Management of Lime in Steel

Abstract

:1. Introduction

2. Lime Supply in Steel Outlook

3. Quality Lime Production for Steel Applications

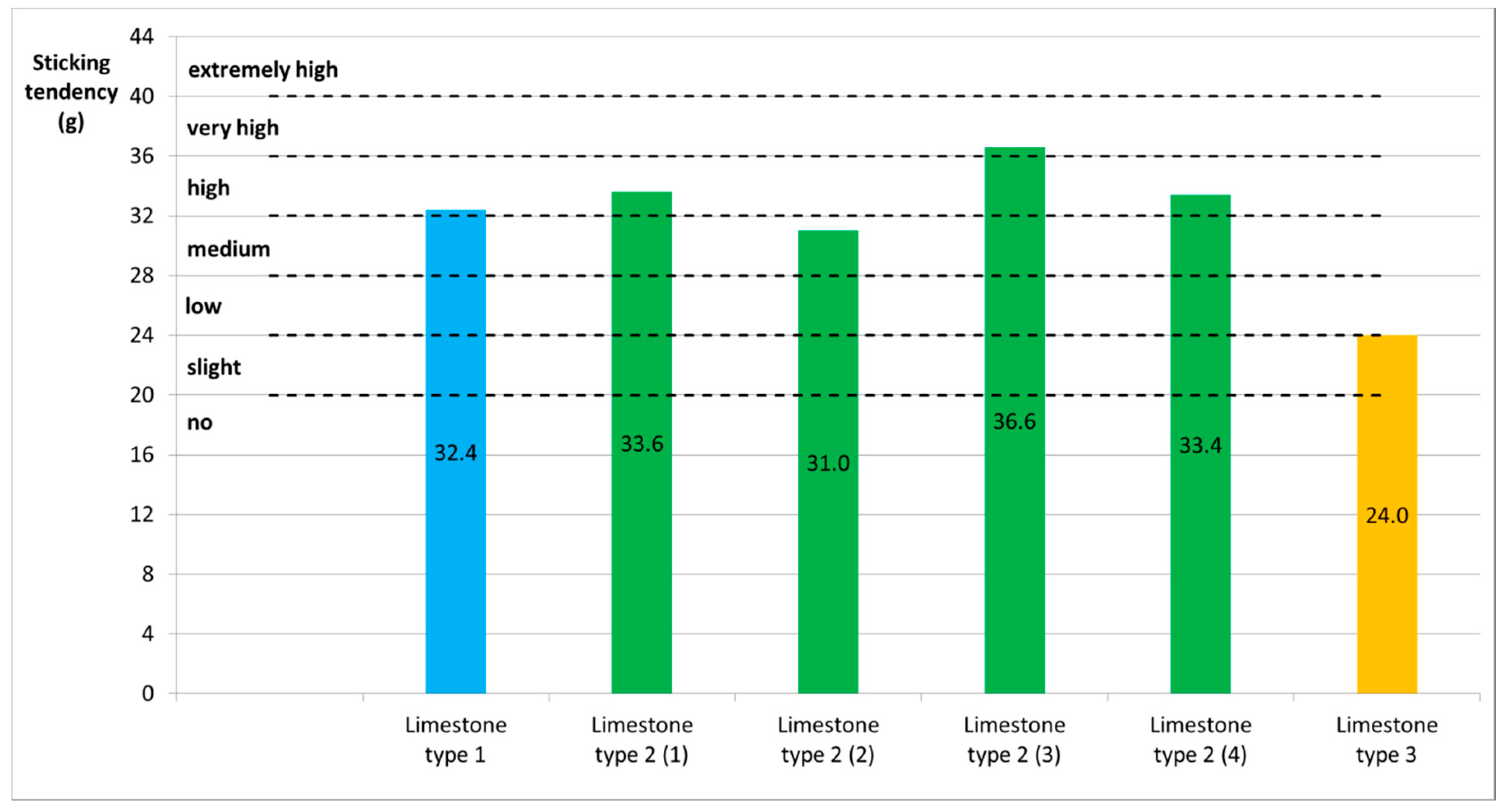

3.1. Limestone Quality

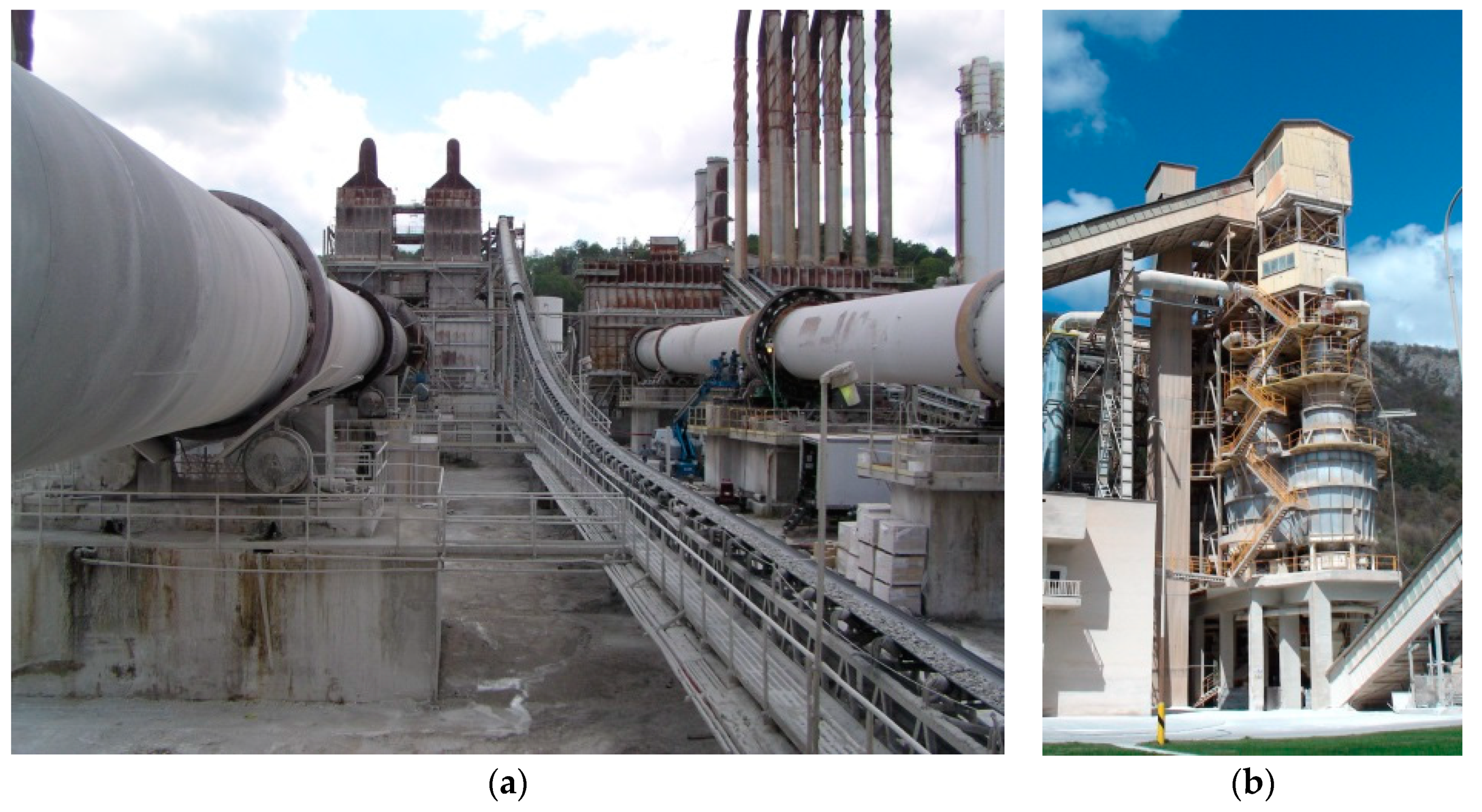

3.2. Calcination

3.3. Lime Quality for Steel Processes

