Effect of Na2O and Rb2O on Inclusion Removal in C96V Saw Wire Steels Using Low-Basicity LF (Ladle Furnace) Refining Slags

Abstract

:1. Introduction

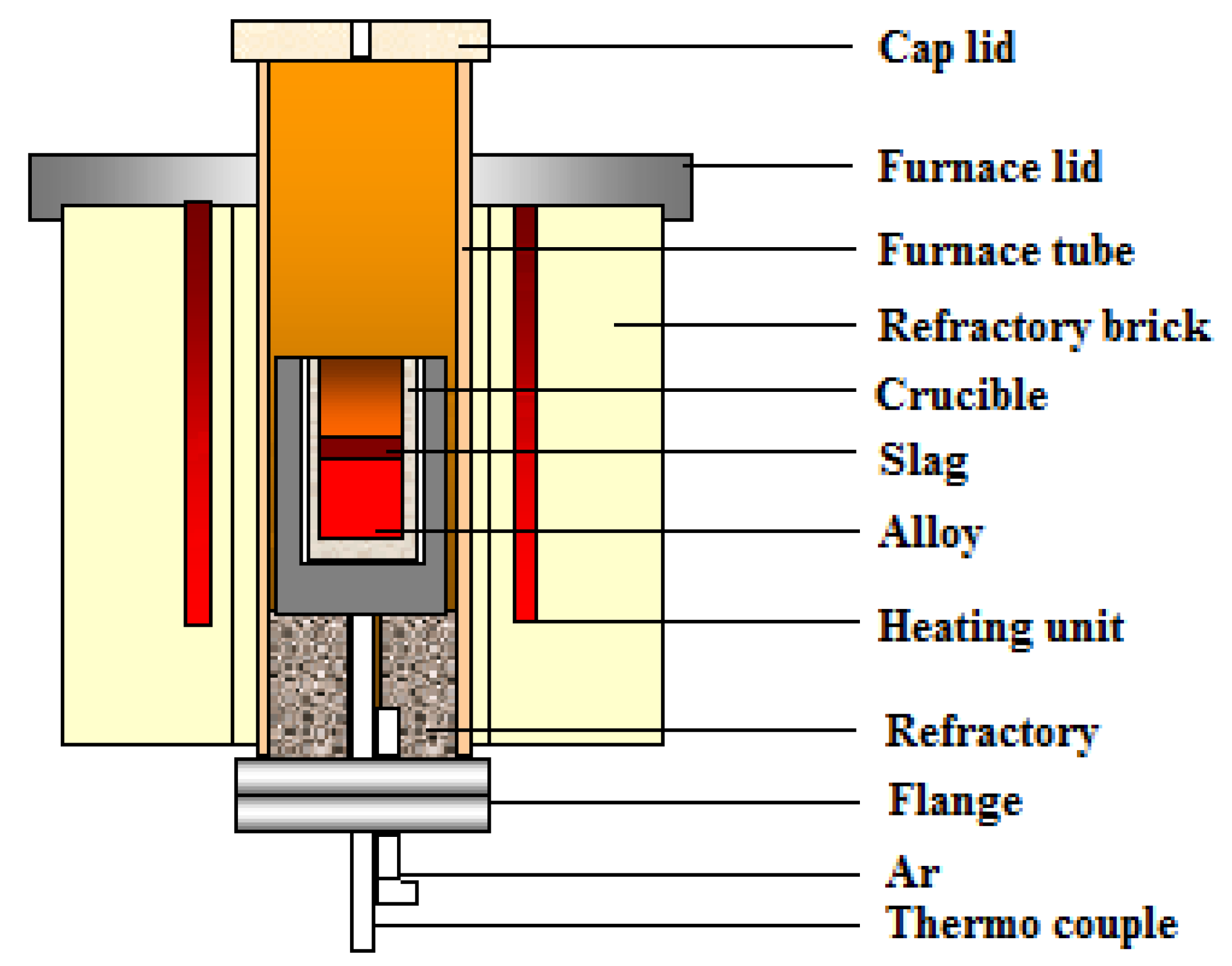

2. Experiment

2.1. Experimental Appratus and Procedure

2.2. Analysis Methods

3. Results

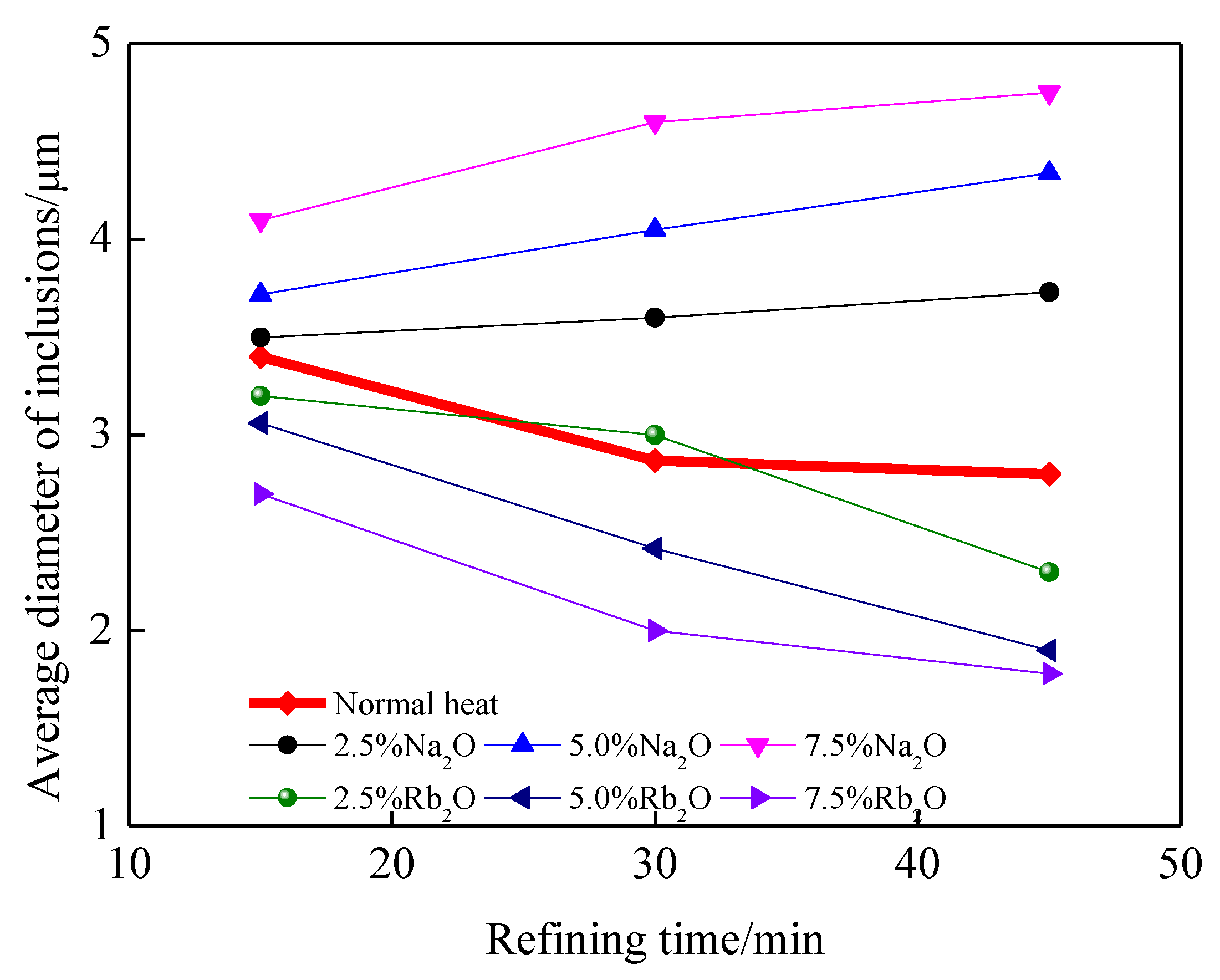

3.1. Effect of Na2O and Rb2O on the Variation in Inclusion Diameter

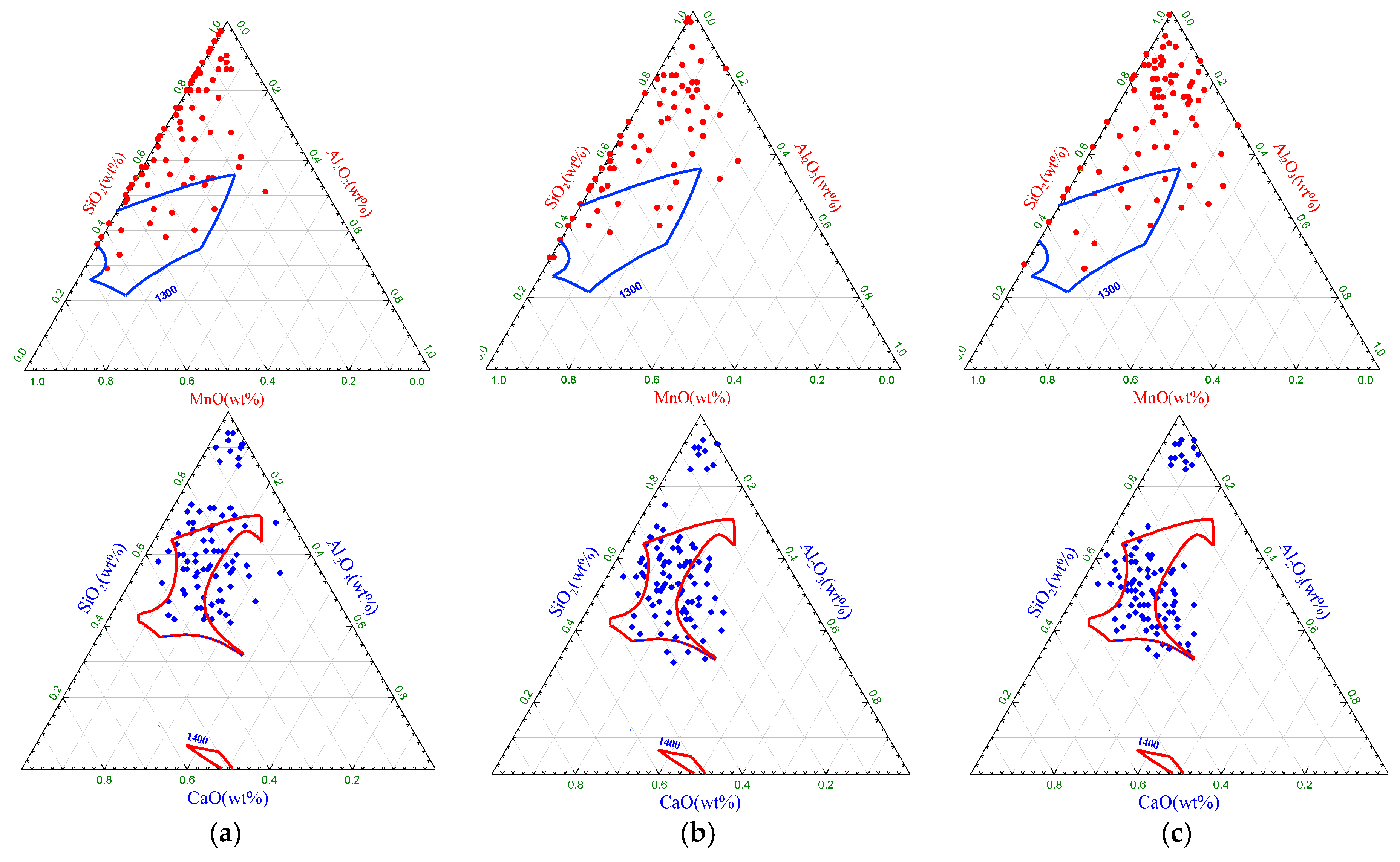

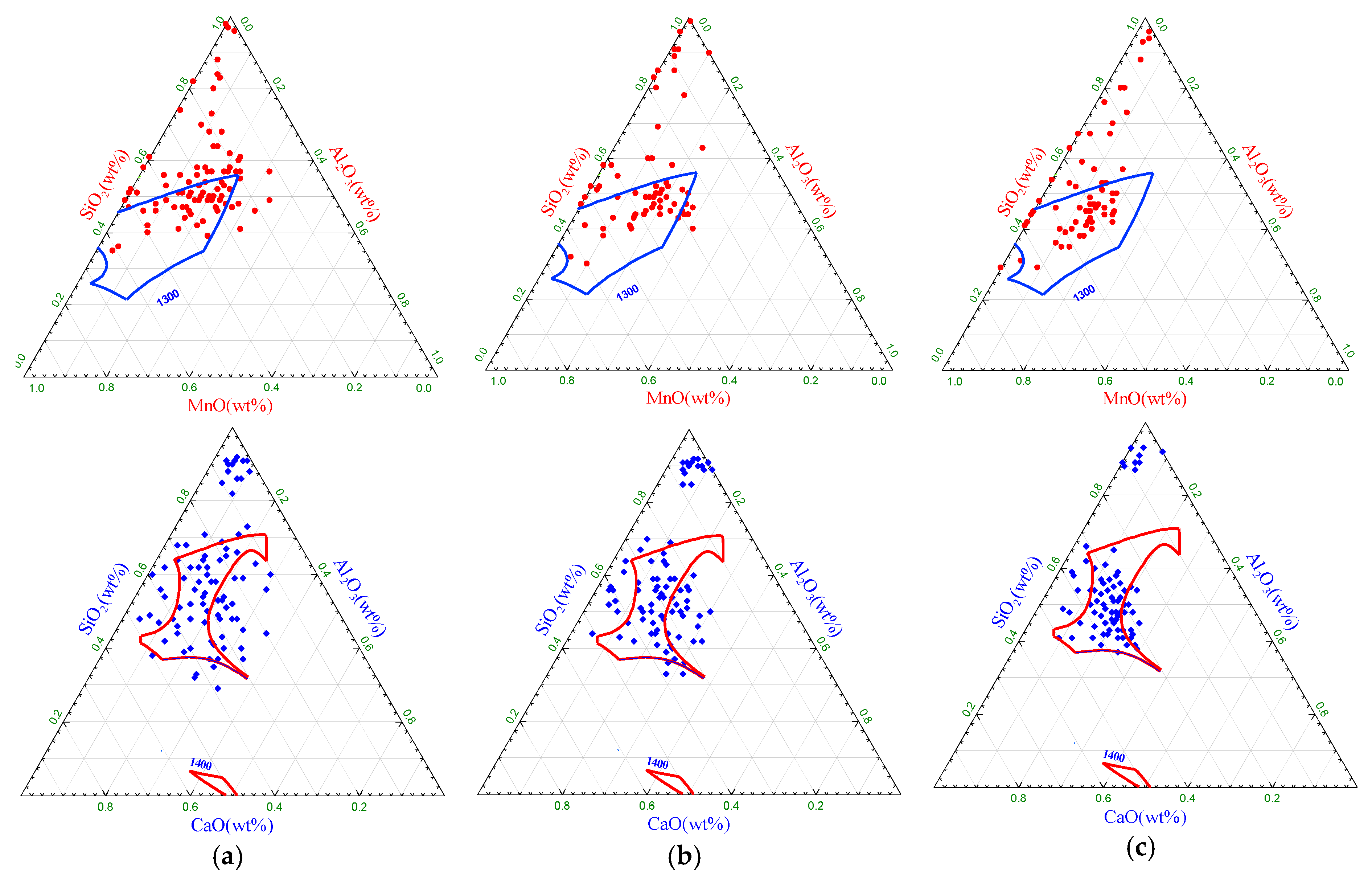

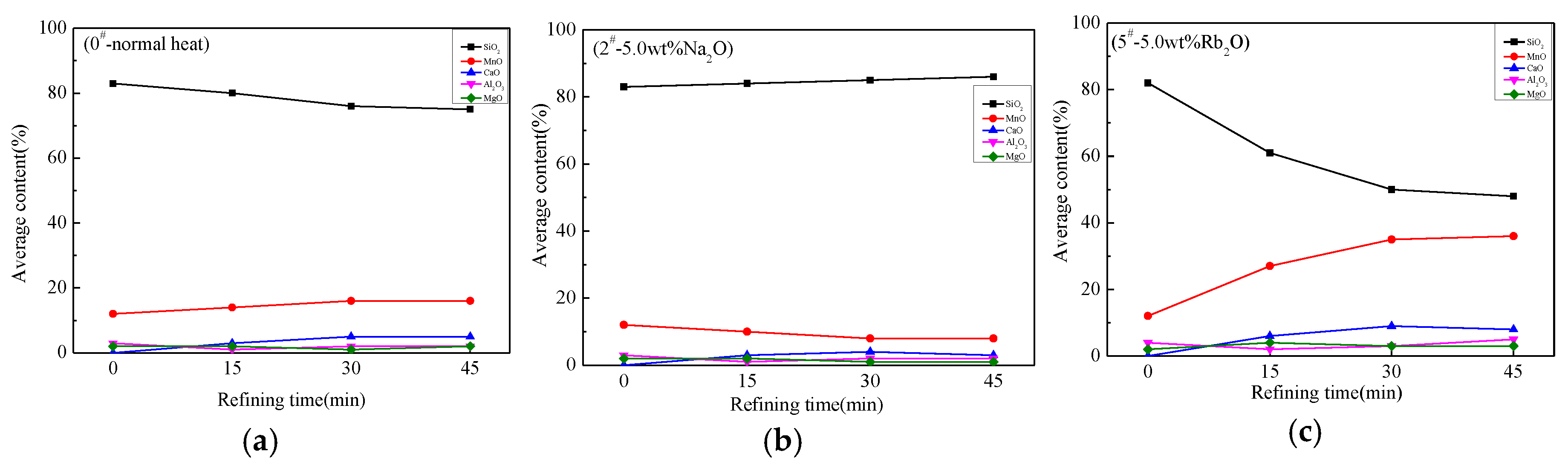

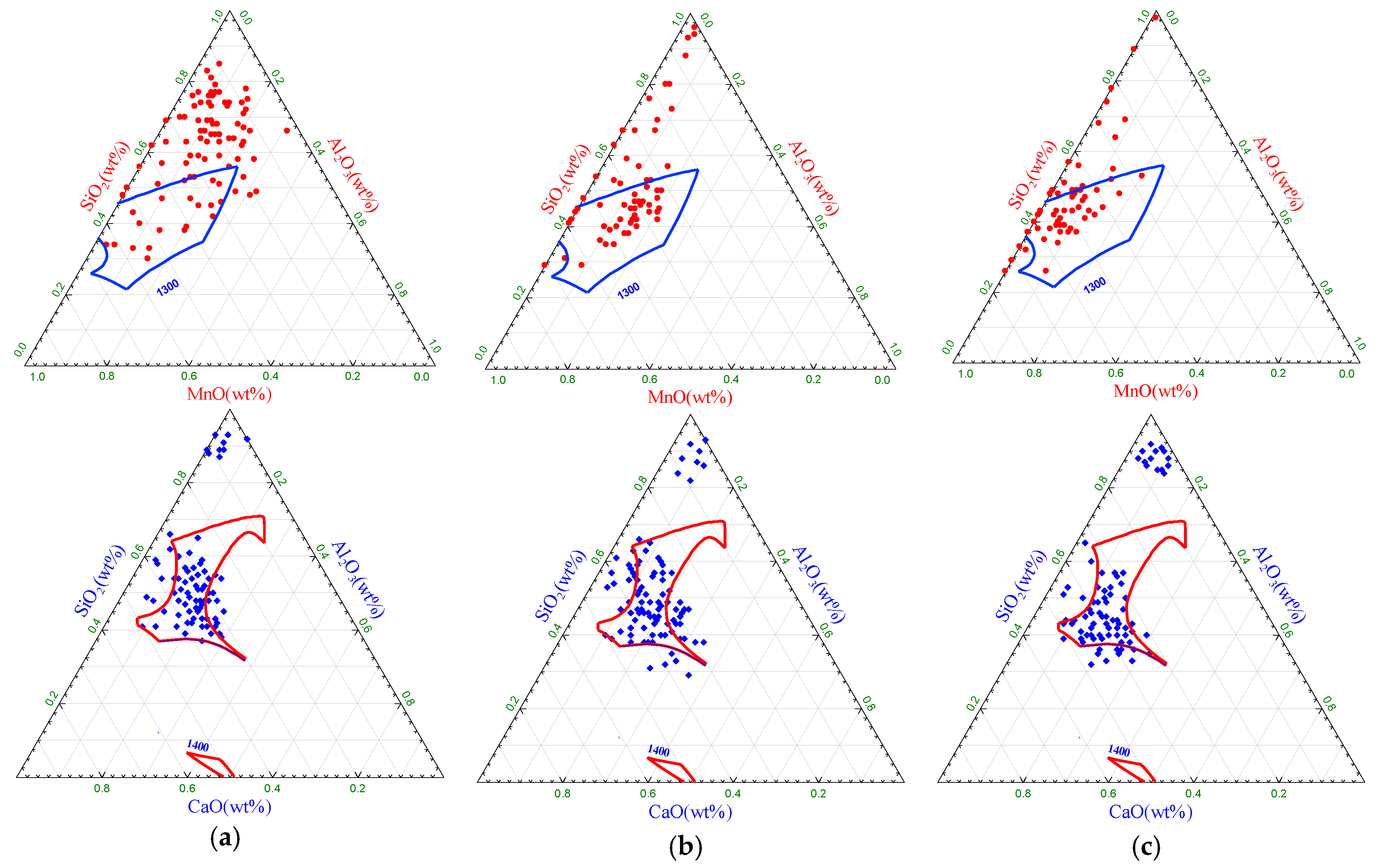

3.2. Effect of Na2O and Rb2O on Inclusion Distribution Overlayed on the Phase Diagram

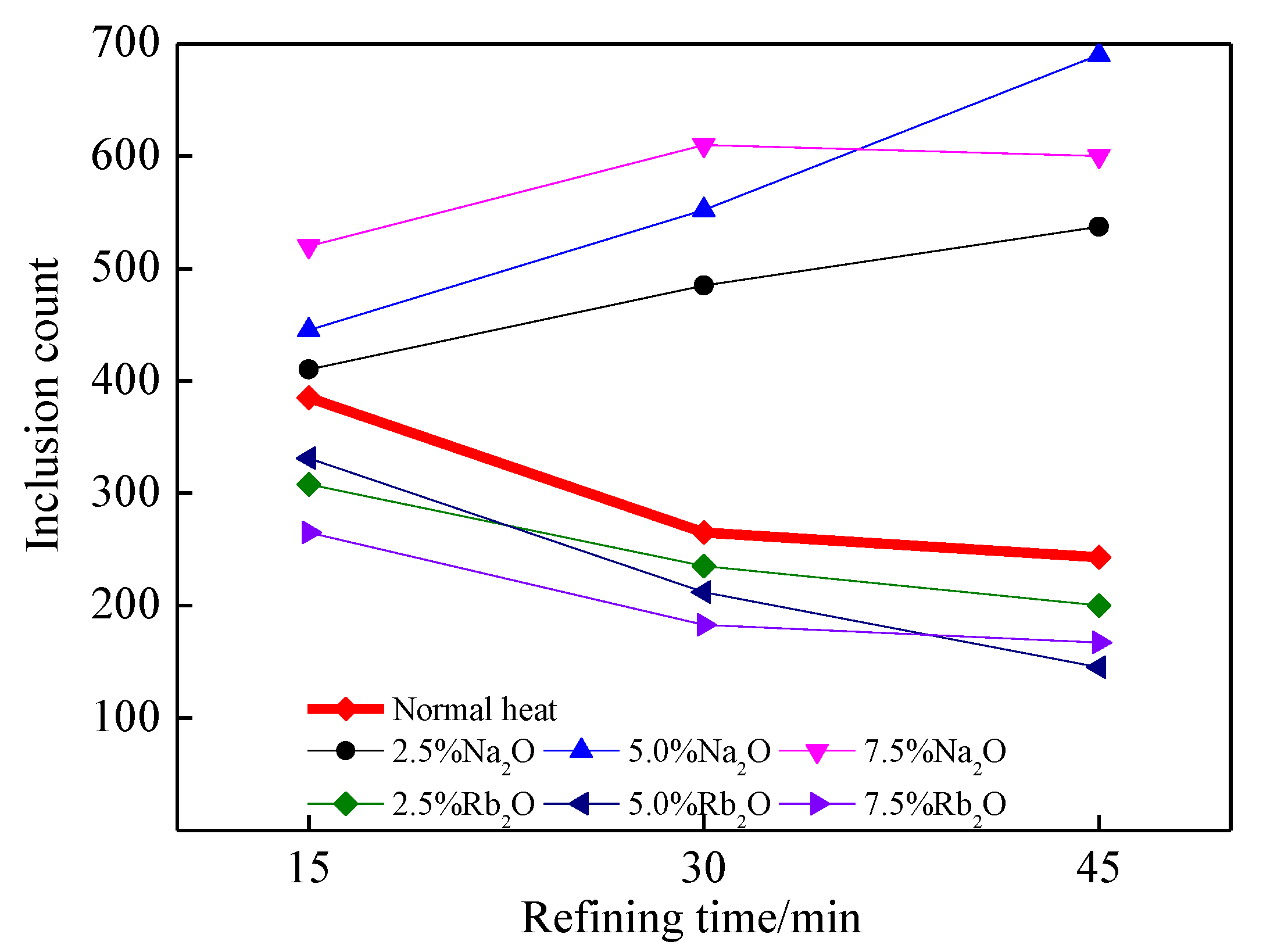

