Fe–Si–Al Coatings with Stable Wear Resistance Prepared by Laser Cladding Industrial Wastes

Abstract

1. Introduction

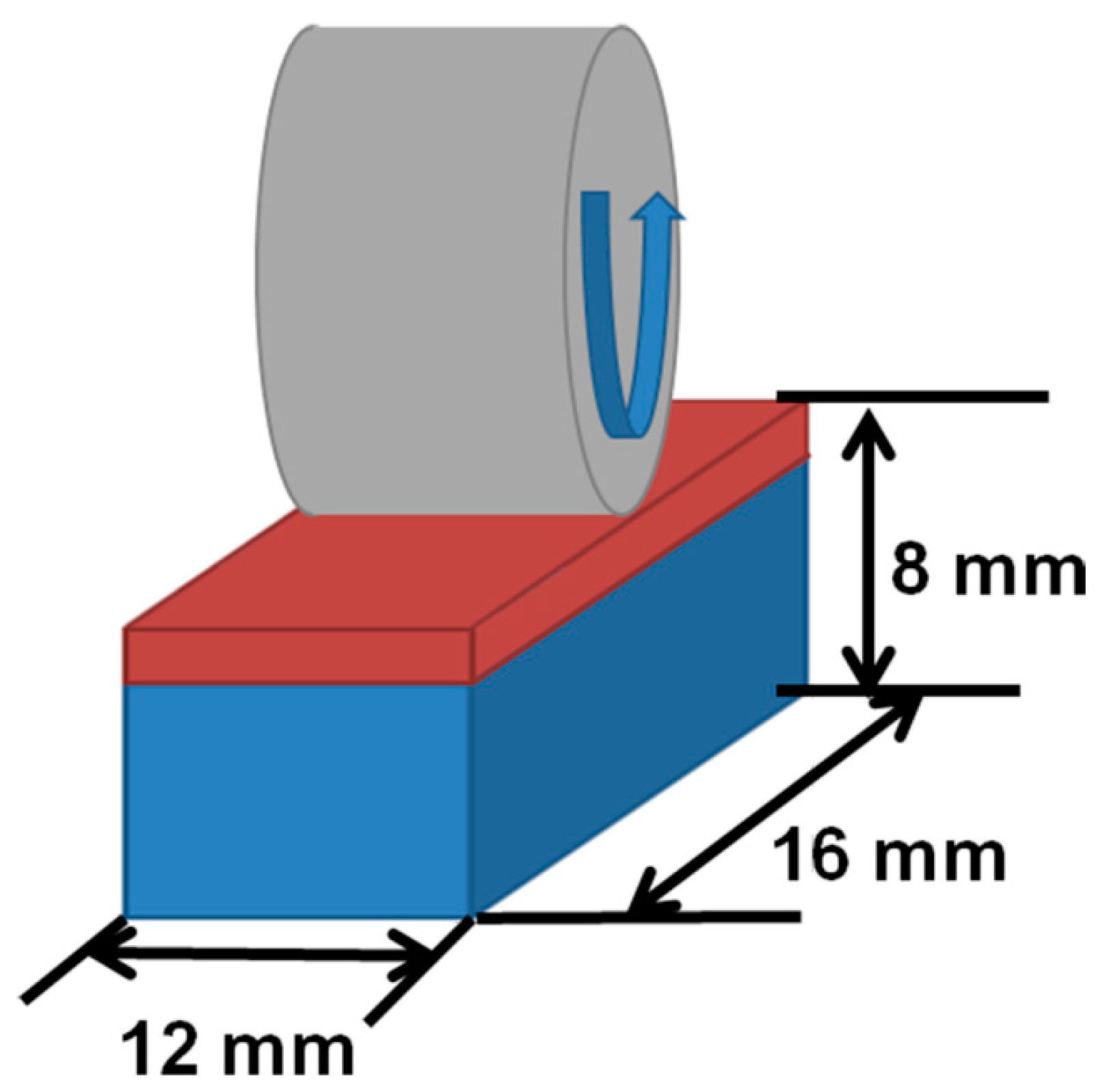

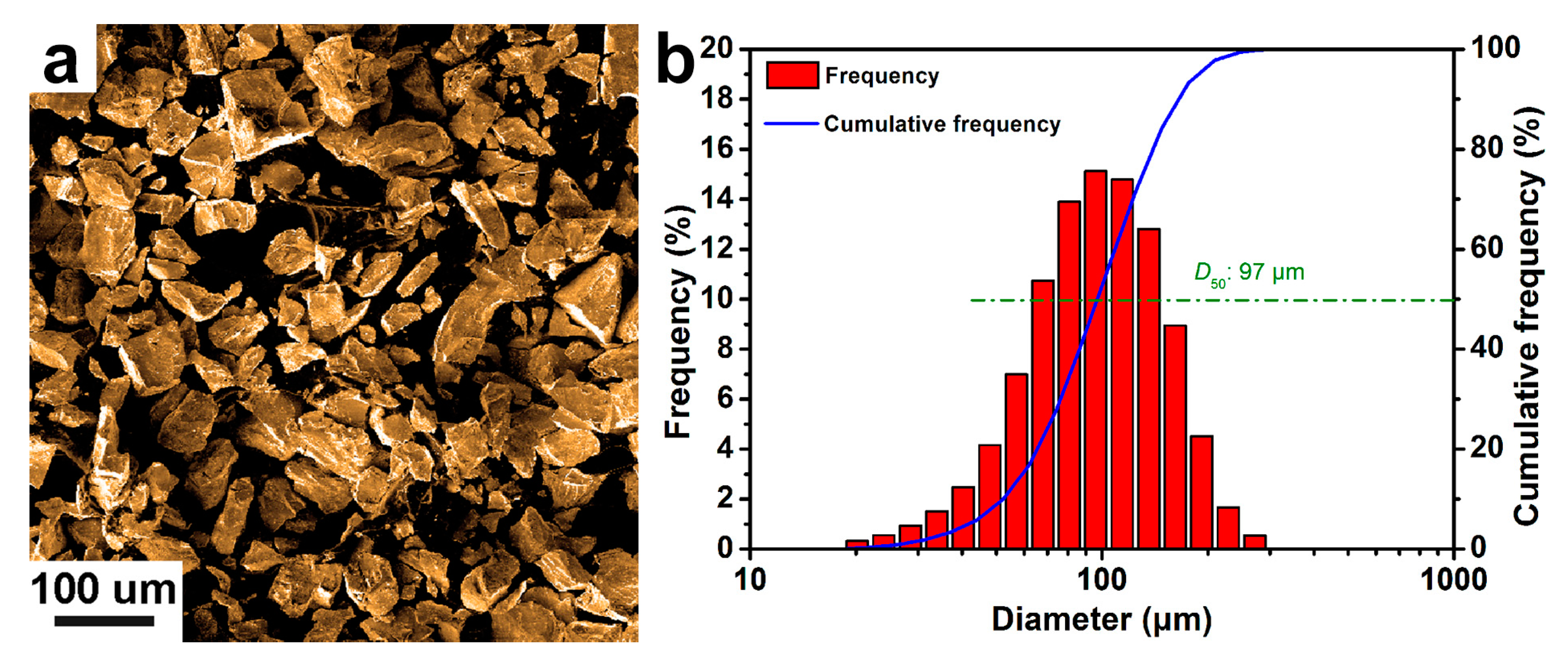

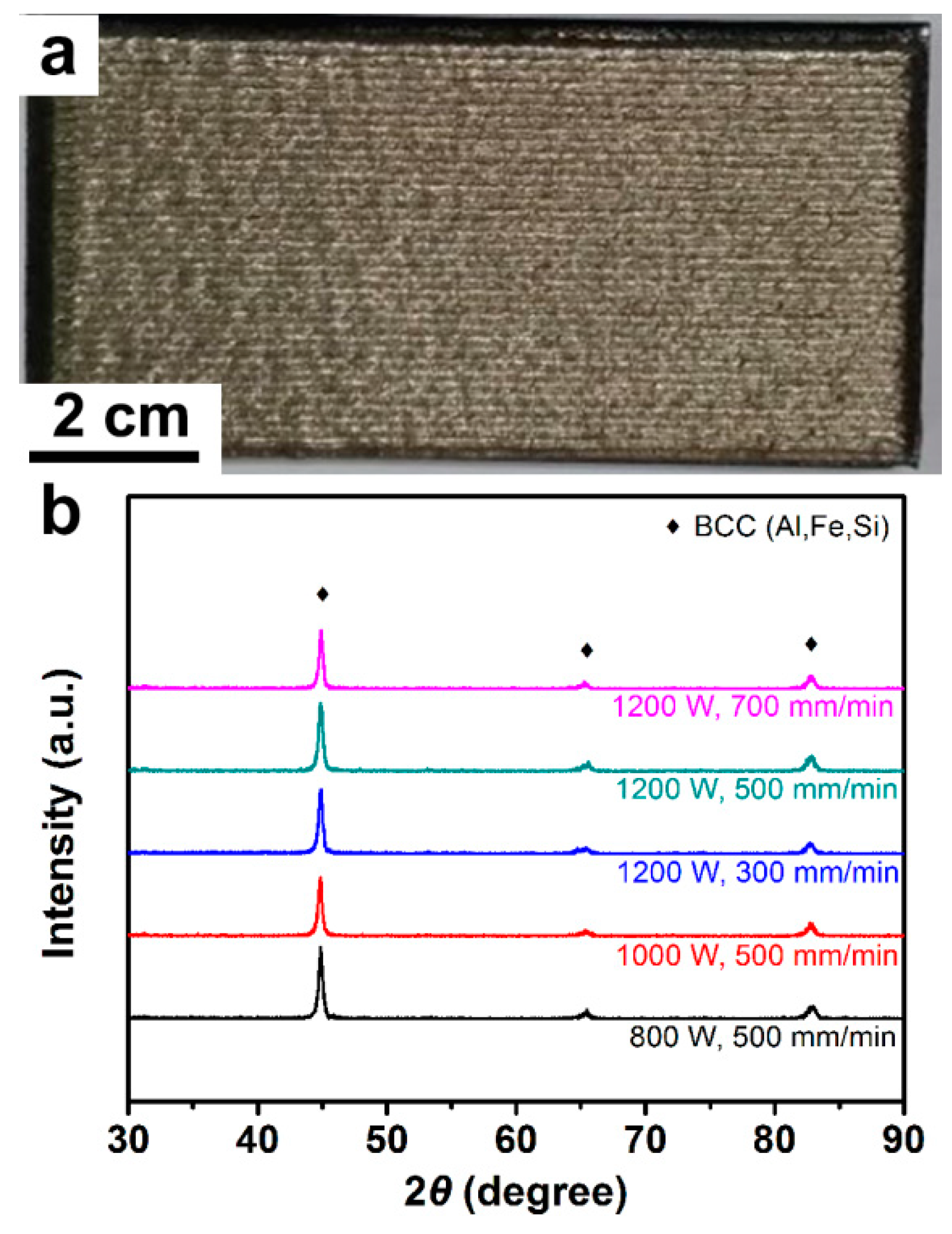

