Thermo-Mechanical Fatigue Lifetime Assessment of Spheroidal Cast Iron at Different Thermal Constraint Levels

Abstract

:1. Introduction

2. Experimental Set-Up and Methods

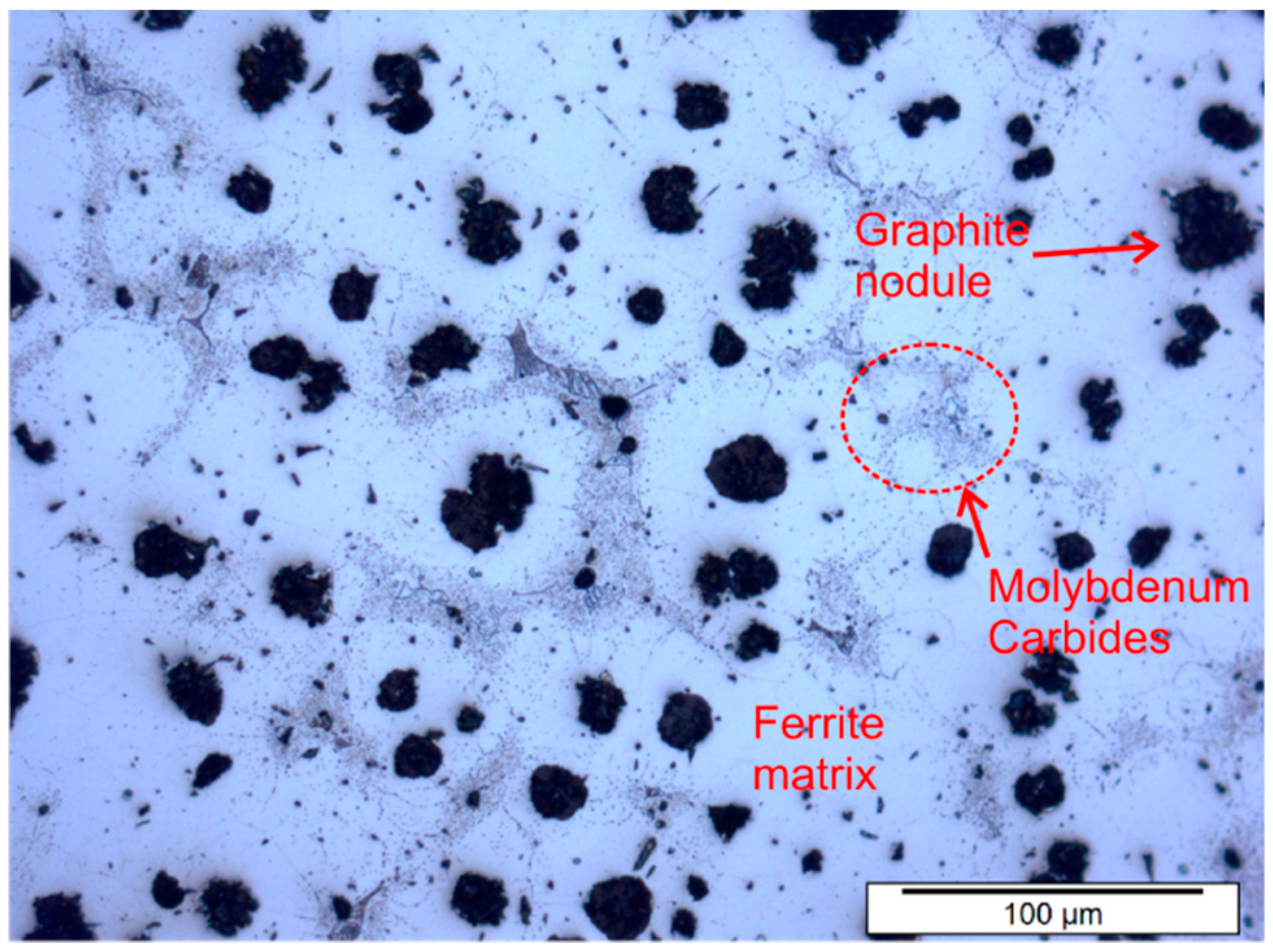

2.1. Material and Specimens

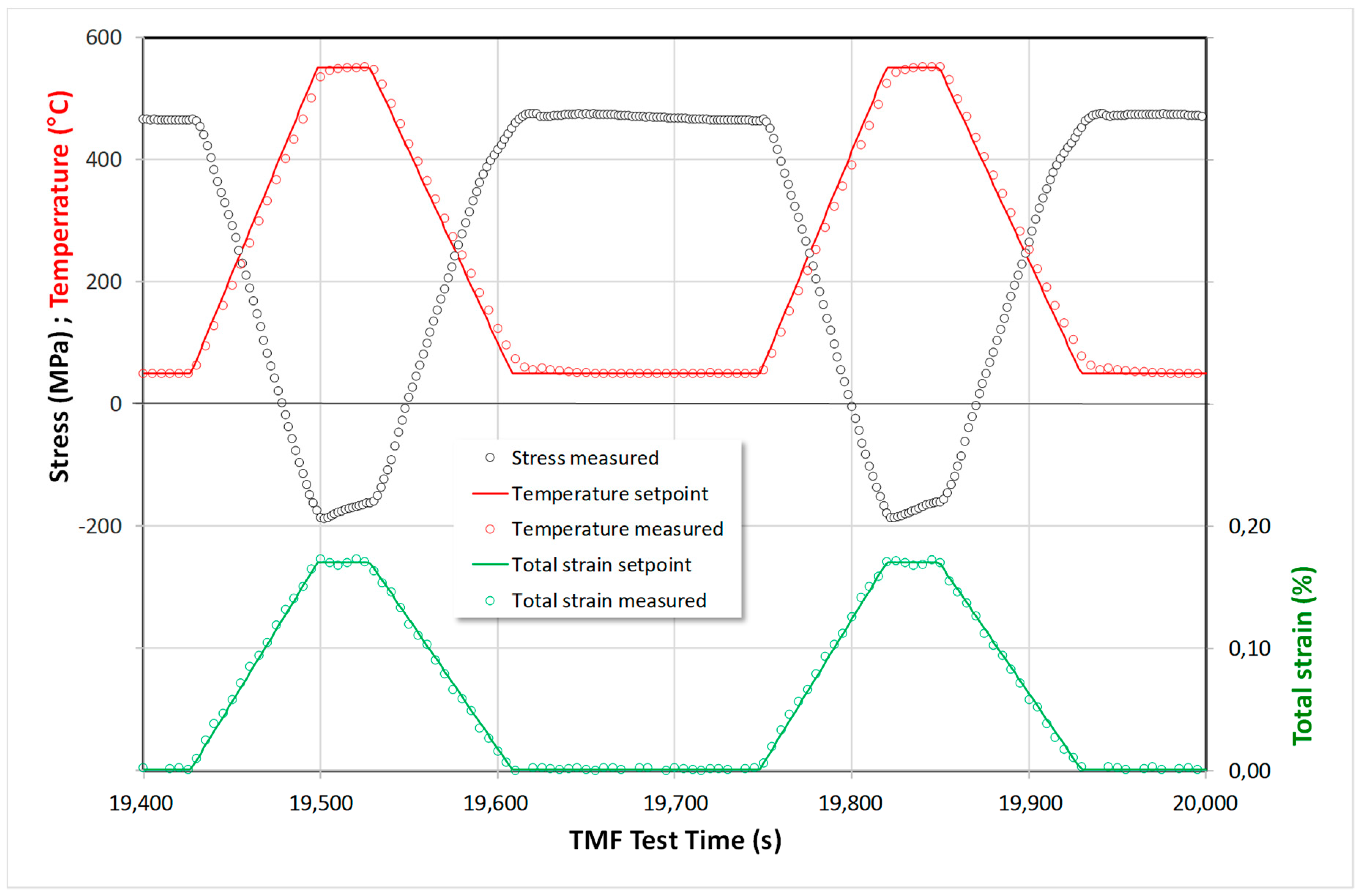

