Effect of Retained Austenite and Non-Metallic Inclusions on the Mechanical Properties of Resistance Spot Welding Nuggets of Low-Alloy TRIP Steels

Abstract

1. Introduction

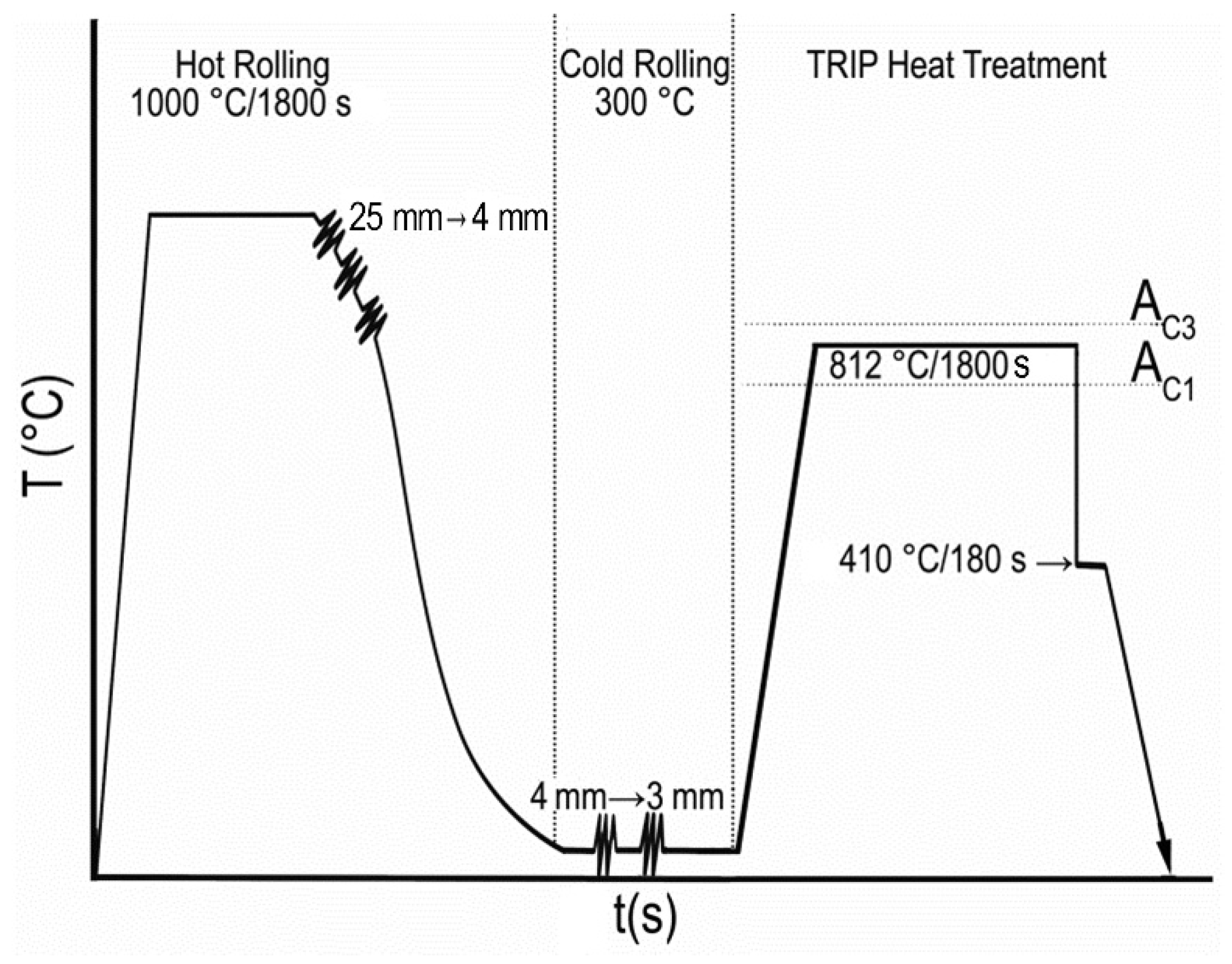

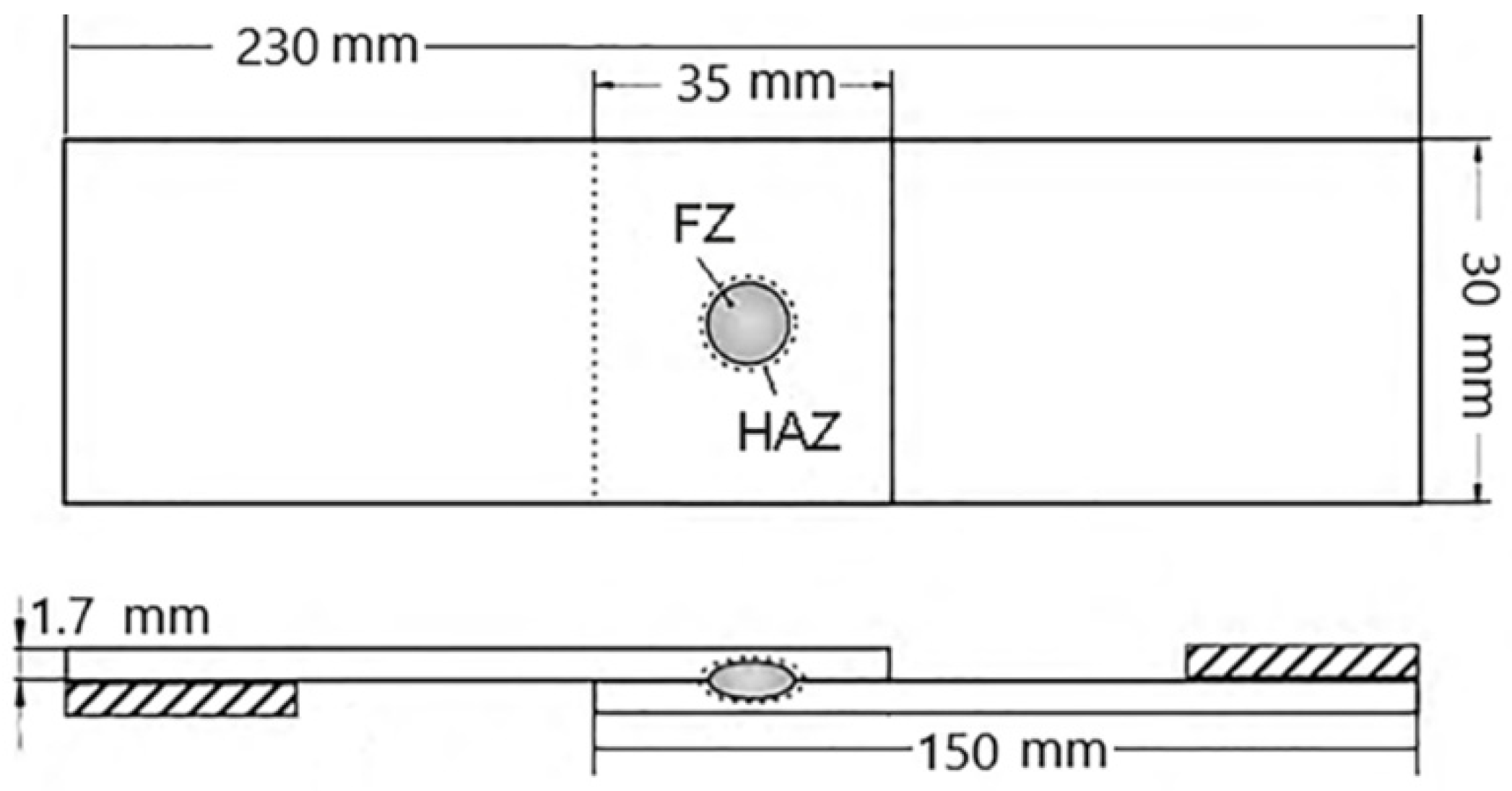

2. Materials and Methods

3. Results and Discussion

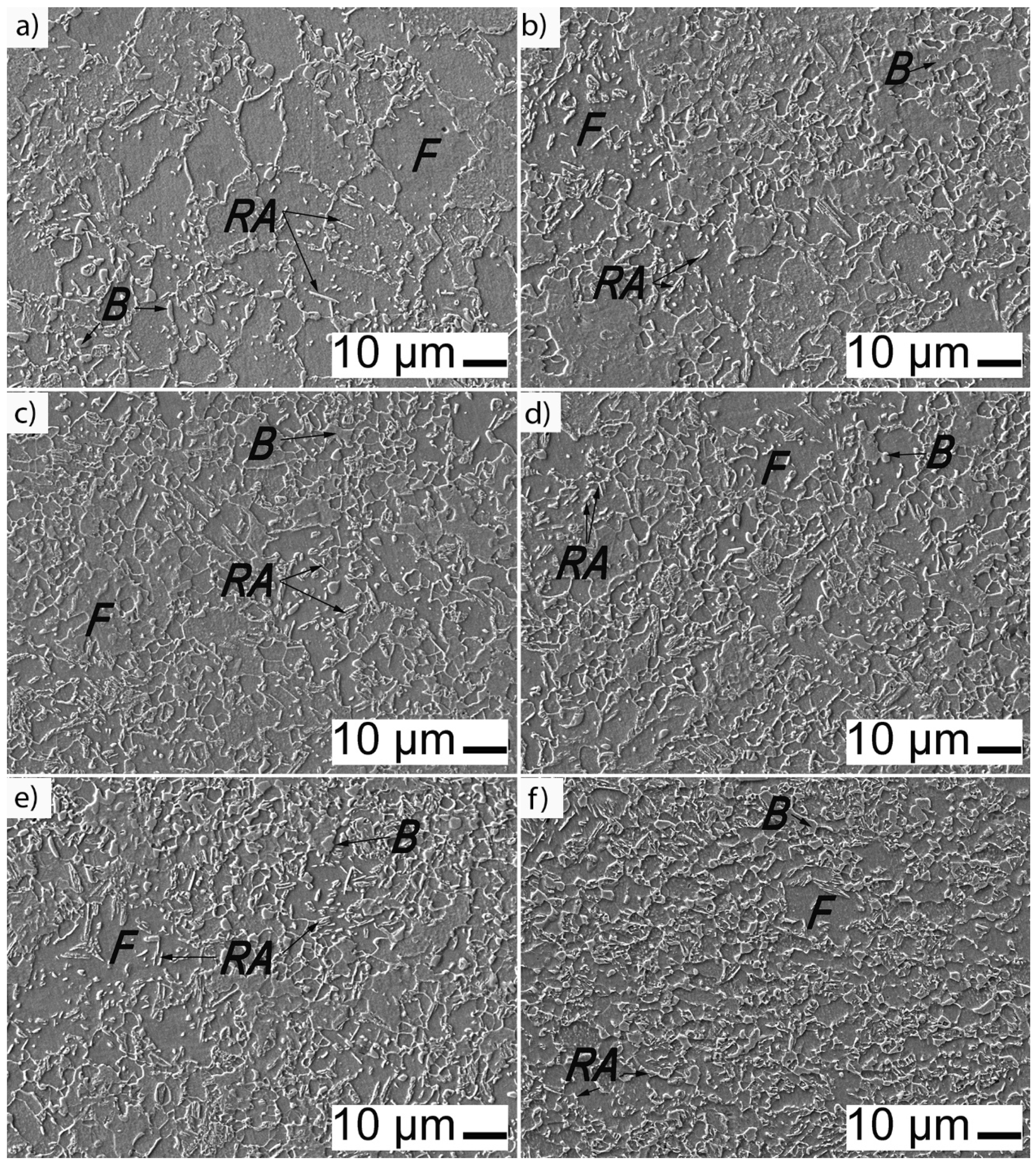

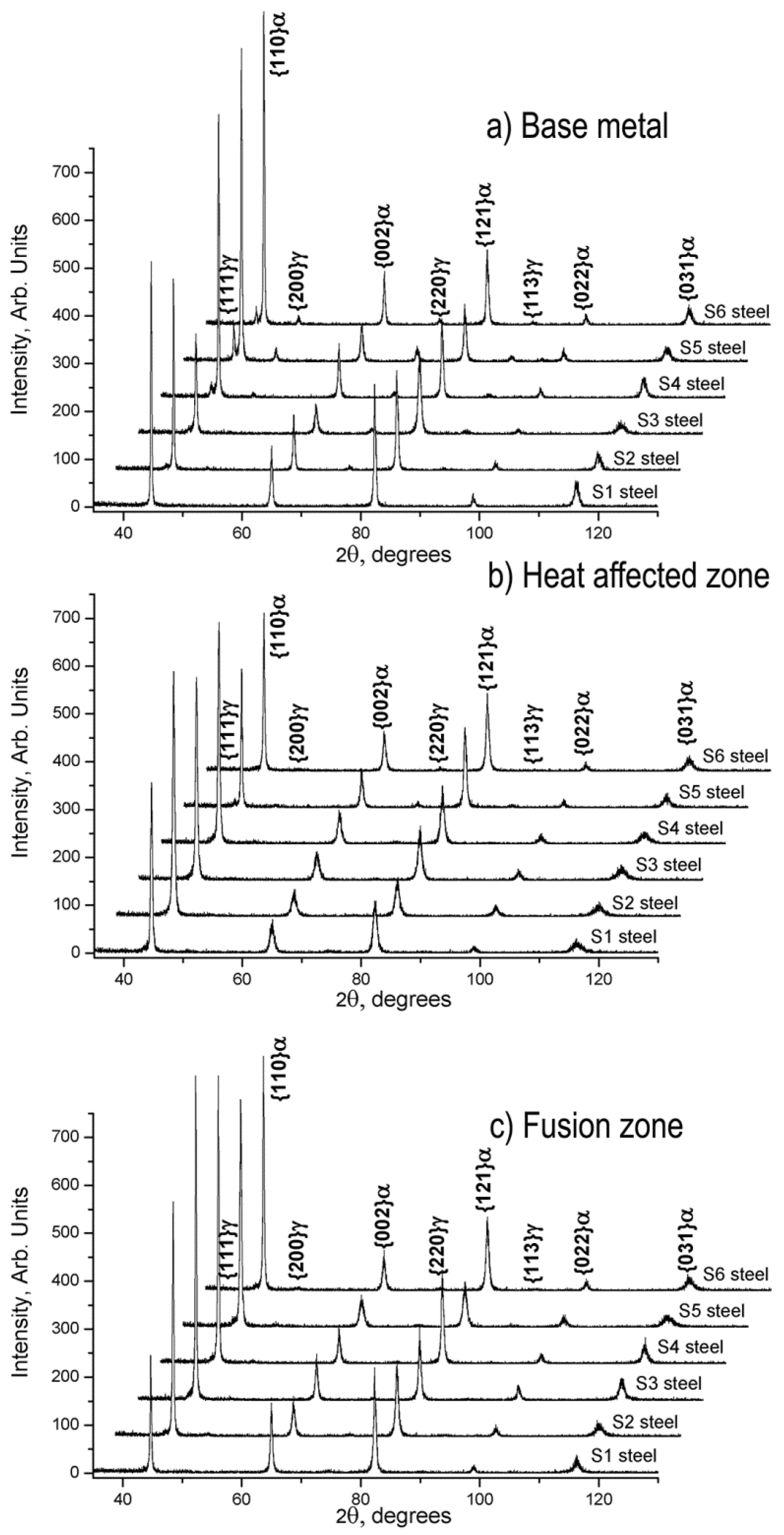

3.1. Microstructural Characterization of the Base Metals

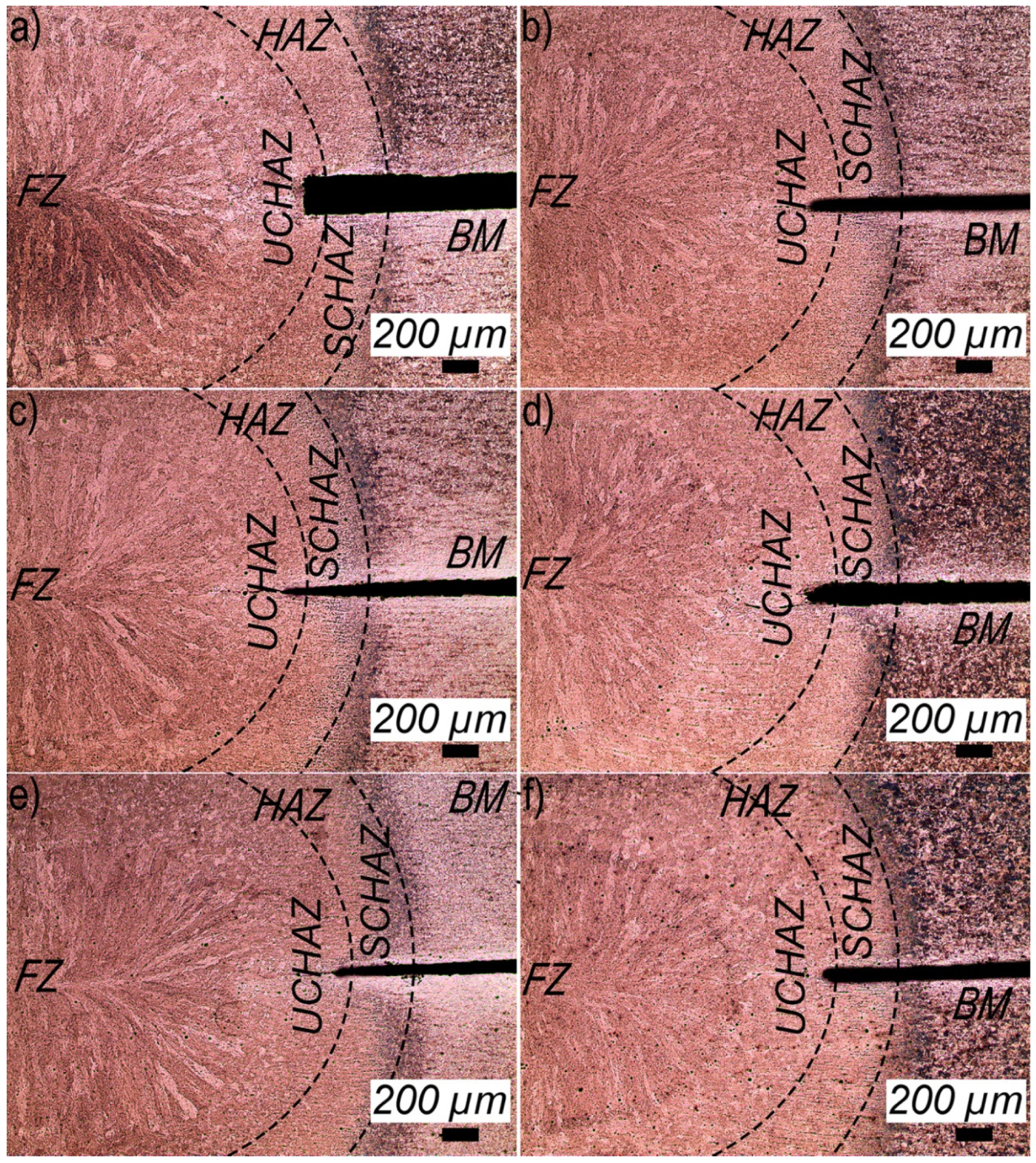

3.2. Microstructural Characterization of the Weld Nuggets

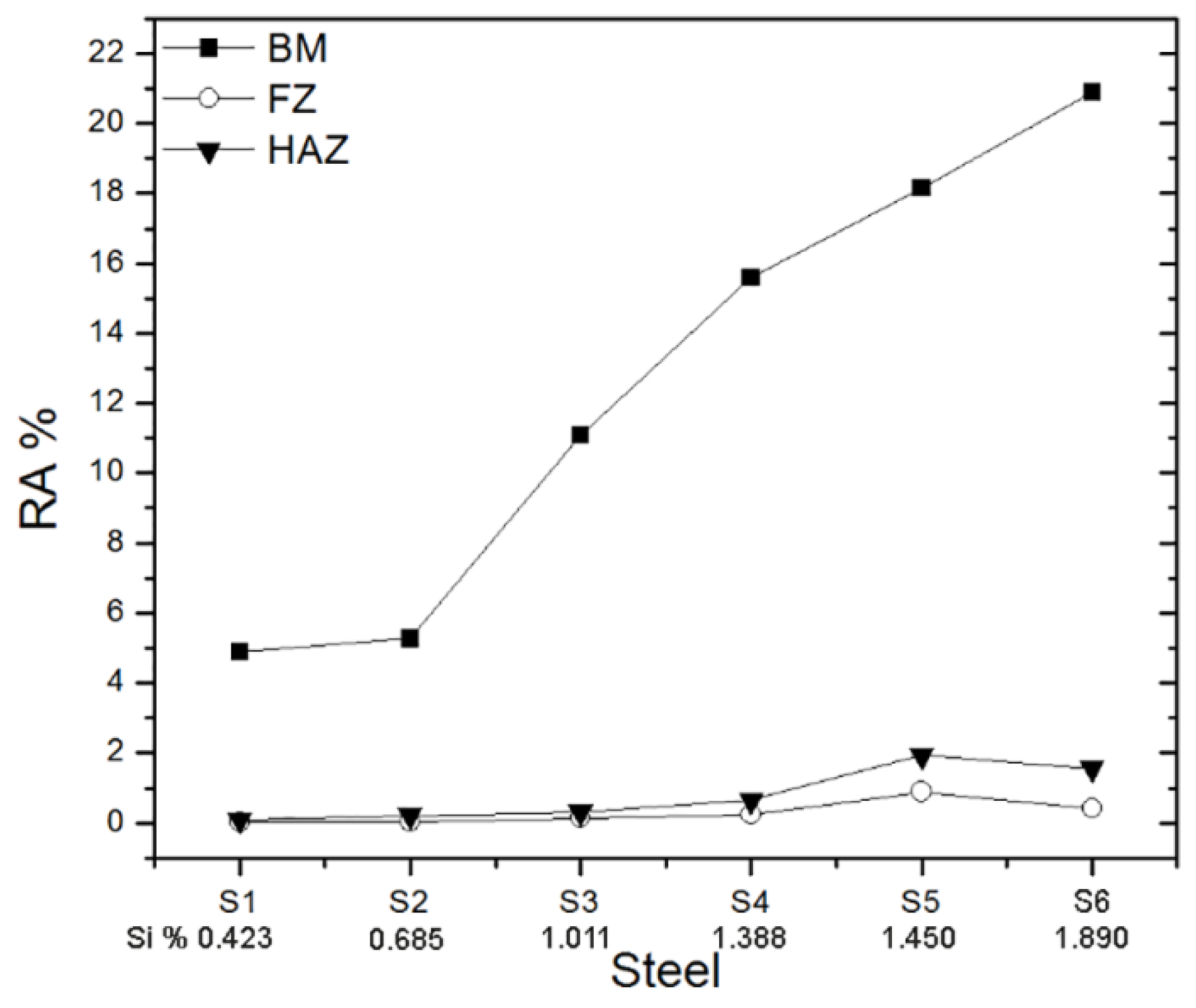

3.3. Quantitative Analysis of RA in the Base Metals and Spot Weld Zones

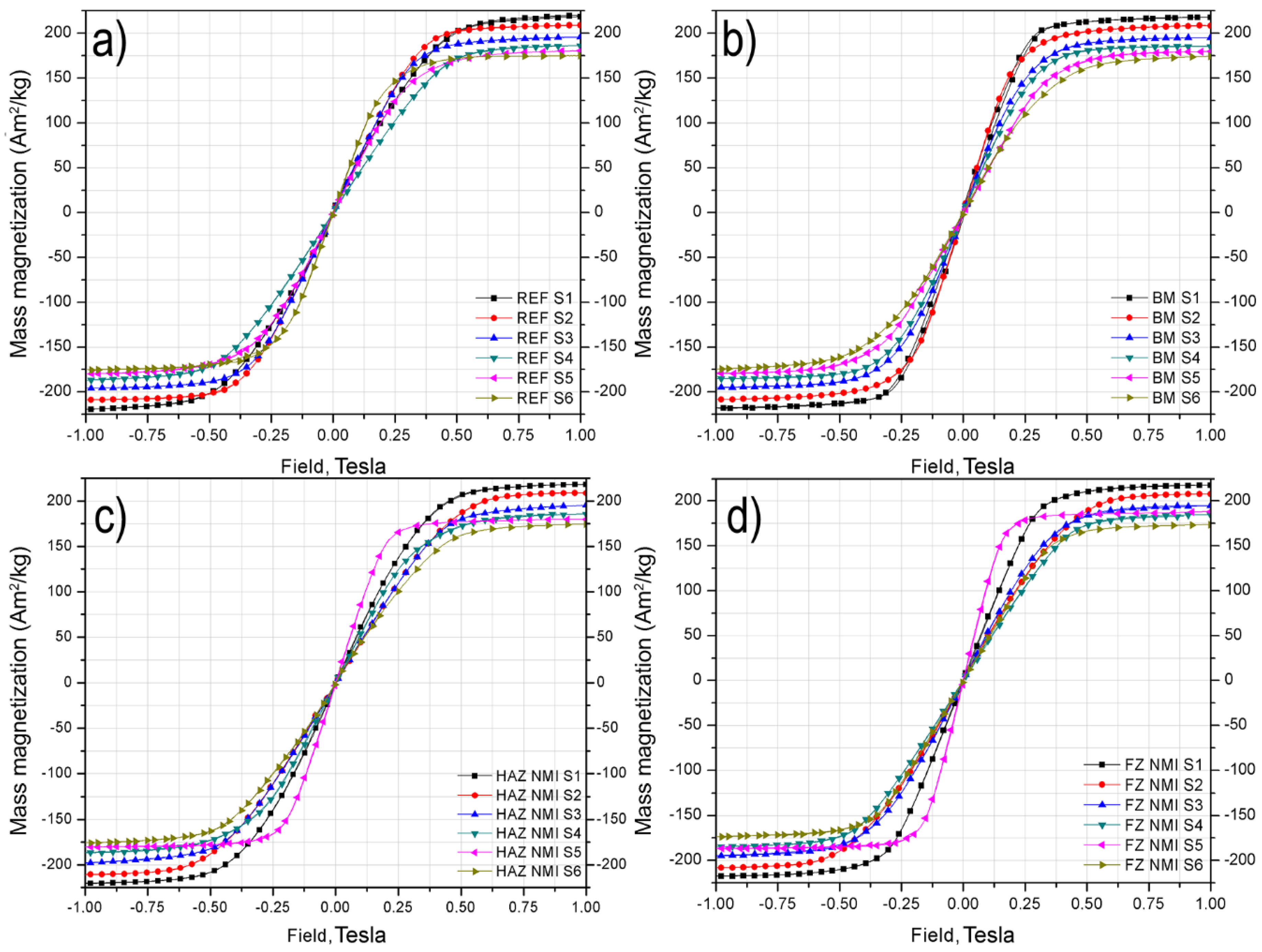

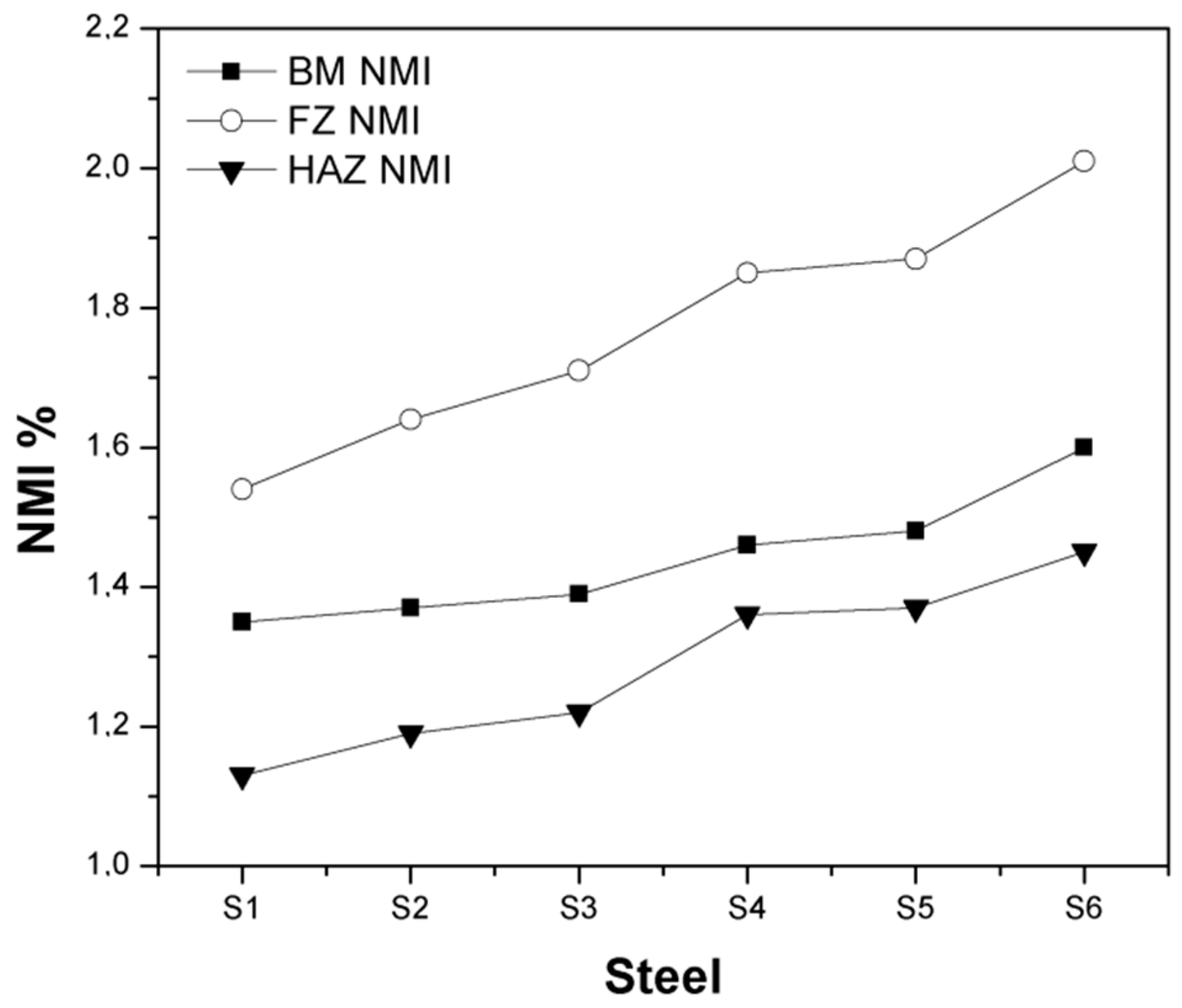

3.4. Quantitative Analysis of NMI in Base Metals and Spot Weld Zones

