Effects of Tempering Temperature on the Microstructure and Mechanical Properties of T92 Heat-Resistant Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

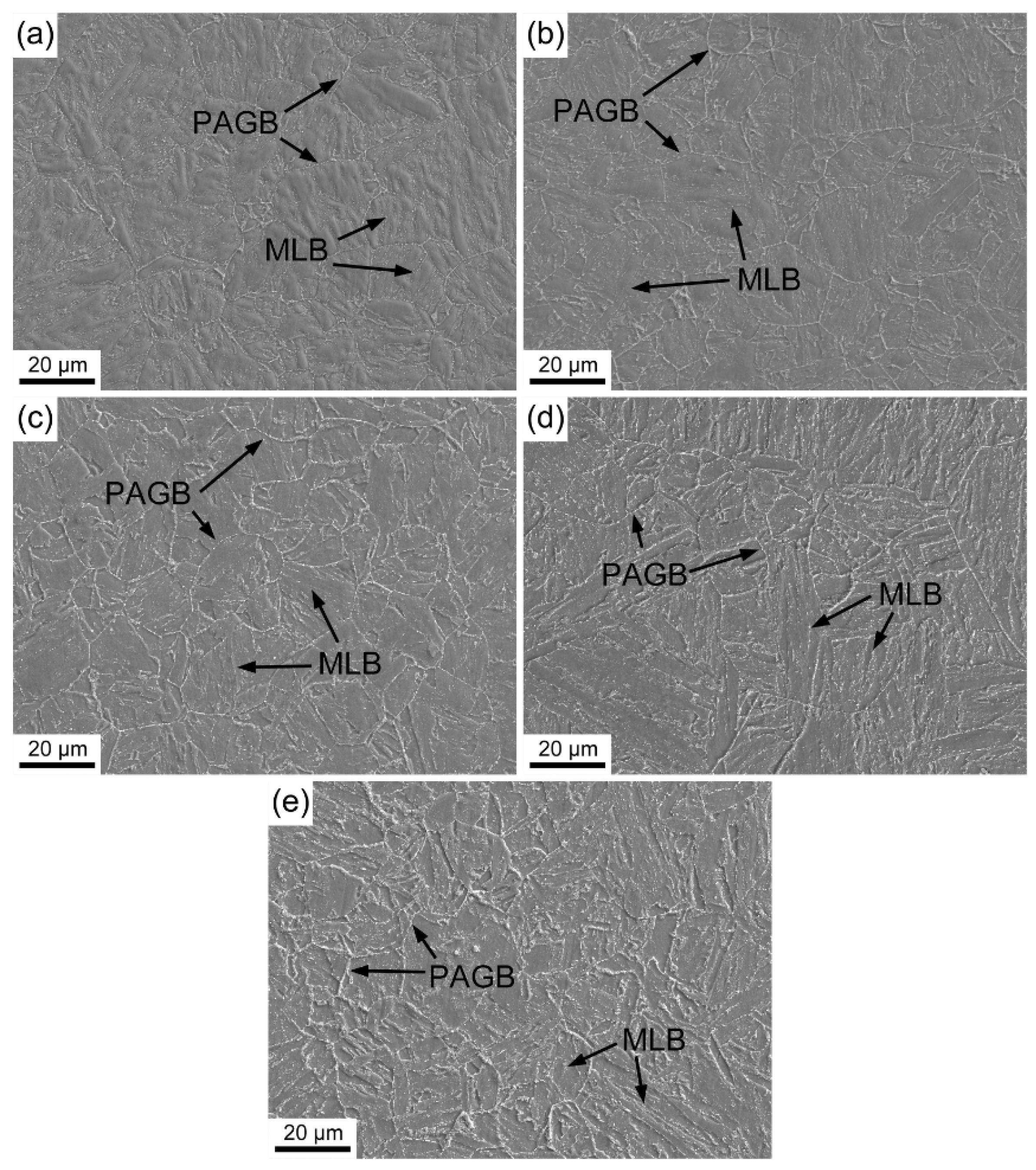

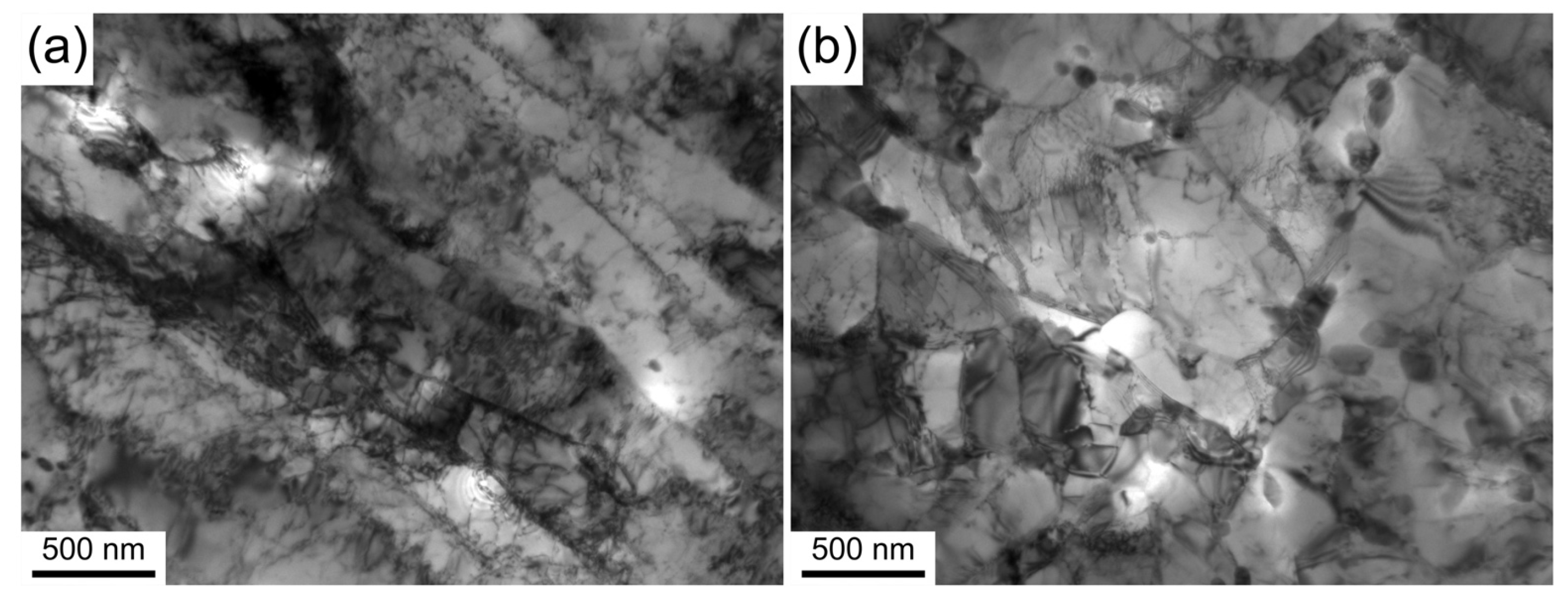

3.1. Microstructure Observation

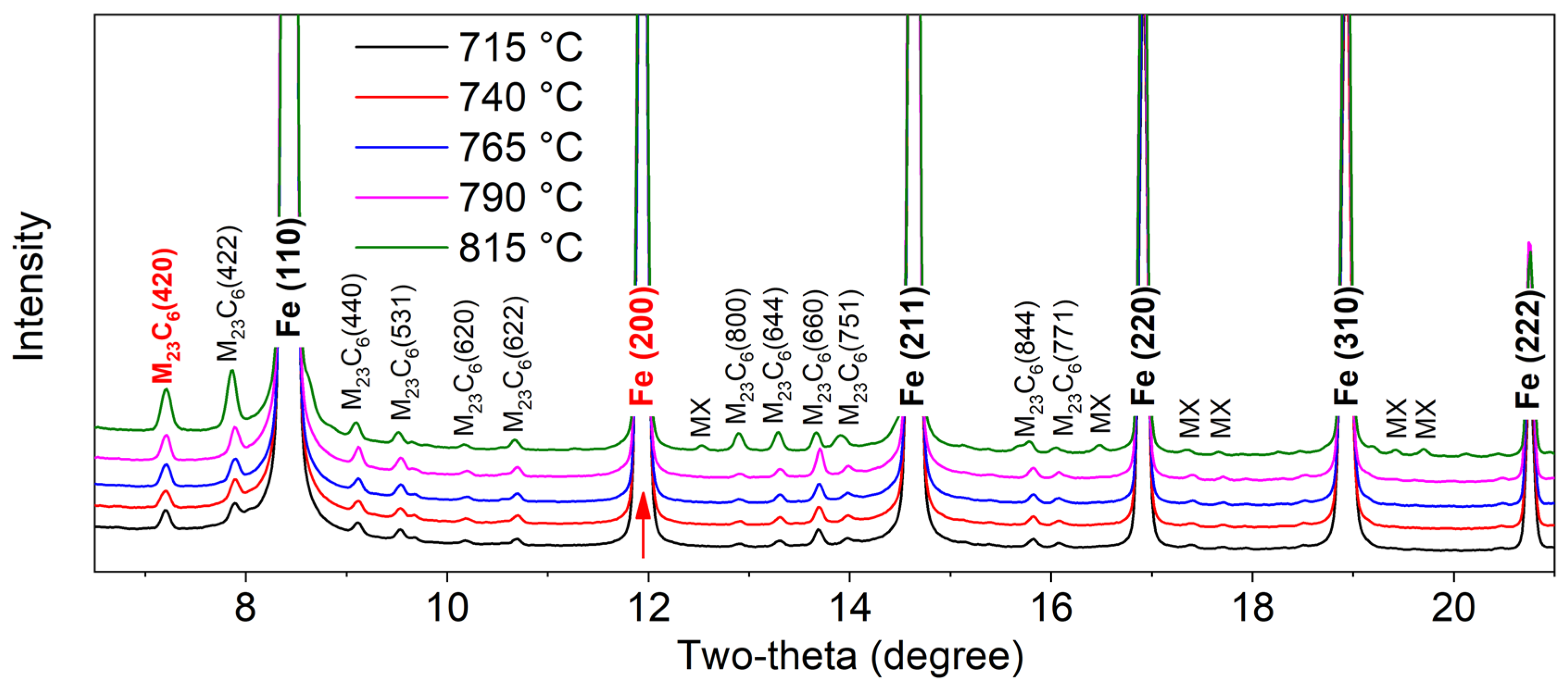

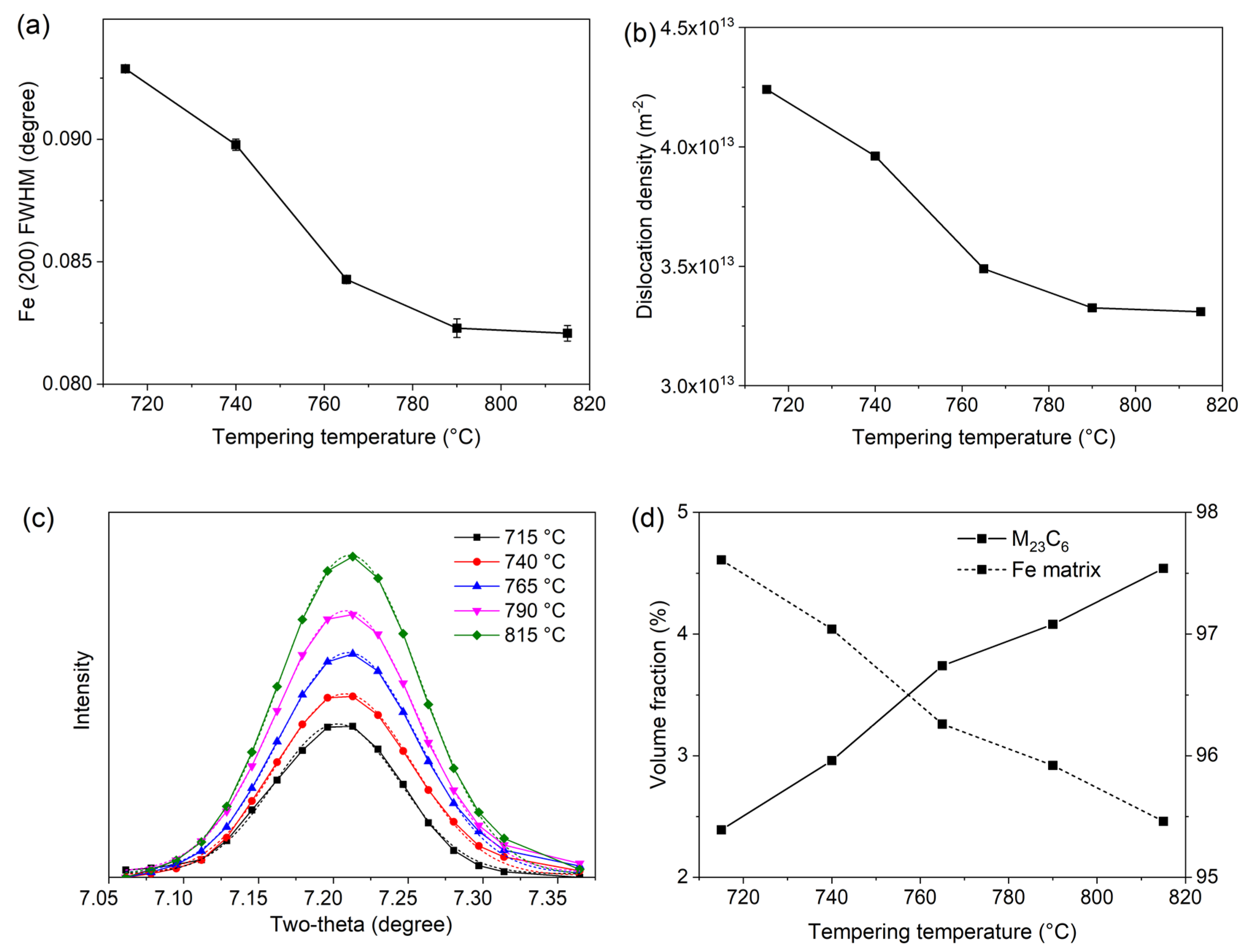

3.2. Synchrotron Radiation X-ray Diffraction

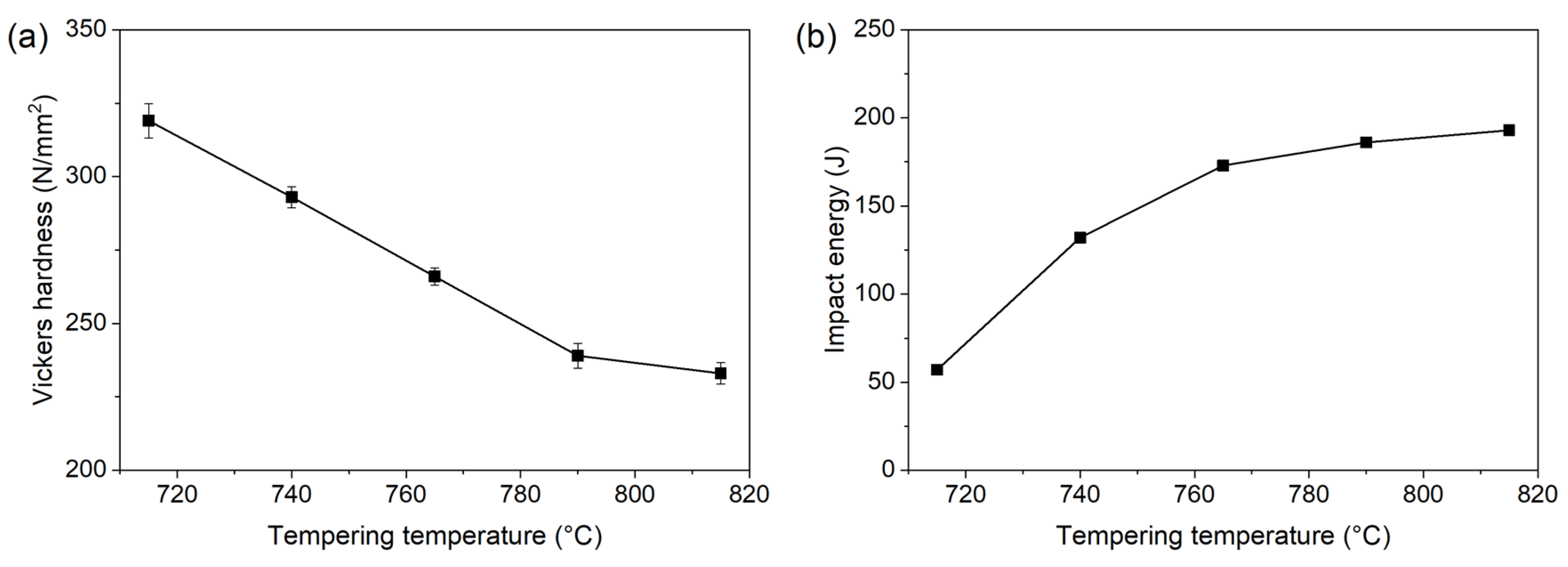

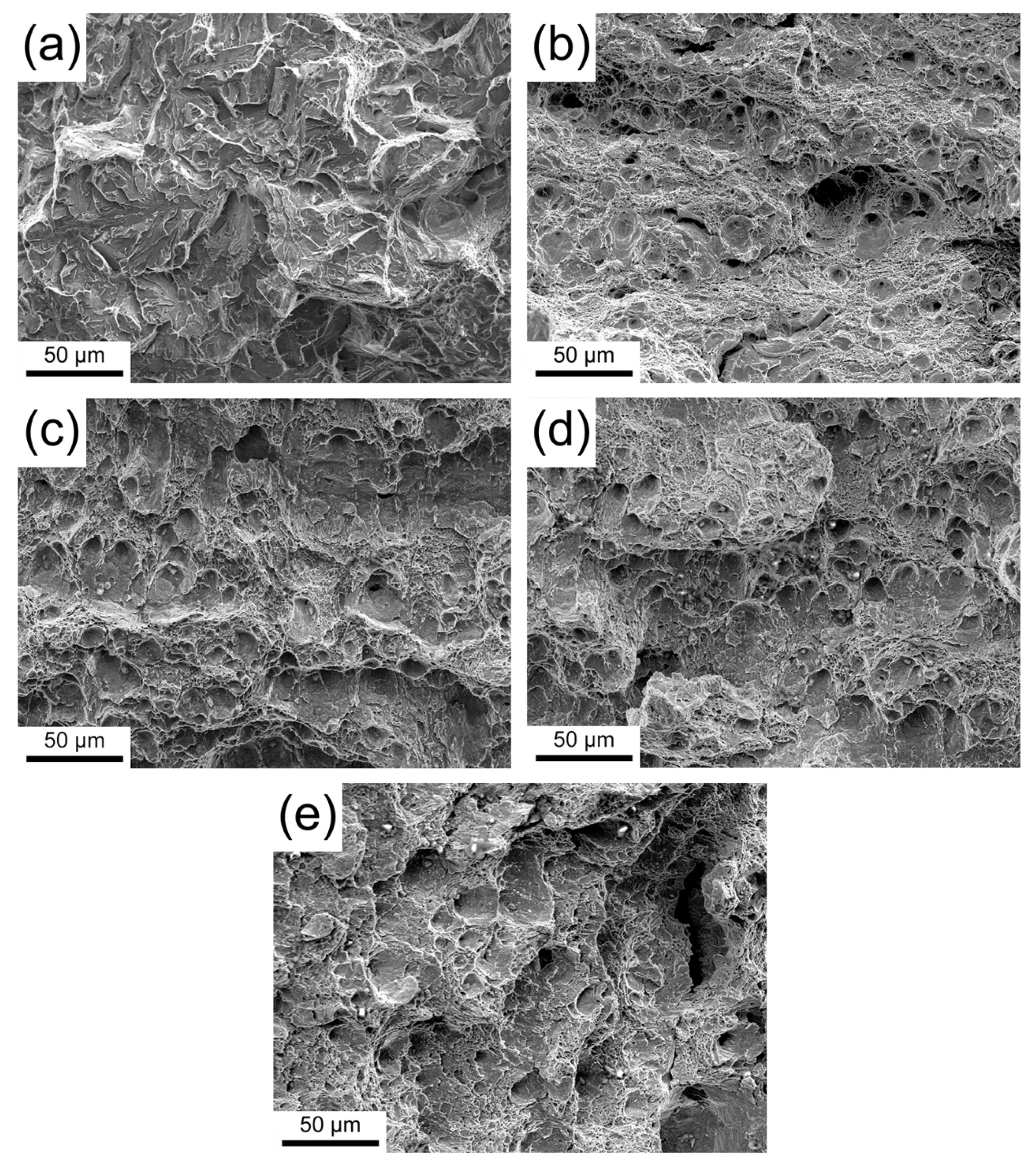

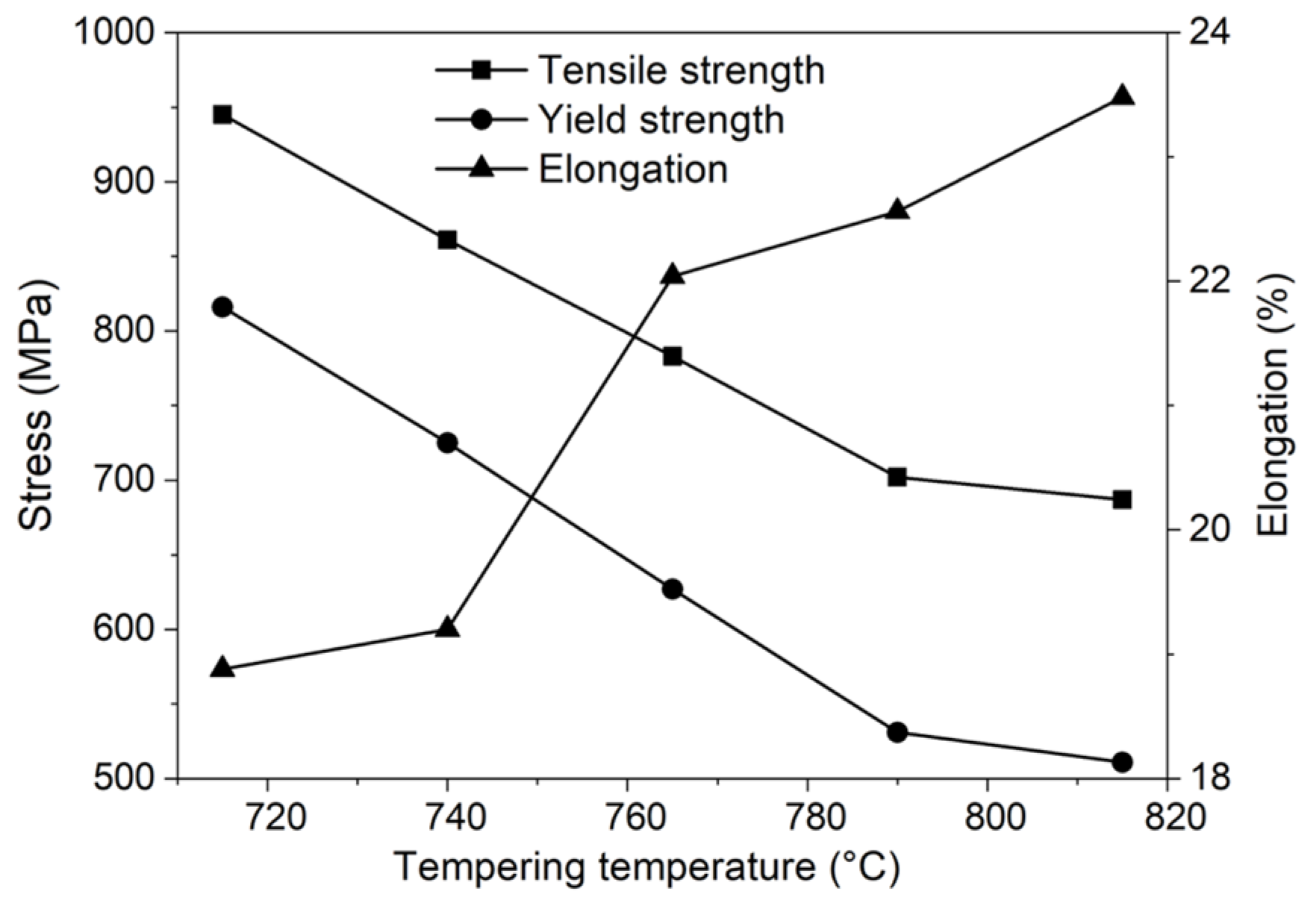

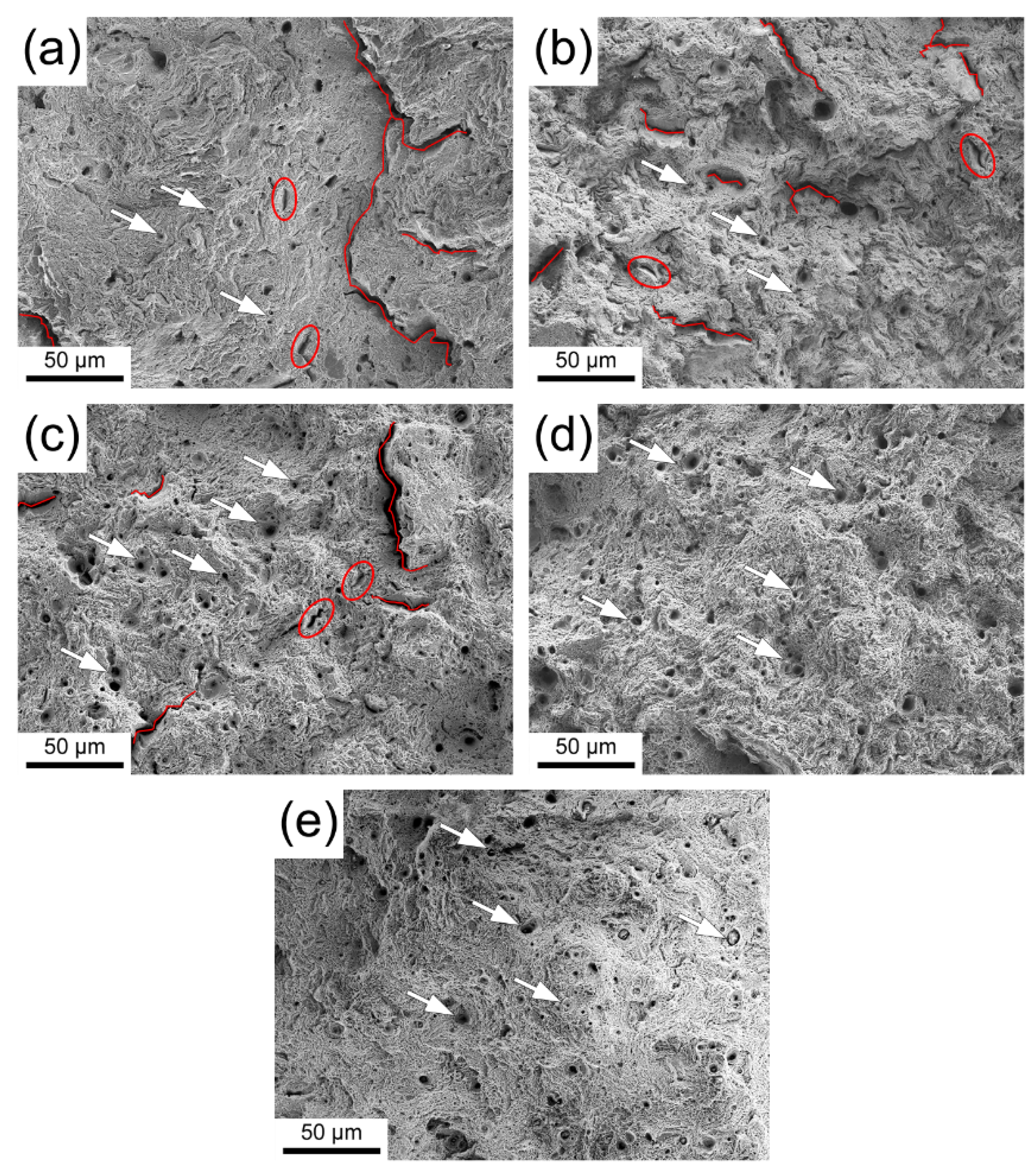

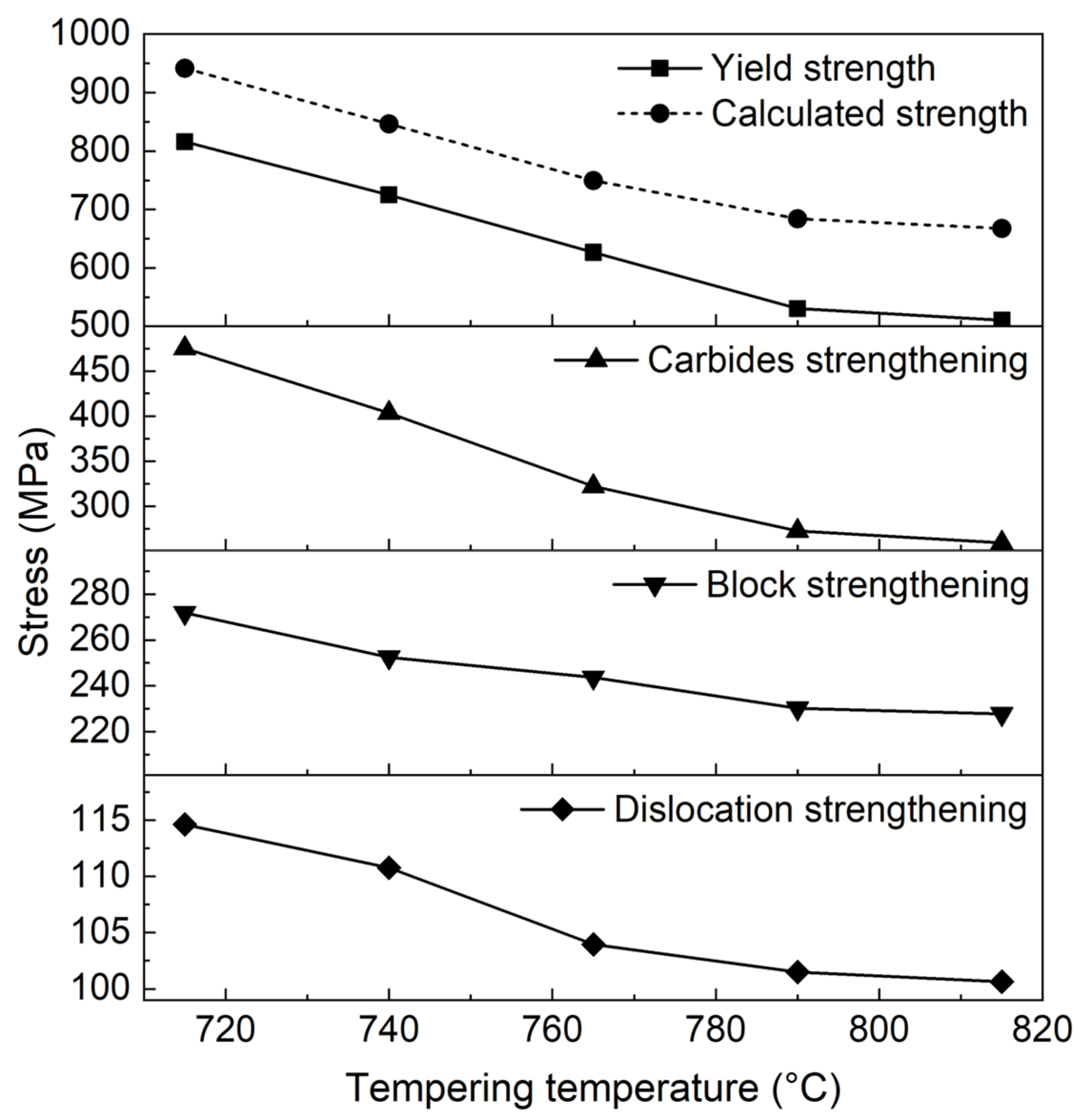

