Study of Sputtered ITO Films on Flexible Invar Metal Foils for Curved Perovskite Solar Cells

Abstract

1. Introduction

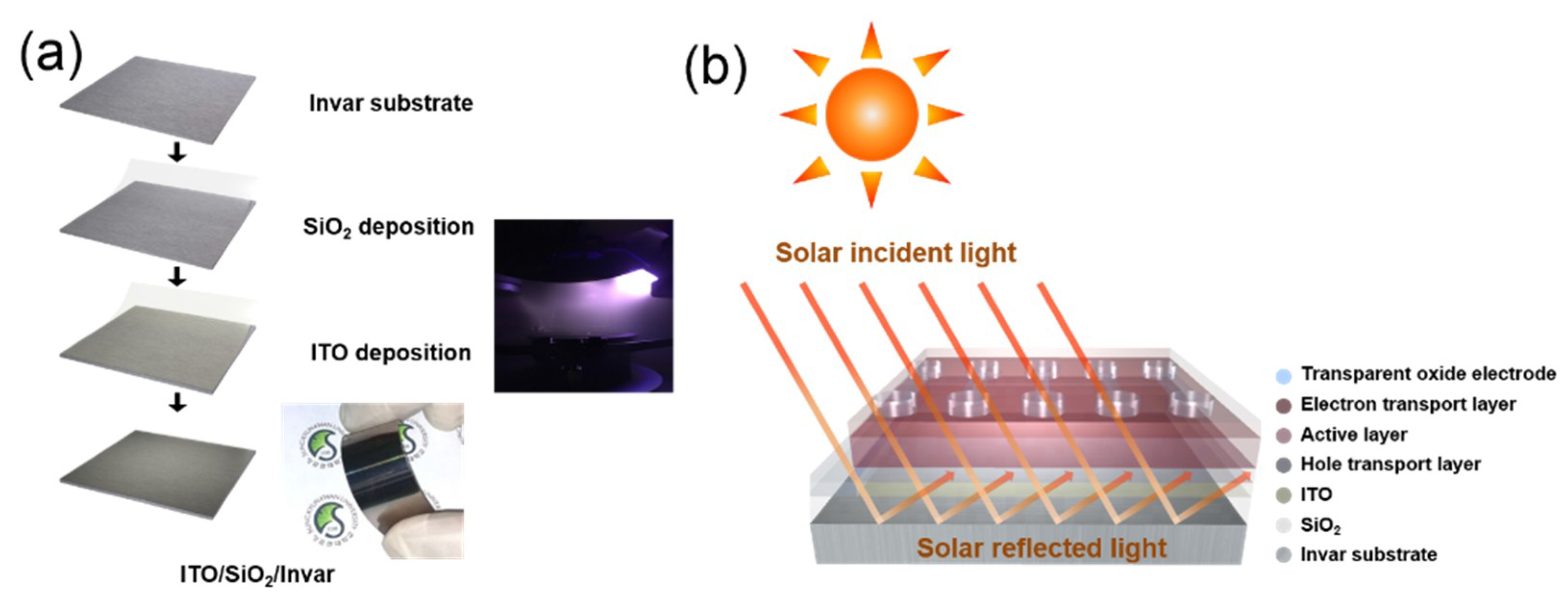

