53] |

| Al0.5CoCrCuFeNi | AC + CR + 1373K/5d | F-1, F-2, B | L12 | - | Cu3Au | Al-Ni | [54] |

| AC + CR + 973K/5d | F-1, F-2, B | σ | - | CrFe | Cr-Fe | [54] | |

| AlCoCrCuFeNi | AC | F | B2 | - | CsCl | Al-Ni | [55] |

| L12 | - | Cu3Au | Al-Ni | ||||

| Al0.2CoCrCu0.8FeNiSi0.2 | AC | F | L12 | - | Cu3Au | Al-Ni | [56] |

| Al0.8CoCrCu0.2FeNiSi0.2 | AC | B | B2 | - | CsCl | Al-Ni | [56] |

| Al0.5CoCrCuFeNiTi | AC | F, B-1, B-2 | σ | CoCr | CrFe | Co-Cr | [57] |

| Al0.5CoCrCuFeNiTi1.2 | AC | F, B-1, B-2 | σ | CoCr | CrFe | Co-Cr | [57] |

| N/A | Ti2Ni | Ti2Ni | Ni-Ti | ||||

| Al0.5CoCrCuFeNiTi2 | AC | F, B-1, B-2 | B2 | - | CsCl | Al-Ni | [57] |

| N/A | Ti2Ni | Ti2Ni | Ni-Ti | ||||

| Al0.5CoCrCuFeNiV | AC | F, B | σ | - | CrFe | Cr-Fe | [58] |

| Al0.4Co6Cr7.5Cu2Mn8.1Ni32.2Sn0.3Ti12V10Zr21.5 | AC | C14 | - | MgZn2 | Al-Zr | [59] | |

| B2 | TiNi | CsCl | Ti-Ni | ||||

| N/A | Zr7Ni10 | Zr7Ni10 | Ni-Zr | ||||

| AlCoCrCuMnTi | AC | F, B-1, B-2 | L21 | - | AlCu2Mn | Al-Cu-Mn | [60] |

| AlCoCrCu0.5Ni | AC | F, B | B2 | - | CsCl | Al-Ni | [61] |

| AlCoCrCuNiTiY | AC | F, B | N/A | Cu2Y | KHg2 | Cu-Y | [62] |

| L21 | AlNi2Ti | AlCu2Mn | Al-Ni-Ti | ||||

| Al0.15CoCrFeMnNi | AC | F, B | B2 | - | CsCl | Al-Ni | [37] |

| Al10Co20Cr10Fe26Mn14Ni10Ti10 | AC + 973K/24h/WQ | F | χ | - | Ti5Re24 | Ti-Cr-Fe | [34] |

| L21 | - | AlCu2Mn | Al-Co-Ti | ||||

| Al0.4CoCrFeMnNiV | AC + 973K/20h/AQ | σ | - | CrFe | Cr-Fe | [33] | |

| AlCoCrFeMo0.5 | AC | B2 | - | CsCl | Al-Co | [63] | |

| σ | - | CrFe | Cr-Fe | ||||

| AlCoCrFeMo0.5Ni | AC | B2 | - | CsCl | Al-Ni | [63] | |

| σ | - | CrFe | Cr-Fe | ||||

| AlCoCrFeNb0.5Ni | AC | B | C14 | (Co, Cr)2Nb | MgZn2 | Co-Nb | [64] |

| Al0.3CoCrFeNi | AC + CR(20%) + 1473K/0.5h/WQ + 823K/150h/WQ | F | L12 | - | Cu3Au | Al-Ni | [44] |

| AC + CR(20%) + 1473K/0.5h/WQ + 973K/50h/WQ | F | B2 | - | CsCl | Al-Ni | [44] | |

| Al0.3CoCr2FeNi | AC + 973K/20h/AC | F, B | σ | - | CrFe | Cr-Fe | [33] |

| Al2CoCrFeNiSi | CL | B | B2 | - | CsCl | Al-Ni | [65] |

| AlCo0.6CrFe0.2NiSiTi0.2 | AC | B | A15 | Cr3Si | Cr3Si | Cr-Si | [66] |

| Al4(CoCrFeNi)94Ti2 | AC + 1473K/4h + CR(30%) + 1273K /2h + 1073K/18h | F | L12 | - | Cu3Au | Al-Ni | [24] |