- Chemical composition and degree of calcination

- Reactivity

- Grain size

- Uniformity

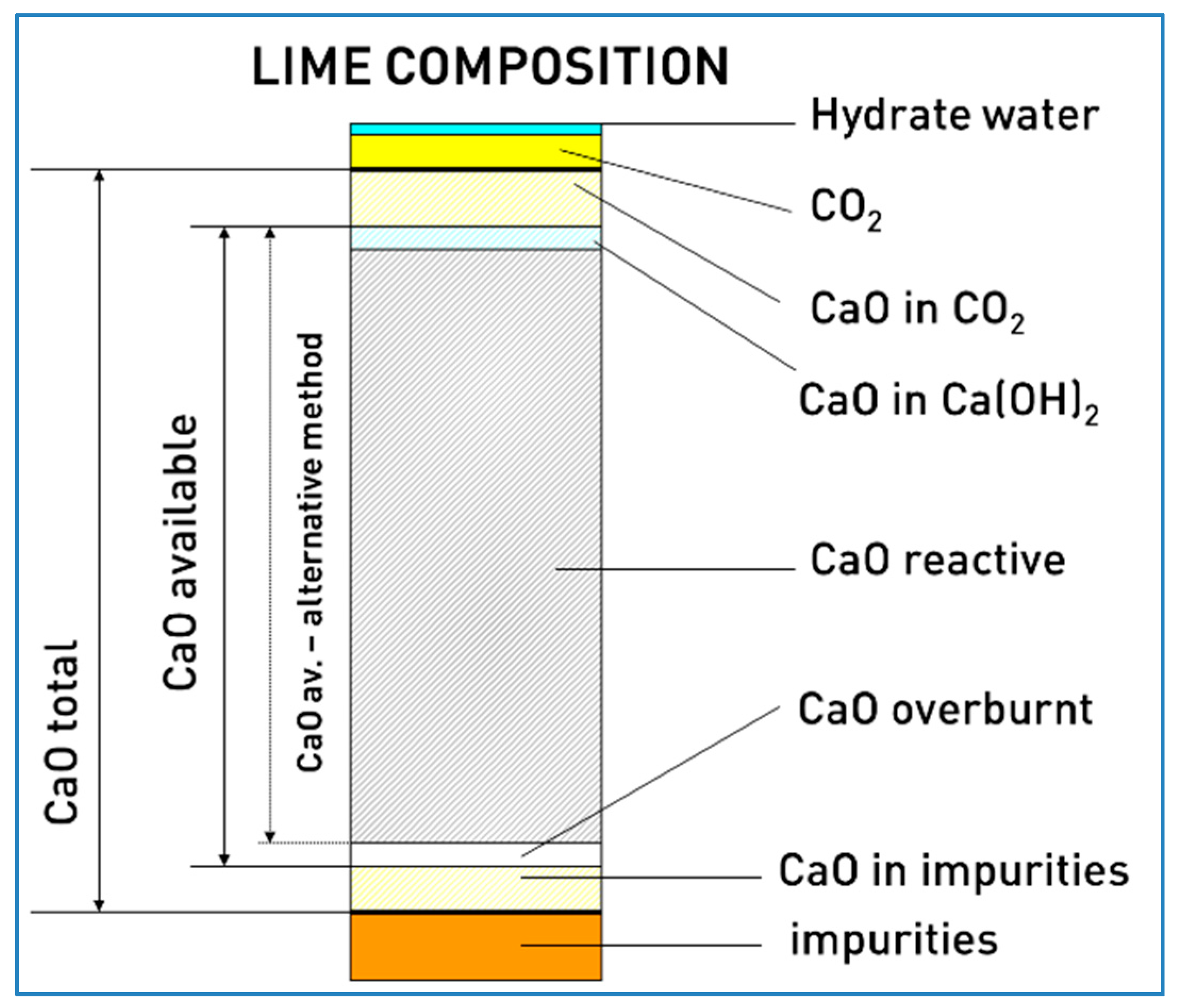

3.3.1. Chemical Composition and Degree of Calcination

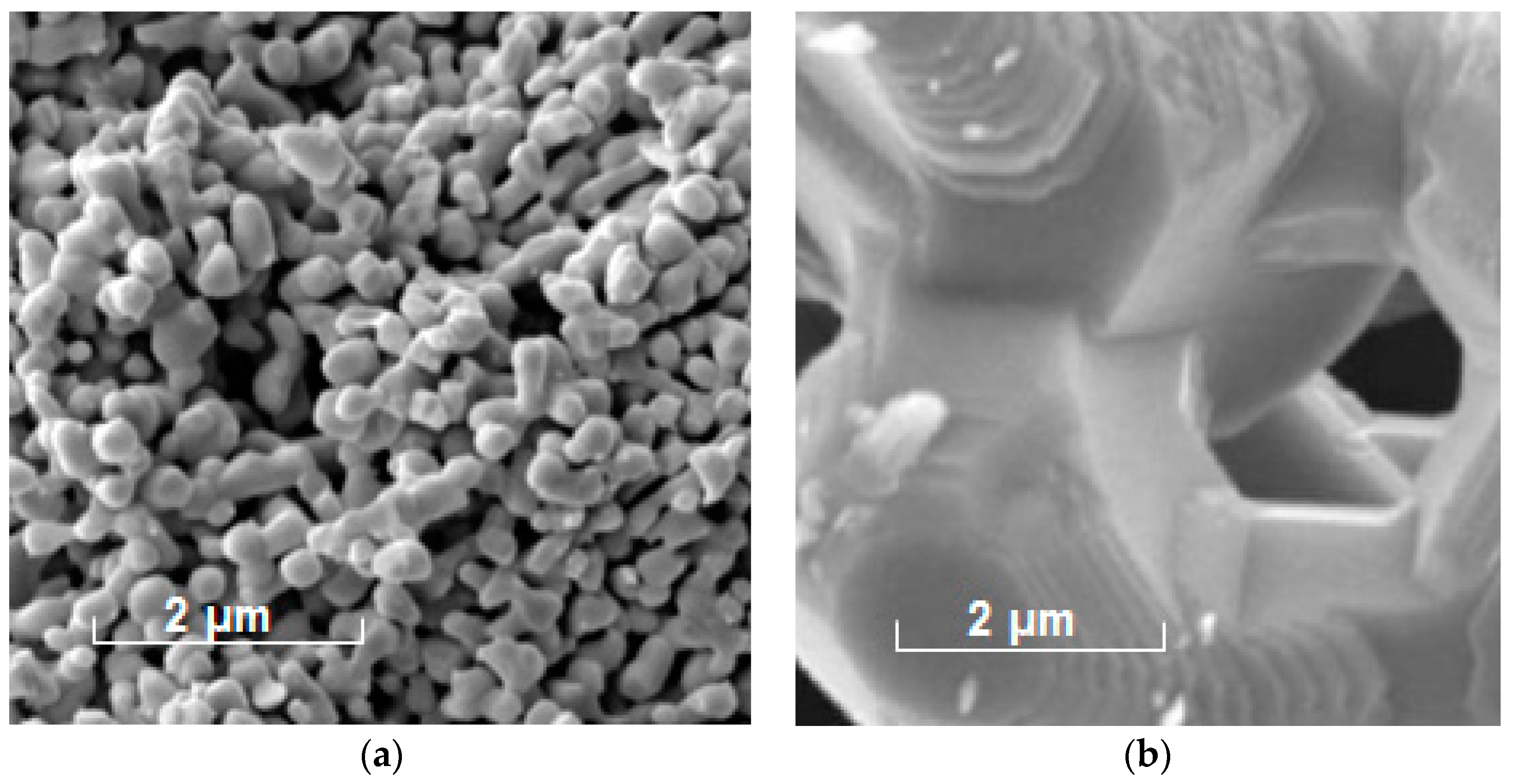

3.3.2. Reactivity

3.3.3. Grain Size

3.3.4. Uniformity

