Fatigue Behaviour and Crack Initiation in CoCrFeNiMn High-Entropy Alloy Processed by Powder Metallurgy

Abstract

:1. Introduction

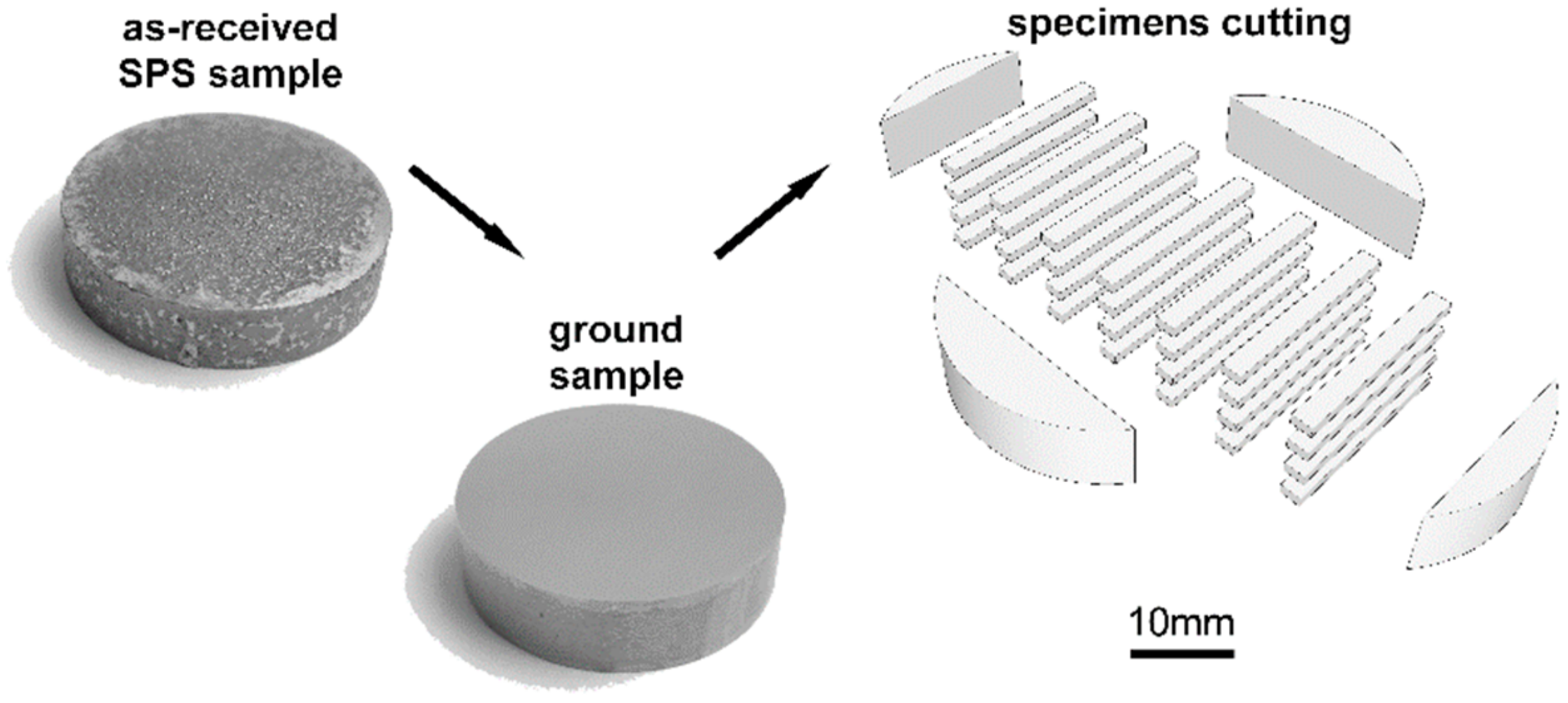

2. Materials and Methods

3. Results

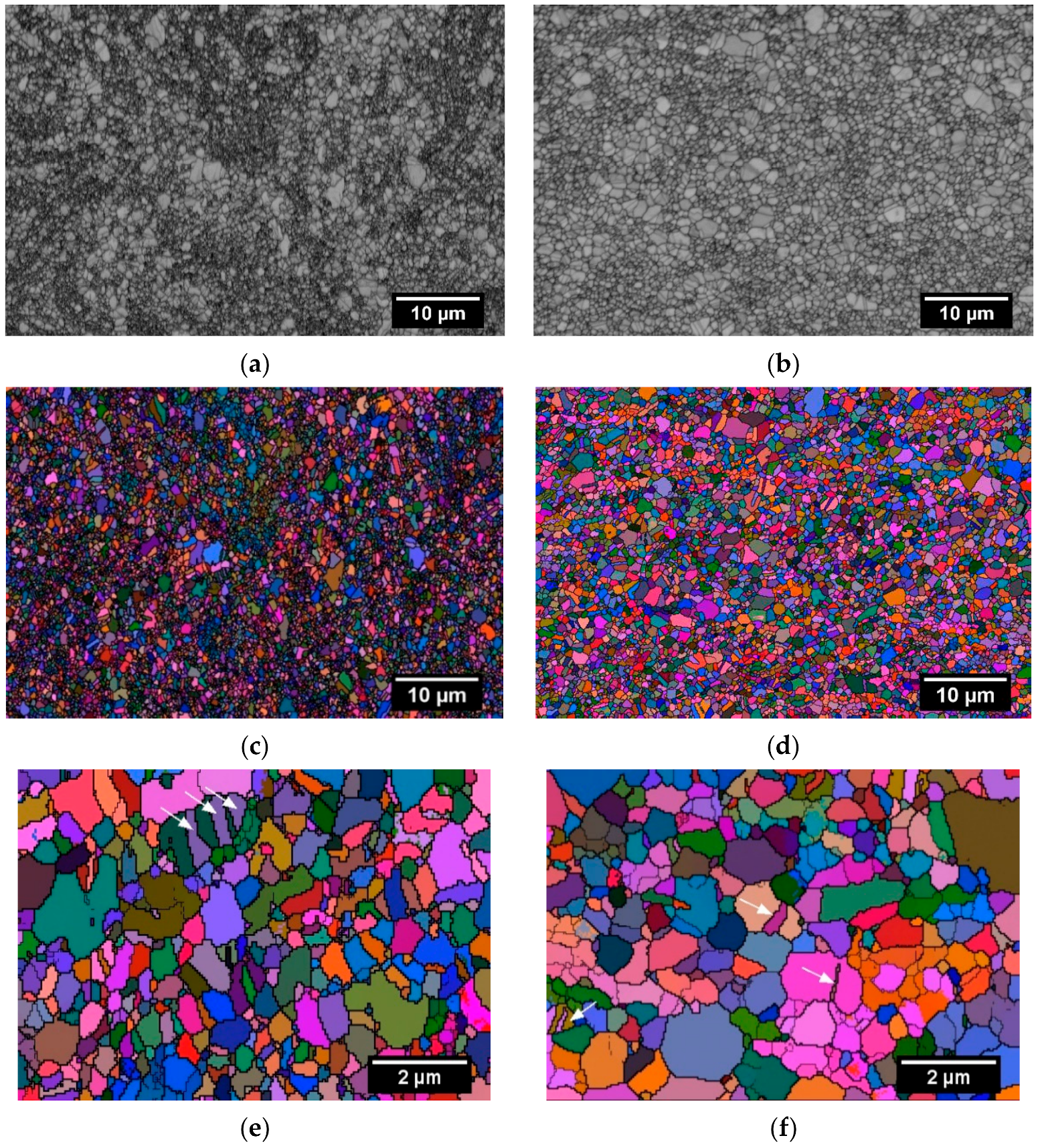

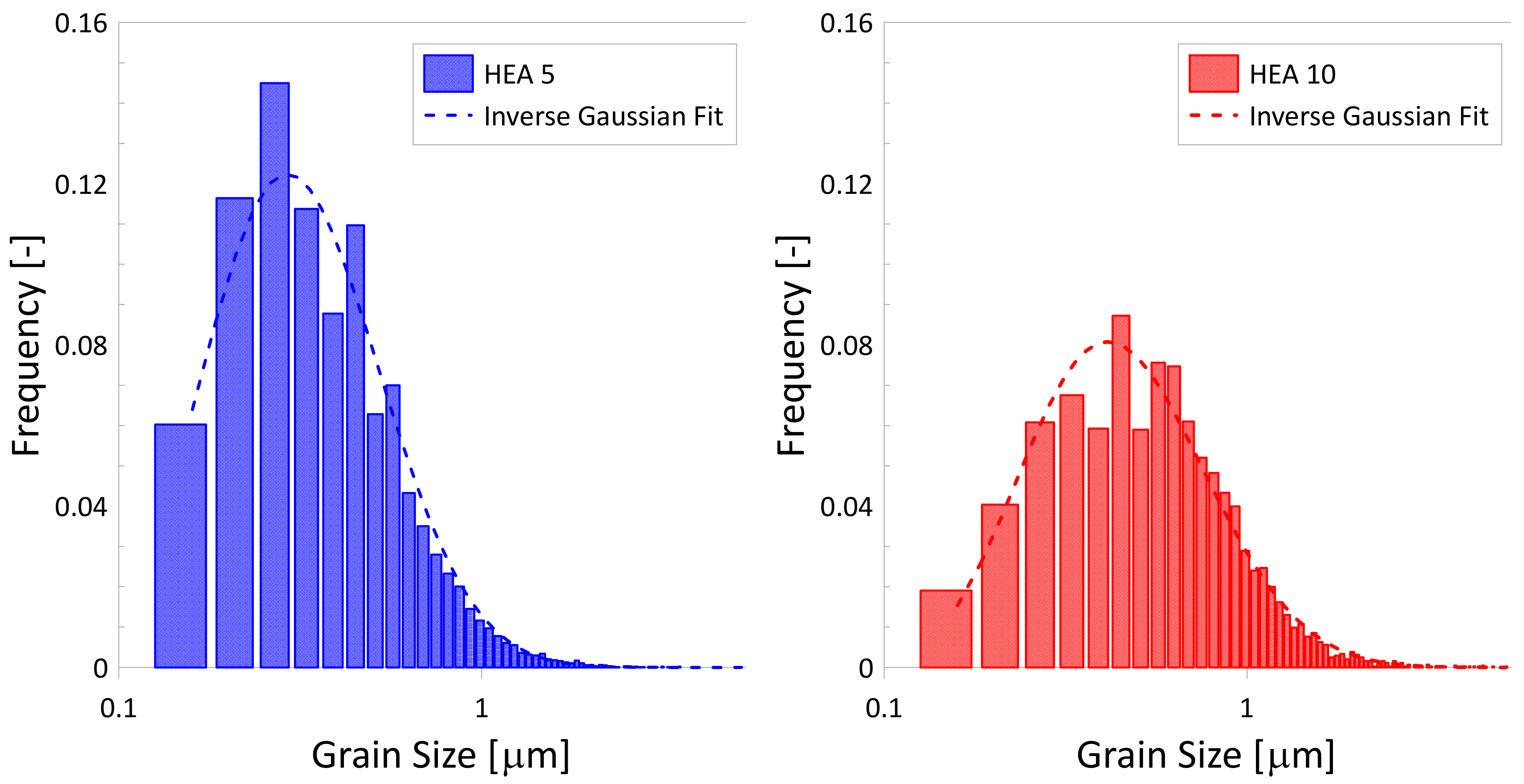

3.1. Microstructure and Physical Properties

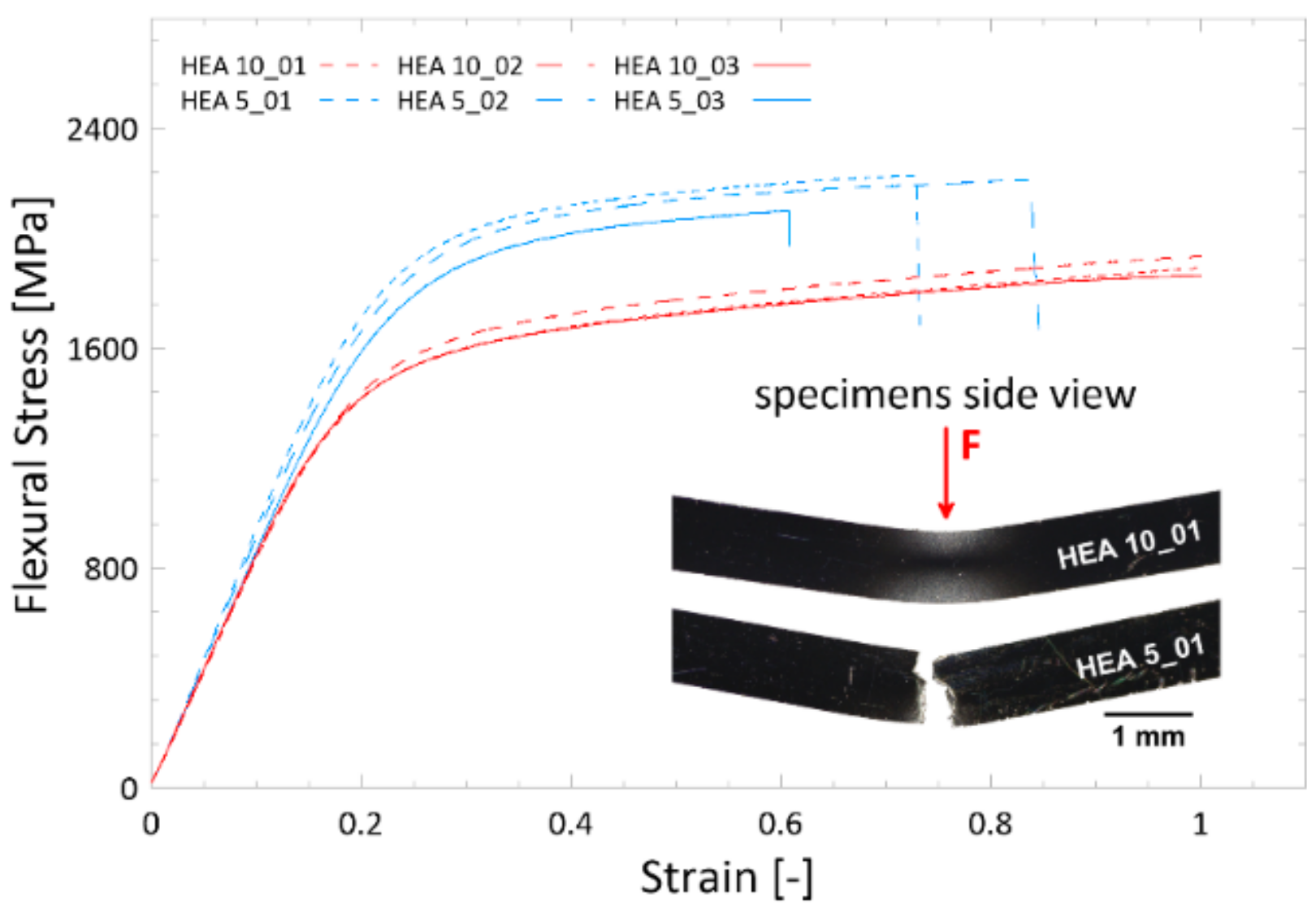