| L21 | - | AlCu2Mn | Al-Ni-Ti | ||||

| Al16.5Co22.5Cr5Fe12.5Ni30Ti13.5 | AC + 973K/24h/WQ | F | L21 | - | AlCu2Mn | Al-Ni-Ti | [34] |

| Al0.5CoCrFeNiTi0.5 | AC | F, B | B2 | - | CsCl | Al-Ni | [67] |

| σ | - | CrFe | Cr-Fe | ||||

| Al0.5CoCrFeNiTi | AC | B-1, B-2 | B2 | - | CsCl | Al-Ni | [68] |

| C14 | - | MgZn2 | Cr-Ti | ||||

| Al0.5CoCrFe2NiTi0.5 | AC | F, B | B2 | - | CsCl | Al-Ni | [67] |

| AlCoCrFeNiTi1.5 | AC | B | C14 | Fe2Ti | MgZn2 | Fe-Ti | [42] |

| CL | F, B | N/A | Ti2Ni | Ti2Ni | Ni-Ti | [43] | |

| AlCoCrFeNiTi2 | CL | F, B | B2 | CsCl | Al-Ni | [43] | |

| N/A | Ti2Ni | Ti2Ni | Ni-Ti | ||||

| AlCoCrFeNiZr0.5 | AC | B | C15 | - | MgCu2 | Co-Zr | [69] |

| B2 | - | CsCl | Al-Ni | ||||

| Al0.5CoCrNiTi0.5 | AC + 1473K/24h | F, B | B2 | - | CsCl | Al-Ni | [70] |

| AC + 1373K/24h | F, B | B2 | - | CsCl | Al-Ni | [70] | |

| σ | - | CrFe | Co-Cr | ||||

| AC + 1173K/24h | F, B | σ | - | CrFe | Co-Cr | [70] | |

| Al2.5CoCuFeNiSn0.1 | AC | B | B2 | - | CsCl | Al-Ni | [71] |

| N/A | Ni17Sn3 | Unkn. | Ni-Sn | ||||

| AlCoCuFeNiVZr | AC | F, B | N/A | Zr2Ni7 | Zr2Ni7 | Ni-Zr | [72] |

| AlCoCuFeNiZr | AC | F, B | N/A | ZrFe3Al | Unkn. | Al-Fe-Zr | [73] |

| AlCoCuNiZn | SPS(873K/FC) | F | L12 | - | Cu3Au | Al-Ni | [74] |

| AlCoFeMo0.5Ni | AC | B2 | - | CsCl | Al-Ni | [75] | |

| σ | - | CrFe | Co-Mo | ||||

| Al22Co28Ni31.75Ti10.75V7.5 | AC + 973K/24h/WQ | F | B2 | - | CsCl | Al-Ni | [34] |

| Al15Cr10Co35Ni35Si5 | AC | F | L10 | - | CuAu | Al-Cr | [76] |

| L12 | - | Cu3Au | Al-Ni | ||||

| Al20Cr25Co25Ni25Si5 | AC | B | B2 | - | CsCl | Al-Ni | [76] |

| σ | - | CrFe | Co-Cr | ||||

| AlCrCuFe | MA + SPS(1073K) | B | σ | - | CrFe | Cr-Fe | [77] |

| AlCrCuFeMg0.5 | MA + SPS(1073K) | B | σ | - | CrFe | Cr-Fe | [77] |

| B2 | AlFe | CsCl | Al-Fe | ||||

| C15 | MgCu2 | MgCu2 | Cu-Mg | ||||

| AlCrCuFeMg | MA + SPS(1073K) | B | σ | CrFe | Cr-Fe | [77] | |

| B2 | AlFe | CsCl | Al-Fe | ||||

| C15 | MgCu2 | MgCu2 | Cu-Mg | ||||

| Cb | Mg2Cu | Mg2Cu | Cu-Mg | ||||

| AlCrCuFeMgNi4.75 | MA + Sinter (1173K/2h) | - | L12 | - | Cu3Au | Al-Ni | [78] |