2.2. Experimental Set-up

2.3. The Necessity and Relevance of Using Notched Specimens

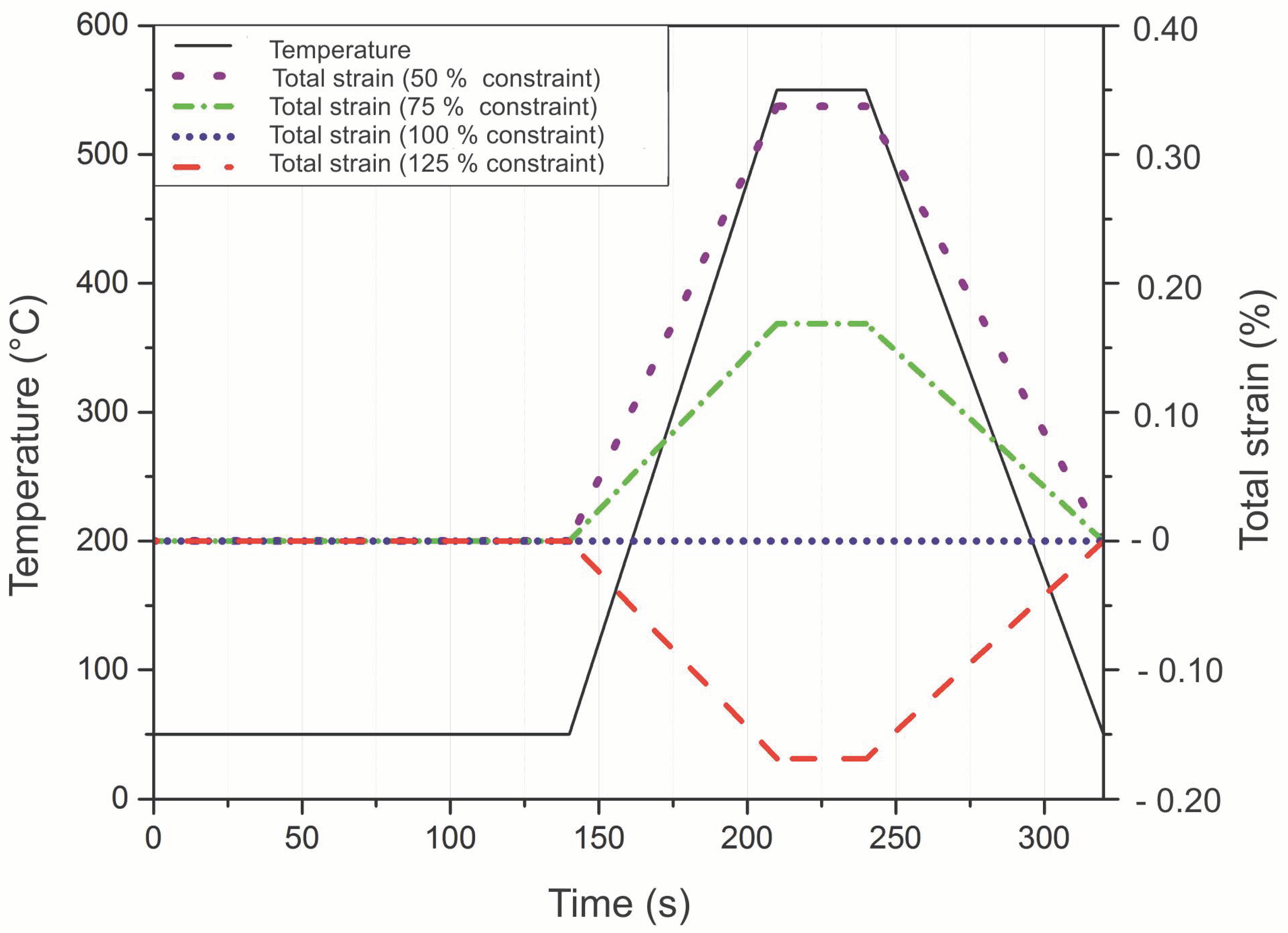

2.4. TMF Test Constraint Levels and TMF Lifetime

3. TMF Crack-Growth Models

3.1. The Local Stress Crack-Growth Model

3.1.1. Calculating TMF Lifetime by Numerical Integration (Local Stress Model)

