Effect of the Average Energy on WC Grain Growth of WC-10Co-4Cr Composite by Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

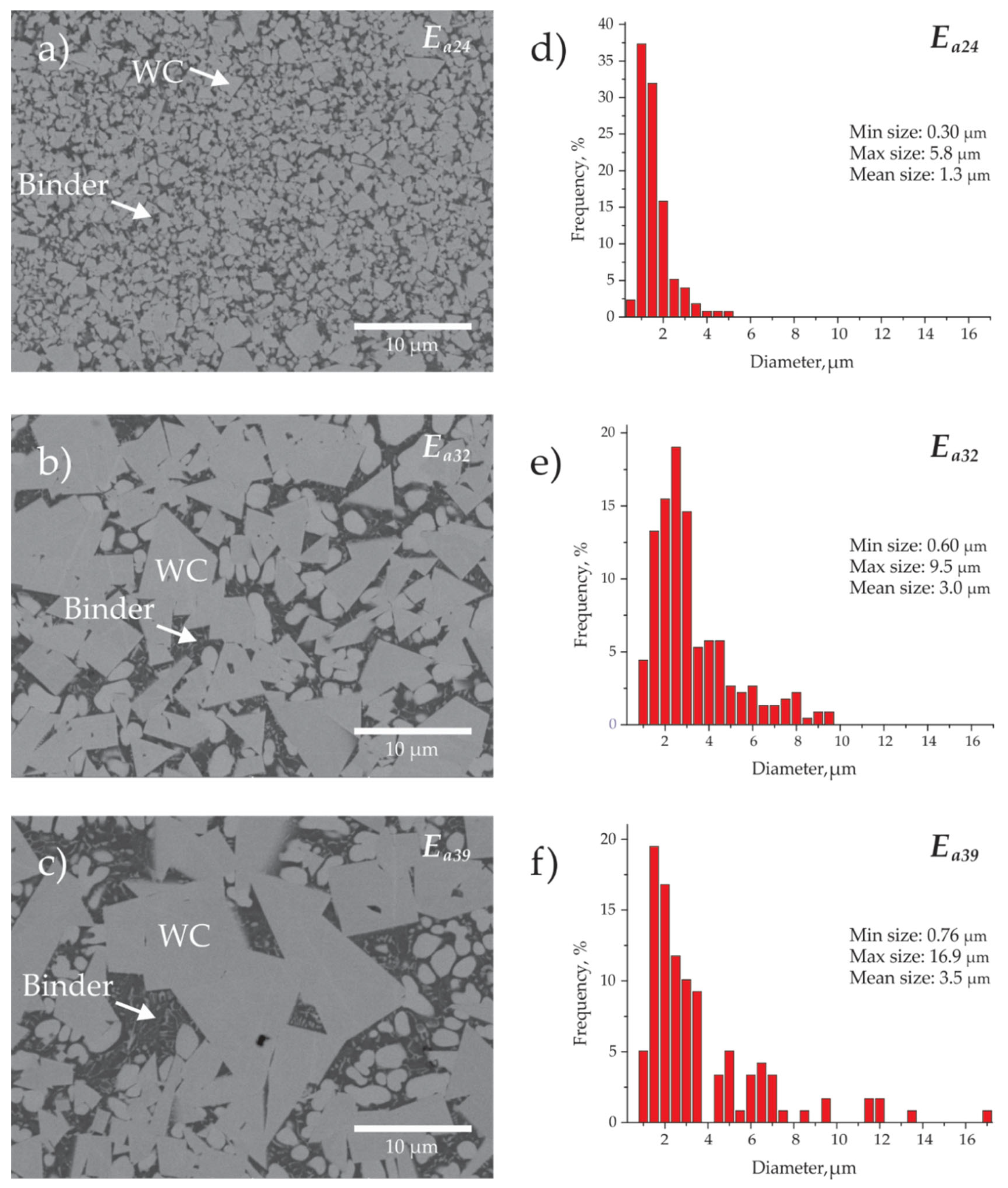

3.1. Microstructure and Phases

