Effect of Cooling Rate on AlN Precipitation in FeCrAl Stainless Steel During Solidification

Abstract

1. Introduction

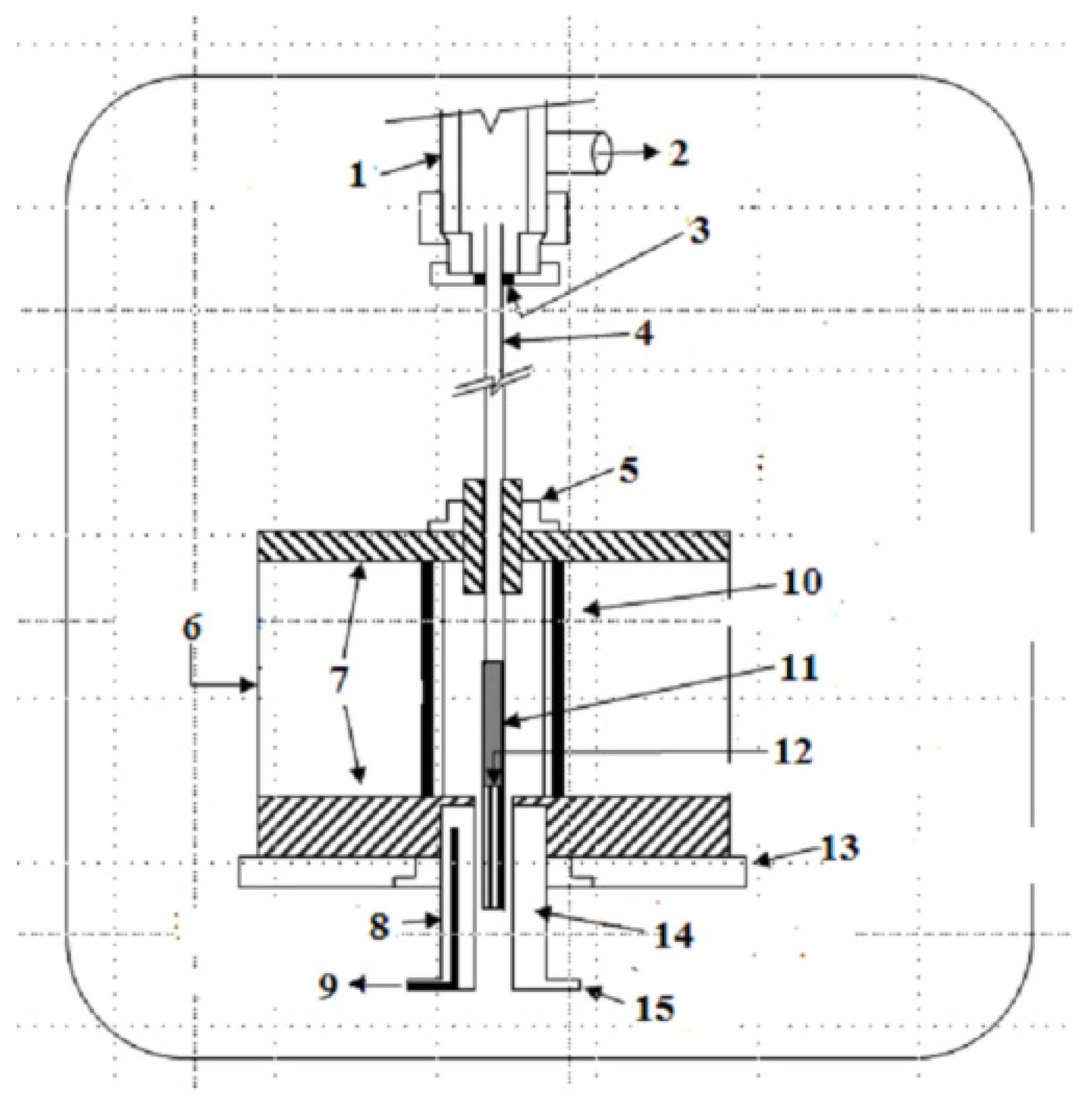