3.3. Influence of Na2O and Rb2O on the Number of Inclusions

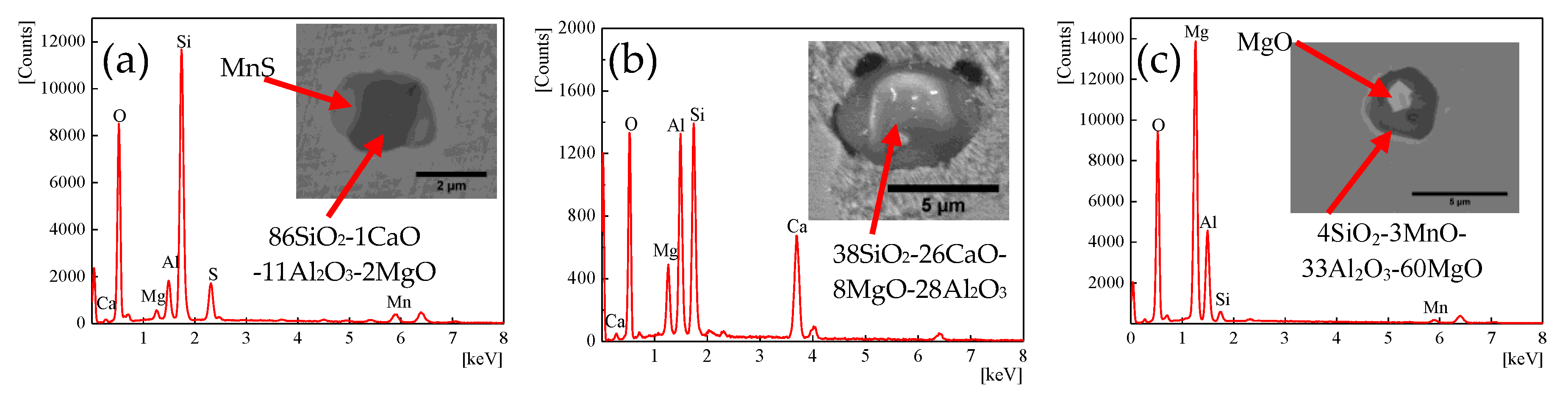

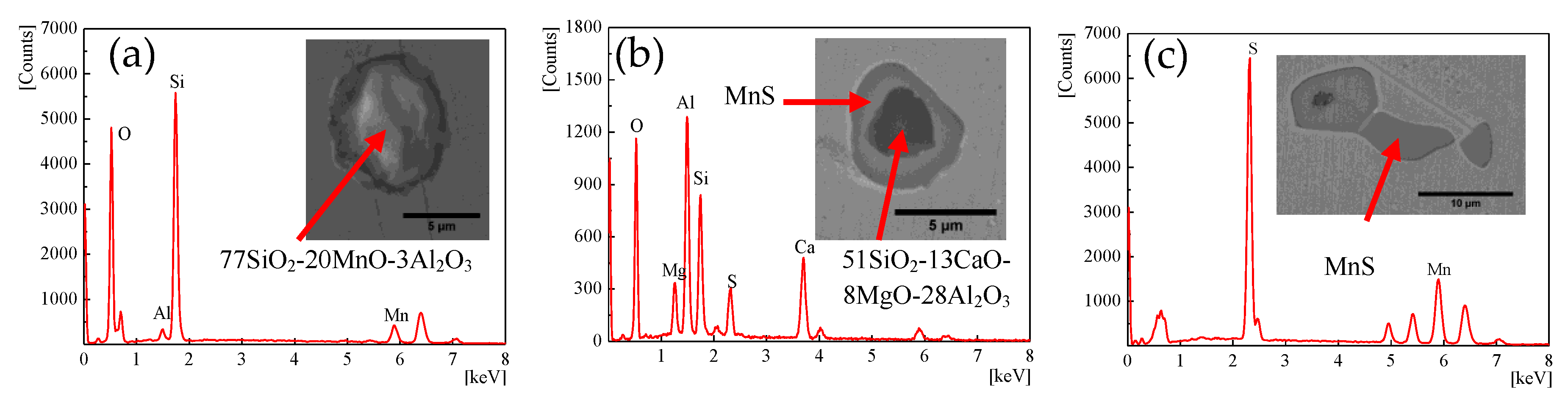

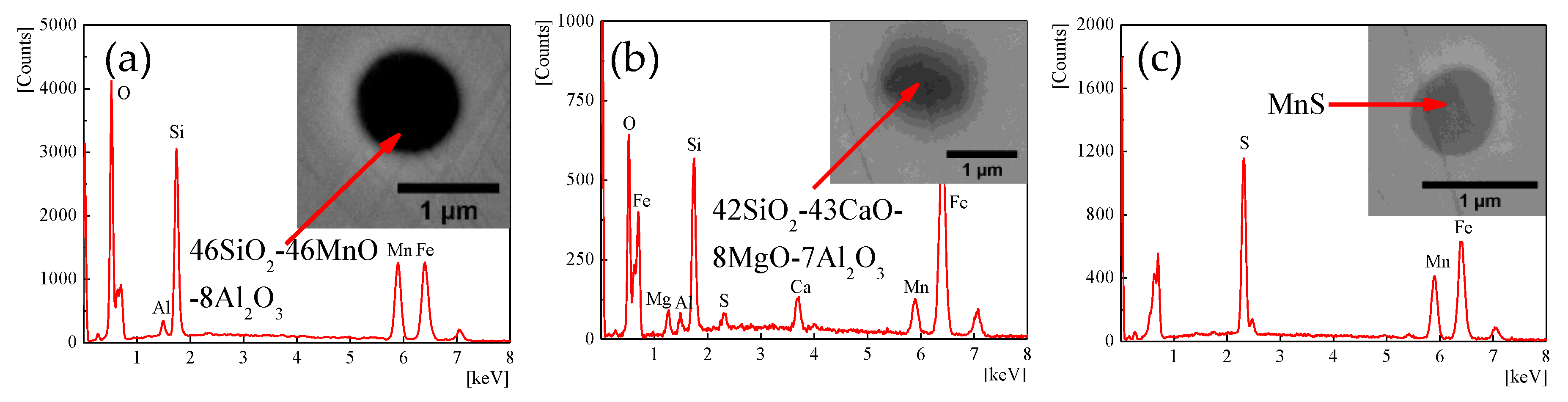

3.4. Morphology and Element Distribution of Typical Inclusions

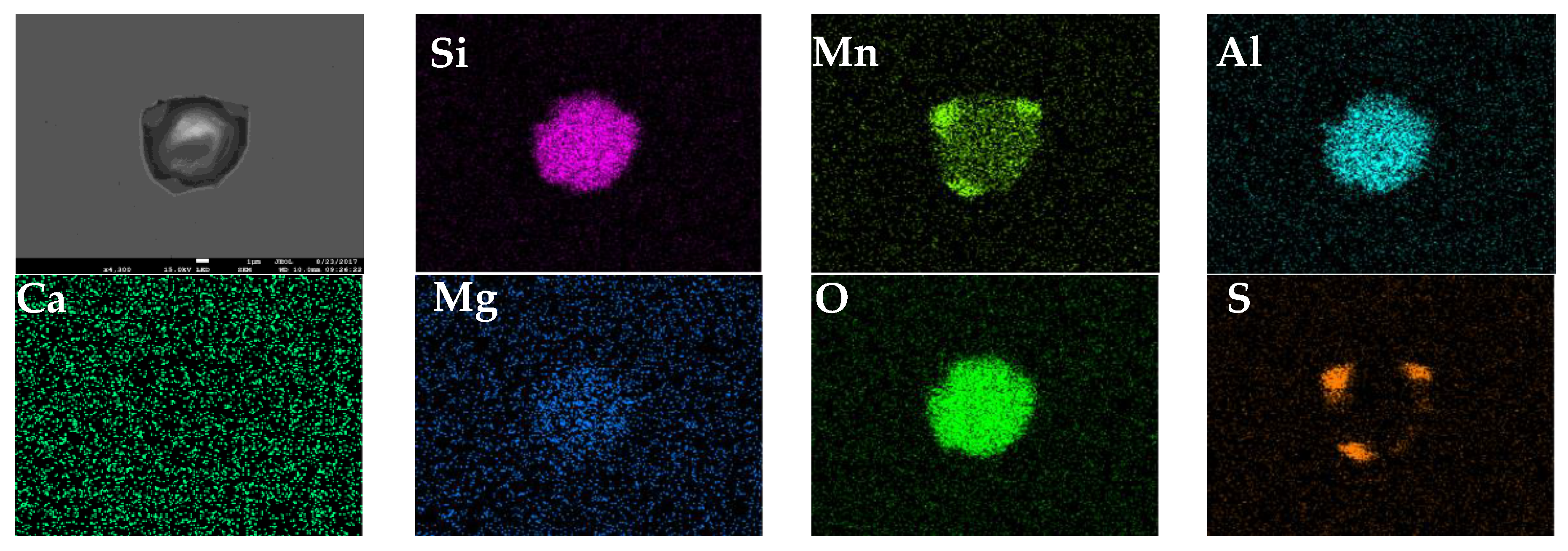

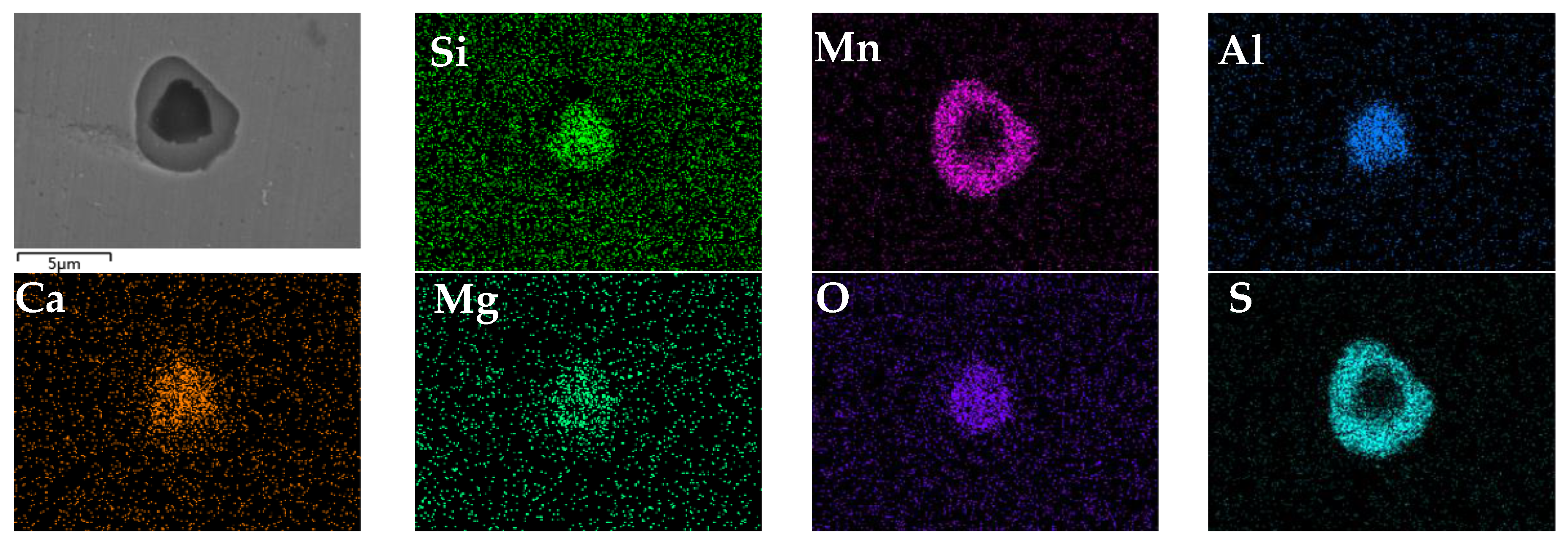

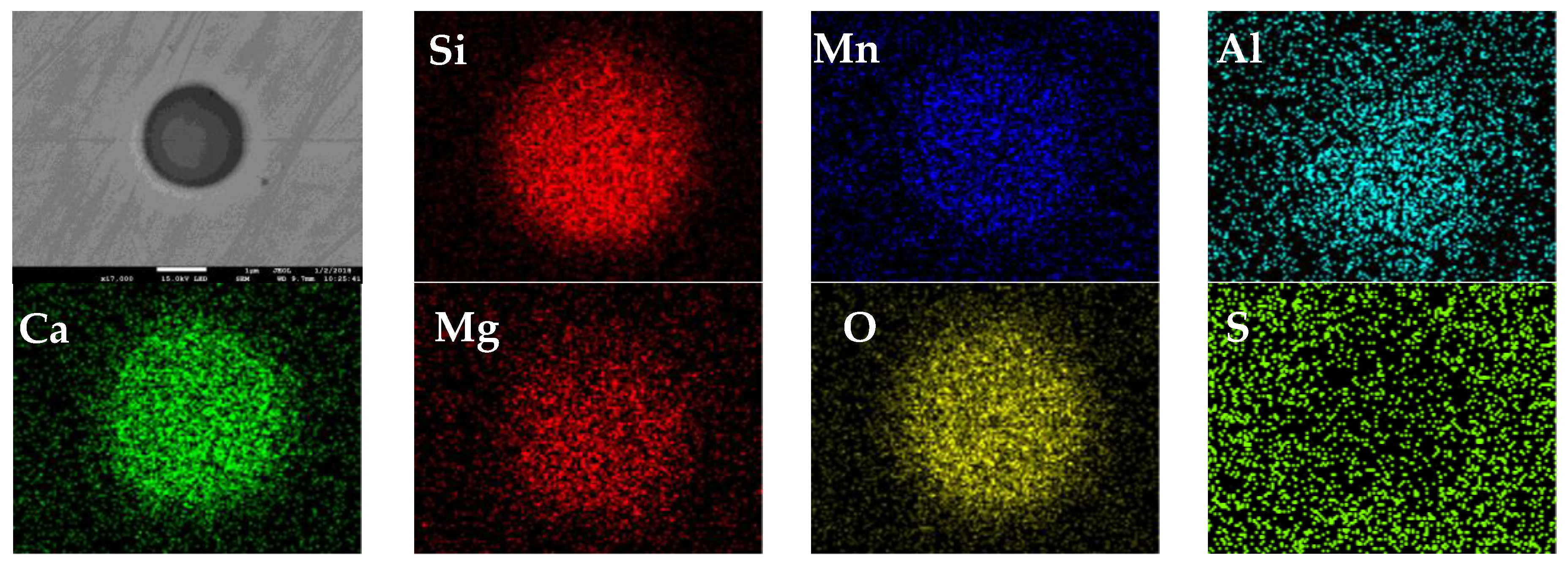

3.5. Element Distribution in Complex Inclusion

4. Discussion

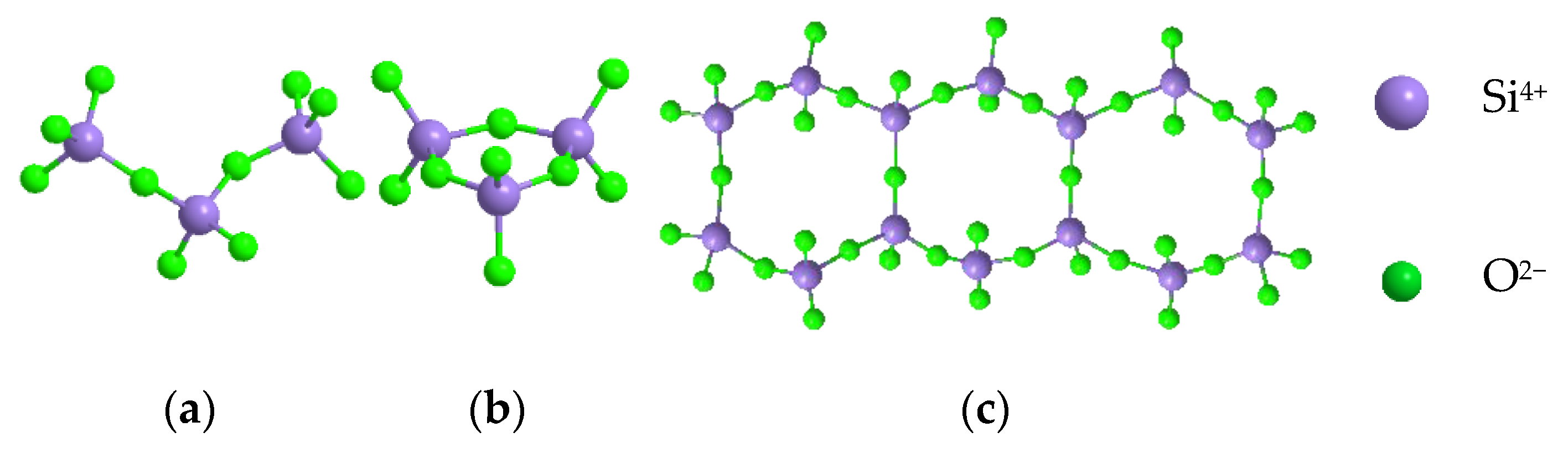

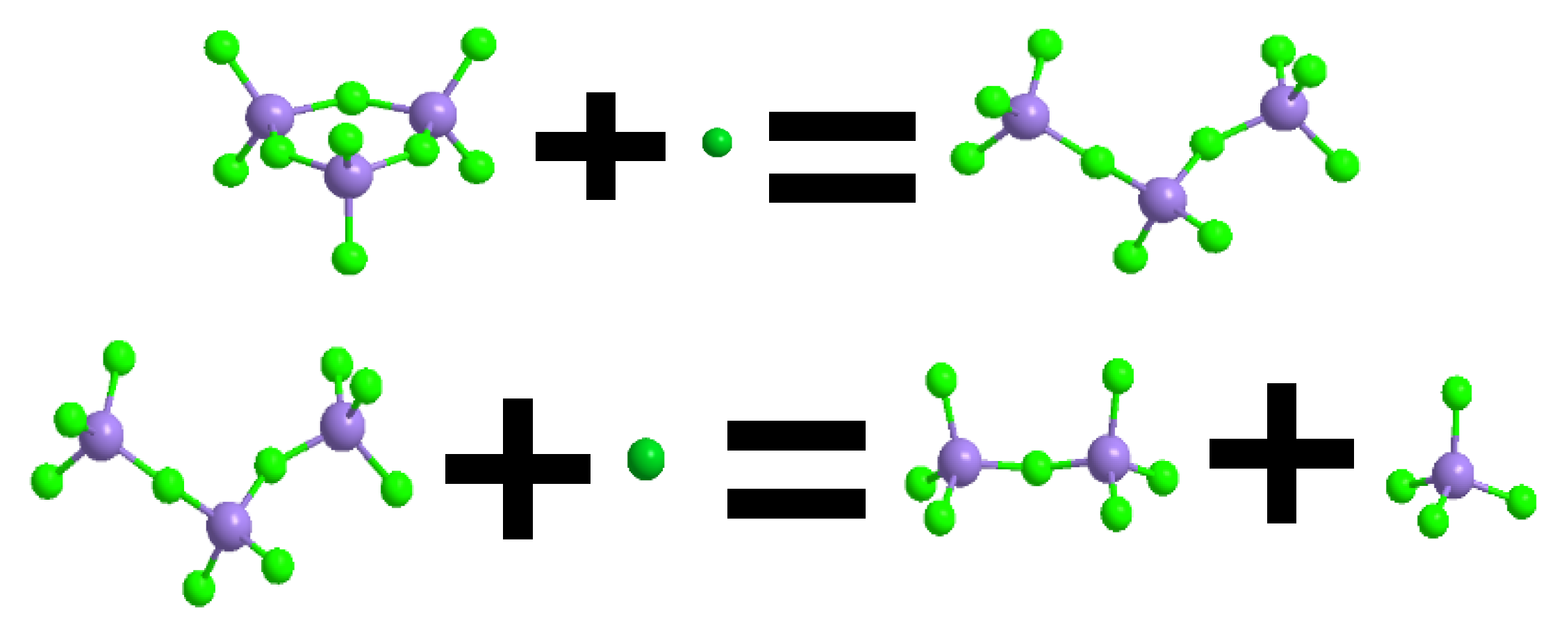

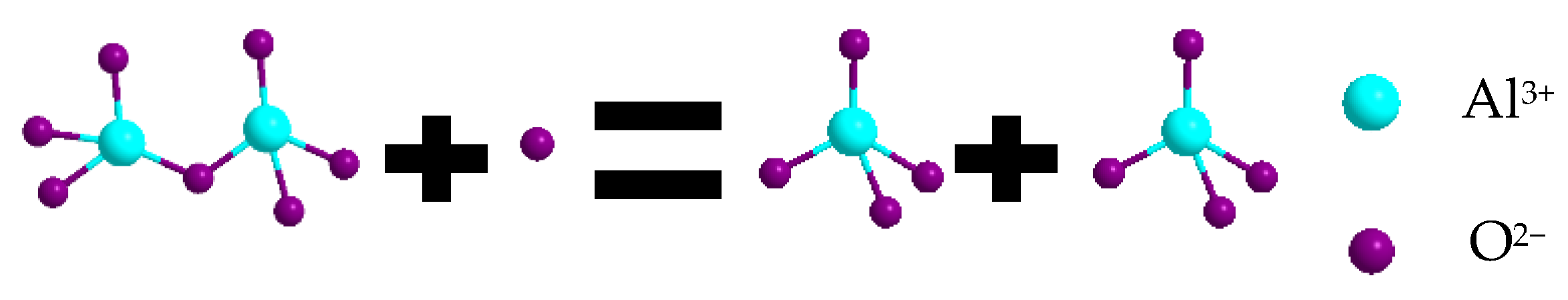

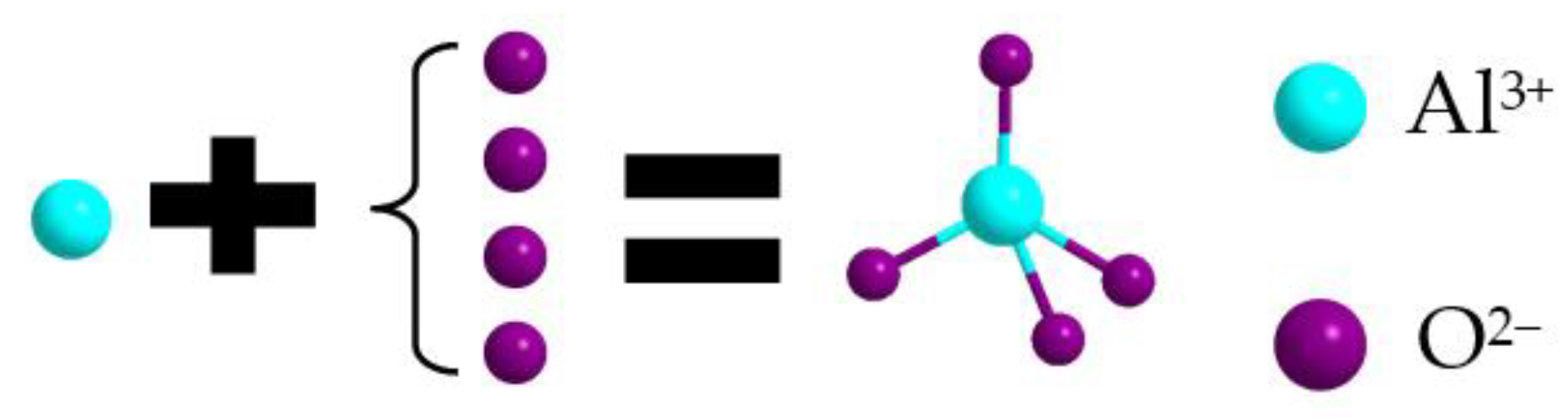

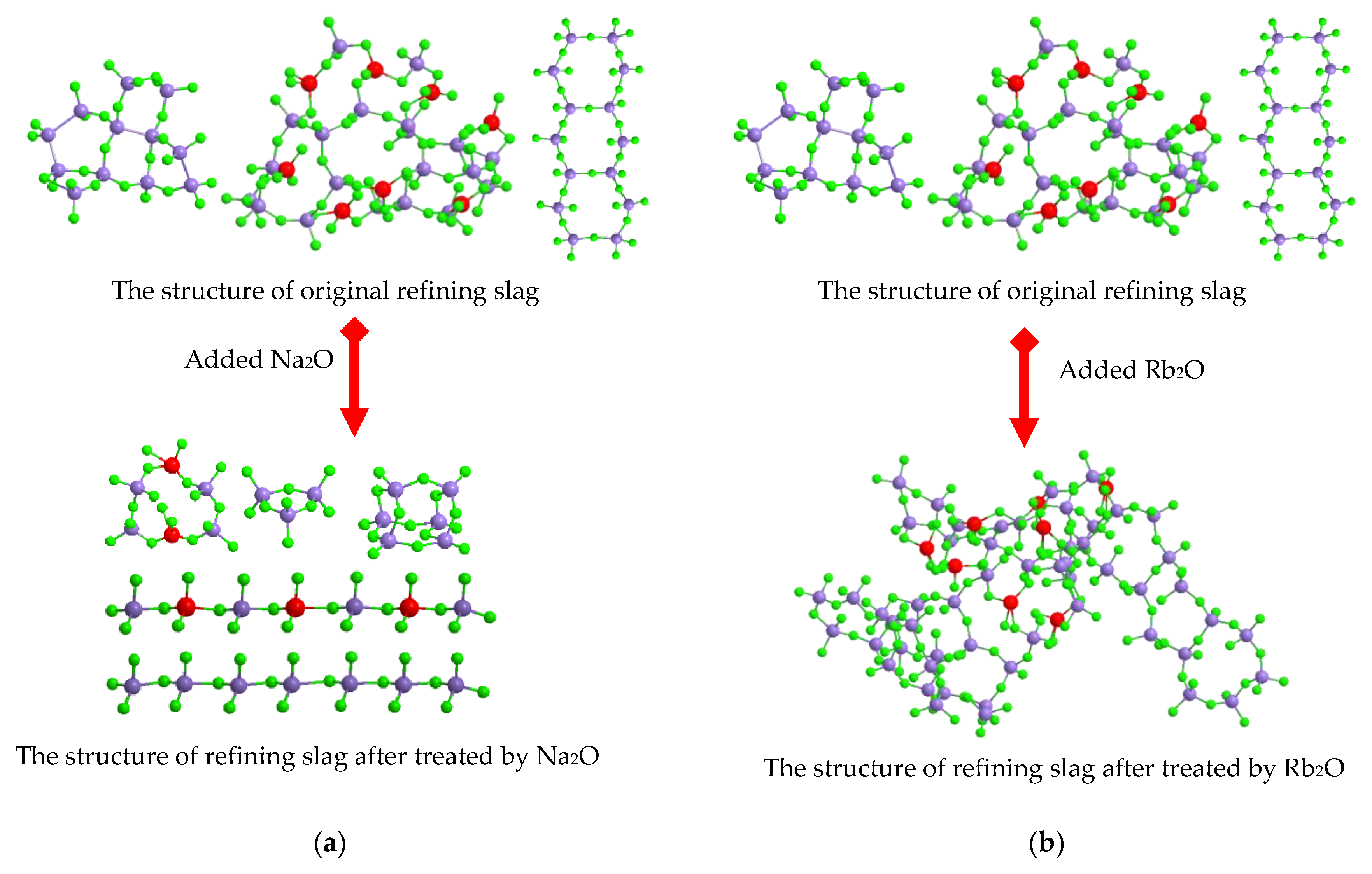

4.1. Influence of Na2O, Rb2O on the Structure and Viscosity of Metallurgical Slags

