Advanced Mechanical Strength in Post Heat Treated SLM 2507 at Room and High Temperature Promoted by Hard/Ductile Sigma Precipitates

Abstract

:1. Introduction

2. Materials and Methods

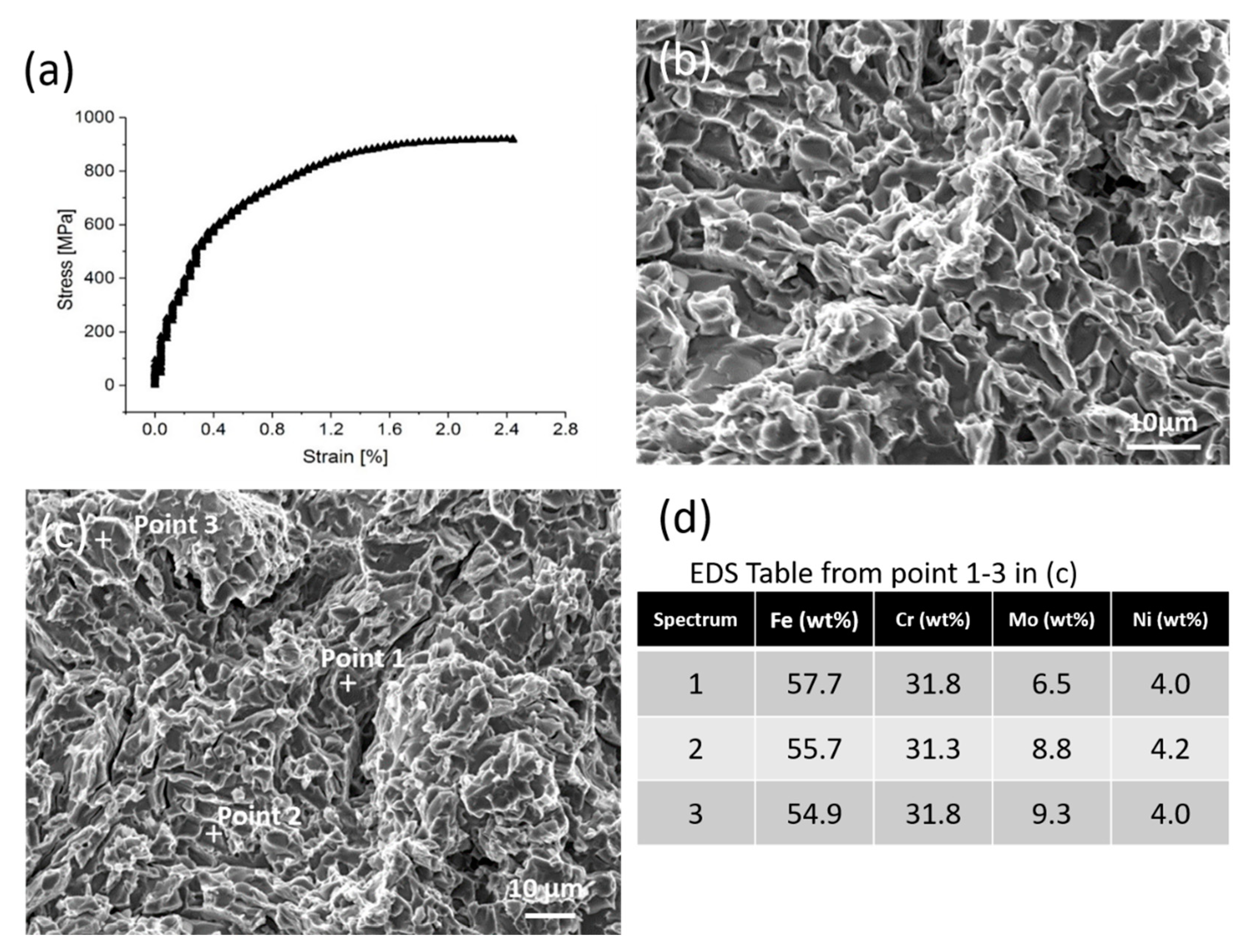

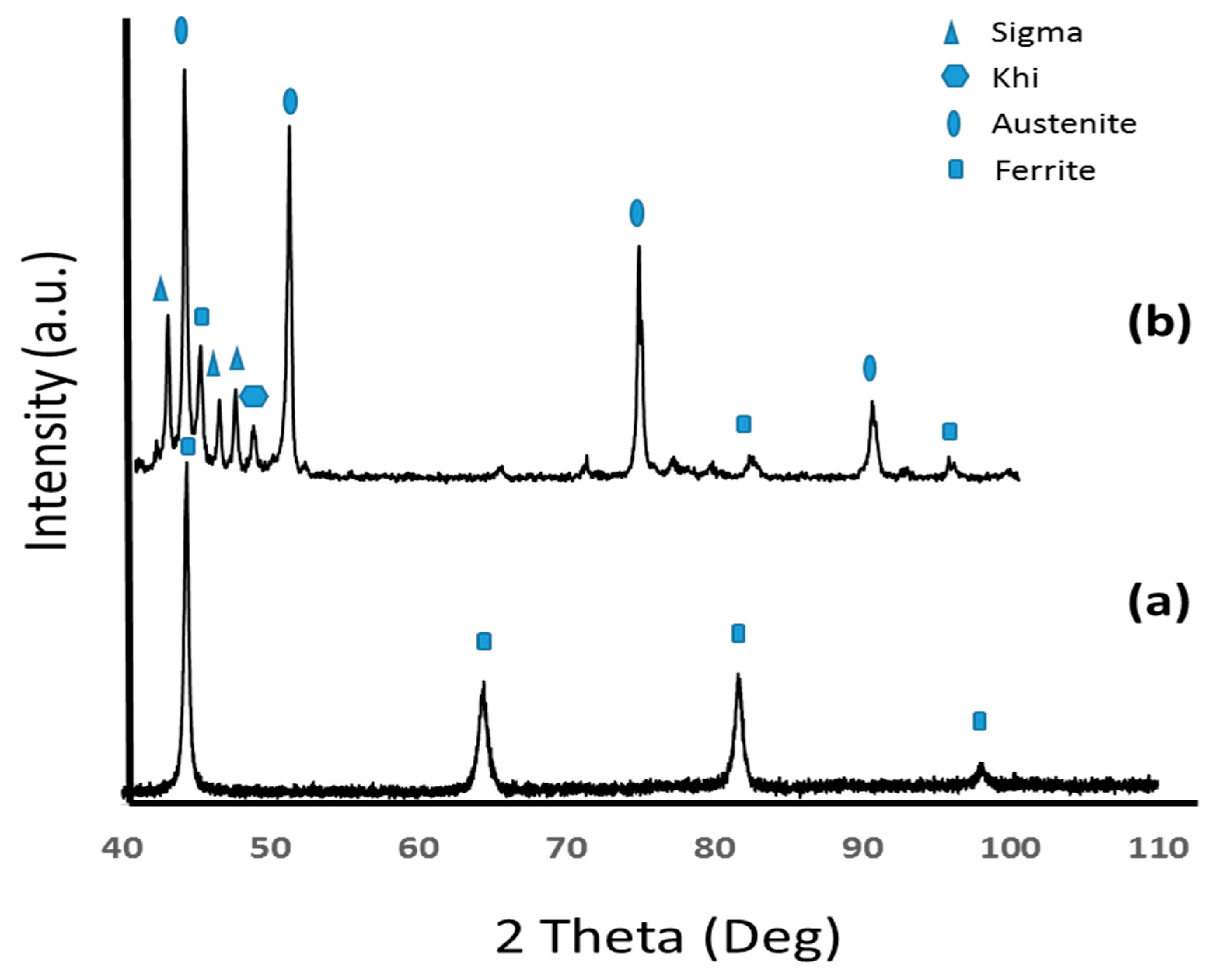

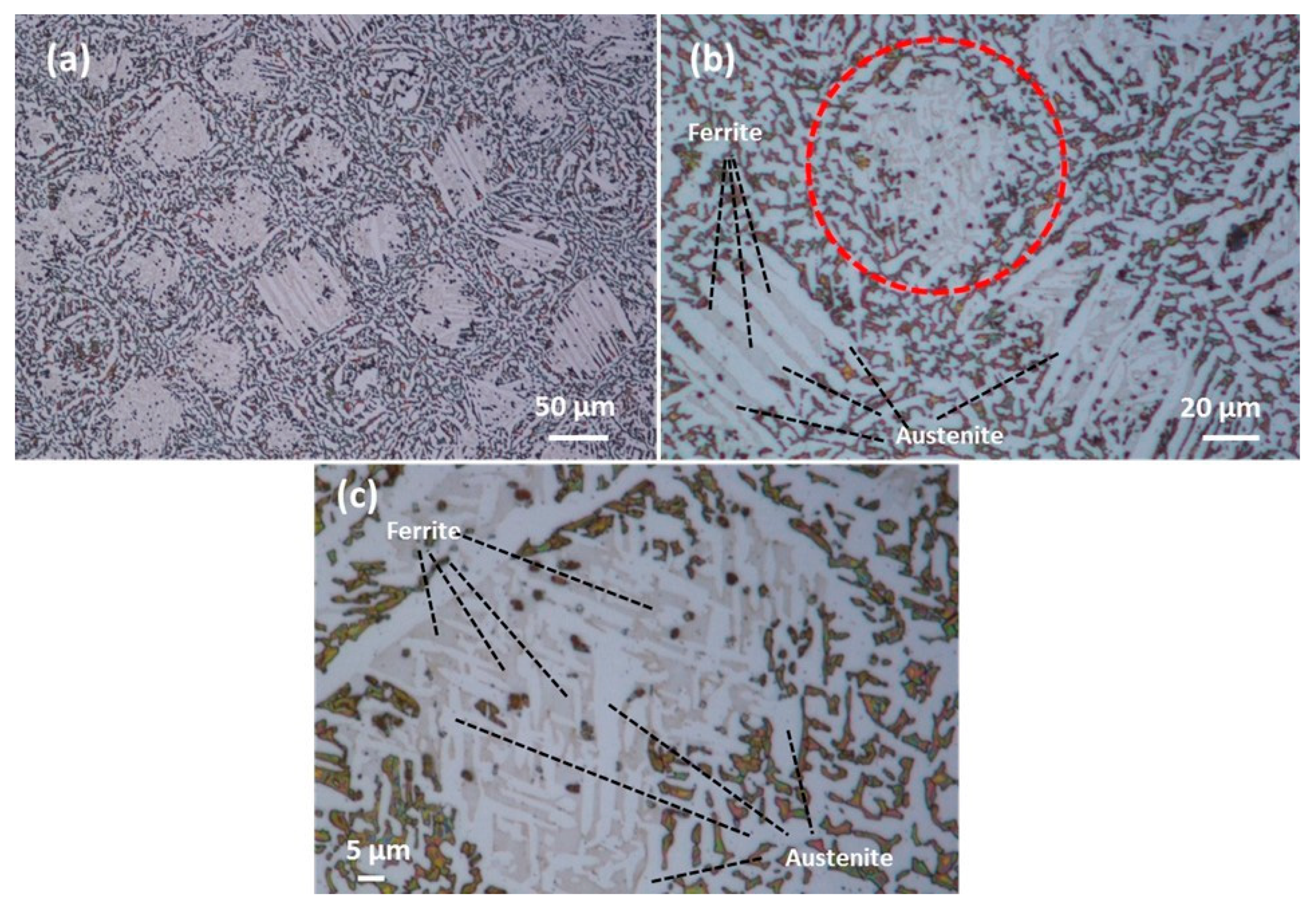

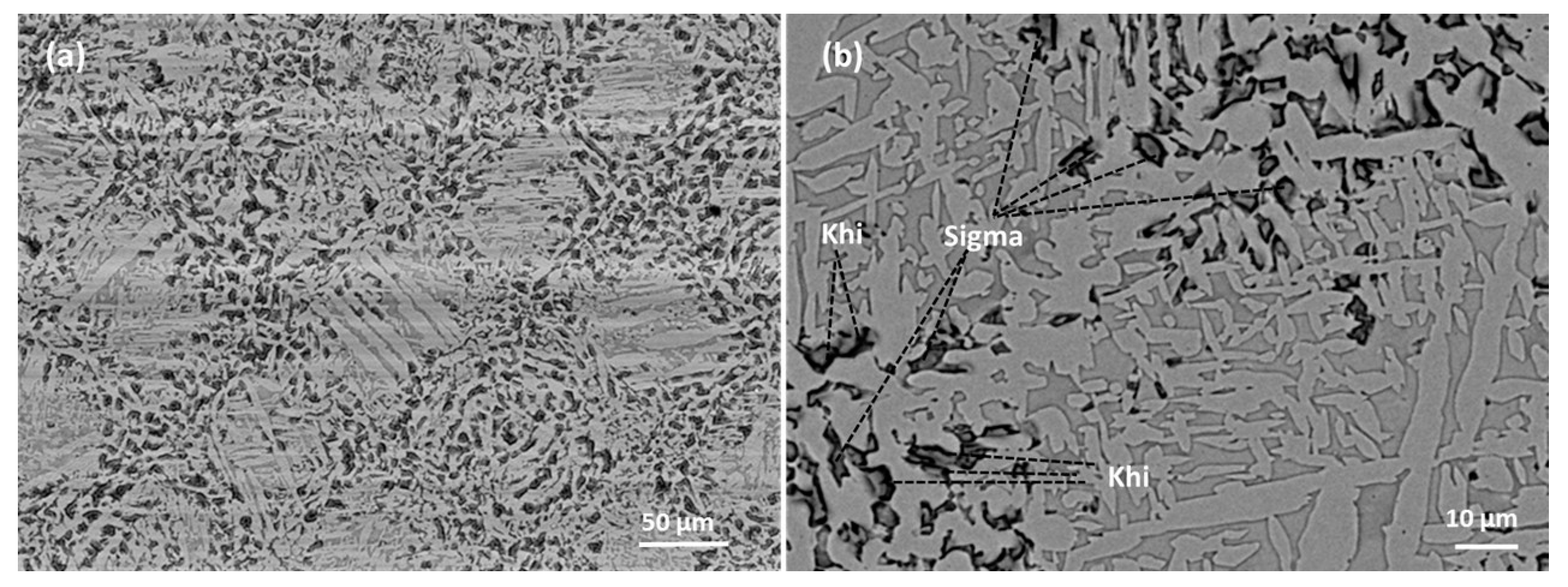

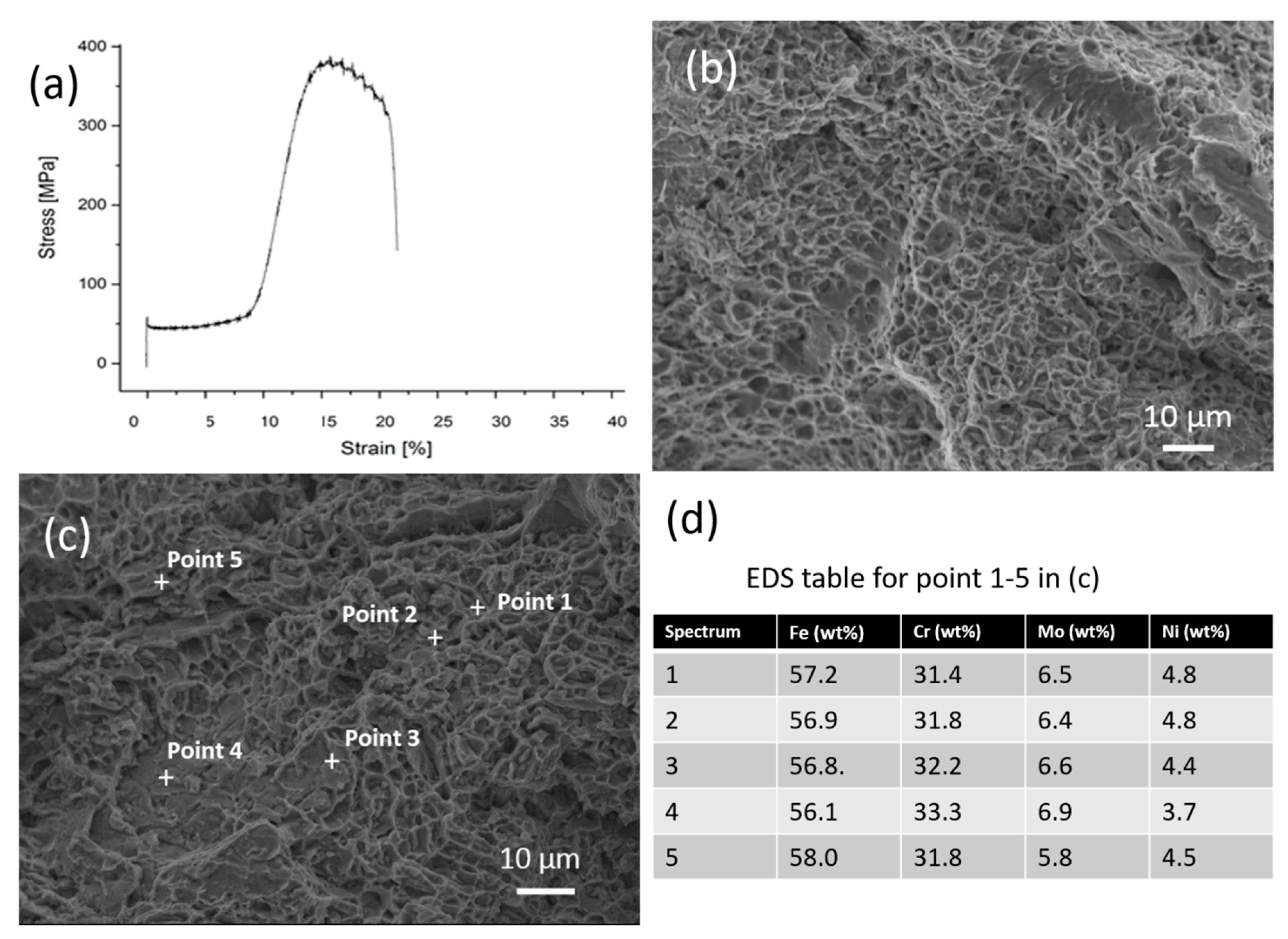