2. Materials and Methods

3. Results and Discussion

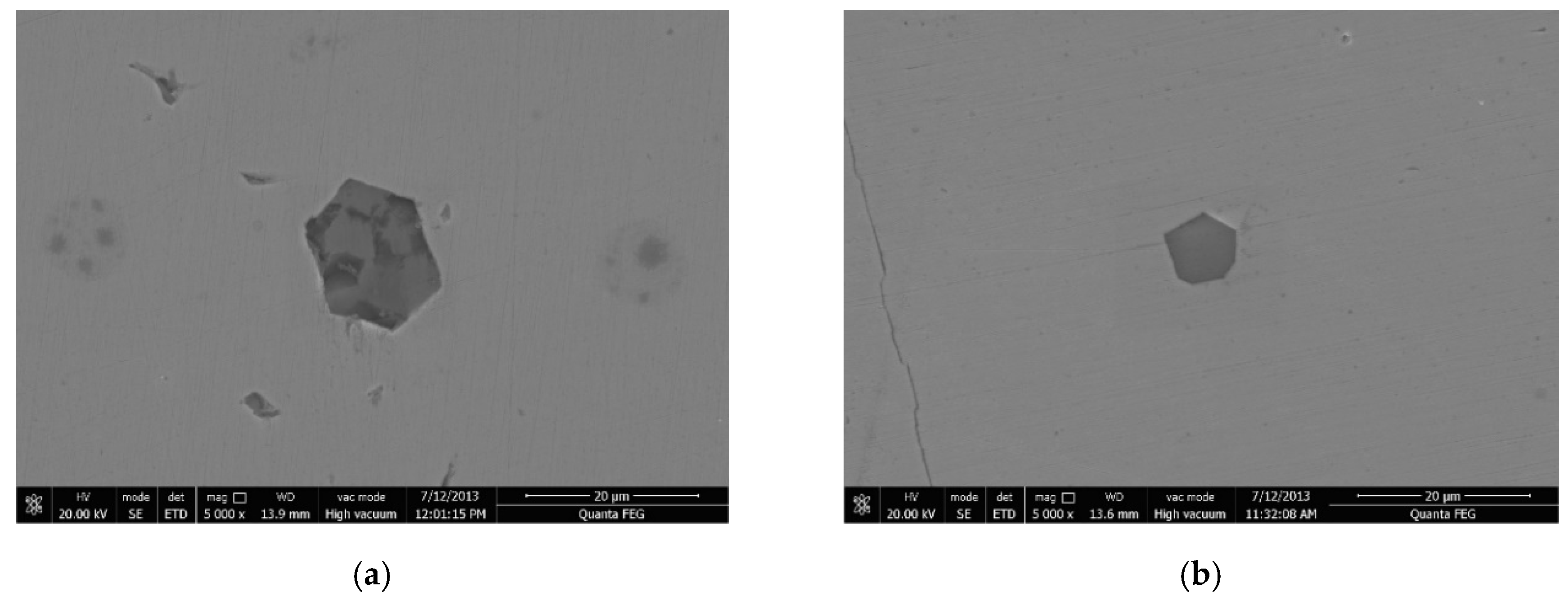

3.1. Morphology of AlN Particles

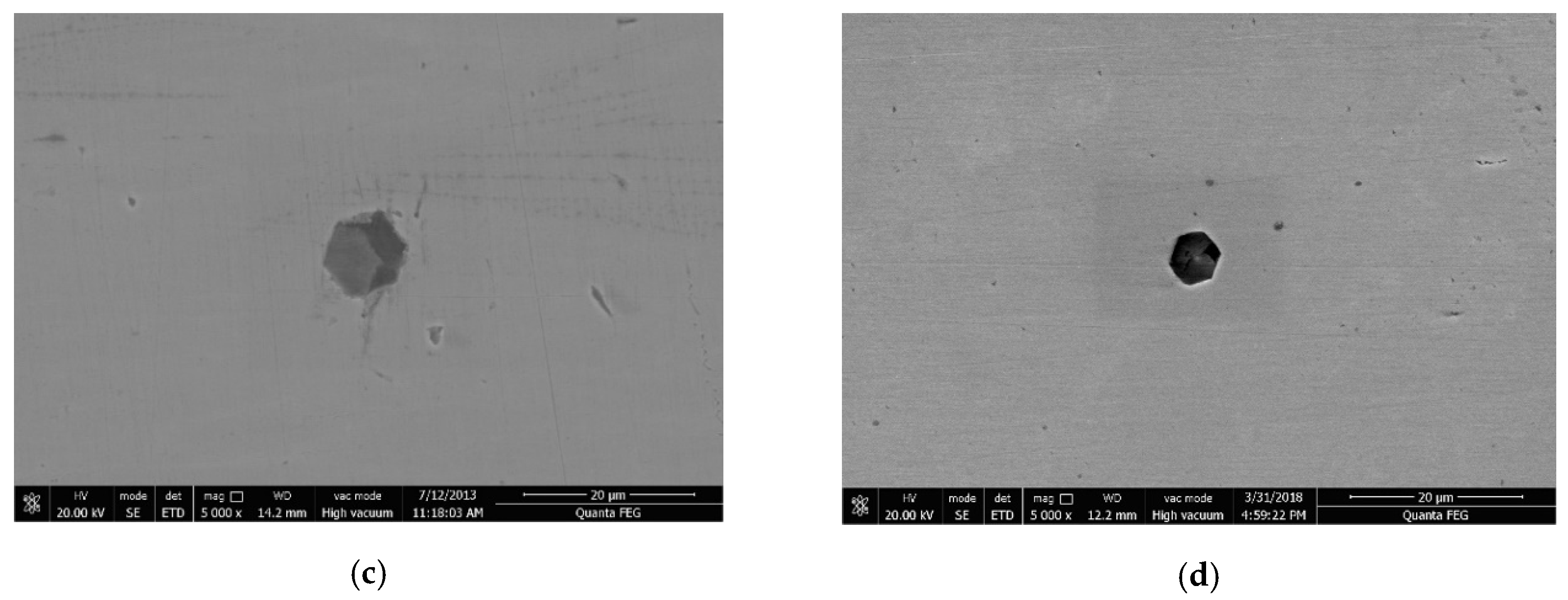