3.3.5. Summary of Lime Quality for Steel

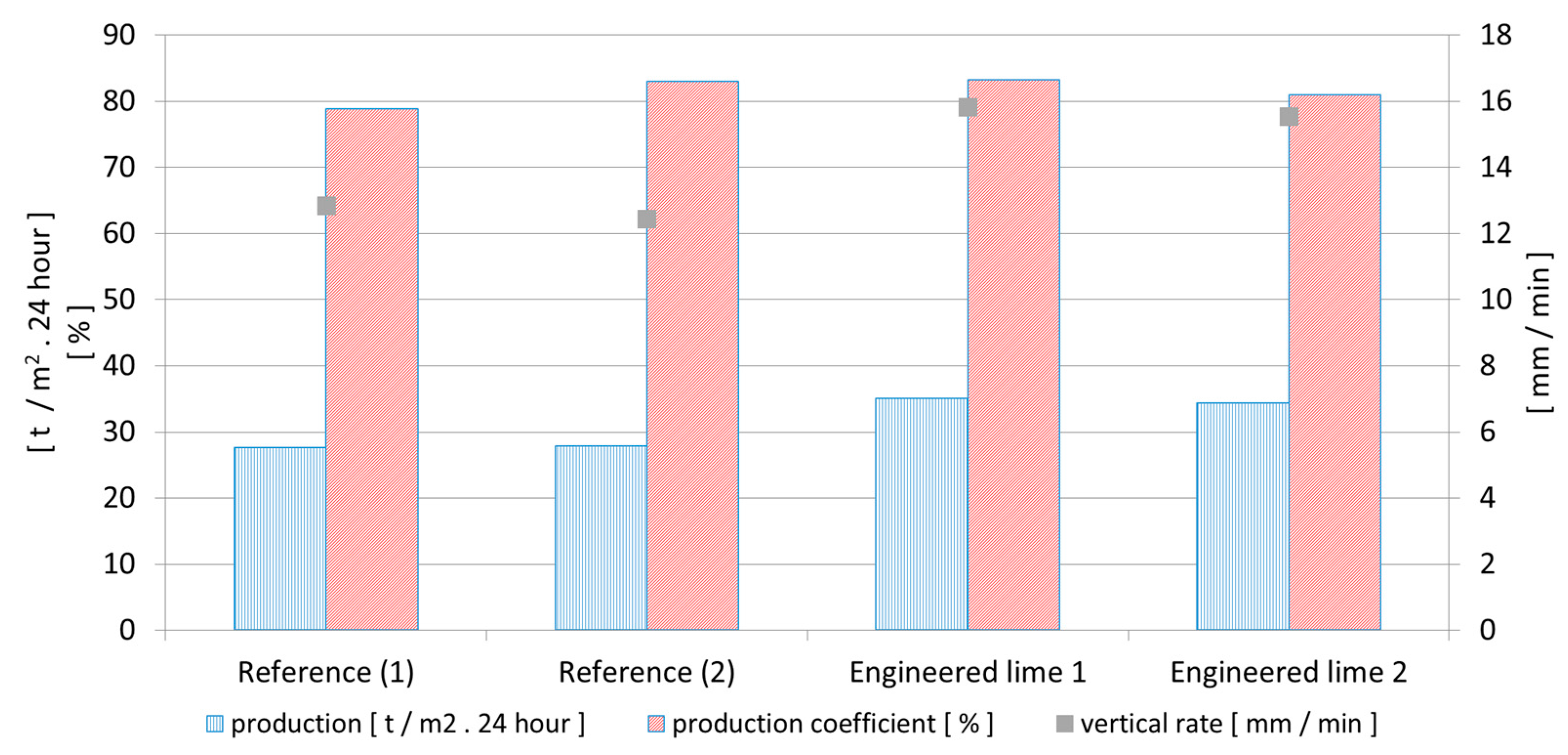

3.4. Engineered Lime Products for Environmental Applications

4. Importance of Lime or/and Dolime in the Production of Quality Steel

4.1. Introduction

- Silica—

- Alumina—

- Sulphur—

- Phosphorus—

- Removing sulphur at the hot metal desulphurization station;

- Phosphorous removal in the BOF;

- Foamy slag preventing nitrogen and hydrogen pickup during melting in the EAF;

- Avoiding over-oxidation of steel during steel melting in EAF and BOF;

- De-oxidation and desulphurization practices in the secondary metallurgy treatment.