2. Materials and Methods

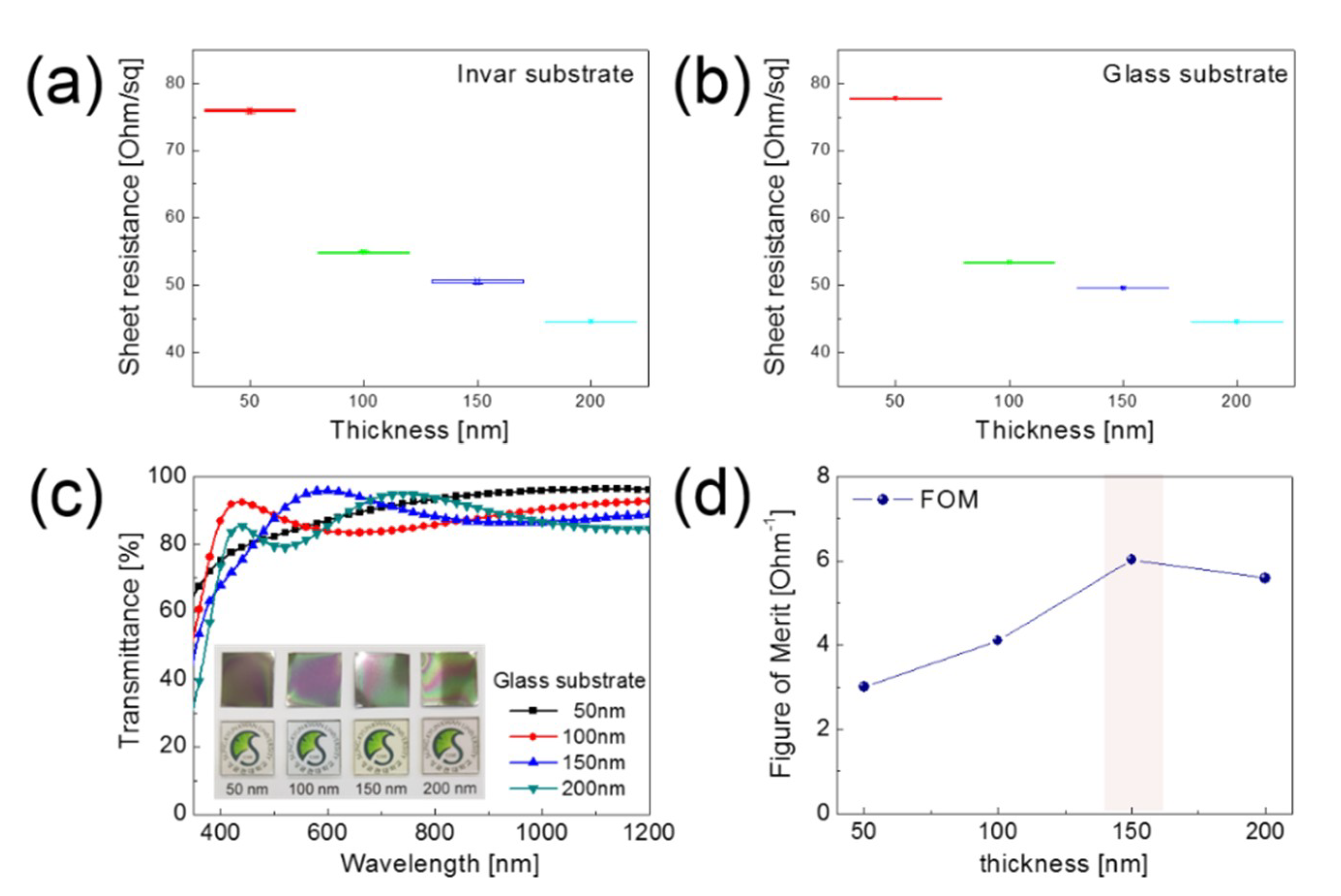

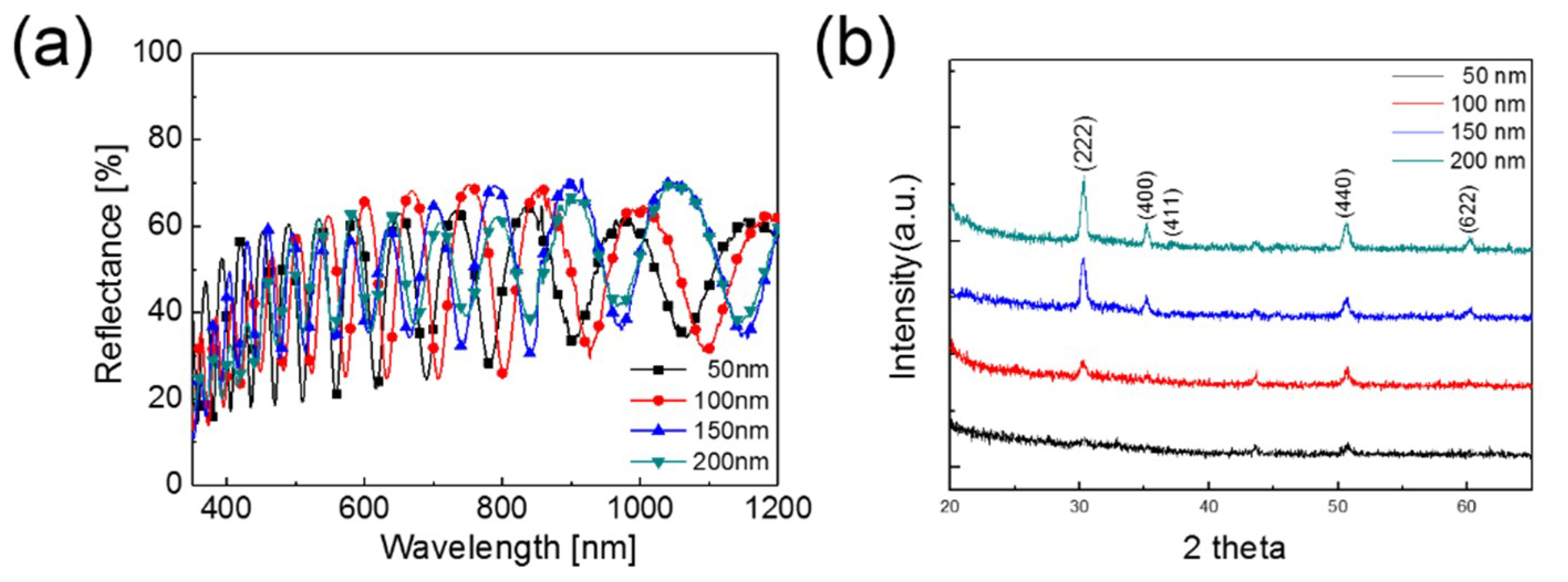

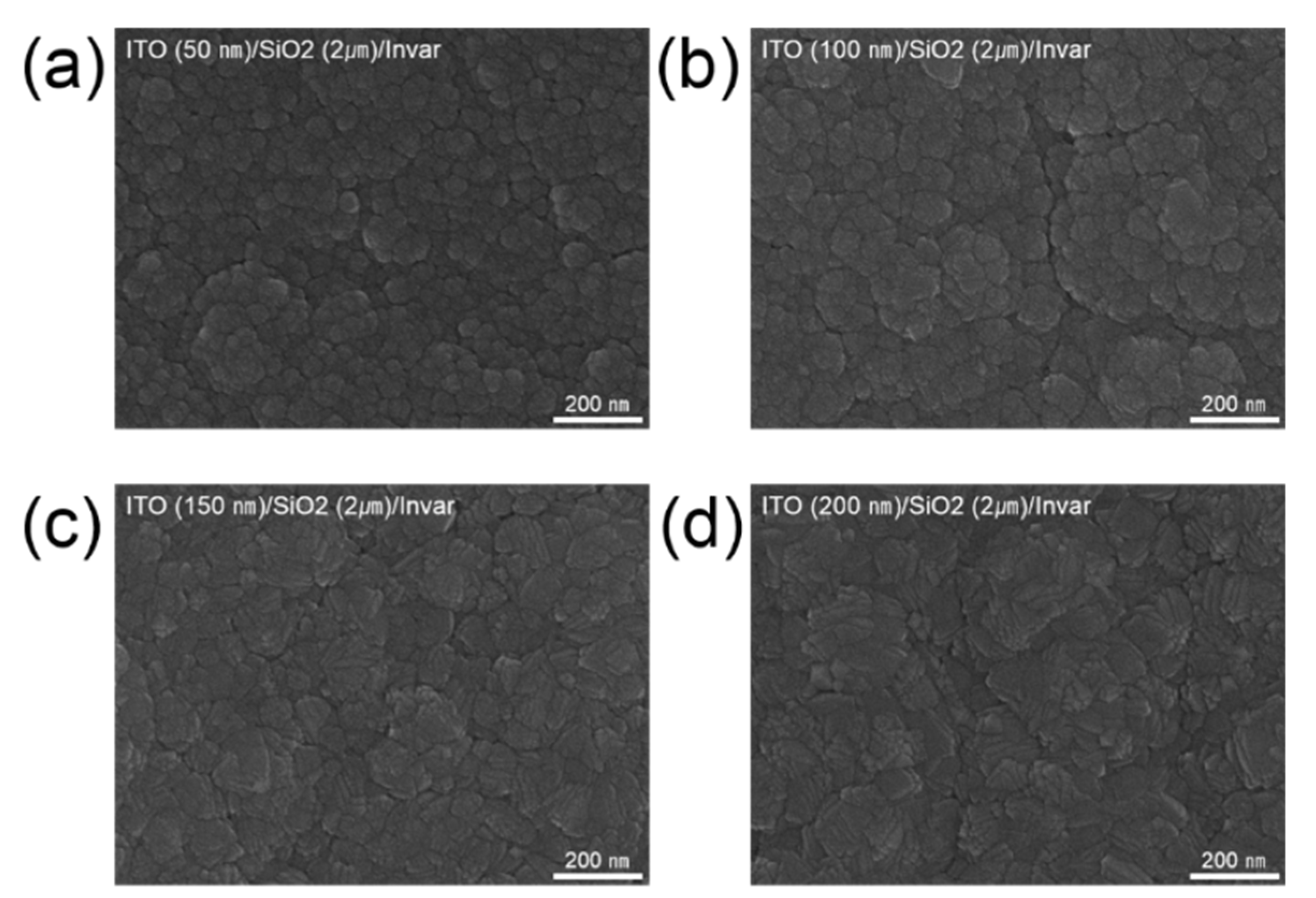