3.3. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, L.; Jing, H.; Xu, L.; Han, Y.; Xiu, J. Analysis of creep crack growth behavior of P92 steel welded joint by experiment and numerical simulation. Mater. Sci. Eng. A 2012, 558, 119–128. [Google Scholar] [CrossRef]

- Cheon, J.S.; Lee, C.B.; Lee, B.O.; Raison, J.P.; Mizuno, T.; Delage, F.; Carmack, J. Sodium fast reactor evaluation: Core materials. J. Nucl. Mater. 2009, 392, 324–330. [Google Scholar] [CrossRef]

- Murty, K.L.; Charit, I. Structural materials for Gen-IV nuclear reactors: Challenges and opportunities. J. Nucl. Mater. 2008, 383, 189–195. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, X.; Song, X.; Ma, C.; Qi, Y.; Chen, X. Microstructure and properties of welded joint for T92 ferritic heat resistant steel. J. Alloys Compd. 2017. [Google Scholar] [CrossRef]

- Rajesh Kannan, P.; Muthupandi, V.; Arivazhagan, B.; Devakumaran, K. Microstructure and mechanical properties of heat-treated T92 martensitic heat resistant steel. High Temp. Mater. Processes 2017, 36, 771–778. [Google Scholar] [CrossRef]

- Zhao, D.; Li, S.; Wang, Y.; Liu, F.; Wang, X. Investigation of ion irradiation hardening behaviors of tempered and long-term thermal aged T92 steel. J. Nucl. Mater. 