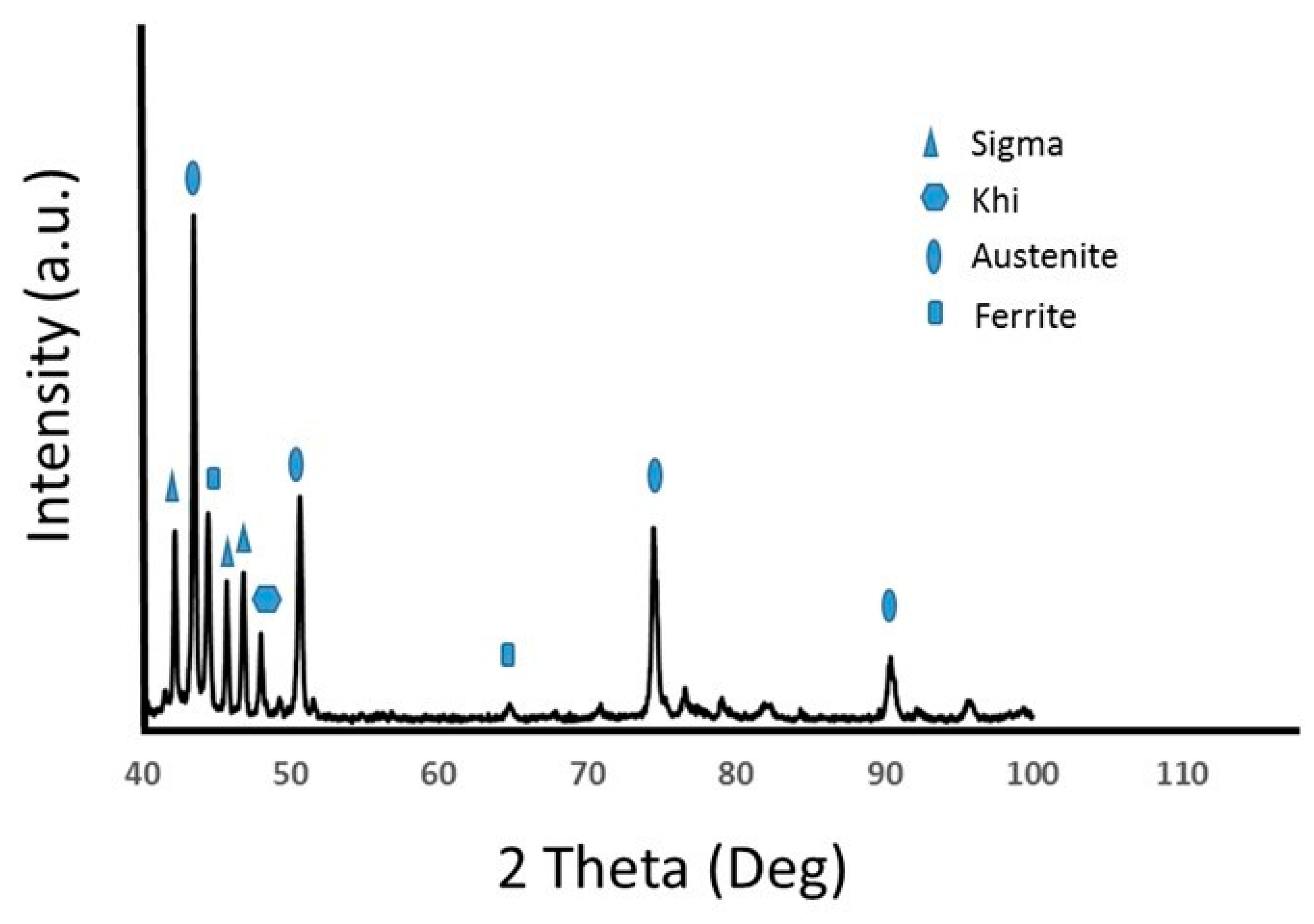

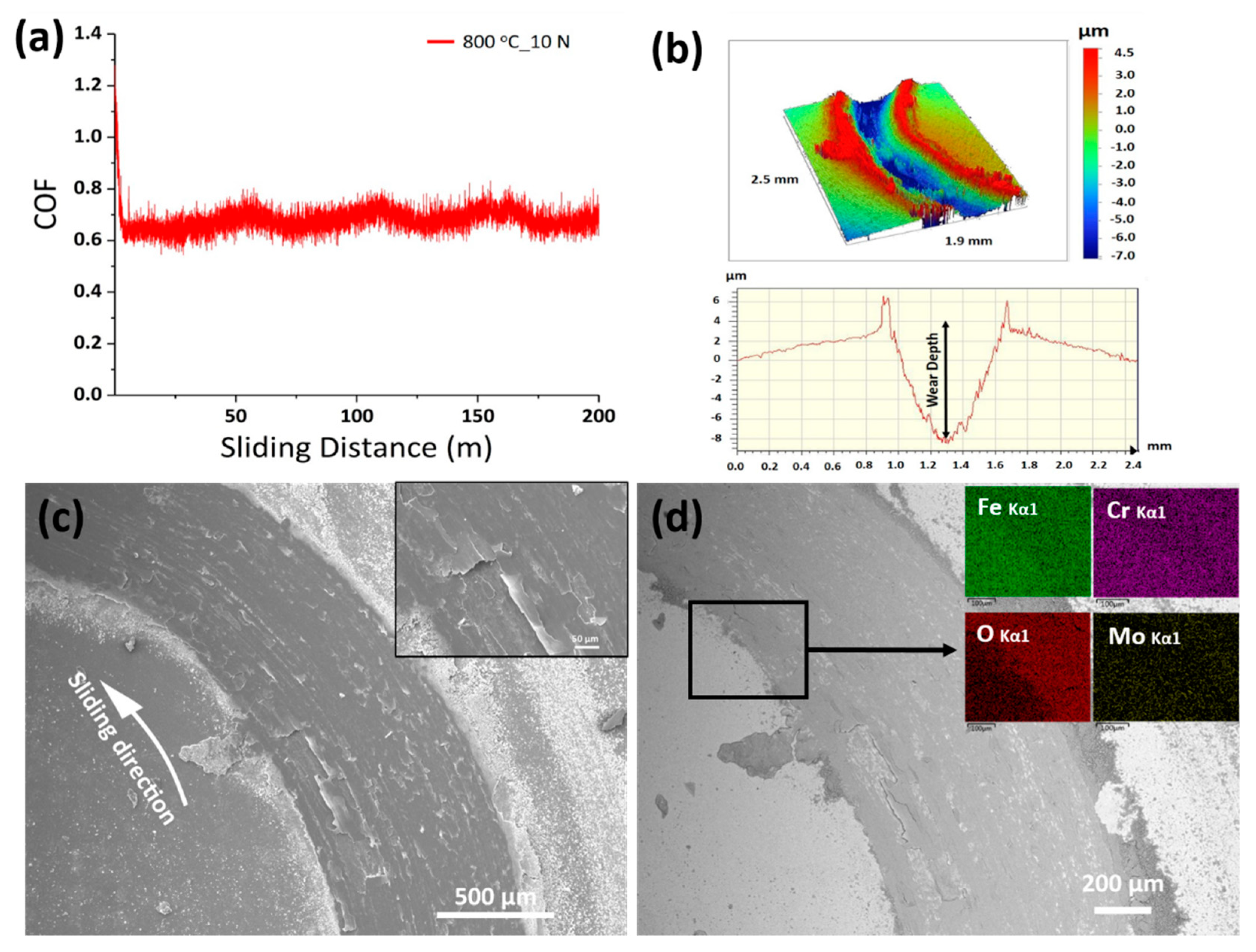

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Shifeng, W.; Shuai, L.; Qingsong, W.; Yan, C.; Sheng, Z.; Yusheng, S. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar] [CrossRef]

- Saeidi, K. Stainless steels fabricated by laser melting: Scaled-down structural hierarchies and microstructural heterogeneities. Ph.D. Thesis, Department