3.2. The Local Strain Crack-Growth Model

3.2.1. The Blunting and Sharpening Mechanisms

3.2.2. Modeling Local Cyclic Plastic Strains for the Sharp and Blunt Crack Stage

3.2.3. Calculating TMF Lifetime by Numerical Integration (Local Strain Model)

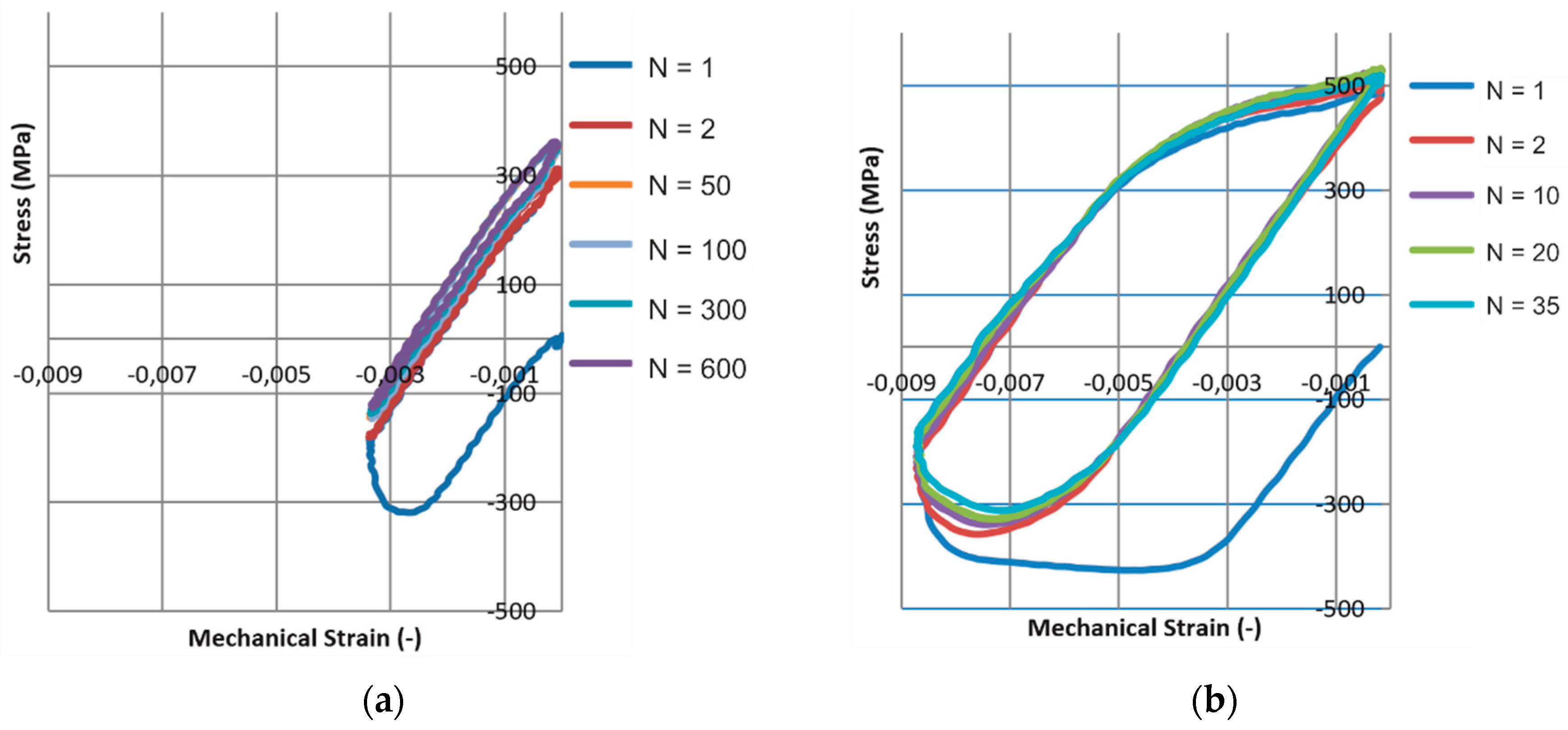

4. Results and Discussion

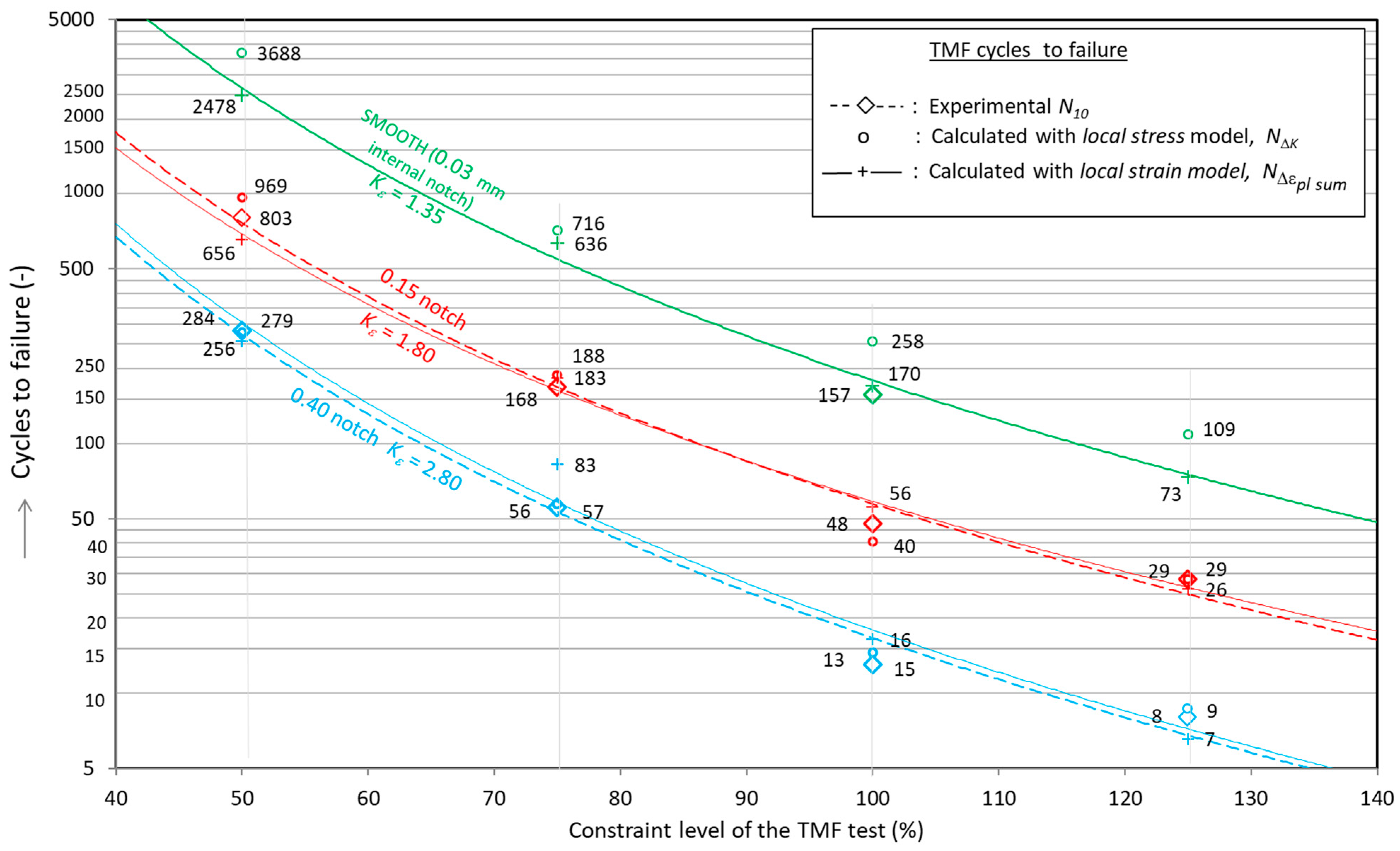

4.1. Results of the Local Stress Crack-Growth Model

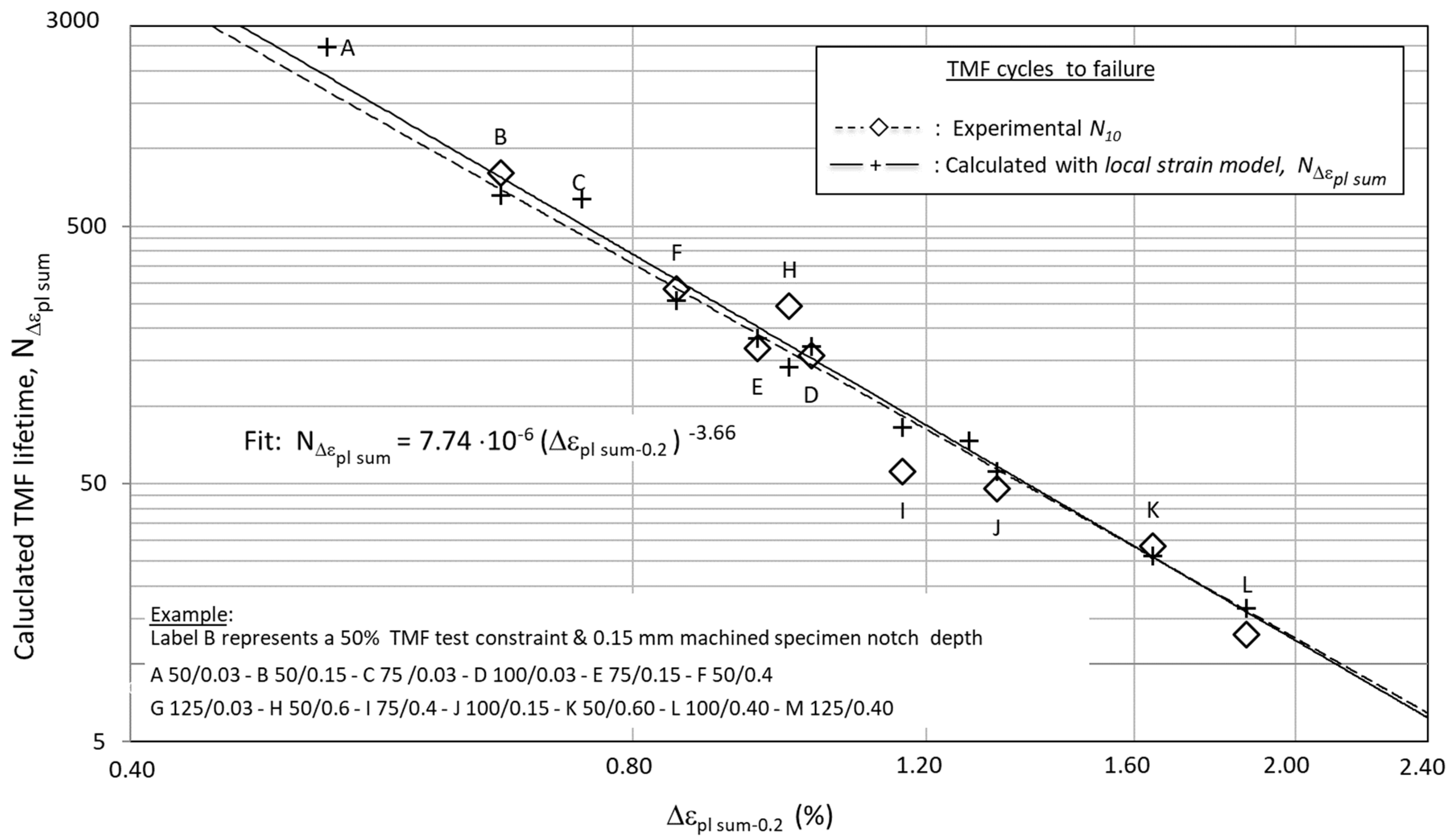

4.2. Results of the Local Strain Crack-Growth Model

4.3. Comparing the Local Stress and the Local Strain Models

4.4. The Balance between LEFM and EPFM Mechanisms during TMF (Local Strain Model)

5. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations and Symbols

| a | TMF crack length |

| A | Proportionality constant, linking to cyclic (sharp) crack-tip plasticity; see Equation (9) |