2. Materials and Methods

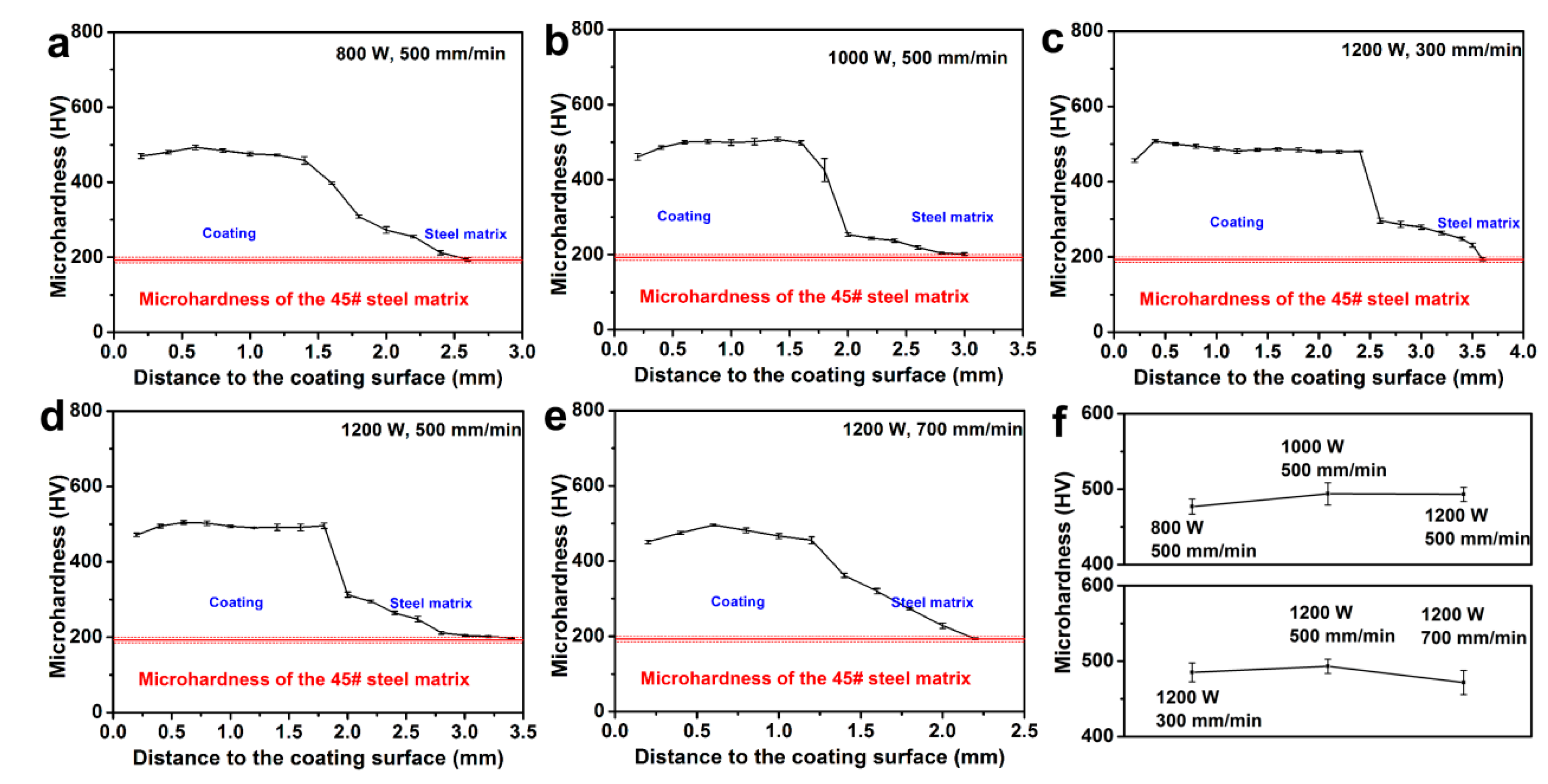

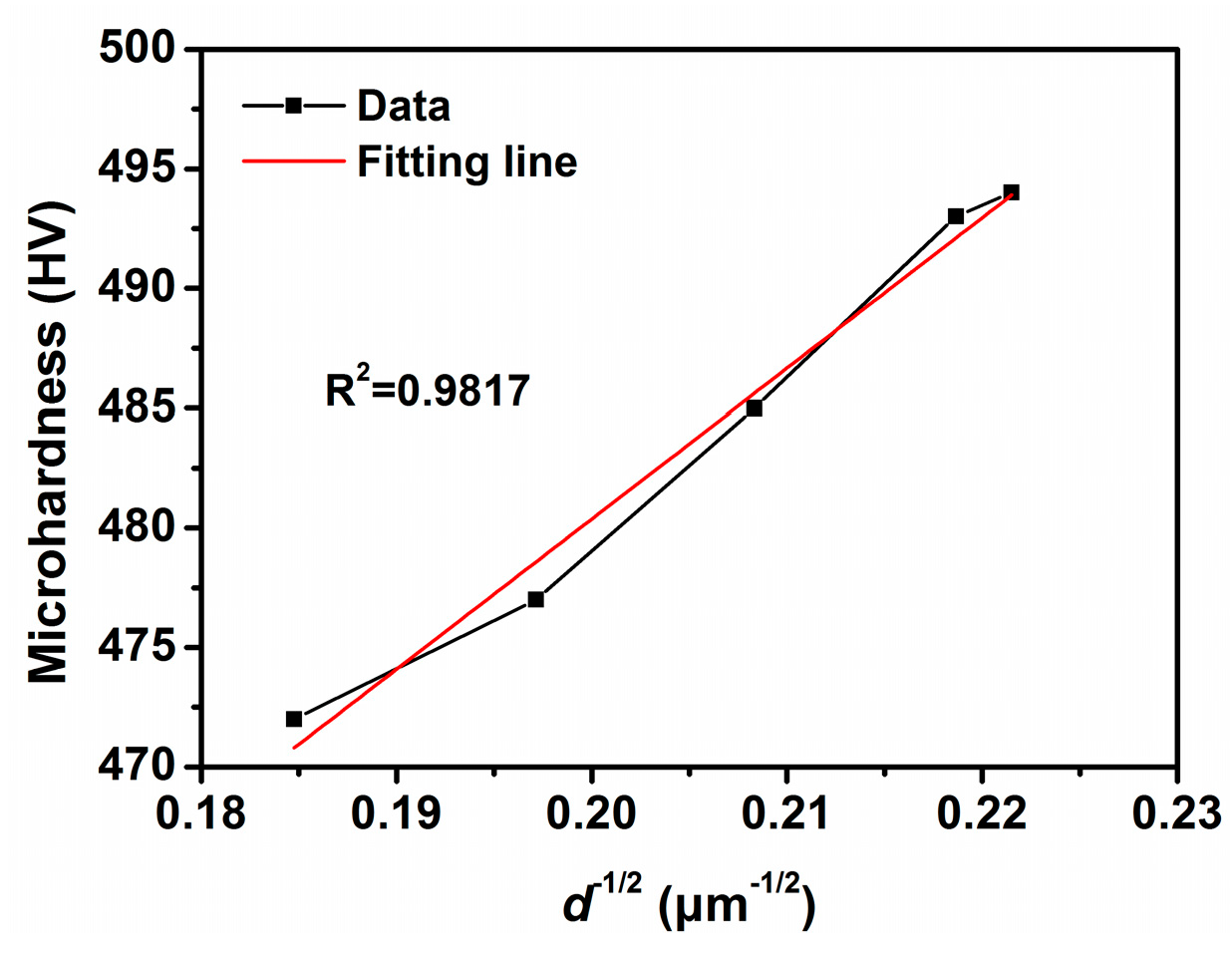