3.2. Quasi-Static Mechanical Properties

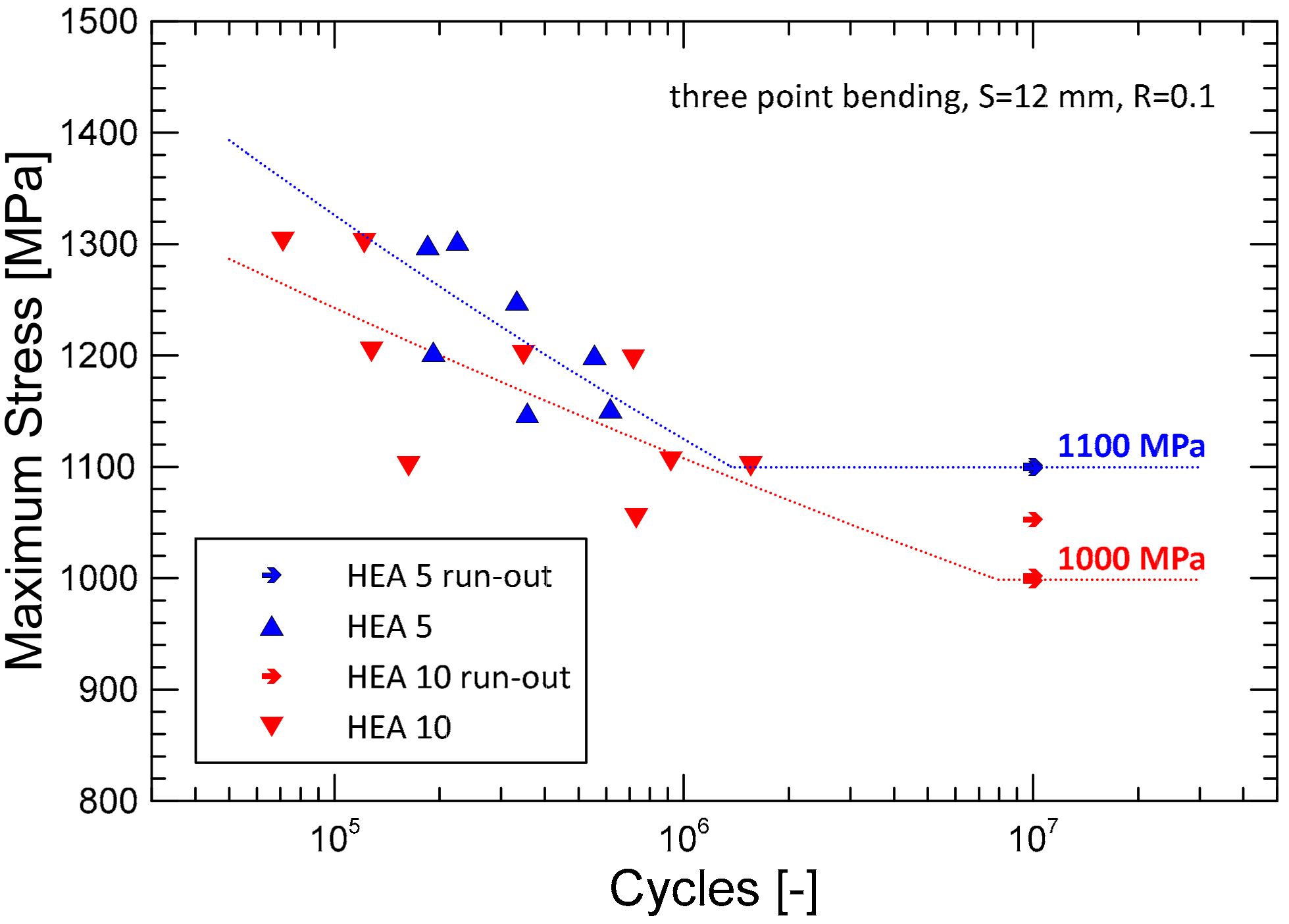

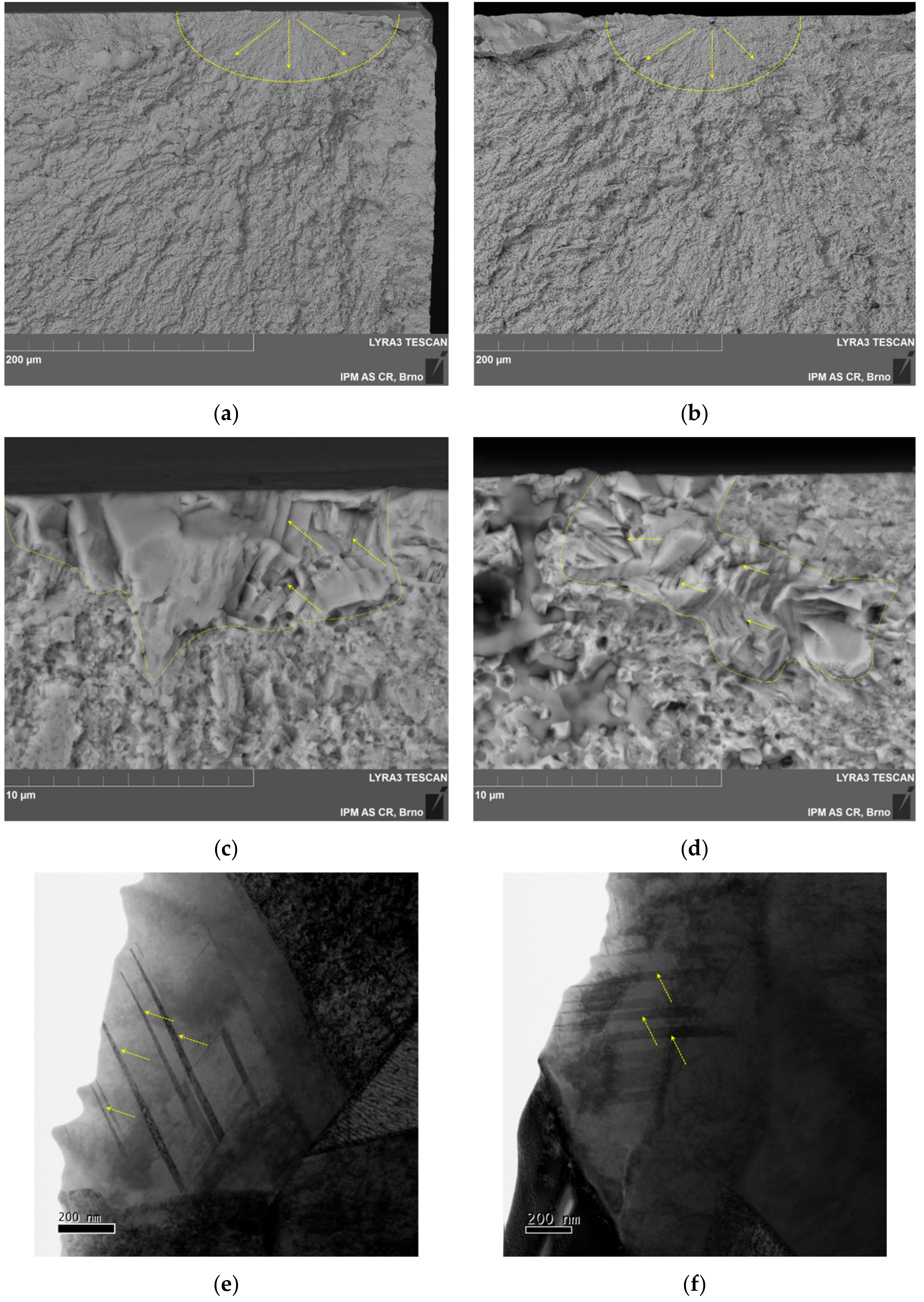

3.3. Fatigue Properties and Fatigue Crack Initiation

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Unit | Description |

| D50 | μm | Median grain size |

| Dgauss location | μm | Inverse Gaussian Fit–location parameter |