4.2. Lime Product Characteristics for Iron- and Steelmaking Process Steps

4.2.1. Agglomeration and Sintering

4.2.2. Hot Metal Desulphurization

4.2.3. BOF Converter Process

4.2.4. Electric Arc Furnace Process

4.2.5. Secondary Metallurgy

5. Lime Handling and Addition Practices

5.1. Sinter Plant Lime Dosing

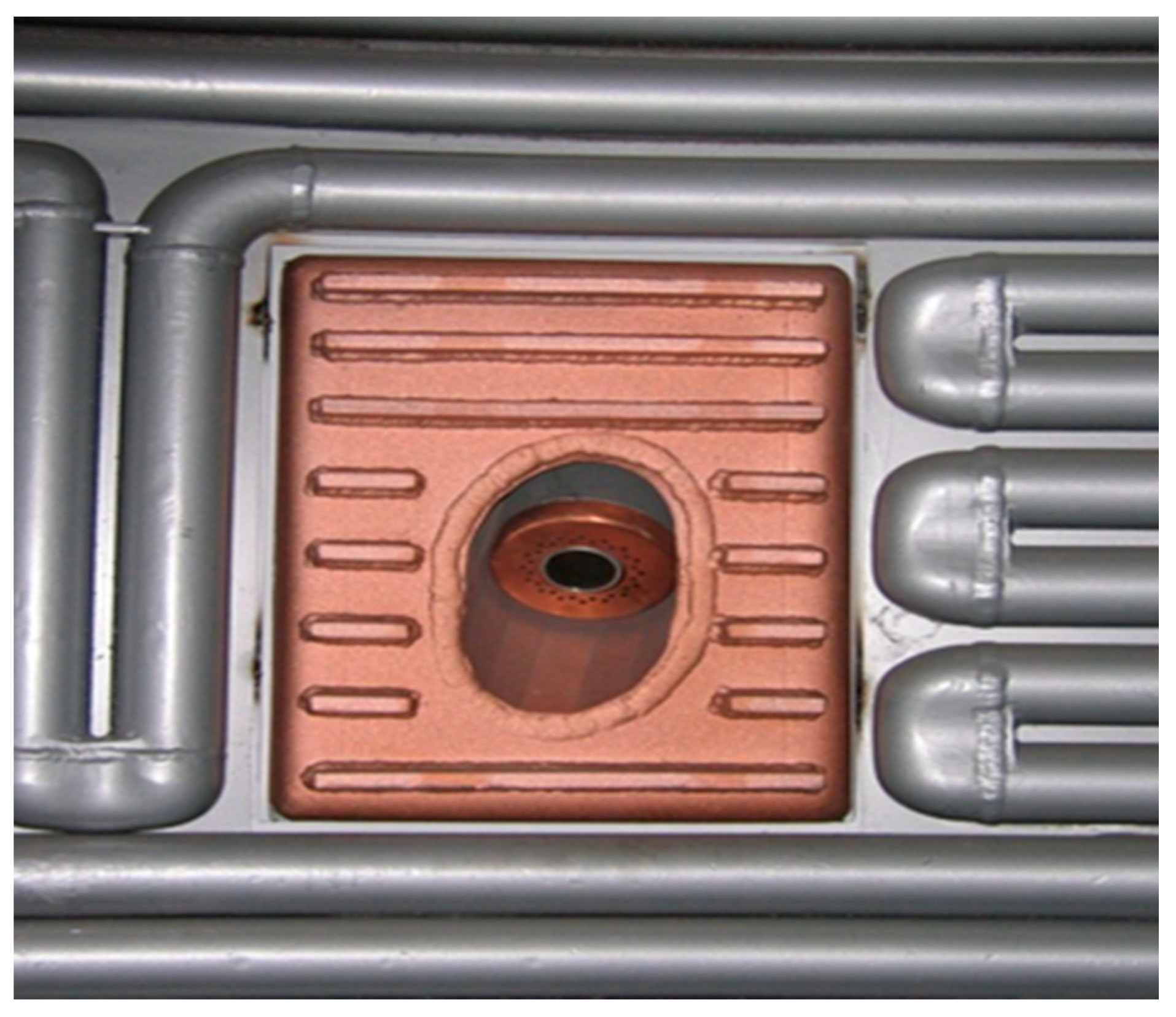

5.2. BOF Lime Injection

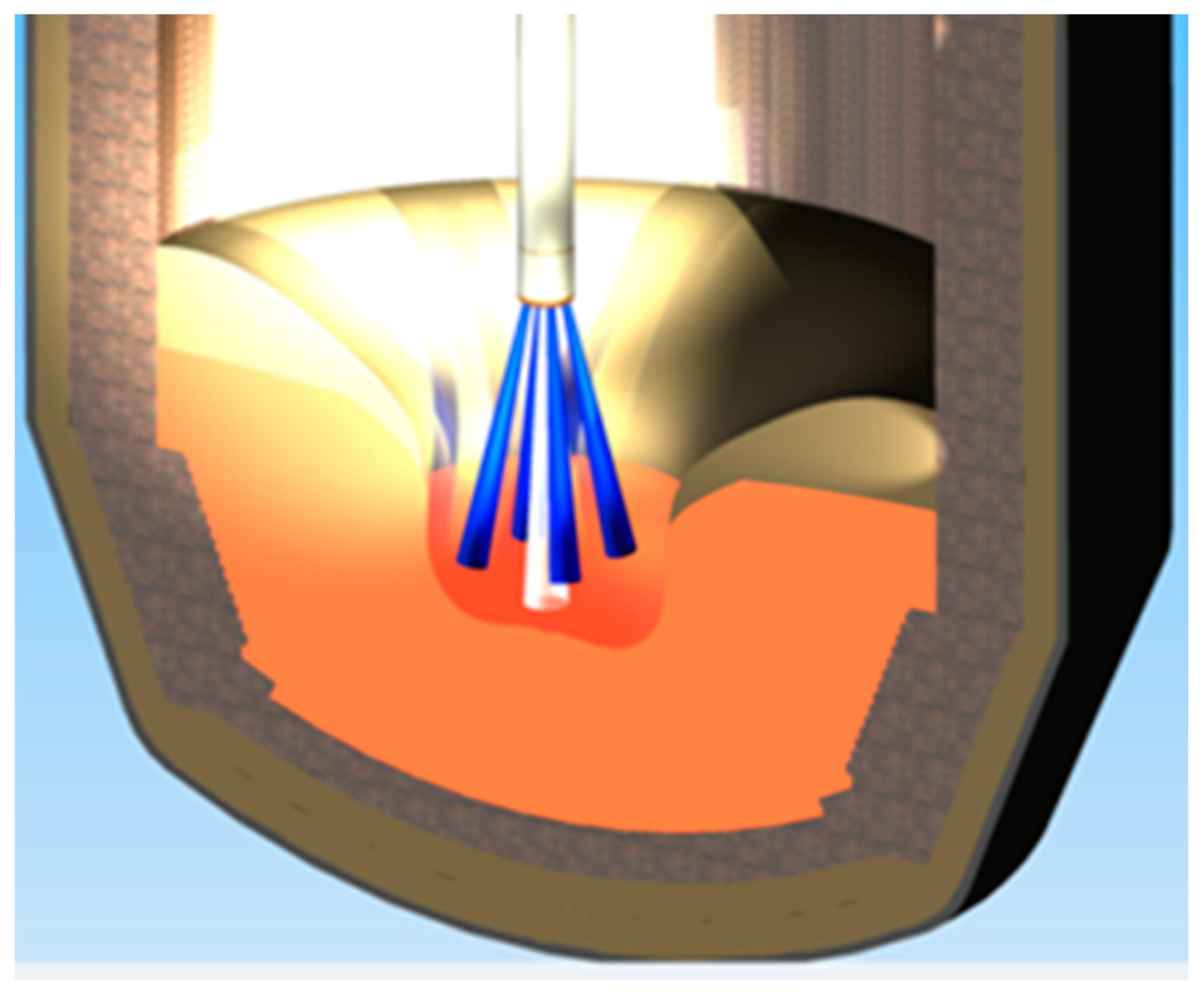

5.3. EAF Lime Injection

6. Impact of Lime Chemistry on Use of Lime and Steel Process Parameters

6.1. CaO Content in Lime

6.2. Silica (SiO2) Content in Lime

6.3. Sulphur Content in Lime

6.4. Loss on Ignition

6.5. Granulometry (Grain Size)

7. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Alaabed, S.; Soltan, M.A.; Abdelghany, O.; Amin, B.E.M.; Tokhi, M.E.; Khaleel, A.; Musalim, A. United Arab Emirates limestones: Impact of petrography on thermal behaviour. Mineral. Petrol. 2014, 108, 837–852. [Google Scholar] [CrossRef]

- Boynton, R.S. Chemistry and Technology of Lime and Limestone, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1980; ISBN 0-471-02771-5. [Google Scholar]

- HaiDo, D.; Specht, E.; Kehse, G.; Ferri, V.; Christiansen, T.L.; Bresciani, P. Simulation of lime calcination in PFR kilns–Influence of source and size of limestone. ZKG Int. 2012, 4, 56–65. [Google Scholar]

- Fuessl, E.; Jahn, F. 25 Years of industrial development on the parallel flow regenerative lime shaft kilns. ZKG Int. 1982, 35, 290–296. [Google Scholar]

- Vola, G.; Sarandrea, L.; Della Porta, G.; Cavallo, A.; Jadoul, F.; Cruciani, G. The influence of petrography, mineralogy and chemistry on burnability and reactivity of quicklime produced in Twin Shaft Regenerative (TSR) kilns from Neoarchean limestone (Transvaal Supergroup, South Africa). Mineral. Petrol. 2018, 112, 555–576. [Google Scholar] [CrossRef]