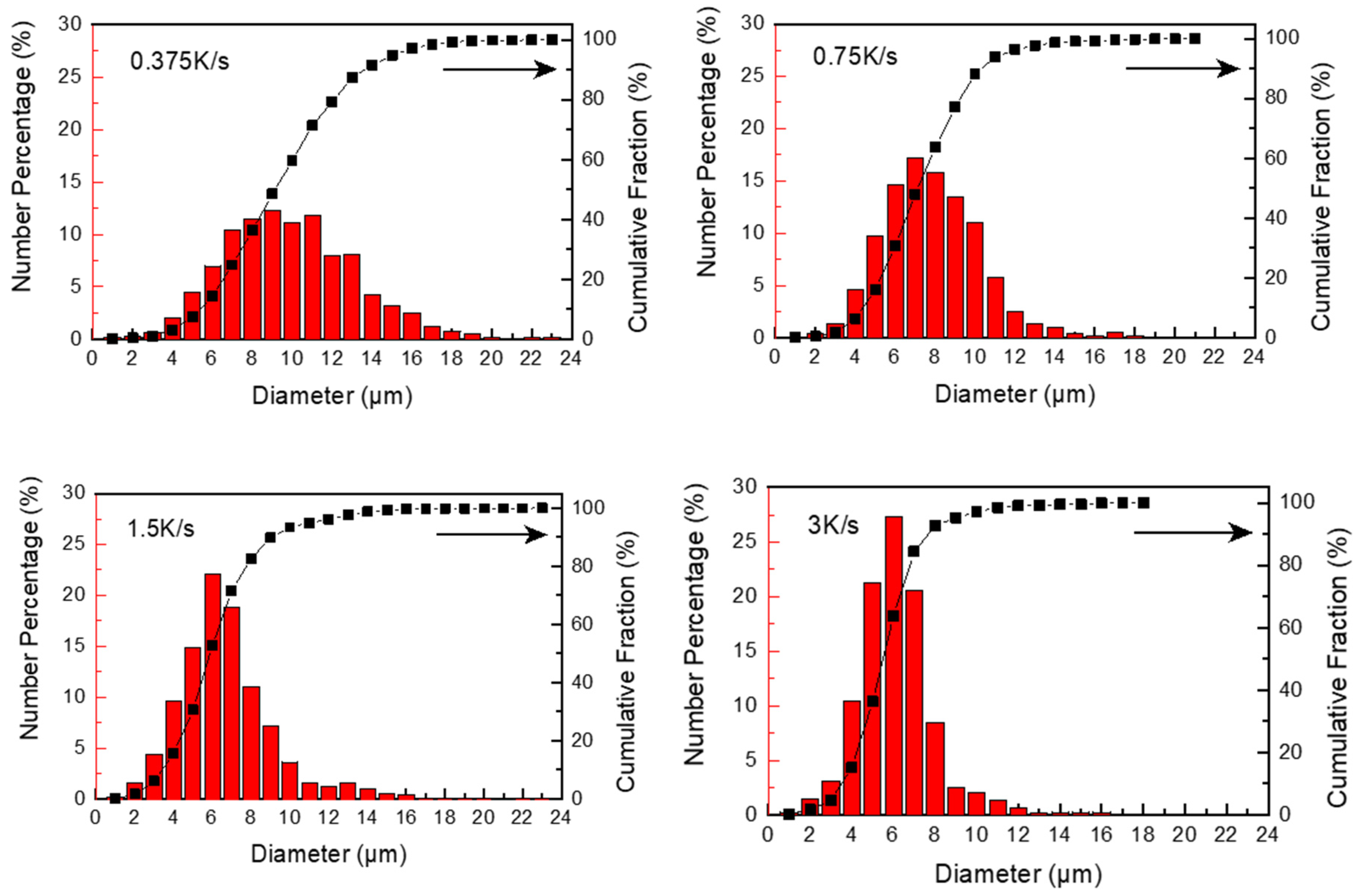

3.2. Number and Size Distribution of AlN Particles

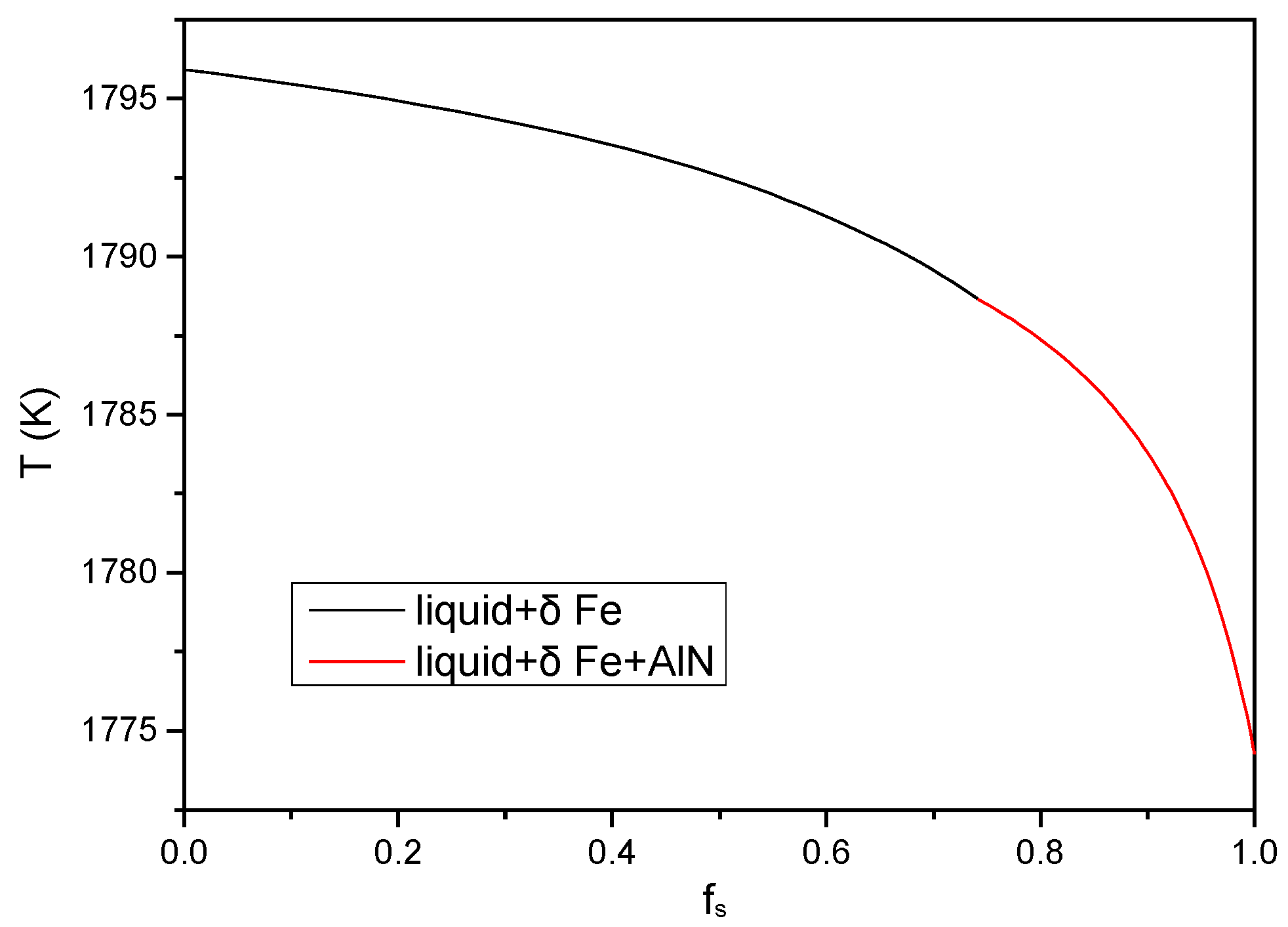

