Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model

Abstract

1. Introduction

1.1. Explosive Welding

1.2. Magnetic Pulse Welding

1.3. Vaporizing Foil Actuator Welding

1.4. Laser Impact Welding

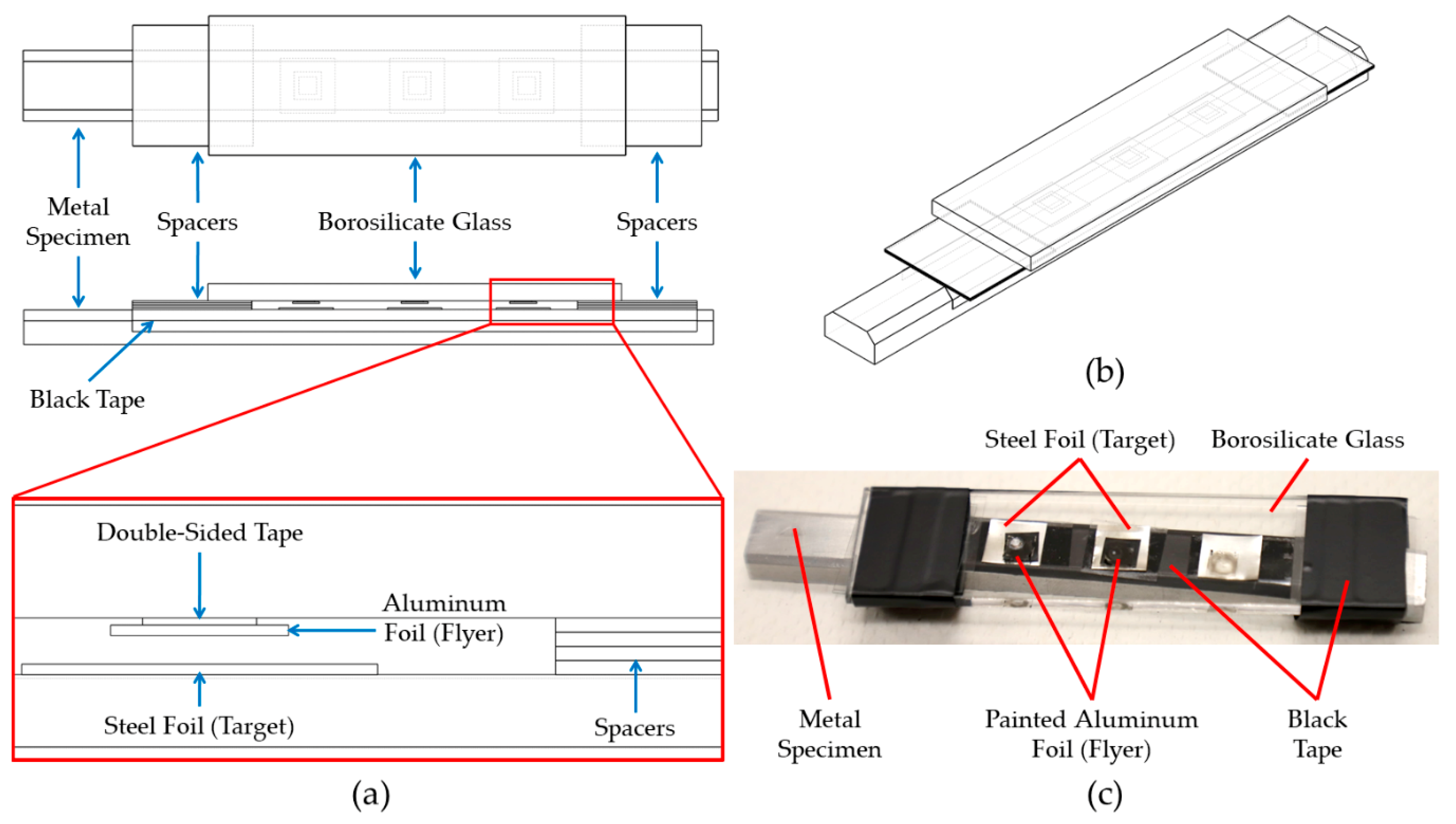

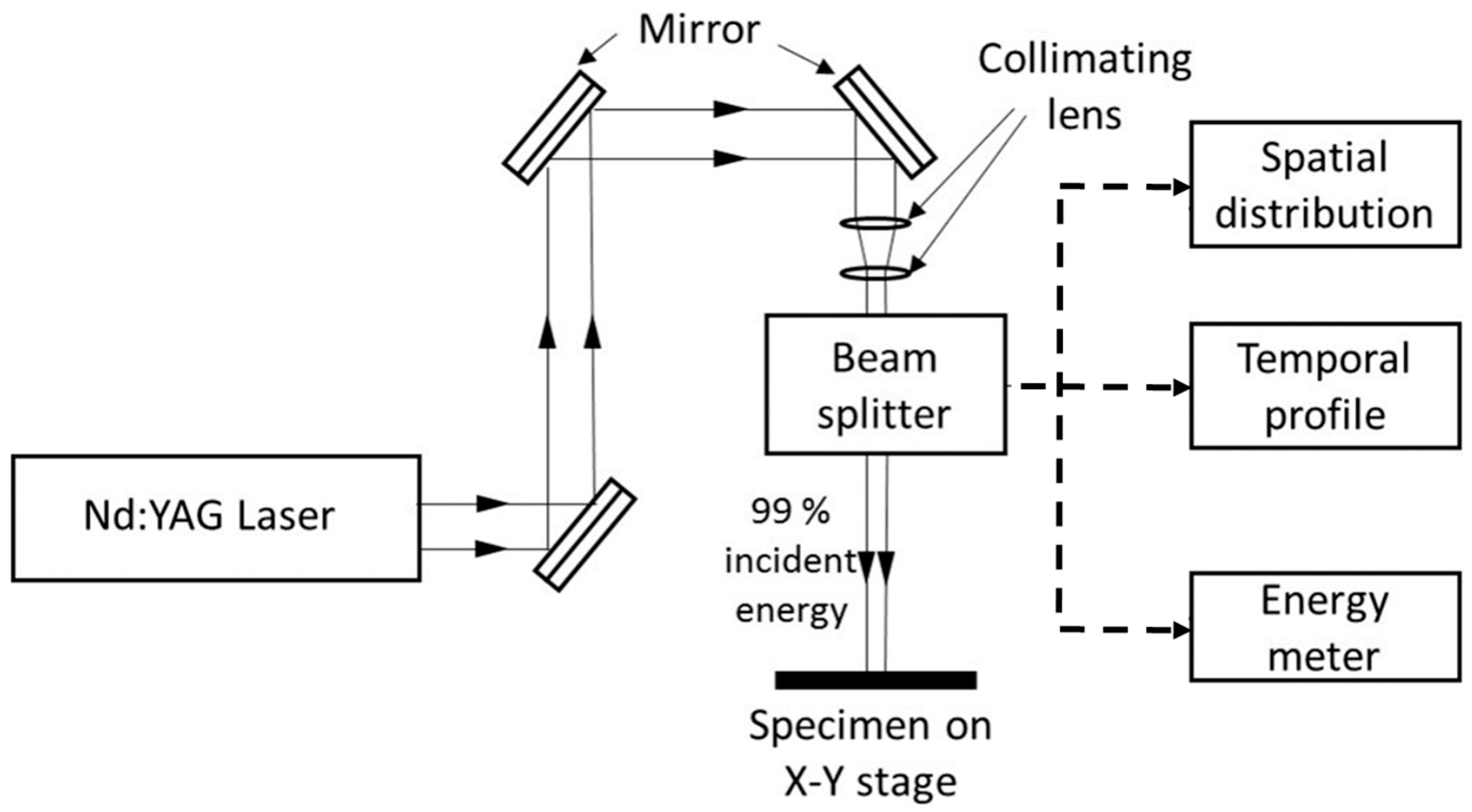

2. Experimental Procedures

3. Numerical Simulations

3.1. Plasma Pressure Model

3.2. Johnson-Cook Model

3.3. Mie-Grüneisen Formulation