2018, 511, 191–199. [Google Scholar] [CrossRef]

- Guo, X.; Gong, J.; Jiang, Y.; Rong, D. The influence of long-term aging on microstructures and static mechanical properties of P92 steel at room temperature. Mater. Sci. Eng. A 2013, 564, 199–205. [Google Scholar] [CrossRef]

- Nie, M.; Zhang, J.; Huang, F.; Liu, J.; Zhu, X.; Chen, Z.; Ouyang, L. Microstructure evolution and life assessment of T92 steel during long-term creep. J. Alloys Compd. 2014, 588, 348–356. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Dudova, N.; Kaibyshev, R.; Belyakov, A. Effect of Tungsten on Creep Behavior of 9%Cr–3%Co Martensitic Steels. Metals 2017, 7, 573. [Google Scholar] [CrossRef]

- Vivas, J.; Capdevila, C.; Jimenez, J.; Benito-Alfonso, M.; San-Martin, D. Effect of ausforming temperature on the microstructure of G91 steel. Metals 2017, 7, 236. [Google Scholar] [CrossRef]

- Heo, H.; Kim, J.; Kim, S.; Kim, J. Evaluation of workability on the microstructure and mechanical property of modified 9Cr-2W steel for fuel cladding by cold drawing process and intermediate heat treatment condition. Metals 2018, 8, 193. [Google Scholar] [CrossRef]