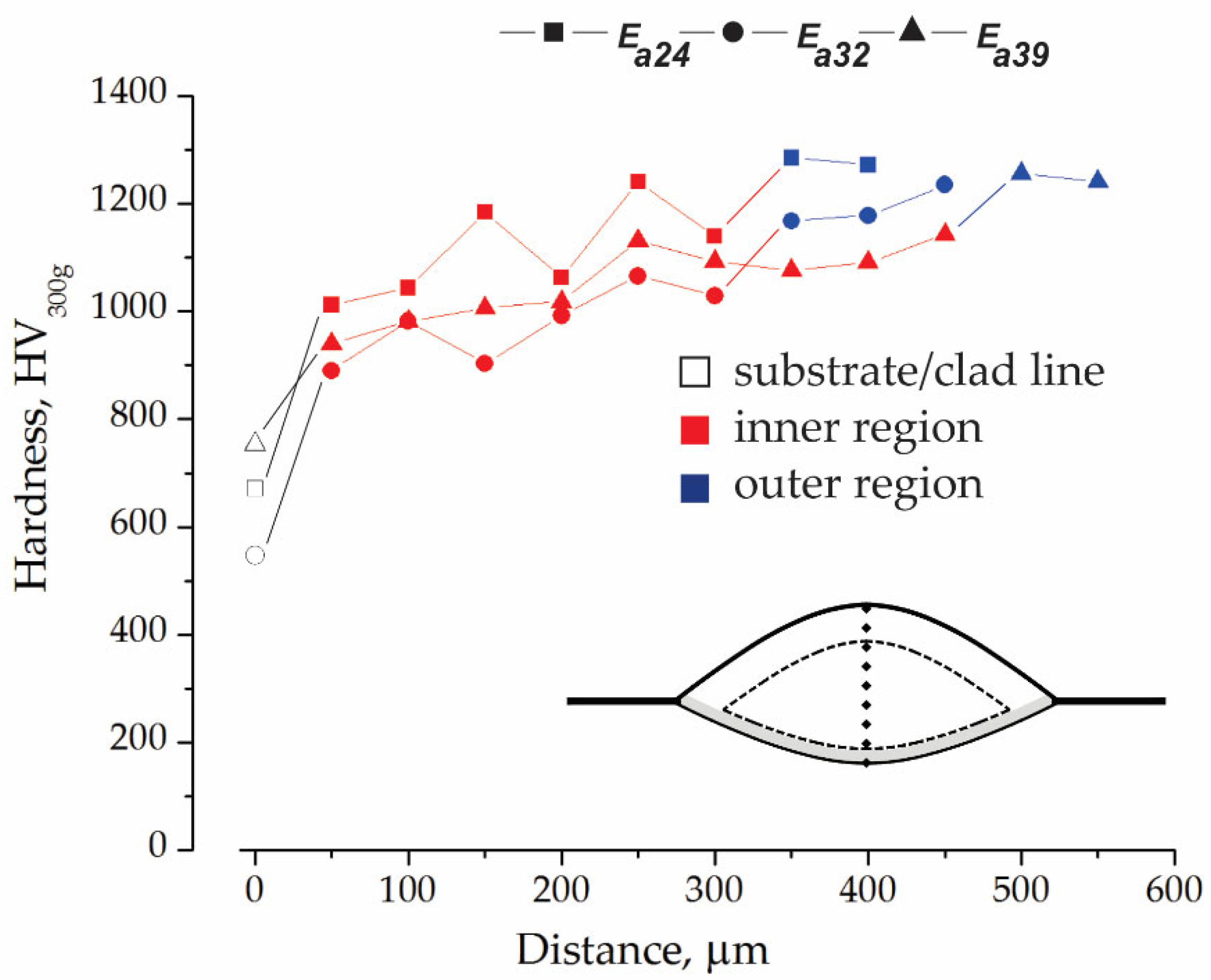

3.2. Hardness

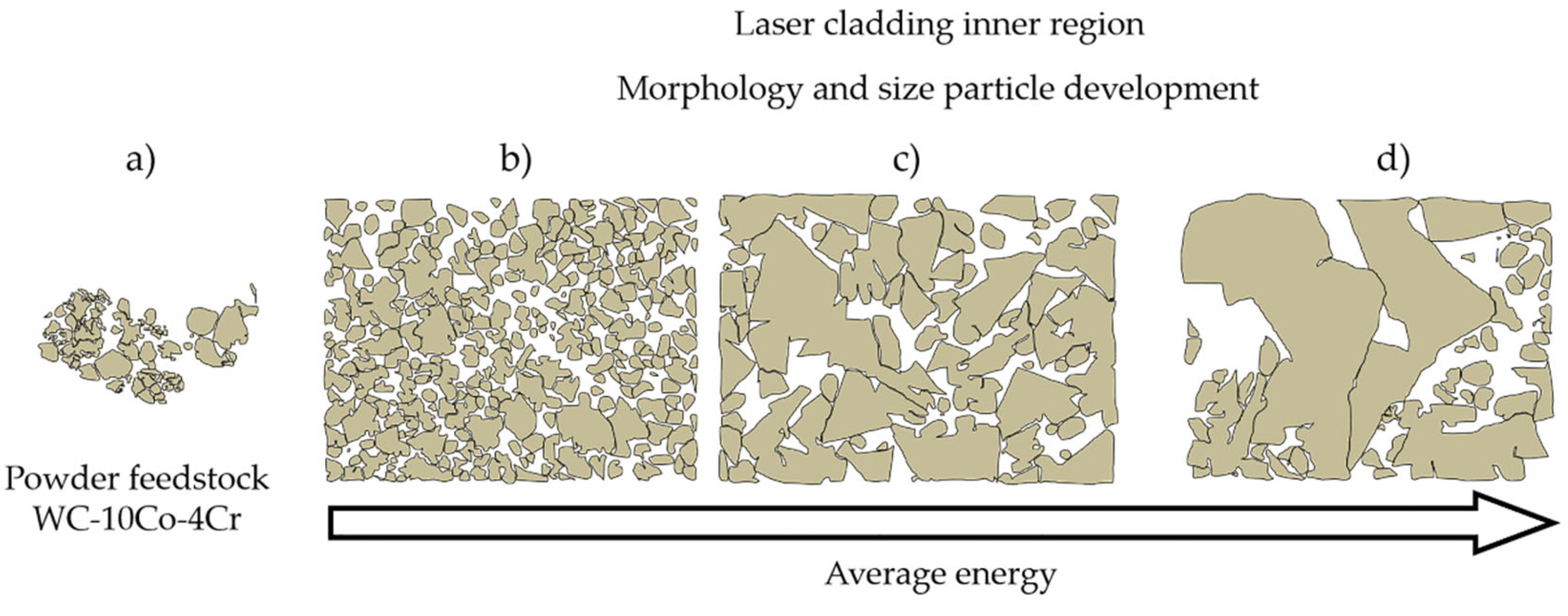

3.3. Effect of the Averange Energy

4. Conclusions

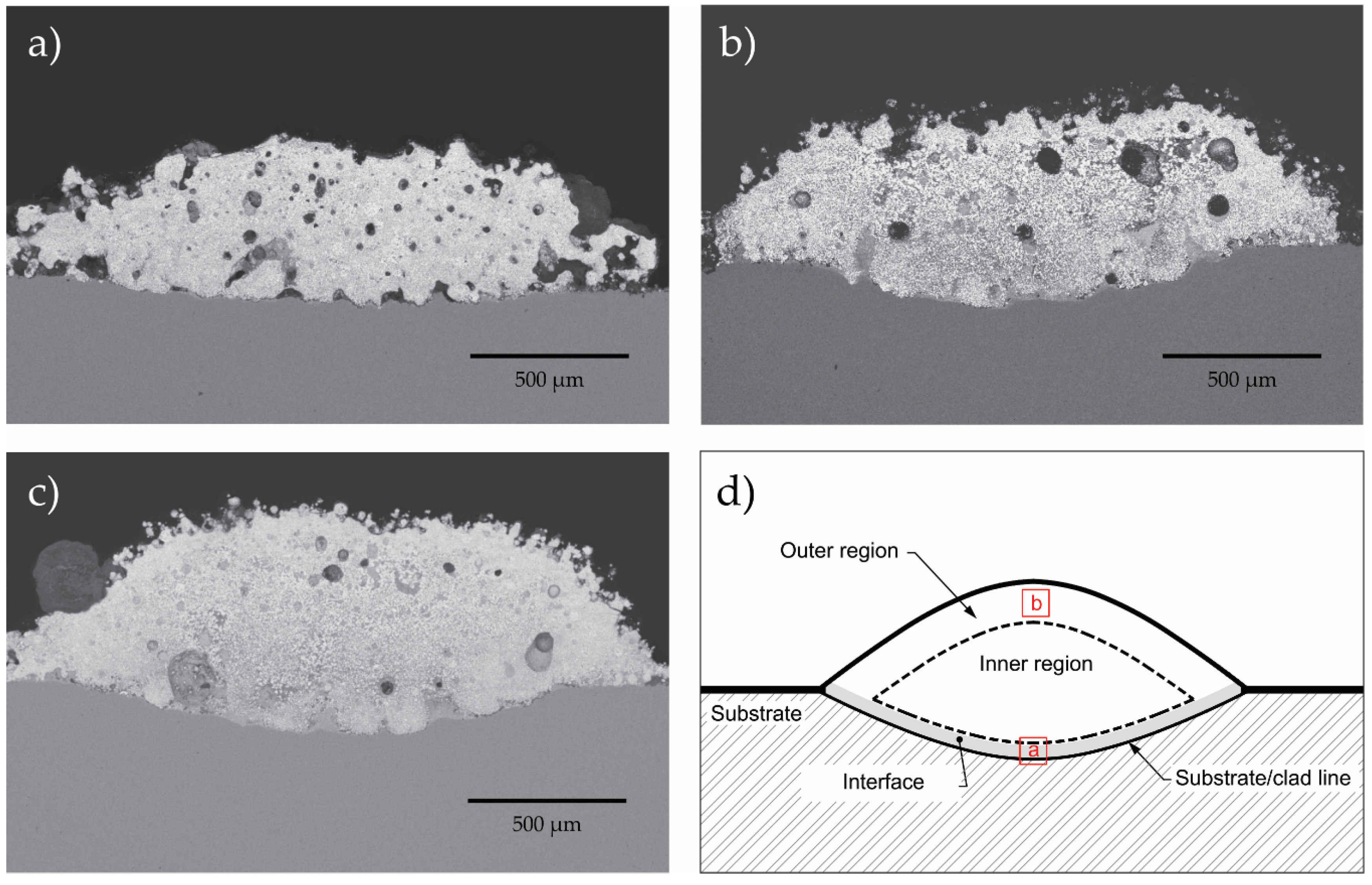

- Results indicated that upon an average energy value of Ea = 24 J/mm2; the porosity was about 11%, whereas the dilution value remained at 15%, thus being acceptable values for both porosity and dilution.