3.4. Axisymmetric LIW Simulation

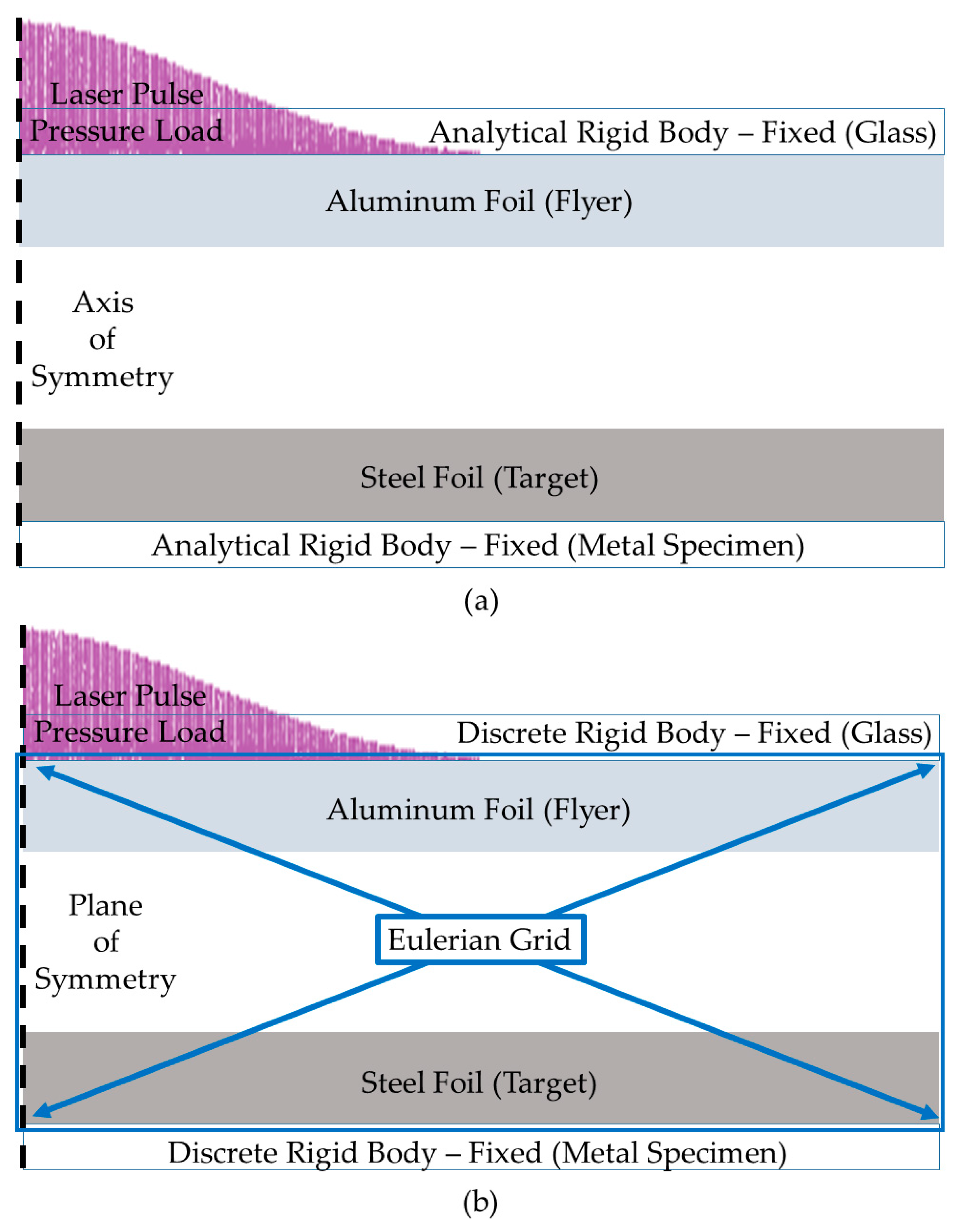

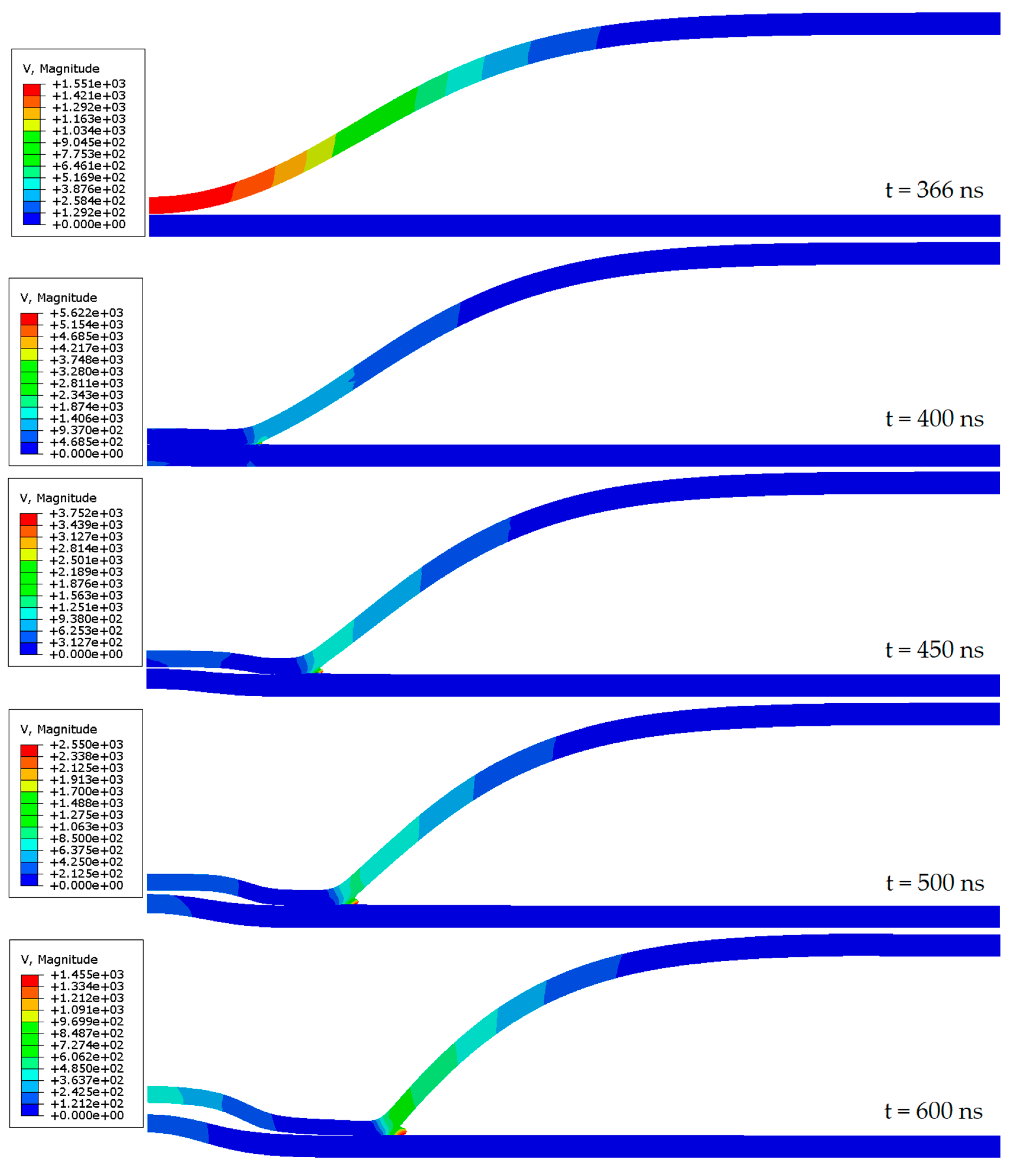

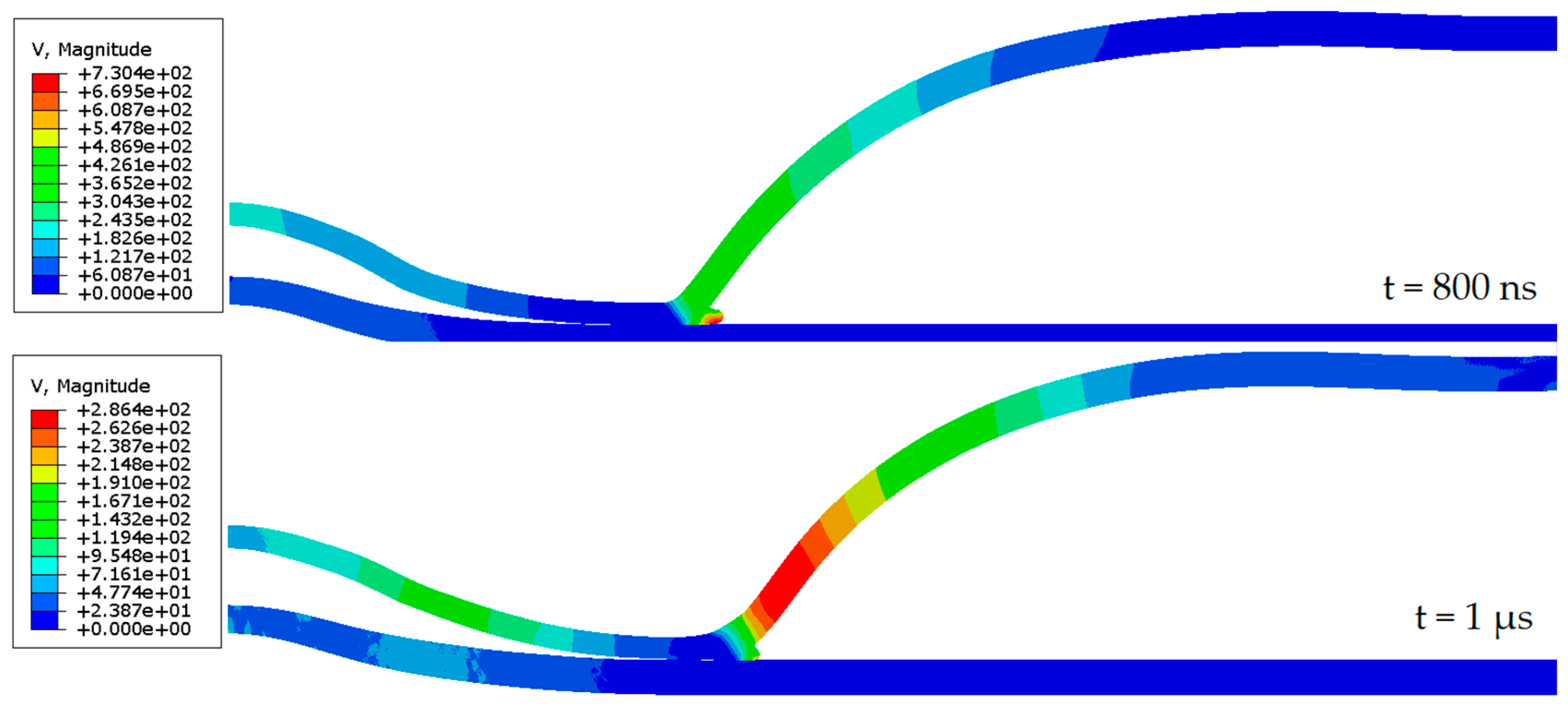

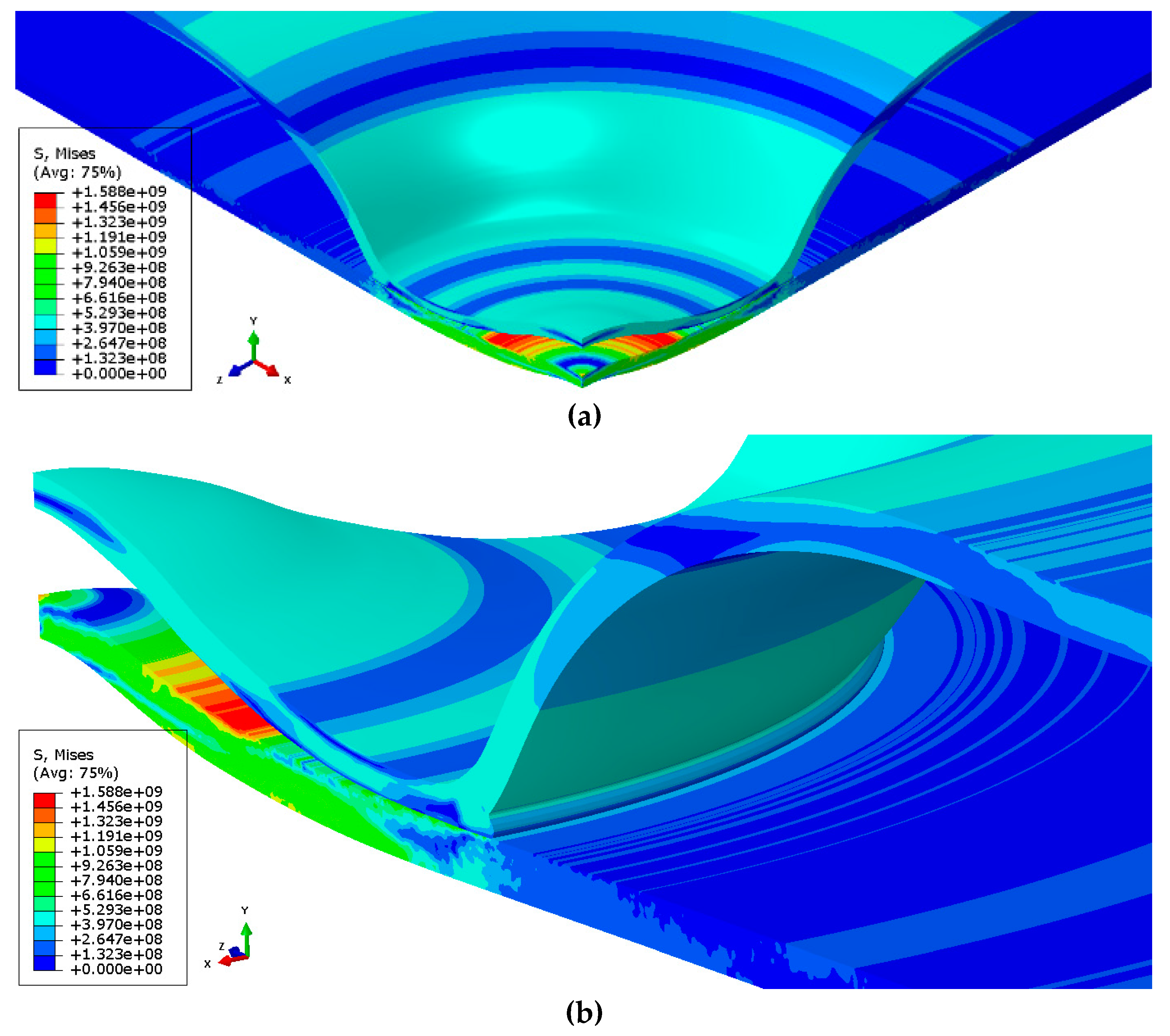

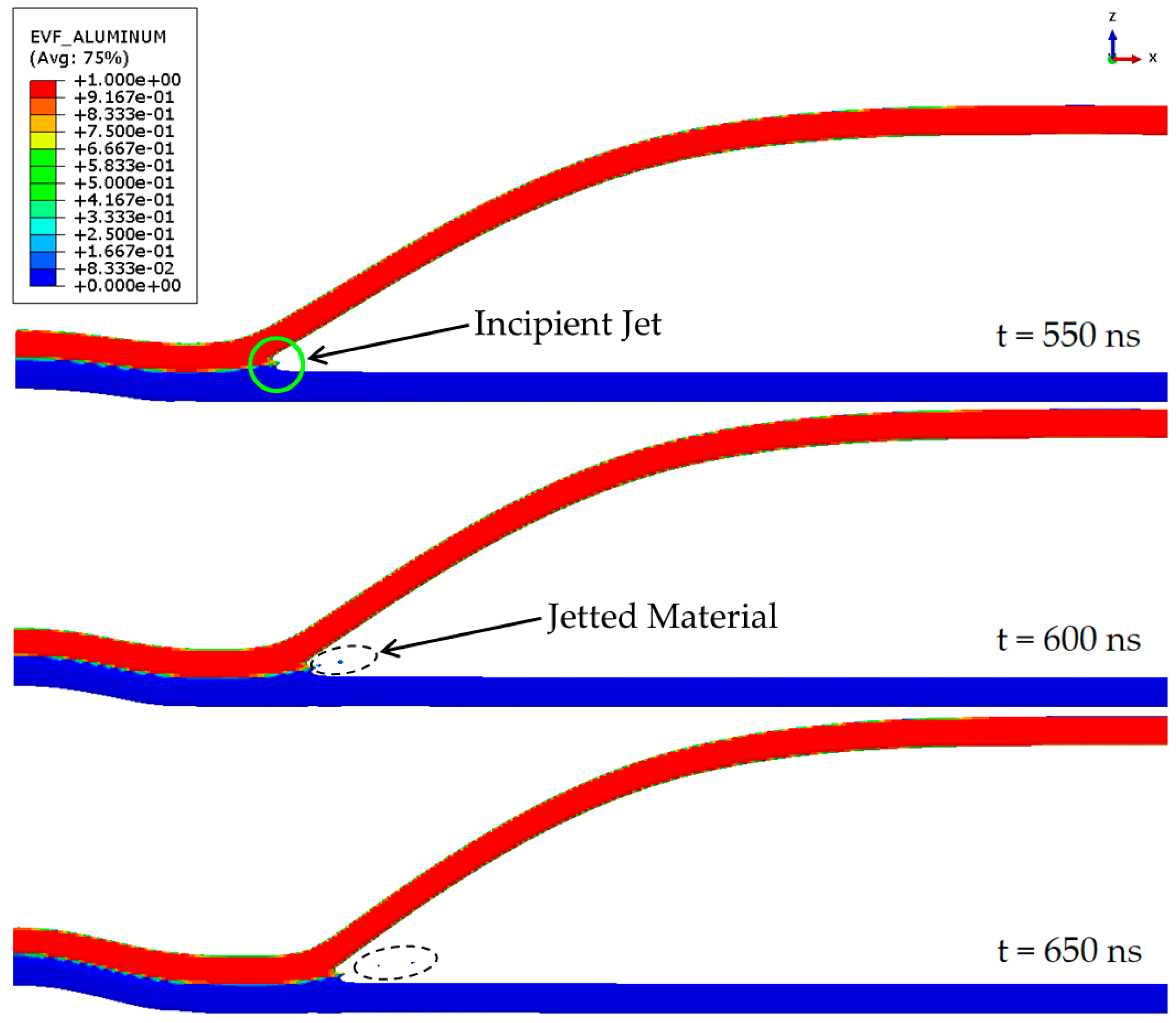

3.5. Eulerian LIW Simulation

4. Results and Discussion

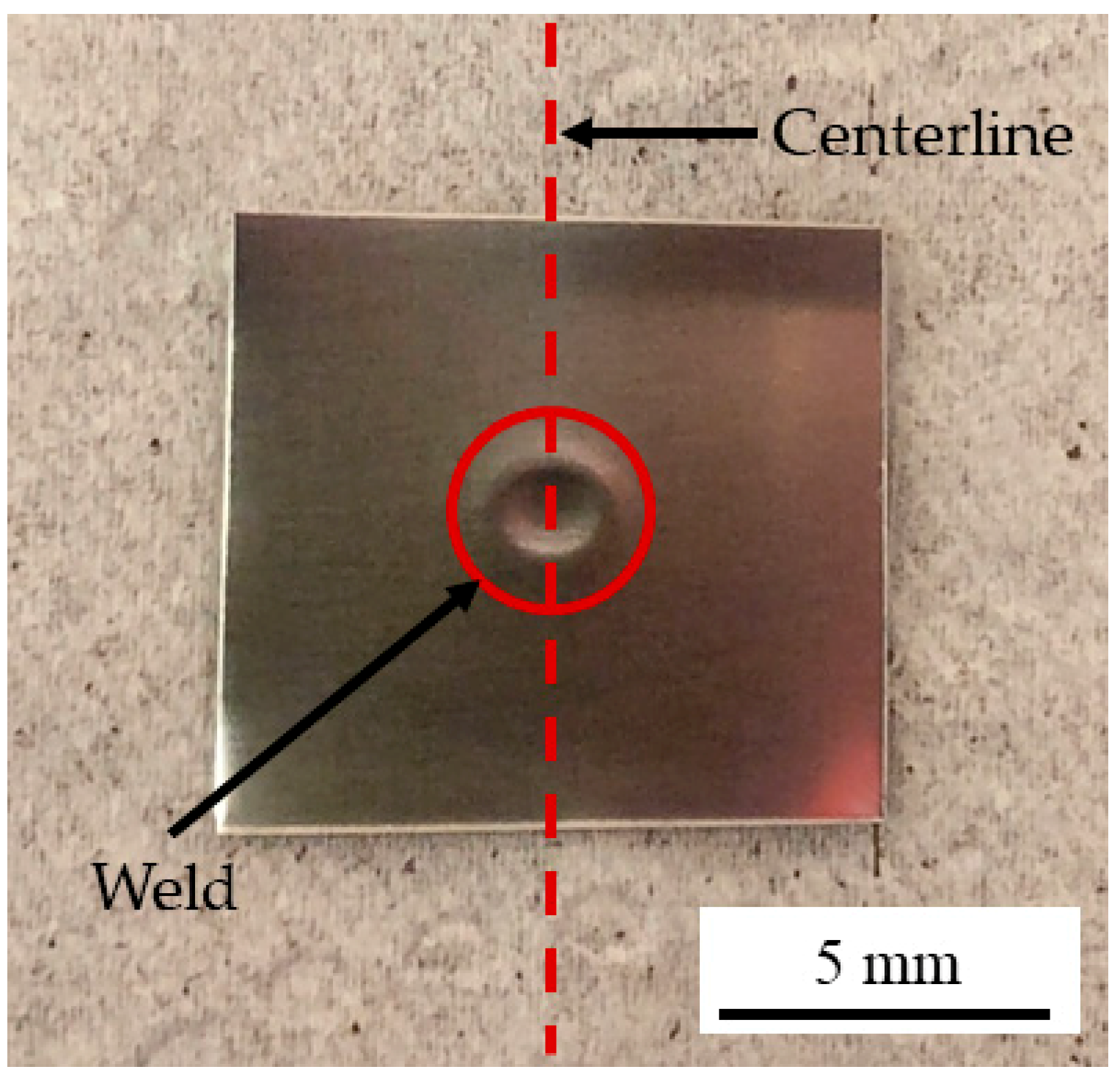

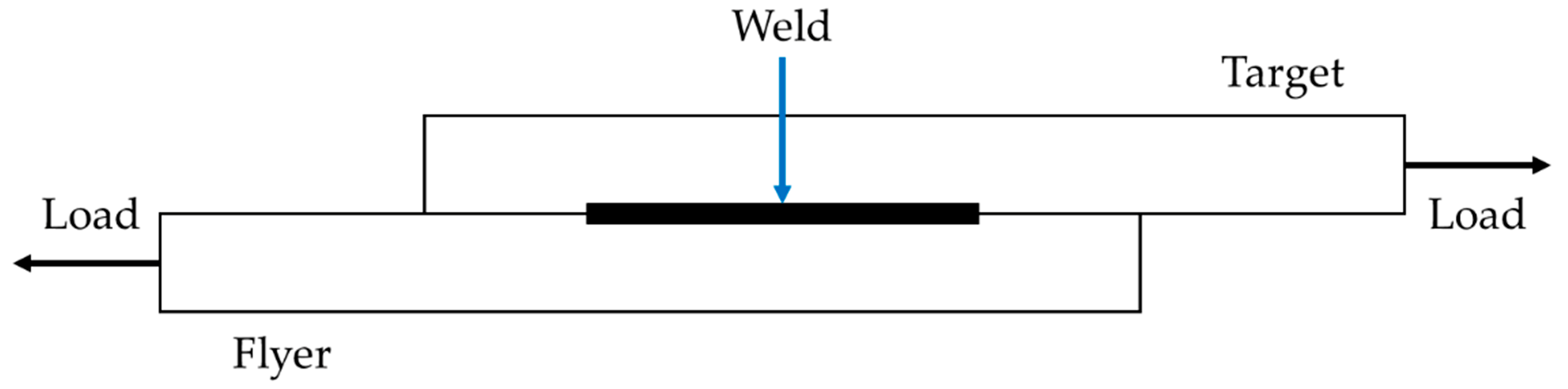

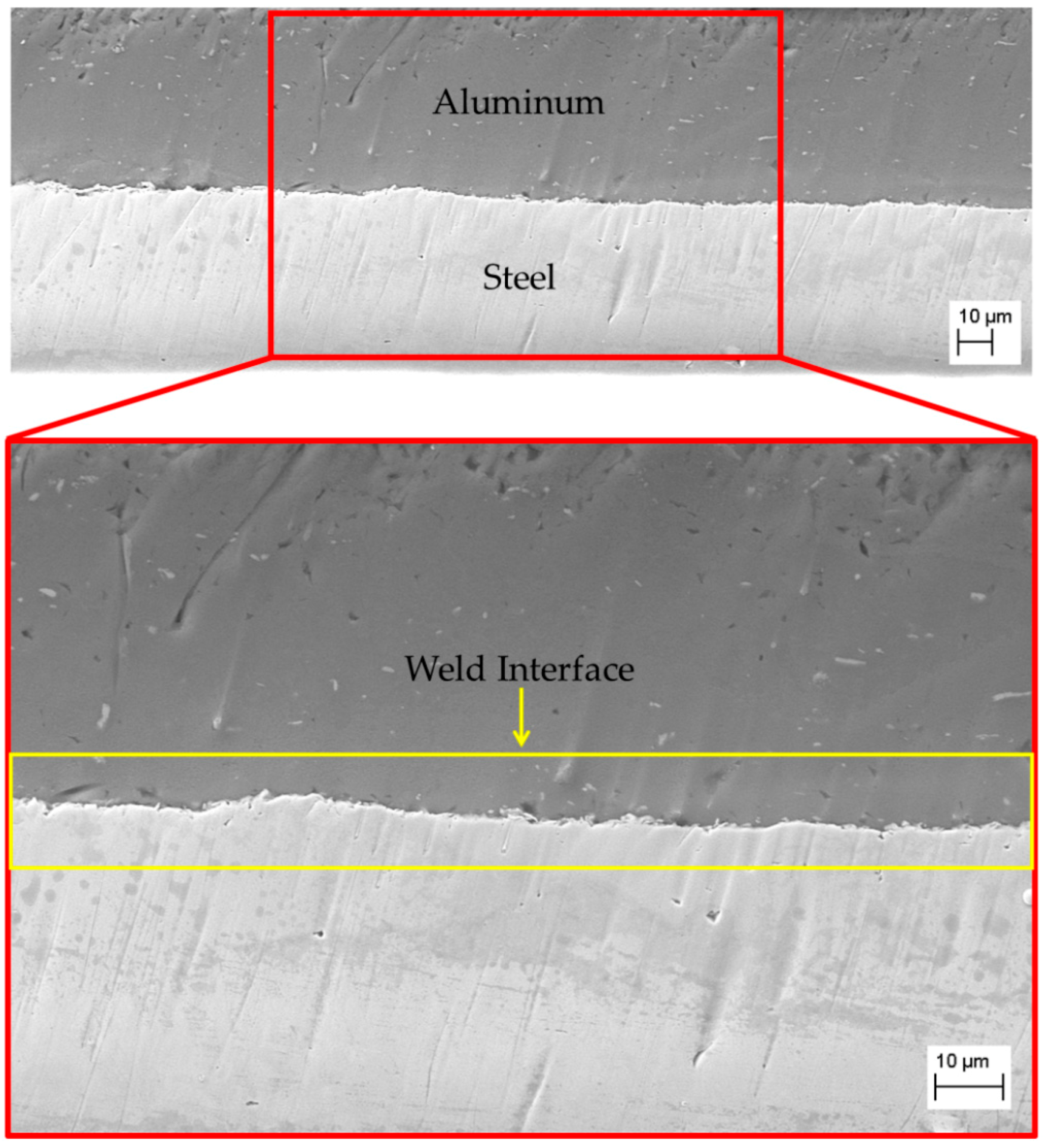