- Gaye, H.; Riboud, P.V. Lime in oxygen steelmaking. Prospects of its consumption and quality requirements. Rev. Met. Paris 1983, 80, 475–482. [Google Scholar] [CrossRef]

- Campbell, A.J. Lime calcination: Time and temperature of calcination expressed as a single variable and the effect of selected impurities on lime properties. Zement-Kalk-Gips 1988, 9, 442–446. [Google Scholar]

- Potgieter, J.H.; Potgieter, S.S.; Moja, S.J.; Mulaba-Bafubiandi, A. The standard reactivity test as a measure of lime’s quality. J. S. Afr. Inst. Min. Metall. 2002, 102, 67–69. [Google Scholar]

- Deng, T. Study on the Dissolution of Lime and Dolomite in Converter Slag. Ph.D. Thesis, Division of Micro Modeling Department of Material Science and Engineering Royal Institute of Technology (KTH), Stockholm, Sweden, 2012. [Google Scholar]

- Moropoulou, A.; Bakolas, A.; Aggelakopoulou, E. The effects of limestone characteristics and calcination temperature to the reactivity of the quicklime. Cem. Concr. Res. 2001, 31, 633–639. [Google Scholar] [CrossRef]

- Mullins, R.C.; Hatfield, J.D. Effects of calcination conditions on the properties of lime. In The Reaction Parameters of Lime; ASTM STP 472; American Society for Testing and Materials: West Conshohocken, PA, USA, 1970; pp. 117–131. [Google Scholar]

- Heiia, A.A.; Howatand, D.D.; Jochen, P.R. The effect of the reactivity of lime on desulphurization efficiency in the basic oxygen furnace. J. S. Afr. Inst. Min. Metall. 1973, 73, 249–257. [Google Scholar]

- Oates, J.A.H. Lime and Limestone Chemistry and Technology, Production and Uses; Wiley VCH Verlag, GmbH: Weinem, Germany, 1998. [Google Scholar]

- Fruehan, R.J. The Making, Shaping and Treating of Steel, Steelmaking and Refining Volume, 11th ed.; The AISE Steel Foundation: Pittsburgh, PA, USA, 1998. [Google Scholar]

- Di Giorgio, N.; Brace, D.; Bennett, A.; Wijekulasuriya, K. BlueScope Steel Australia New Zealand Steel Manufacturing Business. Reengineering Bluescope Steel’s port kembla sinter plant for high productivity and reduced steelworks greenhouse emissions. In Proceedings of the Engineering a Better World, Sydney Hilton Hotel, NSW, Australia, 18–21 September 2011. [Google Scholar]

- Van Loo, F.; Douce, J.-F.; Martinez Pacheco, M.; Evrard, M.; Pietruck, R.; Schmid, H. Improved Sinter Mix Preparation While Using Challenging Raw Materials (IMSIMI)—Final Report; Research Fund for Coal and Steel (European Commission EUR 27901 EN); European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Schrama, F.N.H.; Beunder, E.M.; van den Berg, B.; Yang, Y.; Boom, R. Sulphur removal in ironmaking and oxygen steelmaking. Ironmak. Steelmak. Process. Prod. Appl. 2017, 44, 333–343. [Google Scholar] [CrossRef]

- Obst, K.-H.; Stradtmann, J.; Ullrich, W.; König, G. Present Status and Technical Advances of Steelworks Lime for Basic Oxygen Furnaces in Germany. In The Reaction Parameters o] Lime; ASTM STP 472; American Society for Testing and Materials: West Conshohocken, PA, USA, 1970; pp. 173–192. [Google Scholar]

- Obst, K.-H.; Stradtmann, J. The influence of lime and synthetic lime products on steel production. J. S. Afr. Inst. Min. Metall. 1972, 72, 158–164. [Google Scholar]

- Behrens, K.F.; Koenitzer, J.; Kootz, T.; Macnamara, J. The Effects of Lime Properties on Basic Oxygen Steelmaking. JOM 1965, 17, 776. [Google Scholar] [CrossRef]

- Pretorius, E. Foamy Slag Fundamentals and their Practical Application to Electric Furnace Steelmaking. In Proceedings of the Electric Furnace Conference Proceedings, New Orleans, LA, USA, 15–18 November 1998. [Google Scholar]

- Hassal, G.J. Phosphorus and Sulphur Removal from Liquid Steel by Secondary Steel Making Operations; Commission of the European Communities Technical Steel Research; EUR 11222 EN; European Commission: Brussels, Belgium, 1988. [Google Scholar]

- Conejo, A.N.; Lara, F.R.; Macias-Hernández, M.; Conejo, A.N.; Lara, F.; Macias-Hernández, M.; Morales, R. Kinetic Model of Steel Refining in a Ladle Furnace. Steel Res. Int. 2007, 78, 141–150. [Google Scholar] [CrossRef]