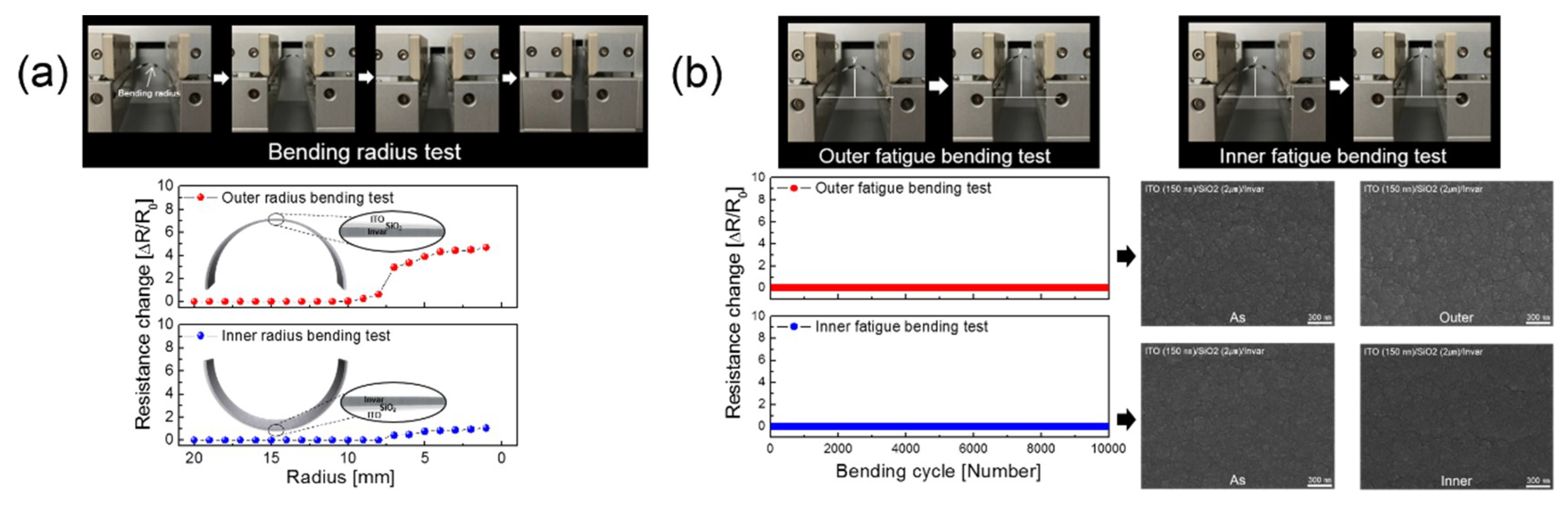

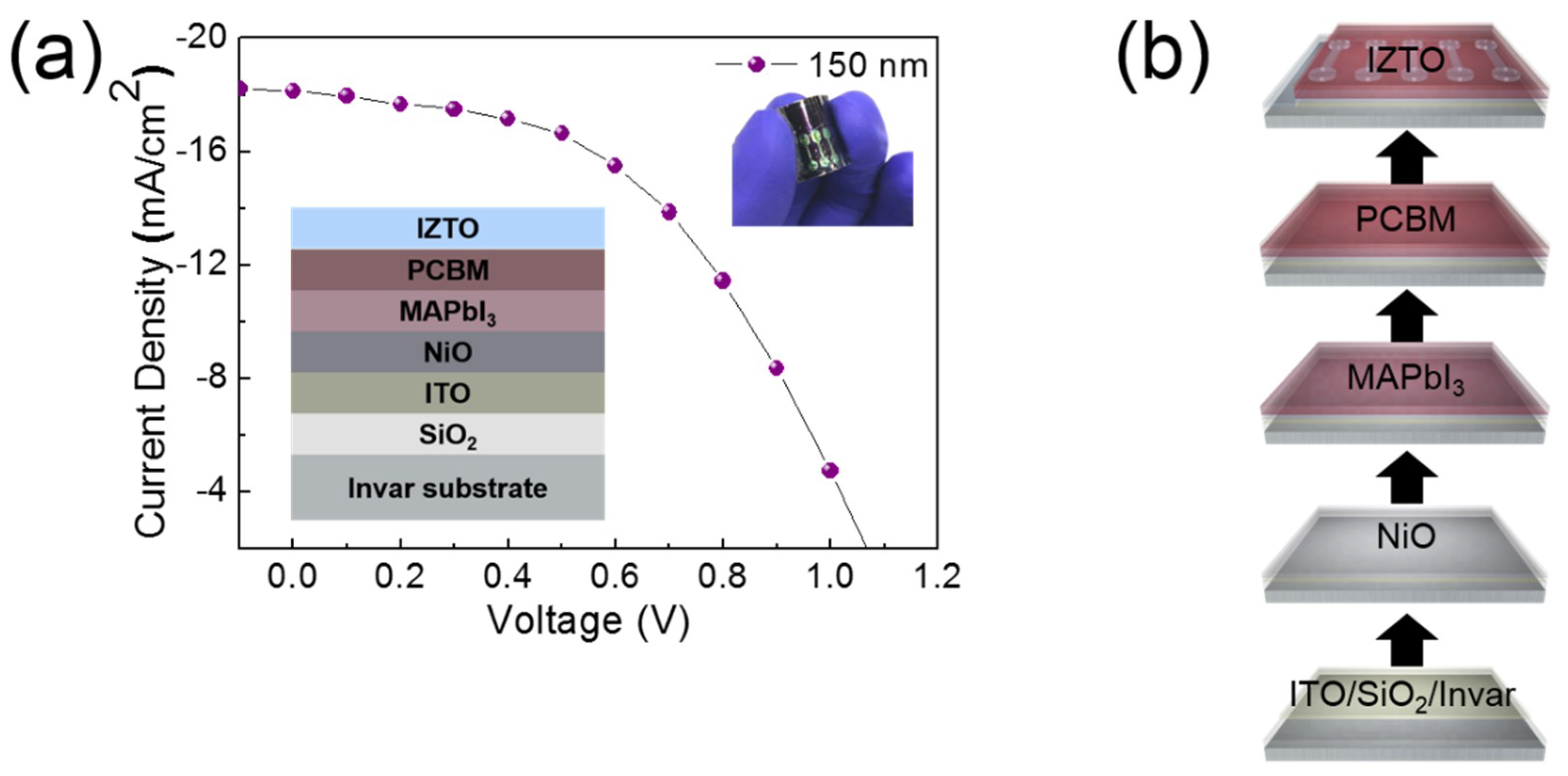

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jamal, M.S.; Bashar, M.S.; Mahmud Hasan, A.K.; Almutairi, Z.A.; Alharbi, H.F.; Alharthi, N.H.; Karim, M.R.; Misran, H.; Amin, N.; Sopian, K.B.; et al. Fabrication techniques and morphological analysis of perovskite absorber layer for high-efficiency perovskite solar cell: A review. Renew. Sustain. Energy Rev. 2018, 98, 469–488. [Google Scholar] [CrossRef]