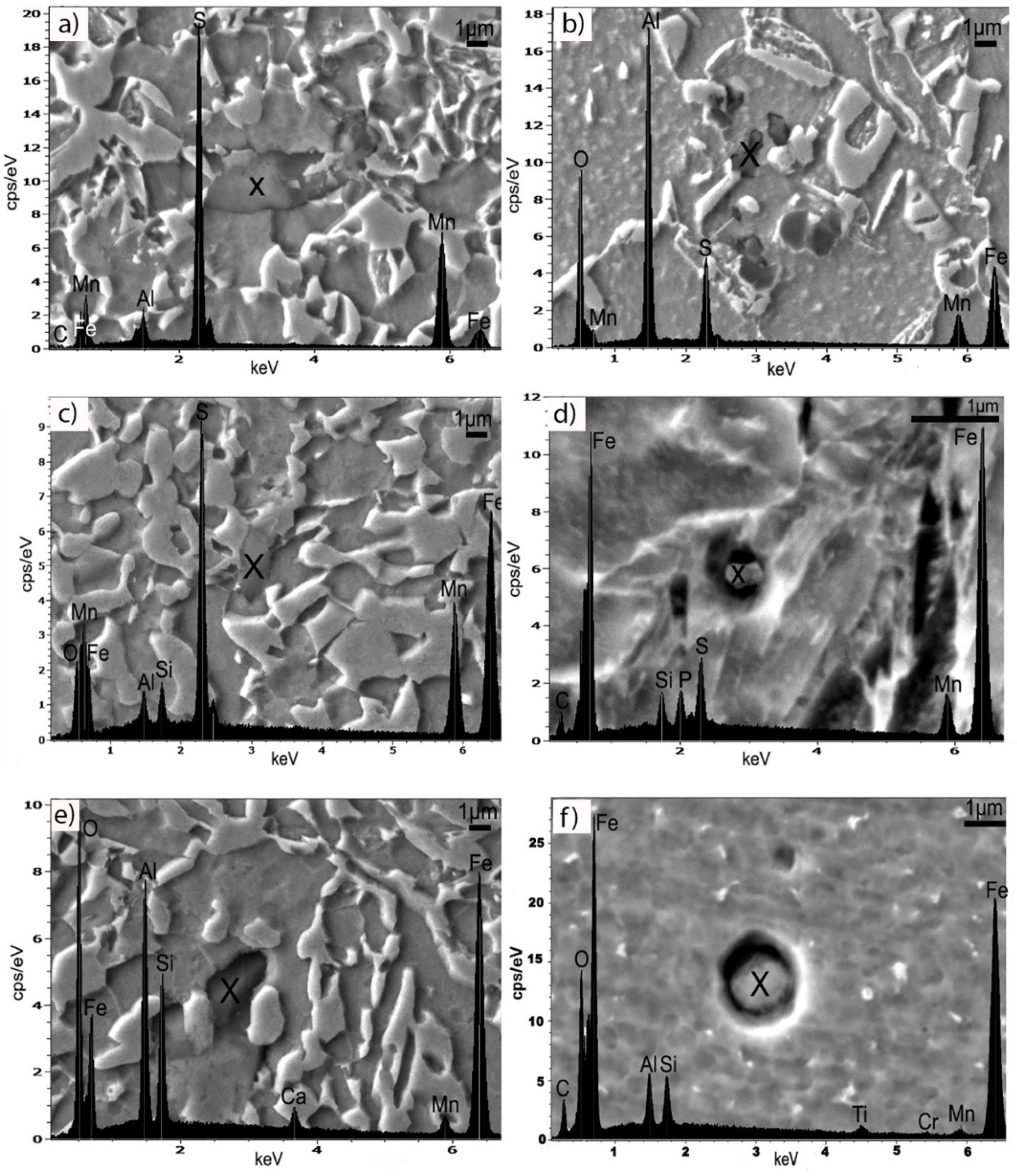

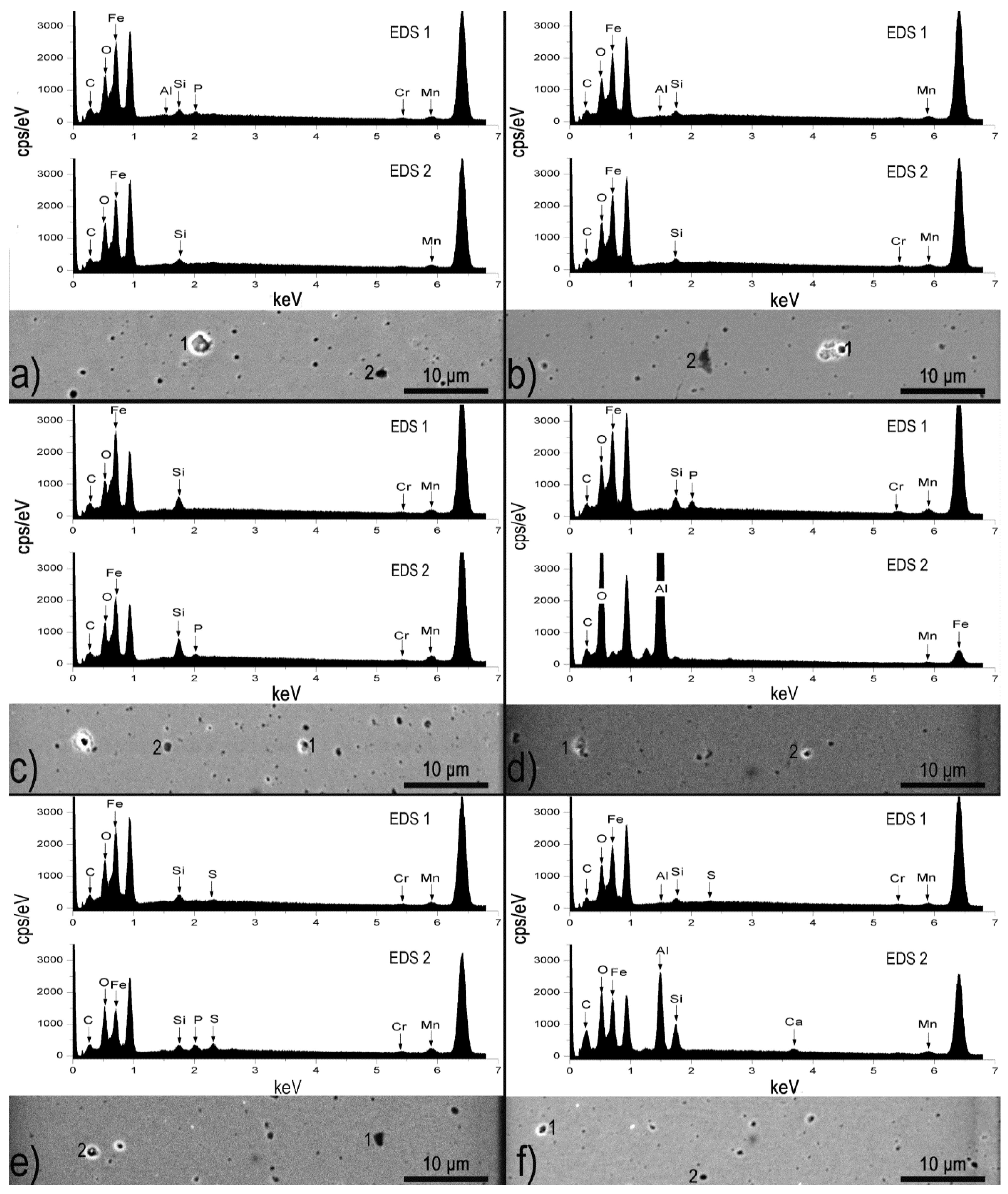

3.5. Non-Metallic Inclusions Characterization in the Base Metals and Spot Weld Zones

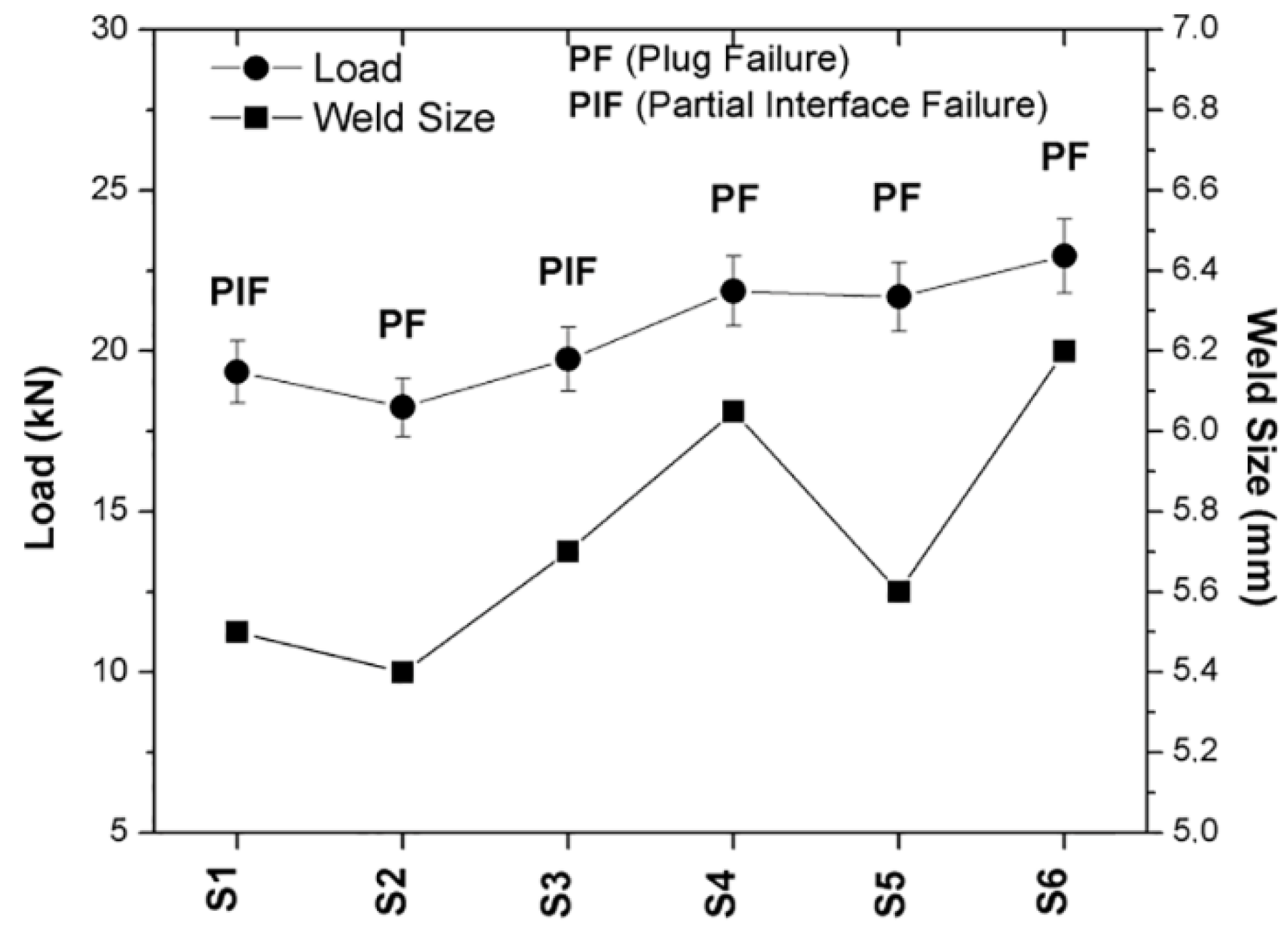

3.6. Mechanical Characterization of Spot Welds

4. Conclusions

- (1)

- Maximum stable retained austenite in TRIP steels was achieved by increasing alloying elements such as Si, P, and Mn, in addition to a properly designed TRIP heat treatment based on the chemical composition (transformation temperatures) of each TRIP steels.

- (2)

- Non-metallic inclusions content within the fusion zones of the steels increased with increasing deoxidizing elements such as Si, Mn, and Al. On the other hand, some parent metal non-metallic inclusions were dissolved during the welding process in the heat affected zones of the steels, so that its content was decreased in comparison with their corresponding base metals.