| Dgauss scale | μm | Inverse Gaussian Fit–scale parameter |

| Eavg, IET | GPa | Elastic modulus by impulse excitation technique (IET) in flexural mode |

| HV0.1 | GPa | Vickers hardness at a load of 100g/0.981N |

| R | - | Fatigue stress ratio σmin/σmax |

| S | mm | The span at three-point bending |

| σmax | MPa | The maximum stress level of the fatigue cycle |

| σmin | MPa | The minimum stress level of the fatigue cycle |

| εfr | - | Strain at fracture |

| ρ | g.cm−3 | Measured density |

| ρrel | % | Relative density |

| ρtheor | g.cm−3 | Theoretical density |

| σf | MPa | Fatigue endurance limit (fatigue strength) |

| σfr, flex | MPa | Flexural fracture stress |

| σYS, flex | MPa | Flexural yield strength at 0.2% of plastic strain |

References

- Gao, M.C.; Yeh, J.-W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Niendorf, T.; Wegener, T.; Li, Z.; Raabe, D. Unexpected cyclic Stress-Strain response of Dual-Phase High-Entropy alloys induced by partial reversibility of deformation. Scr. Mater. 2018, 143, 63–67. [Google Scholar] [CrossRef]

- He, F.; Wang, Z.; Wu, Q.; Li, J.; Wang, J.; Liu, C.T. Phase separation of metastable CoCrFeNi high entropy alloy at intermediate temperatures. Scr. Mater. 2017, 126, 15–19. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Klimova, M.V.; Shaysultanov, D.G.; Zherebtsov, S.V.; Stepanov, N.D. Effect of second phase particles on mechanical properties and grain growth in a CoCrFeMnNi high entropy alloy. Mater. Sci. Eng. A 2019, 748, 228–235. [Google Scholar] [CrossRef]

