A Fast Method for Predicting the Mechanical Properties of Precipitation-Hardenable Aluminum Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Samples

2.2. Experimental Design and Measurements

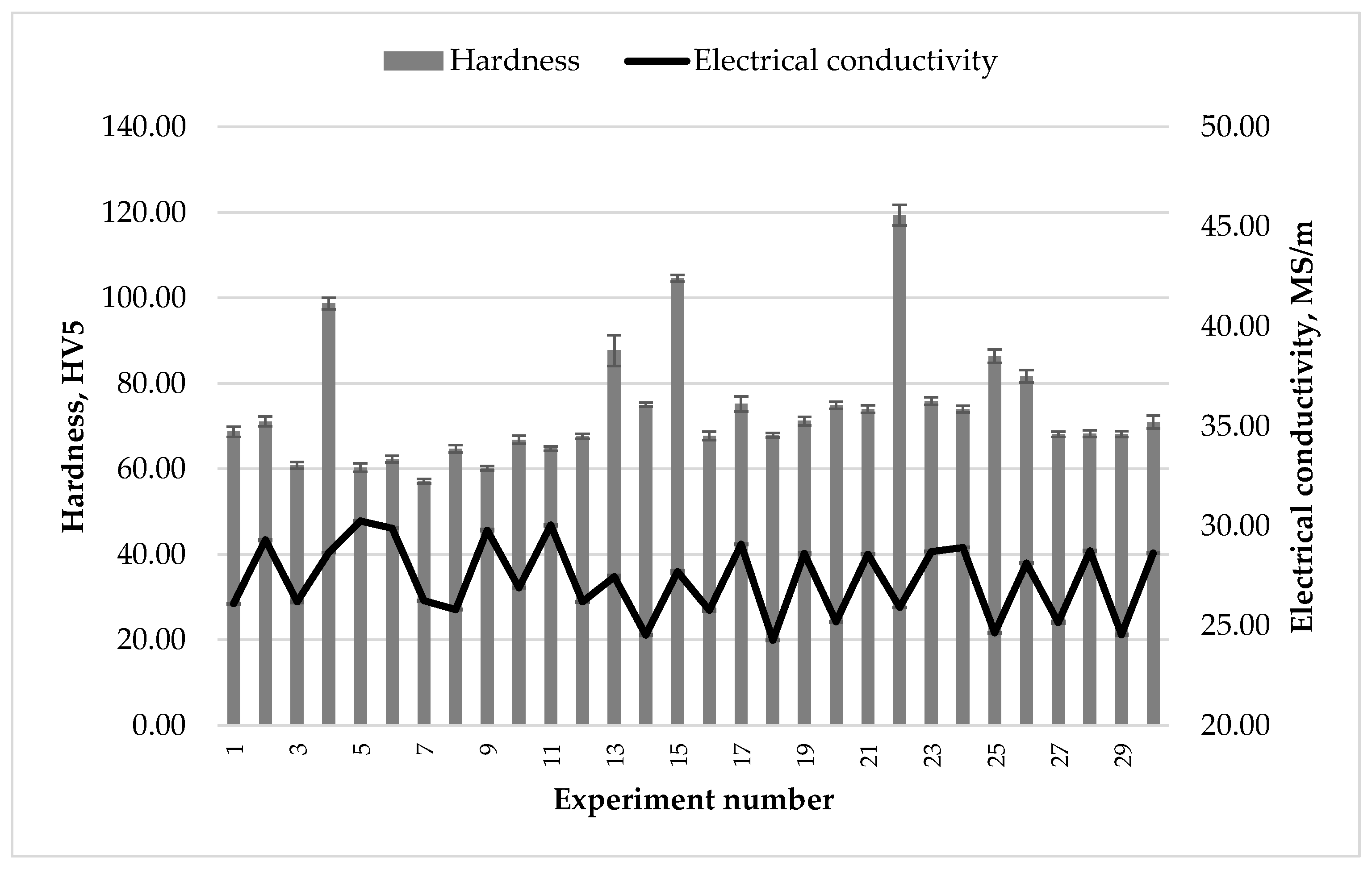

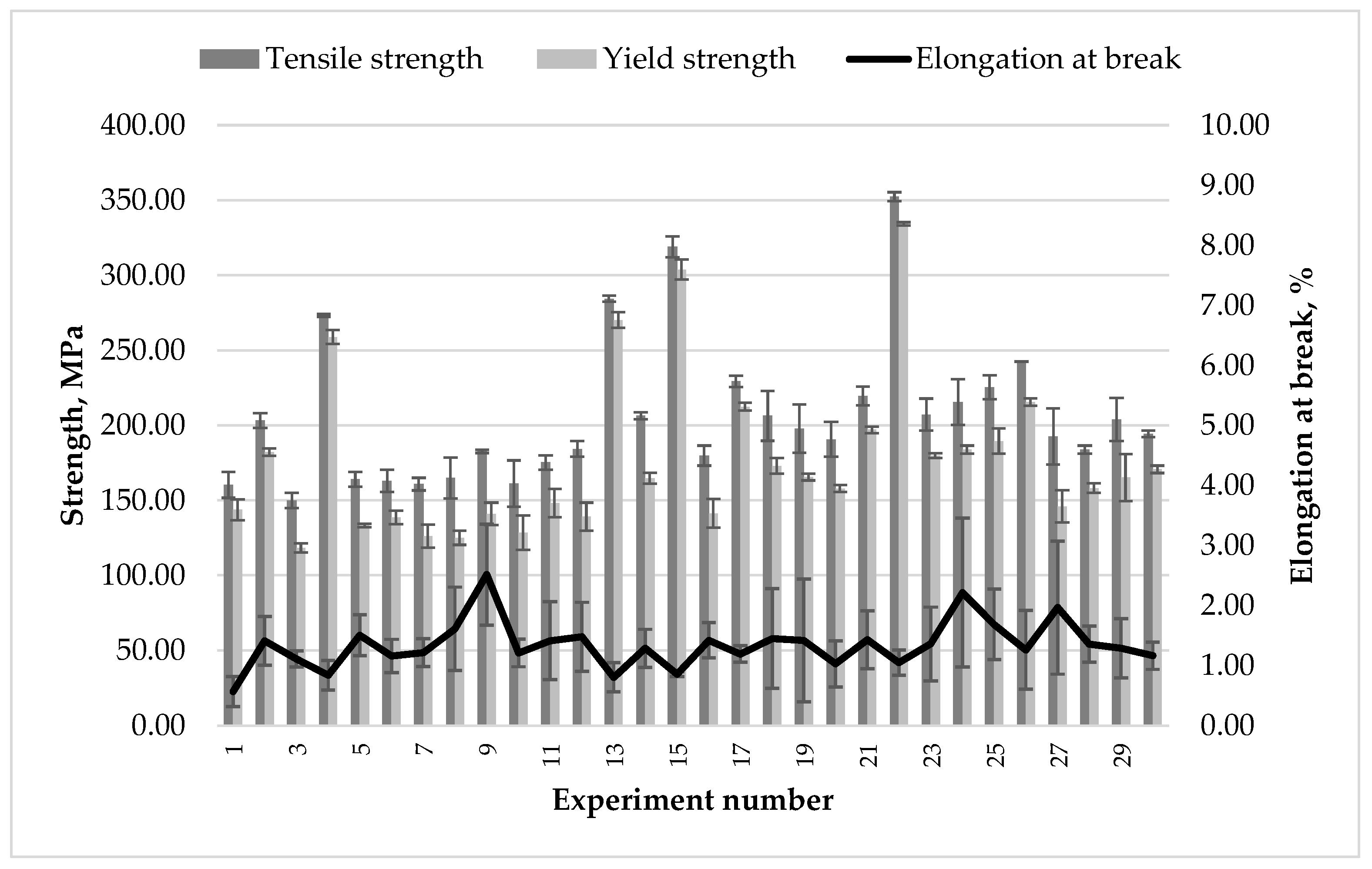