- (3)

- Traces of retained austenite could be found in the heat affected zone where the temperature of the resistance spot welding process was below Ac1 and base metal retained austenite was stable enough to withstand transformation due to temperature.

- (4)

- The development of non-metallic inclusions and the degradation of retained austenite, both had detrimental effects over the post weld mechanical properties of TRIP steel. However, the decomposition of the later had a major effect due to that its absence allowed the load necessary to initiate fracture to be lower.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Turteltaub, S.; Suiker, A.S.J. Transformation-induced plasticity in ferrous alloys. J. Mech. Phys. Solids 2005, 53, 1747–1788. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Pouranvari, M.; Asgari, H.R.; Mosavizadch, S.M.; Marashi, P.H.; Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 2007, 12, 217–225. [Google Scholar] [CrossRef]

- Amirthalingam, M.; Hermans, M.J.M.; Zhao, L.; Richardson, I.M. Quantitative analysis of microstructural constituents in welded transformation induced plasticity steels. Metall. Mater. Trans. A 2010, 41, 431–439. [Google Scholar] [CrossRef][Green Version]

- Amirthalingam, M.; Hermans, M.J.M.; Richardson, I.M. Microstructural development during welding of silicon and aluminum based transformation induced plasticity steels-inclusion and elemental partitioning analysis. Metall. Mater. Trans. A 2009, 40, 901–909. [Google Scholar] [CrossRef]