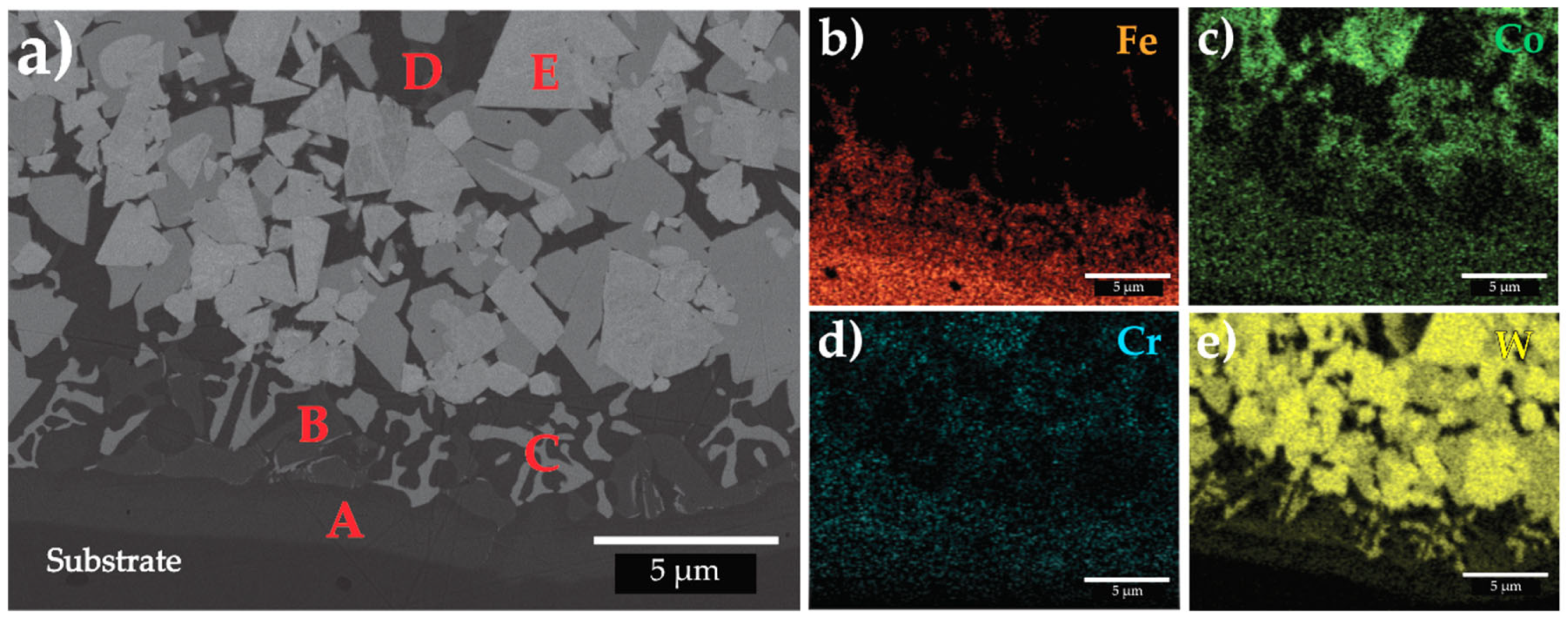

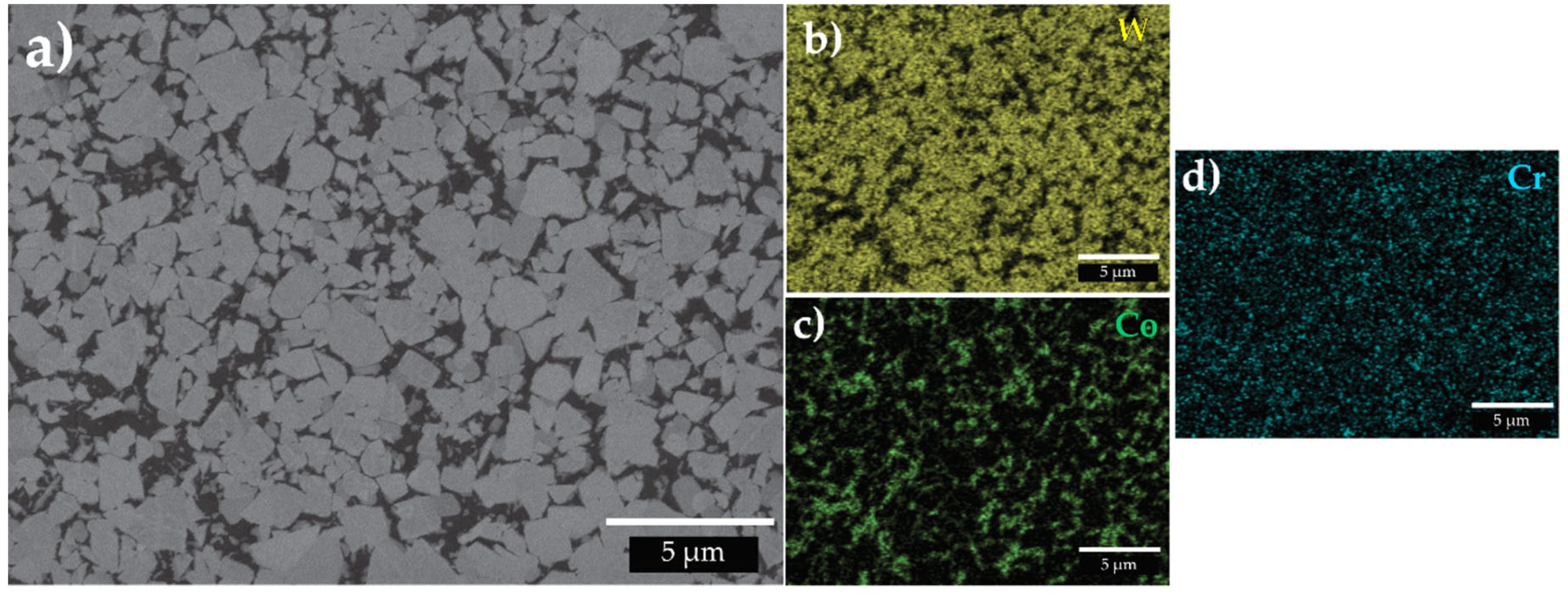

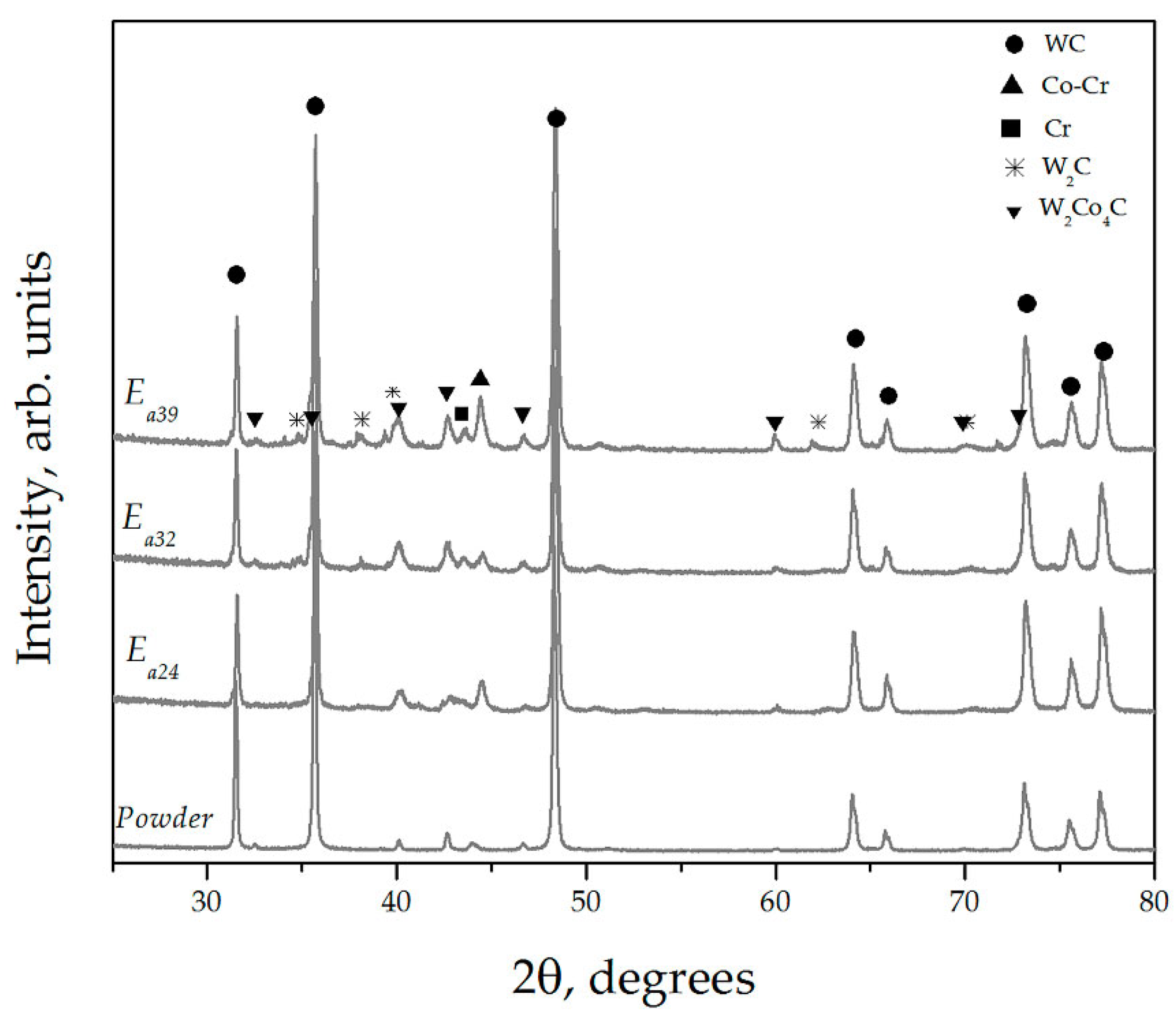

- The microstructure development at the interface was consistent for all conditions; it was composed of a planar grain growth, with presence of eutectic carbides and a mixture of fine columnar dendrites; however, the higher the average energy, the larger the extension of the interface. Whereas the microstructure of the outer region revealed the presence of the Co-Cr binder along with WC particles retaining the original feedstock particle size and morphology.