4.2. Influence of Na2O, Rb2O on the Ability of Slags to Absorb Inclusions

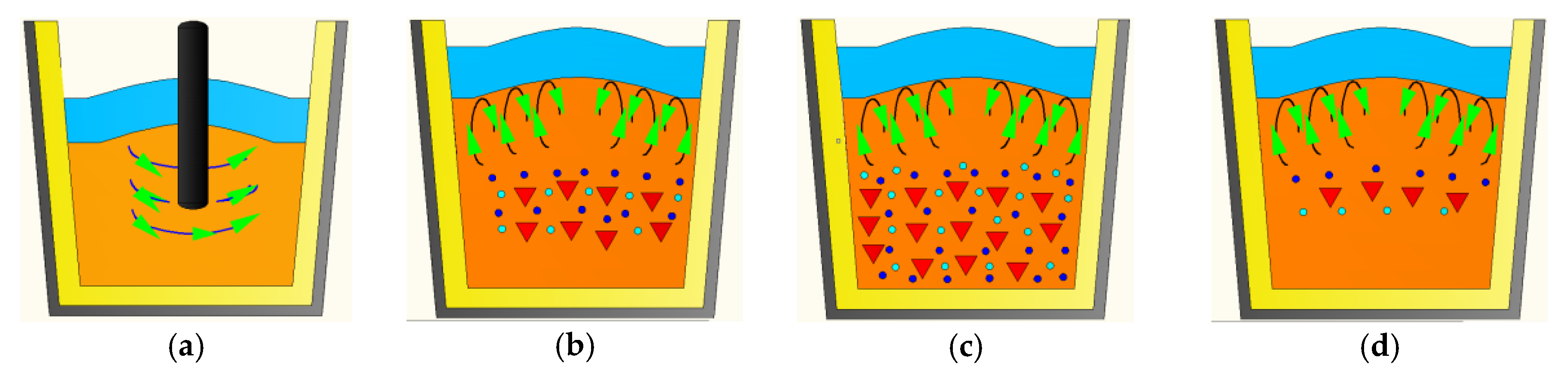

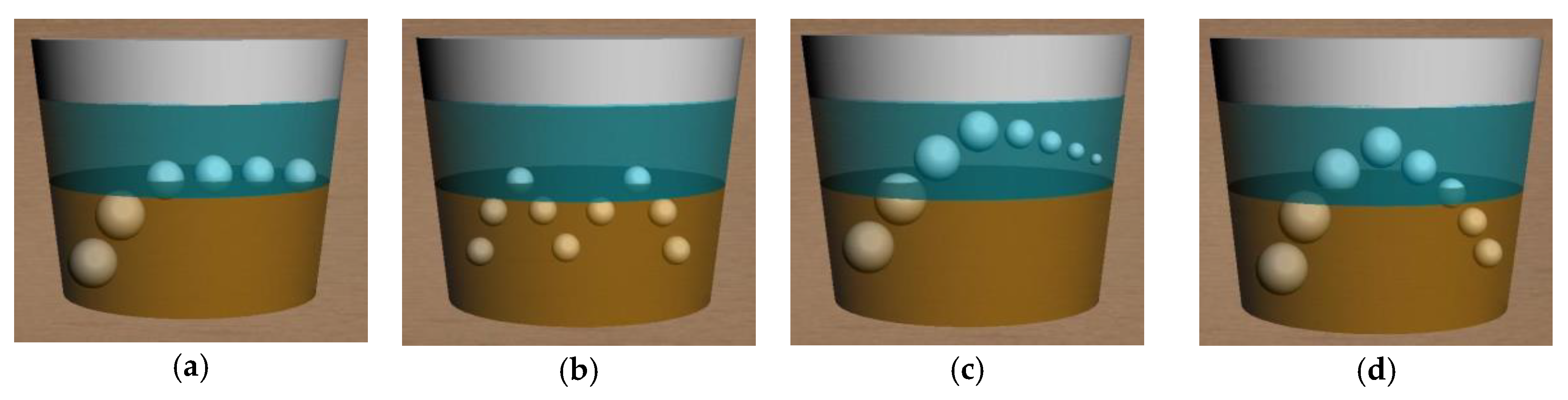

4.2.1. The Slag Entrapment during Refining Process

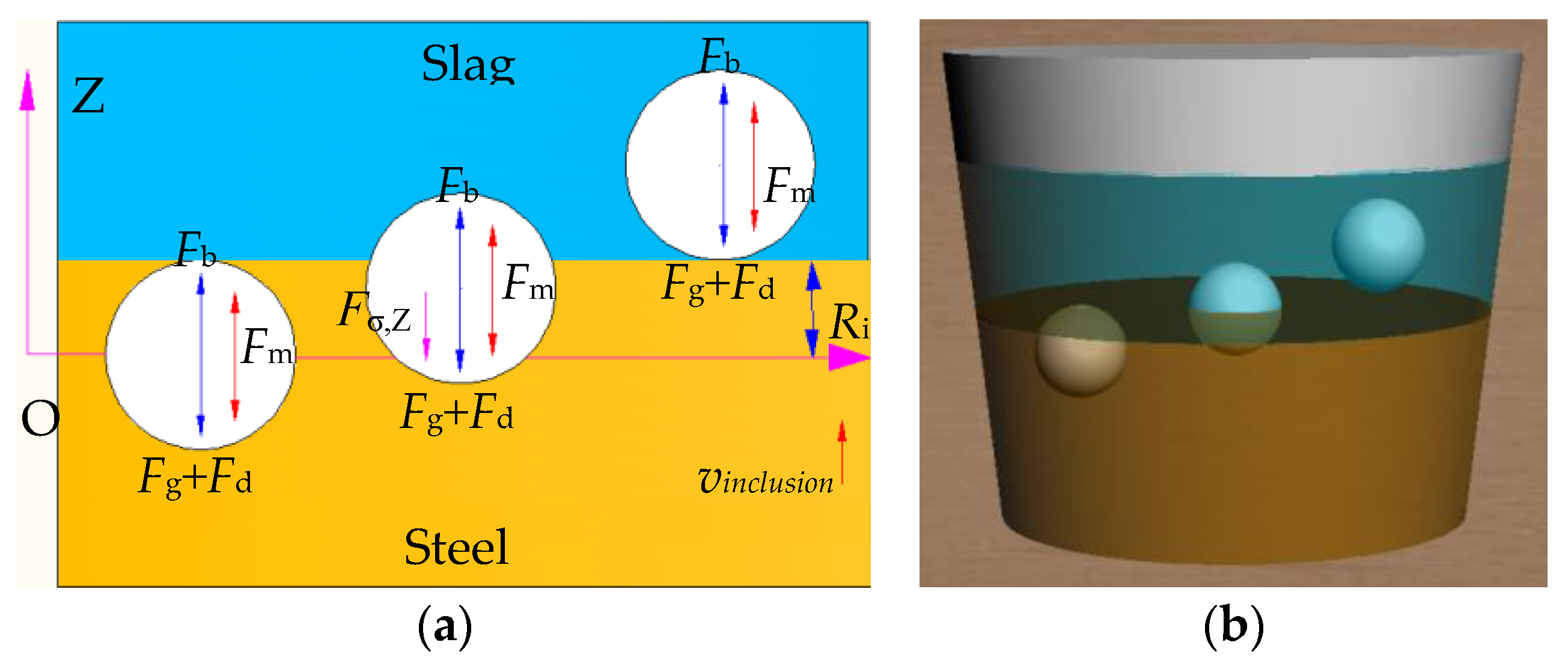

4.2.2. Influence of Na2O, Rb2O on the Second Stage: Separation of Liquid Steel

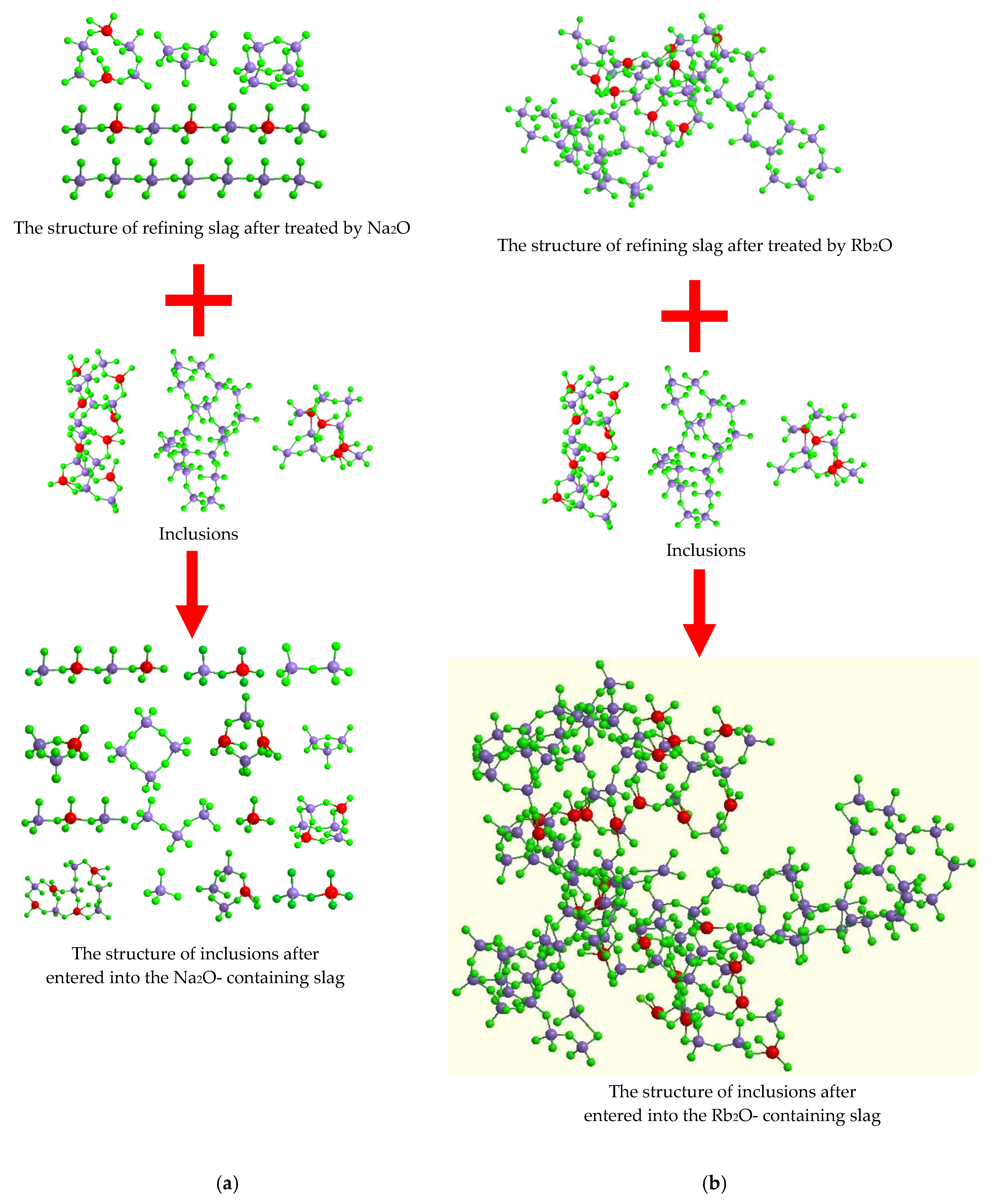

4.2.3. Influence of Na2O, Rb2O on the Third Stage: Dissolution in Slag

5. Conclusions

6. Future Work

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kirhara, K. Production technology of wire rod for high tensile strength steel cord. Kobelco Technol. Rev. 2011, 30, 62–65. [Google Scholar]