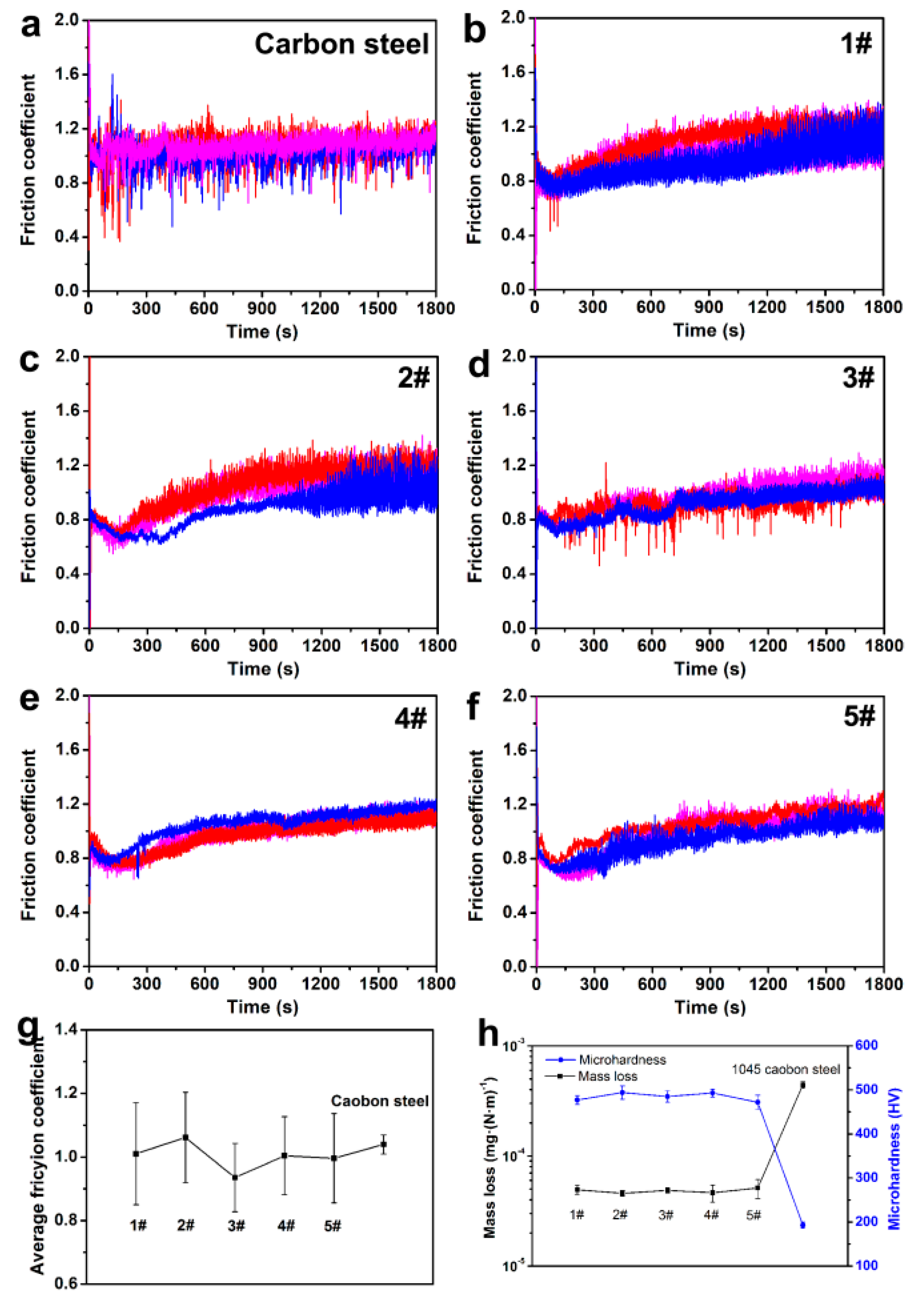

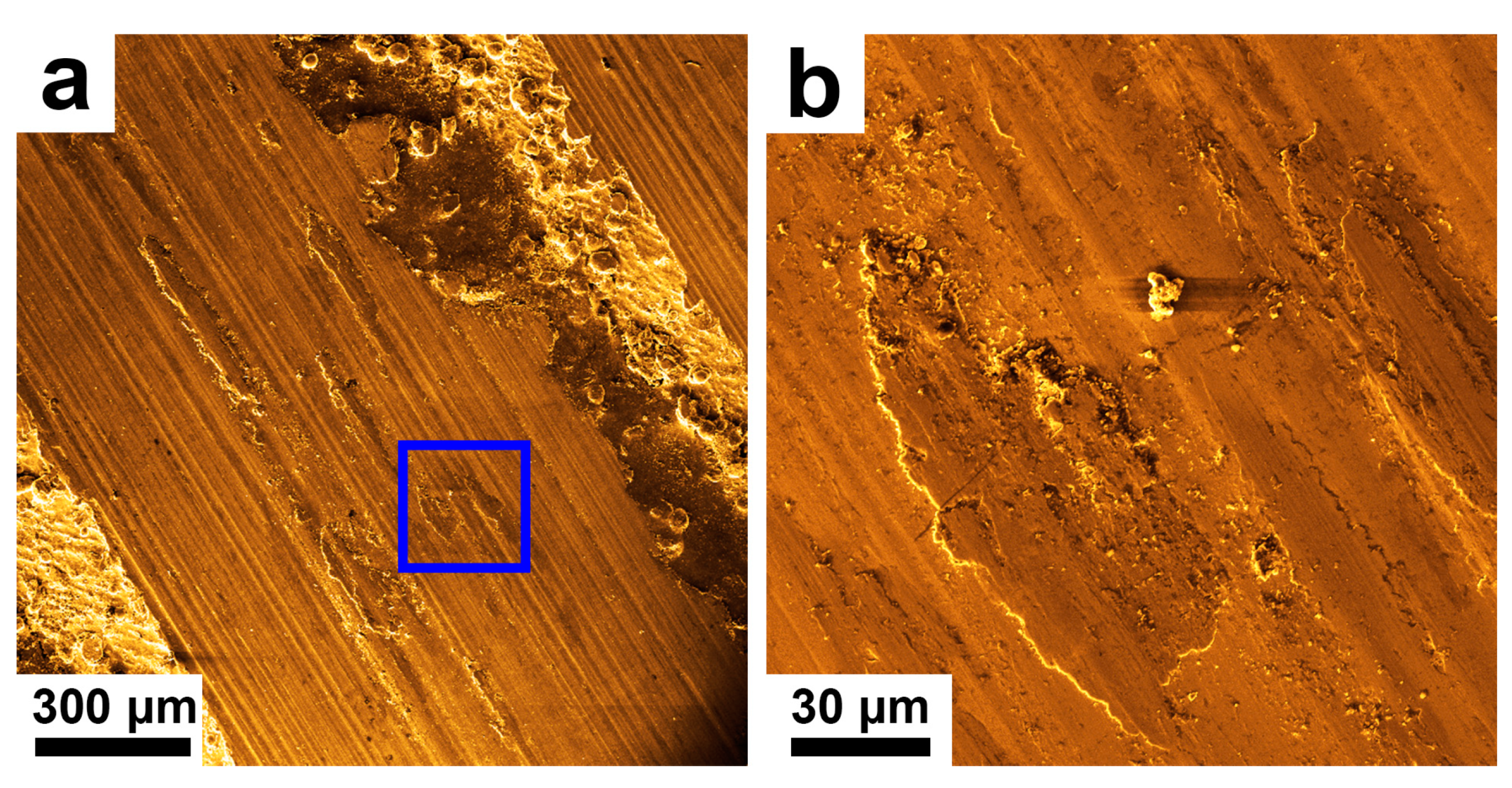

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fu, Z.K.; Ding, H.H.; Wang, W.J.; Liu, Q.Y.; Guo, J.; Zhu, M.H. Investigation on microstructure and wear characteristic of laser cladding Fe-based alloy on wheel/rail materials. Wear 2015, 330, 592–599. [Google Scholar] [CrossRef]

