Damping Capacity and Storage Modulus of SiC Matrix Composites Infiltrated by AlSi Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of AlSi/SiC Composites

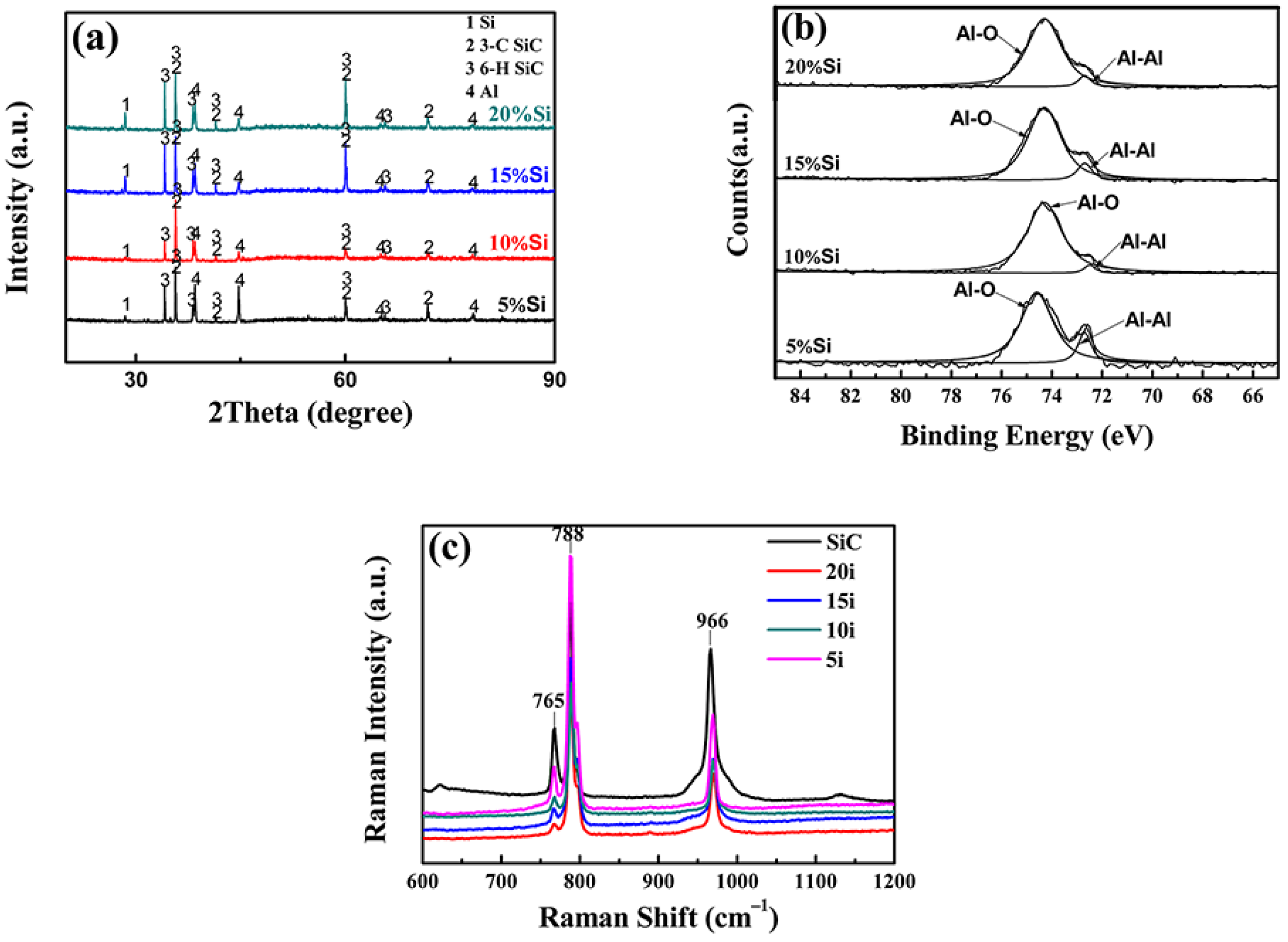

2.2. Microstructure and Phase Composition

2.3. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

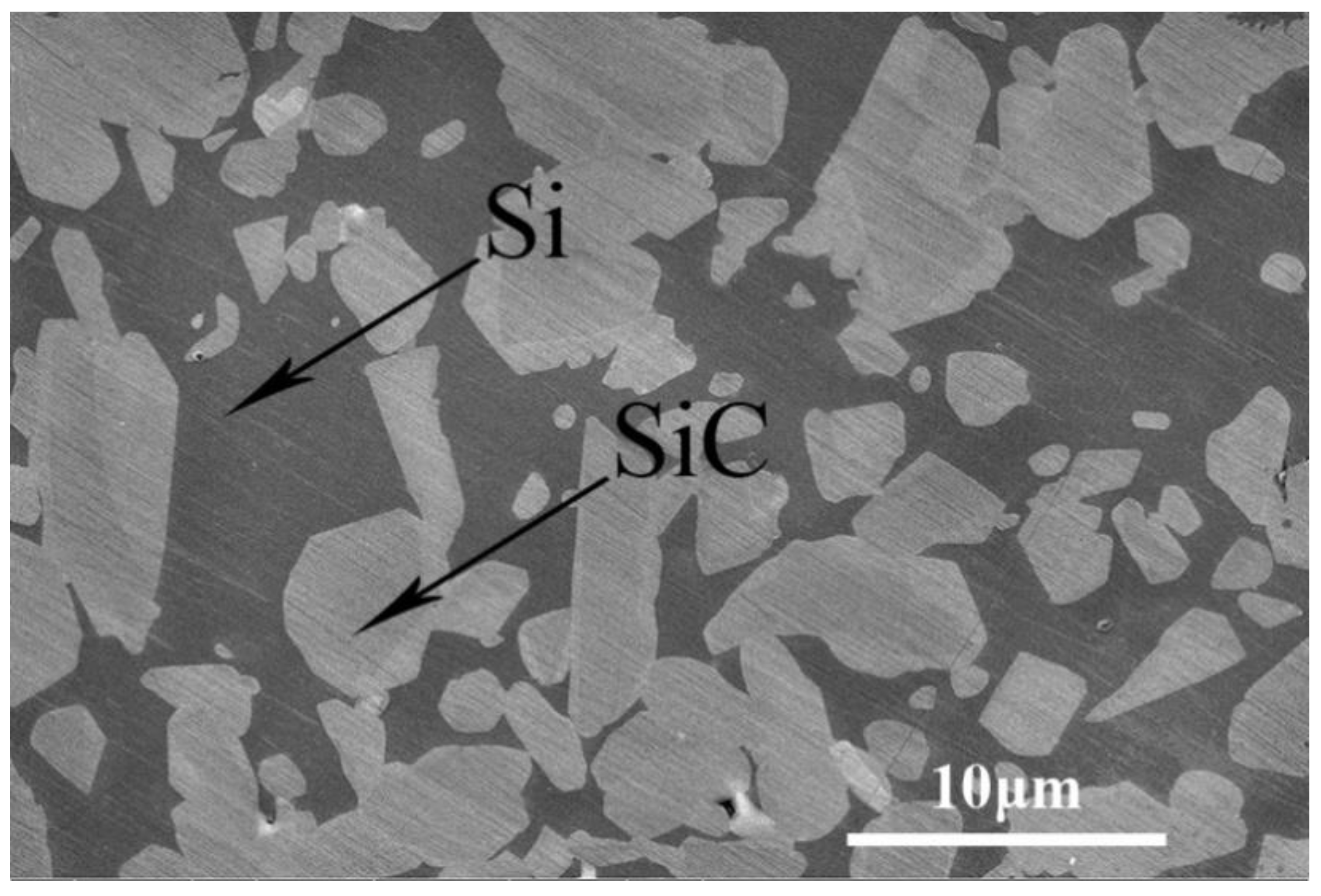

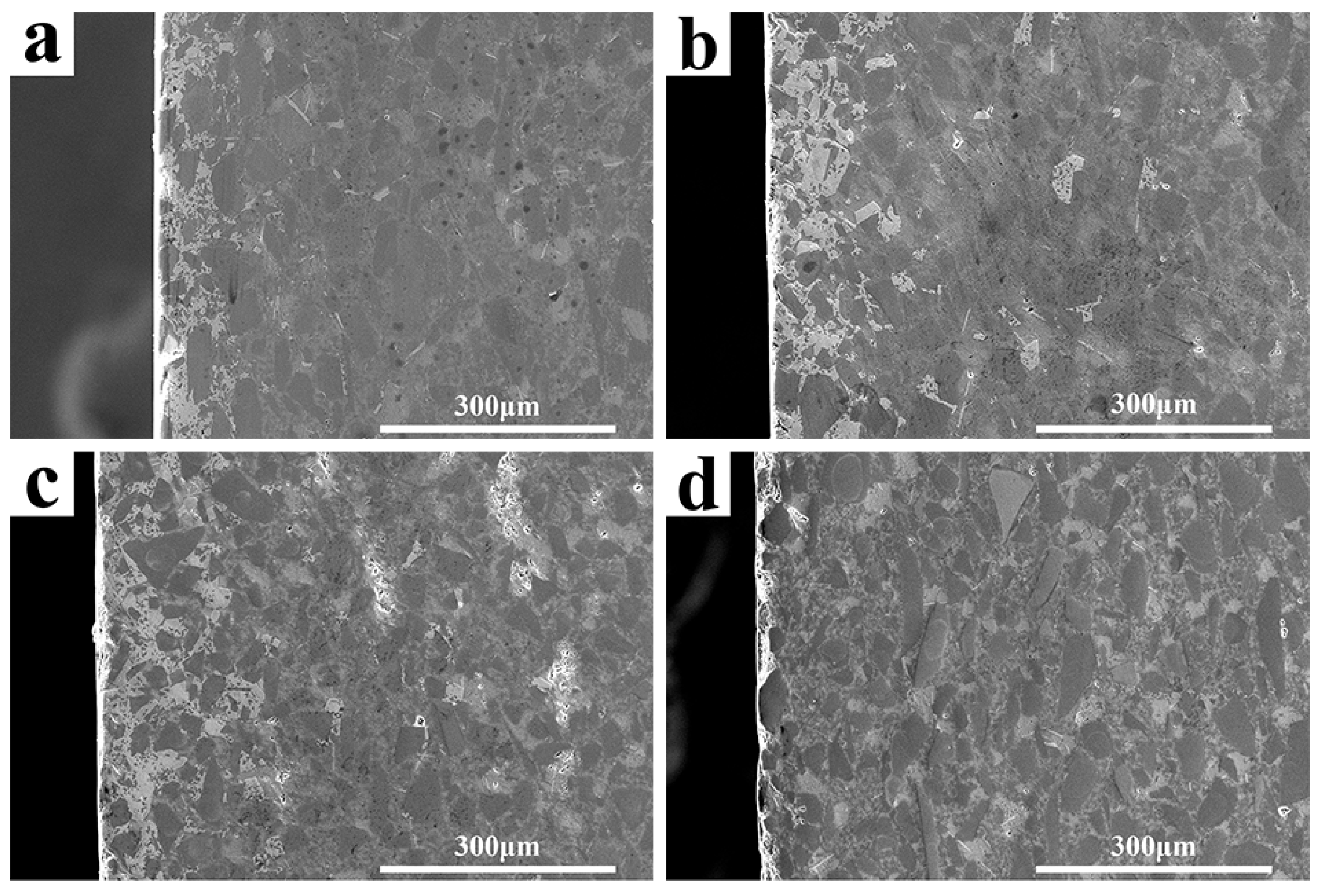

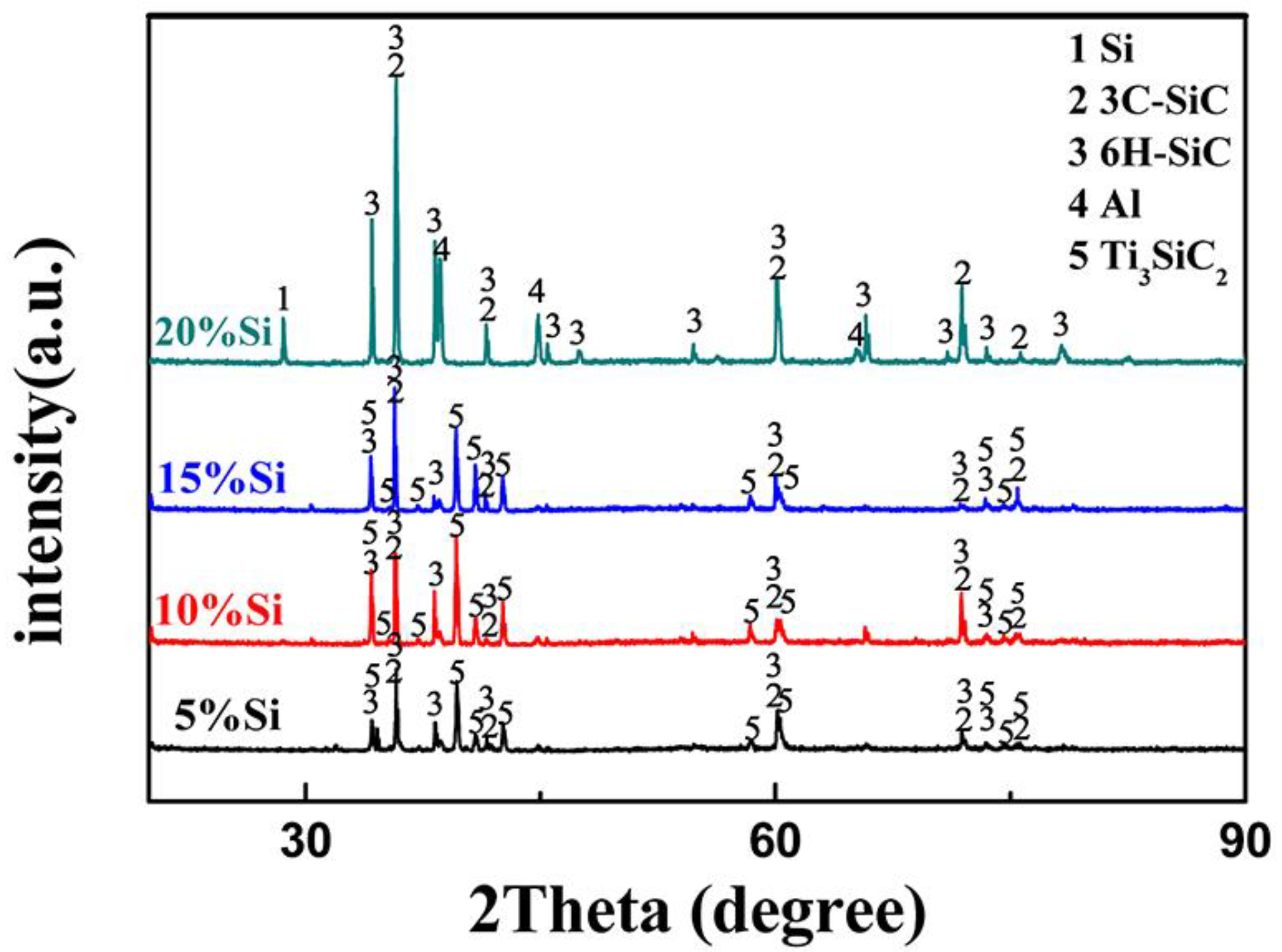

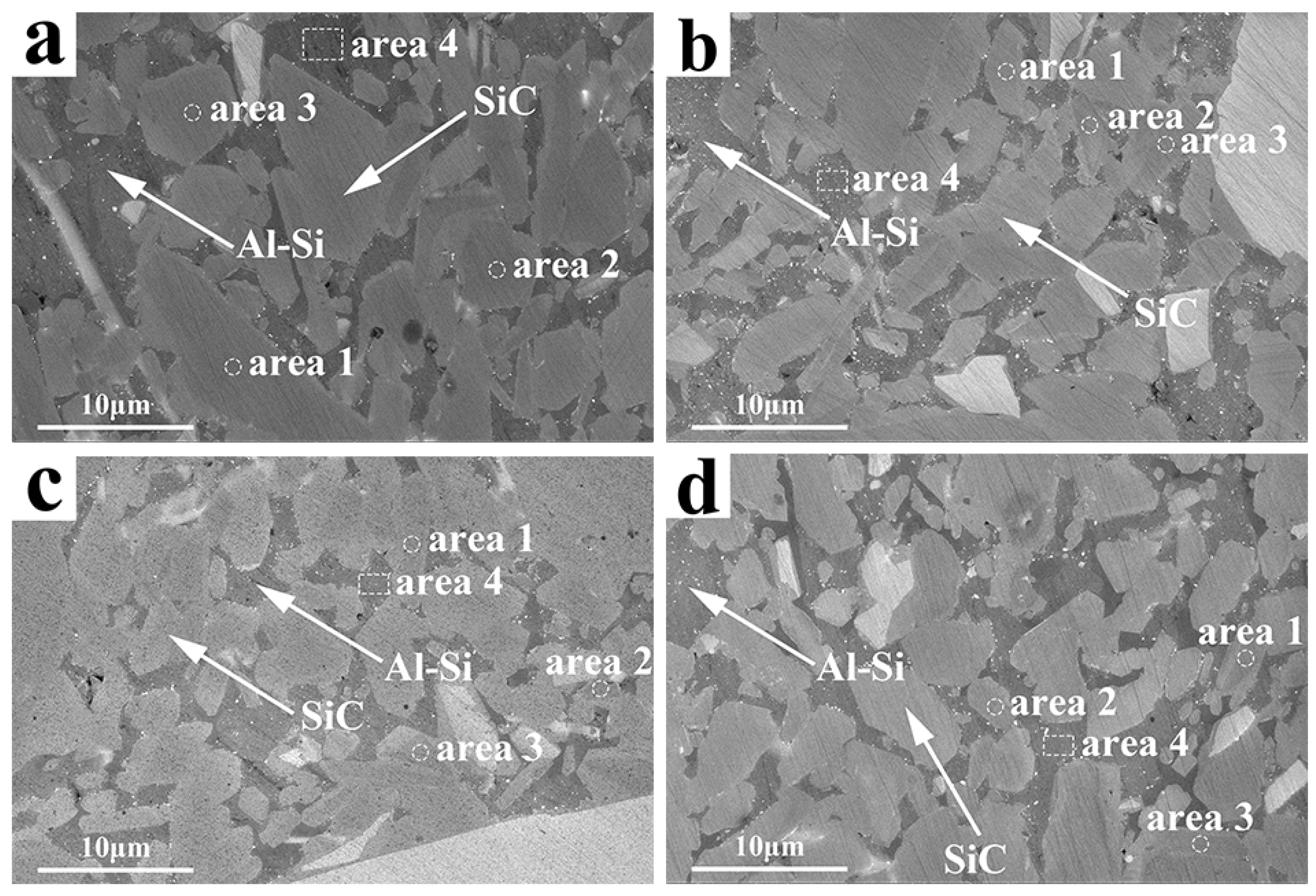