- Findoràk, R.; Department of Ferrous and Foundry Metallurgy, Technical, University of Košice, Košice, Slovak Republic. Confidential research report: The influence of the addition of different types of lime on the sintering process and the quality of the agglomerate. Personal communication, March 2017. [Google Scholar]

- Wolfe, L.D.; Brelowski, R.; McKinney, D.; Cooper, G.; Brand, M.; Valentas, L.; White, J. BOF Lime Injection—Past to Future. SCANMET IV. In Proceedings of the 4th International Conference on Process Development in Iron and Steelmaking, Lulea, Sweden, 10–13 June 2012; Volume 1. [Google Scholar]

- Mombelli, D.; Barella, S.; Mapelli, C.; Gruttadauria, A.; Moreschi, R.; Marras, R.; Bruletti, G.; Frittella, P.; Mora, N.; Angelini, L. Evaluation of the effect of lime injection on the Electric Arc Furnace performances. In Proceedings of the ICS 2018: 7th International Congress on Science and Technology of Steelmaking: The Challenge of Industry 4.0, Venezia, Italy, 13–15 June 2018. [Google Scholar]

- Sarna, S.K. Quality of Lime for Steelmaking in Converter. 2015. Available online: www.ispatguru.com (accessed on 25 June 2018).

- Maruoka, N.; Ito, K.; Hayasaka, M.; Nogami, H. Effect of CO2 Content in Quicklime on Dissolution Rate of Quicklime in Steelmaking Slags. ISIJ Int. 2017, 57, 1684–1690. [Google Scholar] [CrossRef]

- Maruoka, N.; Ishikawa, A.; Shibata, H.; Kitamura, S. Dissolution Rate of Various Limes into Steelmaking Slag. High Temp. Mater. Proc. 2013, 32, 15–24. [Google Scholar] [CrossRef]

| Specification | Steel Plant 1 | Steel Plant 2 |

|---|---|---|

| CaO (min. %) | 92 | 95 |

| SiO2 (max. %) | 2.5 | 1.0 |

| S (max. %) | 0.04 | 0.05 |

| Loss of ignition (LOI) (max. %) | 3.0 | 3.0 |

| Grading | 10–30 mm | 12–38 mm |

| Fine content | 10% max. < 5 mm | 5% max. < 2 mm |

| Reactivity | 385 mL 4N HCl after 10 min. | 120 s from 20 to 60 °C |

| Chemical Content | Limestone | Quicklime |

|---|---|---|

| CaO (%) | 54.51 | 93.68 |

| CO2 (%) | 42.78 | 1.50 |

| MgO (%) | 0.95 | 1.66 |

| SiO2 (%) | 0.05 | 0.09 |

| S (%) | 0.047 | 0.106 |

| Process Step | Lime and Dolime Requirements | Critical Parameters | Typical Consumption (kg/t of Steel) |

|---|---|---|---|

| Sinter Plant |

|

|

|

| Hot Metal Desulphurization |

|

|

|

| BOF Converter |

|

|

|

| Electric Arc Furnace |

|

|

|

| Secondary Metallurgy |

|

|

|

| Stone Quality: | Inerts = 1% | MgCO3 = 1% | CaCO3 = 1% |

| Res. CO2 | CaO av. | CaO tot. | |

| 1.5% | 94.01% | 95.82% | |

| 2.0% | 92.88% | 95.33% | |

| 5.0% | 86.13% | 92.41% | |

| 8.0% | 79.39% | 89.49% | |

| 10.0% | 74.89% | 87.54% | |

| Stone Quality: | Inerts = 2% | MgCO3 = 1% | CaCO3 = 1% |

| Res. CO2 | CaO av. | CaO tot. | |

| 1.5% | 92.34% | 94.15% | |

| 2.0% | 91.22% | 93.67% | |

| 5.0% | 84.52% | 90.80% | |

| 8.0% | 77.83% | 87.93% | |

| 10.0% | 73.36% | 86.02% |

| Lime Quality: | ||

| Lime characteristics | A (10 heats) | B (10 heats) |

| Average CaO | 85.7% | 94.3% |

| Average MgO | 0.5% | 0.5% |

| Average SiO2 | 1.6% | 1.0% |

| Ladle Slag results | ||

| Calculated sulphide capacity | −2.42 | −2.32 |

| Initial sulphur in steel | 0.039% | 0.041% |

| Final sulphur in steel | 0.016% | 0.013% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manocha, S.; Ponchon, F. Management of Lime in Steel. Metals 2018, 8, 686. https://doi.org/10.3390/met8090686

Manocha S, Ponchon F. Management of Lime in Steel. Metals. 2018; 8(9):686. https://doi.org/10.3390/met8090686

Chicago/Turabian StyleManocha, Sanjeev, and François Ponchon. 2018. "Management of Lime in Steel" Metals 8, no. 9: 686. https://doi.org/10.3390/met8090686

APA StyleManocha, S., & Ponchon, F. (2018). Management of Lime in Steel. Metals, 8(9), 686. https://doi.org/10.3390/met8090686