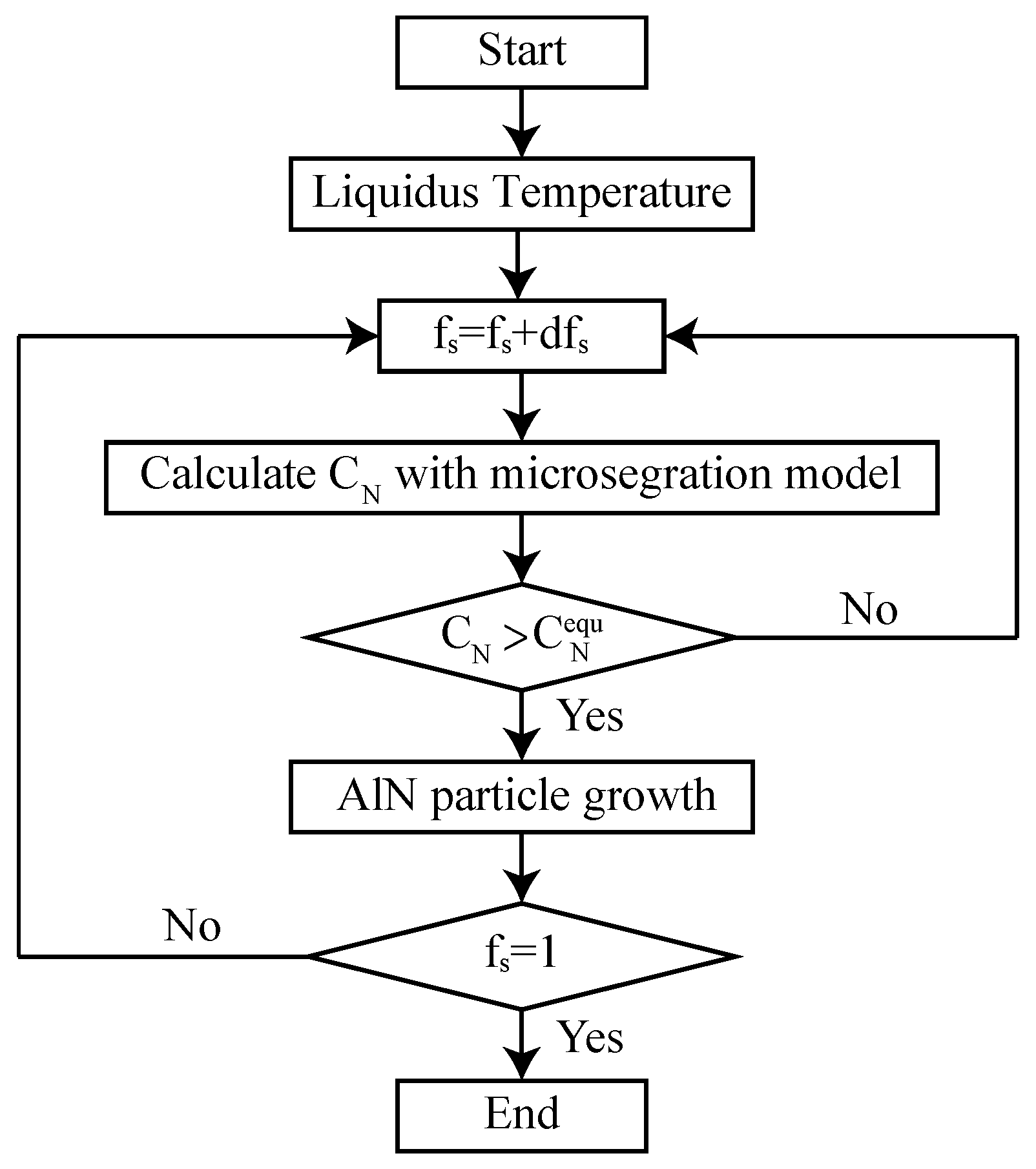

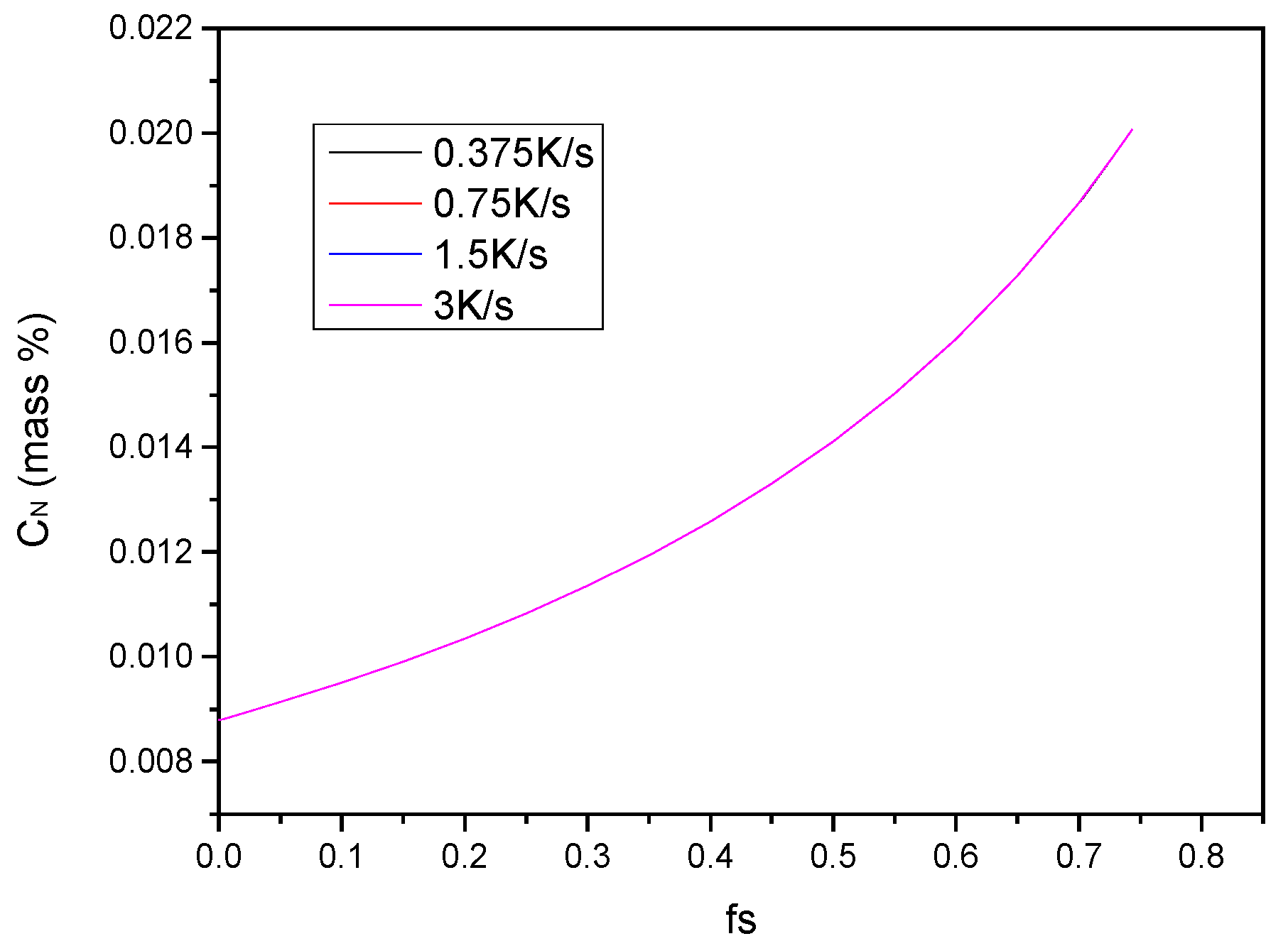

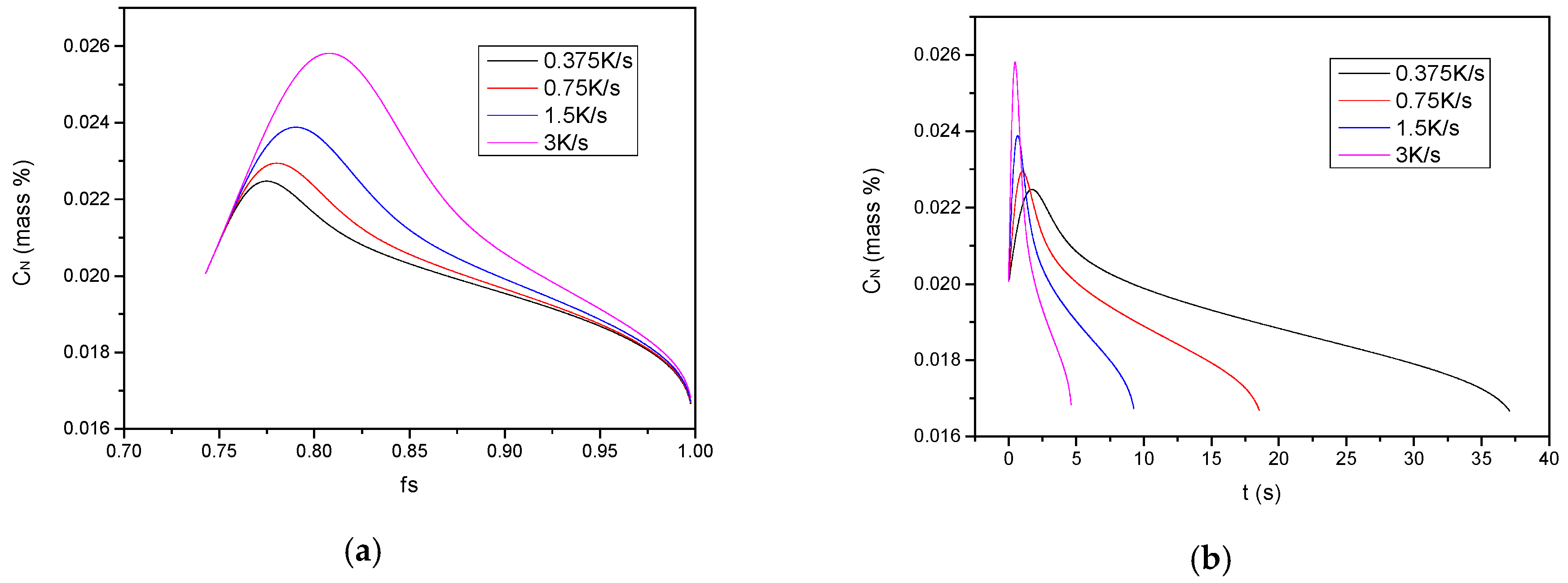

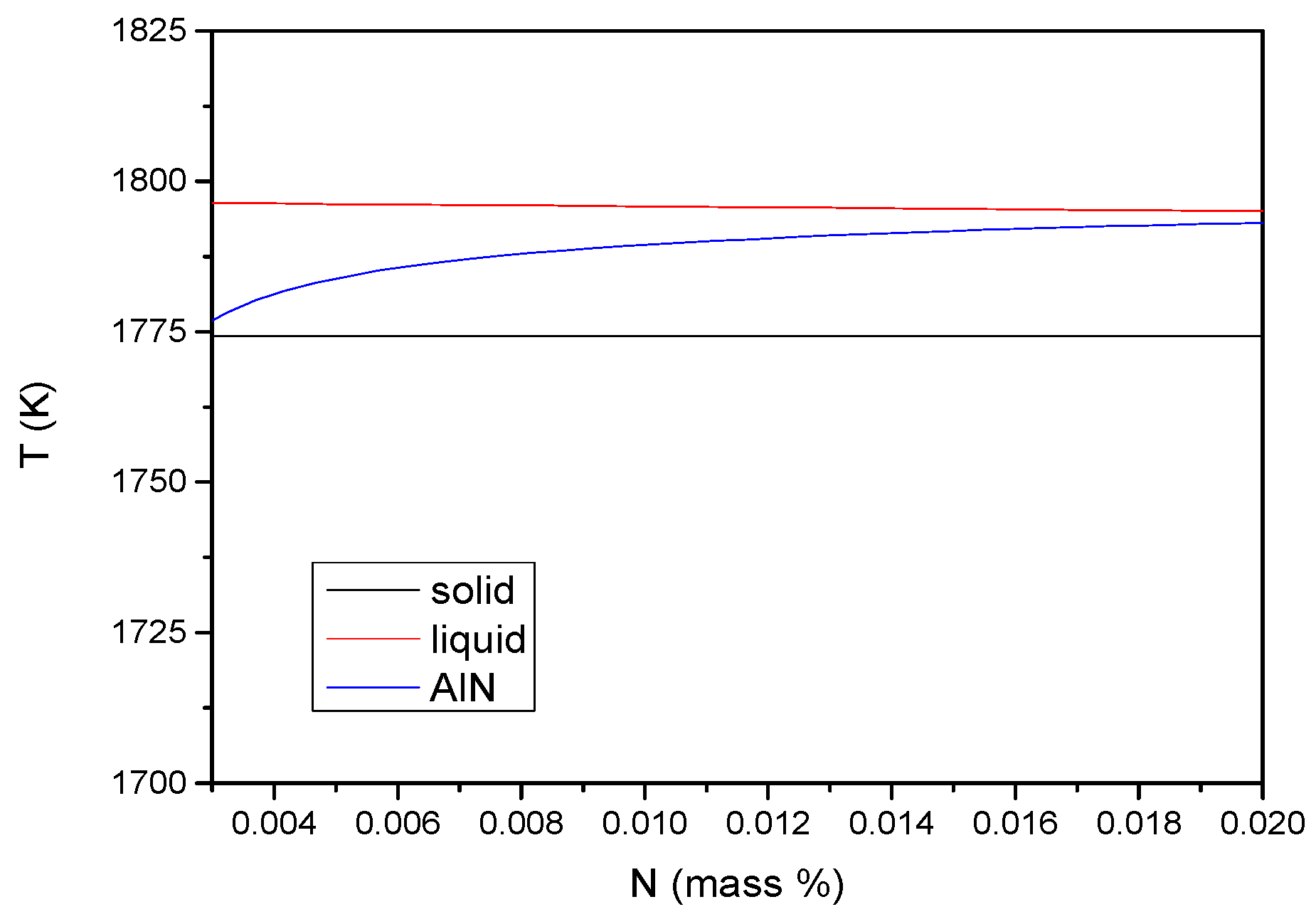