- Stranks, S.D.; Snaith, H.J. Metal-halide perovskites for photovoltaic and light-emitting devices. Nat. Nanotechnol. 2015, 10, 391–402. [Google Scholar] [CrossRef]

- Li, J.; Jiu, T.; Duan, C.; Wang, Y.; Zhang, H.; Jian, H.; Zhao, Y.; Wang, N.; Huang, C.; Li, Y. Improved electron transport in MAPbI3 perovskite solar cells based on dual doping graphdiyne. Nano Energy 2018, 46, 331–337. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Seo, J.Y.; Domanski, K.; Correa-Baena, J.P.; Nazeeruddin, M.K.; Zakeeruddin, S.M.; Tress, W.; Abate, A.; Hagfeldt, A.; Grätzel, M. Cesium-containing triple cation perovskite solar cells: Improved stability, reproducibility and high efficiency. Energy Environ. Sci. 2016, 9, 1989–1997. [Google Scholar] [CrossRef] [PubMed]

- You, S.; Wang, H.; Bi, S.; Zhou, J.; Qin, L.; Qiu, X.; Zhao, Z.; Xu, Y.; Zhang, Y.; Shi, X.; Zhou, H.; Zhiyong, T. A biopolymer heparin sodium interlayer anchoring TiO2 and MAPbI3 enhances trap passivation and device stability in perovskite solar cells. Adv. Mater. 2018, 30, 1706924. [Google Scholar] [CrossRef]

- Bu, T.; Li, J.; Zheng, F.; Chen, W.; Wen, X.; Ku, Z.; Peng, Y.; Zhong, J.; Cheng, Y.B.; Huang, F. Universal passivation strategy to slot-die printed SnO2 for hysteresis-free efficient flexible perovskite solar module. Nat. Commun. 2018, 9, 4609. [Google Scholar] [CrossRef] [PubMed]

- Asghar, M.I.; Zhang, J.; Wang, H.; Lund, P.D. Device stability of perovskite solar cells—A review. Renew. Sustain. Energy Rev. 2017, 77, 131–146. [Google Scholar] [CrossRef]

- Giacomo, F.D.; Fakharuddin, A.; Jose, R.; Brown, T.M. Progress, challenges and perspectives in flexible perovskite solar cells. Energy Environ. Sci. 2016, 9, 3007–3035. [Google Scholar] [CrossRef]

- Shin, S.S.; Yang, W.S.; Noh, J.H.; Suk, J.H.; Jeon, N.J.; Park, J.H.; Kim, J.S.; Seong, W.M.; Seok, S.I. High-performance flexible perovskite solar cells exploiting Zn2SnO4 prepared in solution below 100 °C. Nat. Commun. 2015, 6, 7410. [Google Scholar] [CrossRef] [PubMed]

- Zardetto, V.; Brown, T.M.; Reale, A.; Carlo, A.D. Substrates for flexible electronics: A practical investigation on the electrical, film flexibility, optical temperature, and solvent resistance properties. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 638–648. [Google Scholar] [CrossRef]

- Burrows, P.E.; Graff, G.L.; Gross, M.E.; Martin, P.M.; Shi, M.K.; Hall, M.; Mast, E.; Bonham, C.; Bennett, W.; Sullivan, M.B. Ultra barrier flexible substrates for flat panel displays. Displays 2001, 22, 65–69. [Google Scholar] [CrossRef]

- Kim, K.; Kim, S.; Jung, G.H.; Lee, I.; Kim, S.; Ham, J.; Dong, W.J.; Hong, K.; Lee, J.L. Extremely flat metal films implemented by surface roughness transfer for flexible electronics. RSC Adv. 2018, 8, 10883–10888. [Google Scholar] [CrossRef]