| Al0.3CrCuFeNi2 | AC + CR(20%) + 1473K/0.5h/WQ + 823K/150h/WQ | F | L12 | - | Cu3Au | Al-Ni | [44] |

| Al1.5CrCuFeNi2 | AC | F, B | B2 | - | CsCl | Al-Ni | [79] |

| AlCrCuFeNi2 | AC | F, B | B2 | - | CsCl | Al-Ni | [80] |

| L12 | - | Cu3Au | Al-Ni | ||||

| AlCrCuFeNiTi | AC | B-1, B-2 | C14 | Fe2Ti | MgZn2 | Fe-Ti | [81] |

| Al14.1Cr6Fe28.2Mn32.9Ni18.8 | AC | F | B2 | - | CsCl | Al-Ni | [82] |

| Al0.3CrFe1.5MnNi0.5 | AC + 1373K/4h + 973K/2h/AQ | F | B2 | - | CsCl | Al-Ni | [83] |

| σ | - | CrFe | Cr-Fe | ||||

| AlCrFe2Ni2 | AC | F, B | B2 | - | CsCl | Al-Ni | [84] |

| AlCrFeMoNi | AC | B | σ | FeCrMo | CrFe | Cr-Fe | [85] |

| B2 | AlNi | CsCl | Al-Ni | ||||

| Al15Cr5Fe30Ni30Ti20 | AC + 973K/24h/WQ | - | χ | - | Ti5Re24 | Ti-Cr-Fe | [34] |

| C14 | - | MgZn2 | Cr-Ti | ||||

| L21 | - | AlCu2Mn | Al-Ti-Fe | ||||

| Al5Cr32Fe35Ni22Ti6 | AC | F, B | L21 | - | AlCu2Mn | Al-Ti-Fe | [86] |

| AC + 1373K/6h/WQ + 1173K/1h/WQ | F | L21 | - | AlCu2Mn | Al-Ti-Fe | [86] | |

| σ | - | CrFe | Cr-Fe | ||||

| η | -- | Ni3Ti | Ni-Ti | ||||

| Al0.5CrFeNiTiV | AC + 973K/20h/AQ | - | L21 | - | AlCu2Mn | Al-Ti-Fe | [33] |

| C15 | - | MgCu2 | Cr-Ti | ||||

| AlCr4.5Mn13.6Ni37.1Sn0.3Ti12V10Zr21.5 | AC | - | C14 | - | MgZn2 | Al-Zr | [87] |

| C15 | - | MgCu2 | Cr-Ti | ||||

| TiNi | TiNi/CsCl | Ni-Ti | |||||

| AlCrMoNbTi | AC + 1373K/20h | B | C14 | Cr2Nb | MgZn2 | Cr-Nb | [88] |

| AlCrMoSiTi | AC | - | B2 | - | CsCl | Al-Mo-Ti | [89] |

| D88 | Mo5Si3 | Mn5Si3 | Mo-Si | ||||

| Al0.5CrNbTi2V0.5 | AC + 1473K/24h/AQ | B | C14 | - | MgZn2 | Cr-Nb | [90] |

| AlCrNbTiVZr | AC + 1473K/24h | B | C14-1 | ZrCrAl | MgZn2 | Cr-Nb | [91] |

| C14-2 | ZrAl2 | MgZn2 | Cr-Nb | ||||

| AlCrSiTiV coating on Ti-6Al-4V | CL | B | D88 | Ti5Si3 | Mn5Si3 | Ti-Si | [92] |

| CL + 1073K/24h | B | D88 | Ti5Si3 | Mn5Si3 | Ti-Si | [92] | |

| D82 | Al8V5 | Zn8Cu5 | Al-V | ||||

| AlCu0.2Li0.5MgZn0.5 | AC | - | D8e | Mg32(Al,Zn)49 | Mg32(Zn2Al)49 | Al-Mg-Zn | [93] |