| α | Coefficient of thermal expansion |

| Depth of a machined notch, also being the assumed initial crack length | |

| B | Proportionality constant in the local strain crack-growth model; see Equation (7) |

| A combination of parameters in the analytical solution for TMF lifetime, for crack growth according to local stress model (i.e., Paris’ law) | |

| Proportionality constant in the local stress crack-growth law (i.e., Paris’ law); see Equation (5) | |

| see | |

| CGI | Compacted graphite iron |

| CTE | Coefficient of thermal expansion |

| da/dN | TMF crack-growth rate |

| Bulk strain, as measured by the extensometer (i.e., total strain) | |

| Bulk strain, resulting from stress (i.e., mechanical strain) | |

| Bulk strain, resulting from thermal expansion (i.e., thermal strain) | |

| Cyclic plastic bulk strain, i.e., the width of the hysteresis loop | |

| Local cyclic plastic strain at the crack tip, produced during the sharp crack stage of the local strain model; see Equation (9) (mechanical strain) | |

| Local cyclic plastic strain at the crack tip, produced during the blunt crack stage of the local strain model; see Equation (10) (mechanical strain) | |

| The cumulative local cyclic plastic strain at the crack tip; see Equation (8) (mechanical strain) | |

| The value of at the initial crack length , being the depth of the machined notch (a similar notation is used for initial values of and ) | |

| The value of , at a crack length of (, characterizing TMF lifetime | |

| EPFM | Elastic plastic fracture mechanics |

| The relative contribution on TMF of the blunt crack stage (local strain crack-growth model) | |

| γ | Relative degree of thermal constraint during a TMF test |

| Strain concentration factor (local strain/nominal strain) | |

| Geometrical stress concentration factor (defined for elastic strains only) | |

| Stress concentration factor (local stress/nominal stress) | |

| Minimum value of the stress concentration factor during TMF | |

| Maximum value of the stress concentration factor during TMF | |

| Stress-intensity range = ( − ) | |

| Initial stress-intensity range, with the machined notched depth () taken as initial crack length. For unnotched specimens, the average graphite particle size is taken as initial crack length. | |

| The value of , at a crack length of ( | |

| LCF | Low cycle fatigue |

| LEFM | Linear elastic fracture mechanics |

| Number of cycles at a 10% load drop in a TMF test (i.e., experimental cycles to failure) | |

| Number of TMF cycles to failure, calculated by numerical integration of the local stress crack-growth model (i.e., Paris’ law) | |

| Number of TMF cycles to failure, given by the analytical solution of the local stress crack-growth model (i.e., Paris’ law) | |

| Number of TMF cycles elapsed | |

| Number of TMF cycles to failure, calculated by numerical integration of the local strain crack-growth model | |

| r | Radius of the cylindrical gauge length of the TMF test specimen |

| Bulk stress | |

| Nominal (bulk) stress range | |

| SGI | Spheroidal graphite iron |

| SiMo | Cast iron with silicon and molybdenum as major alloying elements |

| TMF cycle temperature range | |

| TMF | Thermo-mechanical fatigue |

| Z | Number of replicate TMF tests |

Appendix A. Example Calculations of TMF Lifetimes, Using the Local Strain Model

Example Calculation for 100% Constraint TMF Test Results, for a 0.15-mm Machined Notch

- The initial value of value () is calculated according to Equation (6), i.e., considering the notch depth as initial crack length i.e., 0.15 mm), resulting in (see Table 3). Using Equation (9), , and, using the determined value of constant A = It should be noted that the value of A is taken as a constant for all TMF tests performed.

- Using Equation (10), with a value of = 1.80 and = 0.23% results in = 0.41%. It should be noted that the value of = 1.80 is identical for all TMF tests performed using a 0.15-mm notch depth.Superposition of contributions (i) and (ii), according to Equation (8), giveswhich is reported as

Appendix B. Initial Estimation of the Local Stress Model Parameters

The Local Stress Model Parameters

Appendix C. Initial Estimation of the Local Strain Model Parameters

References

- Gocmez, T.; Awarke, A.; Pischinger, S. A new low cycle fatigue criterion for isothermal and out-of-phase thermomechanical loading. Int. J. Fatigue 2010, 32, 769–779. [Google Scholar] [CrossRef]