of Materials and Environmental Chemistry (MMK), Stockholm University, Stockholm, Sweden, 19 May 2016. [Google Scholar]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.; Maier, H. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Rao, H.; Giet, S.; Yang, K.; Wu, X.; Davies, C.H. The influence of processing parameters on aluminium alloy A357 manufactured by Selective Laser Melting. Mater. Des. 2016, 109, 334–346. [Google Scholar] [CrossRef]

- Tillmann, W.; Schaak, C.; Nellesen, J.; Schaper, M.; Aydinöz, M.; Hoyer, K.-P. Hot isostatic pressing of IN718 components manufactured by selective laser melting. Addit. Manuf. 2017, 13, 93–102. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Saeidi, K.; Kevetkova, L.; Lofaj, F.; Shen, Z. Novel ferritic stainless steel formed by laser melting from duplex stainless steel powder with advanced mechanical properties and high ductility. Mater. Sci. Eng. A 2016, 665, 59–65. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsava, I.; Fredriksson, G.; Yadroitsev, I. In situ heat treatment in selective laser melted martensitic AISI 420 stainless steels. Mater. Des. 2015, 87, 380–385. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef]

- Fortunato, A.; Lulaj, A.; Melkote, S.; Liverani, E.; Ascari, A.; Umbrello, D. Milling of maraging steel components produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 94, 1895–1902. [Google Scholar] [CrossRef]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Davidson, K.; Singamneni, S. Selective laser melting of duplex stainless steel powders: An investigation. Mater. Manuf. Processes 2016, 31, 1543–1555. [Google Scholar] [CrossRef]