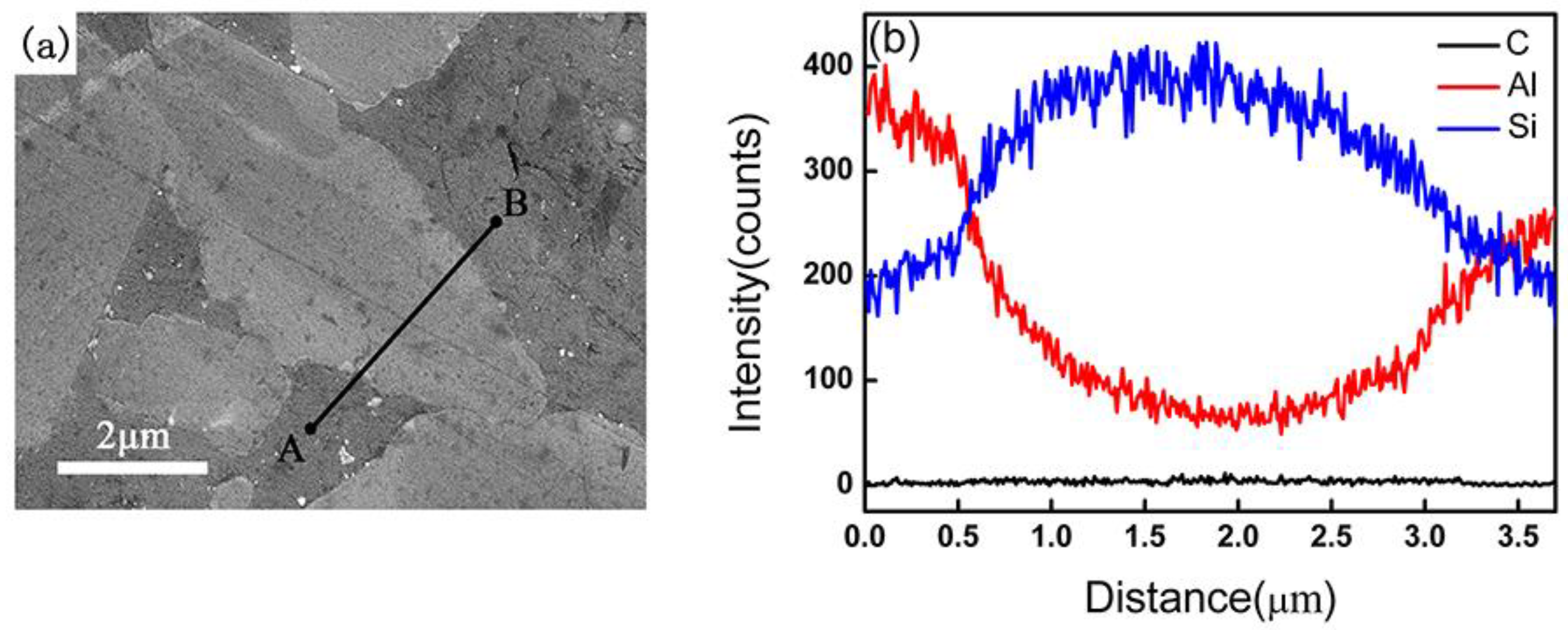

3.1. Microstructure

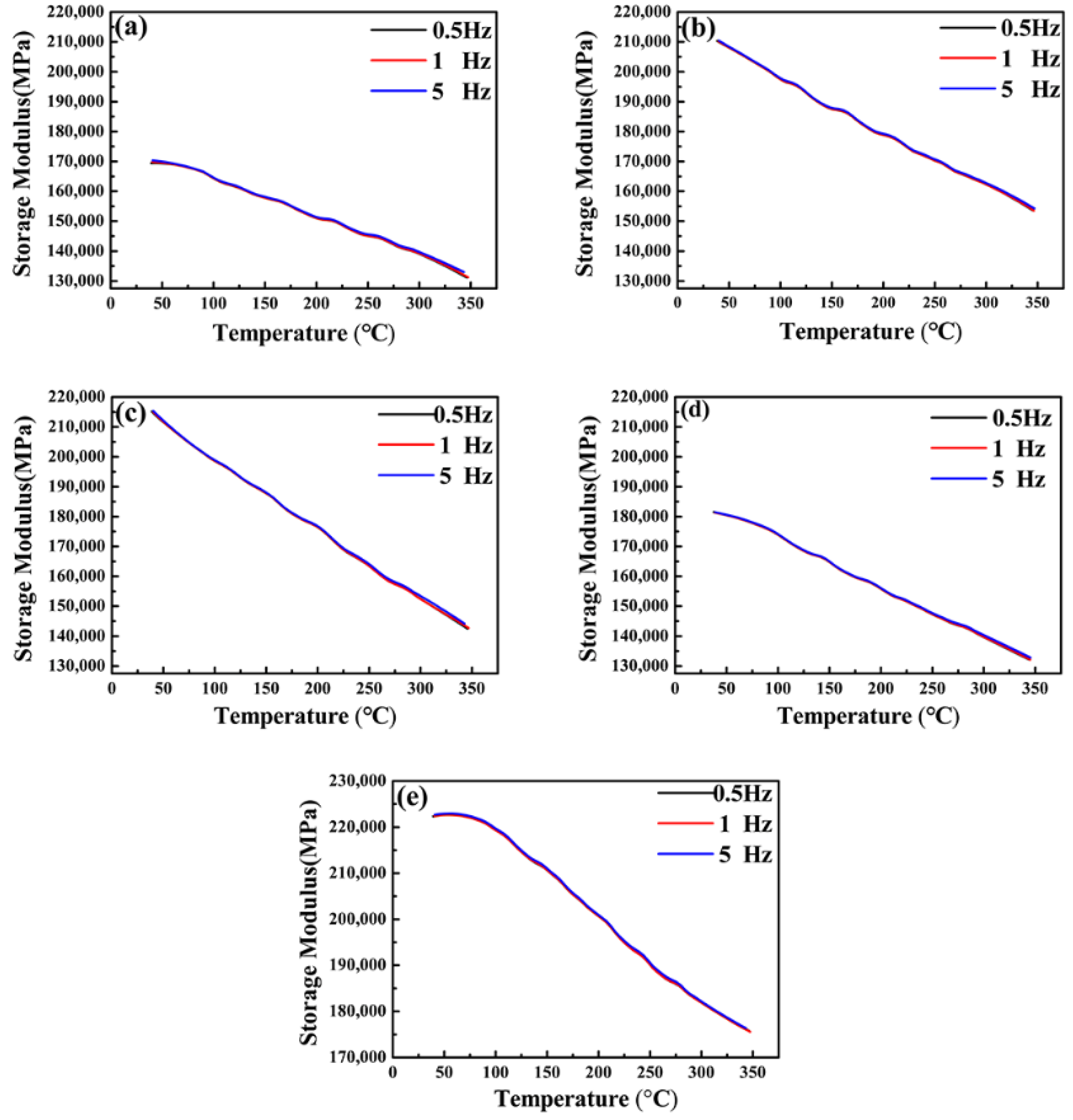

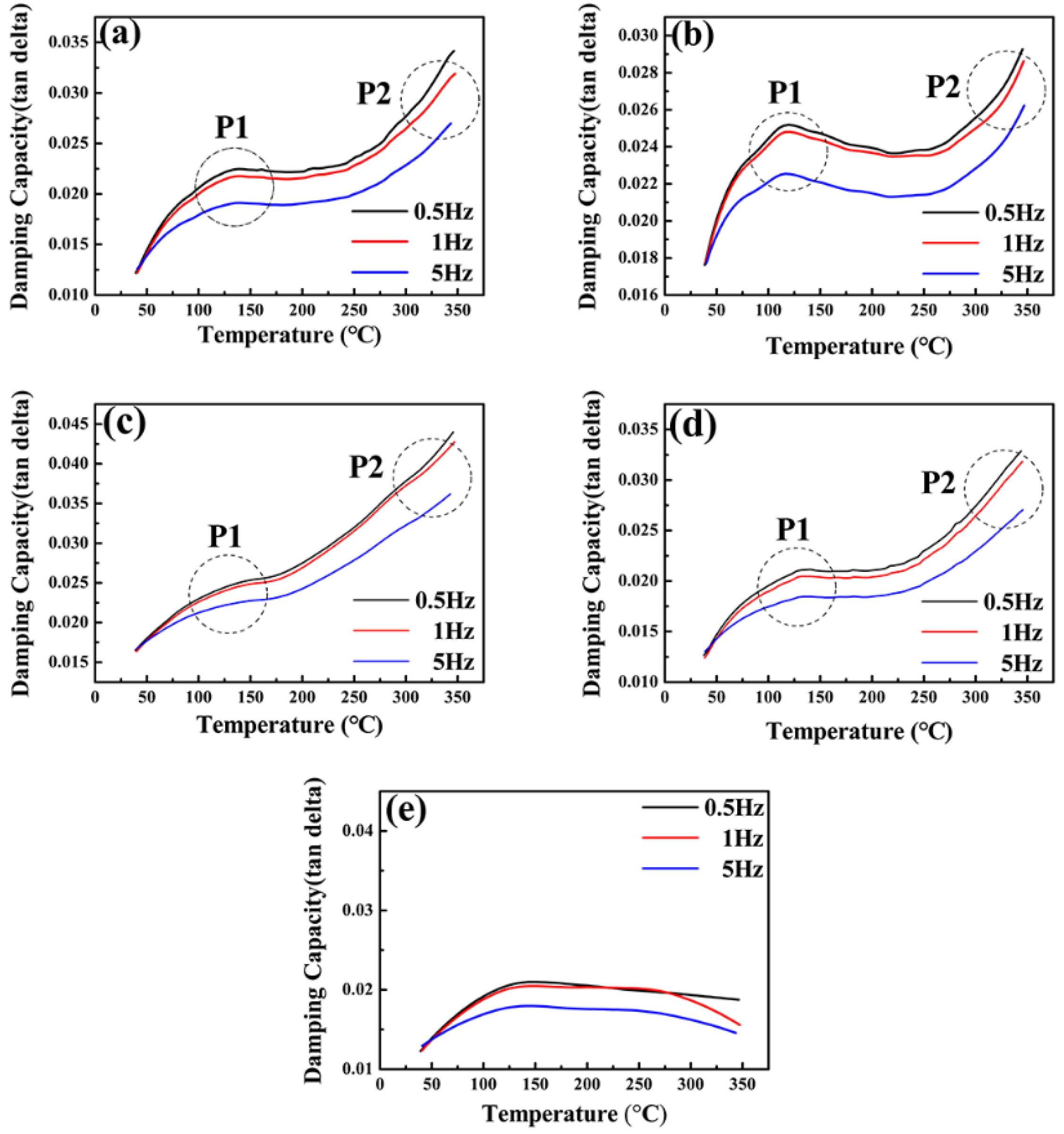

3.2. Damping Behavior

3.3. Influence of Si

4. Conclusions

- All SiCCMCs were successfully fabricated by infiltration.

- Different interface combination statuses were obtained by infiltrating Al alloys with 5, 10, 15, and 20 wt. % Si, A white reaction layer was formed on the surface of the composites when the Si content is less than 