- Zhang, L. Fluid flow, heat transfer and inclusion motion in a four-strand billet continuous casting tundish. Steel Res. Int. 2005, 76, 784–796. [Google Scholar] [CrossRef]

- Fu, C.; Zhao, L. Fracture cause on SWRH72A hard wire. Phys. Test 2013, 31, 34–37. [Google Scholar]

- Zhang, L. State of the art in the control of inclusions in tire cord steels—A review. Steel Res. Int. 2006, 77, 158–169. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, M.; He, X.; Wang, X. Top slag refining for inclusion composition transform control in tire cord steel. Int. J. Min. Metall. Mater. 2012, 19, 490–498. [Google Scholar] [CrossRef]

- Cui, H.; Chen, W. Effect of boron on morphology of inclusions in tire cord steel. J. Iron Steel Res. Int. 2012, 19, 22–27. [Google Scholar] [CrossRef]

- Maede, S.; Soejima, T.; Saito, T.; Matsumoto, T.; Fujimoto, H.; Mimura, T. Shape control of inclusions in wire rods for high tensile tire cord by refining with synthetic slag. In Proceedings of the 72th Steelmaking Conference, Chigago, IL, USA, 2–5 April 1989; pp. 379–385. [Google Scholar]

- Chen, L.; Chen, W.; Hu, Y.; Chen, Z.; Xu, Y.; Yan, W. Effect of Na2CO3 addition on inclusions in high-carbon steel for saw wire. Trans. Indian Inst. Met. 2018, 71, 383–391. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, M.; Wang, X.; Wang, Y.; Zhao, H.; Cao, Z. Formation mechanism of SiO2-type inclusions in Si-Mn-killed steel wires containing limited aluminum content. Metall. Mater. Trans. B 2015, 46, 2198–2207. [Google Scholar] [CrossRef]