- Luo, Z.; Lu, Y.; Singer, D.W.; Berck, M.E.; Somers, L.A.; Goldsmith, B.R.; Charlie Johnson, A.T. Effect of substrate roughness and feedstock concentration on growth of wafer-scale graphene at atmospheric pressure. Chem. Mater. 2011, 23, 1441–1447. [Google Scholar] [CrossRef]

- Calabrese, G.; Pettersen, S.V.; Pfüller, C.; Ramsteiner, M.; Grepstad, J.K.; Brandt, O.; Geelhaar, L.; Fernandez-Garrido, S. Effect of surface roughness, chemical composition, and native oxide crystallinity of the orientation of self-assembled GaN nanowires on Ti foils. Nanotechnology 2017, 28, 425602. [Google Scholar] [CrossRef]

- Hong, K.; Yu, H.K.; Lee, I.; Kim, S.; Kim, Y.; Kim, K.; Lee, J.L. Flexible top-emitting organic light emitting diodes with a functional dielectric reflector on a metal foil substrate. RSC Adv. 2018, 8, 26156–26160. [Google Scholar] [CrossRef]

- Cheon, J.H.; Choi, J.H.; Hur, J.H.; Jang, J.; Shin, H.S.; Jeong, J.K.; Mo, Y.G.; Chung, H.K. Active-matrix OLED on bendable metal foil. IEEE Trans. Electron Devices 2006, 53, 1273–1276. [Google Scholar] [CrossRef]

- Kim, M.; Kim, K.B.; Jeon, C.W.; Lee, D.; Lee, S.N.; Lee, J.M.; Lee, H.C. CIGS solar cell devices on steel substrates coated with Na containing AIPO4. J. Phys. Chem. Solids 2015, 86, 223–228. [Google Scholar] [CrossRef]

- Kim, K.B.; Kim, M.; Lee, H.C.; Park, S.W.; Jeon, C.W. Copper indium gallium selenide (CIGS) solar cell devices on steel substrates coated with thick SiO2-based insulating material. Mater. Res. Bull. 2017, 85, 168–175. [Google Scholar] [CrossRef]

- Kim, K.B.; Kim, M.; Baek, J.; Park, Y.J.; Lee, J.R.; Kim, J.S.; Jeon, C. Influence of Cr thin films on the properties of flexible CIGS solar cells on steel substrates. Electron. Mater. Lett. 2014, 10, 247–251. [Google Scholar] [CrossRef]

- Si, P.Z.; Choi, C.J. High hardness nanocrystalline invar alloys prepared from Fe-Ni nanoparticles. Metals 2018, 8, 28. [Google Scholar] [CrossRef]

- Herz, K.; Eicke, A.; Kessler, F.; Wächter, R.; Powalla, M. Diffusion barrier for CIGS solar cells on metallic substrates. Thin Solid Films 2003, 431–432, 392–397. [Google Scholar] [CrossRef]

- Batchelor, W.K.; Repins, I.L.; Schaefer, J.; Beck, M.E. Impact of substrate roughness on CuInxGa1−xSe2 device properties. Sol. Energy Mater. Sol. Cells 2004, 83, 67–80. [Google Scholar] [CrossRef]

- Platzer-Björkman, C.; Jani, S.; Westlinder, J.; Linnarsson, M.K.; Scragg, J.; Edoff, M. Diffusion of Fe and Na in co-evaporated Cu(In,Ga)Se2 devices on steel substrates. Thin Solid Films 2013, 535, 188–192. [Google Scholar] [CrossRef]

- Heo, J.H.; Shin, D.H.; Lee, M.L.; Kang, M.G.; Im, S.H. Efficient organic-inorganic hybrid flexible perovskite solar cells prepared by lamination of polytriarylamine/CH3NH3PbI3/anodized Ti metal substrate and graphene/PDMS transparent electrode substrate. ACS Appl. Mater. Interfaces 2018, 10, 31413–31421. [Google Scholar] [CrossRef] [PubMed]

- Suyama, T.; Bae, H.; Setaka, K.; Ogawa, H.; Fukuoka, Y.; Suzuki, H.; Toyoda, H. Quantitative evaluation of high-energy O-ion particle flux in a DC magnetron sputter plasma with an indium-tin-oxide target. J. Phys. D Appl. Phys. 2017, 50, 445201. [Google Scholar] [CrossRef]