20 wt. %. No interfacial reaction was detected in the core of all composites. The Al alloy was combined with SiC through diffusion.

- The storage modulus of the composites reached 210 GPa or more at room temperature and 140 GPa or more at 350 °C when the Si content was 10 and 15 wt. %, respectively. The reason for this is twofold: the brittle primary Si was not precipitated during the cooling process of the composites, and the dispersed secondary Si increased the strength of the composites.

- The composites exhibited the best damping capacity at high temperature when the Si content was 15 wt. %, because the interface friction dissipated most of thermal energy.

- The strength and damping capacity of the composites can be controlled by changing the Si content in the Al alloy to facilitate different applications.

Author Contributions

Funding

Conflicts of Interest

References

- Nishiyama, K.; Yamanaka, M.; Omori, M. High-temperature dependence of the internal friction and modulus change of tetragonal ZrO2, Si3N4 and SiC. J. Mater. Sci. Lett. 1990, 9, 526–528. [Google Scholar] [CrossRef]

- Zhang, J.; Perez, R.J.; Lavernia, E.J. Documentation of damping capacity of metallic, ceramic and metal-matrix composite materials. J. Mater. Sci. 1993, 28, 2395–2404. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, N.; Li, X.; Wang, H. Study on damping capacity Aluminum composite reinforced with in situ TiAl3 rod. Mater. Des. 2008, 29, 1057–1059. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, C.; Fan, T.; Zhang, D. In situ synthesis and damping capacities of TiC reinforced magnesium matrix composites. Mater. Sci. Eng. 2008, 496, 242–246. [Google Scholar] [CrossRef]

- Hu, J.; Liu, G.; Tang, S.W. Damping behavior in Al18B4O33w/Al composite containing an interfacial layer with low melting point metal particles. J. Alloys Compd. 2012, 513, 61–67. [Google Scholar] [CrossRef]