- Yang, W.; Guo, C.; Zhang, L.; Ling, H.; Li, C. Evolution of oxide inclusions in Si-Mn killed steels during hot-rolling process. Metall. Mater. Trans. B 2017, 48, 2717–2730. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, M.; Wang, X.; Wang, Y.; Zhao, H.; Cao, Z. Formation mechanism of CaO-SiO2-Al2O3-(MgO) inclusions in Si-Mn-killed steel with limited aluminum content during the low basicity slag refining. Metall. Mater. Trans. B 2016, 47, 282–290. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, M.; Wang, X.; Wang, Y.; Zhao, H.; Cao, Z. Study on formation mechanism of CaO-SiO2-Based inclusions in saw wire steel. Metall. Mater. Trans. B 2017, 48, 2961–2969. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, C.; Yang, W.; Ren, Y.; Ling, H. Deformability of oxide inclusions in tire cord steels. Metall. Mater. Trans. B 2018, 49, 803–811. [Google Scholar] [CrossRef]

- Yu, J.; Kang, Y.; Sohn, I. Novel application of alkali oxides in basic tundish fluxes for enhancing inclusion removal in 321 stainless steels. Metall. Mater. Trans. B 2014, 45, 113–122. [Google Scholar] [CrossRef]

- Choi, K.; Kang, Y.; Sohn, I. Effect of Rb2O and Cs2O on inclusion removal in 321 stainless steels using novel basic tundish fluxes. Metall. Mater. Trans. B 2016, 47, 1520–1526. [Google Scholar] [CrossRef]