- Rémy, L.; Haddar, N.; Alam, A.; Koster, A.; Marchal, N. Growth of small cracks and prediction of lifetime in high-temperature alloys. Mater. Sci. Eng. A 2007, 468–470, 40–50. [Google Scholar] [CrossRef]

- Ghodrat, S.; Riemslag, A.C.; Janssen, M.; Sietsma, J.; Kestens, L.A.I. Measurement and characterization of thermo-mechanical fatigue in compacted graphite iron. Int. J. Fatigue 2013, 48, 319–329. [Google Scholar] [CrossRef]

- Ghodrat, S. Thermo-Mechanical Fatigue of Compacted Graphite Iron in Diesel Engine Components. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 10 June 2013. [Google Scholar]

- Ghodrat, S.; Riemslag, A.S.; Kestens, L.A.I.; Petrov, R.H.; Janssen, M.; Sietsma, J. Effects of Holding Time on Thermo-Mechanical Fatigue Properties of Compacted Graphite Iron through Tests with Notched Specimens. Metall. Mater. Trans. A 2013, 44, 2121–2130. [Google Scholar] [CrossRef]

- Ghodrat, S.; Kestens, L. Microstructural dependence of tensile and fatigue properties of compacted graphite iron in diesel engine component. Steel Res. Int. 2016, 87, 772–779. [Google Scholar] [CrossRef]

- Norman, V.; Calmunger, M. On the micro- and macroscopic elastoplastic deformation behaviour of cast iron when subjected to cyclic loading. Int. J. Plast. 2019, 115, 200–215. [Google Scholar] [CrossRef]

- Norman, V.; Skoglund, P.; Leidermark, D.; Moverare, J. The transition from micro- to macrocrack growth in compacted graphite iron subjected to thermo-mechanical fatigue. Eng. Fract. Mech. 2017, 186, 268–282. [Google Scholar] [CrossRef]

- Kalra, A. Thermo-Mechanical Fatigue-Lifetime Determination of Diesel Engine Exhaust Manifolds. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 30 August 2016. [Google Scholar]

- Tada, H.; Paris, P.; Irwin, G. The Stress Analysis of Cracks Handbook, 2nd ed.; Paris Productions INC: Wilmington, MA, USA, 1985. [Google Scholar]

- Vor, K.; Gardin, C.; Sarrazin-Baudoux, C.; Petit, J. Wake length and loading history effects on crack closure of through-thickness long and short cracks in 304L: Part I–Experiments. Eng. Fract. Mech. 2013, 99, 266–277. [Google Scholar] [CrossRef]

- Fuchs, H.O.; Stephens, R.I. Metal Fatigue in Engineering, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2001; Volume 186–234, pp. 103–110. ISBN 978-0-471-51059-8. [Google Scholar]

- Ding, F.; Feng, M.; Jiang, Y. Modelling of fatigue crack growth from a notch. Int. J. Plast. 2007, 23, 1167–1188. [Google Scholar] [CrossRef]

- Jiang, Y.; Ott, W.; Baum, C.; Vormwald, M.; Nowack, H. Fatigue life predictions by integrating EVICD fatigue damage model and an advanced cyclic plasticity theory. Int. J. Plast. 2009, 25, 780–801. [Google Scholar] [CrossRef]

- Seifert, T.; Riedel, H. Mechanism-based thermomechanical fatigue life prediction of cast iron, Part I: Models. Int. J. Fatigue 2010, 32, 1358–1367. [Google Scholar] [CrossRef]

- Seifert, T.; Maier, G.; Uihlein, A.; Lang, K.-H.; Riedel, H. Mechanism-based thermomechanical fatigue life prediction of cast iron. Part II: Comparison of model predictions with experiments. Int. J. Fatigue 2010, 32, 1368–1377. [Google Scholar] [CrossRef]

- Antunes, F.V.; Rodrigues, S.M.; Branco, R.; Camas, D. A numerical analysis of CTOD in constant amplitude fatigue crack growth. Theor. Appl. Fract. Mech. 2016, 85, 45–55. [Google Scholar] [CrossRef]

- Manson, S.S.; Halford, G.R. Fatigue and Durability of Structural Materials; ASM International: Geauga County, OH, USA, 2006; Volume 179–200, pp. 54–74. ISBN 0-87170-825-6. [Google Scholar]

- Besel, M.; Breitbarth, E. Advanced analysis of crack tip plastic zone under cyclic loading. Int. J. Fatigue 2016, 93, 92–108. [Google Scholar] [CrossRef]