- Hadraba, H.; Chlup, Z.; Dlouhy, A.; Dobes, F.; Roupcova, P.; Vilemova, M.; Matejicek, J. Oxide dispersion strengthened CoCrFeNiMn High-Entropy alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 689, 252–256. [Google Scholar] [CrossRef]

- Li, J.; Gao, B.; Wang, Y.; Chen, X.; Xin, Y.; Tang, S.; Liu, B.; Liu, Y.; Song, M. Microstructures and mechanical properties of nano carbides reinforced CoCrFeMnNi high entropy alloys. J. Alloy. Compd. 2019, 792, 170–179. [Google Scholar] [CrossRef]

- Qin, G.; Chen, R.; Zheng, H.; Fang, H.; Wang, L.; Su, Y.; Guo, J.; Fu, H. Strengthening FCC-CoCrFeMnNi high entropy alloys by Mo addition. J. Mater. Sci. Technol. 2019, 35, 578–583. [Google Scholar] [CrossRef]

- Ma, X.; Chen, J.; Wang, X.; Xu, Y.; Xue, Y. Microstructure and mechanical properties of cold drawing CoCrFeMnNi high entropy alloy. J. Alloy. Compd. 2019, 795, 45–53. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi High-Entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Vaidya, M.; Anupam, A.; Bharadwaj, J.V.; Srivastava, C.; Murty, B.S. Grain growth kinetics in CoCrFeNi and CoCrFeMnNi high entropy alloys processed by spark plasma sintering. J. Alloy. Compd. 2019, 791, 1114–1121. [Google Scholar] [CrossRef]

- Gao, X.; Lu, Y. Laser 3D printing of CoCrFeMnNi high-entropy alloy. Mater. Lett. 2019, 236, 77–80. [Google Scholar] [CrossRef]

- Laurent-Brocq, M.; Goujon, P.A.; Monnier, J.; Villeroy, B.; Perrière, L.; Pirès, R.; Garcin, G. Microstructure and mechanical properties of a CoCrFeMnNi high entropy alloy processed by milling and spark plasma sintering. J. Alloy. Compd. 2019, 780, 856–865. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Ham, G.-S.; Kim, H.S.; Lee, K.-A. High-Cycle fatigue and tensile deformation behaviors of Coarse-Grained equiatomic CoCrFeMnNi high entropy alloy and unexpected hardening behavior during cyclic loading. Intermetallics 2019, 111, 106486. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of High- and Medium-Entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Laplanche, G.; Bonneville, J.; Varvenne, C.; Curtin, W.A.; George, E.P. Thermal activation parameters of plastic flow reveal deformation mechanisms in the CrMnFeCoNi High-Entropy alloy. Acta Mater. 2018, 143, 257–264. [Google Scholar] [CrossRef]

- Bae, J.W.; Moon, J.; Jang, M.J.; Yim, D.; Kim, D.; Lee, S.; Kim, H.S. Trade-off between tensile property and formability by partial recrystallization of CrMnFeCoNi High-Entropy alloy. Mater. Sci. Eng. A 2017, 703, 324–330. [Google Scholar] [CrossRef]

- Schuh, B.; Pippan, R.; Hohenwarter, A. Tailoring bimodal grain size structures in nanocrystalline compositionally complex alloys to improve ductility. Mater. Sci. Eng. A 2019, 748, 379–385. [Google Scholar] [CrossRef]

- Sun, S.J.; Tian, Y.Z.; An, X.H.; Lin, H.R.; Wang, J.W.; Zhang, Z.F. Ultrahigh cryogenic strength and exceptional ductility in ultrafine-grained CoCrFeMnNi High-Entropy alloy with fully recrystallized structure. Mater. Today Nano 2018, 4, 46–53. [Google Scholar] [CrossRef]

- Kang, Y.B.; Shim, S.H.; Lee, K.H.; Hong, S.I. Dislocation creep behavior of CoCrFeMnNi high entropy alloy at intermediate temperatures. Mater. Res. Lett. 2018, 6, 689–695. [Google Scholar] [CrossRef]

- Dobes, F.; Hadraba, H.; Chlup, Z.; Dlouhy, A.; Vilemova, M.; Matejicek, J. Compressive creep behavior of an Oxide-Dispersion-Strengthened CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 732, 99–104. [Google Scholar] [CrossRef]