- Huang, X. Principle of Iron and Steel Metallurgy, 2nd ed.; Metallurgical Industry Press: Beijing, China, 2014; p. 328. [Google Scholar]

- Mysen, B.; Richet, P. Silicate Glasses and Melts: Properties and Structure, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Waseda, Y.; Toguri, J. The Structure and Properties of Oxide Melts: Application of Basic Science to Metallurgical Processing; World Scientific: Singapore, 1998; p. 113. [Google Scholar]

- Waseda, Y.; Toguri, J. The structure of molten binary silicate systems CaO-SiO2 and MgO-SiO2. Metall. Mater. Trans. B 1977, 8, 563–568. [Google Scholar] [CrossRef]

- Sukenaga, S.; Saito, N.; Kawakami, K.; Nakashima, K. Viscosities of CaO-SiO2-Al2O3-(R2O or RO) melts. ISIJ Int. 2006, 46, 352–358. [Google Scholar] [CrossRef]

- Kim, H.; Kim, W.H.; Park, J.H.; Min, D.J. A study on the effect of Na2O on the viscosity for ironmaking slags. Steel Res. Int. 2010, 81, 17–24. [Google Scholar] [CrossRef]

- Zhen, Y.L.; Zhang, G.H.; Tang, X.L.; Chou, K.C. Influences of Al2O3/CaO and Na2O/CaO ratios on viscosities of CaO-Al2O3-SiO2-Na2O melts. Metall. Mater. Trans. B 2014, 45, 123–130. [Google Scholar] [CrossRef]

- Sukenaga, S.; Haruki, S.; Nomoto, Y.; Saito, N.; Nakashima, K. Density and surface tension of CaO–SiO2–Al2O3–R2O (R = Li, Na, K) melts. ISIJ Int. 2011, 51, 1285–1289. [Google Scholar] [CrossRef]

- Warren, B.; Krutter, H.; Morningstar, O. Fourier analysis of X-Ray patterns of vitreous SiO2 and B2O2. J. Am. Ceram. Soc. 1936, 19, 202–206. [Google Scholar] [CrossRef]

- Waseda, Y. Current structural information of molten slags by means of a high temperature X-ray diffraction. Can. Metall. Q. 1981, 20, 57–67. [Google Scholar] [CrossRef]

- Maeda, M. Advanced Physical Chemistry for Process Metallurgy; Sano, N., Lu, W.K., Riboud, P.V., Eds.; Academic Press: San Diego, CA, USA, 1997; Volume 1. [Google Scholar]

- Mysen, B.; Virgo, D.; Scarfe, C.; Cronin, D. Viscosity and structure of iron-and aluminum-bearing calcium silicate melts at 1 atm. Am. Miner. 1985, 70, 487–498. [Google Scholar]

- Iguchi, Y.; Yonezawa, K.; Funaoka, Y.; Ban-ya, S.; Nishina, Y. Raman spectroscopic study on structure of binary silicates and ternary oxide melts with and without fluoride. In Proceedings of the 3rd International Conference on Molten Slags and Fluxes, Institute of Melts, University of Strathclyde, Glasgow, UK, 27–29 June 1988; p. 169. [Google Scholar]

- Hwa, L.; Hwang, S.; Liu, L. Infrared and raman spectra of calcium alumino-silicate glasses. J. Noncryst. Solids 1998, 238, 193–197. [Google Scholar] [CrossRef]

- Park, J.; Jung, I.; Lee, H. Dissolution behavior of Al2O3 and MgO inclusions in the CaO–Al2O3–SiO2 slags: Formation of ring-like structure of MgAl2O4 and Ca2SiO4 around MgO inclusions. ISIJ Int. 2006, 46, 1626–1634. [Google Scholar] [CrossRef]

- Valdez, M.; Shannon, G.; Sridhar, S. The ability of slags to absorb solid oxide inclusions. ISIJ Int. 2006, 46, 450–457. [Google Scholar] [CrossRef]

- Yi, K.; Tse, C.; Park, J.; Valdez, M.; Cramb, A.; Sridhar, S. Determination of dissolution time of Al2O3 and MgO inclusions in synthetic Al2O3-CaO-MgO slags. Scand. J. Metal. 2003, 32, 177–184. [Google Scholar] [CrossRef]

- ATLAS, AFS Inclusion. Inclusion Formation and Removal. Available online: https://www.slideshare.net/msahisri/inclusion-formation-afs (accessed on 12 February 2013).

- Reis, B.; Bielefeldt, W.; Vilela, A. Absorption of non-metallic inclusions by steelmaking slags—A review. J. Mater. Res. Technol. 2014, 3, 179–185. [Google Scholar] [CrossRef]

- Reis, B.; Bielefeldt, W.; Vilela, A. Efficiency of inclusion absorption by slags during secondary refining of steel. ISIJ Int. 2014, 54, 1584–1591. [Google Scholar] [CrossRef]

- Strandh, J.; Nakajima, K.; Eriksson, R.; Jönsson, P. A mathematical model to study liquid inclusion behavior at the steel-slag interface. ISIJ Int. 2005, 45, 1838–1847. [Google Scholar] [CrossRef]

- Bouris, D.; Bergeles, G. Investigation of inclusion re-entrainment from the steel-slag interface. Metall. Mater. Trans. B 1998, 29, 641–649. [Google Scholar] [CrossRef]

- Nakajima, K.; Okamura, K. Inclusion. In Proceedings of the 4th International Confenerce on Molten Slags and Fluxes, Sendai, Japan, 8–11 June 1992; p. 505. [Google Scholar]

- Yang, H.B. Study on Moving Behavior of Inclusions during Process of Passing Steel-Slag Interface. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 27 December 2014. [Google Scholar]

| Heat Number | CaO (wt%) | SiO2 (wt%) | Al2O3 (wt%) | Na2O (wt%) | Rb2O (wt%) | Time/min | CaO/SiO2 |

|---|---|---|---|---|---|---|---|

| 0# | 42.22 | 52.78 | 5.00 | - | - | 0, 15, 30, 45 | 0.8 |

| 1# | 40.11 | 50.14 | 4.75 | 2.50 | - | 0, 15, 30, 45 | 0.8 |

| 2# | 38.00 | 47.50 | 4.50 | 5.00 | - | 0, 15, 30, 45 | 0.8 |

| 3# | 35.89 | 44.86 | 4.25 | 7.50 | - | 0, 15, 30, 45 | 0.8 |

| 4# | 40.11 | 50.14 | 4.75 | - | 2.50 | 0, 15, 30, 45 | 0.8 |

| 5# | 38.00 | 47.50 | 4.50 | - | 5.00 | 0, 15, 30, 45 | 0.8 |

| 6# | 35.89 | 44.86 | 4.25 | - | 7.50 | 0, 15, 30, 45 | 0.8 |

| Heat Number | C | Si | Cr | Mn | V | [Al]s | T.O | N | P | S | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0# | 0.96 | 0.16 | 0.21 | 0.34 | 0.10 | ≤0.0003 | 0.0012 | 0.0027 | 0.0067 | 0.0026 | 0.0027 | 0.0036 |

| 1# | 0.96 | 0.15 | 0.21 | 0.36 | 0.10 | ≤0.0003 | 0.0013 | 0.0033 | 0.0070 | 0.0032 | 0.0028 | 0.0041 |

| 2# | 0.97 | 0.15 | 0.20 | 0.35 | 0.11 | ≤0.0003 | 0.0012 | 0.0031 | 0.0071 | 0.0031 | 0.0031 | 0.0039 |

| 3# | 0.95 | 0.17 | 0.23 | 0.35 | 0.11 | ≤0.0003 | 0.0014 | 0.0033 | 0.0072 | 0.0034 | 0.0029 | 0.0041 |

| 4# | 0.96 | 0.15 | 0.20 | 0.34 | 0.12 | ≤0.0003 | 0.0015 | 0.0030 | 0.0070 | 0.0030 | 0.0022 | 0.0038 |

| 5# | 0.96 | 0.15 | 0.21 | 0.36 | 0.11 | ≤0.0003 | 0.0012 | 0.0028 | 0.0068 | 0.0029 | 0.0035 | 0.0036 |

| 6# | 0.97 | 0.16 | 0.20 | 0.37 | 0.10 | ≤0.0003 | 0.0013 | 0.0029 | 0.0061 | 0.0032 | 0.0033 | 0.0033 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Jiang, Z.; Li, Y.; Sun, M.; Chen, K.; Wang, Q.; Li, H. Effect of Na2O and Rb2O on Inclusion Removal in C96V Saw Wire Steels Using Low-Basicity LF (Ladle Furnace) Refining Slags. Metals 2018, 8, 691. https://doi.org/10.3390/met8090691

Chen C, Jiang Z, Li Y, Sun M, Chen K, Wang Q, Li H. Effect of Na2O and Rb2O on Inclusion Removal in C96V Saw Wire Steels Using Low-Basicity LF (Ladle Furnace) Refining Slags. Metals. 2018; 8(9):691. https://doi.org/10.3390/met8090691

Chicago/Turabian StyleChen, Changyong, Zhouhua Jiang, Yang Li, Meng Sun, Kui Chen, Qi Wang, and Huabing Li. 2018. "Effect of Na2O and Rb2O on Inclusion Removal in C96V Saw Wire Steels Using Low-Basicity LF (Ladle Furnace) Refining Slags" Metals 8, no. 9: 691. https://doi.org/10.3390/met8090691

APA StyleChen, C., Jiang, Z., Li, Y., Sun, M., Chen, K., Wang, Q., & Li, H. (2018). Effect of Na2O and Rb2O on Inclusion Removal in C96V Saw Wire Steels Using Low-Basicity LF (Ladle Furnace) Refining Slags. Metals, 8(9), 691. https://doi.org/10.3390/met8090691