- Lee, K.Y.; Chen, L.C.; Wu, Y.J. Effect of oblique-angle sputtered ITO electrode in MAPbI3 perovskite solar cell structures. Nanoscale Res. Lett. 2017, 12, 556. [Google Scholar] [CrossRef]

- Kim, J.H.; Seong, T.Y.; Ahn, K.J.; Chung, K.B.; Seok, H.J.; Seo, H.J.; Kim, H.K. The effects of film thickness on the electrical, optical, and structural properties of cylindrical, rotating, magnetron-sputtering ITO films. Appl. Surf. Sci. 2018, 440, 1211–1218. [Google Scholar] [CrossRef]

- Kim, J.H.; Seok, H.J.; Seo, H.J.; Seong, T.Y.; Heo, J.H.; Lim, S.H.; Ahn, K.J.; Kim, H.K. Flexible ITO films with atomically flat surfaces for high performance flexible perovskite solar cells. Nanoscale 2018, 10, 20587–20598. [Google Scholar] [CrossRef]

- Akman, E.; Cerkezoglu, E. Compositional and micro-scratch analyses of laser induced colored surface of titanium. Opt. Lasers Eng. 2016, 84, 37–43. [Google Scholar] [CrossRef]

- Pérez del Pino, A.; Fernández-Pradas, J.M.; Serra, P.; Morenza, J.L. Coloring of titanium through laser oxidation: Comparative study with anodizing. Surf. Coat. Technol. 2004, 187, 106–112. [Google Scholar] [CrossRef]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Kim, H.; Horwitz, J.S.; Kushto, G.; Piqué, A.; Kafafi, Z.H.; Gilmore, C.M.; Chrisey, D.B. Effect of film thickness on the properties of indium tin oxide thin films. J. Appl. Phys. 2000, 88, 6021–6025. [Google Scholar] [CrossRef]

- Lee, J.H.; Shin, H.S.; Na, S.I.; Kim, H.K. Transparent and flexible PEDOT:PSS electrodes passivated by thin IZTO film using plasma-damage free linear facing target sputtering for flexible organic solar cells. Sol. Energy Mater. Sol. Cells 2013, 109, 192–198. [Google Scholar] [CrossRef]

| Substrate | Sheet Resistance (Rs) (Ohm/square) | |||

|---|---|---|---|---|

| 50 nm | 100 nm | 150 nm | 200 nm | |

| Invar | 75.54 | 54.74 | 50.21 | 44.57 |

| Glass | 77.64 | 53.30 | 49.51 | 44.52 |

| Substrate | Average Transmittance (400–800 nm) (%) | |||

|---|---|---|---|---|

| 50 nm | 100 nm | 150 nm | 200 nm | |

| Glass | 86.23 | 86.12 | 88.73 | 87.01 |

| ITO Thickness (nm) | VOC (V) | JSC (mA/cm2) | Fill Factor (FF, %) | Power Conversion Efficiency (PCE, %) |

|---|---|---|---|---|

| 150 | 1.11 | 18.12 | 47.0 | 9.70 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seok, H.-J.; Kim, H.-K. Study of Sputtered ITO Films on Flexible Invar Metal Foils for Curved Perovskite Solar Cells. Metals 2019, 9, 120. https://doi.org/10.3390/met9020120

Seok H-J, Kim H-K. Study of Sputtered ITO Films on Flexible Invar Metal Foils for Curved Perovskite Solar Cells. Metals. 2019; 9(2):120. https://doi.org/10.3390/met9020120

Chicago/Turabian StyleSeok, Hae-Jun, and Han-Ki Kim. 2019. "Study of Sputtered ITO Films on Flexible Invar Metal Foils for Curved Perovskite Solar Cells" Metals 9, no. 2: 120. https://doi.org/10.3390/met9020120

APA StyleSeok, H.-J., & Kim, H.-K. (2019). Study of Sputtered ITO Films on Flexible Invar Metal Foils for Curved Perovskite Solar Cells. Metals, 9(2), 120. https://doi.org/10.3390/met9020120