- Rao, M.D. Recent applications of viscoelastic damping for noise control in automobiles and commercial airplane. J. Sound Vib. 2003, 262, 457–474. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Yang, G. The dependence of damping capacity of PMMCs on strain amplitude. Comput. Mater. Sci. 2000, 18, 205–211. [Google Scholar] [CrossRef]

- Liu, Q.; Li, M.; Gu, Y.; Wang, S.; Zhang, Y.; Li, Q. Interlocked CNT networks with high damping and storage modulus. Carbon. 2015, 86, 46–53. [Google Scholar] [CrossRef]

- Lin, R.; Lu, C. Modeling of interfacial friction damping of carbon nanotube-based nanocomposites. Mech. Syst. Sig. Process. 2010, 24, 2996–3012. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, L.F.; Wang, W.; Wei, X.; Zhang, L.T.; Xu, Y.D. Effects of interphase thickness on damping behavior of 2D C/SiC composites. Mater. Sci. Forum 2007, 546, 1531–1534. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, L.F.; Wang, W.; Zhang, L.T.; Xu, Y.D. Effect of SiC coating and heat treatment on damping behavior of C/SiC composites. Mater. Sci. Eng. A 2008, 473, 254–258. [Google Scholar] [CrossRef]

- Zhang, X.C.; Peng, H.X.; Limmack, A.P.; Scarpa, F. Viscoelastic damping behaviour of cup stacked carbon nanotube modified epoxy nanocomposites with tailored interfacial condition and re-agglomeration. Compos. Sci. Technol. 2014, 105, 66–72. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Perez, R.J.; Zhang, J. Damping behavior of discontinuously reinforced Al alloy metal-matrix composites. Metall. Mater. Trans. A 1995, 26, 2803–2818. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S.; Mondal, D.P.; Dixit, G. Dry sliding wear behaviour of cast high strength aluminium alloy (Al–Zn–Mg) and hard particle composites. Wear 2009, 267, 1688–1695. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Nath, D.; Sigh, S.S.; Keshavaram, B.N. Factors affecting the damping capacity of cast Aluminium-matrix composites. J. Mater. Sci. 1994, 29, 5975–5984. [Google Scholar] [CrossRef]

- Hu, J.; Wu, G.; Zhang, Q.; Gou, H. Mechanical properties and damping capacity of SiCp/TiNif/Al composite with different volume fraction of SiC particle. Compos. Part B 2014, 66, 400–406. [Google Scholar] [CrossRef]

- Kang, C.S.; Maeda, K.; Wang, K.J.; WakaSima, K. Dynamic Young′s modulus and internal friction in particulate SiC/Al composites. Acta Mater. 1998, 46, 1209–1220. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Odoni, B.U. Mechanical properties, wear and corrosion behavior of copper matrix composites reinforced with steel machining chips. Eng. Sci. Technol. Int. J. 2016, 19, 1593–1599. [Google Scholar] [CrossRef]

- Peteves, S.D.; Tambuyser, P.; Helbach, P. Microstructure and microchemistry of the Al/SiC interface. J. Mater. Sci. 1990, 25, 3765–3772. [Google Scholar] [CrossRef]

- Zhong, W.M.; Lesperance, G.; Suery, M. Interfacial reactions in Al-Mg (5083)/SiCp composites during fabrication and remelting. Metall. Mater. Trans. A. 1995, 26, 2637–2649. [Google Scholar] [CrossRef]

- Bahrami, A.; Pech-Canul, M.I.; Gutierrez, C.A. Effect of rice-husk ash on properties of laminated and functionally graded Al/SiC composites by one-step pressureless infiltration. J. Alloys Compd. 2015, 644, 256–266. [Google Scholar] [CrossRef]

- Tibbetts, K.M.; Odhner, J.; Vaddypally, S. Amorphous aluminum-carbide and aluminum–magnesium–carbide nanoparticles from gas phase activation of trimethylaluminum and octamethyldialuminummagnesium using simultaneous spatially and temporally focused ultrashort laser pulses. Nano-Struct. Nano-Objects 2016, 6, 1–4. [Google Scholar] [CrossRef]

- Zhang, L.; Qu, X.; Duan, B. Wettability and pressureless infiltration mechanism in SiC-Cu systems. Int. J. Miner. Metall. Mater. 2009, 16, 327–333. [Google Scholar] [CrossRef]

- Ferro, A.C.; Derby, B. Wetting behaviour in the Al-Si/SiC system: Interface reactions and solubility effects. Acta Metall. Mater. 1995, 43, 3061–3073. [Google Scholar] [CrossRef]

- Heera, V.; Panknin, D.; Skorupa, W. p-Type doping of SiC by high dose Al implantation—problems and progress. Appl. Surf. Sci. 2001, 184, 307–316. [Google Scholar] [CrossRef]

- Ward, Y.; Young, R.J.; Shatwell, R.A. Application of Raman microscopy to the analysis of Silicon carbide monofilaments. J. Mater. Sci. 2004, 39, 6781–6790. [Google Scholar] [CrossRef]

- Romero, J.C.; Arsenault, R.J. Anomalous penetration of Al into SiC. Acta Metall. Mater. 1995, 43, 849–857. [Google Scholar] [CrossRef]

- Flom, Y.; Arsenault, R.J. Interfacial bond strength in an aluminium alloy 6061—SiC composite. Mater. Sci. Eng. 1986, 77, 191–197. [Google Scholar] [CrossRef]

- Wang, W.; Li, Q.; Ma, R. Effects of the Si contents of an infiltrating aluminium alloy on the microstructure and strength of SiC matrix composites. J. Ceram. Int. 2017, 43, 12526–12533. [Google Scholar] [CrossRef]