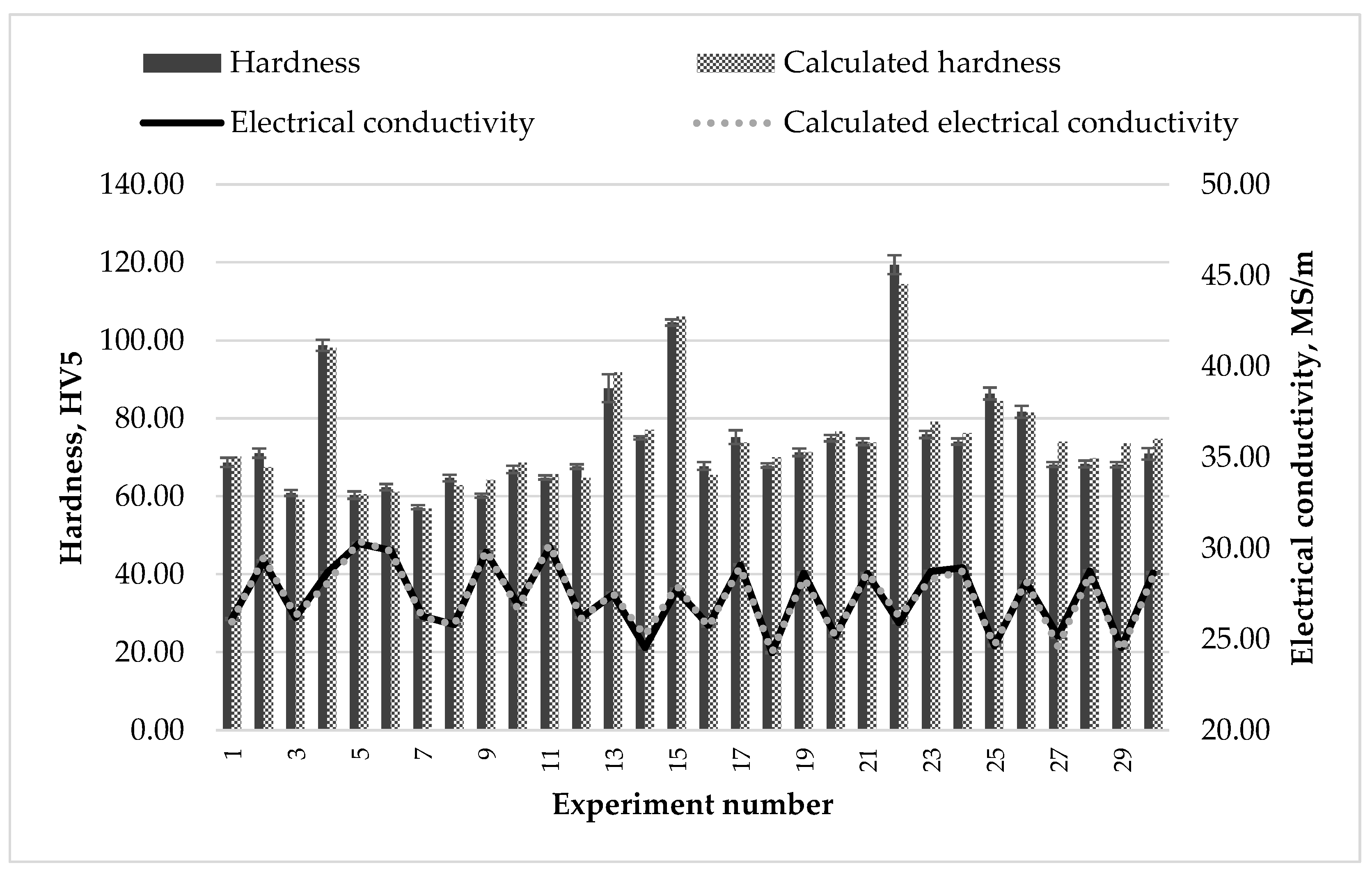

3. Results and Discussion

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nicolas, M.; Deschamps, A. Characterisation and modelling of precipitate evolution in an Al-Zn-Mg alloy during non-isothermal heat treatments. Acta Mater. 2003, 51, 6077–6094. [Google Scholar] [CrossRef]

- Werenskiold, J.C.; Deschamps, A.; Brechet, Y. Characterization and modeling of precipitation kinetics in an Al-Zn-Mg alloy. Mater. Sci. Eng. 2000, A293, 267–274. [Google Scholar] [CrossRef]