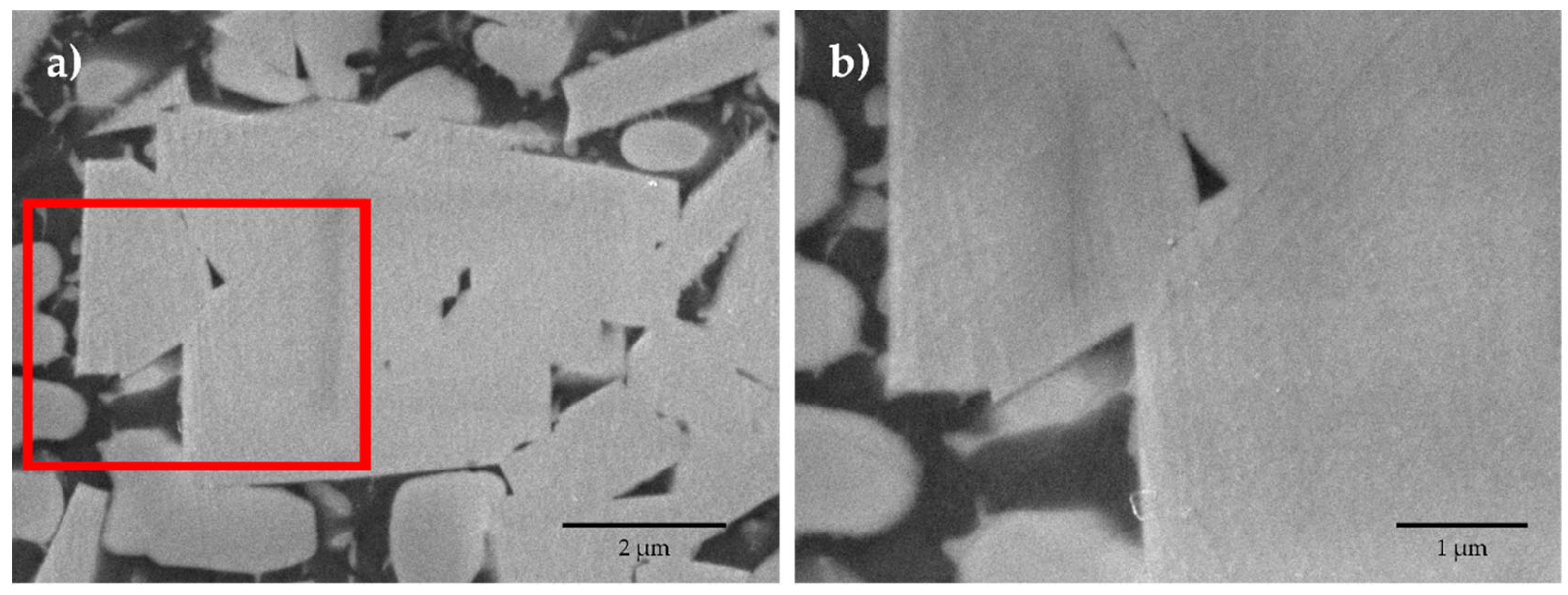

- Considerable grain growth occurred at the inner region of the clad, particularly when employing high average energy (i.e., above 32 J/mm2); WC grain growth increased by three times compared to the original powder particle size. Additionally, the morphology of the growth WC particles developed a triangular and/or polygonal shape.

- A complete merge of small neighboring grains into larger particles and presence of residual pores between partially delimited WC particle boundaries is observed at the inner region; hence, the grain growth is attributable to a coalescence mechanism. Further, the presence of rounded and ellipsoidal WC particles suggested partial solubility of W and C within the Co-Cr binder phase; hence, those particles did not merge (lack of coalescence) due to inhomogeneous dispersion and the lack of faced shaped particles.

- Hardness at the inner region resulted in higher values upon the low average energy condition (i.e., 24 J/mm2), indeed, being the sample with barely observable grain growth; on the contrary, evident grain growth and considerable lower hardness was observed upon higher average energy condition (i.e., above 32 J/mm2).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumari, K.; Anand, K.; Bellacci, M.; Giannozzi, M. Effect of microstructure on abrasive wear behavior of thermally sprayed WC–10Co–4Cr coatings. Wear 2010, 268, 1309–1319. [Google Scholar] [CrossRef]

- Méndez-Medrano, K.O.; Martínez-González, C.J.; Alvarado-Hernández, F.; Jiménez, O.; Baltazar-Hernández, V.H.; Ruiz-Luna, H. Microstructure and Properties Characterization of WC-Co-Cr Thermal Spray Coatings. J. Miner. Mater. Charact. Eng. 2018, 6, 482–497. [Google Scholar] [CrossRef][Green Version]

- Wood, R.J.K.; Herd, S.; Thakare, M.R. A critical review of the tribocorrosion of cemented and thermal sprayed tungsten carbide. Tribol. Int. 2018, 119, 491–509. [Google Scholar] [CrossRef]

- Zhang, S.-H.; Cho, T.-Y.; Yoon, J.-H.; Fang, W.; Song, K.-O.; Li, M.-X.; Joo, Y.-K.; Lee, C.G. Characterization of microstructure and surface properties of hybrid coatings of WC–CoCr prepared by laser heat treatment and high velocity oxygen fuel spraying. Mater. Charact. 2008, 59, 1412–1418. [Google Scholar] [CrossRef]