3.3. Precipitation of AlN

4. Conclusions

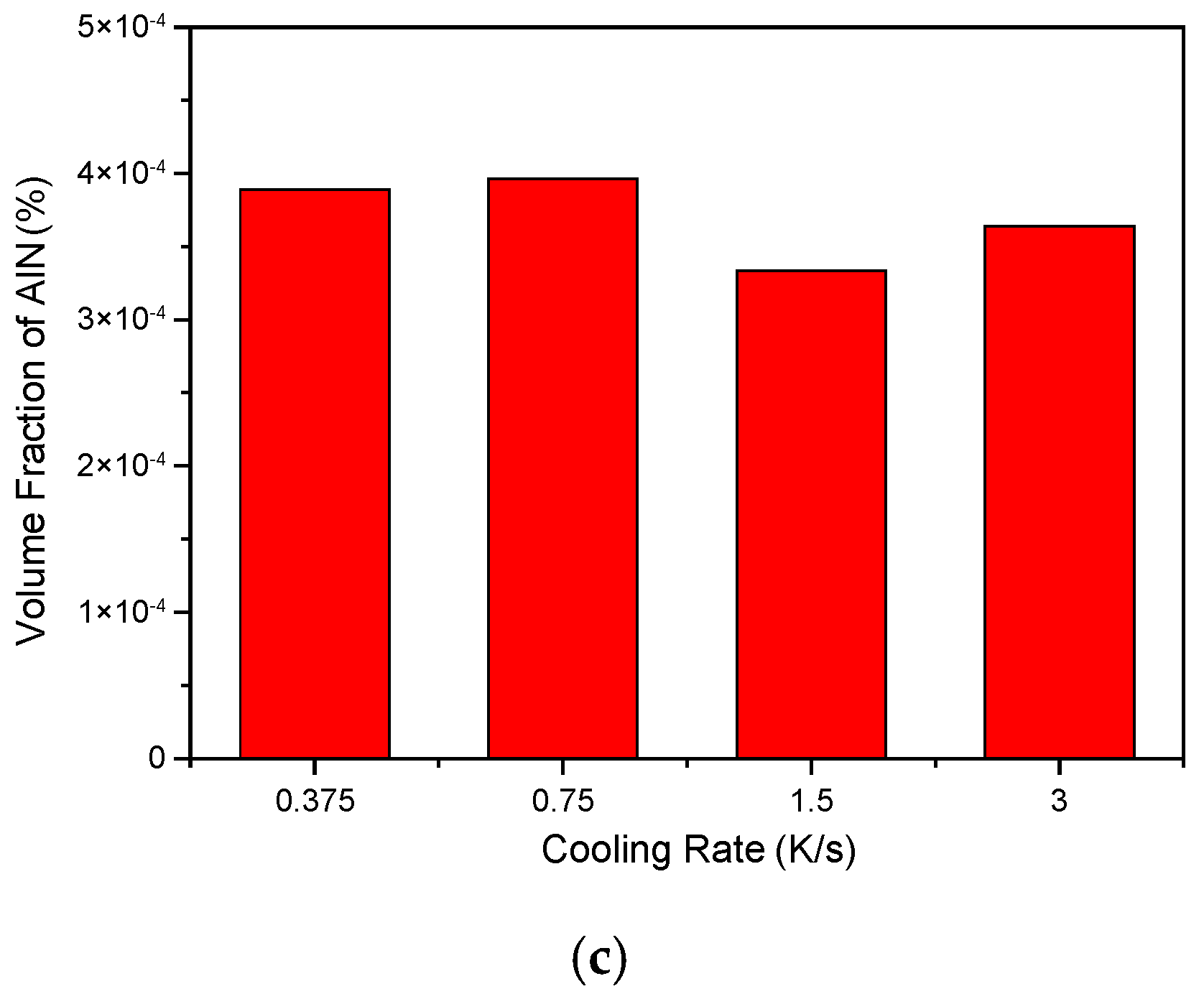

- During solidification, AlN precipitates within the mushy zone. The size of AlN particles decreases and the number of AlN particles increases with increasing cooling rate, although the volume fraction is relatively unaffected.