- Chen, J.; Ning, B. Research status of microstructure evolution and strengthening methods of P92 steel in the process of high temperature creep. Mater. Rev. 2014, 28, 53–59. (In Chinese) [Google Scholar] [CrossRef]

- Totten, G.E. Steel Heat Treatment: Metallurgy and Technologies; CRC Press: Boca Raton, FL, USA, 2006; p. 22. [Google Scholar]

- Yan, P.; Liu, Z.; Bao, H.; Weng, Y.; Liu, W. Effect of normalizing temperature on the strength of 9Cr-3W-3Co martensitic heat resistant steel. Mater. Sci. Eng. A 2014, 597, 148–156. [Google Scholar] [CrossRef]

- Wang, S.; Peng, D.; Chang, L.; Hui, X. Enhanced mechanical properties induced by refined heat treatment for 9Cr-0.5Mo-1.8W martensitic heat resistant steel. Mater. Des. 2013, 50, 174–180. [Google Scholar] [CrossRef]

- Liu, J.; Shu, G.; Wang, Z.; Liu, S.; Cheng, H.; Shi, C. Optimization of heat treatment process parameters for 9Cr-1Mo-V-Nb-N steel pipe. Heat Treat. Met. 2003, 28, 37–41. (In Chinese) [Google Scholar] [CrossRef]

- Renzetti, R.A.; Sandim, H.R.Z.; Bolmaro, R.E.; Suzuki, P.A.; Möslang, A. X-ray evaluation of dislocation density in ODS-Eurofer steel. Mater. Sci. Eng. A 2012, 534, 142–146. [Google Scholar] [CrossRef]