- Ghodrat, S.; Riemslag, A.; Kestens, L. Measuring Plasticity with Orientation Contrast Microscopy in Aluminium 6061-T4. Metals 2017, 7, 108. [Google Scholar] [CrossRef]

| C | Si | Mo | Mn | S | P | Fe |

|---|---|---|---|---|---|---|

| 3.40 | 4.20 | 0.80 | 0.50 | 0.05 | 0.02 | Balance |

| γ (%) | (mm) | Z(1) | Experimental Values | Local Stress Model Calculations (Paris’ Law) | ||||

|---|---|---|---|---|---|---|---|---|

| S(2) (MPa) | (2) (–) | Δemech (%) | (2) (–) | (–) | ||||

| 125 | 0.15 | 3 | 836 ± 3% | 29 ± 41% | 0.84 | 24 ± 12% | 9.0 × 10−11 | 3.58 |

| 0.40 | 2 | 808 ± 3% | 8 ± 0% | 8 ± 12% | ||||

| 100 | 0.03 | 6 | 718 ± 1% | 157 ± 55% | 0.67 | 287 ± 4% | 8.5 × 10−11 | 3.58 |

| 0.15 | 3 | 772 ± 3% | 48 ± 23% | 41 ± 10% | ||||

| 0.40 | 2 | 710 ± 2% | 13 ± 8% | 14 ± 7% | ||||

| 75 | 0.15 | 3 | 654 ± 4% | 168 ± 19% | 0.51 | 193 ± 16% | 3.3 × 10−11 | 3.58 |

| 0.40 | 2 | 631 ± 0% | 56 ± 7% | 55 ± 0% | ||||

| 50 | 0.15 | 3 | 480 ± 2% | 803 ± 28% | 0.34 | 990 ± 8% | 1.8 × 10−11 | 3.58 |

| 0.40 | 4 | 480 ± 7% | 284 ± 20% | 276 ± 21% | ||||

| 0.60 | 3 | 453 ± 2% | 244 ± 14% | 144 ± 7% | ||||

| Z(1) | S ± SD (2) | ± SD (2) | ± SD (2) | (3) | (4) | (5) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| (mm);(–) | (%) | (–) | MPa | (%) | (–) | (–) | (%) | (%) | (–) | |

| 0.03; 1.35 | 125 | - | 836 | 0.37 | - | 73 | - | 0.64 | 9.1 | |

| 100 | 6 | 718 ± 3% | 0.26 | 157 ± 56% | 170 ± 7% | +8 | 0.60 | 7.9 | ||

| 75 | - | 654 | 0.10 | - | 636 | - | 0.39 | 7.1 | ||

| 50 | - | 490 | 0.05 | - | 2478 | - | 0.30 | 5.4 | ||

| 0.15; 1.80 | 125 | 3 | 836 ± 3% | 0.37 | 29 ± 42% | 26 ± 7% | −9 | 0.51 | 21 | |

| 100 | 3 | 772 ± 3% | 0.23 | 48 ± 22% | 56 ± 8% | +17 | 0.42 | 19 | ||

| 75 | 3 | 654 ± 4% | 0.10 | 168 ± 19% | 183 ± 13% | +9 | 0.27 | 16 | ||

| 50 | 3 | 490 ± 2% | 0.05 | 803 ± 28% | 656 ± 7% | −18 | 0.20 | 12 | ||

| 0.40; 2.90 | 125 | 2 | 808 ± 3% | 0.40 | 8 ± 0.5% | 7 ± 6% | −18 | 0.52 | 34 | |

| 100 | 2 | 710 ± 2% | 0.25 | 13 ± 11% | 16 ± 5% | +26 | 0.44 | 30 | ||

| 75 | 2 | 631 ± 0% | 0.05 | 56 ± 6% | 83 ± 0% | +49 | 0.13 | 27 | ||

| 50 | 4 | 480 ± 7% | 0.02 | 284 ± 56% | 256 ± 19% | −10 | 0.07 | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghodrat, S.; Kalra, A.; Kestens, L.A.I.; Riemslag, T. Thermo-Mechanical Fatigue Lifetime Assessment of Spheroidal Cast Iron at Different Thermal Constraint Levels. Metals 2019, 9, 1068. https://doi.org/10.3390/met9101068

Ghodrat S, Kalra A, Kestens LAI, Riemslag T. Thermo-Mechanical Fatigue Lifetime Assessment of Spheroidal Cast Iron at Different Thermal Constraint Levels. Metals. 2019; 9(10):1068. https://doi.org/10.3390/met9101068

Chicago/Turabian StyleGhodrat, Sepideh, Aakarshit Kalra, Leo A.I. Kestens, and Ton (A.C.) Riemslag. 2019. "Thermo-Mechanical Fatigue Lifetime Assessment of Spheroidal Cast Iron at Different Thermal Constraint Levels" Metals 9, no. 10: 1068. https://doi.org/10.3390/met9101068

APA StyleGhodrat, S., Kalra, A., Kestens, L. A. I., & Riemslag, T. (2019). Thermo-Mechanical Fatigue Lifetime Assessment of Spheroidal Cast Iron at Different Thermal Constraint Levels. Metals, 9(10), 1068. https://doi.org/10.3390/met9101068