- Bardel, D.; Perez, M.; Nelias, D.; Deschamps, A.; Hutchinson, C.R.; Maisonnette, D.; Chaise, T.; Garnier, J.; Bourlier, F. Coupled precipitation and yield strength modelling for non-isothermal treatments of a 6061 aluminium alloy. Acta Mater. 2014, 62, 129–140. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J. Modeling of precipitation hardening in pre-aged AlMgSi(Cu) alloys. Acta Mater. 2005, 53, 5257–5271. [Google Scholar] [CrossRef]

- Khan, I.N.; Starink, M.J.; Yan, J.L. A model for precipitation kinetics and strengthening in Al-Cu-Mg alloys. Mater. Sci. Eng. 2008, A472, 66–74. [Google Scholar] [CrossRef]

- Österreicher, J.A.; Papenberg, N.P.; Kumar, M.; Ma, D.; Schwarz, S.; Schlögl, C.M. Quantitative prediction of the mechanical properties of precipitation-hardened alloys with special application to Al-Mg-Si. Mater. Sci. Eng. A 2017, 703, 380–385. [Google Scholar] [CrossRef]

- Sepehrband, P.; Esmaeili, S. Application of recently developed approaches to microstructural characterization and yield strength modeling of aluminum alloy AA7030. Mater. Sci. Eng. A 2008, 487, 309–315. [Google Scholar] [CrossRef]

- Zhu, A.W.; Starke, E.A., Jr. Stress aging of Al-Cu alloys: Computer modeling. Acta Mater. 2001, 49, 3063–3069. [Google Scholar] [CrossRef]

- Jiang, H.; Faulkner, R.G. Modelling of grain boundary segregation, precipitation and precipitate-free zones of high strength aluminium alloys—I. The model. Acta Mater. 1996, 44, 1857–1864. [Google Scholar] [CrossRef]

- Khan, I.N.; Starink, M.J. Microstructure and strength modelling of Al-Cu-Mg alloys during non-isothermal treatments Part 1—Controlled heating and cooling. Mater. Sci. Technol. 2008, 24, 1403–1410. [Google Scholar] [CrossRef]

- Löchte, L.; Gitt, A.; Gottstein, G.; Hurtado, I. Simulation of the evolution of GP zones in Al-Cu alloys: An extended Cahn-Hilliard approach. Acta Mater. 2000, 48, 2969–2984. [Google Scholar] [CrossRef]

- Robson, J.D. A new model for prediction of dispersoid precipitation in aluminium alloys containing zirconium and scandium. Acta Mater. 2004, 52, 1409–1421. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J.; Poole, W.J. A yield strength model for the Al-Mg-Si-Cu alloy AA6111. Acta Mater. 2003, 51, 2243–2257. [Google Scholar] [CrossRef]

- Zander, J.; Sandström, R. One parameter model for strength properties of hardenable aluminium alloys. Mater. Des. 2008, 29, 1540–1548. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Kuang, W.; Zhang, J. Application of the thermodynamic extremal principle to phase-field modeling of non-equilibrium solidification in multi-component alloys. Acta Mater. 2017, 128, 258–267. [Google Scholar] [CrossRef]

- Liu, S.; Gao, M.C.; Liaw, P.K.; Zhang, Y. Microstructures and mechanical properties of AlxCrFeNiTi0.25 alloys. J. Alloy. Compd. 2015, 619, 610–615. [Google Scholar] [CrossRef]

- Lang, P.; Povoden-Karadeniz, E.; Falahati, A.; Kozeschnik, E. Simulation of the effect of composition on the precipitation in 6xxx Al alloys during continuous-heating DSC. J. Alloy. Compd. 2014, 612, 443–449. [Google Scholar] [CrossRef]

- Garrett, R.P.; Lin, J.; Dean, T.A. An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: Experimentation and modelling. Int. J. Plast. 2005, 21, 1640–1657. [Google Scholar] [CrossRef]

- Bates, C.E. Quench optimization for aluminum alloys. AFS Trans. 1994, 93–25, 1045–1054. [Google Scholar]

- Flynn, R.J.; Robinson, J.S. The application of advances in quench factor analysis property prediction to the heat treatment of 7010 aluminium alloy. J. Mater. Process. Technol. 2004, 153–154, 674–680. [Google Scholar] [CrossRef]