- Lian, G.; Zhang, Y.; Zhang, H.; Huang, X.; Chen, C.; Jiang, J. Investigation of Geometric Characteristics in Curved Surface Laser Cladding with Curve Path. Metals 2019, 9, 947. [Google Scholar] [CrossRef]

- Haldar, B.; Saha, P. Identifying defects and problems in laser cladding and suggestions of some remedies for the same. Mater. Today Proc. 2018, 5, 13090–13101. [Google Scholar] [CrossRef]

- Valsecchi, B.; Previtali, B.; Vedani, M.; Vimercati, G. Fiber Laser Cladding with High Content of WC-Co Based Powder. Int. J. Mater. Form. 2010, 3, 1127–1130. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Shoja-Razavi, R. An empirical-statistical model for laser cladding of WC-12Co powder on AISI 321 stainless steel. Opt. Laser Technol. 2017, 97, 180–186. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S. 3-D finite element modeling of laser cladding by powder injection: Effects of laser pulse shaping on the process. Opt. Lasers Eng. 2004, 41, 849–867. [Google Scholar] [CrossRef]

- Paul, C.P.; Alemohammad, H.; Toyserkani, E.; Khajepour, A.; Corbin, S. Cladding of WC–12 Co on low carbon steel using a pulsed Nd:YAG laser. Mater. Sci. Eng. A 2007, 464, 170–176. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H. Influence of using electroless Ni-P coated WC-Co powder on laser cladding of stainless steel. Surf. Coat. Technol. 2018, 348, 41–54. [Google Scholar] [CrossRef]

- Pekkarinen, J.; Kujanpää, V.; Salminen, A. Laser cladding with scanning optics: Effect of power adjustment. J. Laser Appl. 2012, 24, 032003. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Amine, T.; Newkirk, J.W.; Liou, F. An investigation of the effect of direct metal deposition parameters on the characteristics of the deposited layers. Case Stud. Therm. Eng. 2014, 3, 21–34. [Google Scholar] [CrossRef]

- Peng, L.; Taiping, Y.; Sheng, L.; Dongsheng, L.; Qianwu, H.; Weihao, X.; Xiaoyan, Z. Direct laser fabrication of nickel alloy samples. Int. J. Mach. Tools Manuf. 2005, 45, 1288–1294. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, B.; Zeng, X.; Hu, X.; Cui, K. Critical state of laser cladding with powder auto-feeding. Surf. Coat. Technol. 1996, 79, 200–204. [Google Scholar] [CrossRef]

- Emamian, A.; Corbin, S.F.; Khajepour, A. Effect of laser cladding process parameters on clad quality and in-situ formed microstructure of Fe–TiC composite coatings. Surf. Coat. Technol. 2010, 205, 2007–2015. [Google Scholar] [CrossRef]

- Ya, W.; Pathiraj, B.; Liu, S. 2D modelling of clad geometry and resulting thermal cycles during laser cladding. J. Mater. Process. Technol. 2016, 230, 217–232. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N. Studies on energy penetration and marangoni effect during laser melting process. J. Eng. Sci. Technol. 2015, 10, 509–525. [Google Scholar]

- Kumar, L.J.; Nair, C.G.K. Laser metal deposition repair applications for Inconel 718 alloy. Mater. Today Proc. 2017, 4, 11068–11077. [Google Scholar] [CrossRef]

- Corbin, S.F.; Toyserkani, E.; Khajepour, A. Cladding of an Fe-aluminide coating on mild steel using pulsed laser assisted powder deposition. Mater. Sci. Eng. A 2003, 354, 48–57. [Google Scholar] [CrossRef]

- Fu, F.; Zhang, Y.; Chang, G.; Dai, J. Analysis on the physical mechanism of laser cladding crack and its influence factors. Optik 2016, 127, 200–202. [Google Scholar] [CrossRef]

- Angelastro, A.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D. Optimization of Ni-Based WC/Co/Cr Composite Coatings Produced by Multilayer Laser Cladding. Adv. Mater. Sci. Eng. 2013, 2013, 1–7. [Google Scholar] [CrossRef]

- Balla, V.K.; Bose, S.; Bandyopadhyay, A. Microstructure and wear properties of laser deposited WC–12%Co composites. Mater. Sci. Eng. A 2010, 527, 6677–6682. [Google Scholar] [CrossRef]

- Zhang, P.; Pang, Y.; Yu, M. Effects of WC Particle Types on the Microstructures and Properties of WC-Reinforced Ni60 Composite Coatings Produced by Laser Cladding. Metals 2019, 9, 583. [Google Scholar] [CrossRef]

- Yang, Y.; Man, H.C. Microstructure evolution of laser clad layers of W-C-Co alloy powders. Surf. Coat. Technol. 2000, 132, 130–136. [Google Scholar] [CrossRef]

- Zhou, C.; Zhao, S.; Wang, Y.; Liu, F.; Gao, W.; Lin, X. Mitigation of pores generation at overlapping zone during laser cladding. J. Mater. Process. Technol. 2015, 216, 369–374. [Google Scholar] [CrossRef]

- Costa, L.; Felde, I.; Réti, T.; Kálazi, Z.; Colaço, R.; Vilar, R.; Verő, B. A Simplified Semi-Empirical Method to Select the Processing Parameters for Laser Clad Coatings. Mater. Sci. Forum 2003, 414–415, 385–394. [Google Scholar] [CrossRef]