- Silva Prasad, D.; Shoba, C.; Varma, K.R. Damping behavior of commonly used reinforcement powders—An experimental approach. Eng. Sci. Technol. Int. J. 2015, 18, 674–679. [Google Scholar] [CrossRef]

- Prasad, D.S.; Shoba, C. Experimental evaluation onto the damping behavior of Al/SiC/RHA hybrid composites. J. Mater. Res. Technol. 2016, 5, 123–130. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Niroumand, B. Development of Al356/SiCp cast composites by injection of SiCp containing composite powders. Mater. Des. 2011, 32, 1895–1902. [Google Scholar] [CrossRef]

- Guo, C.; He, X.; Ren, S. Effect of (0–40) wt. % Si addition to Al on the thermal conductivity and thermal expansion of diamond/Al composites by pressure infiltration. J. Alloys Compd. 2016, 664, 777–783. [Google Scholar] [CrossRef]

- Granato, A.; Lücke, K. Theory of mechanical damping due to dislocations. J. Appl. Phys. 1956, 27, 583–593. [Google Scholar] [CrossRef]

- An, Q.; Cong, X.; Shen, P. Roles of alloying elements in wetting of SiC by Al. J. Alloys Compd. 2019, 784, 1212–1220. [Google Scholar] [CrossRef]

- Dai, C.; Ma, R.; Wang, W. Microstructure and properties of an Al–Ti–Cu–Si brazing alloy for SiC–metal joining. Int. J. Miner. Metall. Mater. 2017, 24, 557–565. [Google Scholar] [CrossRef]

- Song, S.; Gao, Z.; Lu, B.; Bao, C.; Zheng, B.; Wang, L. Performance optimization of complicated structural SiC/Si composite ceramics prepared by selective laser sintering. Ceram. Int. 2019. [Google Scholar] [CrossRef]

- Chakrabarti, O.P.; Ghosh, S.; Mukerji, J. Influence of grain size, free silicon content and temperature on the strength and toughness of reaction-bonded silicon carbide. Ceram. Int. 1994, 2, 283–286. [Google Scholar] [CrossRef]

| Si Content | 6H-SiC | 3C-SiC | Ti3SiC2 | Al | Si |

|---|---|---|---|---|---|

| 5 wt. % Si | 65 | 23.8 | 11.2 | - | - |

| 10 wt. % Si | 14.3 | 3.3 | 82.4 | - | - |

| 15 wt. % Si | 72.4 | 17.2 | 10.4 | - | - |

| 20 wt. % Si | 73 | 16.6 | - | 8.4 | 2 |

| Area | 5 wt. % Si | 10 wt. % Si | 15 wt. % Si | 20 wt. % Si |

|---|---|---|---|---|

| area1 | ||||

| Al | 3.01 | 8.78 | 13.84 | 10.51 |

| Si | 37.87 | 44.3 | 47.62 | 38.63 |

| C | 59.13 | 46.92 | 38.54 | 50.85 |

| area2 | ||||

| Al | 2.38 | 7.6 | 17.52 | 9.32 |

| Si | 47.39 | 16.36 | 47.26 | 47.64 |

| C | 50.23 | 46.05 | 35.22 | 43.04 |

| area3 | ||||

| Al | 2.67 | 9.08 | 14.38 | 8.47 |

| Si | 65.49 | 45.94 | 50.11 | 47.37 |

| C | 31.84 | 44.98 | 35.51 | 44.15 |

| average Al content | 2.68 | 8.48 | 15.24 | 9.43 |

| area4 | ||||

| Al | 28.37 | 56.39 | 28.55 | 71.81 |

| Si | 49.56 | 32.36 | 56.49 | 15.9 |

| C | 22.02 | 11.25 | 14.96 | 12.29 |

| Si Content | 6H-SiC | 3C-SiC | Al | Si |

|---|---|---|---|---|

| 5 wt. % Si | 65.9 | 22.5 | 10.9 | 0.7 |

| 10 wt. % Si | 73.4 | 18.4 | 7.7 | 0.5 |

| 15 wt. % Si | 74.1 | 19.9 | 5.5 | 0.5 |

| 20 wt. % Si | 68.6 | 16.9 | 9.8 | 4.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Fan, Y.; Zhao, X.; Ma, R.; Du, A.; Cao, X.; Ban, H. Damping Capacity and Storage Modulus of SiC Matrix Composites Infiltrated by AlSi Alloy. Metals 2019, 9, 1195. https://doi.org/10.3390/met9111195

Li X, Fan Y, Zhao X, Ma R, Du A, Cao X, Ban H. Damping Capacity and Storage Modulus of SiC Matrix Composites Infiltrated by AlSi Alloy. Metals. 2019; 9(11):1195. https://doi.org/10.3390/met9111195

Chicago/Turabian StyleLi, Xuan, Yongzhe Fan, Xue Zhao, Ruina Ma, An Du, Xiaoming Cao, and Huiyun Ban. 2019. "Damping Capacity and Storage Modulus of SiC Matrix Composites Infiltrated by AlSi Alloy" Metals 9, no. 11: 1195. https://doi.org/10.3390/met9111195

APA StyleLi, X., Fan, Y., Zhao, X., Ma, R., Du, A., Cao, X., & Ban, H. (2019). Damping Capacity and Storage Modulus of SiC Matrix Composites Infiltrated by AlSi Alloy. Metals, 9(11), 1195. https://doi.org/10.3390/met9111195