- Tsao, T.-K.; Yeh, A.-C.; Kuo, C.-M.; Kakehi, K.; Murakami, H.; Yeh, J.-W.; Jian, S.-R. The High Temperature Tensile and Creep Behaviors of High Entropy Superalloy. Sci. Rep. 2017, 7, 12658. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.Z.; Sun, S.J.; Lin, H.R.; Zhang, Z.F. Fatigue behavior of CoCrFeMnNi High-Entropy alloy under fully reversed cyclic deformation. J. Mater. Sci. Technol. 2019, 35, 334–340. [Google Scholar] [CrossRef]

- Li, W.; Wang, G.; Wu, S.; Liaw, P.K. Creep, fatigue, and fracture behavior of High-Entropy alloys. J. Mater. Res. 2018, 33, 3011–3034. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Petrov, N.; Horstmann, M.; Zherebtsov, S.; Shaysultanov, D.; Sanin, V.; Stepanov, N. Fatigue behaviour of a laser beam welded CoCrFeNiMn-Type high entropy alloy. Mater. Sci. Eng. A 2019, 766, 138358. [Google Scholar] [CrossRef]

- Holste, C. Cyclic plasticity of nickel, from single crystals to submicrocrystalline polycrystals. Philos. Mag. 2004, 84, 299–315. [Google Scholar] [CrossRef]

- Schuh, B.; Mendez-Martin, F.; Völker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef] [Green Version]

- Haase, C.; Barrales-Mora, L.A. Influence of deformation and annealing twinning on the microstructure and texture evolution of Face-Centered cubic High-Entropy alloys. Acta Mater. 2018, 150, 88–103. [Google Scholar] [CrossRef]

- Li, W.; Long, X.; Huang, S.; Fang, Q.; Jiang, C. Elevated fatigue crack growth resistance of Mo alloyed CoCrFeNi high entropy alloys. Eng. Fract. Mech. 2019, 218, 106579. [Google Scholar] [CrossRef]

| Material | ρ | ρrel | D50 | Dgauss Location | Dgauss Scale |

|---|---|---|---|---|---|

| g.cm−3 | % | μm | μm | μm | |

| HEA 5 | 7.821 ± 0.001 | 97.7 | 0.407 | 0.485 | 1.364 |

| HEA 10 | 7.799 ± 0.001 | 97.4 | 0.628 | 0.726 | 1.833 |

| Material | Eavg,IET | σYS,Flex | σfr,Flex | εfr | σf | HV0.1 |

|---|---|---|---|---|---|---|

| GPa | Mpa | MPa | - | MPa | GPa | |

| HEA 5 | 205.4 ± 1.7 | 1301 ± 21 | 2177 ± 68 | 0.72 ± 0.11 | 1100 | 3.95 ± 0.06 |

| HEA 10 | 206.8 ± 1.0 | 1023 ± 6 | N/A | N/A | 1000 | 3.67 ± 0.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chlup, Z.; Fintová, S.; Hadraba, H.; Kuběna, I.; Vilémová, M.; Matějíček, J. Fatigue Behaviour and Crack Initiation in CoCrFeNiMn High-Entropy Alloy Processed by Powder Metallurgy. Metals 2019, 9, 1110. https://doi.org/10.3390/met9101110

Chlup Z, Fintová S, Hadraba H, Kuběna I, Vilémová M, Matějíček J. Fatigue Behaviour and Crack Initiation in CoCrFeNiMn High-Entropy Alloy Processed by Powder Metallurgy. Metals. 2019; 9(10):1110. https://doi.org/10.3390/met9101110

Chicago/Turabian StyleChlup, Zdeněk, Stanislava Fintová, Hynek Hadraba, Ivo Kuběna, Monika Vilémová, and Jiří Matějíček. 2019. "Fatigue Behaviour and Crack Initiation in CoCrFeNiMn High-Entropy Alloy Processed by Powder Metallurgy" Metals 9, no. 10: 1110. https://doi.org/10.3390/met9101110

APA StyleChlup, Z., Fintová, S., Hadraba, H., Kuběna, I., Vilémová, M., & Matějíček, J. (2019). Fatigue Behaviour and Crack Initiation in CoCrFeNiMn High-Entropy Alloy Processed by Powder Metallurgy. Metals, 9(10), 1110. https://doi.org/10.3390/met9101110