- Guo, Y.X.; Shang, X.J.; Liu, Q.B. Microstructure and properties of in-situ tin reinforced laser cladding CoCr2FeNiTix high-entropy alloy composite coatings. Surf. Coat. Technol. 2018, 344, 353–358. [Google Scholar] [CrossRef]

- Mao, J.; Feng, A.; Cheng, B.; Li, Z.; Wu, H.; Huang, Y.; Zhang, H. Microstructure and friction and wear properties of Fe-based alloy coatings by laser cladding. Hot Work. Technol. 2017, 46, 139–142. [Google Scholar]

- Hua, H.; Ting, Z.; Ma, M.; Liu, W. Microstructure and wear resistance of laser cladding particulate reinforced Fe-based composite coating on railway steel. J. Laser Appl. 2017, 29, 022503. [Google Scholar]

- Kumar, S.; Mandal, A.; Das, A.K.; Dixit, A.R. Parametric study and characterization of AlN–Ni–Ti6Al4V composite cladding on titanium alloy. Surf. Coat. Technol. 2018, 349, 37–49. [Google Scholar] [CrossRef]

- Wang, K.M.; Chang, B.H.; Lei, Y.P.; Fu, H.G.; Lin, Y.H. Effect of cobalt on microstructure and wear resistance of Ni-based alloy voating fabricated by laser cladding. Metals 2017, 7, 12. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.H.; Fan, D.Y.; Chen, S.H. Microstructure and wear properties of Fe–6wt.%Cr–0.55wt.%C–xwt.%Nb laser cladding coating and the mechanism analysis. Mater. Des. 2015, 88, 1031–1041. [Google Scholar] [CrossRef]

- Bai, L.; Le, G.; Liu, X.; Li, J.; Xi, S.; Li, X. Grain morphologies and microstructures of laser melting deposited V-5Cr-5Ti alloys. J. Alloys Compd. 2018, 745, 716–724. [Google Scholar] [CrossRef]

- Chen, J.L.; Zhou, Y.J.; Shi, C.; Mao, D.H. Microscopic analysis and electrochemical behavior of Fe-based coating produced by laser cladding. Metals 2017, 7, 9. [Google Scholar] [CrossRef]

- Weng, Z.K.; Wang, A.H.; Wang, Y.Y.; Xiong, D.H.; Tang, H.Q. Diode laser cladding of Fe–based alloy on ductile cast iron and related interfacial behavior. Surf. Coat. Technol. 2016, 286, 64–71. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.S.; Qian, S.N.; Yu, Q.; Dong, C. Microstructure and wear resistance of laser-clad (Co, Ni)(61.2)B26.2Si7.8Ta4.8 coatings. Metals 2017, 7, 7. [Google Scholar] [CrossRef]

- Zhang, H.; Chong, K.; Zhao, W.; Sun, Z.P. Effects of pulse parameters on in-situ Ti-V carbides size and properties of Fe-based laser cladding layers. Surf. Coat. Technol. 2018, 344, 163–169. [Google Scholar] [CrossRef]

- Li, G.; Cui, Y.; Zhang, N.; Wang, X.; Xie, J.L. The precipitation in annealing and its effect on permittivity of Fe-Si-Al powders. Physica B 2016, 481, 1–7. [Google Scholar] [CrossRef]

- Fernandes, L.; Silva, F.J.G.; Paiva, O.C.; Baptista, A.; Pinto, G. Minimizing the adhesion effects in food packages forming by the use of advanced coatings. Procedia Manuf. 2018, 17, 886–894. [Google Scholar] [CrossRef]

- Fernandes, L.; Silva, F.J.G.; Andrade, M.F.; Alexandre, R.; Baptista, A.P.M.; Rodrigues, C. Improving the punch and die wear behavior in tin coated steel stamping process. Surf. Coat. Technol. 2017, 332, 174–189. [Google Scholar] [CrossRef]

- Krajewski, W.K.; Greer, A.L.; Krajewski, P.K. Trends in the development of high-aluminium zinc alloys of stable structure and properties. Arch. Metall. Mater. 2013, 58, 845–847. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Li, Y.J.; Dong, S.Y.; Yan, S.X.; He, P.; Xu, B.S. Phase evolution of ductile iron during laser cladding processing. Surf. Coat. Technol. 2018, 339, 37–47. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, X.L.; Jing, T.F. Effect of initial microstructure on warm deformation behavior of 45 steel. J. Iron Steel Res. Int. 2012, 19, 75–78. [Google Scholar] [CrossRef]