- Adhe, K.; Kain, V.; Madangopal, K.; Gadiyar, H. Influence of sigma-phase formation on the localized corrosion behaviour of a duplex stainless steel. J. Mater. Eng. Perform. 1996, 5, 500–506. [Google Scholar] [CrossRef]

- Chen, T.; Yang, J. Effects of solution treatment and continuous cooling on σ-phase precipitation in a 2205 duplex stainless steel. Mater. Sci. Eng. A 2001, 311, 28–41. [Google Scholar] [CrossRef]

- Femenia, M.; Pan, J.; Leygraf, C.; Luukkonen, P. In situ study of selective dissolution of duplex stainless steel 2205 by electrochemical scanning tunnelling microscopy. Corros. Sci. 2001, 43, 1939–1951. [Google Scholar] [CrossRef]

- Plaut, R.L.; Herrera, C.; Escriba, D.M.; Rios, P.R.; Padilha, A.F. A short review on wrought austenitic stainless steels at high temperatures: Processing, microstructure, properties and performance. Mater. Res. 2007, 10, 453–460. [Google Scholar] [CrossRef]

- Padilha, A.F.; Aguiar, D.; Plaut, R. Duplex Stainless Steels: A Dozen of Significant Phase Transformations. Defect Diffus. Forum 2012, 322, 163–174. [Google Scholar] [CrossRef]

- Totten, G.E. Steel Heat Treatment Handbook, -2 Volume Set; CRC press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Reick, W.; Pohl, M.; Padilha, A. Three Types of Embrittlement in Ferritic-Austenitic Duplex Stainless Steels. Metal. Int. 1990, 3, 46–50. [Google Scholar]

- Calliari, I.; Straffelini, G.; Ramous, E. Investigation of secondary phase effect on 2205 DSS fracture toughness. Mater. Sci. Technol. 2010, 26, 81–86. [Google Scholar] [CrossRef]

- AF, P. Decomposition of austenite in austenitic stainless steels. ISIJ Int. 2002, 42, 325–327. [Google Scholar]

- Davanageri, M.B.; Narendranath, S.; Kadoli, R. Effect of Sigma (σ) phase on Mechanical and Dry sliding wear. Mater. Today Proc. 2017, 4, 10189–10196. [Google Scholar] [CrossRef]

- Hengsbach, F.; Koppa, P.; Duschik, K.; Holzweissig, M.J.; Burns, M.; Nellesen, J.; Tillmann, W.; Tröster, T.; Hoyer, K.-P.; Schaper, M. Duplex stainless steel fabricated by selective laser melting-Microstructural and mechanical properties. Mater. Des. 2017, 133, 136–142. [Google Scholar] [CrossRef]

- Ghosh, S.; Mondal, S. Effect of heat treatment on microstructure and mechanical properties of duplex stainless steel. Trans. Indian Inst. Met. 2008, 61, 33–37. [Google Scholar] [CrossRef]

- Hsieh, C.-C.; Wu, W. Overview of Intermetallic Sigma Phase (σ) Precipitation in Stainless Steels. ISRN Metall. 2012, 2012. [Google Scholar] [CrossRef]

- Kim, S.-K.; Kang, K.-Y.; Kim, M.-S.; Lee, J.-M. Low-temperature mechanical behaviour of super duplex stainless steel with sigma precipitation. Metals 2015, 5, 1732–1745. [Google Scholar] [CrossRef]

- Hau, J.L.; Seijas, A.L. Sigma phase embrittlement of stainless steel in FCC service. In Proceedings of the 61st Annual Conference and Exposition (Corrosion 2006), San Diego, CA, USA, 12–16 March 2006. paper no: 06578. [Google Scholar]

- Ezuber, H.M.; El-Houd, A.; El-Shawesh, F. Effects of sigma phase precipitation on seawater pitting of duplex stainless steel. Desalination 2007, 207, 268–275. [Google Scholar] [CrossRef]

- Martins, M.; Casteletti, L.C. Effect of heat treatment on the mechanical properties of ASTM A 890 Gr6A super duplex stainless steel. J. ASTM Int. 2005, 2, 1–14. [Google Scholar]

- Cho, H.-S.; Lee, K. Effect of cold working and isothermal aging on the precipitation of sigma phase in 2205 duplex stainless steel. Mater. Charact. 2013, 75, 29–34. [Google Scholar] [CrossRef]

- Llorca-Isern, N.; López-Luque, H.; López-Jiménez, I.; Biezma, M.V. Identification of sigma and chi phases in duplex stainless steels. Mater. Charact. 2016, 112, 20–29. [Google Scholar] [CrossRef]

- Tehovnik, F.; Zuzek, B.; Burja, J. Hot tensile testing of SAF 2205 duplex stainless steel. Mater. Technol. 2016, 50, 989–993. [Google Scholar]