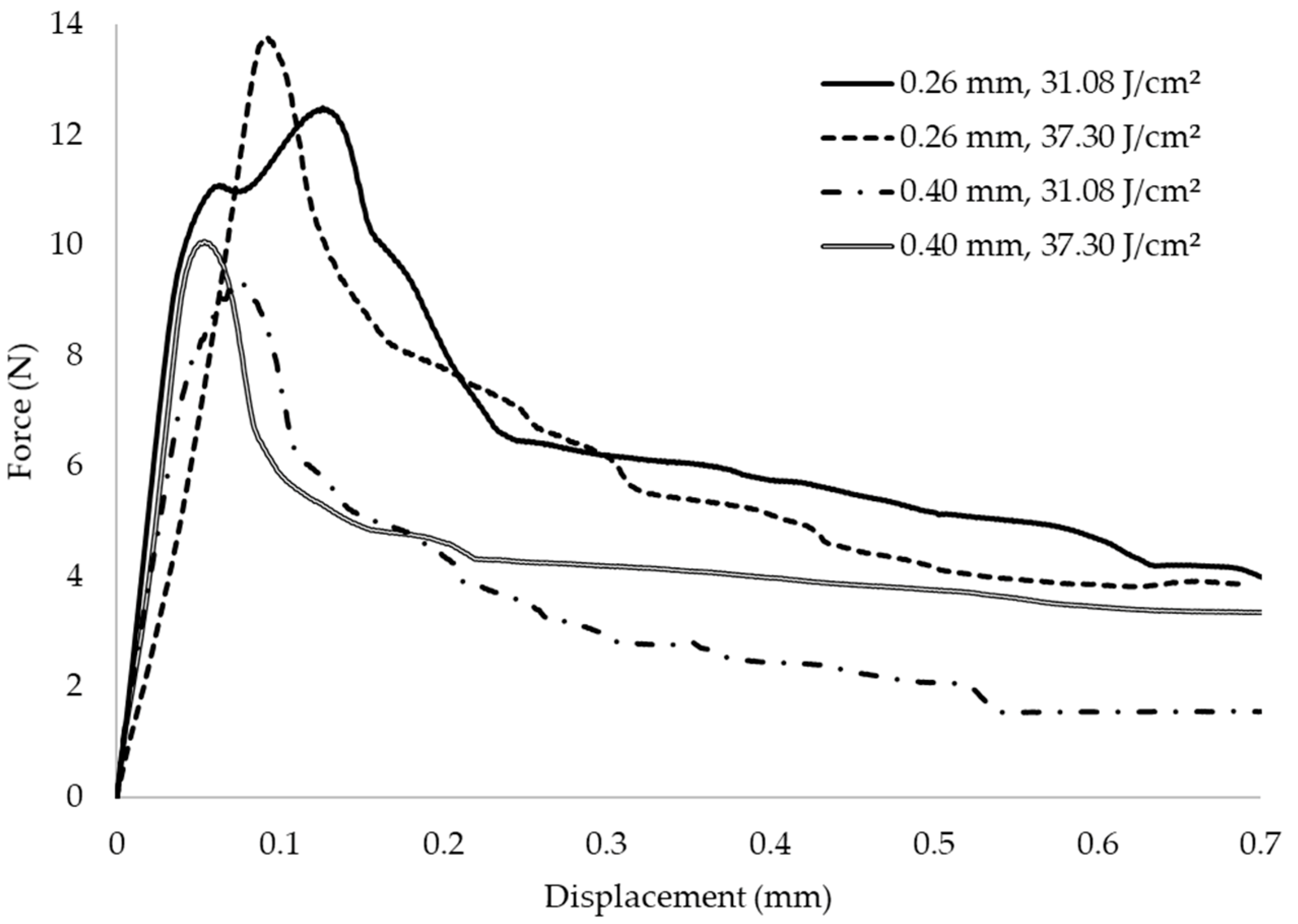

4.1. Experimental Results

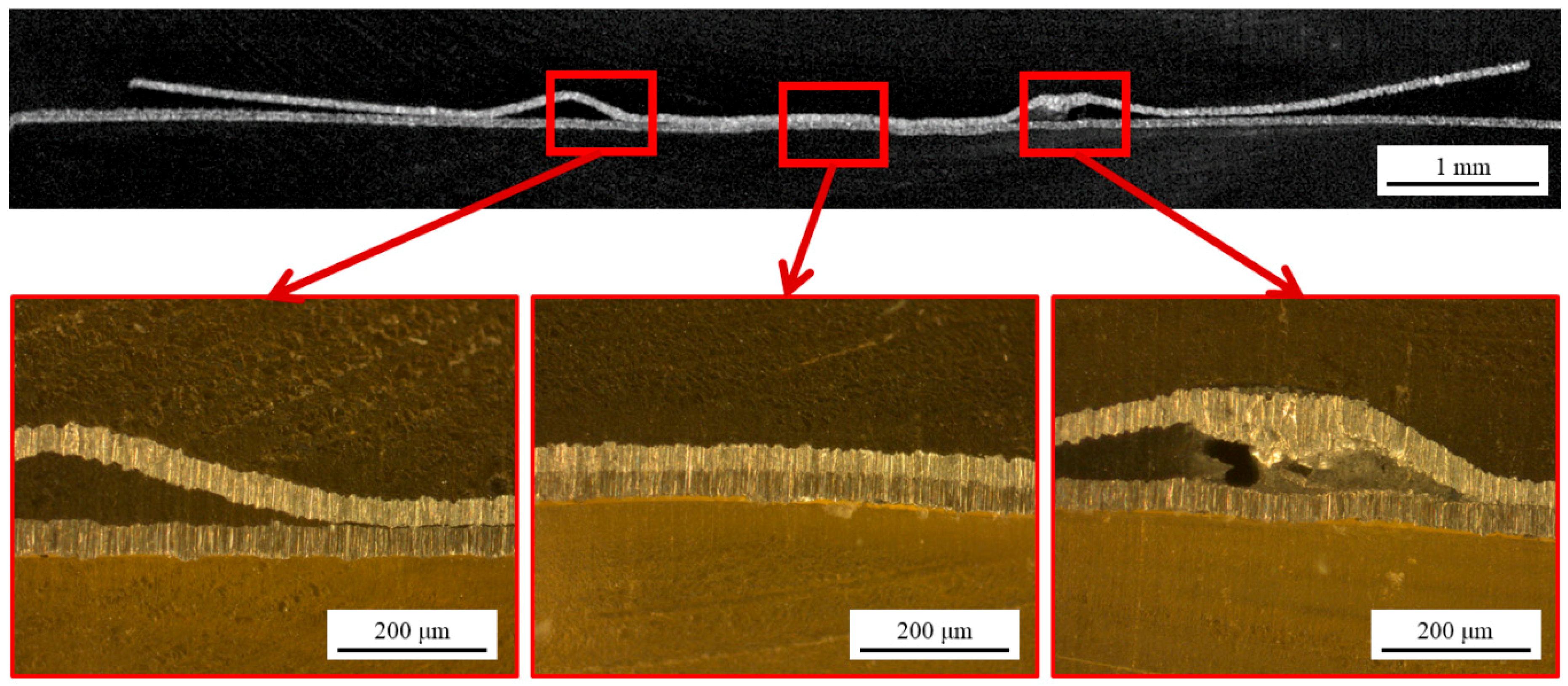

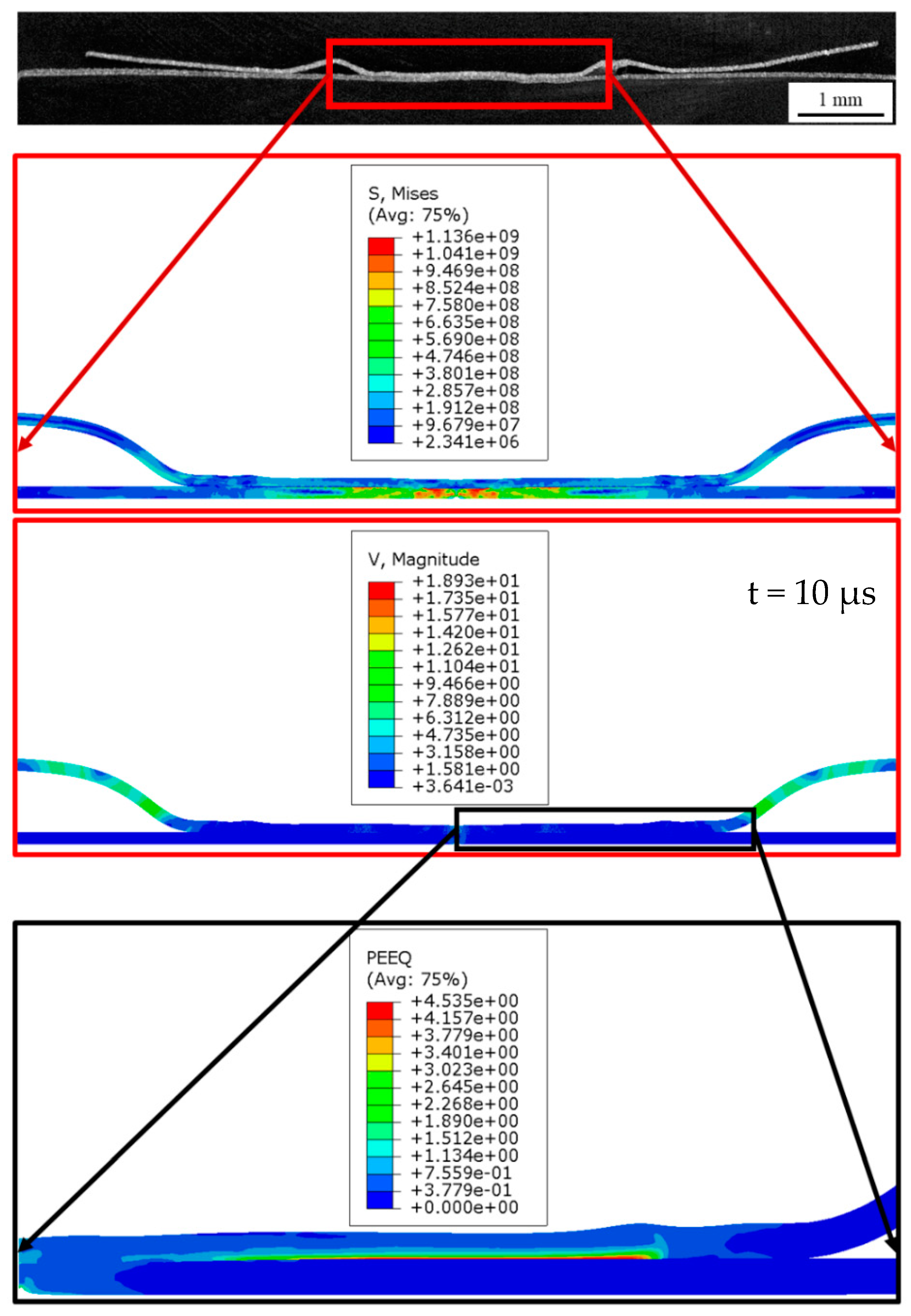

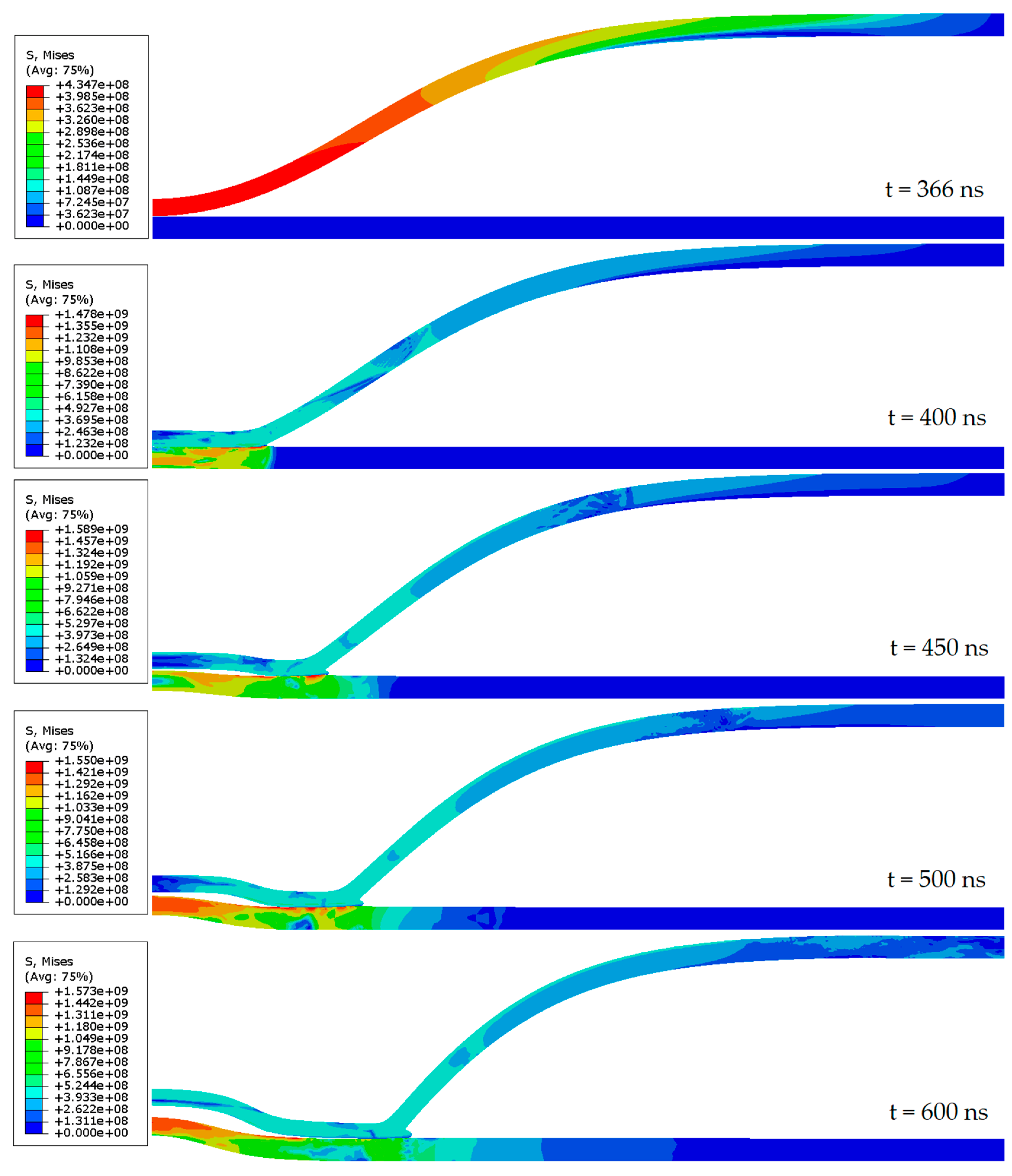

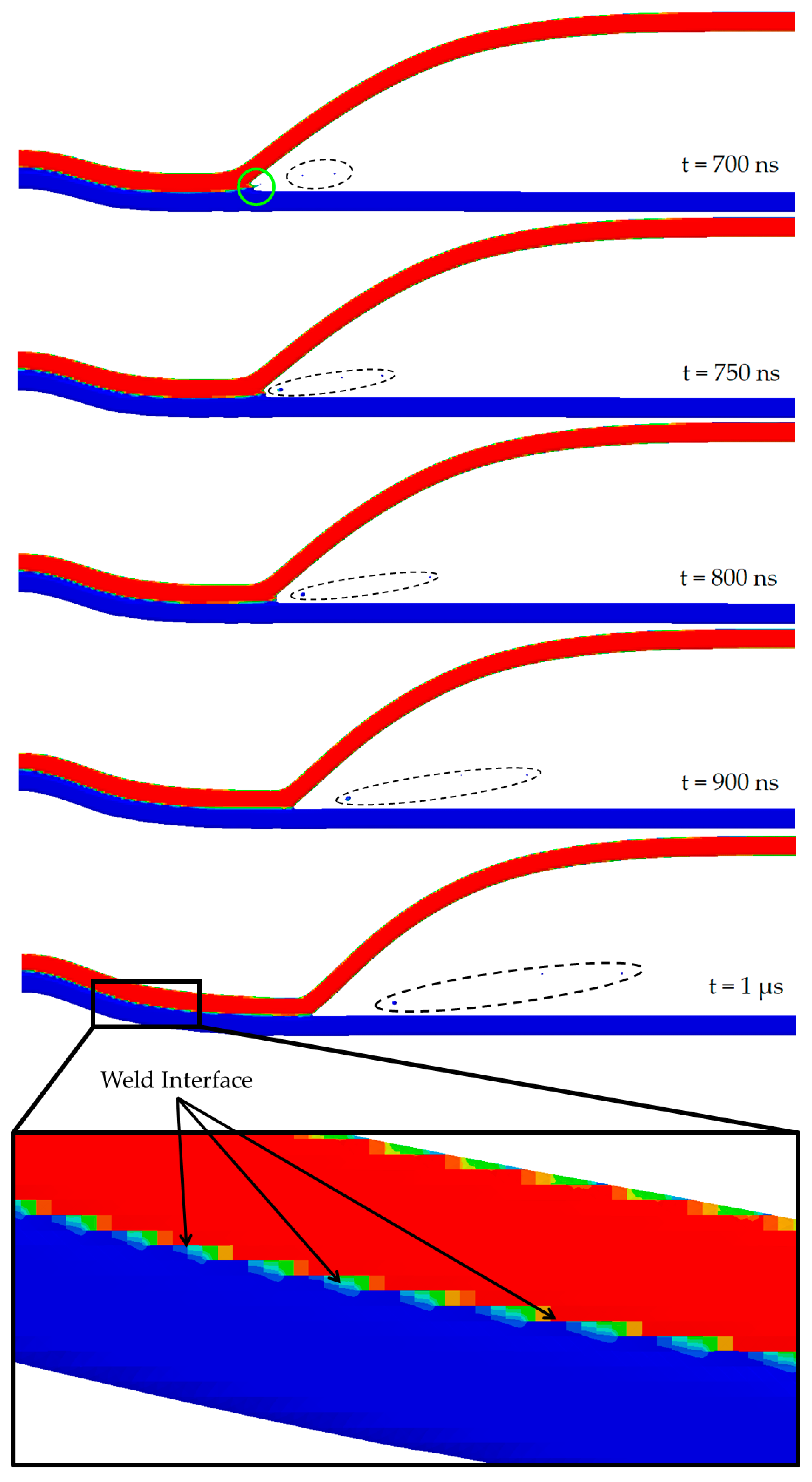

4.2. Numerical Results

5. Conclusions and Future Work

- A more realistic prediction of velocities and deformed shapes in different regions of the foils was achieved through incorporation of the measured temporal and spatial profiles of a Gaussian laser beam pulse pressure, leading to improved simulation of the LIW process in both axisymmetric ALE and Eulerian numerical models.

- LIW experiments were performed using standoff distances of 0.12, 0.26, 0.40, and 0.54 mm, as well as laser fluence values of 31.08 and 37.30 J/cm2. Irrespective of the laser fluence value, successful welds were obtained only at standoff distances of 0.26 and 0.40 mm.

- Successful welds were obtained without springback in the central region.

- Lap shear test results revealed that the greatest value of maximum force (13.76 N), and thus the strongest weld, was achieved using a standoff distance of 0.26 mm and a laser fluence of 37.30 J/cm2. In all tests, the failure occurred on the flyer (aluminum) side of the weld.

- Numerical results were compared to experiments, and good agreement was shown between the two.

- The jetting phenomenon and interlocking of the foils along the weld interface were successfully simulated.

- Investigations into the effect of LIW phenomena and factors such as the air medium, jet composition, use of double-sided tape, and the fixed metal specimen material type are deemed as potential topics for future research.