- Lu, S.Y.; Yao, K.F.; Chen, Y.B.; Wang, M.H.; Liu, X.; Ge, X.Y. The effect of tempering temperature on the microstructure and electrochemical properties of a 13wt.% Cr-type martensitic stainless steel. Electrochim. Acta 2015, 165, 45–55. [Google Scholar] [CrossRef]

- Wang, Y.F.; Li, G.; Wang, C.S.; Xia, Y.L.; Sandip, B.; Dong, C. Microstructure and properties of laser clad Zr-based alloy coatings on Ti substrates. Surf. Coat. Technol. 2004, 176, 284–289. [Google Scholar] [CrossRef]

- Lee, Y.S.; Ha, S.; Park, J.H.; Lee, S.B. Structure-dependent mechanical behavior of copper thin films. Mater. Charact. 2017, 128, 68–74. [Google Scholar] [CrossRef]

- Raynor, D.; Silcock, J.M. Strengthening mechanisms in γ′ precipitating alloys. Met. Sci. J. 1970, 4, 121–130. [Google Scholar] [CrossRef]

- Andrade, M.F.C.; Martinho, R.P.; Silva, F.J.G.; Alexandre, R.J.D.; Baptista, A.P.M. Influence of the abrasive particles size in the micro-abrasion wear tests of TiAlSiN thin coatings. Wear 2009, 267, 12–18. [Google Scholar] [CrossRef]

- Pereira, D.; Gandra, J.; Pamies-Teixeira, J.; Miranda, R.M.; Vilaca, P. Wear behaviour of steel coatings produced by friction surfacing. J. Mater. Process. Technol. 2014, 214, 2858–2868. [Google Scholar] [CrossRef]

- Deng, X.K.; Zhang, G.J.; Wang, T.; Ren, S.; Bai, Z.L.; Cao, Q. Investigations on microstructure and wear resistance of Fe-Mo alloy coating fabricated by plasma transferred arc cladding. Surf. Coat. Technol. 2018, 350, 480–487. [Google Scholar] [CrossRef]

- Chen, X.; Qin, X.; Zhu, Z.; Gao, K. Microstructural evolution and wear properties of the continual local induction cladding NiCrBSi coatings. J. Mater. Process. Technol. 2018, 262, 257–268. [Google Scholar] [CrossRef]

- Wang, Z. Microstructure and wear resistance of laser-cladding NiCrSiB coating. Spec. Cast. Nonferr. Alloys 2013, 33, 509–511. [Google Scholar]

- Liu, X.; Liu, H.; Wang, D.; Wang, E.P.; Liu, W.J.; Yao, K.F.; Chen, N. Metallic glass-strengthened thermoplastic elastomer composites. Physica E 2017, 90, 37–41. [Google Scholar] [CrossRef]

| Sample No. | Laser Powder (W) | Scan Speed (mm/min) | Heat Import (kJ) |

|---|---|---|---|

| Specimen 1 | 800 | 500 | 403 |

| Specimen 2 | 1000 | 500 | 468 |

| Specimen 3 | 1200 | 300 | 744 |

| Specimen 4 | 1200 | 500 | 432 |

| Specimen 5 | 1200 | 700 | 319 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Ma, B.-B.; Hu, L.-W.; Li, J.-F.; Qu, F.-S.; Le, G.-M.; Li, X.-Y. Fe–Si–Al Coatings with Stable Wear Resistance Prepared by Laser Cladding Industrial Wastes. Metals 2019, 9, 96. https://doi.org/10.3390/met9010096

Liu X, Ma B-B, Hu L-W, Li J-F, Qu F-S, Le G-M, Li X-Y. Fe–Si–Al Coatings with Stable Wear Resistance Prepared by Laser Cladding Industrial Wastes. Metals. 2019; 9(1):96. https://doi.org/10.3390/met9010096

Chicago/Turabian StyleLiu, Xue, Bin-Bin Ma, Li-Wei Hu, Jin-Feng Li, Feng-Sheng Qu, Guo-Min Le, and Xiu-Yan Li. 2019. "Fe–Si–Al Coatings with Stable Wear Resistance Prepared by Laser Cladding Industrial Wastes" Metals 9, no. 1: 96. https://doi.org/10.3390/met9010096

APA StyleLiu, X., Ma, B.-B., Hu, L.-W., Li, J.-F., Qu, F.-S., Le, G.-M., & Li, X.-Y. (2019). Fe–Si–Al Coatings with Stable Wear Resistance Prepared by Laser Cladding Industrial Wastes. Metals, 9(1), 96. https://doi.org/10.3390/met9010096