- The particle sizes predicted with the aid of a diffusion-controlled growth model correlate well with the size of AlN particles observed in samples obtained from the unidirectional solidification experiments.

- The model results also confirm that AlN particles in the FeCrAl alloy grow during solidification when the solute content in the liquid exceeds the concentration in equilibrium with AlN.

- The calculated results show that after AlN begins to precipitate, the nitrogen content in the molten alloy varies significantly with the cooling rate.

- Higher cooling rates result in shorter growth times and consequently AlN particles of smaller size.

- Smaller AlN particles can also be achieved by reducing the nitrogen content in the molten alloy.

Author Contributions

Funding

Conflicts of Interest

References

- Sastry, S.D.; Rohatgi, P.K.; Abraham, K.P.; Prasad, Y.V.R.K. Mechanism of strengthening in high temperature treated Fe12Cr6Al ferritic stainless steel. Scr. Metall. 1979, 13, 817–822. [Google Scholar] [CrossRef]

- Inoue, Y.; Kikuchi, M.; Tendo, M.; Kajimura, H. Oxidation behavior of Al-containing ferritic stainless steel in an exhaust gas atmosphere. J. Jpn. Inst. Met. 2006, 70, 880–889. [Google Scholar] [CrossRef][Green Version]

- Liu, F.; Halvarsson, M.; Hellström, K.; Svensson, J.E.; Johansson, L.G. First Three-Dimensional Atomic Resolution Investigation of Thermally Grown Oxide on a FeCrAl Alloy. Oxid. Met. 2015, 83, 441–451. [Google Scholar] [CrossRef]

- He, Y.; Wang, F.; Li, C.; Yang, Z.; Zhang, J.; Li, Y. Effect of Mg content on the hot ductility of wrought Fe-36Ni alloy with Ti addition. Mater. Sci. Eng. A 2016, 673, 99–107. [Google Scholar] [CrossRef]

- Dekkers, R.; Blanpain, B.; Wollants, P.; Haers, F.; Vercruyssen, C.; Gommers, B. Non-metallic inclusions in aluminium killed steels. Ironmak. Steelmak. 2002, 29, 437–444. [Google Scholar] [CrossRef]

- Deng, Z.; Zhu, M. Evolution Mechanism of Non-metallic Inclusions in Al-Killed Alloyed Steel during Secondary Refining Process. ISIJ Int. 2013, 53, 450–458. [Google Scholar] [CrossRef]

- Massardier, V.; Ngansop, A.; Fabrègue, D.; Merlin, J. Identification of the parameters controlling the grain refinement of ultra-rapidly annealed low carbon Al-killed steels. Mater. Sci. Eng. A 2010, 527, 5654–5663. [Google Scholar] [CrossRef]

- Herrera, M.; Castro, F.; Castro, M.; Méndez, M.; Solís, H.; Castellá, A.; Barbaro, M. Modification of Al2O3 inclusions in medium carbon aluminium killed steels by AlCaFe additions. Ironmak. Steelmak. 2006, 33, 45–51. [Google Scholar] [CrossRef]

- Goto, H.; Miyazawa, K.; Yamada, W.; Tanaka, K. Effect of the Cooling Rate on Compositions of the Oxides Precipitated during Solidification of Steels. ISIJ Int. 1995, 35, 708–714. [Google Scholar] [CrossRef]

- He, Y.; Liu, J.; Qiu, S.; Deng, Z.; Yang, Y.; McLean, A. Thermodynamic analysis of inclusion characteristics in as-cast FeCrAl-(La) alloys. Ironmak. Steelmak. 2018, 1–9. [Google Scholar] [CrossRef]

- Lorig, C.H.; Elsea, A.R. Occurrence of intergranular fracture in cast steels. Transactions 1947, 55, 160. [Google Scholar]

- Turkdogan, E.T. Causes and effects of nitride and carbonitride precipitation during continuous casting. Iron Steelmak. 1989, 16, 61. [Google Scholar]

- Leger, M.-T.; Guillaume, B. Microfractographic Diagnosis of the Embrittlement of Steel Castings by Aluminum. Int. Cast Met. J. 1980, 5, 40–46. [Google Scholar]

- Funnell, D.G.; Davies, J.R. Effect of aluminium nitride particles on hot ductility of steel. Met. Technol. 1978, 5, 150–153. [Google Scholar] [CrossRef]

- Tacikowski, M.; Osinkolu, G.A.; Kobylanski, A. The synergetic effect of aluminium nitride precipitation and sulphur segregation on hot intergranular brittleness of high purity iron alloys. Acta Metall. 1988, 36, 995–1004. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Ghosh, A. Mathematical Model for Prediction of Composition of Inclusions Formed during Solidification of Liquid Steel. ISIJ Int. 2009, 49, 1819–1827. [Google Scholar] [CrossRef]

- You, D.; Michelic, S.K.; Presoly, P.; Liu, J.; Bernhard, C. Modeling Inclusion Formation during Solidification of Steel: A Review. Metals 2017, 7, 460. [Google Scholar] [CrossRef]

- Han, Z.; Liu, J.; He, Y. Solidification Structure and Inclusions of Ti-containing FeCrAl Stainless Steel. Iron Steel Vanadium Titan. 2016, 37, 125–132. [Google Scholar]

- Lindborg, U. A Collision Model for the Growth and Separation of Deoxidation Products. Trans. Metall. Soc. AIME 1968, 242, 94. [Google Scholar]

- Sakao, H.; Ito, K.; Wanibe, Y. Principles of deoxidation. Tetsu-to-Hagané 1971, 57, 1863–1882. [Google Scholar] [CrossRef]