- Wang, L.; Li, M.; Almer, J. Investigation of deformation and microstructural evolution in Grade 91 ferritic–martensitic steel by in situ high-energy X-rays. Acta Mater. 2014, 62, 239–249. [Google Scholar] [CrossRef]

- Li, M.; Wang, L.; Almer, J.D. Dislocation evolution during tensile deformation in ferritic–martensitic steels revealed by high-energy X-rays. Acta Mater. 2014, 76, 381–393. [Google Scholar] [CrossRef]

- Abe, F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 13002. [Google Scholar] [CrossRef]

- Sánchez Egea, A.J.; González Rojas, H.A.; Celentano, D.J.; Jorba Peiró, J. Mechanical and metallurgical changes on 308L wires drawn by electropulses. Mater. Des. 2016, 90, 1159–1169. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Q.; Ren, J.; Li, R.; Wang, M.; Zhang, F.; Yan, Z. Effect of microstructure on the strength of 25CrMo48V martensitic steel tempered at different temperature and time. Mater. Des. 2012, 36, 220–226. [Google Scholar] [CrossRef]

- Wang, L.; Li, M.; Almer, J. In situ characterization of Grade 92 steel during tensile deformation using concurrent high energy X-ray diffraction and small angle X-ray scattering. J. Nucl. Mater. 2013, 440, 81–90. [Google Scholar] [CrossRef]

- Sánchez Egea, A.J.; González Rojas, H.A.; Celentano, D.J.; Jorba Perió, J.; Cao, J. Thermomechanical analysis of an electrically assisted wire drawing process. J. Manuf. Sci. Eng. 2017, 139, 111017. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, J.; Wang, H.; Wu, X. Effect of tempering on microstructure and mechanical properties of a non-quenched bainitic steel. Mater. Sci. Eng. A 2010, 527, 3433–3437. [Google Scholar] [CrossRef]

- Morito, S.; Yoshida, H.; Maki, T.; Huang, X. Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng. A 2006, 438–440, 237–240. [Google Scholar] [CrossRef]

- Wang, C. Study on Control Unit of Strength and Toughness Microstructure of Low Alloy Martensite Steel. Ph.D. Thesis, Central Iron and Steel Research Institute, Beijing, China, May 2008. [Google Scholar]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Sabirov, I.; Kolednik, O. The effect of inclusion size on the local conditions for void nucleation near a crack tip in a mild steel. Scr. Mater. 2005, 53, 1373–1378. [Google Scholar] [CrossRef]

- Shabrov, M.N.; Needleman, A. An analysis of inclusion morphology effects on void nucleation. Model. Simul. Mater. Sci. Eng. 2002, 10, 163–183. [Google Scholar] [CrossRef]

- Pan, X.; Wu, X.; Chen, X.; Mo, K.; Almer, J.; Haeffner, D.R.; Stubbins, J.F. Temperature and particle size effects on flow localization of 9–12%Cr ferritic/martensitic steel by in situ X-ray diffraction and small angle scattering. J. Nucl. Mater. 2010, 398, 220–226. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | P | S | Cr | W | Mo | Ni | V | Nb | B | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T92 steel | 0.12 | 0.2 | 0.53 | 0.017 | 0.0008 | 8.86 | 1.65 | 0.38 | 0.20 | 0.20 | 0.048 | 0.0024 | 0.046 | Balance |

| Tempering Temperature (°C) | 715 | 740 | 765 | 790 | 815 |

|---|---|---|---|---|---|

| Prior austenite grain size (μm) | 20.1 ± 5.3 | 19.7 ± 6.1 | 19.9 ± 6.3 | 20.2 ± 7.9 | 19.8 ± 5.5 |

| Length of martensite lath (μm) | 9.8 ± 4.1 | 10.7 ± 3.9 | 9.9 ± 3.6 | 11.6 ± 5.1 | 11.2 ± 3.7 |

| Width of martensite lath (nm) | 348 ± 98 | 407 ± 96 | 437 ± 78 | 489 ± 131 | 495 ± 117 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, D.; Zhang, S.; Zhang, H.; Li, S.; Xiao, H.; Wang, Y.; Wang, X. Effects of Tempering Temperature on the Microstructure and Mechanical Properties of T92 Heat-Resistant Steel. Metals 2019, 9, 194. https://doi.org/10.3390/met9020194

Zhao D, Zhang S, Zhang H, Li S, Xiao H, Wang Y, Wang X. Effects of Tempering Temperature on the Microstructure and Mechanical Properties of T92 Heat-Resistant Steel. Metals. 2019; 9(2):194. https://doi.org/10.3390/met9020194

Chicago/Turabian StyleZhao, Dandan, Shenghua Zhang, Hai Zhang, Shilei Li, Huifang Xiao, Yanli Wang, and Xitao Wang. 2019. "Effects of Tempering Temperature on the Microstructure and Mechanical Properties of T92 Heat-Resistant Steel" Metals 9, no. 2: 194. https://doi.org/10.3390/met9020194

APA StyleZhao, D., Zhang, S., Zhang, H., Li, S., Xiao, H., Wang, Y., & Wang, X. (2019). Effects of Tempering Temperature on the Microstructure and Mechanical Properties of T92 Heat-Resistant Steel. Metals, 9(2), 194. https://doi.org/10.3390/met9020194