- Ma, S.; Maniruzzaman, M.D.; MacKenzie, D.S.; Sisson, R.D., Jr. A methodology to predict the effects of quench rates on mechanical properties of cast aluminum alloys. Metall. Mater. Trans. 2007, 38B, 583–589. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Schaffer, G.B.; Yao, J.-Y.; Couper, M.J. Application of quench factor analysis to A356.0 and A357.0 foundry alloys. In Proceedings of the 6th International Conference on Aluminum Alloys, Toyohashi, Japan, 5–10 July 1998. [Google Scholar]

- Staley, J.T. Quench factor analysis of aluminium alloys. Mater. Sci. Technol. 1987, 3, 923–935. [Google Scholar] [CrossRef]

- Dolan, G.P.; Flynn, R.J.; Tanner, D.A.; Robinson, J.S. Quench factor analysis of aluminium alloys using Jominy end quench technique. Mater. Sci. Technol. 2005, 21, 687–692. [Google Scholar] [CrossRef]

- Järvsträt, N.; Tjøtta, S. Modelling cooling of aluminium extrusions. In Proceedings of the Abaqus Users’ Conference, Newport, RI, USA, 19–22 May 1994; pp. 307–316. [Google Scholar]

- Robinson, J.S.; Cudd, R.L.; Tanner, D.A.; Dolan, G.P. Quench sensitivity and tensile property inhomogeneity in 7010 forgings. J. Mater. Process. Technol. 2001, 119, 261–267. [Google Scholar] [CrossRef]

- Güzel, A.; Jäger, A.; Ben Khalifa, N.; Tekkaya, A.E. Simulation of the quench sensitivity of the aluminum alloy 6082. Key Eng. Mater. 2010, 424, 51–56. [Google Scholar] [CrossRef]

- Box, G.E.P.; Lucas, H.L. Design of experiments in nonlinear situations. Biometrika 1959, 46, 77–90. [Google Scholar] [CrossRef]