Author Contributions

Funding

Conflicts of Interest

References

- Crossland, B.; Williams, J.D. Developments in explosive welding. Aircr. Eng. Aerosp. Technol. 1968, 40, 11–13. [Google Scholar] [CrossRef]

- Szecket, A.; Mayseless, M. The triggering and controlling of stable interfacial conditions in explosive welding. Mater. Sci. Eng. 1983, 57, 149–154. [Google Scholar] [CrossRef]

- Mousavi, A.A.; Al-Hassani, S.T.S. Numerical and experimental studies of the mechanism of the wavy interface formations in explosive/impact welding. J. Mech. Phys. Solids 2005, 53, 2501–2528. [Google Scholar]

- Wang, Y.; Beom, H.G. Numerical simulation of explosive welding using the material point method. Int. J. Impact Eng. 2011, 38, 51–60. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, Y. Numerical study of the mechanism of explosive/impact welding using smoothed particle hydrodynamics method. Mater. Des. 2012, 35, 210–219. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Feng, D.L. Investigation of explosive welding through whole process modeling using a density adaptive SPH method. J. Manuf. Process. 2018, 35, 169–189. [Google Scholar] [CrossRef]

- Okagawa, K.; Aizawa, T. Impact seam welding with magnetic pressure for aluminum sheets. Mater. Sci. Forum 2004, 465, 231–236. [Google Scholar] [CrossRef]

- Watanabe, M.; Kumai, S. Interfacial microstructure of magnetic pressure seam welded Al-Fe, Al-Ni and Al-Cu lap joints. Mater. Sci. Forum 2006, 519, 1145–1150. [Google Scholar] [CrossRef]

- Lee, K.J.; Kumai, S. Interfacial microstructure and strength of steel/aluminum alloy lap joint fabricated by magnetic pressure seam welding. Mater. Sci. Eng. A 2007, 471, 95–101. [Google Scholar] [CrossRef]

- Ben-Artzy, A.; Stern, A. Wave formation mechanism in magnetic pulse welding. Int. J. Impact Eng. 2010, 37, 397–404. [Google Scholar] [CrossRef]

- Göbel, G.; Beyer, E.; Kaspar, J. Dissimilar metal joining: Macro-and microscopic effects of MPW. In Proceedings of the 5th International Conference on High Speed Forming, Dortmund, Germany, 24–26 April 2012; pp. 179–188. [Google Scholar]

- Raoelison, R.N.; Sapanathan, T. Interfacial kinematics and governing mechanisms under the influence of high strain rate impact conditions: Numerical computations of experimental observations. J. Mech. Phys. Solids 2016, 96, 147–161. [Google Scholar] [CrossRef]

- Cui, J.; Li, Y. Joining of tubular carbon fiber-reinforced plastic/aluminum by magnetic pulse welding. J. Mater. Process. Technol. 2019, 264, 273–282. [Google Scholar] [CrossRef]

- Vivek, A.; Hansen, S.R. Vaporizing foil actuator: A tool for collision welding. J. Mater. Process. Technol. 2013, 213, 2304–2311. [Google Scholar] [CrossRef]

- Hahn, M.; Weddeling, C. Vaporizing foil actuator welding as a competing technology to magnetic pulse welding. J. Mater. Process. Technol. 2016, 230, 8–20. [Google Scholar] [CrossRef]

- Vivek, A.; Presley, M. Solid state impact welding of BMG and copper by vaporizing foil actuator welding. Mater. Sci. Eng. A 2015, 634, 14–19. [Google Scholar] [CrossRef]

- Nassiri, A.; Kinsey, B. Numerical studies on high-velocity impact welding: Smoothed particle hydrodynamics (SPH) and arbitrary Lagrangian–Eulerian (ALE). J. Manuf. Process. 2016, 24, 376–381. [Google Scholar] [CrossRef]

- Nassiri, A.; Zhang, S. Numerical investigation of CP-Ti & Cu110 impact welding using smoothed particle hydrodynamics and arbitrary Lagrangian-Eulerian methods. J. Manuf. Process. 2017, 28, 558–564. [Google Scholar]

- Chen, S.; Daehn, G.S. Interfacial microstructures and mechanical property of vaporizing foil actuator welding of aluminum alloy to steel. Mater. Sci. Eng. A 2016, 659, 12–21. [Google Scholar] [CrossRef]

- Chen, S.; Huo, X. Interfacial characteristics of Ti/Al joint by vaporizing foil actuator welding. J. Mater. Process. Technol. 2019, 263, 73–81. [Google Scholar] [CrossRef]

- Gupta, V.; Lee, T. A robust process-structure model for predicting the joint interface structure in impact welding. J. Mater. Process. Technol. 2019, 264, 107–118. [Google Scholar] [CrossRef]

- Groche, P.; Becker, M. Process window acquisition for impact welding processes. Mater. Des. 2017, 118, 286–293. [Google Scholar] [CrossRef]

- Daehn, G.S.; Lippold, J.C. Low-Temperature Spot Impact Welding Driven without Contact. U.S. Patent No. PCT/US09/36499, 27 December 2011. [Google Scholar]

- Wang, H.; Liu, D.; Taber, G. Laser Impact Welding-Process Introduction and Key Variables. Available online: https://eldorado.tu-dortmund.de/bitstream/2003/29542/6/Wan12.pdf (accessed on 7 October 2019).

- Wang, H.; Taber, G. Laser impact welding: Design of apparatus and parametric optimization. J. Manuf. Process. 2015, 19, 118–124. [Google Scholar] [CrossRef]

- Wang, H.; Vivek, A. Laser impact welding application in joining aluminum to titanium. J. Laser Appl. 2016, 28, 032002. [Google Scholar] [CrossRef]

- Levieil, B.; Bridier, F. Numerical simulation of low-cycle fatigue behavior of welded joints for naval applications: Influence of residual stresses. Weld. World 2017, 61, 551–561. [Google Scholar] [CrossRef]

- Wang, X.; Gu, C. Laser shock welding of aluminum/aluminum and aluminum/copper plates. Mater. Des. 2014, 56, 26–30. [Google Scholar] [CrossRef]

- Peyre, P.; Berthe, L.; Fabbro, R. Laser shock processing of materials: Basics mechanisms and applications. In Proceedings of the 65th Laser Materials Processing Conference, Tokyo, Japan, 2–5 December 2005; pp. 95–109. [Google Scholar]

- Wang, X.; Gu, Y. An experimental and numerical study of laser impact spot welding. Mater. Des. 2015, 65, 1143–1152. [Google Scholar] [CrossRef]

- Wang, X.; Shao, M. Numerical simulation of laser impact spot welding. J. Manuf. Process. 2018, 35, 396–406. [Google Scholar] [CrossRef]

- Wang, X.; Li, F. Experimental and numerical study on the laser shock welding of aluminum to stainless steel. J. Opt. Lasers Eng. 2019, 115, 74–85. [Google Scholar] [CrossRef]

- Wang, X.; Shao, M. Laser impact welding of aluminum to brass. J. Mater. Process. Technol. 2019, 269, 190–199. [Google Scholar] [CrossRef]

- Wang, X.; Luo, Y. Experimental investigation on laser impact welding of Fe-Based amorphous alloys to crystalline copper. Materials 2017, 10, 523. [Google Scholar] [CrossRef]

- Liu, H.; Gao, S. Investigation on a novel laser impact spot welding. Metals 2016, 6, 179. [Google Scholar] [CrossRef]

- Liu, H.; Jin, H. Investigation on Interface Morphology and Mechanical Properties of Three-Layer Laser Impact Welding of Cu/Al/Cu. Metallur. Mater. Trans. A 2019, 50, 1273–1282. [Google Scholar] [CrossRef]

- Hatamleh, M.I.; Mahadevan, J. Prediction of Residual Stress Random Fields for Selective Laser Melted A357 Aluminum Alloy Subjected to Laser Shock Peening. ASME J. Manuf. Sci. Eng. 2019, 141, 101011. [Google Scholar] [CrossRef]

- Hatamleh, M.I.; Sadeh, S.; Farooq, T. Finite Element Study of Laser Peening on Selective Laser Melted A357 Aluminum Alloy During Tension Test. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; p. V004T03A046. [Google Scholar]

- Mahadevan, J.S. Probabilistic Material Modeling of Selective Laser Melted A357 Aluminum Alloy Subjected to Laser Shock Peening. Master’s Thesis, University of Texas at Dallas, Richardson, TX, USA, 2017. [Google Scholar]

- Ding, K.; Ye, L. 1 General introduction. In Laser Shock Peening: Performance and Process Simulation; Woodhead Publishing: Cambridge, UK, 2006; p. 2. [Google Scholar]

- Fabbro, R.; Fournier, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Hong, X.; Wang, S.B. Confining medium and absorptive overlay: Their effects on a laser-induced shock wave. J. Opt. Lasers Eng. 1998, 29, 447–455. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Dassault Systèmes. Abaqus Analysis User’s Guide, v6.14; Dassault Systèmes: Waltham, MA, USA, 2014. [Google Scholar]

- Altair Engineering Inc. Radioss Theory Manual, v14; Altair Engineering Inc.: Troy, MI, USA, 2015. [Google Scholar]