- Elmer, J.; Palmer, T.; Specht, E. In-situ observation of sigma phase dissolution in 2205 duplex stainless steel using synchtron X-ray diffraction. Mater. Sci. Eng. A 2006, 459, 151–155. [Google Scholar] [CrossRef]

- Levin, E.; Pivnik, E.; Libman, P. The effect of sigma phase on the mechanical properties of heat resistant steels. Met. Sci. Heat Treat. 1959, 1, 19–21. [Google Scholar] [CrossRef]

- Rotundo, F.; Ceschini, L.; Martini, C.; Montanari, R.; Varone, A. High temperature tribological behaviour and microstructural modifications of the low-temperature carburized AISI 316L austenitic stainless steel. Surf. Coat. Technol. 2014, 258, 772–781. [Google Scholar] [CrossRef]

- Stott, F. High-temperature sliding wear of metals. Tribol. Int. 2002, 35, 489–495. [Google Scholar] [CrossRef]

- Fargas, G.; Mestra, A.; Mateo, A. Effect of sigma phase on the wear behaviour of a super duplex stainless steel. Wear 2013, 303, 584–590. [Google Scholar] [CrossRef]

- Davanageri, M.B.; Narendranath, S.; Kadoli, R. Influence of Heat Treatment on Microstructure, Hardness and Wear Behavior of Super Duplex Stainless Steel AISI 2507. Am. J. Mater. Sci. 2015, 5, 48–52. [Google Scholar]

- Pereira Neto, J.O.; Silva, R.O.d.; Silva, E.H.d.; Moreto, J.A.; Bandeira, R.M.; Manfrinato, M.D.; Rossino, L.S. Wear and Corrosion Study of Plasma Nitriding F53 Super duplex Stainless Steel. Mater. Res. 2016, 19, 1241–1252. [Google Scholar] [CrossRef]

| Material | Tensile Strength (MPa) | Elongation (%) | Microhardness (Hv) |

|---|---|---|---|

| Post heat treated SLM 2507 (this work) | 920 MPa | 1.8% | 400 Hv |

| As built-SLM 2507 [9] | 1320 MPa | 8% | 450 Hv |

| Post heat treated SLM 2205 [25] | 750 MPa | 20% | - |

| Heat treated conventional duplex [26] | 649 MPa | 34% | 227 Hv |

| As Casted duplex [26] | 660 MPa | 29% | 235 Hv |

| Tensile Test at 1200 °C | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| Post heat treated SLM 2507 (this work) | 400 MPa | 20% |

| As-built SLM duplex (this work) | 200 MPa | 30% |

| Conventional duplex [34] | 19 MPa | - |

| Material | Wear Volume (mm3) | Wear Rate (mm3/mN) | Ave. COF |

|---|---|---|---|

| SLM DSS (800 °C, 10 N load) (This work) | 0.003819 | 4.5 × 10−5 | 0.6 |

| Heat treated DSS (RT, 20 N load) [39] | 0.8–1 | 2–2.5 × 10−4 | 0.4 |

| Heat treated DSS 2507 (RT, 30 N load) [40] | 0.01 | 1.66 × 10−6 | - |

| Plasma Nitrided F53 DSS (RT, 8–16 N load) [41] | 0.25–0.5 | 1.25–1.75 × 10−4 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeidi, K.; Alvi, S.; Lofaj, F.; Petkov, V.I.; Akhtar, F. Advanced Mechanical Strength in Post Heat Treated SLM 2507 at Room and High Temperature Promoted by Hard/Ductile Sigma Precipitates. Metals 2019, 9, 199. https://doi.org/10.3390/met9020199

Saeidi K, Alvi S, Lofaj F, Petkov VI, Akhtar F. Advanced Mechanical Strength in Post Heat Treated SLM 2507 at Room and High Temperature Promoted by Hard/Ductile Sigma Precipitates. Metals. 2019; 9(2):199. https://doi.org/10.3390/met9020199

Chicago/Turabian StyleSaeidi, Kamran, Sajid Alvi, Frantisek Lofaj, Valeri Ivanov Petkov, and Farid Akhtar. 2019. "Advanced Mechanical Strength in Post Heat Treated SLM 2507 at Room and High Temperature Promoted by Hard/Ductile Sigma Precipitates" Metals 9, no. 2: 199. https://doi.org/10.3390/met9020199

APA StyleSaeidi, K., Alvi, S., Lofaj, F., Petkov, V. I., & Akhtar, F. (2019). Advanced Mechanical Strength in Post Heat Treated SLM 2507 at Room and High Temperature Promoted by Hard/Ductile Sigma Precipitates. Metals, 9(2), 199. https://doi.org/10.3390/met9020199