| AlCuTiYZr | AC | B-1, B-2, H | N/A | AlTi2 | Unkn. | Al-Ti | [94] |

| Al13Fe36Mn33Ni18 | AC | F | B2 | - | CsCl | Al-Ni | [95] |

| Al13Fe36Mn33Ni18Ti6 | AC | F | B2 | - | CsCl | Al-Ni | [95] |

| AlMo0.5NbTa0.5TiZr | AC + 1673K/24h/FC | B | B2 | - | CsCl | Al-Mo-Ti | [56] |

| AlNbTaTiZr | HT-DSC (1823K/2cycles) | B | N/A | Al4Zr5 | Ti5Ga4 | Al-Zr | [96] |

| Al2NbTi3V2Zr | MA + SPS (1173K/2h) | B | L12 | - | Cu3Au | Al-Zr | [97] |

| N/A | Ti2ZrAl | Mg3Cd | Al-Ti | ||||

| AlNbTiVZr | AC + 1473K/24h | B | C14 | MgZn2 | Al-Zr | [98] | |

| N/A | Zr2Al | Co1.75Ge | Al-Zr | ||||

| Al1.5NbTiVZr | AC + 1473K/24h + 1273K/100h | B | C14 | MgZn2 | Al-Zr | [98] | |

| N/A | Zr2Al | Co1.75Ge | Al-Zr | ||||

| σ | AlNb2 | CrFe | Al-Nb | ||||

| B22(CoCrFeNi)78 | AC + 1023K/10min | F | C16 | Fe2B | CuAl2 | B-Fe | [99] |

| B26(CoCrFeNi)74 | AC + 873K/10min | F | C16 | Fe2B | CuAl2 | B-Fe | [99] |

| D8l | Cr5B3 | Cr5B3 | B-Cr | ||||

| FeB | FeB-b/TlI | B-Fe | |||||

| C0.1CoCrFeMnNi | AC + 1473K/14h/AQ | F | D84 | Cr23C6 | Cr23C6 | C-Cr | [100] |

| C0.25CoCrFeMnNi | AC + 873K/14h/AQ | F | Cr7C3 | Cr7C3/Mn7C3 | C-Cr | [100] | |