| Laser Parameter (Units) | Type/Value(s) |

|---|---|

| Pulse Type | Q-Switched |

| Laser Wavelength (nm) | 1064 |

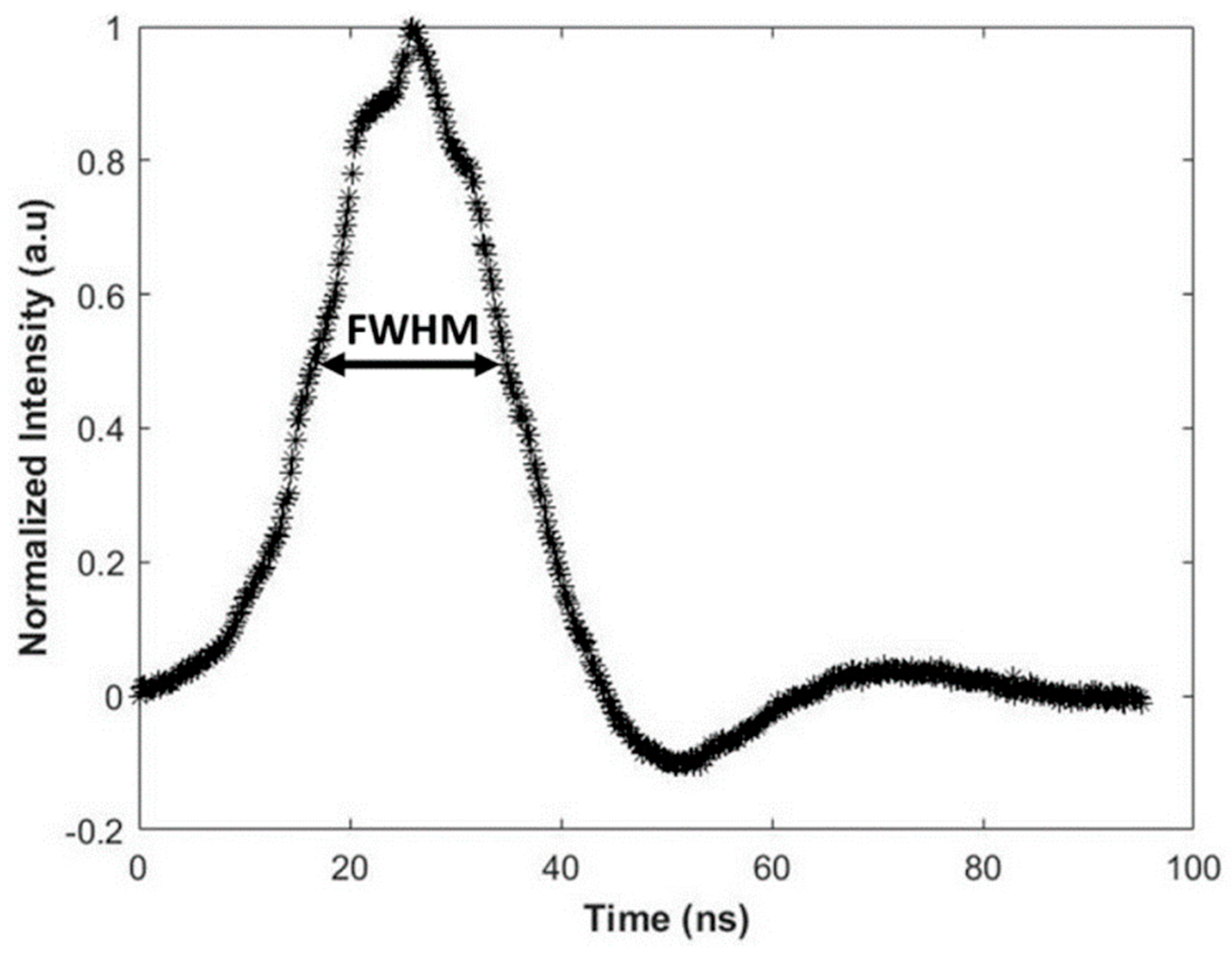

| FWHM Pulse Width (ns) | 17 |

| Average Pulse Energy (J) | 2.5–3 (±2%) |

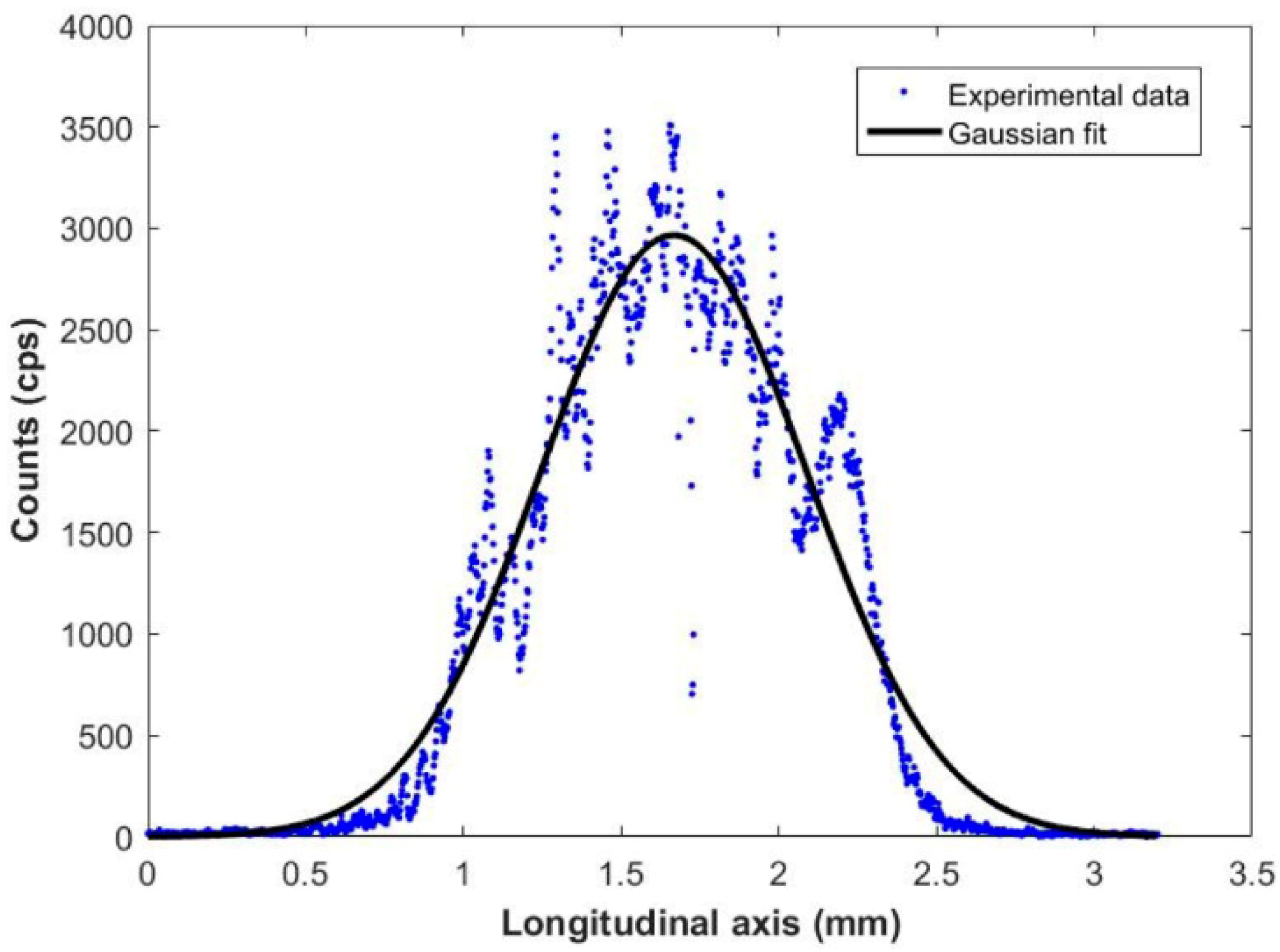

| Laser Spot Size (mm) | 3.2 ± 0.1 |

| Incident Peak Power Density (GW/cm2) | 1.8–2.2 |

| Parameter | Magnitude (Units) |

|---|---|

| Energy ratio () | 0.25 |

| Adiabatic constant () | 1.4 |

| Glass impedance () | 1.14 (106 g/cm2s) |

| Aluminum impedance () | 2.75 (106 g/cm2s) |

| Material | A (MPa) | B (MPa) | n | C | m | T0 (K) | Tm (K) |

|---|---|---|---|---|---|---|---|

| 1100 Aluminum | 148.4 | 345.5 | 0.183 | 0.001 | 0.895 | 293 | 916 |

| 304 Stainless Steel | 110 | 1500 | 0.36 | 0.014 | 1 | 293 | 1673 |

| Material | ρ (kg/m3) | c0 (m/s) | s | Γ0 |

|---|---|---|---|---|

| 1100 Aluminum | 2710 | 5380 | 1.337 | 2.1 |

| 304 Stainless Steel | 7905 | 4570 | 1.490 | 2.0 |

| Laser Spot Diameter (mm) | Laser Pulse Energy (J) | Laser Fluence (J/cm2) | Standoff Distance (mm) | Successful Weld? |

|---|---|---|---|---|

| 3.2 | 2.5 | 31.08 | 0.12 | No |

| 3.0 | 37.30 | |||

| 2.5 | 31.08 | 0.26 | Yes | |

| 3.0 | 37.30 | |||

| 2.5 | 31.08 | 0.40 | Yes | |

| 3.0 | 37.30 | |||

| 2.5 | 31.08 | 0.54 | No | |

| 3.0 | 37.30 |

| Standoff Distance (mm) | Maximum Impact Velocity (m/s) | Maximum Impact Angle (degrees) | Collision Time (ns) |

|---|---|---|---|

| 0.1 | 1110 | 5 | 146 |

| 0.2 | 1370 | 15 | 220 |

| 0.3 | 1580 | 20 | 293 |

| 0.4 | 1550 | 30 | 366 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeh, S.; Gleason, G.H.; Hatamleh, M.I.; Sunny, S.F.; Yu, H.; Malik, A.S.; Qian, D. Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model. Metals 2019, 9, 1196. https://doi.org/10.3390/met9111196

Sadeh S, Gleason GH, Hatamleh MI, Sunny SF, Yu H, Malik AS, Qian D. Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model. Metals. 2019; 9(11):1196. https://doi.org/10.3390/met9111196

Chicago/Turabian StyleSadeh, Sepehr, Glenn H. Gleason, Mohammad I. Hatamleh, Sumair F. Sunny, Haoliang Yu, Arif S. Malik, and Dong Qian. 2019. "Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model" Metals 9, no. 11: 1196. https://doi.org/10.3390/met9111196

APA StyleSadeh, S., Gleason, G. H., Hatamleh, M. I., Sunny, S. F., Yu, H., Malik, A. S., & Qian, D. (2019). Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model. Metals, 9(11), 1196. https://doi.org/10.3390/met9111196