- Suzuki, M.; Yamaguchi, R.; Murakami, K.; Nakada, M. Inclusion Particle Growth during Solidification of Stainless Steel. ISIJ Int. 2001, 41, 247–256. [Google Scholar] [CrossRef]

- Inouye, M.; Kojima, Y.; Choh, T.; Uekawa, S.; Yamada, Y. On the measurements of diffusion coefficients of nitrogen in the liquid Fe. Tetsu-to-Hagane 1973, 59, 205–213. [Google Scholar] [CrossRef][Green Version]

- Ueshima, Y.; Isobe, K.; Mizoguchi, S.; Maede, H.; Kajioka, H. Analysis of the Rate of Crystallization and Precipitation of MnS in the Resulphurized Free-cutting Steel. Tetsu-to-Hagané 1988, 74, 465–472. [Google Scholar] [CrossRef]

- Liu, Z.; Wei, J.; Cai, K. A Coupled Mathematical Model of Microsegregation and Inclusion Precipitation during Solidification of Silicon Steel. ISIJ Int. 2002, 42, 958–963. [Google Scholar] [CrossRef]

- Saffman, P.G.; Turner, J.S. On the collision of drops in turbulent clouds. J. Fluid Mech. 1956, 1, 16–30. [Google Scholar] [CrossRef]

- Goto, H.; Miyazawa, K.; Yamaguchi, K.; Ogibayashi, S.; Tanaka, K. Effect of Cooling Rate on Oxide Precipitation during Solidification of Low-Carbon Steels. ISIJ Int. 1994, 34, 414–419. [Google Scholar] [CrossRef]

- Ma, Z.; Janke, D. Characteristics of Oxide Precipitation and Growth during Solidification of Deoxidized Steel. ISIJ Int. 1998, 38, 46–52. [Google Scholar] [CrossRef]

- Aakuma, T. Growth of Carbide and Nitride Particle in Steel. Bull. Jpn. Inst. Met. 1981, 20, 247–256. [Google Scholar]

- Chiu, S.N.; Stoyan, D.; Kendall, W.S.; Mecke, J. Stochastic Geometry and Its Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 1118658256. [Google Scholar]

- Ohnaka, I. Mathematical analysis of solute redistribution during solidification with diffusion in solid phase. Trans. Iron Steel Inst. Jpn. 1986, 26, 1045–1051. [Google Scholar] [CrossRef]

- Won, Y.-M.; Thomas, B.G. Simple model of microsegregation during solidification of steels. Metall. Mater. Trans. A 2001, 32, 1755–1767. [Google Scholar] [CrossRef]

- He, Y.; Liu, J.; Han, Z.; Deng, Z.; Su, X.; Ji, Y. Phase transformation and precipitation during solidification of FeCrAl alloy for automobile exhaust gas purifying systems. J. Alloy. Compd. 2017, 714, 251–257. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, J.; He, Y.; Han, Z.; Su, X.; Ding, H. Phase transformations and precipitation behavior in FeCrAl stainless steel during equilibrium solidification. Chin. J. Eng. 2017, 39, 710–720. [Google Scholar]

- Hino, M.; Ito, K. Thermodynamic Data for Steelmaking; Tohoku University Press: Sendai, Japan, 2010. [Google Scholar]

- Wagner, C. Thermodynamics of Alloys; Addison-wesley: Boston, MA, USA, 1952. [Google Scholar]

- Jo, J.-O.; Jung, M.-S.; Park, J.-H.; Lee, C.-O.; Pak, J.-J. Thermodynamic Interaction between Chromium and Aluminum in Liquid Fe–Cr Alloys Containing 26 mass% Cr. ISIJ Int. 2011, 51, 208–213. [Google Scholar] [CrossRef]

- Wang, Y.N.; Yang, J.; Xin, X.L.; Wang, R.Z.; Xu, L.Y. The Effect of Cooling Conditions on the Evolution of Non-metallic Inclusions in High Manganese TWIP Steels. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2016, 47, 1378–1389. [Google Scholar] [CrossRef]

- Villegas, E.A. The diffusion of nitrogen in liquid iron alloys at 16000C. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 1976. Dep. Appl. Geosci., 247. [Google Scholar]

- Goto, H.; Miyazawa, K.; Honma, H. Effect of the Primary Oxide on the Behavior of the Oxide Precipitated during Solidification of Steel. ISIJ Int. 1996, 36, 537–542. [Google Scholar] [CrossRef]

| Chemical Component | C | Si | Mn | Cr | P | S | N | O | Al | Fe + Other |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.022 | 0.13 | 0.20 | 19.90 | 0.0058 | 0.0045 | 0.0088 | 0.0020 | 4.07 | balance |

| 0.043 | −0.001 | 0.0122 | 0 | 0.033 | 0 | 0.017 | 0 | −0.06 | 0.0007 | 0 | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; He, Y.; Liu, J.; Yan, B.; Yang, Y.; McLean, A. Effect of Cooling Rate on AlN Precipitation in FeCrAl Stainless Steel During Solidification. Metals 2019, 9, 1091. https://doi.org/10.3390/met9101091

Deng Z, He Y, Liu J, Yan B, Yang Y, McLean A. Effect of Cooling Rate on AlN Precipitation in FeCrAl Stainless Steel During Solidification. Metals. 2019; 9(10):1091. https://doi.org/10.3390/met9101091

Chicago/Turabian StyleDeng, Zhenqiang, Yang He, Jianhua Liu, Baijun Yan, Yindong Yang, and Alexander McLean. 2019. "Effect of Cooling Rate on AlN Precipitation in FeCrAl Stainless Steel During Solidification" Metals 9, no. 10: 1091. https://doi.org/10.3390/met9101091

APA StyleDeng, Z., He, Y., Liu, J., Yan, B., Yang, Y., & McLean, A. (2019). Effect of Cooling Rate on AlN Precipitation in FeCrAl Stainless Steel During Solidification. Metals, 9(10), 1091. https://doi.org/10.3390/met9101091