| AC + 1273K/14h/AQ | F | D84 | Cr23C6 | Cr23C6 | C-Cr | [100] | |

| Cr7C3 | Cr7C3/Mn7C3 | C-Cr | |||||

| C0.1Hf0.5Mo0.5NbTiZr | AC | B | B1 | CHf | NaCl | C-Hf | [101] |

| CoCrCuFeMnNiTiV | AC | F, B | σ | CrFe | Cr-Fe | [51] | |

| CoCrCuFeNi | MA + SPS(1173K) | F-1, F-2 | σ | - | CrFe | Cr-Fe | [50] |

| CoCrCuFeNiTi | AC | F | C14 | Fe2Ti | MgZn2 | Fe-Ti | [102] |

| CoCrCuFeNiZr | AC | C15b | Zr(Ni, Cu)5 | Be5Au | Cu-Zr | [103] | |

| CoCrFeHfNi | AC | B | C36 | MgNi2 | Cr-Hf | [32] | |

| CoCrFeMnNbNi | CL | F | C14 | Fe2Nb | MgZn2 | Fe-Nb | [104] |

| Co0.5CrFeMn1.5Ni | AC + 973K/20h/AQ | F | σ | - | CrFe | Cr-Fe | [33] |

| CoCrFeMnNiV | AC + 1273K/24h | F | σ | - | CrFe | Cr-Fe | [105] |

| CoCrFeMo0.85Ni | AC | F | σ | - | CrFe | Cr-Fe | [106] |

| μ | - | W6Fe7 | Co-Mo | ||||

| AC + 1273K/6d/WQ | F | μ | - | W6Fe7 | Co-Mo | [107] | |

| CoCrFeMoNi | AC | F | σ | - | CrFe | Cr-Fe | [32] |

| Co1.5CrFeMo0.5Ni1.5Ti0.5 | AC | F | σ | - | CrFe | Cr-Fe | [108] |

| CoCrFeNb0.3Ni | AC | F | C14 | - | MgZn2 | Co-Nb | [109] |

| CoCrFeNbNi | AC | F | C14 | - | MgZn2 | Cr-Nb | [32] |

| CoCr2FeNi | AC + 973K/20h/AQ | F | σ | - | CrFe | Cr-Fe | [33] |

| CoCrFeNiTa | AC | F | C14 | - | MgZn2 | Co-Ta | [32] |

| CoCrFeNiTi0.3 | AC | F, H | L12 | - | Cu3Au | Co-Ni | [110] |

| CoCrFeNiTi0.5 | AC | F | C36 | Co2Ti | MgNi2 | Co-Ti | [111] |

| σ | CrFe | CrFe | Cr-Fe | ||||

| R | TiNi2 | TiNi2 | Ni-Ti | ||||

| AC + 1273K/6h/FC | F | σ | CrFe | Cr-Fe | [112] | ||

| R | TiNi2 | TiNi2 | Ni-Ti | ||||

| CoCrFeNiTi | AC | χ | Ti5Re24 | Ti-Cr-Fe | [32] | ||

| C14 | MgZn2 | Cr-Ti | |||||

| η | Ni3Ti | Ni-Ti | |||||

| AC + 1273K/2h | F, B | N/A | CoTi2 | Ti2Ni | Co-Ti | [113] | |

| B2 | - | CsCl | Co-Fe | ||||

| Co1.5CrFeNi1.5Ti | AC + 1373K/4h + 1073K/10h/AQ | F | η | - | Ni3Ti | Ni-Ti | [22] |

| CoCrFeNiV | AC | F | σ | CrFe | Cr-Fe | [32] | |

| CoCrFeNiW | AC | F | μ | W6Fe7 | Fe-W | [32] | |

| CoCrFeNiY | AC | B | N/A | YNi3 | PuNi3 | Ni-Y | [32] |

| N/A | Y2Ni17 | Th2Ni17 | Ni-Y | ||||

| B27 | YNi | FeB-b | Ni-Y | ||||

| CoCrFeNiZr | AC | B | C15 | - | MgCu2 | Co-Zr | [32] |

| CoCrMnNiV | AC + 1273K/3d | F | σ | - | CrFe | Co-Cr | [114] |

| CoCrNiTiV | MA + VHP (1423K/1h/FC) | F, B | σ | Ni2V3 | CrFe | Ni-V | [115] |

| η | Ni3Ti | Ni-Ti | |||||

| CoCuFeNiSn0.5 | AC | F | N/A | Cu81Sn22 | Cu41Sn11 | Cu-Sn | [116] |

| CoCuFeNiTi | AC | F-1, F-2, B | C15 | - | MgCu2 | Co-Ti | [117] |

| CoFeMnMoNi | AC + 1273K/3d | F | μ | - | W6Fe7 | Co-Mo | [114] |

| Co25Fe25Mn15Ni15Ti12.5V7.5 | AC + 973K/24h/WQ | F | C14 | - | MgZn2 | Fe-Ti | [34] |

| CoFeMnNiV | AC + 1273K/3d | F | σ | - | CrFe | Fe-V | [114] |

| CoFeMnTiVZr | AC | C14 | - | MgZn2 | Fe-Ti | [118] | |

| CoFeMoNiV | AC | F | σ | Co2Mo3 | CrFe | Co-Mo | [119] |

| CoFeNb0.75Ni2V0.5 | AC | F | C14 | - | MgZn2 | Co-Nb | [120] |

| CoFeNiSi0.5 | AC | F | D011 | Ni3Si | Fe3C | Ni-Si | [121] |

| Co25Fe25Ni10Ti30V10 | AC + 973K/24h/WQ | C14 | - | MgZn2 | Fe-Ti | [34] | |

| C15 | - | MgCu2 | Co-Ti | ||||

| Co28.75Fe31.25Ni7.5Ti30V2.5 | AC + 973K/24h/WQ | C14 | - | MgZn2 | Fe-Ti | [34] | |