- Zhou, S.; Zeng, X. Growth characteristics and mechanism of carbides precipitated in WC–Fe composite coatings by laser induction hybrid rapid cladding. J. Alloys Compd. 2010, 505, 685–691. [Google Scholar] [CrossRef]

- Morton, C.W.; Wills, D.J.; Stjernberg, K. The temperature ranges for maximum effectiveness of grain growth inhibitors in WC–Co alloys. Int. J. Refract. Met. Hard Mater. 2005, 23, 287–293. [Google Scholar] [CrossRef]

- Wang, X.; Fang, Z.Z.; Sohn, H.Y. Grain growth during the early stage of sintering of nanosized WC–Co powder. Int. J. Refract. Met. Hard Mater. 2008, 26, 232–241. [Google Scholar] [CrossRef]

- Kumar, V.; Fang, Z.Z.; Wright, S.I.; Nowell, M.M. An Analysis of Grain Boundaries and Grain Growth in Cemented Tungsten Carbide Using Orientation Imaging Microscopy. Metall. Mater. Trans. A 2006, 37, 599–607. [Google Scholar] [CrossRef]

- Borgh, I.; Hedström, P.; Persson, T.; Norgren, S.; Borgenstam, A.; Ågren, J.; Odqvist, J. Microstructure, grain size distribution and grain shape in WC–Co alloys sintered at different carbon activities. Int. J. Refract. Met. Hard Mater. 2014, 43, 205–211. [Google Scholar] [CrossRef]

- Warren, R.; Waldron, M.B. Microstructural Development During the Liquid-Phase Sintering of Cemented Carbides, I. Wettability and Graing Contact. Symp. Role Surf. Prop. Powder Metall. 1972, 15, 166–201. [Google Scholar] [CrossRef]

- Fang, Z.; Maheshwari, P.; Wang, X.; Sohn, H.Y.; Griffo, A.; Riley, R. An experimental study of the sintering of nanocrystalline WC–Co powders. Int. J. Refract. Met. Hard Mater. 2005, 23, 249–257. [Google Scholar] [CrossRef]

- Kishino, J.; Nomura, H.; Shin, S.G.; Matsubara, H.; Tanase, T. Computational study on grain growth in cemented carbides. Int. J. Refract. Met. Hard Mater. 2002, 20, 31–40. [Google Scholar] [CrossRef]

- Lee, H.R.; Kim, D.J.; Hwang, N.M.; Kim, D.Y. Role of Vanadium Carbide Additive during Sinteing of WC-Co: Mechanism of Grain Growth Inhibition. J. Am. Ceram. Soc. 2003, 86, 152–154. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhu, H.; Shaw, L.L.; Ramprasad, R. The equilibrium morphology of WC particles—A combined ab initio and experimental study. Acta Mater. 2011, 59, 3748–3757. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2013, 57, 133–164. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W. Laser surface cladding: The state of the art and challenges. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 1041–1060. [Google Scholar] [CrossRef]

| Sample ID | Laser Energy Per Pulse (J) | Scan Speed (mm/s) | Powder Feed Rate (g/s) | Shielding Gas Flow (L/min) | Carrier Gas Flow (L/min) | Ea (J/mm2) |

|---|---|---|---|---|---|---|

| Ea24 | 18 | 10 | 0.42 | 20 | 18 | 24 |

| Ea32 | 24 | 10 | 0.42 | 20 | 18 | 32 |

| Ea39 | 30 | 10 | 0.42 | 20 | 18 | 39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Baltazar, E.A.; Ruiz-Luna, H.; Baltazar-Hernández, V.H.; Ruiz-Mondragón, J.J.; Ibarra-Medina, J.; Alvarado-Orozco, J.M. Effect of the Average Energy on WC Grain Growth of WC-10Co-4Cr Composite by Laser Cladding. Metals 2019, 9, 1245. https://doi.org/10.3390/met9121245

López-Baltazar EA, Ruiz-Luna H, Baltazar-Hernández VH, Ruiz-Mondragón JJ, Ibarra-Medina J, Alvarado-Orozco JM. Effect of the Average Energy on WC Grain Growth of WC-10Co-4Cr Composite by Laser Cladding. Metals. 2019; 9(12):1245. https://doi.org/10.3390/met9121245

Chicago/Turabian StyleLópez-Baltazar, Enrique A., Haideé Ruiz-Luna, Víctor H. Baltazar-Hernández, José Jorge Ruiz-Mondragón, Juansethi Ibarra-Medina, and Juan Manuel Alvarado-Orozco. 2019. "Effect of the Average Energy on WC Grain Growth of WC-10Co-4Cr Composite by Laser Cladding" Metals 9, no. 12: 1245. https://doi.org/10.3390/met9121245

APA StyleLópez-Baltazar, E. A., Ruiz-Luna, H., Baltazar-Hernández, V. H., Ruiz-Mondragón, J. J., Ibarra-Medina, J., & Alvarado-Orozco, J. M. (2019). Effect of the Average Energy on WC Grain Growth of WC-10Co-4Cr Composite by Laser Cladding. Metals, 9(12), 1245. https://doi.org/10.3390/met9121245