- Grajcar, A.; Rozanski, M.; Kaminska, M.; Grzegorczyk, B. Study on non-metallic inclusions in laser-welded trip-aided Nb-microalloyed steel. Arch. Metall. Mater. 2014, 59, 1163–1169. [Google Scholar] [CrossRef]

- Grajcar, A.; Kaminska, M.; Galisz, U.; Bulkowski, L.; Opiela, M.; Skrzypczyk, P. Modification of non-metallic inclusions in high-strength steels containing increased Mn and Al contents. J. Achiev. Mater. Manuf. Eng. 2012, 55, 245–255. [Google Scholar]

- Yurioka, N.; Suzuki, H.; Ohshita, S.; Saito, S. Determination of necessary preheating temperature in steel welding. Weld. J. 1998, 62, 147–153. [Google Scholar]

- Zhao, L.; van Dijk, N.H.; Bruck, E. Magnetic and X-ray diffraction measurements for the determination of retained austenite in TRIP steels. Mater. Sci. Eng. A 2000, 313, 145–152. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; Wiley: Hoboken, NJ, USA, 2009; pp. 141–149. [Google Scholar]

- Zhuang, L.; Di, W.; Jianxun, L. Effects of austempering on the mechanical properties of the hot rolled Si-Mn trip steels. J. Wuhan Univ. Technol. Mat. Sci. Ed. 2006, 21, 21–25. [Google Scholar] [CrossRef]

- Sakuma, Y.; Matsumura, O.; Takechi, H. Mechanical properties and retained austenite in intercritically heat treated bainite-transformed steel and their variation with Si and Mn additions. Metall. Trans. A 1991, 22, 489–498. [Google Scholar] [CrossRef]

- Tsukatani, I.; Hashimoto, S.; Inoue, T. Effect of silicon and manganese addition on mechanical properties of high-strength hot-rolled sheet steel containing retained austenite. ISIJ Int. 1992, 31, 992–1000. [Google Scholar] [CrossRef]

- Nayak, S.S.; Baltazar Hernandez, V.H.; Okita, Y.; Zhou, Y. Microstructure–hardness relationship in the fusion zone of TRIP steel welds. Mater. Sci. Eng. A 2012, 551, 73–81. [Google Scholar] [CrossRef]

- Alexopoulos, N.D. Low-alloy trip steels: Evaluation of the mechanical performance with regard to material design requirements in the automotive industry steel. Steel Res. Int. 2006, 77, 129–138. [Google Scholar] [CrossRef]

- Matsumura, O.; Sakuma, Y.; Takechi, H. Retained austenite in 0.4C-SÌ- 1.2Mn Steel sheet intercritically heated and austempered. ISIJ Int. 1992, 32, 1014–1020. [Google Scholar] [CrossRef]

- Yin, H.X.; Zhao, A.M.; Zhao, Z.; Li, X.; Li, S.J.; Hu, H.J.; Xia, W.G. Influence of original microstructure on the transformation behavior and mechanical properties of ultra-high-strength TRIP-aided steel. Int. J. Miner. Metall. Mater. 2015, 22, 262–270. [Google Scholar] [CrossRef]