| CoHfNbNiTiZr | AC | F, B | μ | NbNi | W6Fe7 | Nb-Ni | [122] |

| AC + 1073K/1h | F, B | μ | NbNi | W6Fe7 | Nb-Ni | [122] | |

| N/A | NbHf2 | Unkn. | Hf-Nb | ||||

| Co2Mo0.8Ni2VW0.8 | AC | F | μ | - | W6Fe7 | Co-Mo | [123] |

| CrFe1.5MnNi0.5 | AC | F | σ | CrFe | CrFe | Cr-Fe | [124] |

| CrFeMnNiTi | AC + 1273K/3d | χ | - | Ti5Re24 | Ti-Cr-Fe | [114] | |

| C14 | - | MgCu2 | Co-Ti | ||||

| CrFeNiTiVZr | AC + 1273K/24h | H | C14 | - | MgZn2 | Fe-Ti | [125] |

| CrFeNiV0.5W | AC | F, B | σ | - | CrFe | Cr-Fe | [126] |

| CrHfNbTiZr | AC + 1173K/10min | B | C15 | - | MgCu2 | Cr-Hf | [127] |

| Cr4.5Mn13.6Ni38.1Sn0.3Ti12V10Zr21.5 | AC | - | C14 | - | MgZn2 | Cr-Ti | [87] |

| C15 | - | MgCu2 | Cr-Ti | ||||

| - | TiNi | TiNi/CsCl | Ti-Ni | ||||

| CrNbMo0.5Ta0.5TiZr | HIP(1723K/3h) | B-1, B-2 | C15 | - | MgCu2 | Cr-Ta | [128] |

| CrNbTaTiZr | HT-DSC (1823K/2cycles) | B, H | C14 | - | MgZn2 | Cr-Nb | [96] |

| C15 | - | MgCu2 | Cr-Nb | ||||

| CrNbTiVZr | HIP(1473K/2h) + 1473K/24h | B | C15 | - | MgCu2 | Cr-Nb | [129] |

| CrNbTiZr | HIP(1473K/2h) + 1473K/24h | B | C15 | - | MgCu2 | Cr-Nb | [129] |

| CuFeMnNiPt | AC + 1373K/12h/FC | L12 | - | Cu3Au | Fe-Ni | [130] | |

| Hf0.5Mo0.5NbSi0.9TiZr | AC | B | D88 | Zr5Si3 | Mn5Si3 | Si-Zr | [131] |

| HfNbSi0.5TiV | AC | B | D88 | Ti5Si3 | Mn5Si3 | Si-Ti | [132] |

| HfNbTiVZr | AC + 1173K/10min | B | C15 | - | MgCu2 | V-Zr | [127] |

| Mo0.7NbTiV0.3Zr | AC + 1273K/72h | B-1, B-2 | C15 | - | MgCu2 | V-Zr | [133] |

| MoTaVWZr | AC | B-1, B-2, H | C15 | - | MgCu2 | V-Ta | [134] |

| NbSnTaTiZr | AC | B | N/A | Sn3Zr5 | Ti5Ga4 | Sn-Zr | [96] |

| NbTiVZr | AC + 1273K/100h | B, H | C15 | - | MgCu2 | V-Zr | [98] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, M.-H.; Tsai, R.-C.; Chang, T.; Huang, W.-F. Intermetallic Phases in High-Entropy Alloys: Statistical Analysis of their Prevalence and Structural Inheritance. Metals 2019, 9, 247. https://doi.org/10.3390/met9020247

Tsai M-H, Tsai R-C, Chang T, Huang W-F. Intermetallic Phases in High-Entropy Alloys: Statistical Analysis of their Prevalence and Structural Inheritance. Metals. 2019; 9(2):247. https://doi.org/10.3390/met9020247

Chicago/Turabian StyleTsai, Ming-Hung, Ruei-Chi Tsai, Ting Chang, and Wen-Fei Huang. 2019. "Intermetallic Phases in High-Entropy Alloys: Statistical Analysis of their Prevalence and Structural Inheritance" Metals 9, no. 2: 247. https://doi.org/10.3390/met9020247

APA StyleTsai, M.-H., Tsai, R.-C., Chang, T., & Huang, W.-F. (2019). Intermetallic Phases in High-Entropy Alloys: Statistical Analysis of their Prevalence and Structural Inheritance. Metals, 9(2), 247. https://doi.org/10.3390/met9020247