| Material | Chemical Composition in wt % | |||||||

|---|---|---|---|---|---|---|---|---|

| Al | Si | Mg | Mn | Fe | Cu | Others | ||

| Samples alloy | bal. | 0.916 | 0.727 | 0.437 | 0.381 | 0.086 | <0.05 | |

| DIN EN 573-3:2013-12 | min. | bal. | 0.7 | 0.6 | 0.40 | - | - | - |

| max. | 1.3 | 1.2 | 1.0 | 0.50 | 0.10 | 0.15 | ||

| Abbreviation | Parameters | Base | Selected Range |

|---|---|---|---|

| Ts | Solution temperature, °C | 530 | 500–560 |

| ts | Solution time, h | 2.13 | 0.25–4 |

| QM | Quenching medium | Water | Gas, Polymer, Water |

| Ta | Aging temperature, °C | 170 | 100–240 |

| ta | Aging time, h | 11 | 2–20 |

| No. | Ts (°C) | ts (h) | QM | Ta (°C) | ta (h) |

|---|---|---|---|---|---|

| 1 | 500 | 0.25 | Water | 100 | 20 |

| 2 | 500 | 0.25 | Water | 240 | 2 |

| 3 | 500 | 0.25 | Gas | 100 | 2 |

| 4 | 500 | 0.25 | Gas | 170 | 11 |

| 5 | 500 | 0.25 | Gas | 240 | 20 |

| 6 | 500 | 0.25 | Polymer | 240 | 20 |

| 7 | 500 | 2.13 | Polymer | 100 | 2 |

| 8 | 500 | 4 | Water | 100 | 2 |

| 9 | 500 | 4 | Water | 240 | 20 |

| 10 | 500 | 4 | Gas | 100 | 20 |

| 11 | 500 | 4 | Gas | 240 | 2 |

| 12 | 500 | 4 | Polymer | 100 | 20 |

| 13 | 500 | 4 | Polymer | 170 | 2 |

| 14 | 530 | 0.25 | Polymer | 100 | 11 |

| 15 | 530 | 2.13 | Gas | 170 | 20 |

| 16 | 530 | 4 | Gas | 100 | 2 |

| 17 | 530 | 4 | Polymer | 240 | 2 |

| 18 | 560 | 0.25 | Water | 100 | 2 |

| 19 | 560 | 0.25 | Water | 240 | 20 |

| 20 | 560 | 0.25 | Gas | 100 | 20 |

| 21 | 560 | 0.25 | Gas | 240 | 2 |

| 22 | 560 | 0.25 | Polymer | 170 | 20 |

| 23 | 560 | 0.25 | Polymer | 240 | 11 |

| 24 | 560 | 2.13 | Polymer | 240 | 11 |

| 25 | 560 | 4 | Water | 100 | 20 |

| 26 | 560 | 4 | Water | 240 | 2 |

| 27 | 560 | 4 | Gas | 100 | 11 |

| 28 | 560 | 4 | Gas | 240 | 20 |

| 29 | 560 | 4 | Polymer | 100 | 2 |

| 30 | 560 | 4 | Polymer | 240 | 20 |

| Parameters | Hardness | Electrical Conductivity | Yield Strength | Tensile Strength | Elongation at Break |

|---|---|---|---|---|---|

| Constant | 0.009 | 0.000 | 1 × 10−4 | 0.001 | 0.073 |

| Ts | 0.016 | 2 × 10−11 | 4 × 10−4 | 0.003 | 0.005 |

| ts | 0.291 | 0.028 | 0.127 | 0.784 | 0.022 |

| QM | 0.066 | 1 × 10−4 | 1 × 10−4 | 9 × 10−4 | 0.215 |

| Ta | 0.000 | 0.457 | 0.000 | 0.000 | 0.879 |

| ta | 3 × 10−6 | 0.019 | 0.771 | 1 × 10−3 | 0.155 |

| Ts2 | 0.019 | 0.147 | 5 × 10−4 | 0.004 | 0.485 |

| ts × Ts | 0.232 | 0.975 | 0.151 | 0.788 | 0.021 |

| QM × Ts | 0.046 | 0.533 | 0.298 | 0.785 | 0.229 |

| Ta × Ts | 0.670 | 0.334 | 0.418 | 0.167 | 0.016 |

| ta × Ts | 0.213 | 0.478 | 0.276 | 0.334 | 0.773 |

| ts2 | 0.486 | 0.037 | 0.120 | 0.797 | 0.229 |

| QM × ts | 0.021 | 0.459 | 0.344 | 0.206 | 0.067 |

| Ta × ts | 0.410 | 0.179 | 0.149 | 0.984 | 0.294 |

| ta × ts | 0.805 | 0.708 | 0.613 | 0.428 | 0.058 |

| QM × Ta | 0.923 | 0.114 | 0.852 | 0.253 | 0.158 |

| QM × ta | 0.139 | 0.714 | 0.400 | 0.407 | 0.301 |

| Ta2 | 0.000 | 0.092 | 0.000 | 0.000 | 0.003 |

| ta × Ta | 5 × 10−6 | 0.965 | 5 × 10−7 | 1 × 10−4 | 0.064 |

| ta2 | 0.104 | 0.231 | 0.033 | 0.390 | 0.011 |

| Adj R-Square | 0.952 | 0.979 | 0.976 | 0.955 | 0.537 |

| Legend: | 1st significance level | 2nd significance level | 3rd significance level | 4th significance level | out of the model |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toenjes, A.; von Hehl, A. A Fast Method for Predicting the Mechanical Properties of Precipitation-Hardenable Aluminum Alloys. Metals 2019, 9, 147. https://doi.org/10.3390/met9020147

Toenjes A, von Hehl A. A Fast Method for Predicting the Mechanical Properties of Precipitation-Hardenable Aluminum Alloys. Metals. 2019; 9(2):147. https://doi.org/10.3390/met9020147

Chicago/Turabian StyleToenjes, Anastasiya, and Axel von Hehl. 2019. "A Fast Method for Predicting the Mechanical Properties of Precipitation-Hardenable Aluminum Alloys" Metals 9, no. 2: 147. https://doi.org/10.3390/met9020147

APA StyleToenjes, A., & von Hehl, A. (2019). A Fast Method for Predicting the Mechanical Properties of Precipitation-Hardenable Aluminum Alloys. Metals, 9(2), 147. https://doi.org/10.3390/met9020147