- Jacques, P.J.; Allain, S.; Bouaziz, O.; De, A.; Gourgues, A.F.; Hance, B.M.; Houbaert, Y.; Huang, J.; Iza-Mendia, A.; Kruger, S.E.; et al. On measurement of retained austenite in multiphase TRIP steels-results of blind round robin test involving six different techniques. Mater. Sci. Technol. 2009, 25, 567–574. [Google Scholar] [CrossRef]

- Baltazar Hernandez, V.H.; Okita, Y.; Zhou, Y. Second pulse current in resistance spot welded TRIP steel-Effects on the microstructure and mechanical behavior. Weld. J. 2012, 91, 278–285. [Google Scholar]

- Pichler, A.; Stiaszny, P. TRIP steel with reduced silicon content. Steel Res. 1999, 70, 459–465. [Google Scholar] [CrossRef]

- Brauser, S.; Pepke, L.A.; Weber, G.; Rethmeier, M. Deformation behaviour of spot-welded high strength steels for automotive applications. Mater. Sci. Eng. A 2010, 527, 7099–7108. [Google Scholar] [CrossRef]

- Green, J.R.; Margerison, D. Statistical Treatment of Experimental Data; Elsevier: Amsterdam, The Netherlands, 1978. [Google Scholar]

- Bigdeli Karimi, M.; Arabi, H.; Khosravani, A.; Samei, J. Effect of rolling strain on transformation induced plasticity of austenite to martensite in high-alloy austenitic steel. J. Mater. Process. Tech. 2008, 203, 349–356. [Google Scholar] [CrossRef]

- Gomez, M.; Garcia, C.I.; Deardo, A.J. The role of new ferrite on retained austenite stabilization in al-trip steels. ISIJ Int. 2010, 50, 139–146. [Google Scholar] [CrossRef]

- DeArdo, A.J.; Garcia, C.I.; Cho, K.; Hua, M. New method of characterizing and quantifying complex microstructures in steels. Mater. Manuf. Process. 2010, 25, 33–40. [Google Scholar] [CrossRef]

- Da Costa e Silva, A.L.V. Non-metallic inclusions in steels-origin and control. J. Mater. Res. Technol. 2018, 7, 283–299. [Google Scholar] [CrossRef]

- Russo Spena, P.; Cortese, L.; De Maddis, M.; Lombardi, F. Effects of process parameters on spot welding of trip and quenching and partitioning steels Steel. Res. Int. 2016, 87, 1592–1600. [Google Scholar] [CrossRef]

- Zuniga, S.; Sheppard, S.D. Fatigue Fracture Mechanics; Piascik, R.S., Newman, J.C., Dowling, N.E., Eds.; ASTM: West Conshohocken, PA, USA, 1997; Volume 27, pp. 469–489. [Google Scholar]

- Khan, M.I.; Kuntz, M.L.; Biro, E.; Zhou, Y. Microstructure and mechanical properties of resistance spot welded advanced high strength steels. Mater. Trans. 2008, 49, 1629–1637. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Cr | Mo | Ni | Al | Ti | V | N | CEY | Ac1 | Ac3 | Ms |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.266 | 0.423 | 1.407 | 0.022 | 0.0048 | 0.321 | 0.027 | 0.138 | 0.105 | 0.00040 | 0.0095 | 0.0025 | 0.503 | 726 | 823 | 366 |

| S2 | 0.274 | 0.685 | 1.428 | 0.024 | 0.0050 | 0.345 | 0.025 | 0.139 | 0.050 | 0.00072 | 0.0095 | 0.020 | 0.524 | 732 | 825 | 354 |

| S3 | 0.268 | 1.011 | 1.325 | 0.025 | 0.0063 | 0.350 | 0.026 | 0.133 | 0.082 | 0.0016 | 0.0096 | 0.016 | 0.516 | 738 | 834 | 360 |

| S4 | 0.329 | 1.388 | 1.752 | 0.021 | 0.0055 | 0.232 | 0.025 | 0.115 | 0.125 | 0.0017 | 0.011 | 0.014 | 0.625 | 739 | 826 | 330 |

| S5 | 0.215 | 1.450 | 1.373 | 0.018 | 0.0096 | 0.163 | 0.021 | 0.101 | 0.091 | 0.00094 | 0.0058 | 0.015 | 0.461 | 739 | 851 | 384 |

| S6 | 0.325 | 1.890 | 1.724 | 0.022 | 0.0084 | 0.230 | 0.028 | 0.116 | 0.283 | 0.0026 | 0.012 | 0.013 | 0.639 | 760 | 860 | 337 |

| Steel | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|

| BM Ms(c) (Am2/kg) | 206.74 | 196.9 | 172.2 | 155.9 | 146.5 | 137.1 |

| REF Ms(f) (Am2/kg) | 218.3 | 208.8 | 195.6 | 186.1 | 180.4 | 175.1 |

| Steel | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|

| FZ Ms(i) (Am2/kg) | 217.1 | 207.44 | 193.4 | 184.49 | 178.9 | 173.31 |

| HAZ Ms(i) (Am2/kg) | 218.0 | 208.4 | 194.35 | 185.42 | 179.81 | 174.3 |

| REF Ms(f) (Am2/kg) | 218.3 | 208.8 | 195.6 | 186.1 | 180.4 | 175.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas Cortés, V.H.; Altamirano Guerrero, G.; Mejía Granados, I.; Baltazar Hernández, V.H.; Maldonado Zepeda, C. Effect of Retained Austenite and Non-Metallic Inclusions on the Mechanical Properties of Resistance Spot Welding Nuggets of Low-Alloy TRIP Steels. Metals 2019, 9, 1064. https://doi.org/10.3390/met9101064

Vargas Cortés VH, Altamirano Guerrero G, Mejía Granados I, Baltazar Hernández VH, Maldonado Zepeda C. Effect of Retained Austenite and Non-Metallic Inclusions on the Mechanical Properties of Resistance Spot Welding Nuggets of Low-Alloy TRIP Steels. Metals. 2019; 9(10):1064. https://doi.org/10.3390/met9101064

Chicago/Turabian StyleVargas Cortés, Víctor H., Gerardo Altamirano Guerrero, Ignacio Mejía Granados, Víctor H. Baltazar Hernández, and Cuauhtémoc Maldonado Zepeda. 2019. "Effect of Retained Austenite and Non-Metallic Inclusions on the Mechanical Properties of Resistance Spot Welding Nuggets of Low-Alloy TRIP Steels" Metals 9, no. 10: 1064. https://doi.org/10.3390/met9101064

APA StyleVargas Cortés, V. H., Altamirano Guerrero, G., Mejía Granados, I., Baltazar Hernández, V. H., & Maldonado Zepeda, C. (2019). Effect of Retained Austenite and Non-Metallic Inclusions on the Mechanical Properties of Resistance Spot Welding Nuggets of Low-Alloy TRIP Steels. Metals, 9(10), 1064. https://doi.org/10.3390/met9101064